Patents

Literature

145results about How to "Improve coloring ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

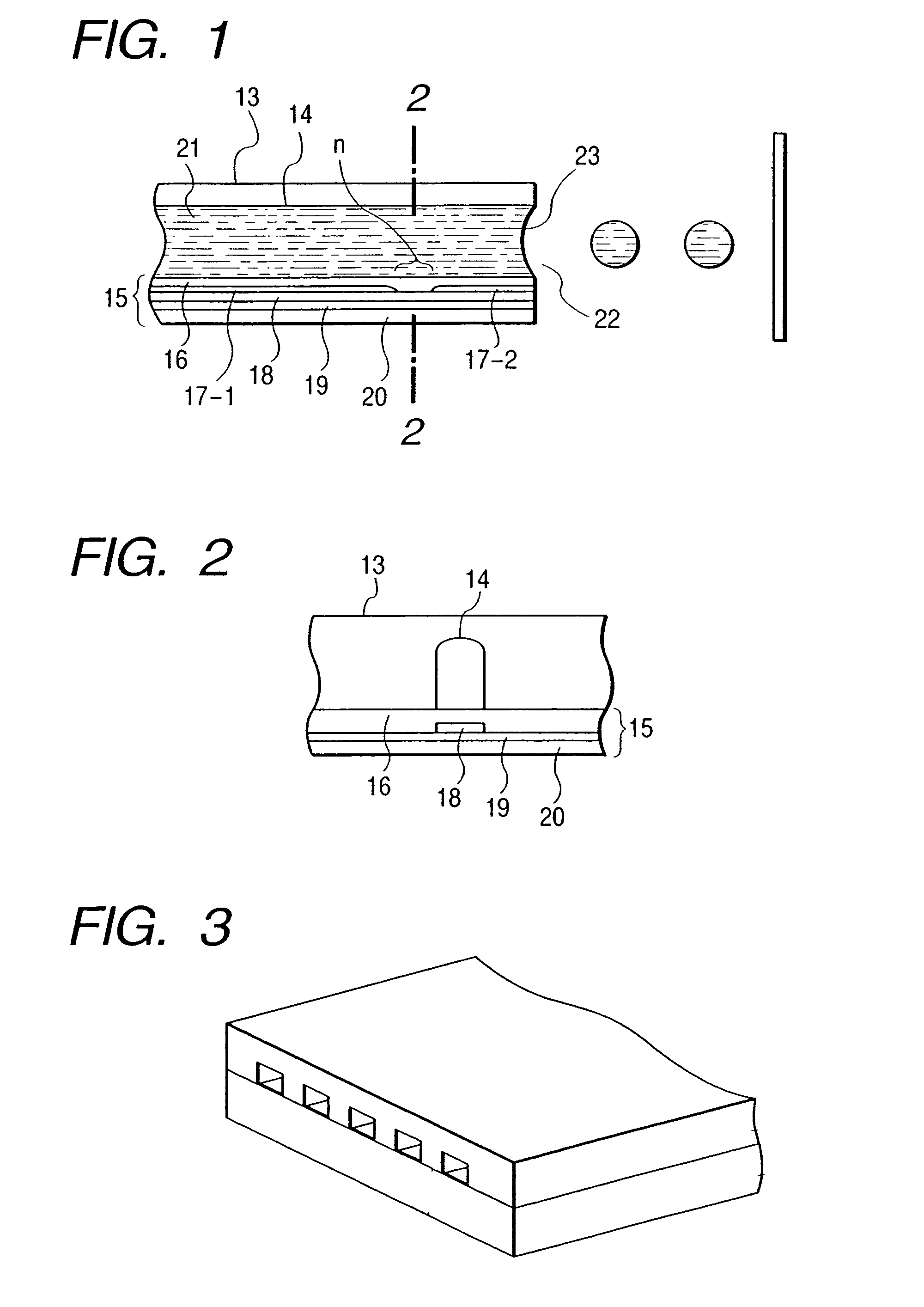

Colored fine resin particles and production process thereof, aqueous dispersion of colored fine resin particles and production process of aqueous dispersion of colored fine resin particles, ink , ink cartridge, recording unit, ink-jet recording apparatus, and ink-jet recording process

InactiveUS7008977B2Good rub-off resistanceExcellent water fastnessInksOrganic dyesDispersion stabilityWater insoluble

The invention provides colored fine resin particles useful as coloring materials for inks which can provide images having good water fastness, weather fastness and rub-off resistance and are excellent in dispersion stability, and a production process thereof. The colored fine resin particles have a structure in which a pigment coated with a water-insoluble resin is encapsulated with a copolymer composed of at least a polymerizable unsaturated monomer and a reactive emulsifier.

