Patents

Literature

208 results about "ASA-polymer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acrylonitrile styrene acrylate (ASA), also called acrylic styrene acrylonitrile, is a thermoplastic developed as an alternative to acrylonitrile butadiene styrene (ABS), but with improved weather resistance, and is widely used in the automotive industry.

Glass fiber reinforced polybutylece terephthalate (PBT)/acrylonitrile styrene acrylate (ASA) alloy material and preparation method thereof

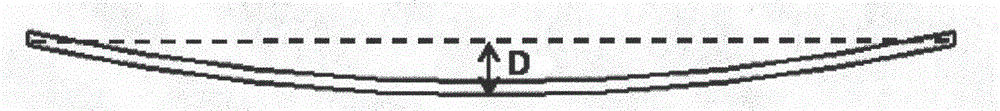

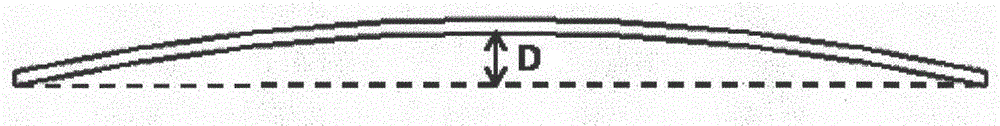

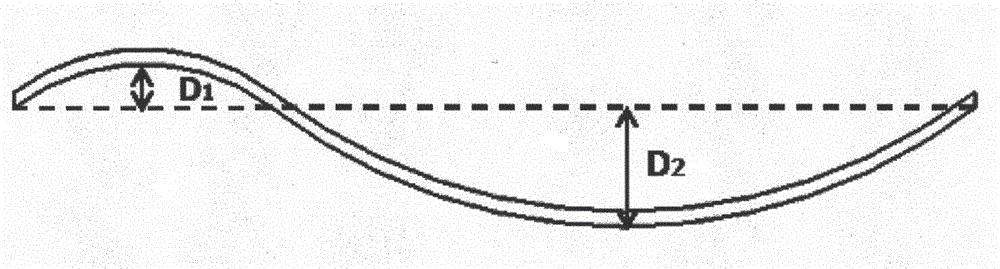

The invention discloses a glass fiber reinforced polybutylece terephthalate (PBT) / acrylonitrile styrene acrylate (ASA) alloy material and a preparation method thereof. The glass fiber reinforced PBT / ASA alloy material is characterized by comprising raw materials of 5-87.6 wt.% of a PBT resin, 1-30 wt.% of an ASA resin, 0-20 wt.% of a styrene-arcylonitrile (SAN) resin, 10-30 wt.% of glass fiber, 1-8 wt.% of a flexibilizer, 0.1-4 wt.% of a compatilizer, 0.1-1wt.% of an antioxidant, 0.1-1wt.% of a lubricating agent and 0.1-1wt.% of a nucleating agent. The preparation method includes feeding the raw materials into a double-screw extruder, adding the glass fiber from a side feeding port, and extruding produced granules at the temperature of 210-280 DEG C. The glass fiber reinforced PBT / ASA alloy material has an excellent low-warpage performance and size stability and simultaneously has a good processing performance of a glass fiber reinforced PBT material.

Owner:SHANGHAI KINGFA SCI & TECH +1

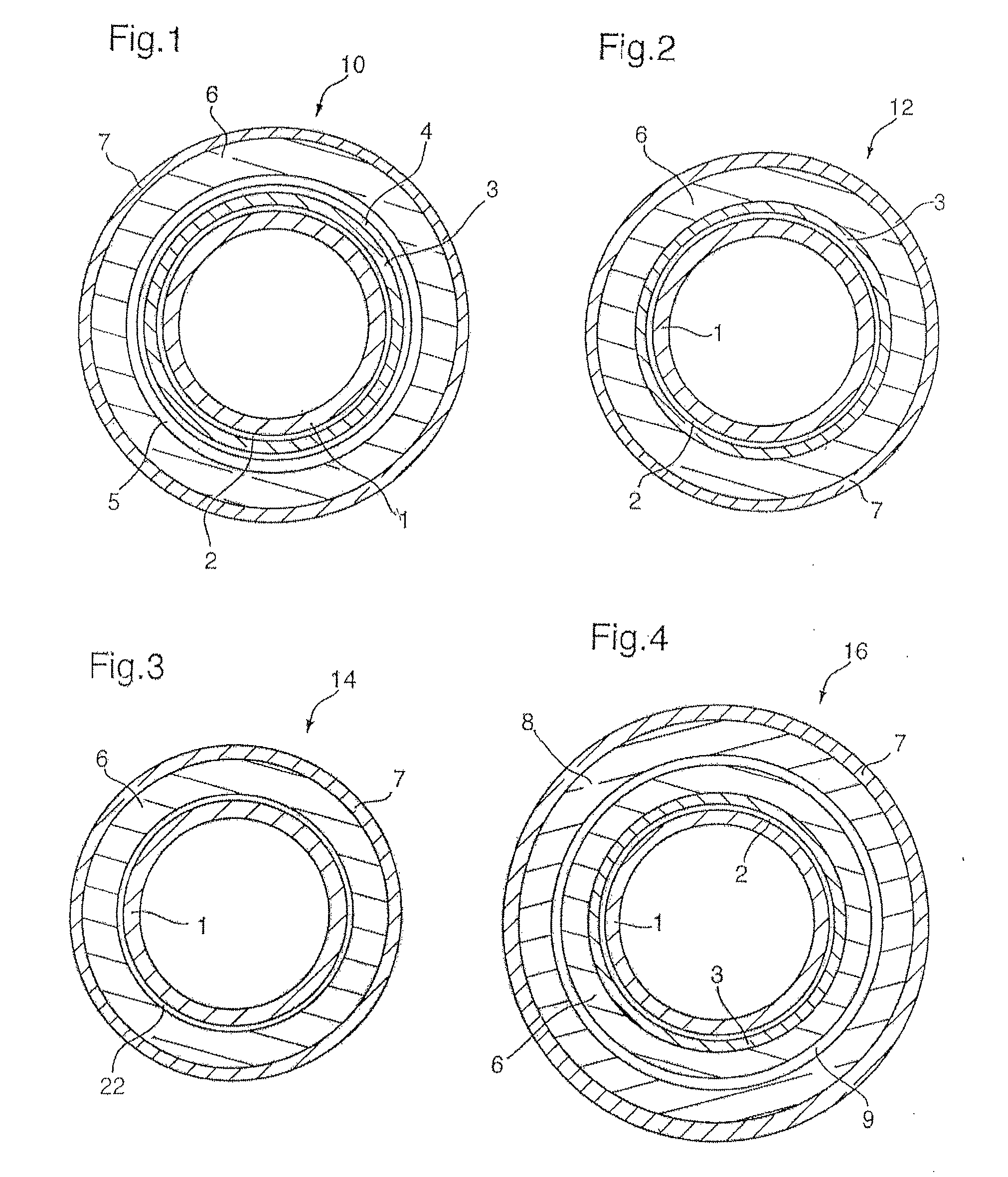

High temperature resistant insulation for pipe

ActiveUS8397765B2Low thermal conductivityImprove thermal stabilityThermal insulationSynthetic resin layered productsElastomerPolyetherimide

A polymeric composition for insulating fluid and / or gas transport conduits, such as off-shore oil and gas pipelines operating at temperatures of 130° C. or higher in water depths above 1,000 meters. The outer surface of the conduit is provided with at least one layer of solid or foam insulation comprising a high temperature resistant thermoplastic having low thermal conductivity, high thermal softening point, high compressive strength and high compressive creep resistance. The high temperature resistant thermoplastic is selected from one or more members of the group comprising: polycarbonate; polyphenylene oxide; polyphenylene oxide blended with polypropylene, polystyrene or polyamide; polycarbonate blended with polybutylene terephthalate, polyethylene terephthalate, acrylonitrile butadiene styrene, acrylonitrile styrene acrylate, or polyetherimide; polyamides, including polyamide 12 and 612 and elastomers thereof; polymethylpentene and blends thereof; cyclic olefin copolymers and blends thereof; and, partially crosslinked thermoplastic elastomers, also known as thermoplastic vulcanizates or dynamically vulcanized elastomers.

