A centrifugal emulsified asphalt production device and its production method

A technology for emulsified asphalt and production equipment, which is applied to building components, building thermal insulation materials, buildings, etc., can solve the problems of high colloid mill power, high production cost of emulsified asphalt, and high maintenance cost, achieve uniform emulsified asphalt particles, and solve emulsification efficiency. Low, the effect of increasing the emulsification speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

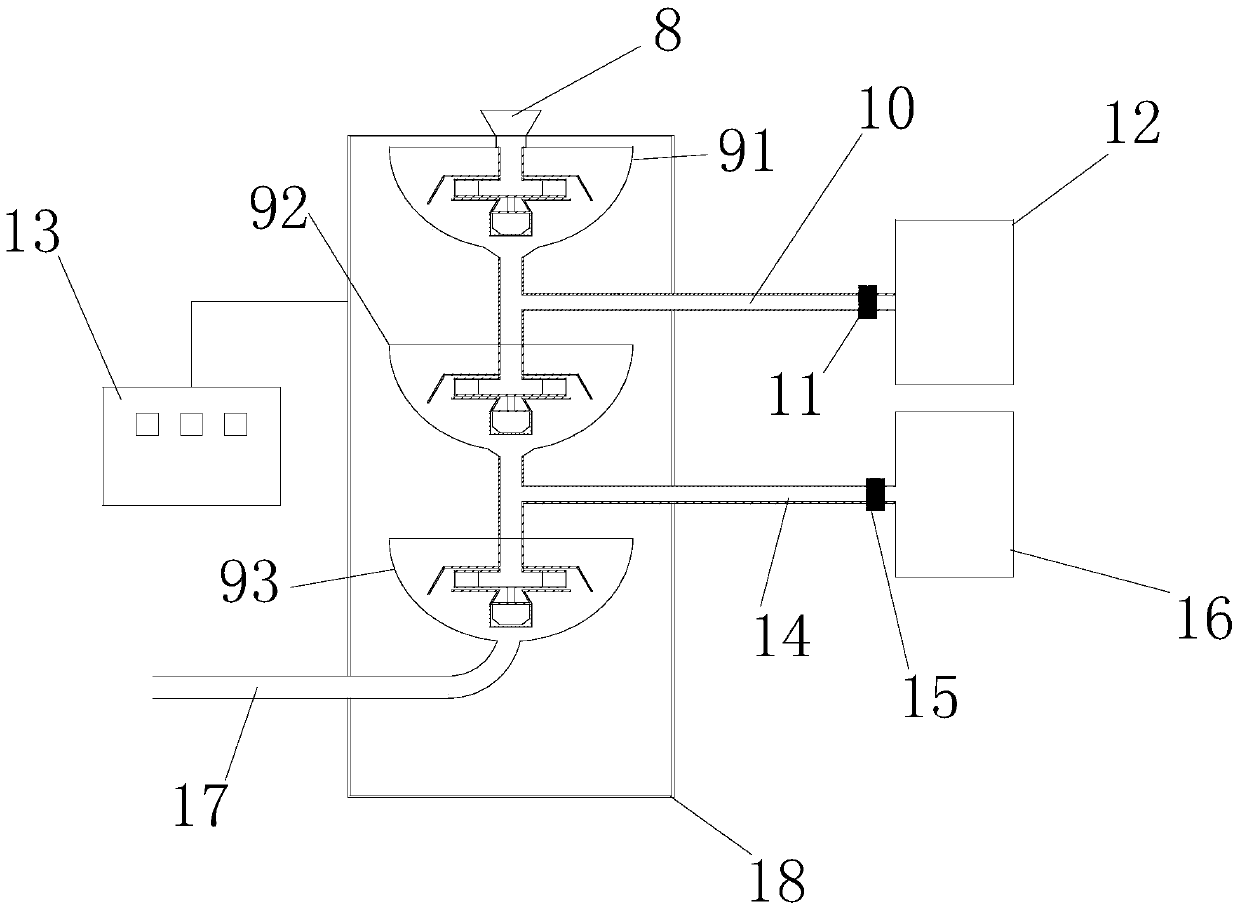

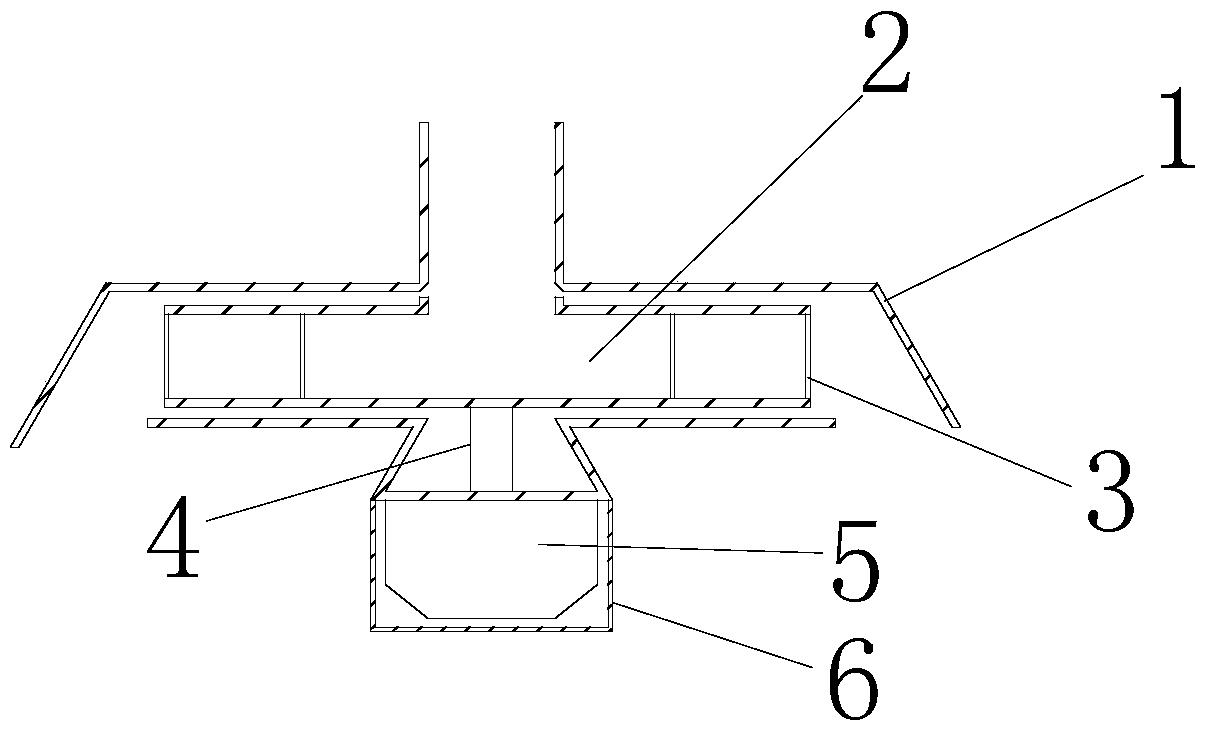

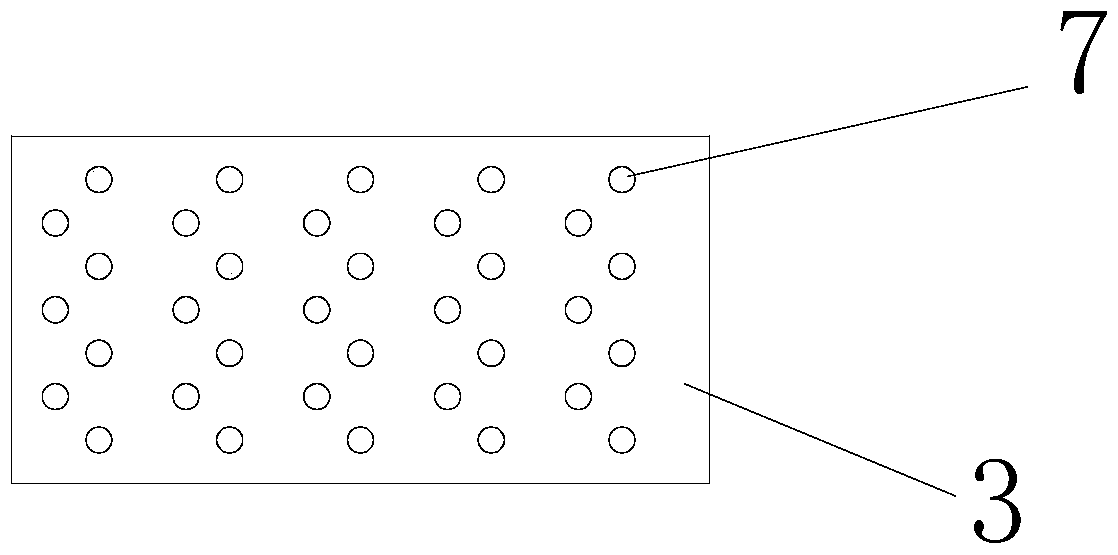

[0017] This embodiment provides a centrifugal emulsified asphalt production device, the structure is as follows Figure 1 to Figure 3 As shown, it includes an outer casing 18 and a flow guide mechanism arranged in the outer casing, a centrifuge 2, an upper flow guide tube 10 and a lower flow guide tube 14. The flow guide mechanism consists of three layers of funnel-shaped flow guides 91, 92 , 93 in series, an asphalt feed inlet 8 is arranged on the top of the diversion mechanism, and a flow-adjustable mechanism is installed on the asphalt inlet 8, and the bottom of the diversion mechanism is connected to the asphalt discharge pipe 17, and the three-layer deflector The adjacent joints of the upper flow guide tube 10 and the lower flow guide tube 14 are respectively connected, and the upper flow guide tube 10 links to each other with the upper soap liquid tank 12, and the lower flow guide tube 14 links to each other with the lower part soap liquid tank 16, and in the upper part f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com