Hybrid unequal space patterned substrate and manufacturing method thereof

A patterned substrate and hybrid technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problem that the effect is not obvious, and achieve the effect of reducing total reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with specific drawings.

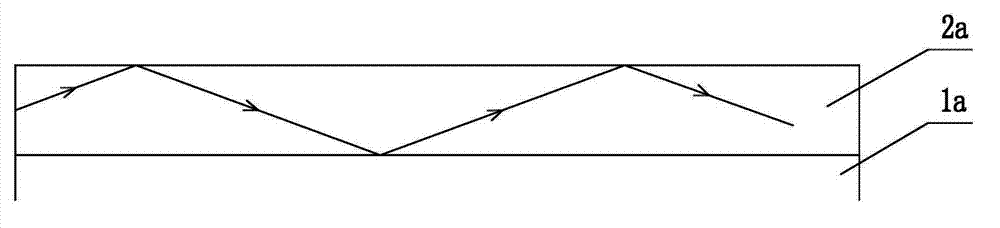

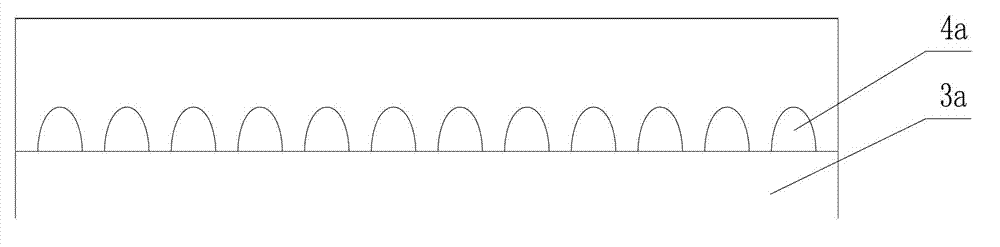

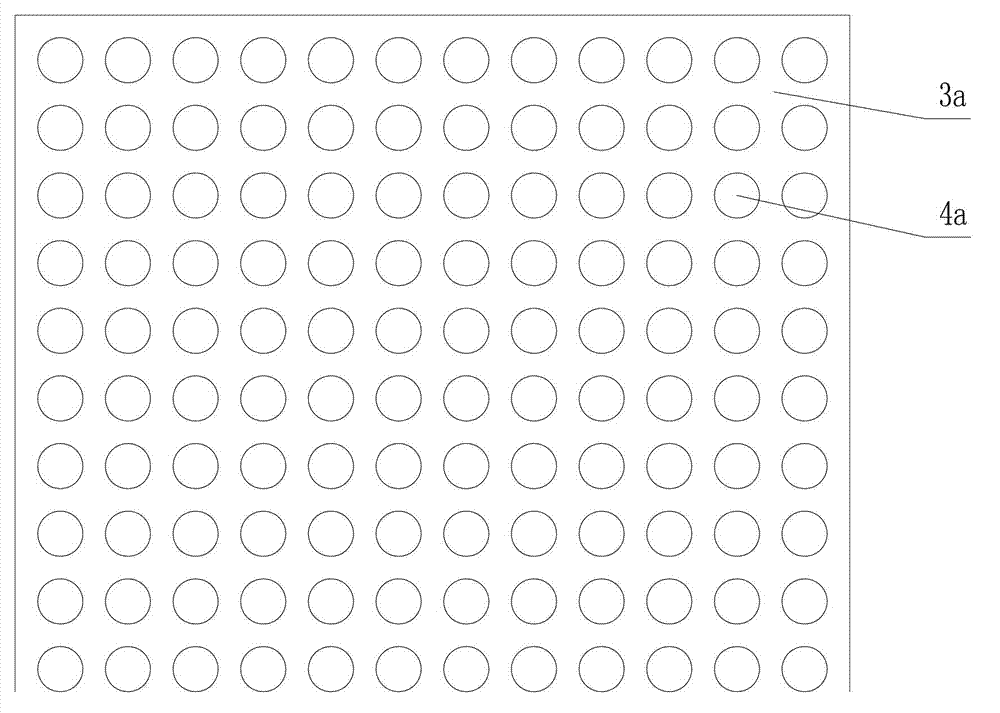

[0025] Such as Figure 4 ~ Figure 7 As shown: the patterned substrate of the present invention includes a basic substrate 1, and the basic substrate 1 adopts a sapphire substrate, a silicon carbide substrate or other substrates; the front side of the basic substrate 1 is etched to form an array Arranged protruding periods 2; each protruding period 2 includes at least two protruding 2b of different sizes and shapes, and the shape of the protruding 2b is hemispherical, semi-ellipsoidal, conical or pyramidal. The diameter of 2b is 0.1~100μm;

[0026] Such as Figure 4 , Figure 5 As shown, the distance between the bumps 2b in the same bump cycle 2 is not equidistant;

[0027] The height of the protrusions 2b is 0.1-100 μm; the distance between adjacent protrusions 2b is 0.1-100 μm.

[0028] The present invention adopts a number of protrusions of different sizes arranged at d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com