Owner:SHAWCOR LTD

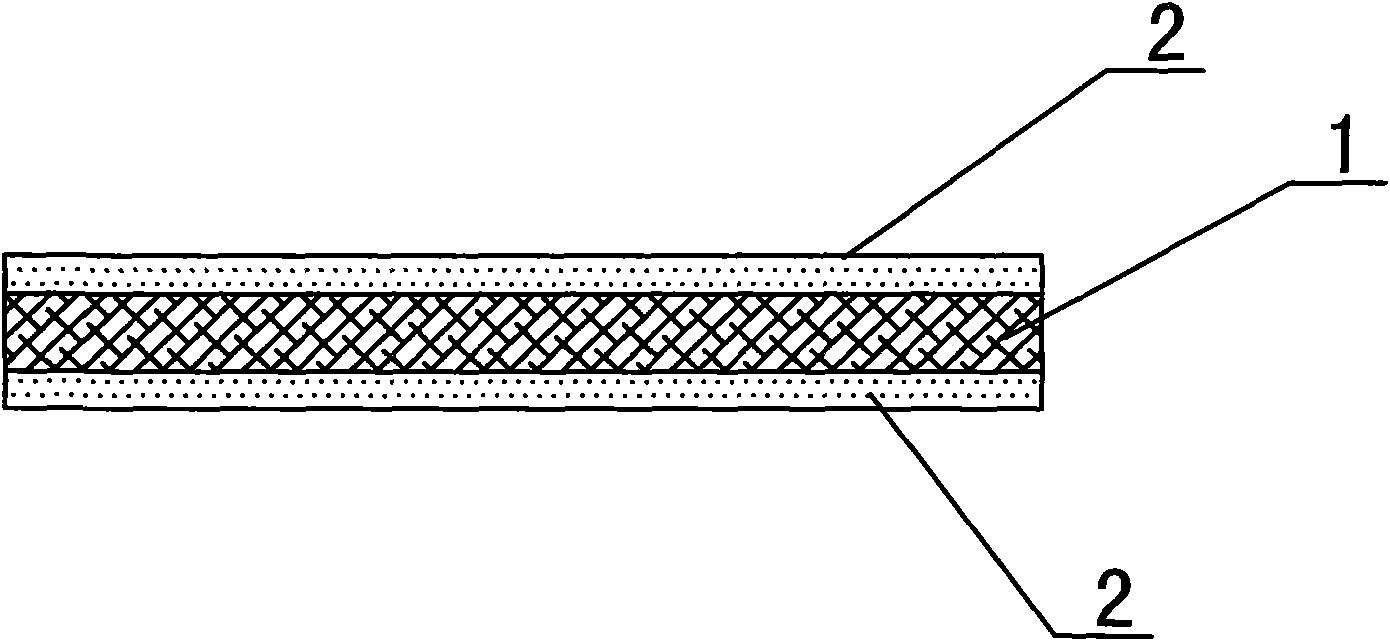

PVC (Poly Vinyl Chloride) wood-plastic foaming composite and preparation method thereof

ActiveCN102501506AGood weather resistanceReduce formulation costsSynthetic resin layered productsASA-polymerWeather resistance

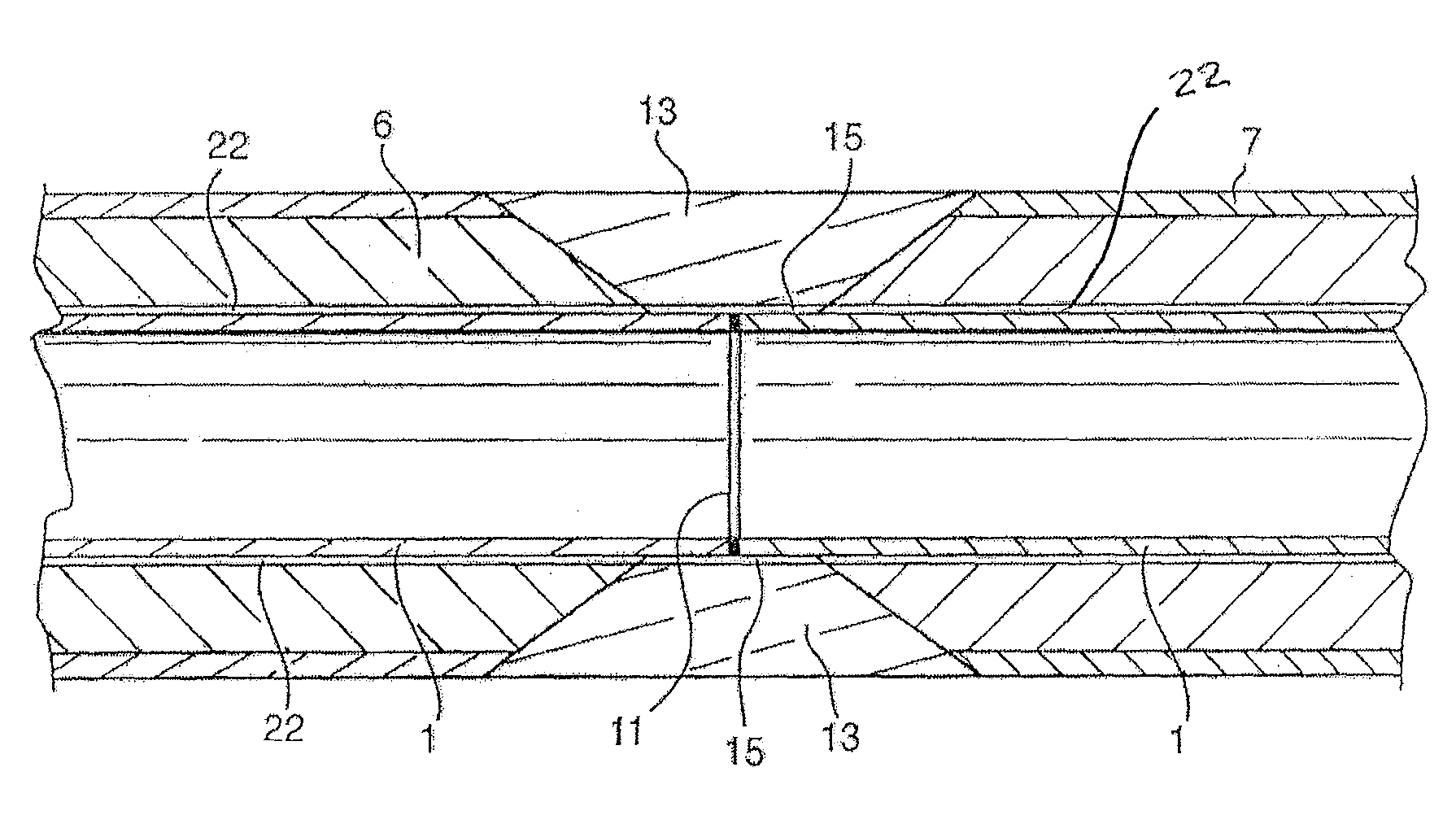

The invention discloses a PVC (Poly Vinyl Chloride) wood-plastic foaming composite and a preparation method of the wood-plastic foaming composite. The PVC wood-plastic foaming composite comprises a PVC wood-plastic foaming base material layer and an ASA (Acrylonitrile Styrene Acrylate) layer which is co-extruded and formed on at least one side of the PVC wood-plastic foaming base material layer, wherein the PVC wood-plastic foaming base material layer comprises the following components in parts by weight: 100 parts of PVC, 50-100 parts of paddings, 1-1.5 parts of coupling agents, 5-7 parts of compound stabilizers, 1.0-1.5 parts of compound foaming agents and 6-8 parts of blowing promoters. The PVC wood-plastic foaming composite disclosed by the invention has the characteristics of light weight, high specific strength, water prevention, corrosion prevention, heat preservation, good weather resistance, low formula cost and low material density, and can be widely used in outdoor product markets such as exterior decoration of buildings, garden landscapes, fences, plank ways and the like.