Owner:CANON KK

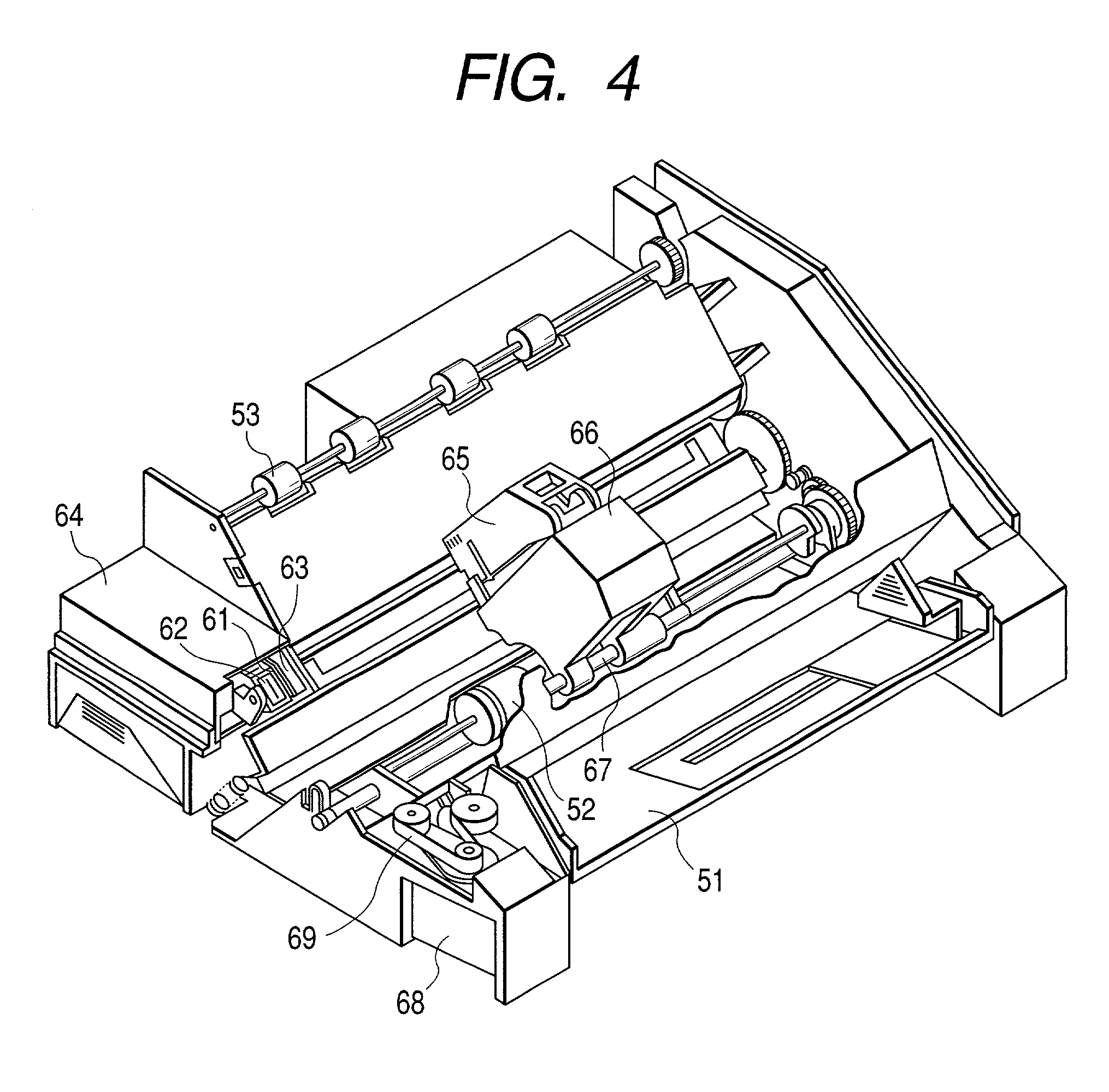

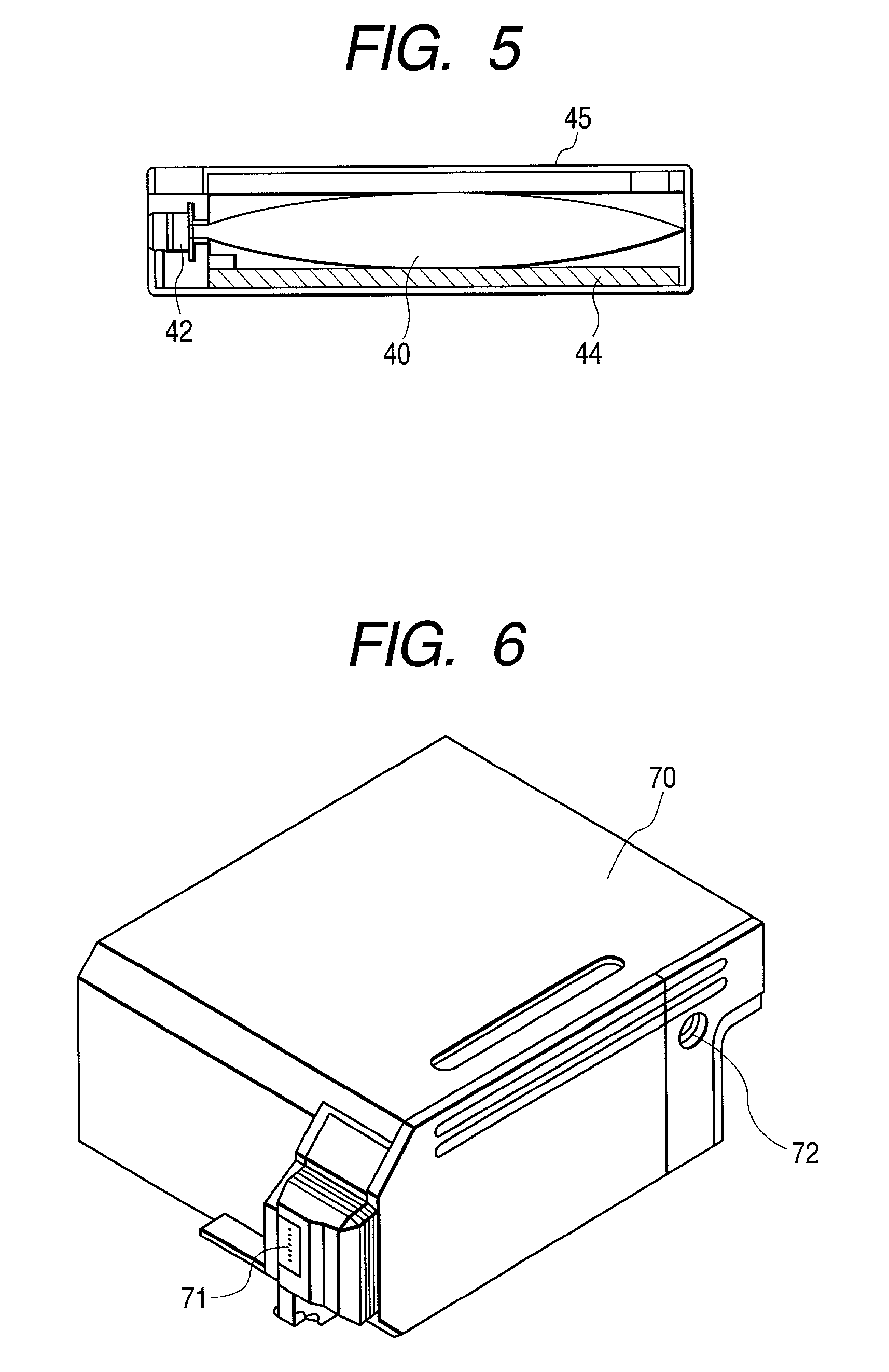

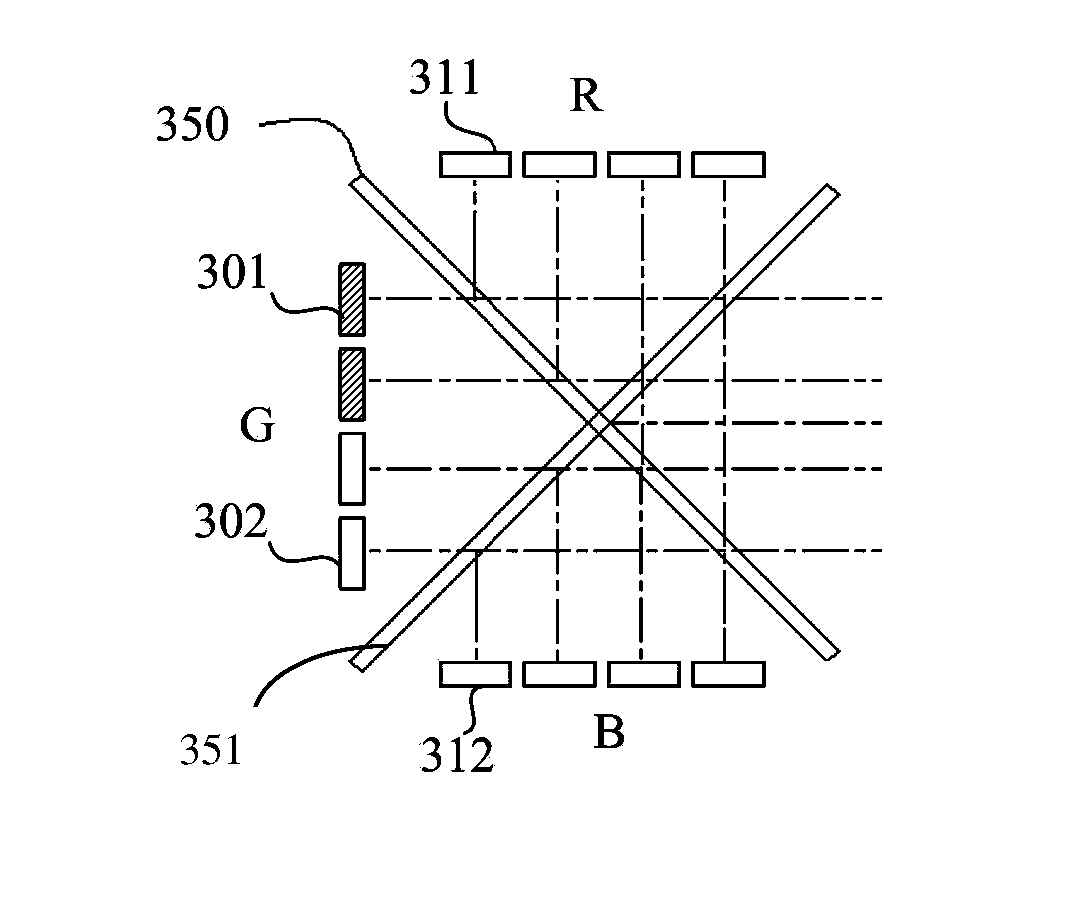

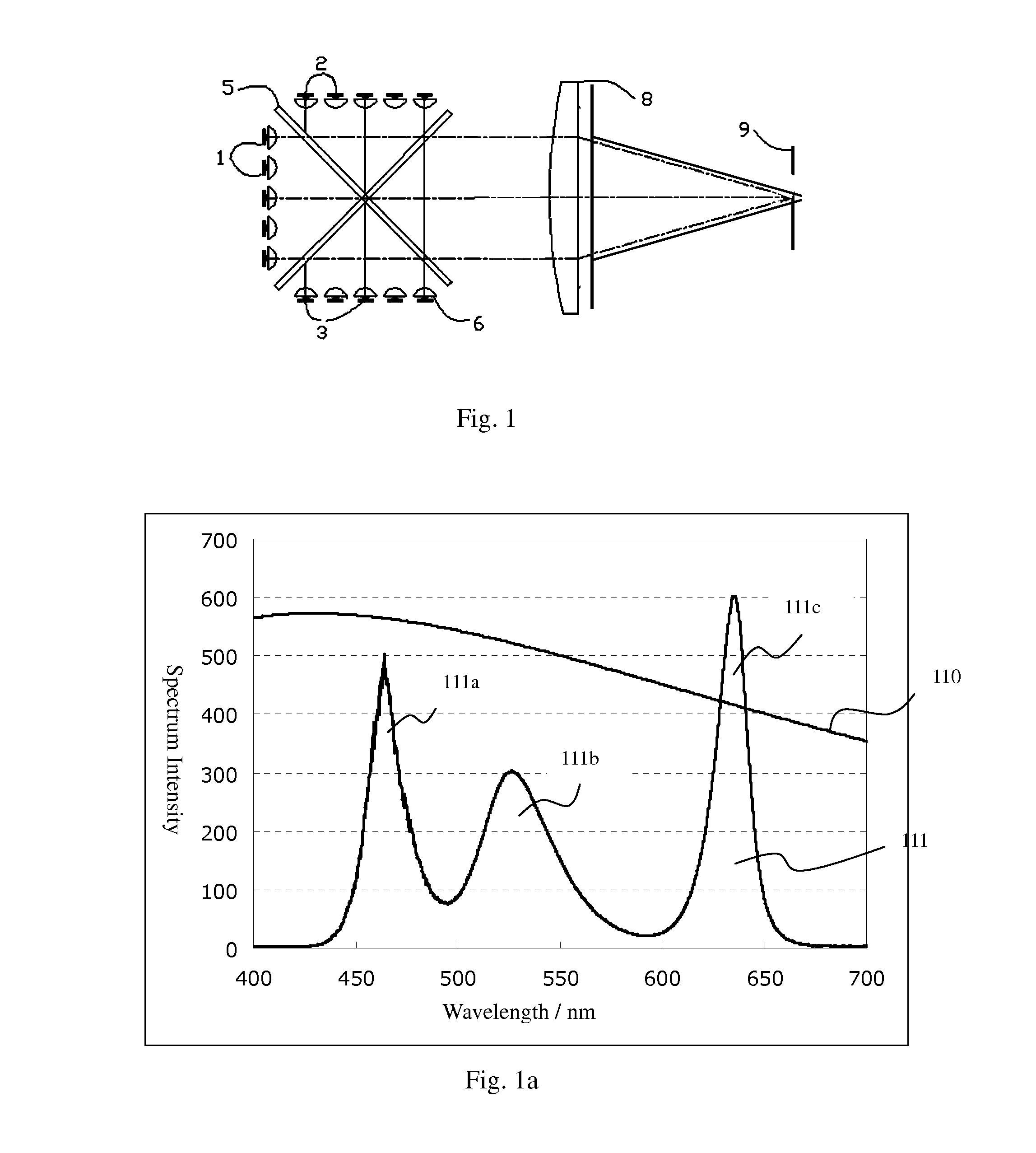

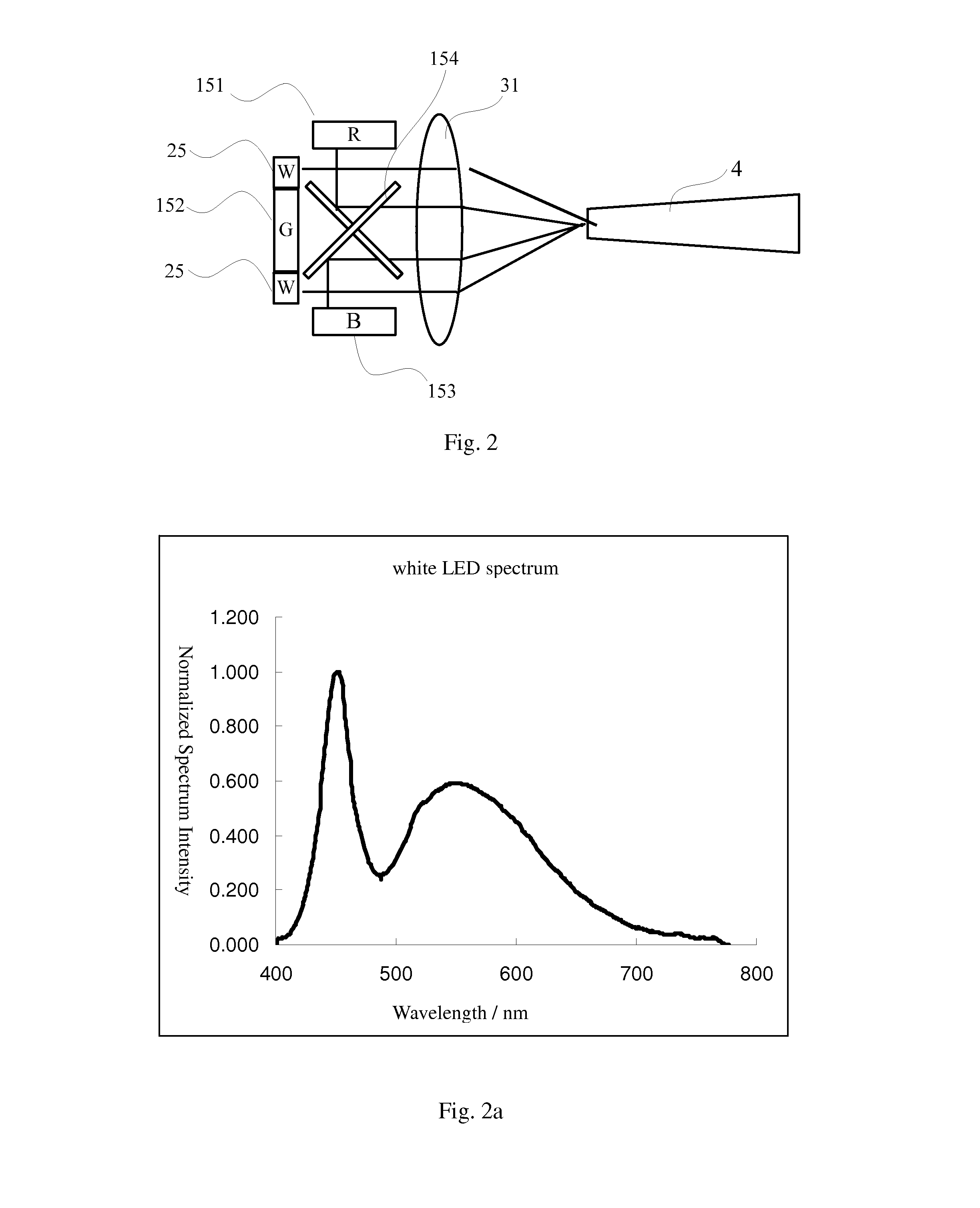

High luminance multicolor illumination devices and related methods and projection system using the same

ActiveUS20130100639A1Improve coloring abilityIncreasing spectrum widthProjectorsColor photographyProjection systemNarrow band

An illumination device and a projection system using the same. The illumination device includes two or more color channels each including one or more light sources for generating a color light. At least one of the color channels includes light sources of a first type for generating a first (narrow band) light and light sources of a second type for generating a second light. The dominant wavelengths of the first and second lights are within 50 nm of each other, and the width of the combined spectrum (sum of normalized spectra of the first and second lights) is greater than the width of the spectrum of the first light by at least 10 nm. A wavelength-based light combiner is used to combine the color lights from the color channels into a combined light

Owner:APPOTRONICS CORP LTD

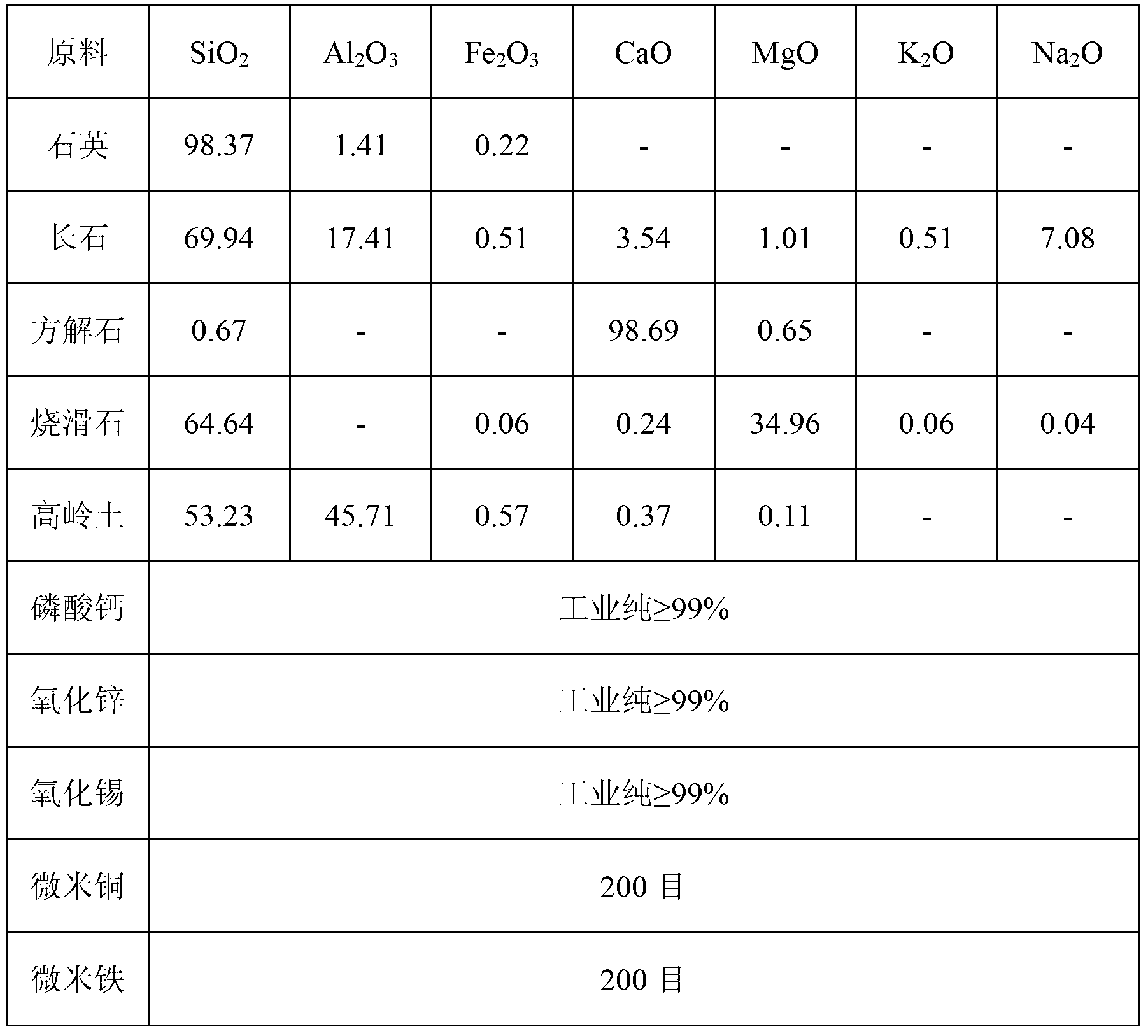

Reddish-black jun porcelain glaze prepared by utilizing metal copper and iron and preparation method of reddish-black jun porcelain glaze

InactiveCN103288493AImprove coloring abilityReduce energy consumption and pollutionCalciteCeramic glaze

The invention discloses a reddish-black jun porcelain glaze prepared by utilizing metal copper and iron and a preparation method of the reddish-black jun porcelain glaze, belonging to the preparation filed of ceramic glazes. The preparation method of the reddish-black jun porcelain glaze comprises the following steps of: (1), mixing the following components in percentage by weight: 45%-50% of feldspar, 20%-30% of quartz, 14%-17% of calcite, 5%-7% of talcum, 2.5%-3.5% of kaolin and 2.9%-3.5% of calcium phosphate, so as to obtain a material mixture, and adding and sufficiently mixing the following materials (based on the total weight of the material mixture): 0.3%-2% of ZnO, 1.5%-4% of SnO2, 0.2%-2% of Fe, 0.1%-1.5% of Cu, 0.1%-0.5% of cellulose and 0.5%-1.5% of sodium tripolyphosphate, so as to obtain a glaze mixture; (2), carrying out wet-process ball-milling on the glaze mixture to obtain glaze pulp; (3), applying the glaze pulp on a biscuit firing billet for firing for 20 minutes-40minutes in a neutral or weak oxidative atmosphere, and cooling to obtain the reddish-black jun porcelain glaze. The preparation method of the reddish-black jun porcelain glaze is simple and easy to implement, board in firing temperature range and easily controllable in firing atmosphere. And the reddish-black jun porcelain glaze obtained by the preparation method disclosed by the invention is simple in composition, smooth and flat in glazed surface, high in stability and bright in reddish-black color.

