Construction method of building waterproofing engineering

A construction method and technology for building waterproofing, which are applied in construction, building construction, infrastructure engineering, etc., can solve problems such as low work efficiency and uneven application of waterproof coatings, achieve safe and convenient use, make up for low proficiency, reduce The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

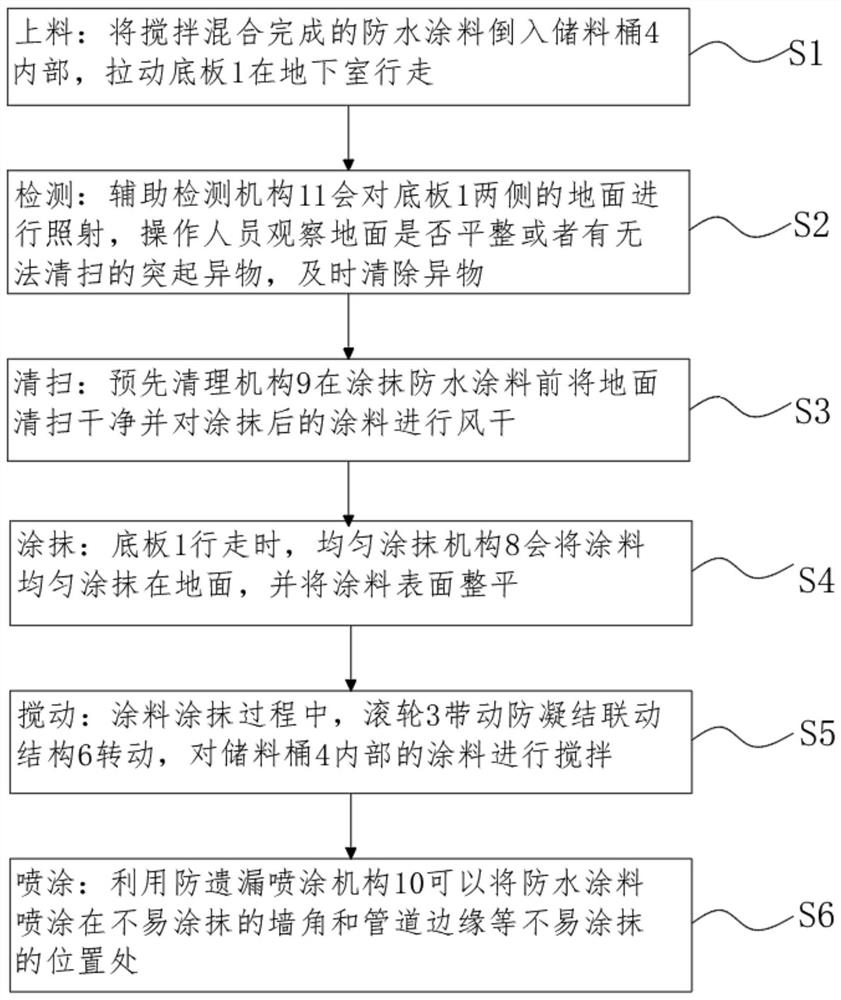

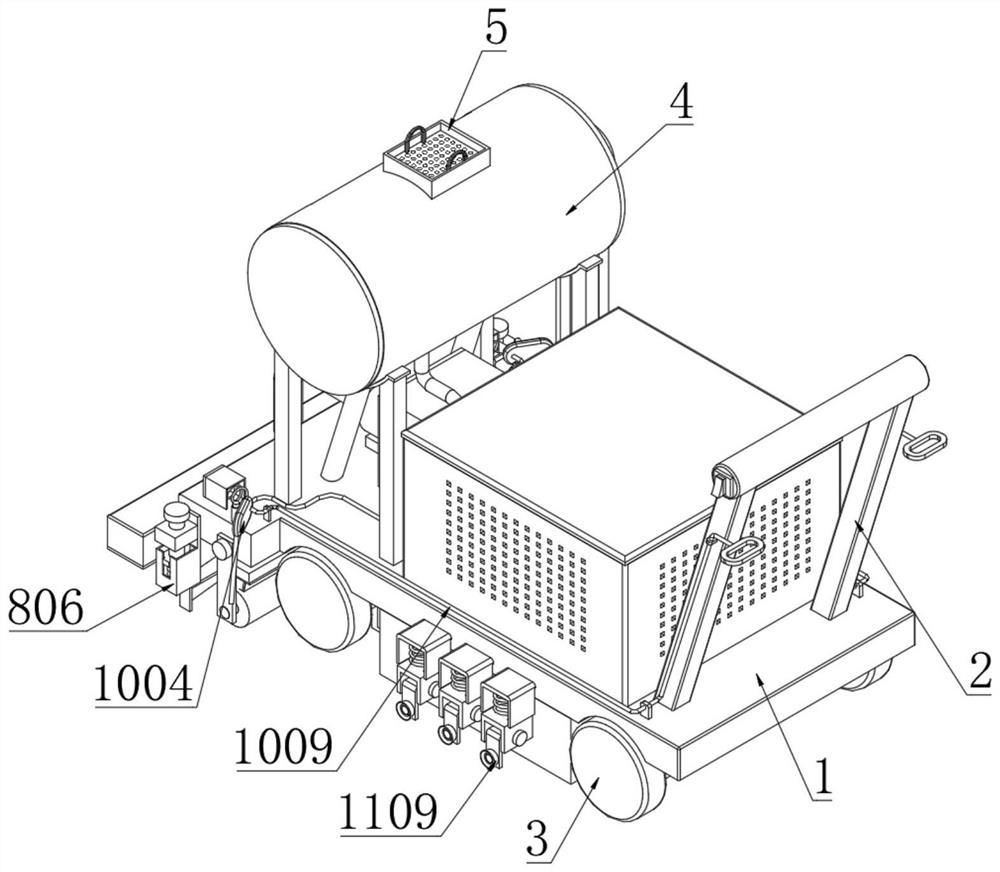

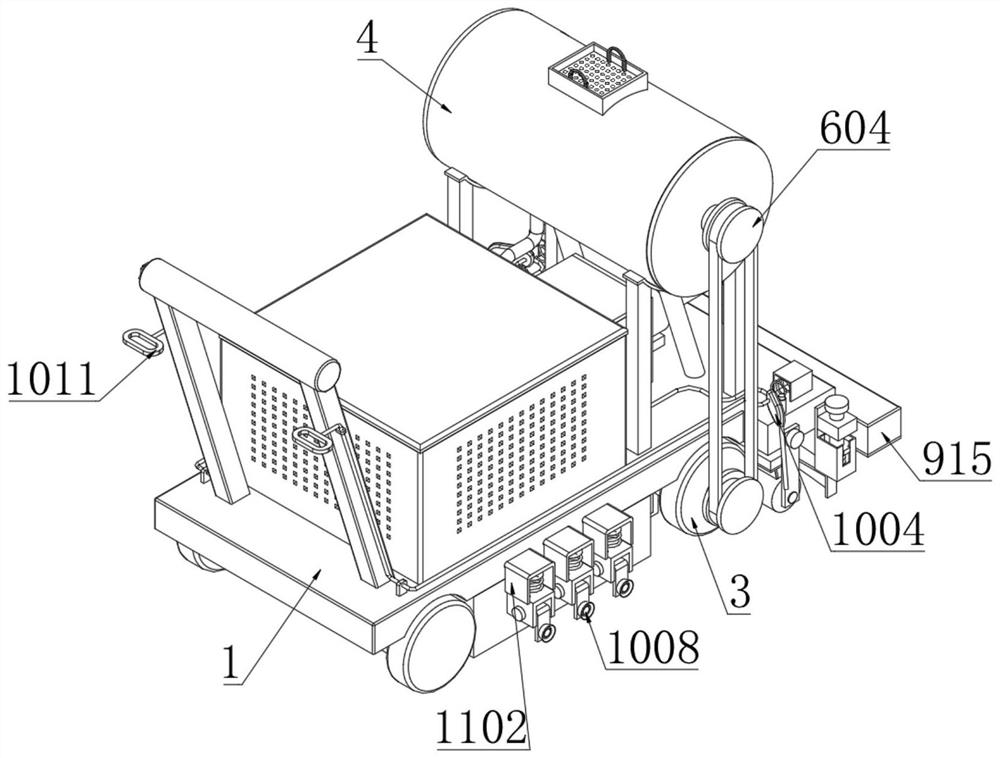

[0046] Example: such as Figure 2-10 As shown, the present invention provides a technical solution, a construction method of a building waterproofing project. The storage tank 4 is fixedly installed on the top of the bottom plate 1 at the end away from the handrail 2, and the two ends of the bottom of the bottom plate 1 are fixedly fixed with rollers 3. The end of the top of the bottom plate 1 away from the handrail 2 is fixed with a storage tank 4, the top of the storage tank 4 is provided with a material injection port 5, and the inside of the storage tank 4 is equipped with an anti-condensation linkage structure 6 to prevent the waterproof coating from coagulating and not working properly. discharge;

[0047] The bottom end of the material storage barrel 4 is symmetrically fixedly connected with a feeding pipe 7, and the bottom end of the feeding pipe 7 is fixedly installed with an even coating mechanism 8, so that the waterproof paint is evenly applied to the ground, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com