Owner:北京欧尼克新型材料有限公司

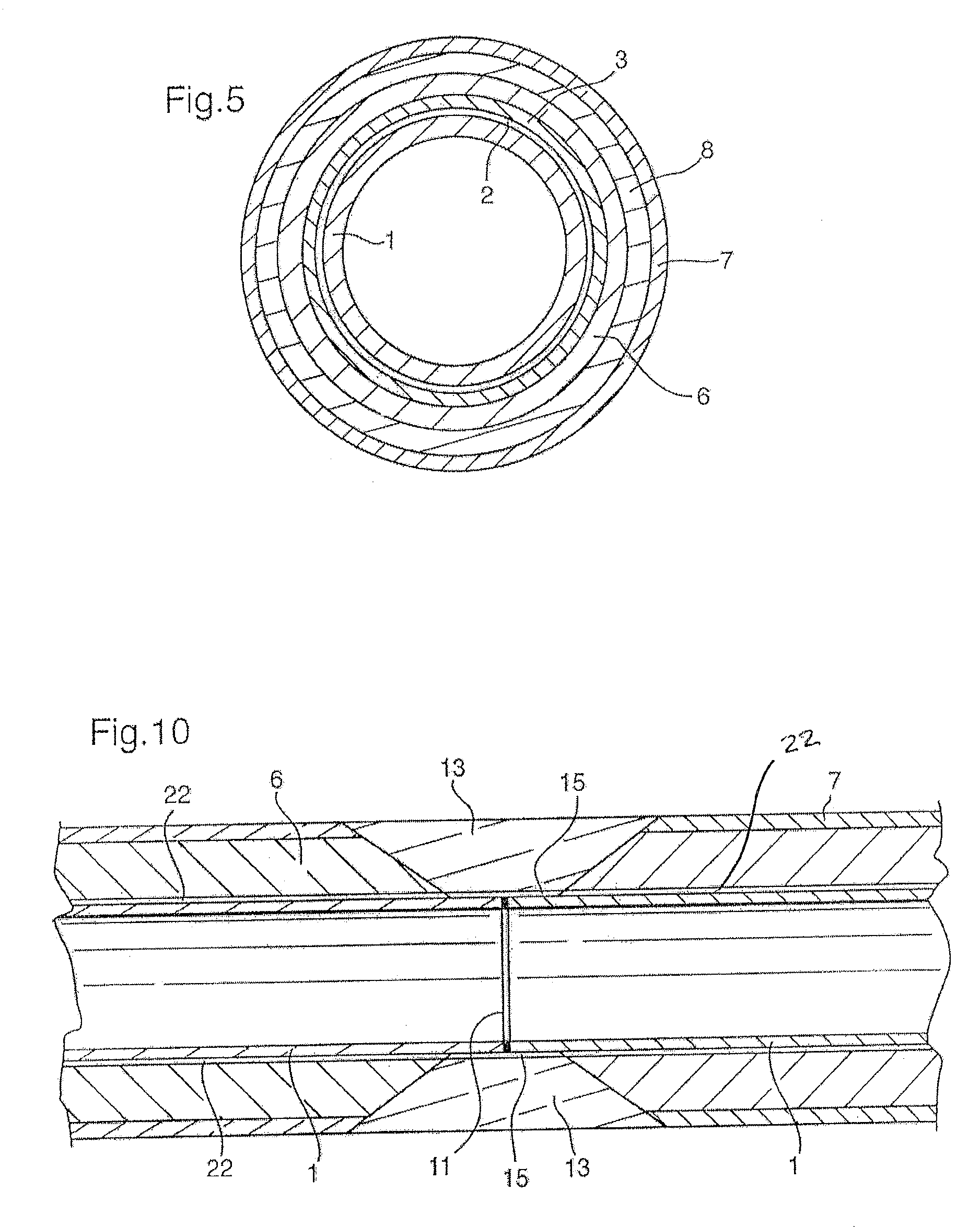

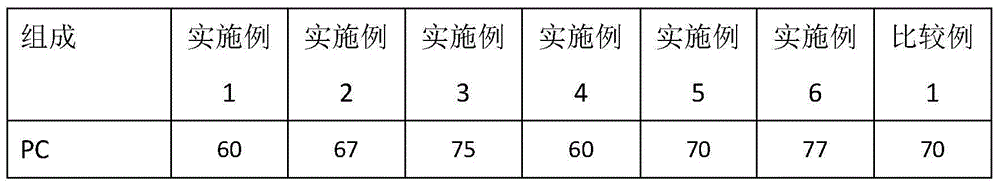

Antistatic PC/ASA (polycarbonate/acrylonitrile styrene acrylate copolymer) alloy plastic for automotive interior trim parts and method for manufacturing antistatic PC/ASA alloy plastic

ActiveCN104830043AImprove antistatic performanceImprove mechanical propertiesASA-polymerAntistatic agent

The invention discloses an antistatic PC / ASA (polycarbonate / acrylonitrile styrene acrylate copolymer) alloy plastic for automotive interior trim parts and a method for manufacturing the antistatic PC / ASA alloy plastic. The antistatic PC / ASA alloy plastic for the automotive interior trim parts comprises, by weight, 60-80% of PC resin, 10-20% of ASA resin, 2-6% of toughening agents, 0.3-0.9% of antioxidants, 0.2-0.6% of ultraviolet absorbents, 0.1-0.3% of lubricants, 5-15% of antistatic agents and 0.2-0.6% of chain extenders. The antistatic PC / ASA alloy plastic for the automotive interior trim parts and the method have the advantages that the antistatic PC / ASA alloy plastic is excellent in antistatic performance and mechanical performance, high in strength and good in rigid-tough balance and is heat-resistant, light-resistant and anticorrosion, dust cannot be easily sucked by the surfaces of the antistatic PC / ASA alloy plastic, and the automotive interior trim parts in various shape can be made of the antistatic PC / ASA alloy plastic by means of injection molding.

Owner:上海跃贝新材料科技股份有限公司

Polycarbonate/acrylonitrile-styrene-acrylate copolymer alloy material and preparation method thereof

InactiveCN102399424AImprove processing fluidityImproved stress crack resistanceAcrylonitrileUltraviolet lights

The invention relates to a polycarbonate / acrylonitrile-styrene-acrylate copolymer alloy material and a preparation method thereof. The polycarbonate / acrylonitrile-styrene-acrylate copolymer alloy material is prepared mainly from 40 to 70 parts by weight of polycarbonate (PC), 20 to 50 parts by weight of acrylonitrile-styrene-acrylate copolymer (ASA), 2 to 10 parts by weight of a compatilizer, 3 to 15 parts by weight of a flexibilizer, 0.1 to 0.8 parts by weight of anti-oxidants, 0.5 to 5 parts by weight of a lubricant, 0.2 to 1 part by weight of an ultraviolet light absorber and 0.2 to 1.5 parts by weight of teflon through melt blending extrusion. The polycarbonate / acrylonitrile-styrene-acrylate copolymer alloy material obtained by the preparation method has good comprehensive mechanical properties, processing properties and weatherability, and is especially suitable for manufacture of interior and exterior trim parts of automobiles.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Low gloss thermoplastic composition, method of making, and articles formed therefrom

A thermoplastic composition comprises a polycarbonate, an acrylonitrile-styrene-acrylate terpolymer, and a low gloss additive, wherein the 60° gloss is measured to be less than or equal to 90 GU according to ASTM D2457. The thermoplastic composition has excellent low gloss performance and mechanical performance. A method of making the thermoplastic composition, and an article comprising the thermoplastic composition are also disclosed.

Owner:SABIC GLOBAL TECH BV

Formable thermoplastic multi-layer laminate, a formed multi-layer laminate, an article, and a method of making an article

InactiveUS20040175593A1Nice appearanceDesirable qualitySynthetic resin layered productsLaminationPolyesterASA-polymer

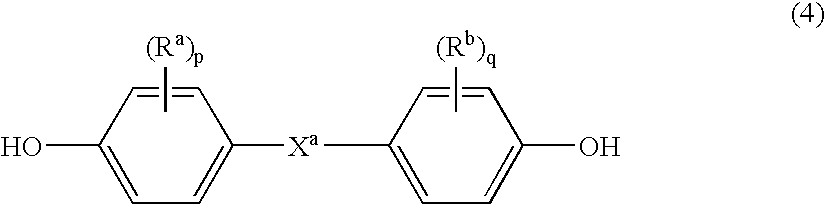

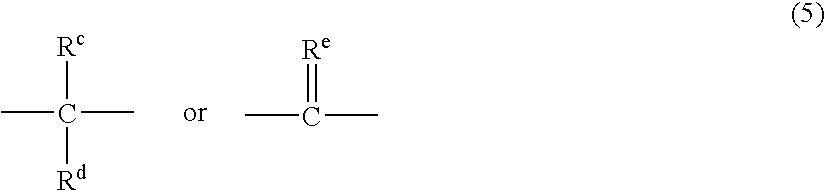

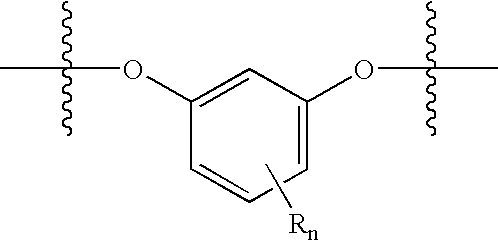

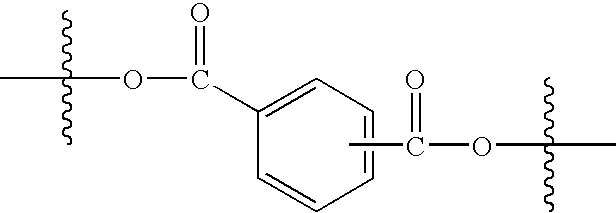

Disclosed is a formable thermoplastic multi-layer laminate comprising an outer layer comprising a polymer comprising resorcinol arylate polyester chain members, a middle layer comprising a thermoplastic polymer, an inner-tie layer comprising a thermoplastic polymer comprising a carbonate polymer and an acrylonitrile-styrene graft copolymer comprising at least one of an acrylonitrile-styrene-acrylate graft copolymer (ASA) or an acrylonitrile-butadiene-styrene graft copolymer (ABS), the middle layer being between the outer layer and the inner-tie layer and being in contact with both the outer layer and the inner-tie layer. Also disclosed are a formed multi-layer laminate and an article comprising the multi-layer laminate bonded to a substrate. A method of making the article is also disclosed.

Owner:SABIC GLOBAL TECH BV

Solar cell module rear panel and manufacturing method thereof

ActiveCN103158312AEasy to processImprove the environmentSynthetic resin layered productsPhotovoltaic energy generationEnvironmental resistanceAcrylonitrile

The invention provides a solar cell module rear panel which can be in a single-layer structure or a multi-layer structure. At least an outmost film which directly contacts the environment is mainly composed of one or more of acrylonitrile-styrene-acrylate copolymer (ASA), acrylonitrile-ethylene-styrol copolymer (AES) and polymethyl methacrylate (PMMA), or the outmost film is mainly composed of ASA, AES, PMMA, and polycarbonate (PC) or polyamide (PA) or polybutylene terephthalate (PBT) or polyvinyl chloride (PVC). The invention further provides a manufacturing method of the rear panel, namely layers are directly glued to form a rear film or the layers are subjected to coextru-lamination through fusion. The solar cell module rear panel has good machining property and reliable weather resistance property, use of fluorine-containing materials is avoided, cost of a solar cell module is lowered, and the rear panel is environmental-friendly and safe.