Owner:SHAANXI UNIV OF SCI & TECH

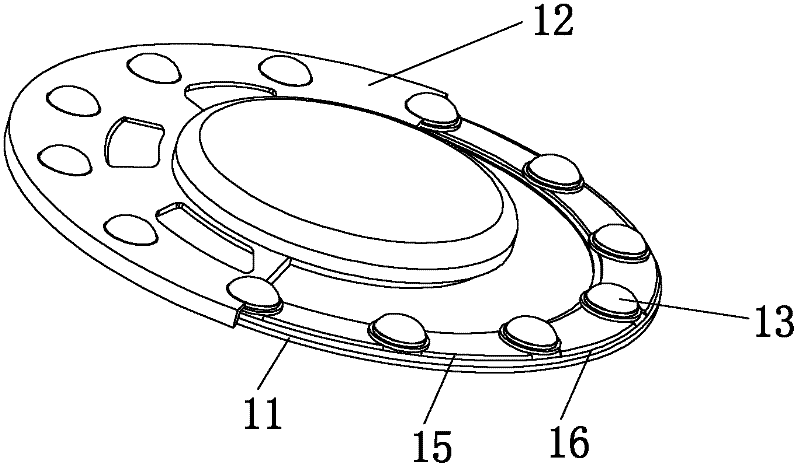

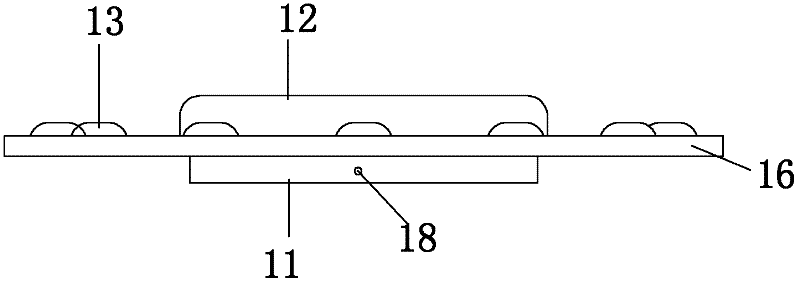

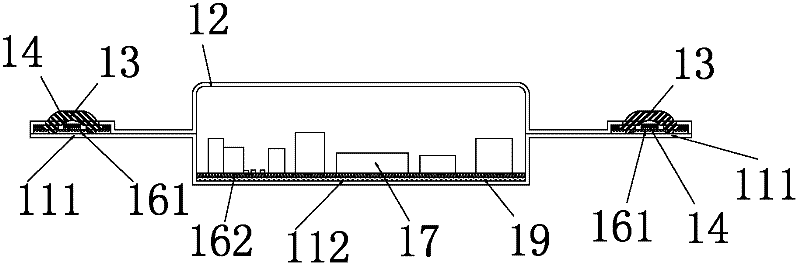

Integrated LED lighting source

ActiveCN102410462AUniform and soft glowHigh light efficiency and effective lighting ratePoint-like light sourceLighting heating/cooling arrangementsElectricityEngineering

The invention provides an integrated LED lighting source which comprises a bottom housing, a circuit board, an optical lens and a drive power supply, wherein the circuit board is attached on the bottom housing and is provided with a plurality of LED light-emitting bodies backing on to the bottom housing, the optical lens covers above the LED light-emitting bodies and is used for carrying out secondary optical distribution on light rays of each LED light-emitting body, and the drive power supply is electrically connected to the circuit board. The LED light-emitting bodies are used as the light source, thus emitted light rays are uniform and soft through secondary optical distribution and an arrangement mode calculated through simulation, electricity-saving lighting is realized, and high light efficiency and effective lighting rate of LED lighting are kept.

Owner:深圳市亿量光电科技有限公司

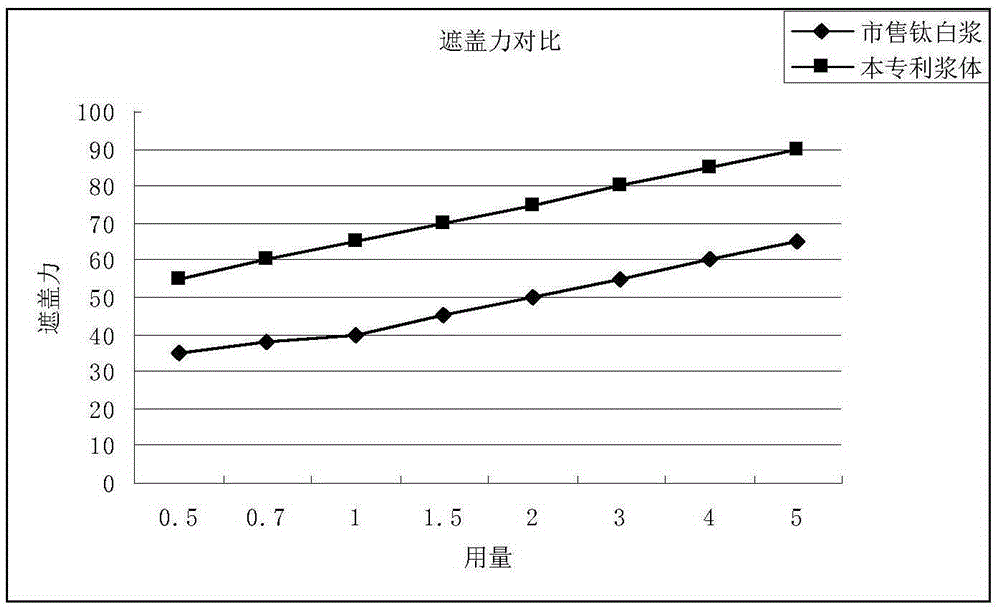

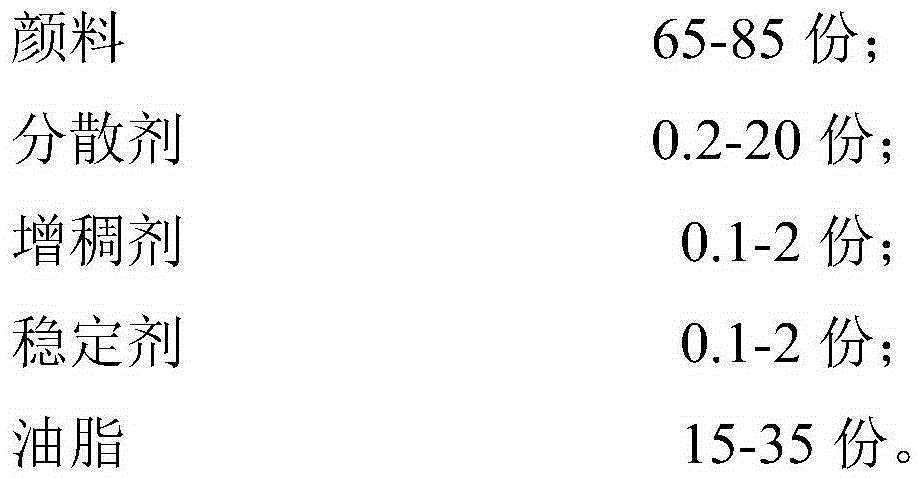

High-pigment-content pure oil non-emulsification cosmetic color paste and preparation method

ActiveCN105331200AHigh solid contentIncrease coverageCosmetic preparationsMake-upCosmetic ingredientReady to use

The invention discloses high-pigment-content pure oil non-emulsification cosmetic color paste and a preparation method. The color paste is prepared from, by weight, 65-85% of pigment, 0.2-2% of a dispersing agent, 0.2-2% of stabilizer and 12-35% of grease. The high-pigment-content pure oil non-emulsification cosmetic color paste is characterized in that the pigment content is high, and the color paste belongs to pure oil non-emulsification color paste. The utilized pigment, the grease, the dispersing agent and the stabilizer are all raw materials which are allowed to be used by a China Cosmetic Ingredient Dictionary, a product is high in solid content, high in covering power, good in stability, high in safety, convenient to use, free of water, easy to add, easy to scatter, simple in preparation process and easy to produce, is the best substitute of traditional powdery pigment and is suitable for the field of cosmetics, food and the like.

Owner:广州联锴粉体科技有限公司

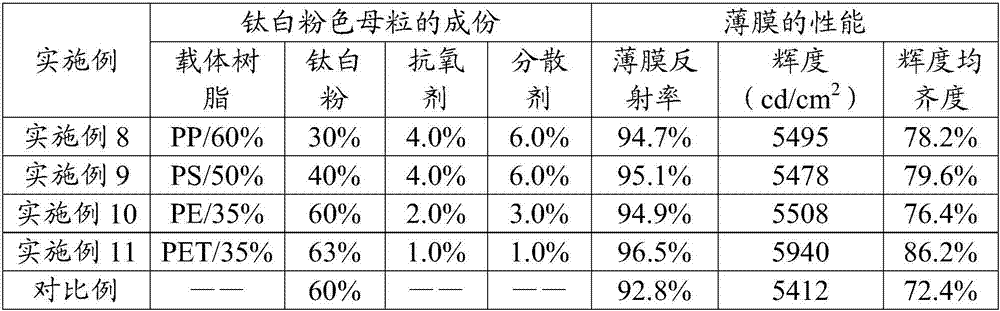

Titanium dioxide masterbatch and preparation method thereof

The invention relates to the field of plastic coloring and in particular to titanium dioxide masterbatch and a preparation method thereof. In order to solve the problem that existing white masterbatch is relatively poor in compatibility with PET, the invention provides the titanium dioxide masterbatch and the preparation method thereof. The titanium dioxide masterbatch comprises the following raw materials in percentages by weight: 20-60% of carrier resin, 30-70% of titanium dioxide, 1-6% of a dispersant and 1-4% of an antioxidant. The titanium dioxide masterbatch provided by the invention has the advantages of being strong in coloring ability and good in dispersibility and good in compatibility with PET. The preparation method of the titanium dioxide masterbatch provided by the invention is simple in process and suitable for scaled production.

Owner:NINGBO CHANGYANG TECH

Compound feed for fattening period of yellow-head catfish

InactiveCN103535562AGuaranteed nutritionBody color back to normalAnimal feeding stuffFish mealAnimal science

The invention discloses a compound feed for the fattening period of yellow-head catfish. The feed comprises the following materials in parts by weight: 0.1-0.3 part of microelements, 0.03-0.06 part of vitamins, 1-2 parts of mineral substances, 20-40 parts of bean pulp, 5-8 parts of corn gluten meal, 15-25 parts of import fish meal, 0.04-0.08 part of bile salts materials, 1-2 parts of spiral seaweed powder, 4-6 parts of kelp powder, 4-6 parts of grease, 0.004-0.008 part of xanthophyll and 20-30 parts of flour. According to the feed, various nutrition ingredients are balanced, matching is reasonable, and the compound feed is suitable for fast growth of the yellow-head catfish; the body color of the yellow-head catfish can be close to that of wild yellow-head catfish.

Owner:TIANJIN CHENHUI FEED

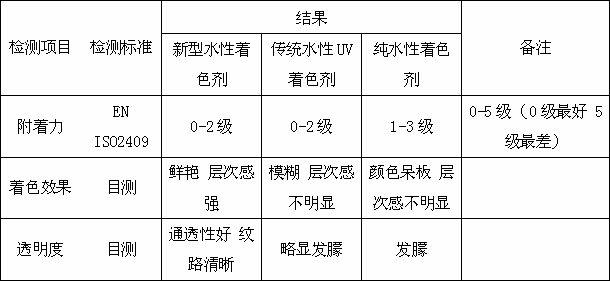

Water-based coloring base material and preparation method thereof

The invention discloses a water-based coloring base material and a preparation method thereof. The water-based coloring base material comprises the following raw materials in percentage by weight: 30-40% of water-base resin 1, 20-30% of water-base resin 2, 20-30% of water, 1-1.5% of sensitiser, 1-2% of thickener, 5-8% of alcohol ether solvent, 0.1-0.5% of defoamer, and 0.5-1% of PH value regulator. The water-based coloring base material has the advantages of high permeability, high coloring effect, environmental protection and no odor, good adhesion, convenience in construction and the like, besides the basic properties of both of a UV (Ultraviolet) water-based coloring base material and a purely water-based coloring base material. In addition, the water-based coloring base material can be directly matched with a water-based pigment and a water-based dye, and diluted by water to obtain appropriate color concentration, thereby achieving perfect ornamental effect and meeting the requirements of customers.

