Fuel pump

A fuel pump and fuel injector technology, which is applied to liquid fuel feeders, adding non-fuel substances to fuel, engine components, etc., can solve the problems of stratification, limitation of the stable period of emulsified oil, and high cost, and is easy to install and use. , good emulsifying effect and fast emulsifying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

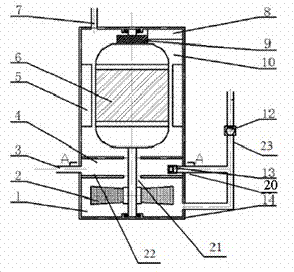

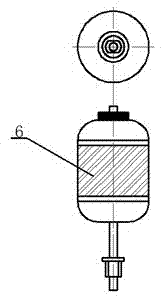

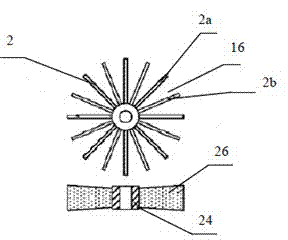

[0024] Please refer to Figure 1 to Figure 4 As shown, the fuel pump of the present invention includes a housing 14 provided with a rotor chamber 10, a return chamber 4 and an emulsification chamber 1, a stator pole 5 fixed on the housing 14, a motor rotor 6 installed in the rotor chamber 10, and a motor rotor 6 arranged on the housing 14. The oil inlet at the upper end, the water inlet arranged on one side of the return chamber 4, the oil outlet 27 connected to the casing 14 and the impeller 2 driven by the motor, the impeller 2 is installed in the emulsification chamber 1 and fixed on the motor rotor 6 On the main shaft, it is fixed by axle sleeve 24. Wherein the motor spindle extends into the emulsification chamber 1 after passing through the recirculation chamber 4 , an oil inlet pipe 7 is connected to the oil inlet, and a water inlet pipe 3 is connected to the water inlet 3 .

[0025] Two baffles 22 are set inside the shell 14 to divide the inside of the shell 14 into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com