Owner:DSM SUNSHINE SOLAR TECH (SUZHOU) CO LTD

Wear-resistant ASA/PMMA (acrylonitrile-styrene-acrylate/polymethylmethacrylate) blend material with high weather resistance and high gloss and preparation method thereof

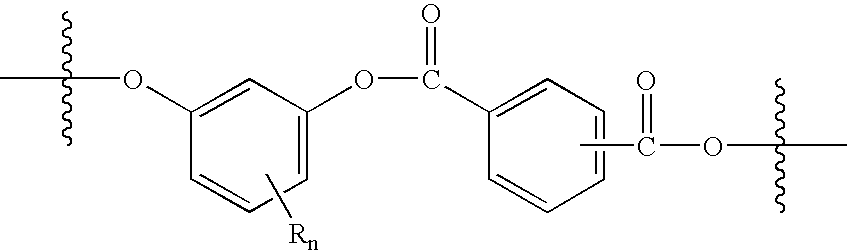

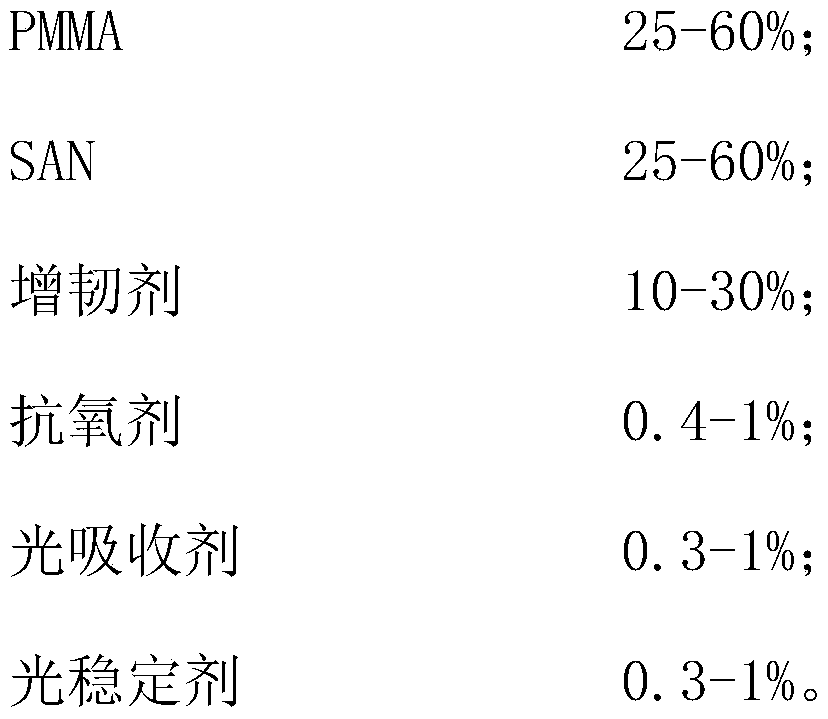

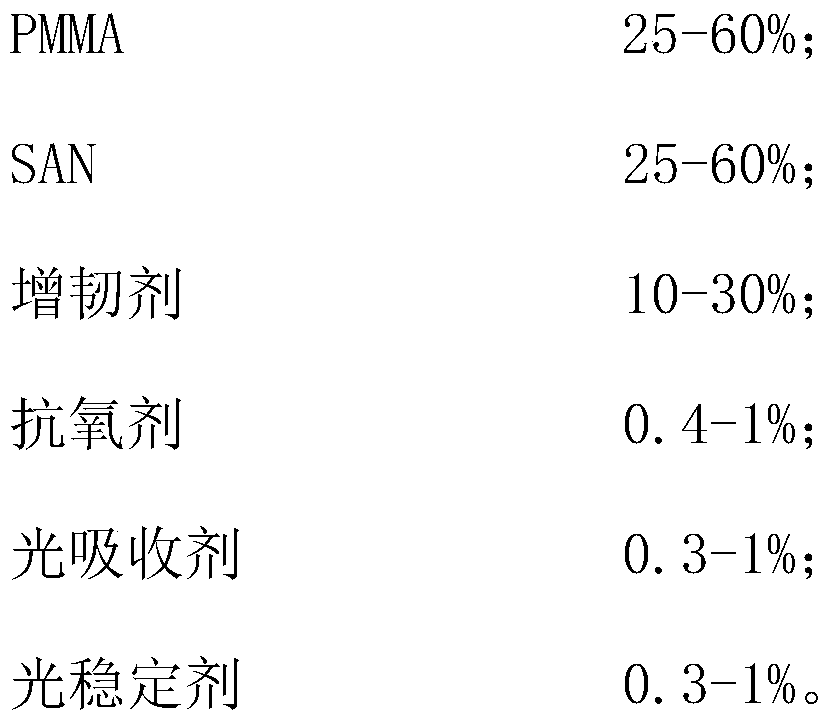

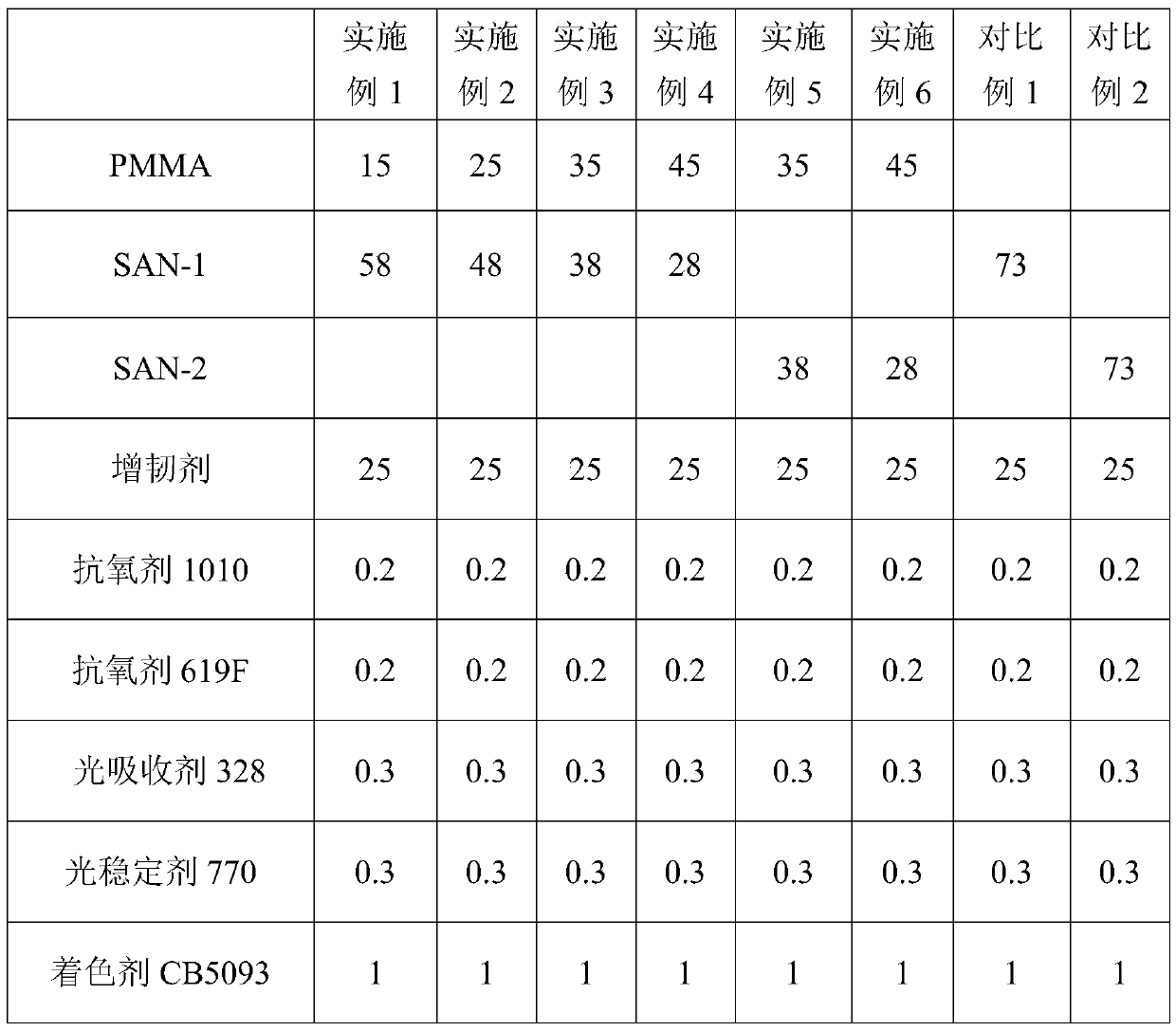

The invention discloses a wear-resistant ASA / PMMA (acrylonitrile-styrene-acrylate / polymethylmethacrylate) blend material with high weather resistance and high gloss and a preparation method thereof. The blend material is prepared from the following raw materials in parts by weight: 25-60 parts of PMMA, 25-60 parts of styrene-acrylonitrile copolymer, 10-30 parts of impact modifier, 0.4-1 part of antioxidant, 0.3-1 part of light absorber and 0.3-1 part of light stabilizer. By adopting the technical solution, the wear-resistant PMMA / ASA resin blend material with high weather resistance and high gloss has excellent weather resistance, high gloss and wear resistance and can be applied to automobile exterior trim, home appliances, buildings and the like.

Owner:SHANGHAI PRET COMPOSITES

Impact-modified compositions and method

InactiveUS20060252883A1Surprising level of improvement in weathering performanceHigh impact strengthSynthetic resin layered productsThin material handlingElastomerASA-polymer

The present invention relates to a composition comprising (i) at least one polycarbonate; (ii) optionally, at least one additional thermoplastic resin different from polycarbonate; and (iii) an acrylonitrile-styrene-acrylate (ASA) type resin comprising a discontinuous elastomeric phase dispersed in a rigid thermoplastic phase, wherein at least a portion of the rigid thermoplastic phase is grafted to the elastomeric phase, and wherein the elastomeric phase comprises a polymer having structural units derived from at least one (C1-C12)alkyl(meth)acrylate monomer, and wherein the rigid thermoplastic phase comprises structural units derived from at least one vinyl aromatic monomer, at least one monoethylenically unsaturated nitrile monomer, and at least one monomer selected from the group consisting of (C1-C12)alkyl- and aryl-(meth)acrylate monomers. Another aspect of the invention is a process to improve the resistance to color formation or loss of gloss in a method to make articles manufactured from a thermoplastic composition comprising at least one polycarbonate; and an ASA type resin. Articles made from the composition and a method for preparing the composition are also provided.