Owner:JIANGSU HIMONIA TECH

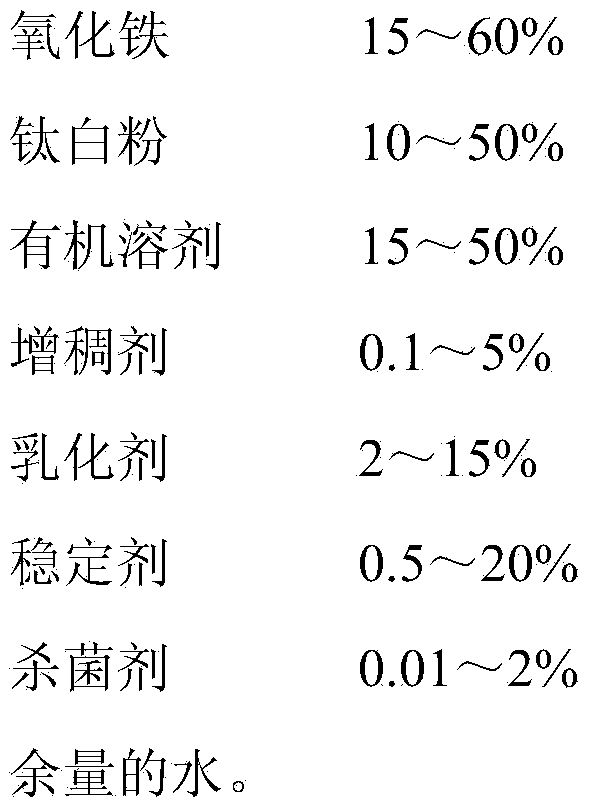

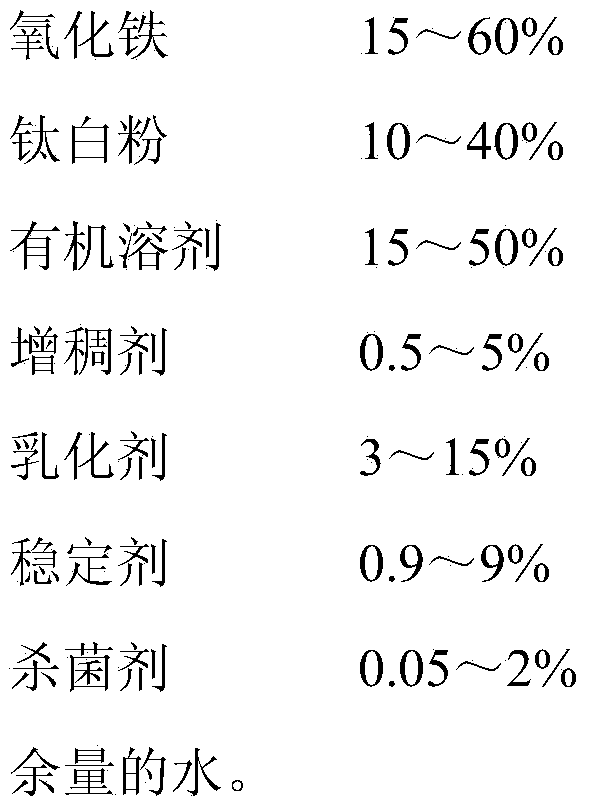

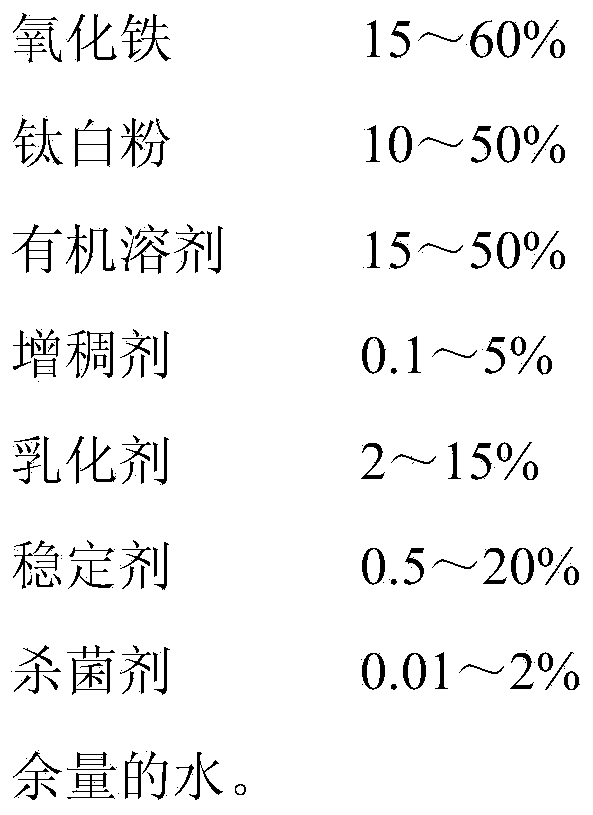

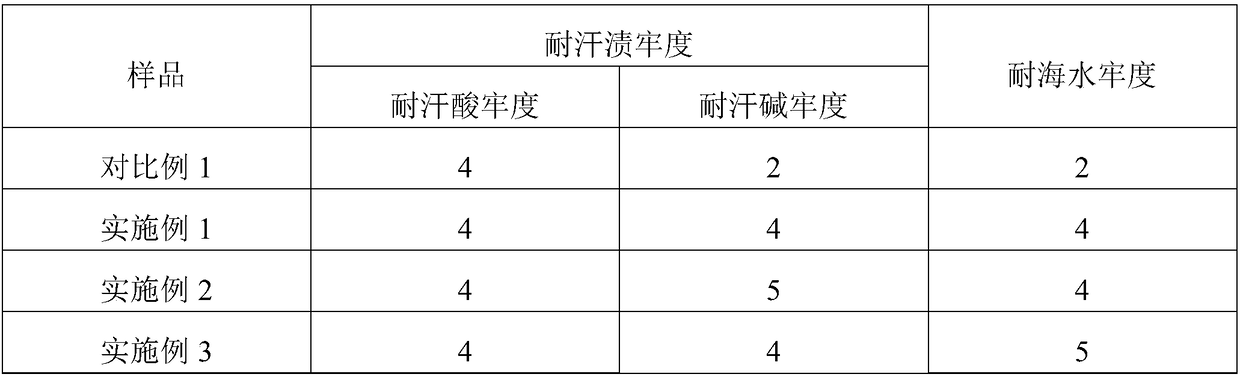

Ferric oxide oily color paste

ActiveCN104212246AImprove lipophilicityIncrease viscosityCosmetic preparationsAntifouling/underwater paintsOrganic solventSolid content

The invention provides ferric oxide oily color paste which comprises the following components in percentage by weight: 15%-60% of ferric oxide, 10%-50% of titanium dioxide, 15%-50% of an organic solvent, 0.1%-5% of a thickener, 2%-15% of an emulsifier, 0.5%-20% of a stabilizer, 0.01%-2% of a microbicide and the balance of water. The ferric oxide oily color paste has the advantages of good coloring and covering capability, high solid content, excellent waterproof performance, good in stability and the like, and is safe, nontoxic, convenient to use; moreover, the ferric oxide oily color paste is relatively low, a preparation process is simple and easy for industrialized production, and the ferric oxide oily color paste can replace conventional ferric oxide powder and is widely applied in the fields of cosmetics, food package and the like.

Owner:ZHANGJIAGANG GREAT CHEM

High-color-fastness low-melting-point polyamide masterbatch preparation method

The invention discloses a high-color-fastness low-melting-point polyamide masterbatch preparation method. The method includes: well mixing, by weight, 60-95 parts of a carrier, 4-40 parts of a coloring agent and 0.1-7 parts of a dispersing agent in a mixer, adopting a double-screw extruder for melt blending at 200-230 DEG C, and granulating to obtain high-color-fastness low-melting-point polyamidemasterbatch, wherein the carrier is prepared from low-melting-point copolyamide and ethylene-vinyl acetate copolymer; the low-melting-point copolyamide is prepared from 30-40 parts of caprolactam, 10-20 parts of nylon 66 salt and 50-60 parts of diacid and diamine, and a mole ratio of diacid to diamine is 1:(0.9-1.1). The masterbatch prepared according to the method is high in dispersity, colorability and color fastness.

Owner:GUANGDONG XINHUI MEIDA NYLON

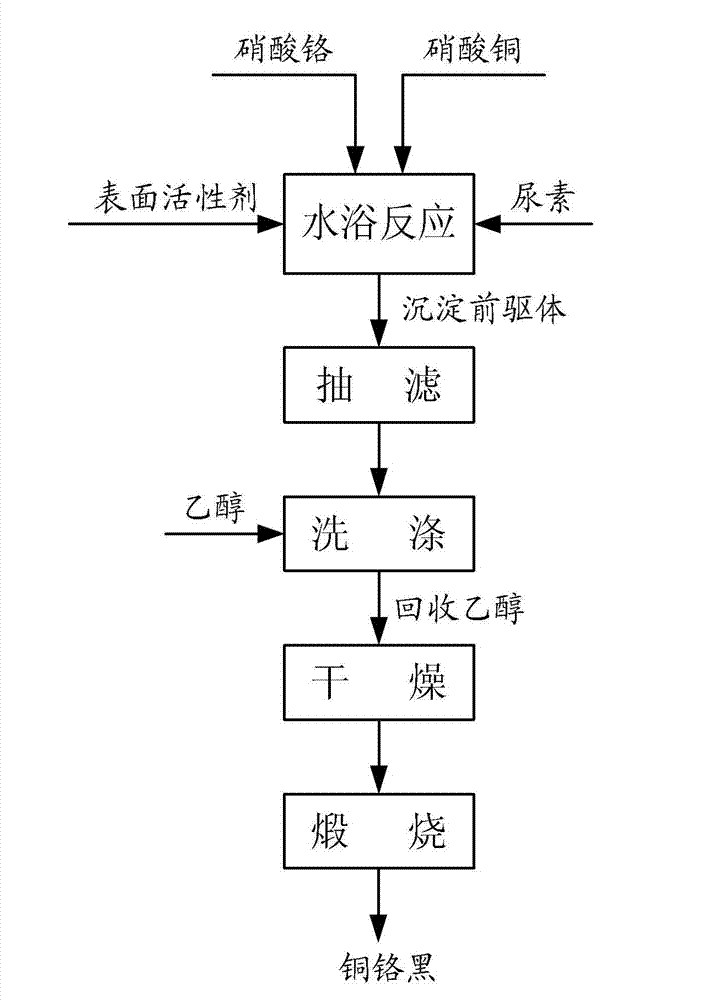

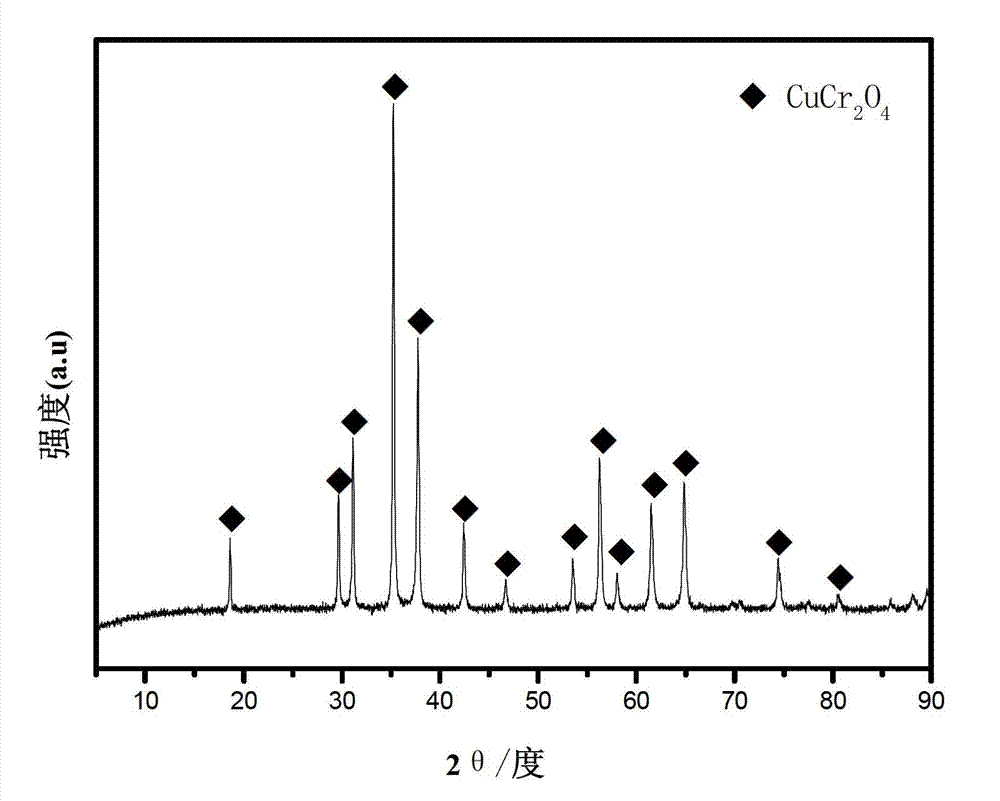

Copper chromite black pigment, and preparation method and application thereof

ActiveCN103708555ASmall particle sizeEvenly distributedChromium oxides/hydratesAlcoholCopper chromite

The invention relates to a preparation method of a copper chromite black pigment. The method comprises the steps of adding a urea solution into a mixed solution of a divalent copper salt and a trivalent chromic salt to generate a copper chromite black precipitate in an environment in presence of a surfactant; washing the precipitate with alcohol; and drying the precipitate to obtain the copper chromite black precipitate. The preparation method of the copper chromite black is high in reactive activity; a sintering temperature is reduced by about 200 DEG C than that of a solid phase method; the obtained copper chromite black powder is very fluffy; and the copper chromite black pigment with small particle size and uniform distribution can be obtained without any grinding or ball-milling process.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Yellowing-resistant water-based glaze, and preparation method and application thereof

