Emulsion explosive and preparation method thereof

An emulsion explosive and explosive technology, which is applied to explosives processing equipment, explosives, explosive compound components, etc., can solve the problems of large labor workload, high production cost of emulsion explosives, high price, etc., so as to improve the emulsification efficiency and improve the effect. , good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

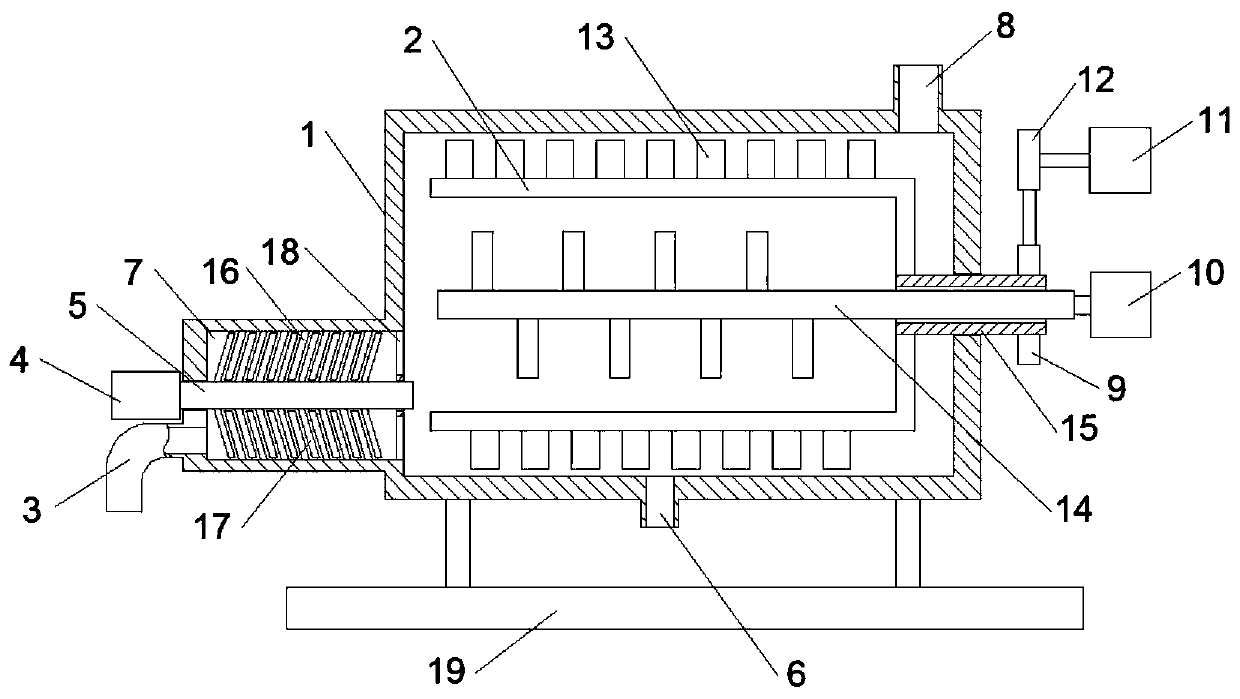

Image

Examples

Embodiment 1

[0035] The emulsion explosive proposed by the present invention comprises the following raw materials in parts by weight:

[0036] 80 parts of ammonium nitrate, 12 parts of water, 4 parts of composite wax for explosives, 2.5 parts of emulsifier, 0.2 part of sensitizer, 0.2 part of accelerator, 1 part of hydroxyethyl acrylate, and 1 part of acrylic acid.

[0037] The emulsifier is a mixture of EX9139 and span-80; the sensitizer is sodium nitrite; the accelerator is phosphoric acid.

[0038] The method steps of the preparation of the emulsifying device proposed by this method are as follows:

[0039] S1: Preparation of oil phase

[0040] Transport the special compound wax for explosives to the oil phase tank and heat to 85°C to melt, then add emulsifier and hydroxyethyl acrylate, stir evenly, add acrylic acid after 2 hours, and continue stirring for 2 hours;

[0041] S2: Aqueous phase preparation

[0042] Transport ammonium nitrate and water to the water phase tank, melt it w...

Embodiment 2

[0048] The emulsion explosive proposed by the present invention comprises the following raw materials in parts by weight:

[0049] Ammonium nitrate 75 parts, water 10 parts, explosive compound wax 3 parts, emulsifier 2 parts, sensitizer 0.1 part, accelerator 0.1 part, hydroxyethyl acrylate 0.5 part, acrylic acid 0.5 part.

[0050] The emulsifier is EX9139; the sensitizer is sodium nitrite; the accelerator is phosphoric acid.

[0051] The method steps of the preparation of the emulsifying device proposed by this method are as follows:

[0052] S1: Preparation of oil phase

[0053] Transport the special composite wax for explosives to the oil phase tank and heat to 80°C to melt, then add emulsifier and hydroxyethyl acrylate, stir evenly, add acrylic acid after 1 hour, and continue stirring for 1 hour;

[0054] S2: Aqueous phase preparation

[0055] Transport ammonium nitrate and water to the water phase tank, melt it with steam not higher than 0.4MPa, and store it at 115°C; ...

Embodiment 3

[0061] The emulsion explosive proposed by the present invention comprises the following raw materials in parts by weight:

[0062]Ammonium nitrate 85 parts, water 13 parts, explosive compound wax 5 parts, emulsifier 3 parts, sensitizer 0.3 parts, accelerator 0.3 parts, hydroxyethyl acrylate 2 parts, acrylic acid 2 parts.

[0063] The emulsifier is span-80; the sensitizer is perlite; the accelerator is phosphoric acid.

[0064] The method steps of the preparation of the emulsifying device proposed by this method are as follows:

[0065] S1: Preparation of oil phase

[0066] Transport the special composite wax for explosives to the oil phase tank and heat to 90°C to melt, then add emulsifier and hydroxyethyl acrylate, stir evenly, add acrylic acid after 3 hours, and continue stirring for 3 hours;

[0067] S2: Aqueous phase preparation

[0068] Transport the ammonium nitrate and water to the water phase tank, melt it with steam not higher than 0.4MPa, and store it at 125°C;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com