Owner:SABIC INNOVATIVE PLASTICS IP BV

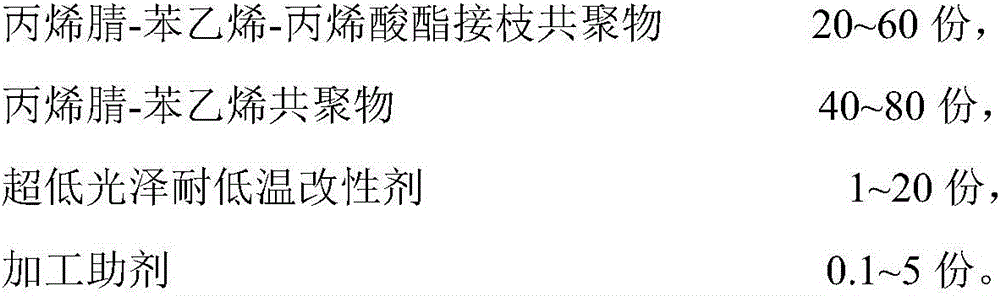

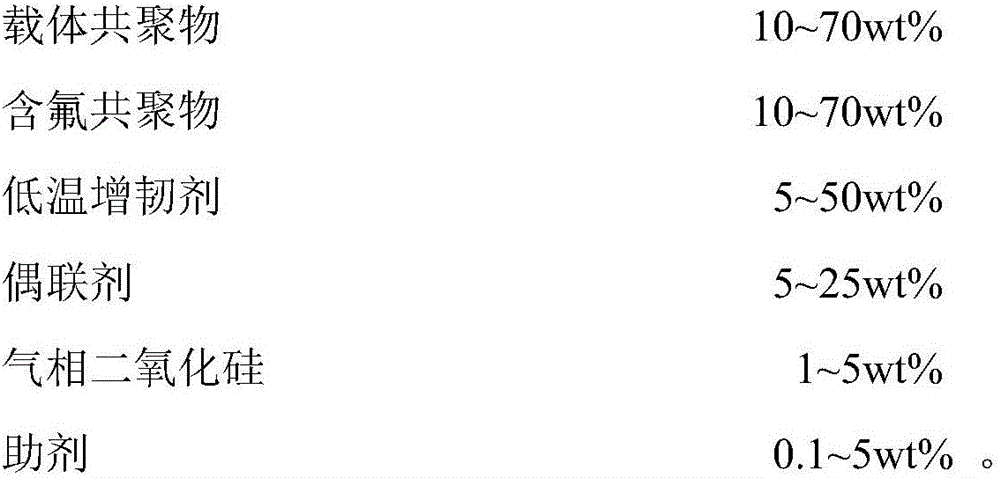

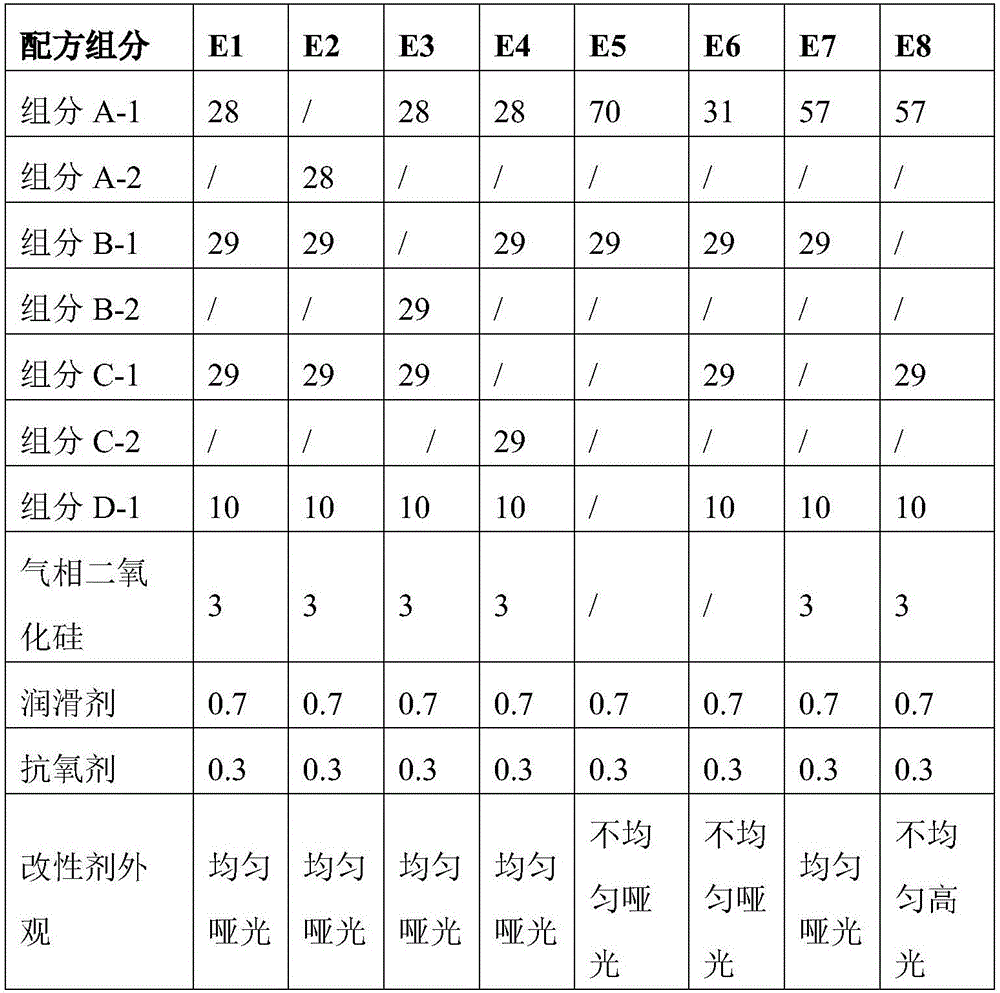

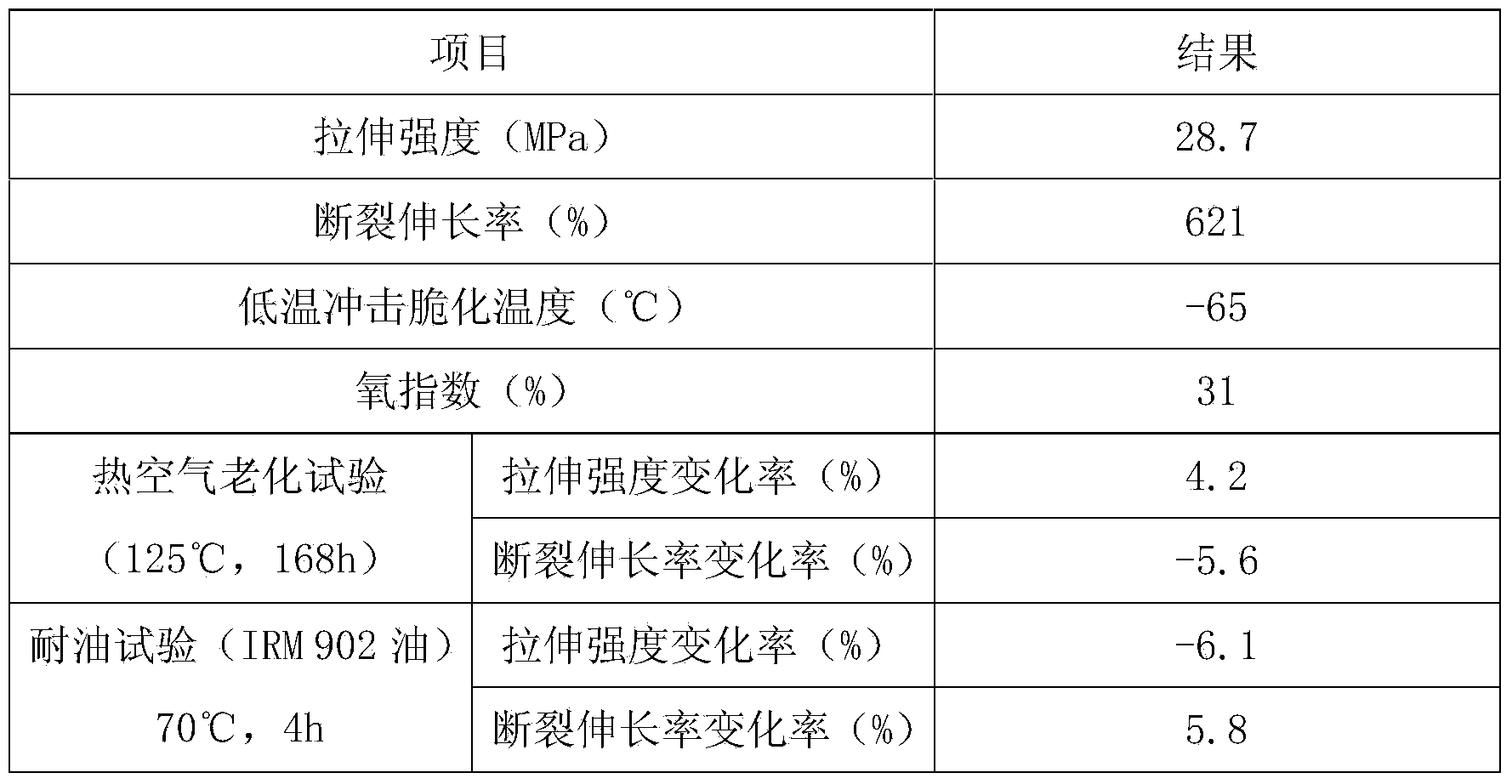

Ultralow-glossiness ultralow-temperature-resistant ASA resin composition and preparation method thereof