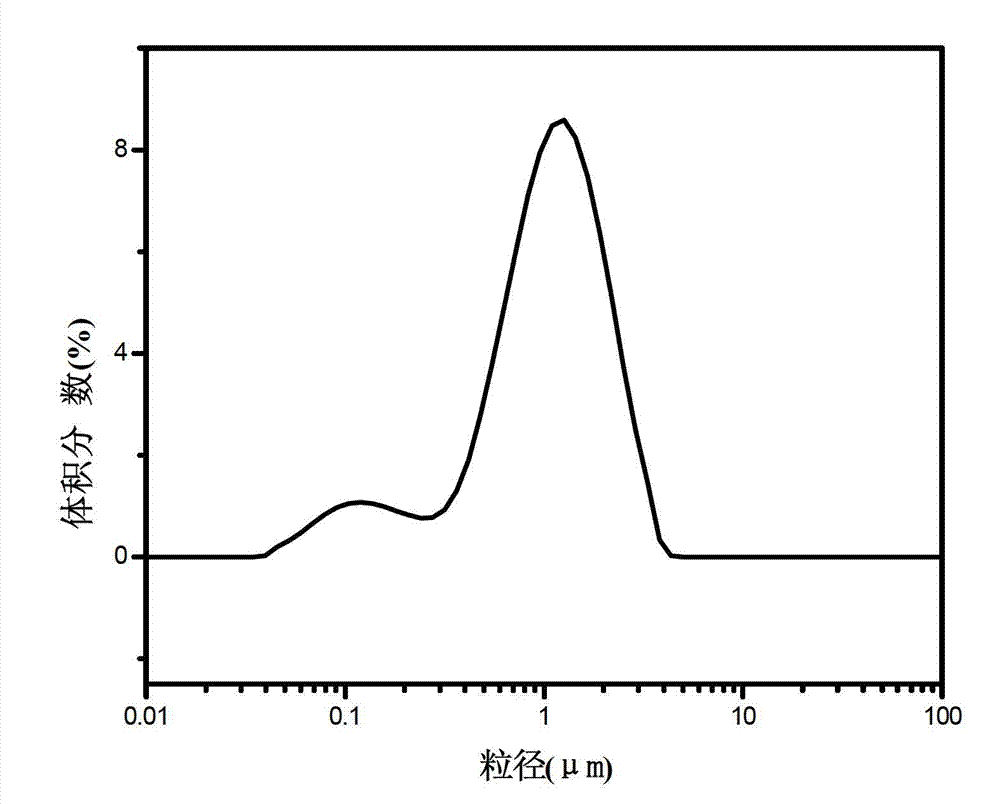

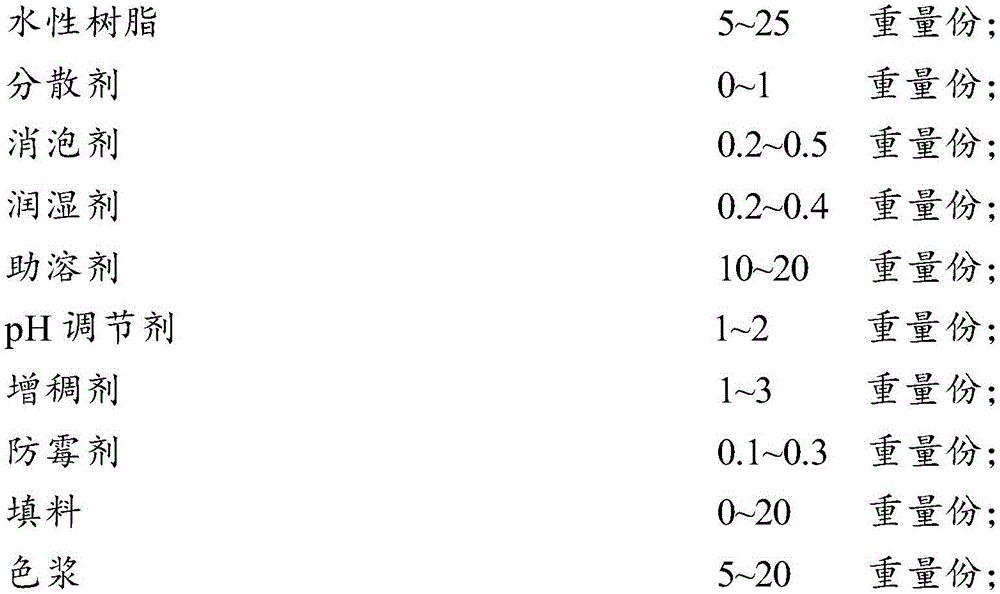

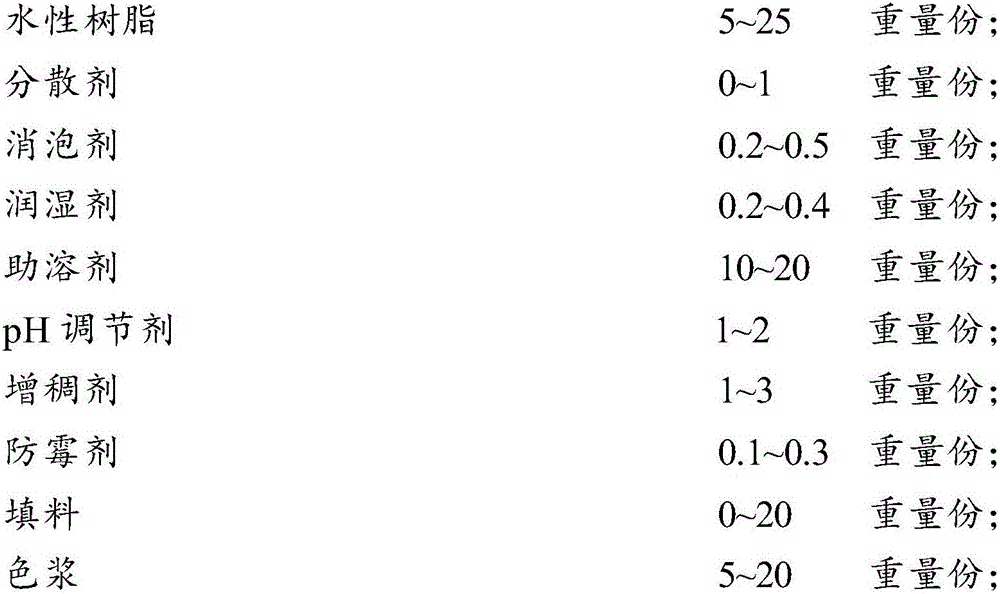

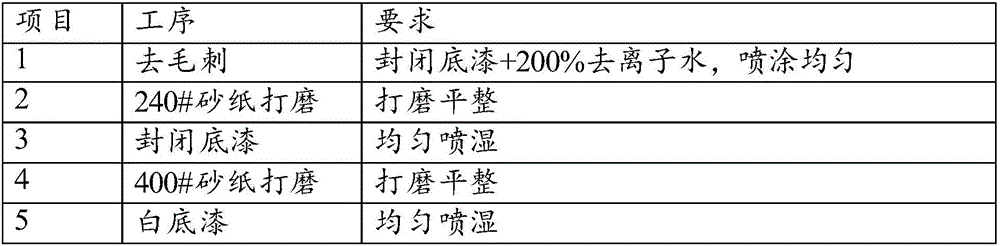

The invention provides a water-based glaze which comprises the following components in parts by weight: 5-25 parts of water-based resin, 0-1 part of dispersing agent, 0.2-0.5 part of defoaming agent, 0.2-0.4 part of wetting agent, 10-20 parts of cosolvent, 1-2 parts of pH regulator, 1-3 parts of thickener, 0.1-0.3 part of mildew preventive, 0-20 parts of filler, 5-20 parts of color paste and the balance of water. The yellowing-resistant water-based glaze has excellent wiping property and excellent yellowing resistance, and can keep no discoloration for a long time under illumination conditions. Thus, the furniture color of the wood products applied by the glaze can keep constant. The water-based glaze has the advantages of high coloration effect, high transparency, high layering sensation and moderate drying time, and is very convenient for on-site construction.

Owner:SHENZHEN EGO NEW MATERIALS CO LTD

Method for preparing nontoxic coloured silicasol

InactiveCN101177273AOvercome the shortcomings of colorless and transparentBright colorSilicon compoundsGranularityDissolution

The invention provides a preparation method for nontoxic colored silica sol, which comprises the following steps: firstly, the colorless silica sol is prepared, and the pH of the colorless silica sol is adjusted into neutral, and then the colorless silica sol is mixed with the nontoxic colored metal ionized water solution; the pH value of the mixture is adjusted to 2 to 4, and the mixture is reacted for 6 to 10 hours under the conditions of heating and stirring, and then is filtered and concentrated for producing the nontoxic colored silica sol. The invention overcomes the shortcomings of colorlessness and transparence existing in the prior silica sol; the nontoxic colored metallic particles are adopted to make the generative silica sol be colorful during the process of preparing the silica sol with silicon dissolution method. The granularity of the prepared silica sol is 5 to 37nm. The silica sol which is prepared with the method of the invention has the advantages of stable quality, innocuity, bright color and strong colouration, thereby the invention can be widely used in preparing nontoxic colored medical equipment, food package film and other products.

Owner:国家复合改性聚合物材料工程技术研究中心

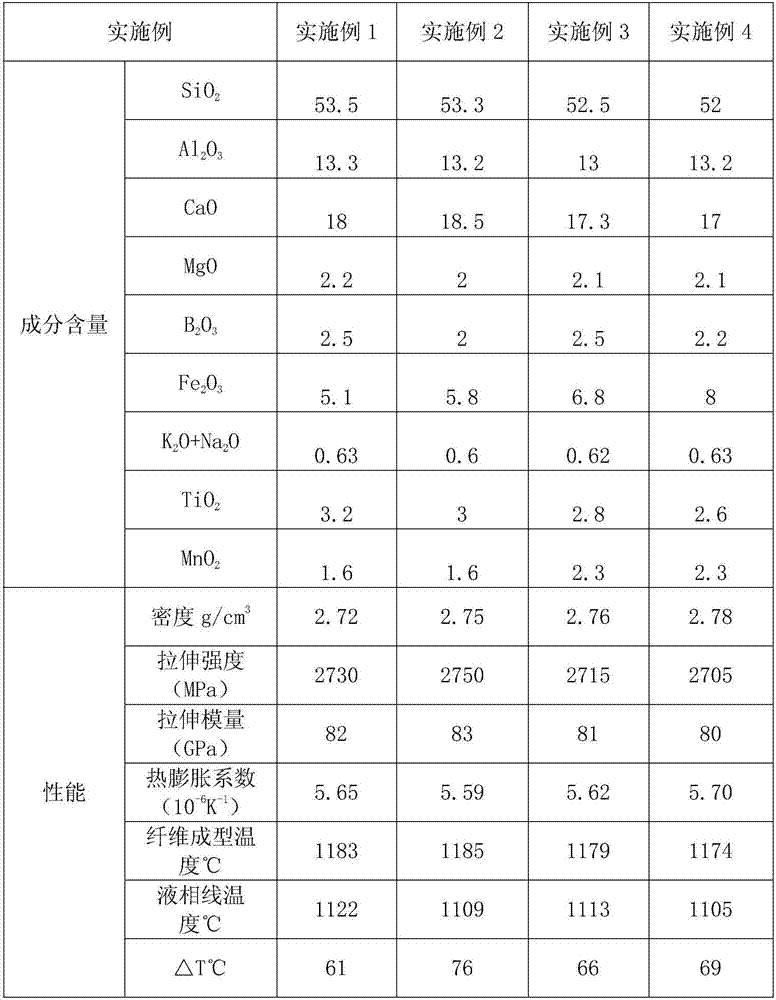

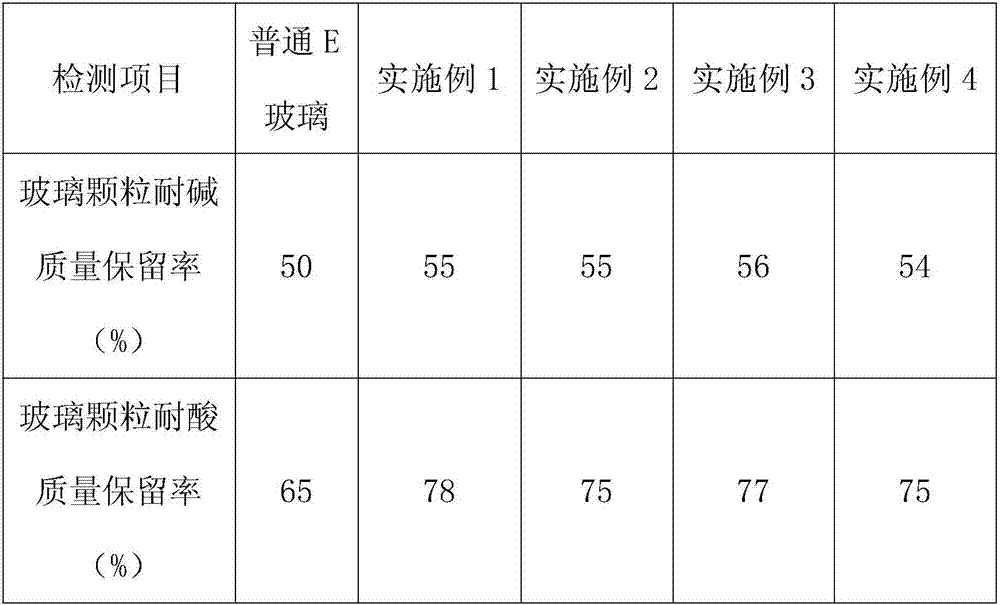

Black glass fiber and preparation method thereof

InactiveCN106927672AImprove coloring abilityGood crystallization performanceGlass making apparatusFiberGlass fiber

The invention provides black glass fiber and a preparation method thereof. The black glass fiber prepared by virtue of the preparation method contains SiO2, Al2O3, CaO, MgO, B2O3, Fe2O3, TiO2, MnO2 and K2O+Na2O. The black glass fiber is prepared through direct wiredrawing in a preparation process, and secondary dip dyeing is omitted, so that the problems in the prior art that the dyeing is not uniform, the dyeing adhesive force is poor and the fiber is easy to fall in a secondary dip dyeing process are solved. The preparation method provided by the invention has the beneficial effects that the prepared black glass fiber is low in melting temperature and high in acid-base resistance, and the main raw material is basalt which is widely distributed, high in reserve and low in cost, so that the production cost is greatly lowered.

Owner:TAISHAN FIBERGLASS INC

Method for preparing fluorophlogopite compound titanium dioxide

ActiveCN102093759AImprove product qualityHigh whitenessInorganic pigment treatmentTitanium dioxideFiltrationTitanium metal

The invention discloses a method for preparing fluorophlogopite compound titanium dioxide. The method comprises the steps of: soaking fluorophlogopite powder in water to obtain mixed solution, adding oxalic acid to adjust the pH value to be between 2 and 3, and then adding a nonionic surfactant; then adding titanium tetrachloride and stirring, and stopping adding and preserving heat for a period of time when the hue of the mixed solution turns blue, wherein titanium metal can be cladded on the surface of fluorophlogopite through the process; and then performing filtration treatment to obtain primary raw materials of the fluorophlogopite compound titanium dioxide, and then performing drying and calcination treatment to finally obtain a finished product of the fluorophlogopite compound titanium dioxide. The fluorophlogopite compound titanium dioxide prepared by the method can be used for coatings, and the coatings have high whiteness (can reach over 99.8), bright and clean surfaces as well as good high temperature resistance and weather resistance, and can never change color and fade. The fluorophlogopite compound titanium dioxide also has the characteristics of good electrical insulating property, antistatic performance, acid and alkali corrosion resistance, strong coloring power and the like, and is simple in processing technology and low in cost.

