Photosynthetic hydrogen preparation device

A technology for photosynthetic hydrogen production and hydrogen production equipment, which is applied in photobioreactors, biochemical equipment and methods, biochemical instruments, etc., and can solve problems such as excessive auxiliary energy, insufficient reaction, and short contact process between photosynthetic bacteria and organic raw materials , to achieve the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

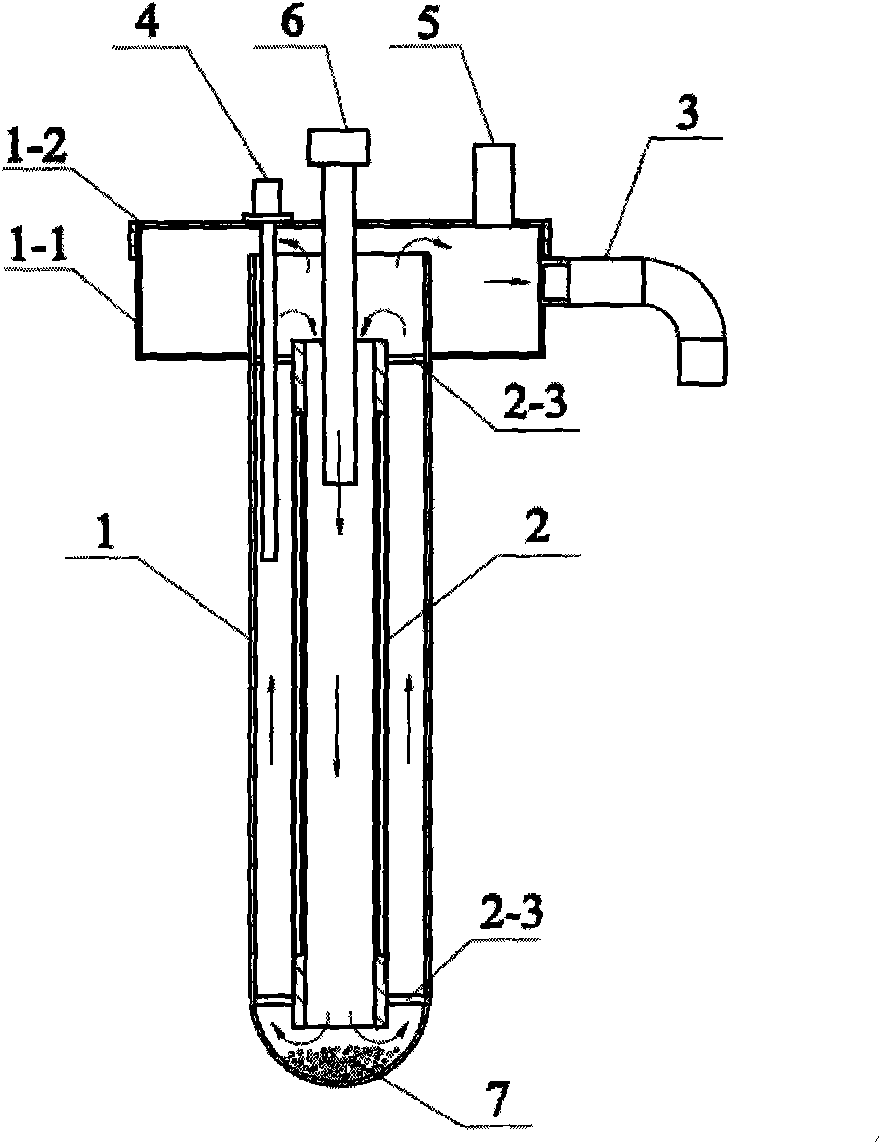

[0017] see figure 1 The reaction cylinder 1 of the photosynthetic hydrogen production device of this embodiment is a cylindrical cylinder with an open upper end and a closed lower end, and an annular groove 1-1 is arranged on the outer side of the upper part, and the top surface of the annular groove 1-1 is higher than the cylindrical cylinder. top of the barrel. A reaction solution outlet 3 is provided on the side wall of the annular groove 1-1, and a cylinder cover 1-2 is provided at the upper end. A reaction liquid inlet pipe 6 is arranged at the center of the top of the cylinder cover 1-2, and an electric heating pipe 4 and a gas outlet 5 are arranged beside the reaction liquid inlet pipe 6 .