The invention provides an ultralow-glossiness ultralow-temperature-resistant ASA resin composition and a preparation method thereof. The composition comprises, by weight, 20-60 parts of acrylonitrile-styrene-acrylate (ASA) grafted copolymer, 40-80% of acrylonitrile-styrene copolymer, 1-20% of ultralow-glossiness low-temperature-resistant modifier and 0.1-5 parts of processing aid, and the ultralow-glossiness low-temperature-resistant modifier comprises carrier polymer, fluorine-containing copolymer, low-temperature toughener, coupling agent, fumed silica and aids. The ASA resin composition prepared by the method has ultralow glossiness, and a try can be given to replace die treating processes like mark stretching and texturing, so that die cost and manufacturing cost are saved greatly; the composition has excellent low-temperature resistance and can be well applied in some occasions having requirements on low-temperature resistance and low glossiness, like auto parts, outdoor sections, building materials and electrical appliances.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Thermoplastic polyurethane elastomer cable sheath material and preparation method thereof

InactiveCN103881360AImprove performanceImprove wear resistanceInsulated cablesInsulated conductorsEpoxyMelamine phosphate

The invention discloses a thermoplastic polyurethane elastomer cable sheath material and a preparation method thereof. The material is prepared from the following raw materials in parts by weight: 50-70 parts of thermoplastic polyurethane elastomer, 20-30 parts of acrylonitrile-styrene-acrylate copolymer, 10-15 parts of polyformaldehyde, 10-15 parts of smoked sheet rubber, 5-10 parts of boron nitride nanopowder, 12-16 parts of melamine phosphate borate, 8-14 parts of antimony trioxide, 5-10 parts of encapsulated red phosphorous, 10-15 parts of titanium dioxide, 10-15 parts of nano-fluorite, 5-10 parts of organic bentonite, 20-30 parts of acetylene black, 1-2 parts of antioxidant 1010, 1-2 parts of antioxidant DLTP, 2-3 parts of magnesium stearate, 1.5-2.5 parts of zinc stearate, 2-3 parts of zinc oxide, 1-2 parts of stearic acid, 10-15 parts of epoxy tetrahydro-dioctyl phthalate, 5-10 parts of trimellitic triacylglyceride and 3-5 parts of composite filler. The cable material has excellent comprehensive performance, has the advantages of excellent abrasion resistance, flame retardance, oil resistance, high and low temperature resistance, toughness and tear resistance, as well as excellent processing performance and electric insulation performance, is durable, and has a wide application prospect.

Owner:ANHUI WANGDA COPPER DEV

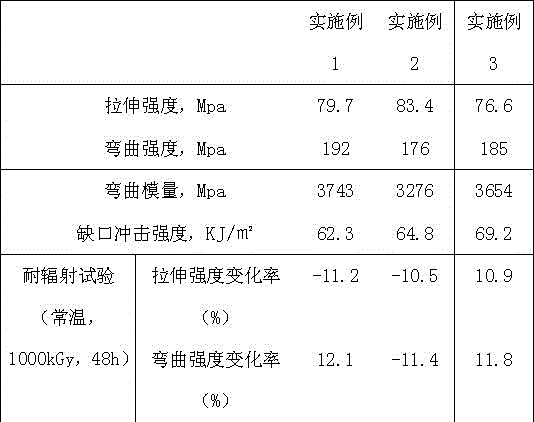

Anti-radiation and shock-resistant polycarbonate sheet for protective window and preparation method of polycarbonate sheet

The invention discloses an anti-radiation and shock-resistant polycarbonate sheet for a protective window and a preparation method of the polycarbonate sheet. The anti-radiation and shock-resistant polycarbonate sheet is prepared from raw materials in parts by weight as follows: 120-130 parts of polycarbonate, 10-12 parts of graphene nanofibers, 3-5 parts of dialkyl cyclohexanedicarboxylate, 10-14 parts of cyclic butylene terephthalate, 8-10 parts of a tetrafluoroethylene-hexafluoropropylene copolymer, 5-7 parts of dihydroxyaluminium stearate, 10-12 parts of an acrylonitrile-styrene-acrylate copolymer, 6-8 parts of oxidized paraffin, 5-7 parts of triisononyl trimellitate, 6-8 parts of flocking powder, 2-4 parts of dipentaerythritol hexacarboxylate and the like. Through blending of cyclic butylene terephthalate, the tetrafluoroethylene-hexafluoropropylene copolymer and the like with polycarbonate, the toughness, the abrasion resistance, the chemical stability, the impact strength and the radiation resistance of the sheet are improved, polycarbonate is modified with the raw materials including the flocking powder, the graphene nanofibers, magnesium oxide whiskers and the like, so that the anti-radiation performance and the shock resistance of the sheet can be improved, and the sheet has very high shock resistance and anti-radiation performance.

Owner:肖丽燕

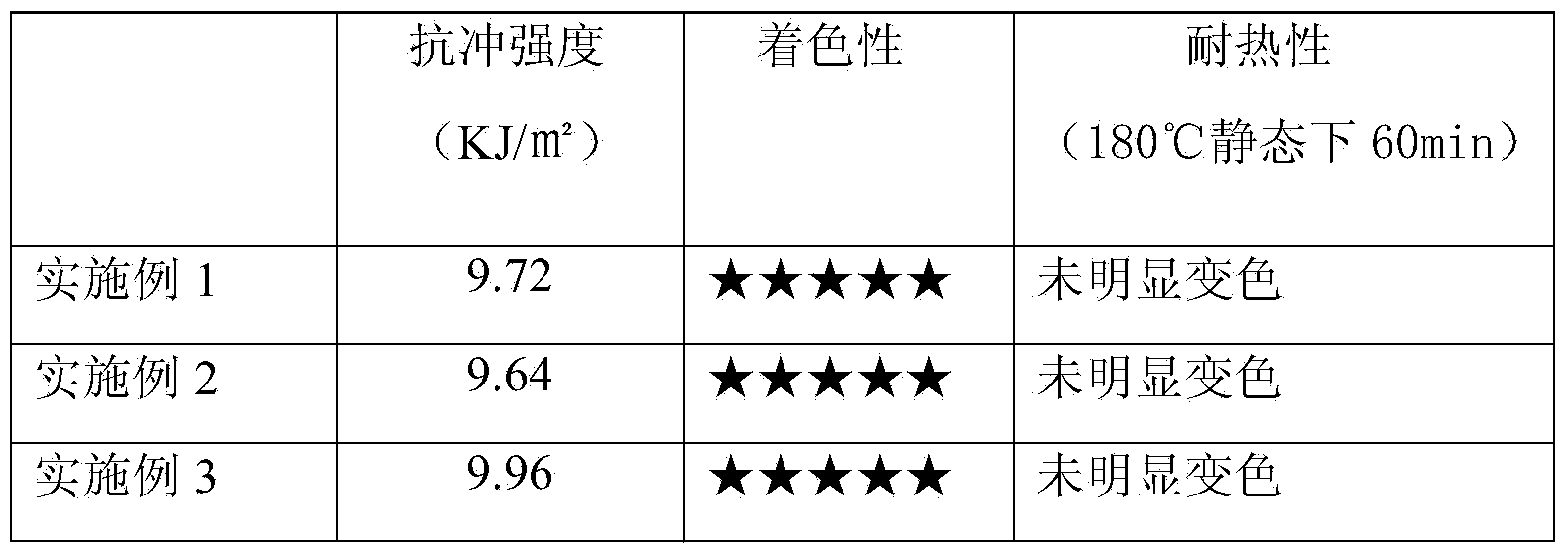

Preparation method of ASA (acrylonitrile styrene acrylate) powder

The invention relates to ASA (acrylonitrile styrene acrylate) powder and a preparation method thereof. The preparation method comprises the following steps: adding de-ionized water, an expanding agent, an emulsifying agent, acrylate monomers, a cross-linking agent and an initiating agent into a reaction container, and reacting to obtain acrylate seed latex; adding the acrylate monomers into the acrylate seed latex, and reacting to obtain core-layer latex; adding styrene and acrylonitrile into the core-layer latex, and compatibilizing and grafting the monomers to the core-layer latex to obtain primary graft polymerization emulsion; mixing the rest of styrene, acrylonitrile, the emulsifying agent and the de-ionized water, and emulsifying to obtain stable emulsion; dropwise adding the emulsion to the primary graft polymerization emulsion containing the initiating agent for reaction, heating for curing to finish a secondary graft polymerization process, adding a compound antioxidant into the polymerization emulsion, and condensing, dehydrating and drying to obtain the ASA powder. According to the preparation method, the reaction speed and the particle size can be satisfactorily controlled, the dyeing property and the impact resistance of a product are improved, and the problem of product defects caused by non-tight coverage of a core layer is avoided.

Owner:淄博华星助剂有限公司

Highly-weather-resistant type ASA (acrylonitrile Styrene acrylate copolymer)-based color co-extrusion material with low heat absorption effect and preparation method thereof

ActiveCN104212107AReduced heat absorption capacityLow weather resistanceASA-polymerWeather resistance

The invention discloses a highly-weather-resistant type ASA (acrylonitrile Styrene acrylate copolymer)-based color co-extrusion material with low heat absorption effect and a preparation method thereof. The highly-weather-resistant type ASA-based color co-extrusion material is characterized by comprising the following components in parts by weight: 85-94 parts of ASA, 1-4 parts of a light stabilizer, 1-2 parts of an ultraviolet absorber, 1-3 parts of an antioxidant and 2-6 parts of pigments. The preparation method of the highly-weather-resistant type ASA-based color co-extrusion material comprises the following steps: (1) weighing base stock, the light stabilizer, the ultraviolet absorber, the antioxidant and the pigments in proportion; (2) firstly adding the light stabilizer, the ultraviolet absorber, the antioxidant and the pigments to uniformly mix, and then adding the base stock to uniformly mix; and (3) extruding and pelletizing the uniformly-mixed materials to prepare the highly-weather-resistant type ASA-based color co-extrusion material with low heat absorption effect. Compared with the prior art, the highly-weather-resistant type ASA-based color co-extrusion material has low heat absorption and more superior weather resistance.