Owner:JIANGYIN YOUJIA PEARLESCENT MICA

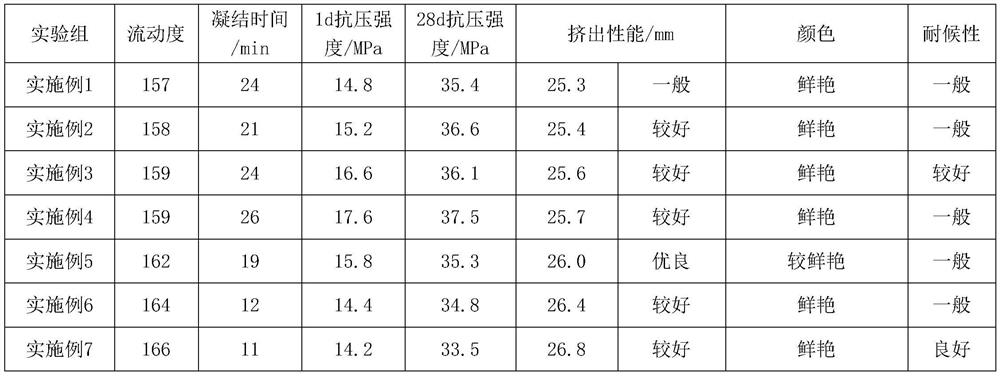

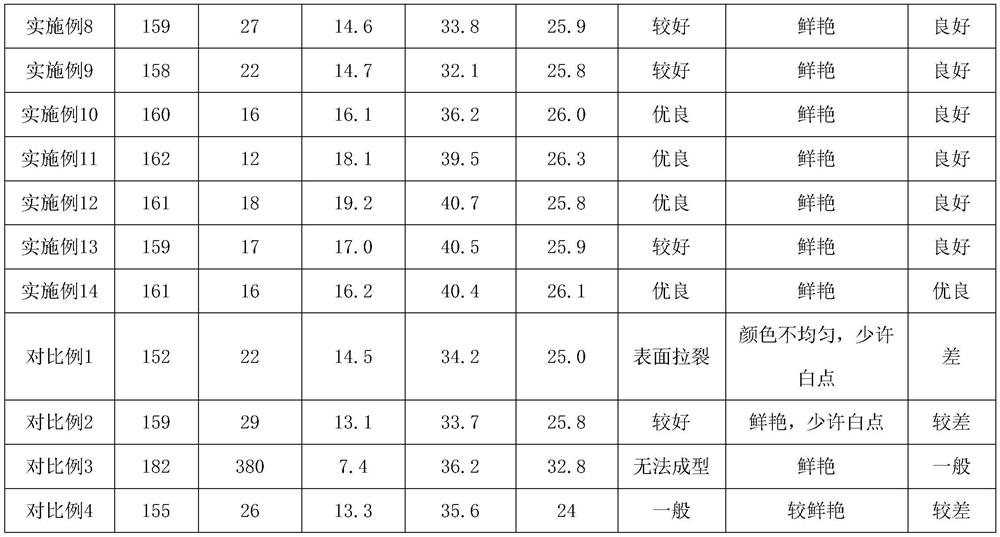

Colored 3D printing mortar and preparation method thereof

InactiveCN112723829AImprove thixotropyPrinting time is controllableAdditive manufacturing apparatusSolid waste managementFiberPolymer science

The invention relates to the field of 3D printing mortar, and particularly discloses colored 3D printing mortar and a preparation method thereof, the colored 3D printing mortar comprises the following components: white Portland cement, limestone powder, metakaolin, an organic pigment, an internal curing agent, quartz sand, fibers, a water reducing agent, an alkali-free accelerator, an early strength agent, a defoaming agent, a polymer emulsion and water; the preparation method comprises the following steps: S1, uniformly mixing quartz sand and fibers to obtain M1; S2, uniformly mixing cement, limestone powder, metakaolin, an internal curing agent and M1 to obtain M2; S3, uniformly mixing a water reducing agent, an early strength agent, a defoaming agent and water to obtain M3; S4, uniformly stirring the polymer emulsion and the organic pigment to obtain M4; and S5, uniformly mixing and stirring M3 and M2, adding M4 while stirring, finally adding an accelerator, and uniformly mixing. The prepared mortar is proper in flowability, good in thixotropy and excellent in extrusion performance; and after printing is completed, early strength and later strength are well developed, and the product is bright in color and good in weather resistance.

Owner:成都建工赛利混凝土有限公司

Doped yellow near infrared reflecting pigment and preparation method thereof

ActiveCN109911938AReduce the content of toxic metal elementsHigh near-infrared reflectivityMolybdeum compoundsNear infrared reflectanceReaction step

The invention provides a doped yellow near infrared reflecting pigment and a preparation method thereof, and belongs to the technical field of inorganic oxide pigments. The chemical formula of the pigment provided by the invention is Bi1-x (Na0.5La0.5) xV1-yMoyO4, wherein x equals to 0.1-0.5 and y equals to 0.1-0.5. Part of Bi3+ ions in BiVO4 are replaced by La3+ ions, and part of V5+ ions in BiVO4 are replaced by Mo6+ ions, so that the use amounts of Bi and V elements can be reduced, and the content of toxic metal elements in the pigment can be reduced; meanwhile, La and Mo are doped in BiVO4to regulate the color of the pigment, so that the colors of the pigment are rich, and the near infrared reflectivity is high. The preparation method of the doped yellow near infrared reflecting pigment is simple in reaction step and easy to operate, and the obtained pigment is complete in crystal form, low in agglomeration degree and high in coloring capacity.

Owner:SHAANXI SCI TECH UNIV

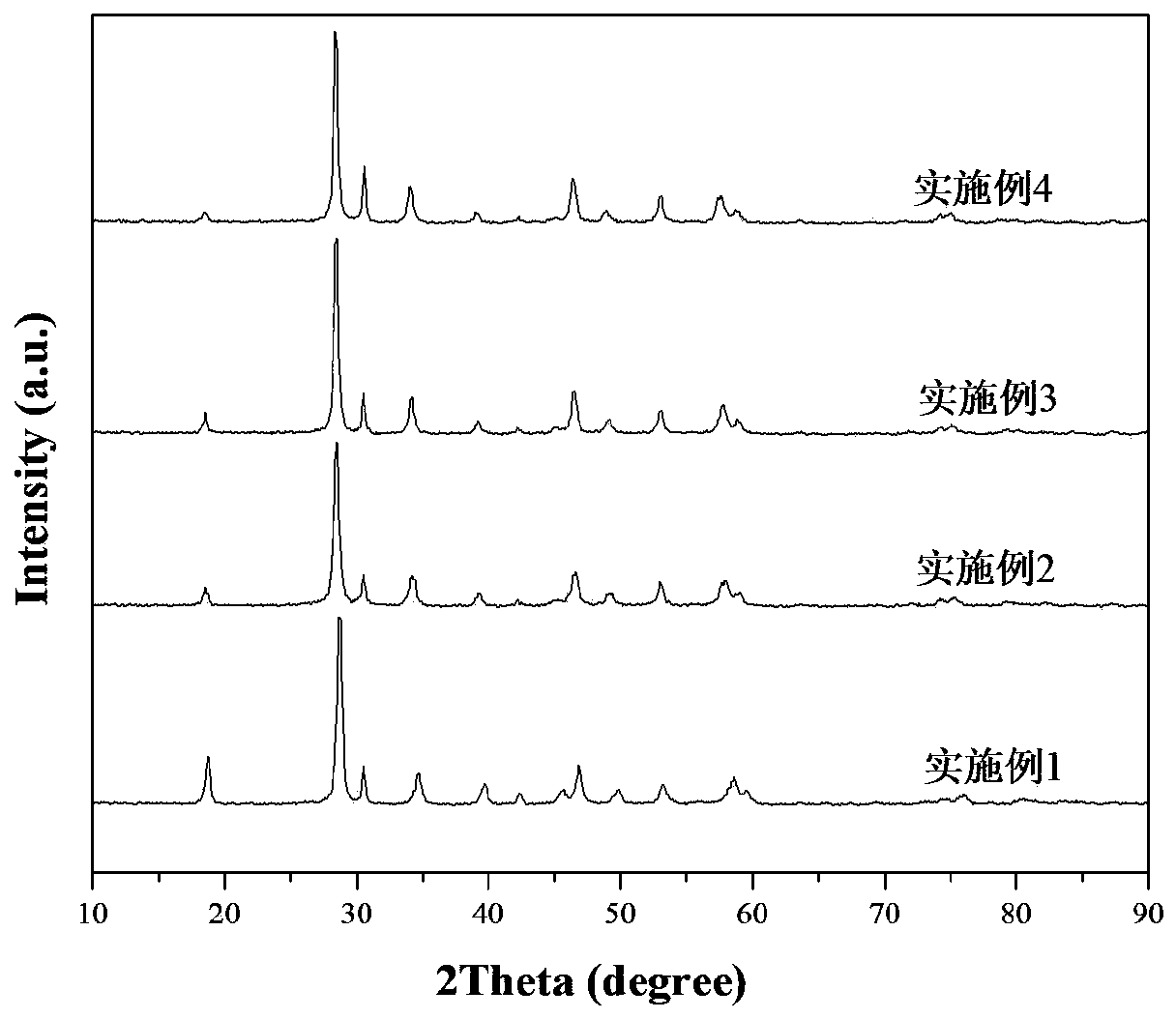

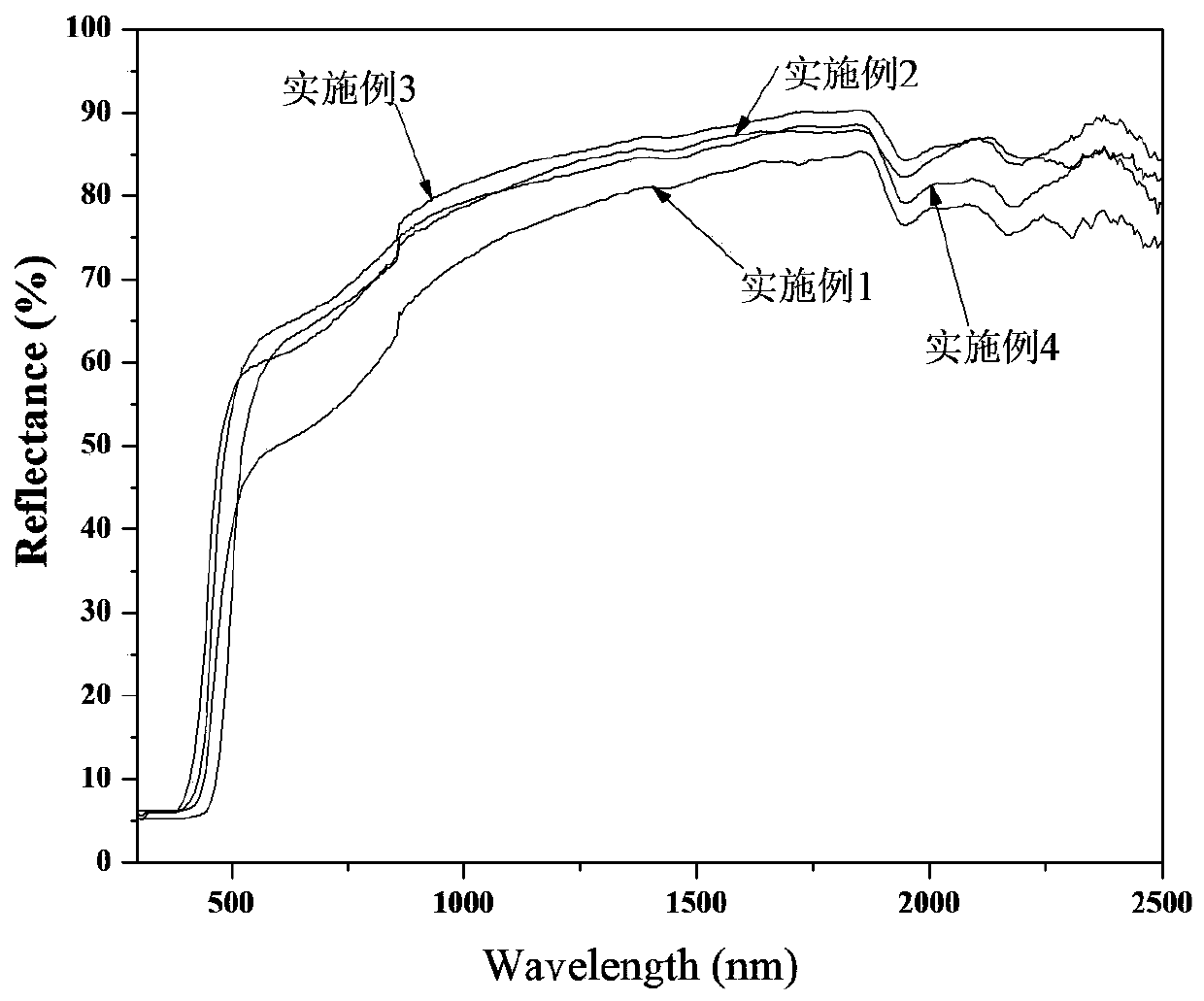

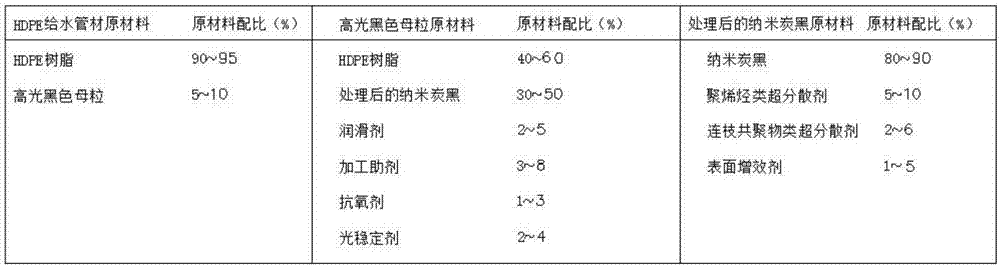

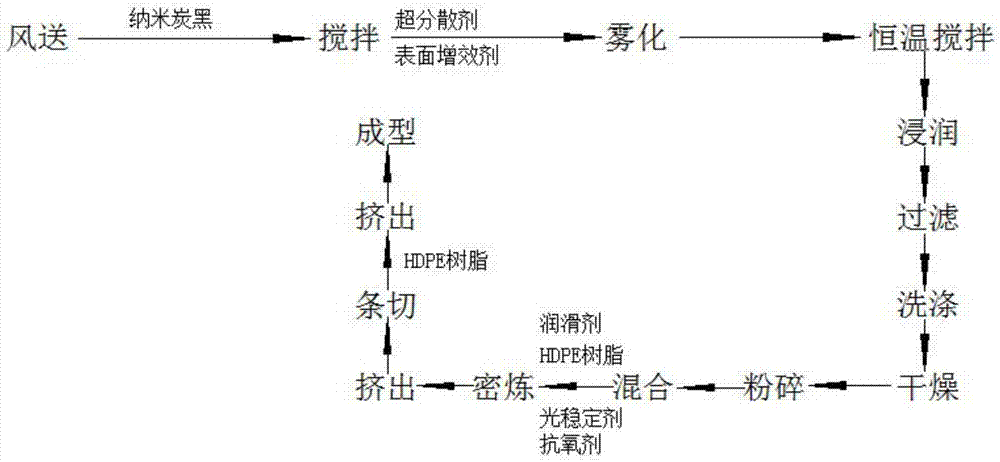

Super dispersant surface activation treatment nanometer carbon black reinforced HDPE water supply pipe material

InactiveCN107286434ALarge specific surface areaImprove coloring abilityTubular articlesMasterbatchPhoto stability

The invention discloses a super dispersant surface activation treatment nanometer carbon black reinforced HDPE water supply pipe material. According to the present invention, the prepared high brightness black masterbatch has advantages of large specific surface area of nanometer carbon black, strong coloring ability, good light stability, and significant enhancement effect; and the strength, the oxidation degree and the hydrostatic strength of the HDPE water supply and drain pipe material prepared from the high brightness black masterbatch are significantly improved.

