High-heat resistance and high-weatherability material specially for heat radiation grid

A cooling grille, high heat-resistant technology, applied in the field of high heat-resistant, high weather-resistant ASA/PBT/GF composite co-extrusion materials and its preparation, can solve the problems of poor heat resistance, high cost, single color, etc., to achieve weather resistance outstanding performance, low cost, and excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

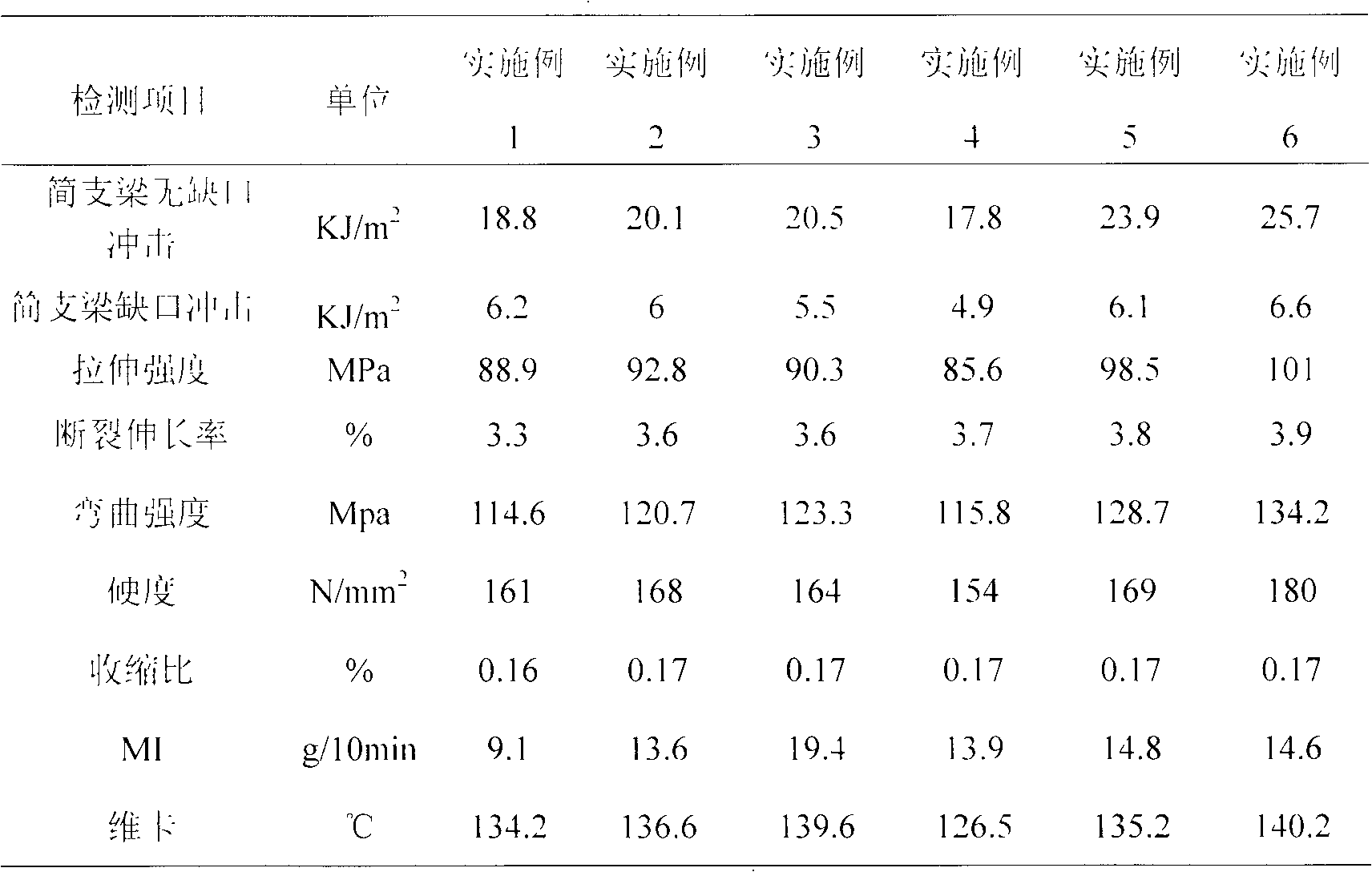

[0014] Mix 60 parts of ASA resin, 20 parts of PBT resin, 20 parts of long glass fiber, 5 parts of compatibilizer (SMA), 1.5 parts of lubricant, 0.7 part of antioxidant, and 0.5 part of coupling agent through a high-speed mixer for 2 to 5 minutes After discharging, the mixture is extruded and granulated through a twin-screw extruder with a diameter of 30mm. The screw speed of the extruder is 100-350r / min, and the barrel temperature is 190-250°C. The performance test results are shown in Table 1.

Embodiment 2

[0016] Mix 50 parts of ASA resin, 30 parts of PBT resin, 20 parts of long glass fiber, 5 parts of compatibilizer (SMA), 1.5 parts of lubricant, 0.7 part of antioxidant, and 0.5 part of coupling agent through a high-speed mixer for 2 to 5 minutes After discharging, the mixture is extruded and granulated through a twin-screw extruder with a diameter of 30mm. The screw speed of the extruder is 100-350r / min, and the barrel temperature is 190-250°C. The performance test results are shown in Table 1.

Embodiment 3

[0018] Mix 40 parts of ASA resin, 40 parts of PBT resin, 20 parts of long glass fiber, 5 parts of compatibilizer (SMA), 1.5 parts of lubricant, 0.7 part of antioxidant, and 0.5 part of coupling agent through a high-speed mixer for 2 to 5 minutes After discharging, the mixture is extruded and granulated through a twin-screw extruder with a diameter of 30mm. The screw speed of the extruder is 100-350r / min, and the barrel temperature is 190-250°C. The performance test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com