Owner:FOSHAN KAIYUE GRAND SKY PLASTIC TECH CO LTD

Polycarbonate resin / styryl resin non-halogen flame-retardant composite material

The invention relates to the technical field of the high polymer materials, in particular to a halogen-free flame-retardant compound material consisting of polycarbonate resin and acrylonitrile-styrene-acrylate. The halogen-free flame-resistant compound materials comprise polycarbonates (PC), acrylonitrile-styrene-acrylates, anti-flamming agents, and antioxidant additives. The invention is characterized in that the compound materials also comprise nanometer kaolin accounting for 3 per cent to 20 per cent of the total weight. The invention enhances the rigidity of the material, greatly improves the size stability of the material and maintains the impact ductility of the material simultaneously.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Highly wear-proof corrosion resisting synthetic resin decorative tile

InactiveCN103254525AImprove insulation effectImprove sound insulation and noise reductionASA-polymerThermal insulation

The invention discloses a highly wear-proof corrosion resisting synthetic resin decorative tile which is prepared by the following steps: uniformly stirring materials; compositing and moulding through an extruder; and then cooling and setting through a cooling liquid. The material comprises the following components in parts by weight: 40-45 parts of polyvinyl chloride resin, 32-36 parts of ASA (Acrylonitrile Styrene Acrylate) resin, 2-5 parts of antioxygen, 10-15 parts of a fire retardant, 2-5 parts of a delustering agent, 1-3 parts of a corrosion inhibitor, 2-5 parts of a shock resisting modifier and 0.5-1.5 parts of an ultraviolet light absorber. Through above manner, the synthetic resin decorative tile provided by the invention has good heat insulating performance, sound insulating and noise reducing performance, thermal insulation, waterproof performance and windproof and earthquake-proof performance, and is green and environment-friendly and free from pollution, and is simple in machining process, low in cost and small in energy consumption.

Owner:SUZHOU IND PARK FANGYUAN METAL PROD

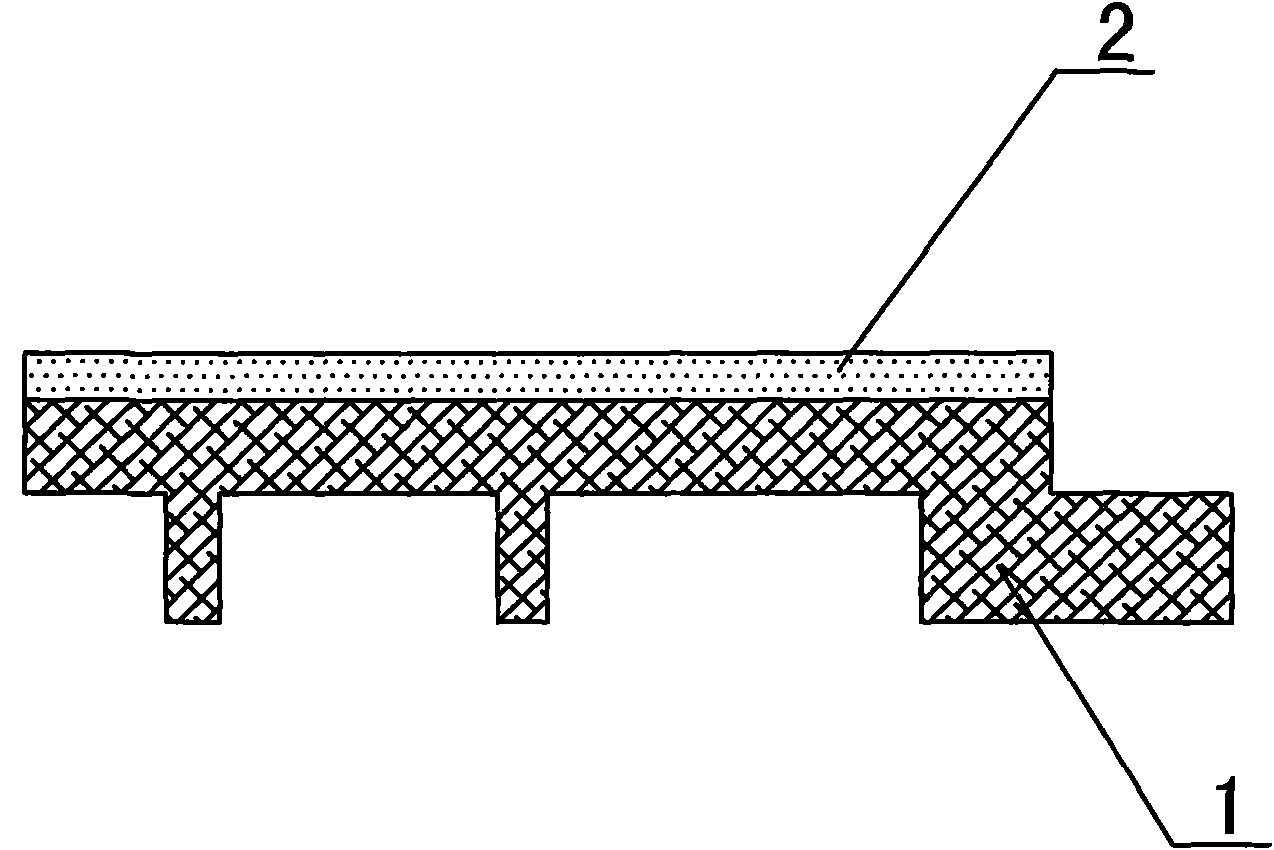

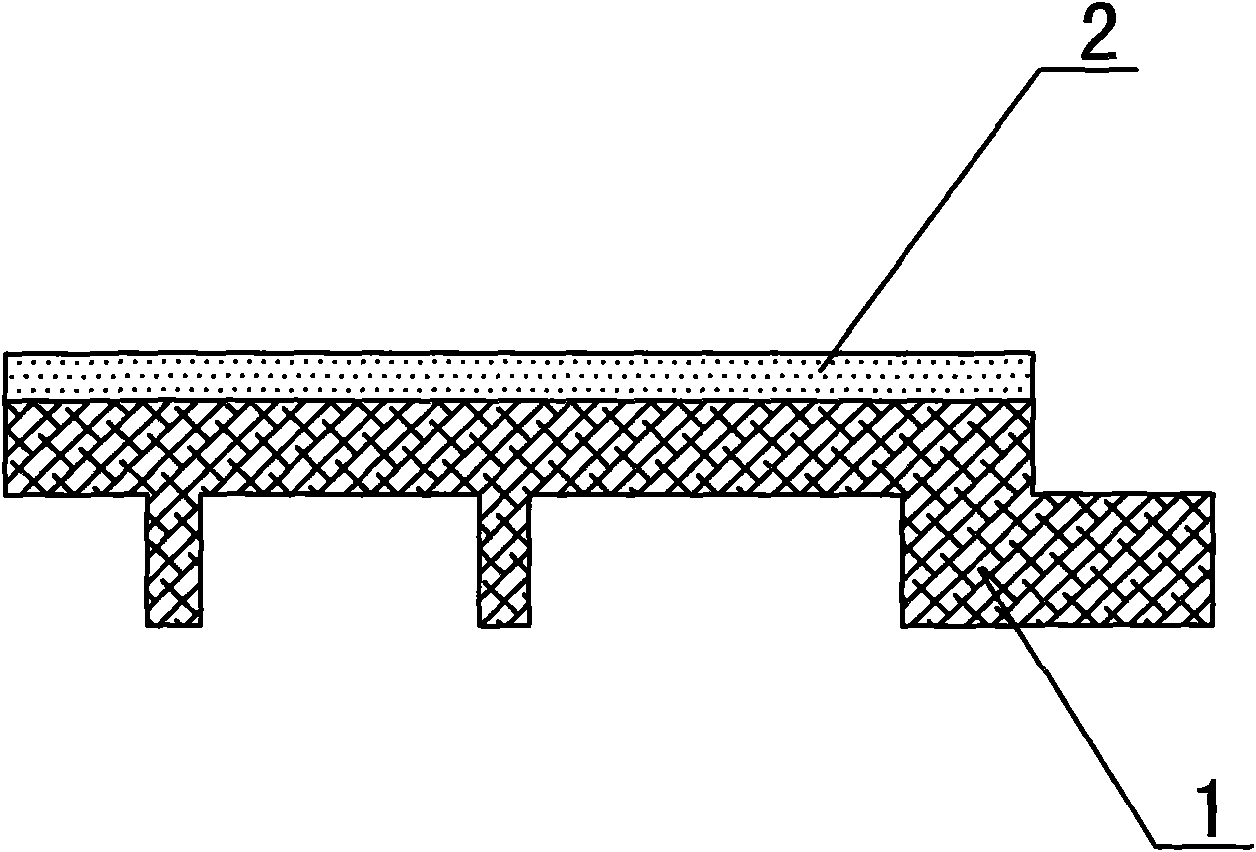

Plastic wood board with high weather resistance and processing method thereof

ActiveCN101941310AWon't releaseGood physical propertiesRubber layered productsASA-polymerSocial benefits

The invention discloses a plastic wood board with high weather resistance, comprising a plastic wood base board. The plastic wood base board mainly takes wood flour and PVC (Poly Vinyl Chloride) raw material as main raw materials; the surface of the plastic wood base board is provided with an ASA (Acrylonitrile-Styrene-Acrylate) coextrusion layer; and the coverage range of the ASA coextrusion layer is an upper surface of the integral plastic wood board. The plastic wood board with high weather resistance can not only enable the surface of the plastic wood board to be rich in luster and the integral effect to be more attractive by matching with the inherent color of the plastic wood board, but also solve the problem of color fading of the plastic wood board used outdoors and select different models as required and has the advantages of convenient installation, low price and very well social benefit and economic benefit.