Owner:ANHUI JIELANTE NEW MATERIAL CO LTD

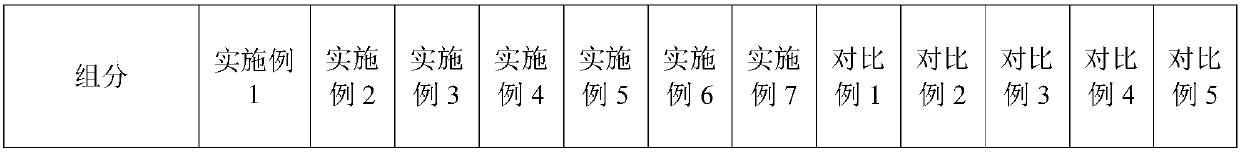

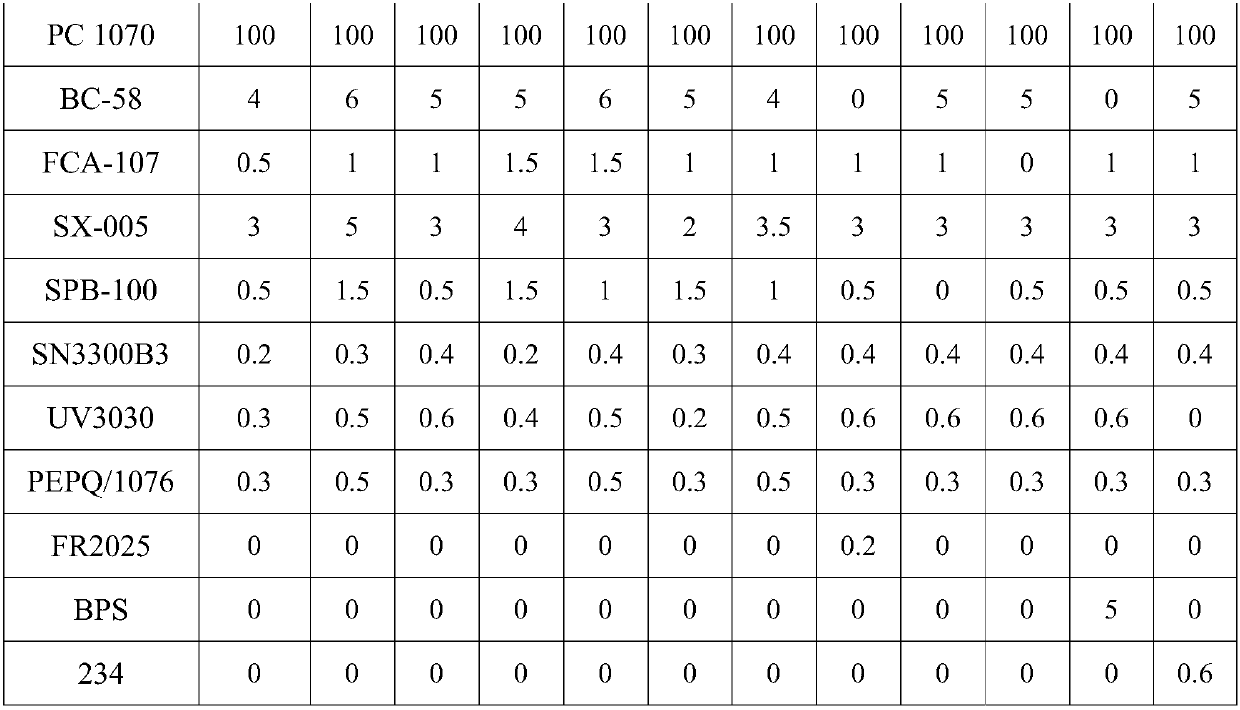

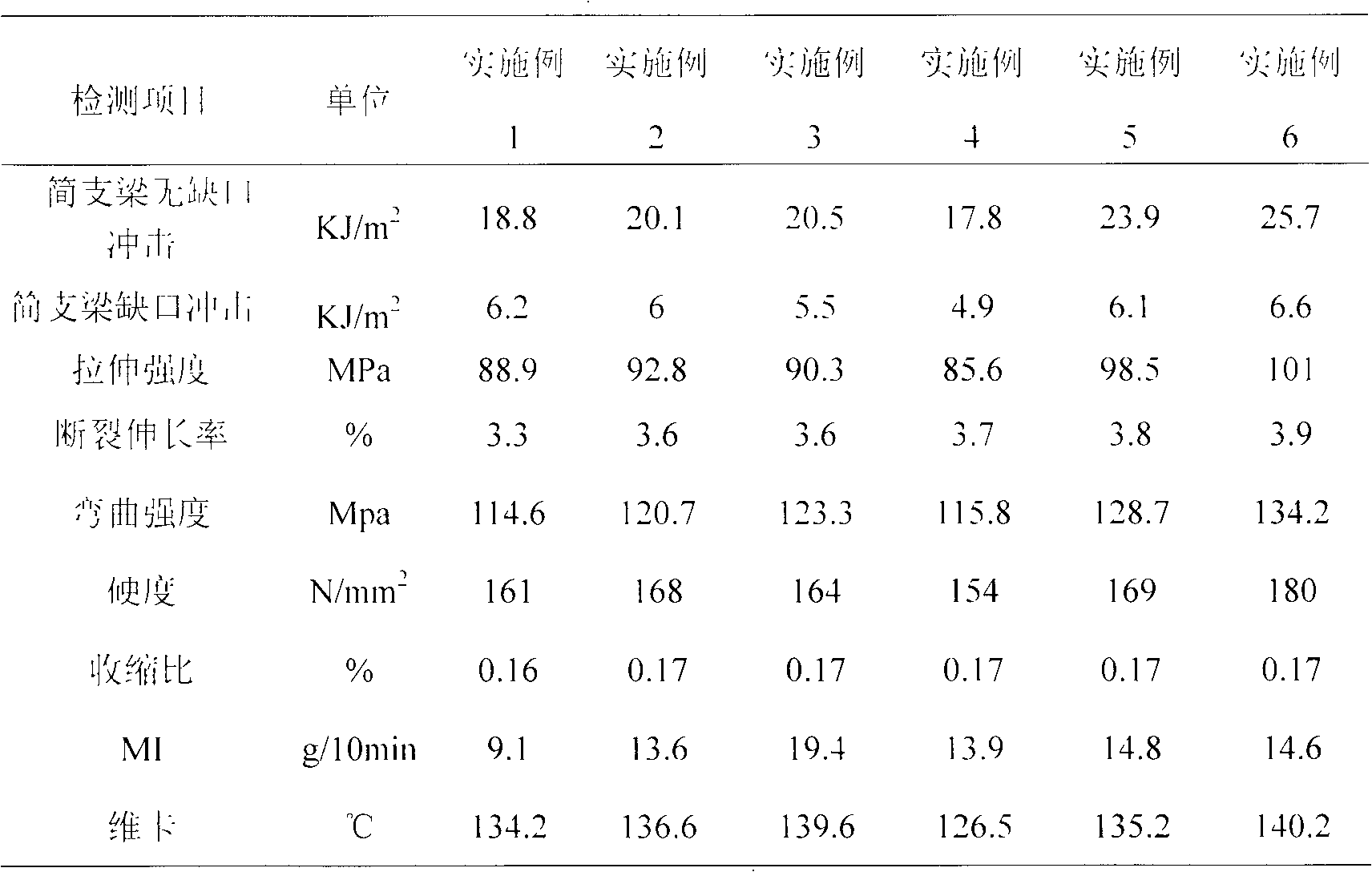

Low-temperature-resistant, damp-heat-resistant and flame-retardant PC (polycarbonate) material for charging gun casing and preparation method of PC material

ActiveCN108047679AGood moisture and heat aging resistanceAffect heat and humidity resistanceAging resistanceHeat resistance

The invention relates to a low-temperature-resistant, damp-heat-resistant and flame-retardant PC (polycarbonate) material for a charging gun casing and a preparation method of the PC material. The PCmaterial is prepared from components of raw materials in parts by weight as follows: 100 parts of PC, 4-6 parts of a flame retardant, 0.5-1 part of a flame retardant synergist, 3-4 parts of a low-temperature-resistant flexibilizer, 0.5-1.5 parts of poly[nitrilo(diphenoxyphosphoranylidyne)], 0.2-0.4 parts of an anti-drip agent, 0.3-0.6 parts of an ultraviolet light absorber and 0.3-0.5 parts of anantioxidant. The raw materials are put in a high-speed mixer to be mixed, then the mixture is extruded by a double-screw extruder and granulated by a granulator, and the PC material can be obtained. The flame-retardant PC material has excellent low-temperature impact resistance, excellent damp and heat ageing resistance and excellent heat resistance, is particularly applicable to the field of thecharging gun casings used in changeable, harsh and complicated environments and has excellent safety protection capability.

Owner:上海日之升科技有限公司

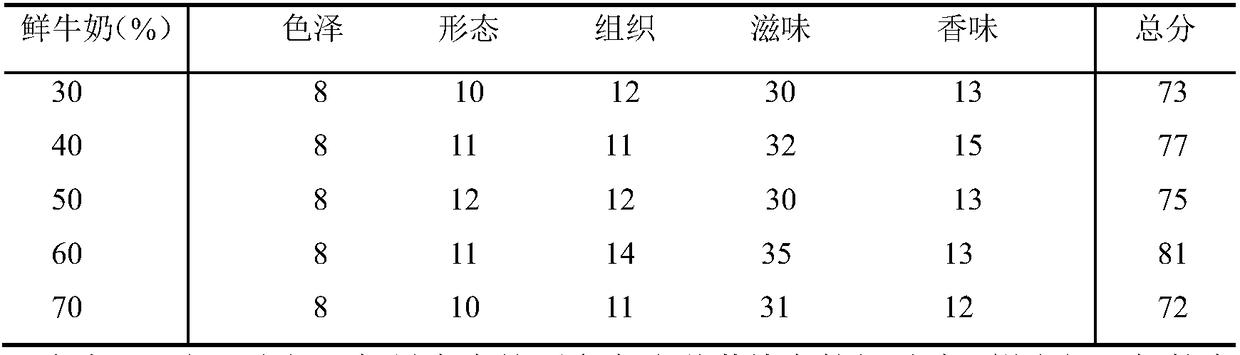

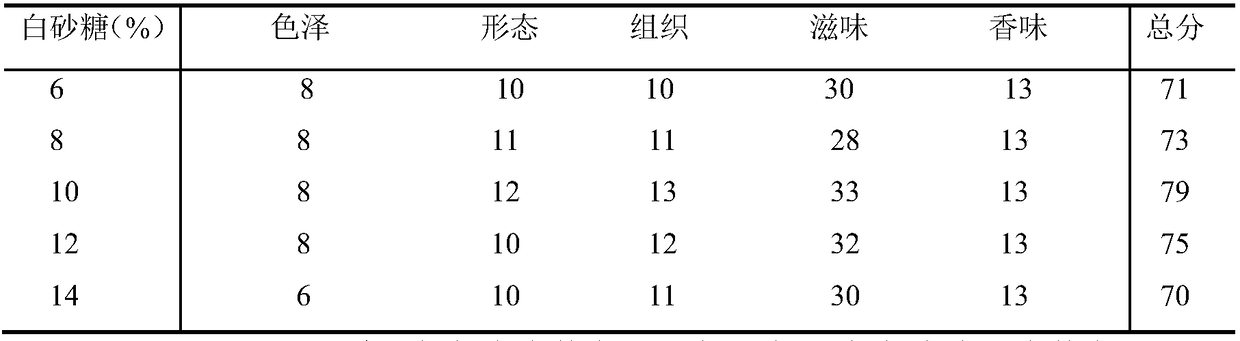

Lycium ruthenicum variety ice cream and manufacture method thereof

The present invention discloses lycium ruthenicum variety ice cream and a manufacture method thereof. The variety ice cream comprises the following components in parts by weight: 40-70 parts of milk,5-8 parts of eggs, 7-12 parts of white granulated sugar, 8-12 parts of lycium ruthenicum fruit pulp, 0.13-0.19 part of xanthan gum, 0.13-0.18 part of molecular distillation monoglyceride, 0.05-0.12 part of CMC, 3.1-3.8 parts of milk powder and 11.5-13 parts of water. The manufacture method comprises steps of softening and slurrying, raw and accessory material mixing, homogenizing, sterilizing, cooling and aging, freezing, filling and hardening. Based on common ice cream, the lycium ruthenicum variety ice cream utilizes nutritional and health-care properties and unique pigments of lycium ruthenicum to grant the product with special taste, flavor and color and luster. The manufacture method increases the nutritional and health-care functions of ice cream, enriches the varieties of the ice cream, meets various preferences of cold drink consumer groups, and has very good market prospects for expanding the deep processing of lycium ruthenicum and other aspects.

Owner:湖北多点教育科技有限公司

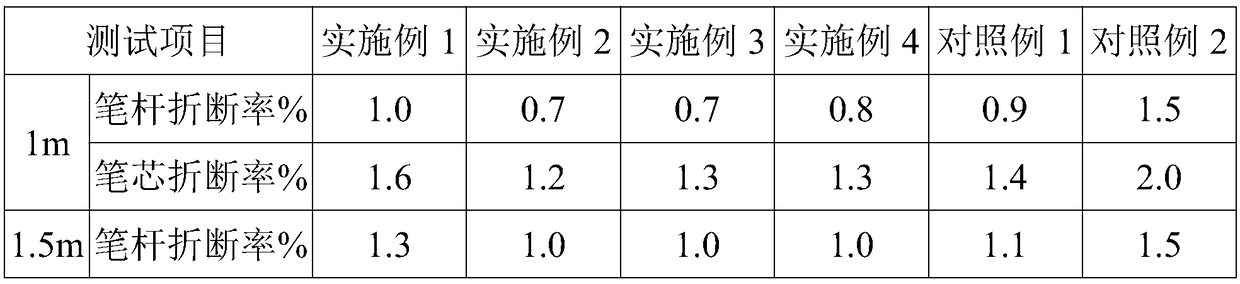

Elastic plastic pencil with strong dyeing property

InactiveCN103847300AIncrease elasticityNo breakagePencil leadsNon-propelling pencilsCross-linkPolystyrene

The invention relates to an elastic plastic pencil with strong dyeing property. The elastic plastic pencil with strong dyeing property comprises a penholder and a pencil core, and is characterized in that the pencil core is a tough pencil core which is basically composed of the following components in parts by weight: 50 parts of graphite powder, 25 parts of polystyrene (PS), 8 parts of polyethylene (PE), 3 parts of chlorinated polyethylene (CPE), 3.5 parts of calcium stearate and 3 parts of octadecanamide; the penholder is an elastic penholder which is basically composed of the following components in parts by weight: 25-30 parts of thermoplastic elastomer (JEP), 8.5 parts of polystyrene (PS), 60 parts of talcum powder, 2.5 parts of bulking agents, 0.4 parts of cross linking agents and 0.4 parts of foaming agents. According to the elastic plastic pencil with strong dyeing property, the penholder is very good in elasticity, does not break in bending, and even can rebound when being thrown on the ground; the pencil core has toughness, and is not easy to break, fluent in writing and strong in dyeing property.

