Color paste formula for water-based paint and production process thereof

A technology of water-based paint and production process, which is applied in the direction of pigment paste, mixing method, chemical instrument and method, etc. It can solve the problems of discontinuous emulsification process, poor coloring ability of color paste, and poor fluidity of color paste, so as to improve the dispersion effect , Improve emulsification efficiency and avoid waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A color paste formula for water-based paint, made according to the following ratio of raw materials, including: 30% color paste resin, 20% toner, 2% dispersant, 10% titanium dioxide, 20% deionized water, and 5% emulsifier , anti-sticking agent 3%, thickener 3%, carboxylic acid 5% and defoamer 2%.

[0035] A production process for color paste for water-based paint, comprising the following steps;

[0036] Step S1: Add deionized water, color paste resin, toner, titanium dioxide and dispersant to the reaction pot in sequence, and perform preliminary dispersion. Use a disperser to disperse the color paste at high speed and heat it to 50 -80°C, the above-mentioned heated color paste is sanded and refined, and the above-mentioned sand-milled color paste is finely ground with a three-roll mill;

[0037] Step S2: After grinding, sieve through a 200-mesh sieve. After sieving, put the material into an emulsification mixing device, add a carboxylic acid solution for blending, and...

Embodiment approach

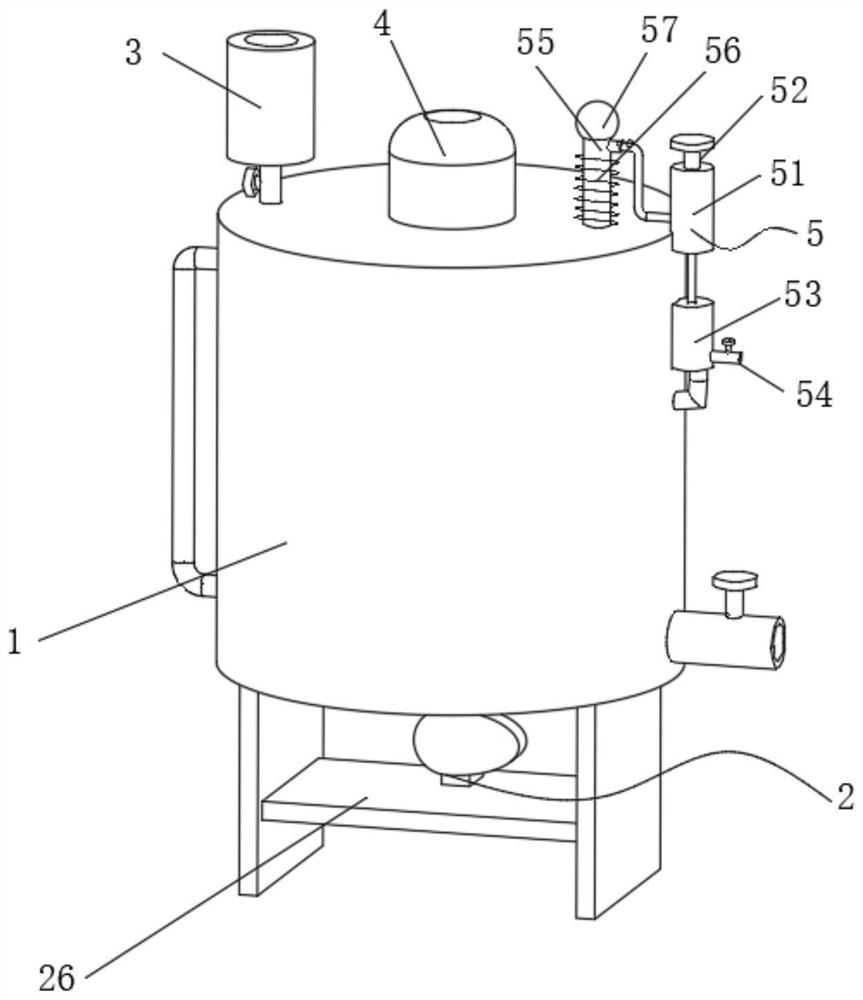

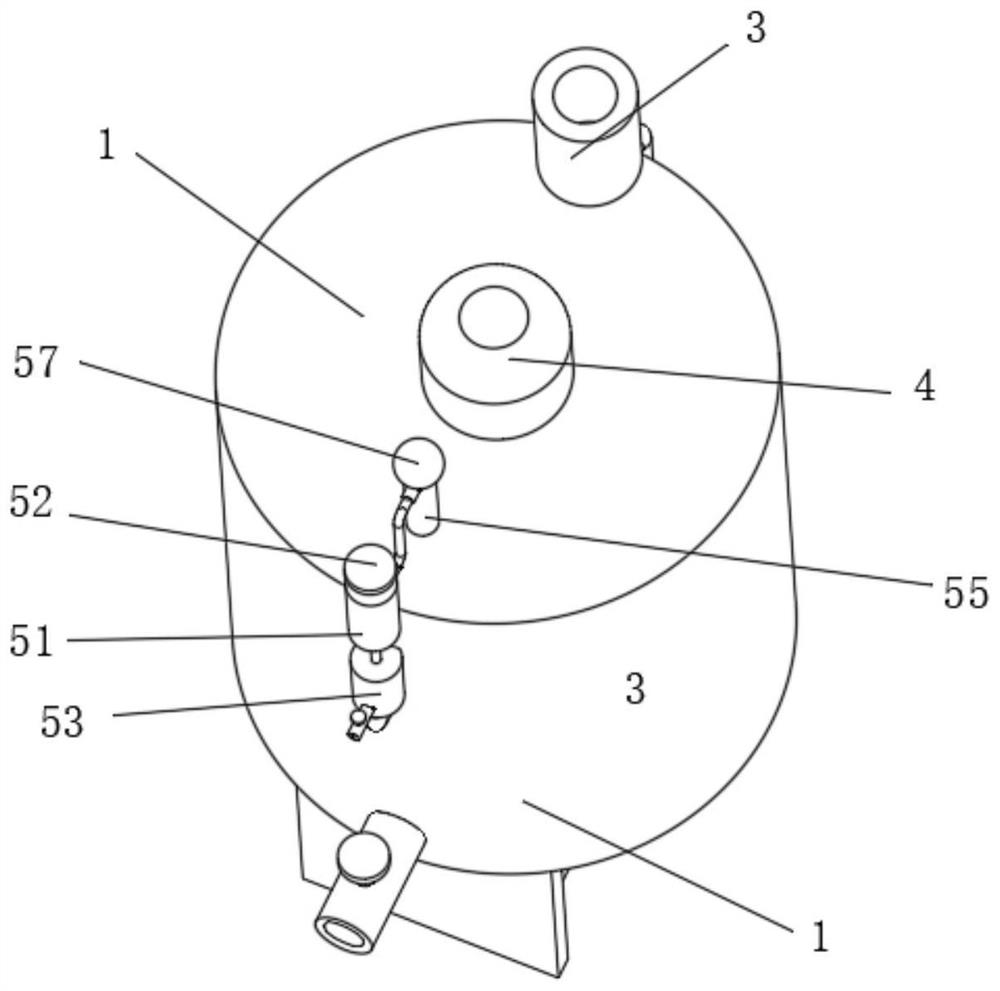

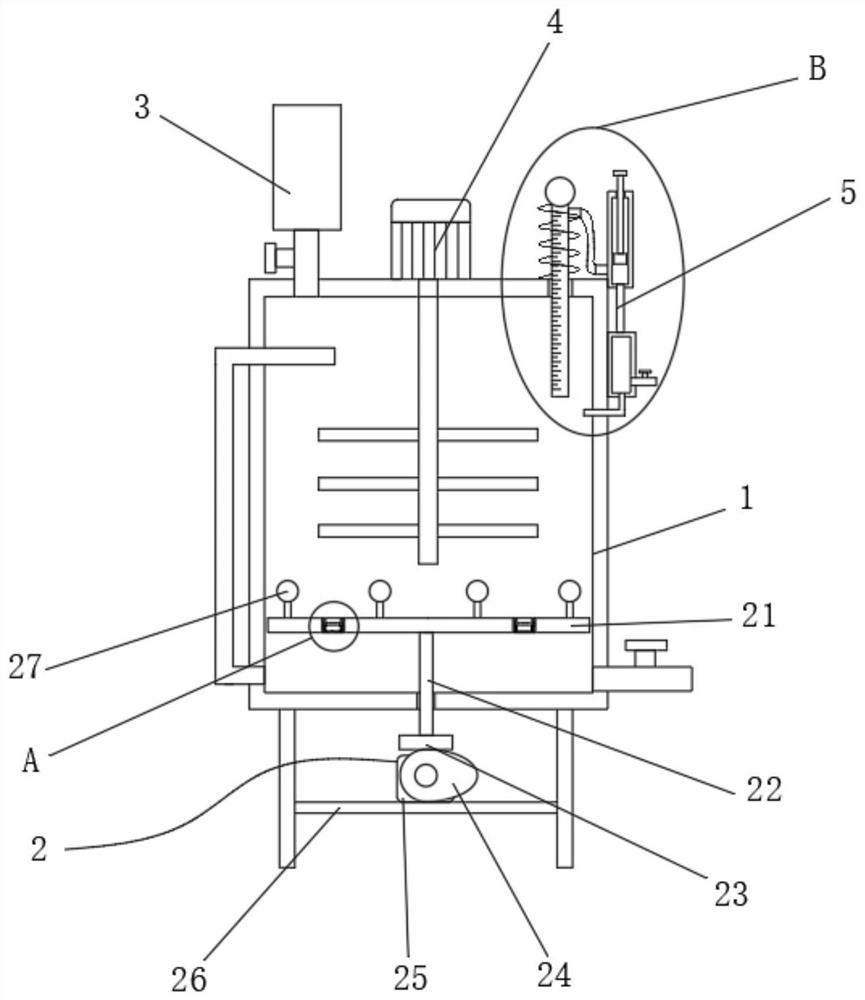

[0042] As an embodiment of the present invention, the vibration emulsification structure 2 includes a piston plate 21, a connecting rod 22, a supporting plate 23, a cam 24, a cam motor 25, a bracket 26, a vibrating rod 27, a contraction spring 28, a sealing plate 29, a guide Flow plate 210, stop rod 211 and diversion hole 212, bracket 26 is welded between two support legs at the bottom of emulsification tank 1, cam motor 25 is installed on the top side of bracket 26, and the rotating shaft of cam motor 25 is equipped with The cam 24 and the piston plate 21 are arranged inside the emulsification tank 1, the top side of the piston plate 21 is provided with a vibrating rod 27, the bottom side of the piston plate 21 is welded with a connecting rod 22, and the bottom end of the connecting rod 22 is welded with a support Plate 23, the inside of piston plate 21 is provided with through hole, is fixed with baffle 210 in the through hole, is provided with rod hole symmetrically in the s...

Embodiment 2

[0046] A color paste formula for water-based paint, made according to the following proportions of raw materials, including: 35% color paste resin, 15% toner, 2% dispersant, 10% titanium dioxide, 20% deionized water, and 5% emulsifier , anti-sticking agent 3%, thickener 3%, carboxylic acid 5% and defoamer 2%.

[0047] A production process for color paste for water-based paint, comprising the following steps;

[0048] Step S1: Add deionized water, color paste resin, toner, titanium dioxide and dispersant to the reaction pot in sequence, and perform preliminary dispersion. Use a disperser to disperse the color paste at high speed and heat it to 50 -80°C, the above-mentioned heated color paste is sanded and refined, and the above-mentioned sand-milled color paste is finely ground with a three-roll mill;

[0049] Step S2: After grinding, sieve through a 200-mesh sieve. After sieving, put the material into an emulsification mixing device, add a carboxylic acid solution for blendin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com