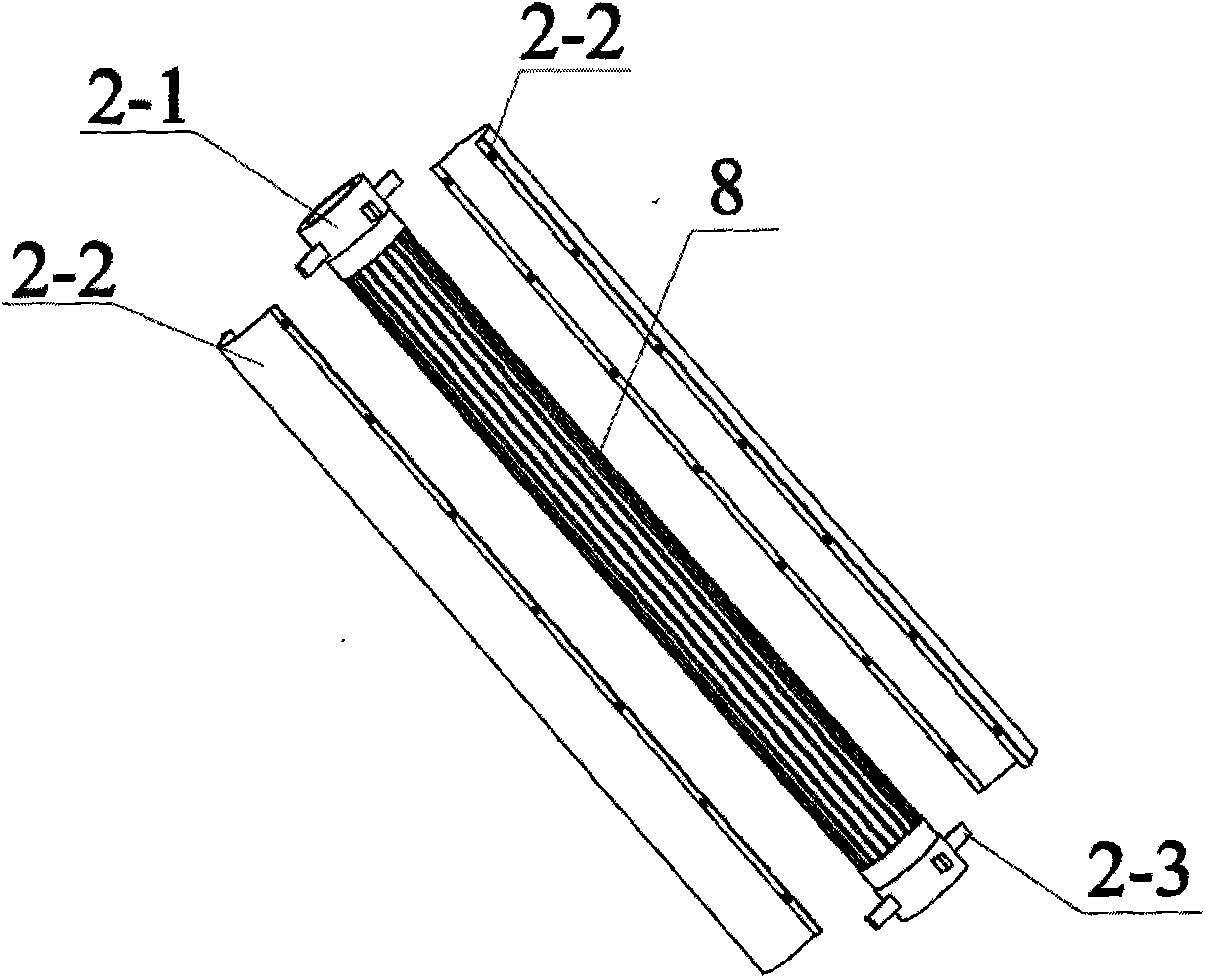

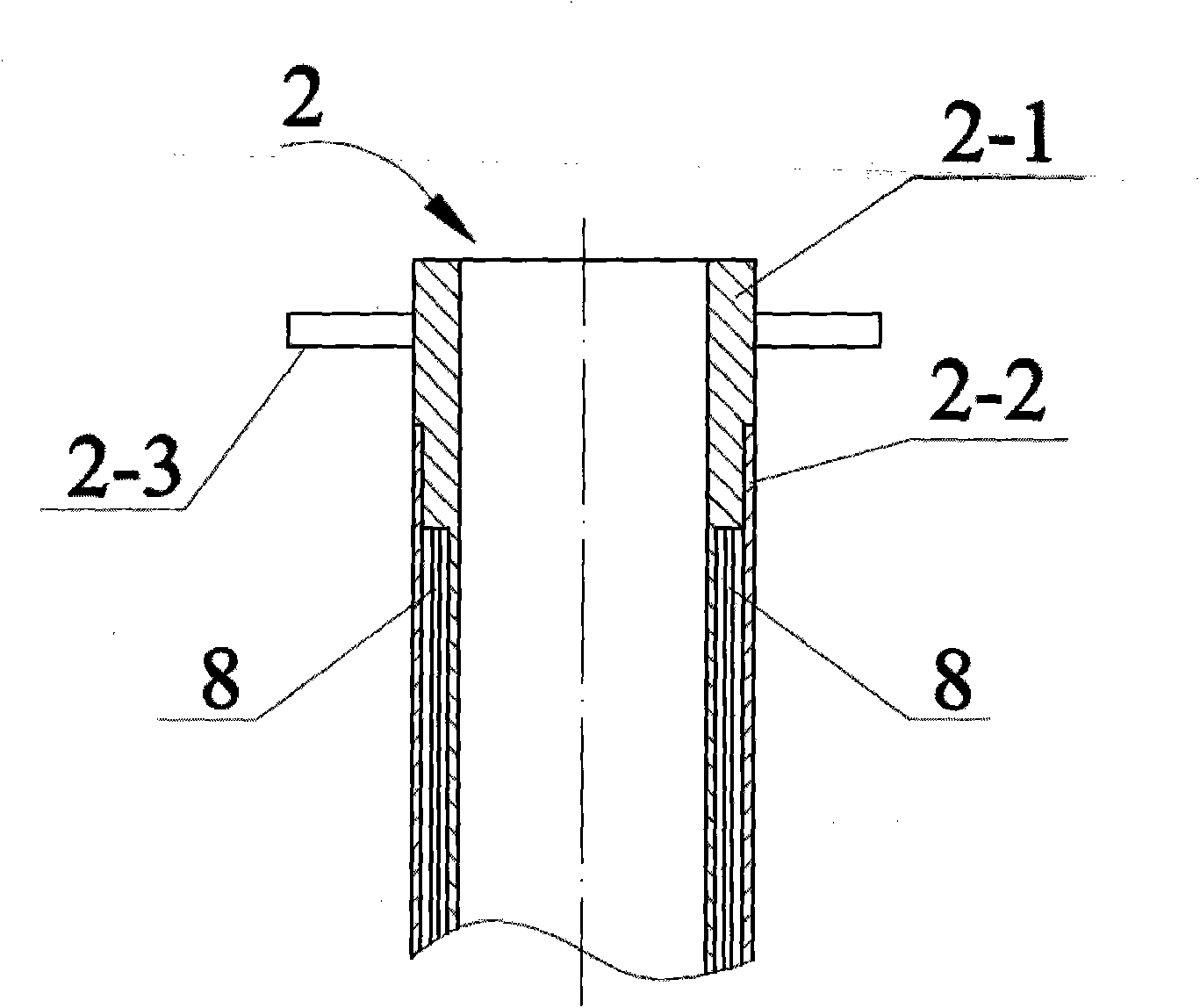

[0018] see Figure 1 ~ Figure 3 , the guide tube 2 is a double-layer structure made of transparent glass, the middle part of its inner tube wall 2-1 is provided with an annular groove, and the wavelength is 500nm fluorescent tube 8 is installed in the annular groove; its outer tub...

example 2

[0020] see Figure 4 , The guide tube in this embodiment is a cylindrical tube 2, the inner and outer walls of which are densely covered with LEDs 2-4, and the head of each LED lamp 2-4 is exposed from the wall of the cylindrical tube 2. In this example, the length of the reaction liquid inlet pipe 6 protruding into the inner cavity of the draft tube 2 is 1 / 3 of the length of the draft tube 2 .

[0021] In this example, other embodiments than the above are the same as in Example 1.

[0022] Describe the working principle of the photosynthetic hydrogen production device of the present invention below in conjunction with embodiment and accompanying drawing:

[0023] see figure 1 , the organic reaction liquid enters the reaction cylinder 1 from the reaction liquid inlet pipe 6 through the guide cylinder 2 under the action of the liquid flow pump. Once the reaction solution is full of reaction cylinder 1 and overflows from the upper end, the newly entered reaction solution will...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com