Owner:青岛普乐斯铅笔有限公司

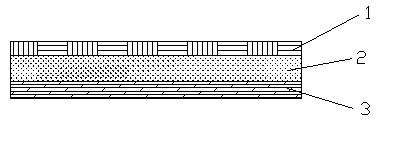

Novel cloth art curtain fabric

InactiveCN102806718ASoft textureImprove coloring abilityWeft knittingSynthetic resin layered productsFiberPolymer science

The invention provides a novel cloth art curtain fabric, which comprises an outer layer, a middle layer and an inner layer, wherein the outer layer is a terylene textile fabric layer, the middle layer is an antibacterial deodorization fabric layer, the inner layer is a natural silk fabric layer, the fabric of the outer layer is prepared by using a weaving process, and the fabrics of the middle layer and the inner layer are prepared by using a knitting process. According to the present invention, a novel cloth art curtain fabric is disclosed; the fabric has characteristics of soft texture, strong coloring capability, and simple preparation process; with the fabric of the outer layer, ultraviolet radiation can be effectively obstructed; and with the unique antibacterial deodorization fibers in the fabric of the middle layer, bacterial invasion can be prevented during convection of indoor air and outdoor air, and odor gas molecules in air can be absorbed, and are voluntarily decomposed through illumination so as to create a clean and comfortable indoor environment.

Owner:KUSN HUAHONG IMPORTS & EXPORTS

Novel formula and processing process of polypropylene melt-blown nonwoven

PendingCN111334931AAdvantages of processing technologyGood light fastnessSpinning solution de-aeratingNon-woven fabricsAlkanePolymer science

The invention discloses a novel formula of a polypropylene melt-blown nonwoven. The novel formula comprises the following ingredients in percentage by weight: 2 to 15 percent of a graphene material, 0.001 to 0.1 percent of high-carbon alkanes, 80 to 87 percent of polypropylene particles, 1 to 6 percent of an auxiliary agent and 5 to 9 percent of titanium dioxide. The graphene material comprises one of graphene and oxidized graphene, or a combination of the graphene and the oxidized graphene. The auxiliary agent comprises any one of a coupling agent, a dispersant and an antioxidant, or a combination of more of the coupling agent, the dispersant and the antioxidant. The dispersant is any one of triethyl hexyl phosphate, methyl anyl alcohol, cellulose derivatives, polyacrylamide and fatty acid polyethylene glycol ester. The coupling agent comprises titanates, and the titanates comprise butyl titanate and titanium tetraisopropanolate. The polypropylene melt-blown nonwoven has an antibacterial property and a charge adsorption property; the filtering effect is good; the dust holding capacity is great; the use safety is high; and the quality and the performance of the melt-blown nonwovenare excellent. A preparation method has the advantages of mild melting condition and low production difficulty.

Owner:嘉兴市阿福信息科技有限公司

High-heat resistance and high-weatherability material specially for heat radiation grid

The invention discloses a high-heat resistance and high-weatherability material specially for a heat radiation grid, and a preparation method thereof. The high-heat resistance and high-weatherability material specially for a heat radiation grid is prepared from main raw materials of 20 to 70 parts of an acrylonitrile-styrene-acrylate copolymer (ASA), 20 to 50 parts of polybutylene terephthalate (PBT) and 10 to 30 parts of long glass fibers (GF), and additives of appropriate amounts of one or more compatilizers, a glass fiber rich surface resistant agent, one or more lubricants, a dispersing agent, one or more antioxidants and a coupling reagent. The raw materials are weighted according to the ratio and are blended and extruded by a twin-screw extruder to form an ASA / PBT / GF composite material. The invention provides the ASA / PBT / GF composite material having good heat resistance, chemical resistance and weather resistance. Compared with common ABS or PC / ABS and PC / PET alloys used for automobiles, the ASA / PBT / GF composite material has the advantages of high heat resistance, high weatherability, high chemical resistance, easy coloring and low cost, and is particularly popular with clients.

Owner:HEILONGJIANG XINDA ENTERPRISE GRP

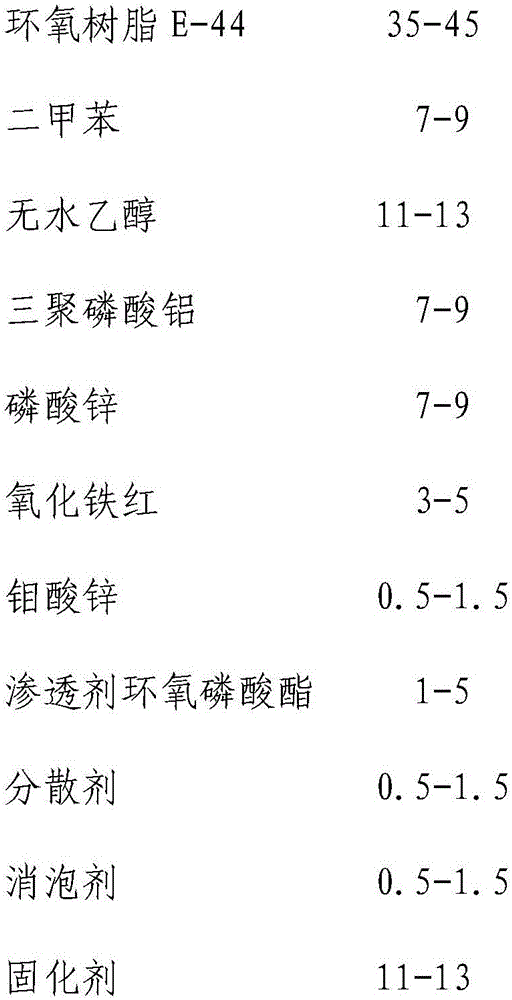

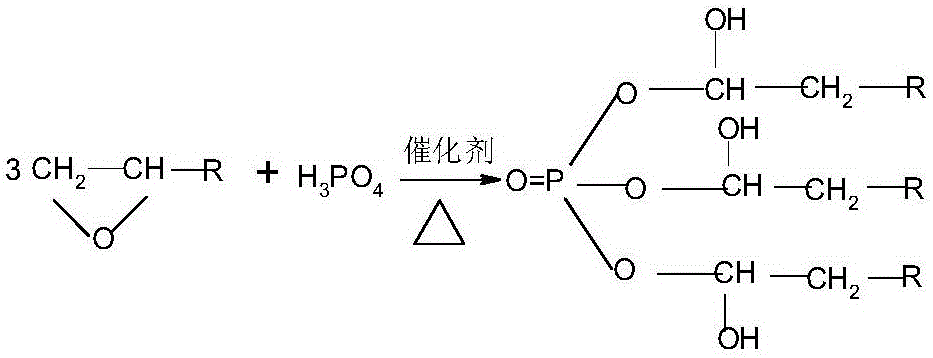

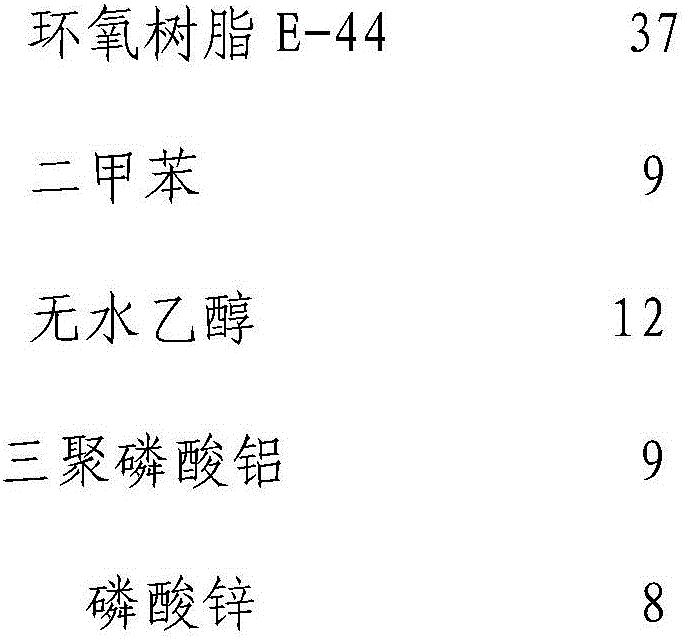

Stable permeation composite type rust coating and preparation method thereof

ActiveCN105885631AHigh hardnessStrong adhesionAnti-corrosive paintsMetallic material coating processesEpoxyPhosphate ion

The invention discloses stable permeation composite type rust coating and a preparation method thereof. The stable permeation composite type rust coating is formed by mixing epoxy resin E-44, xylene, absolute ethyl alcohol, aluminum triphosphate, zinc phosphate, iron oxide red, zinc molybdate, penetrant epoxy phosphate, a dispersing agent, a defoaming agent and a curing agent. Antirust agents are aluminum triphosphate, zinc phosphate and zinc molybdate. Triphosphate radical ions can have a stronger chelating ability with various metal ions, and a passive film is formed on the surface of a coated object; zinc phosphate and ferric ions have a higher condensation ability, phosphate anions react with iron anodes, a firm protection film with ion phosphate as a main body can be formed, and the compact purification film is insoluble in water, high in hardness and excellent in adhesive force; zinc molybdate can release molybdic acid ions, a composite insoluble substance formed on the surface of steel has an anti-rust effect; in this way, the anti-corrosion performance of the coating is excellent through the synergistic effect of the components.

Owner:SHANDONG UNIV OF SCI & TECH

Environment-friendly wood-like plastic pencil

ActiveCN109050080AAppropriate material selectionReasonable formulaNon-propelling pencilsEcological environmentPolystyrene

The invention discloses an environment-friendly wood-like plastic pencil and relates to the technical field of pencil manufacturing processing. The pencil comprises a pencil rod, a pencil lead, a pencil cover and an eraser head. The pencil rod is prepared from 40-60 parts of polystyrene, 40-60 parts of talcum powder, 1-5 parts of titanium dioxide, 0.1-1 part of zinc stearate, 0.5-3 parts of calcium stearate and 1-5 parts of pigment. The pencil lead is prepared from 70-90 parts of polystyrene, 5-25 parts of talcum powder, 5-25 parts of thermoplastic elastomer SBS, 70-90 parts of graphite, 0.1-1part of zinc stearate and 0.5-3 parts of calcium stearate. The pencil cover is prepared from 80-100 parts of polystyrene, 20-40 parts of thermoplastic elastomer SBS and 10-30 parts of pigment. According to the plastic pencil, material selection is appropriate, the formula is reasonable, the produced pencil is attractive in appearance, free of lead shifting and breakage, moderate in roll cutting hardness, smooth in writing and high in colorability, wood is replaced with plastic, a large amount of wood is saved, and national forest resources and ecological environment are reasonably and effectively protected.

Owner:安徽得亿文教用品有限公司

Soft plastic pencil composition

The invention provides a kind of prescription for soft plastic lead pencil. The prescription of pencil core is: graphite 45í½55%, PVC 36í½48%, stearic acid imide 3.3í½3.7%, stearate calcium 4.3í½6.2%, the prescription of the pole is: PVC 45í½60%, calcium carbonate 38í½50%, dibutyl ester 1.0í½2.2%, dieitester 0.8í½2.2%, vesicant 0.2í½0.3%. The vesicant is azo compound.

Owner:方福庆

Spinning synthetic fiber yarn

The invention discloses a spinning synthetic fiber yarn. The spinning synthetic fiber yarn comprises 25-40 wt% of cotton fibers, 25-40 wt% of bamboo fibers, 25-40 wt% of milk protein fibers and 5-7 wt% of silver-plated fibers. The spinning synthetic fiber yarn disclosed by the invention has the advantages of overcoming disadvantages of a single fiber, enabling the synthetic fiber yarn to be good in moisture absorption and air permeability, soft, warm-keeping, anti-bacterial, wear-resisting, anti-pilling, and strong in dyeing power, achieving good skin touch ability and avoiding arousing skin sensibility.

Owner:WUXI YUTONG FABRIC IND

Extraction process for green pigment

The invention relates to an extraction process for a food pigment. The invention provides an extraction process for a green pigment, and the process has the advantages of simple operation, a high extraction rate and strong stability of a prepared product. According to the invention, sansevieria trifasciata prain is used as a raw material, an ultrasonic method is used for extraction, and the process comprises the steps of cleaning, drying, crushing, extraction, filtering, condensation of a supernatant and drying.

Owner:王露

Drawing color pencil

InactiveCN103847311AIncrease elasticityNo breakagePencil leadsNon-propelling pencilsThermoplastic elastomerPolystyrene

The invention relates to a drawing color pencil, which comprises a pencil rod and a pencil lead. The pencil is characterized in that the pencil lead is a tough pencil lead, and comprises the following components in parts by weight: 50 to 60 parts of graphite powder, 20 to 30 parts of PS (polystyrene), 3 parts of CPE (chlorinated polyethylene), and 3 to 5 parts of calcium stearate; the pencil rod comprises the following raw materials in parts by weight: 30 to 40 parts of thermoplastic elastomer (JEP), 9 parts of PS, 80 parts of talcum powder, 3.5 parts of fillers and 0.6 part of cross-linking agent. The pencil has the advantages that the elasticity of the pencil rod is good, the breaking is avoided even if the pencil is bent, and the pencil can bounce when falling onto the ground; the pencil lead is tough, so the easiness in breaking is avoided, the writing is fluent, and the coloring performance is good.

Owner:青岛普乐斯铅笔有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com