Owner:无锡唯景建材科技有限公司

Weatherable colored resinous composition and method

Disclosed are weatherable compositions comprising (i) 25-45 wt. % of an acrylonitrile-styrene-acrylate graft copolymer (ASA) or acrylate-modified ASA, (ii) 75-55 wt. % of at least one rigid thermoplastic polymer comprising structural units derived from styrene and acrylonitrile; alpha-methylstyrene and acrylonitrile; alpha-methylstyrene, styrene, and acrylonitrile; styrene, acrylonitrile, and methyl methacrylate; alpha-methyl styrene, acrylonitrile, and methyl methacrylate; or alpha-methylstyrene, styrene, acrylonitrile, and methyl methacrylate, or mixtures thereof, (iii) at least one iron oxide-coated mica, and (iv) at least one organic or inorganic colorant. A process for making the compositions is also disclosed. Articles made from said compositions are also disclosed.

Owner:SABIC INNOVATIVE PLASTICS IP BV

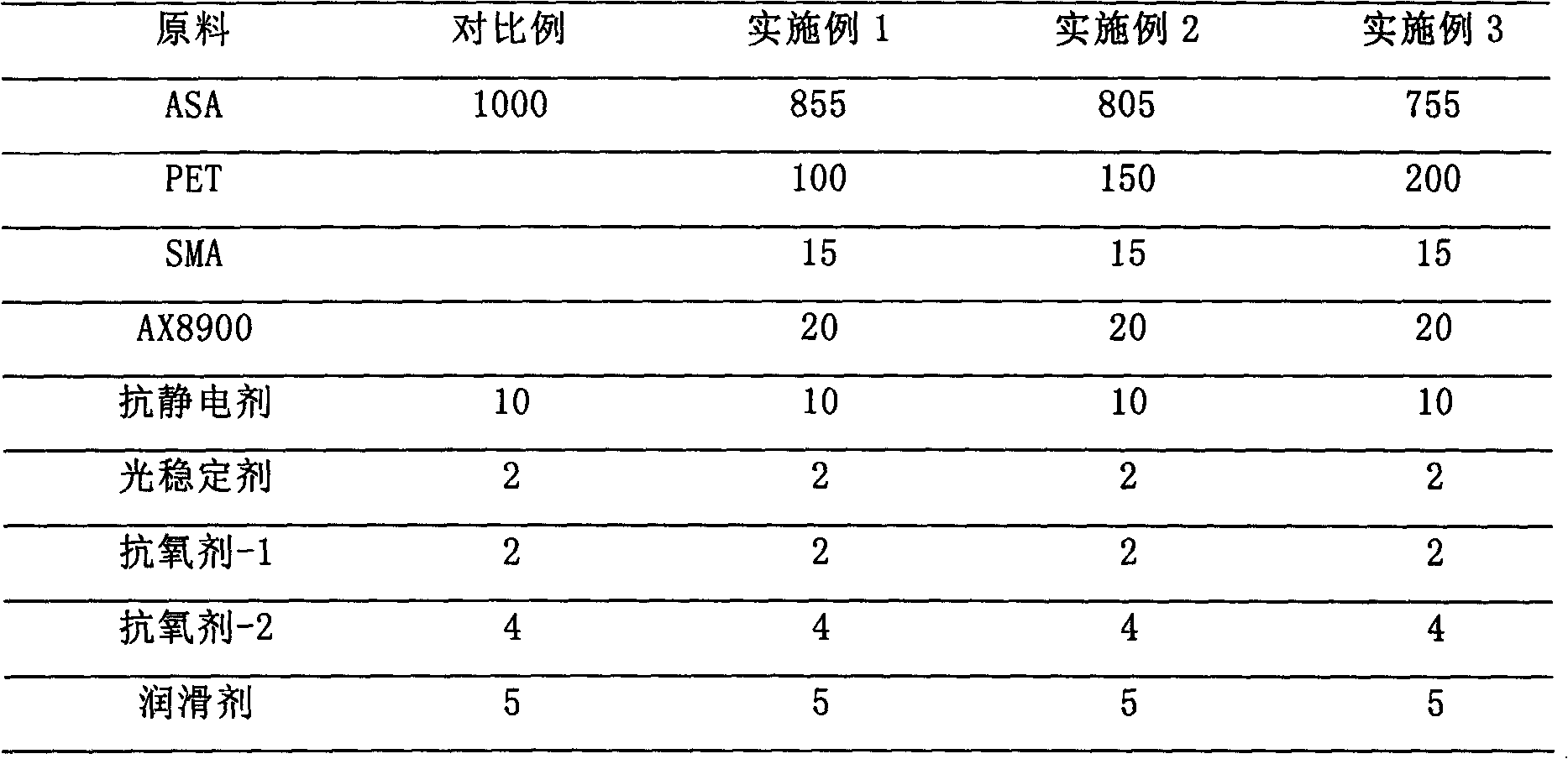

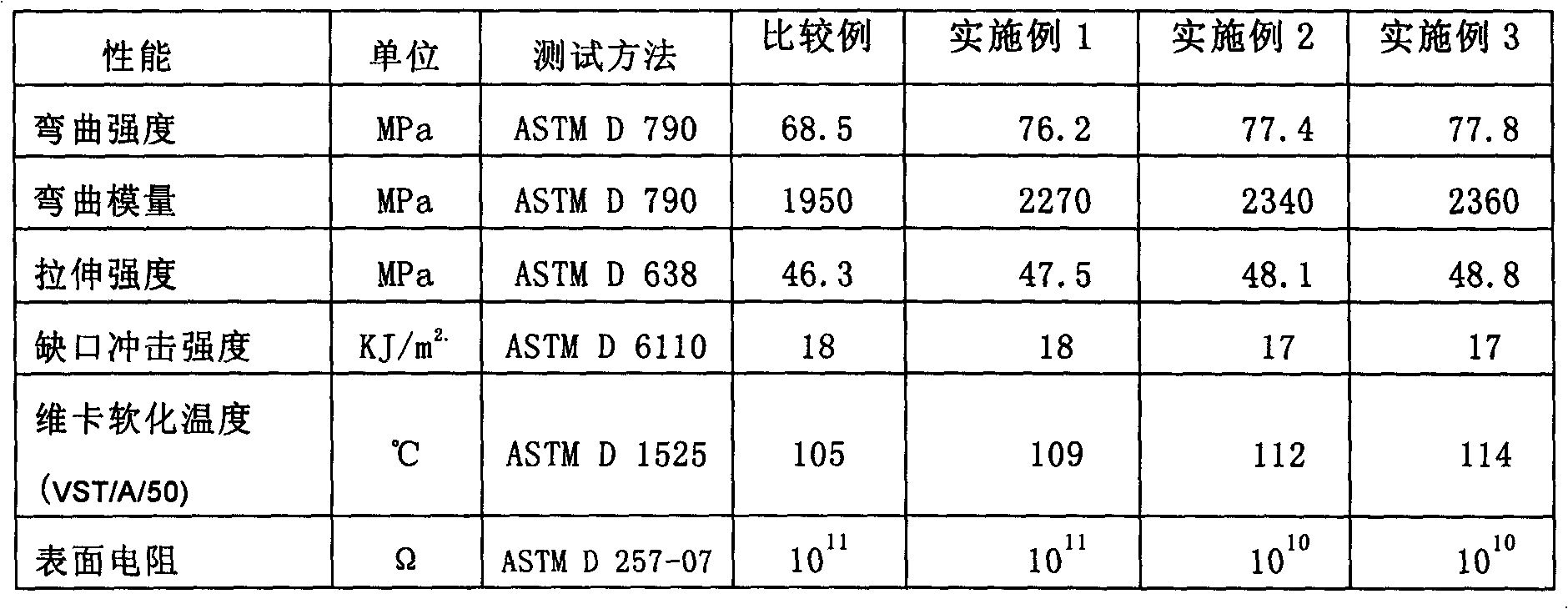

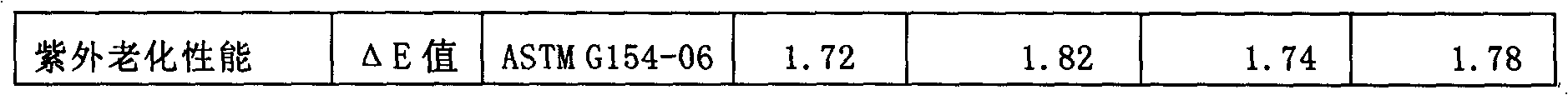

Antistatic ultraviolet-resistant ASA/PET alloy material and preparation method thereof

The invention relates to an antistatic ultraviolet-resistant ASA / PET alloy material and a preparation method thereof; the material is prepared from the following components by weight: 60-90 parts of acrylonitrile-styrene-acrylate copolymer (ASA), 10-30 parts of polyethylene terephthalate (PET), 1-5 parts of styrene-grafted maleic anhydride copolymer, 2-5 parts of ethylene-acrylate copolymer, 0.2-3 parts of antistatic agents, 0.3-1 part of lubricants, 0.2-2 parts of light stabilizers, and 0.2-1 part of antioxidants. The product is prepared by preparing the raw materials in proportion, premixing, performing extrusion by a double screw extruder, and performing granulation. Compared with the prior art, the alloy material of the invention has the advantages of excellent mechanical properties, weatherability, antistatic performance, ultraviolet resistance, reduced cost, suitability of industrial scale production and popularization application, and the like.

Owner:HEFEI GENIUS NEW MATERIALS

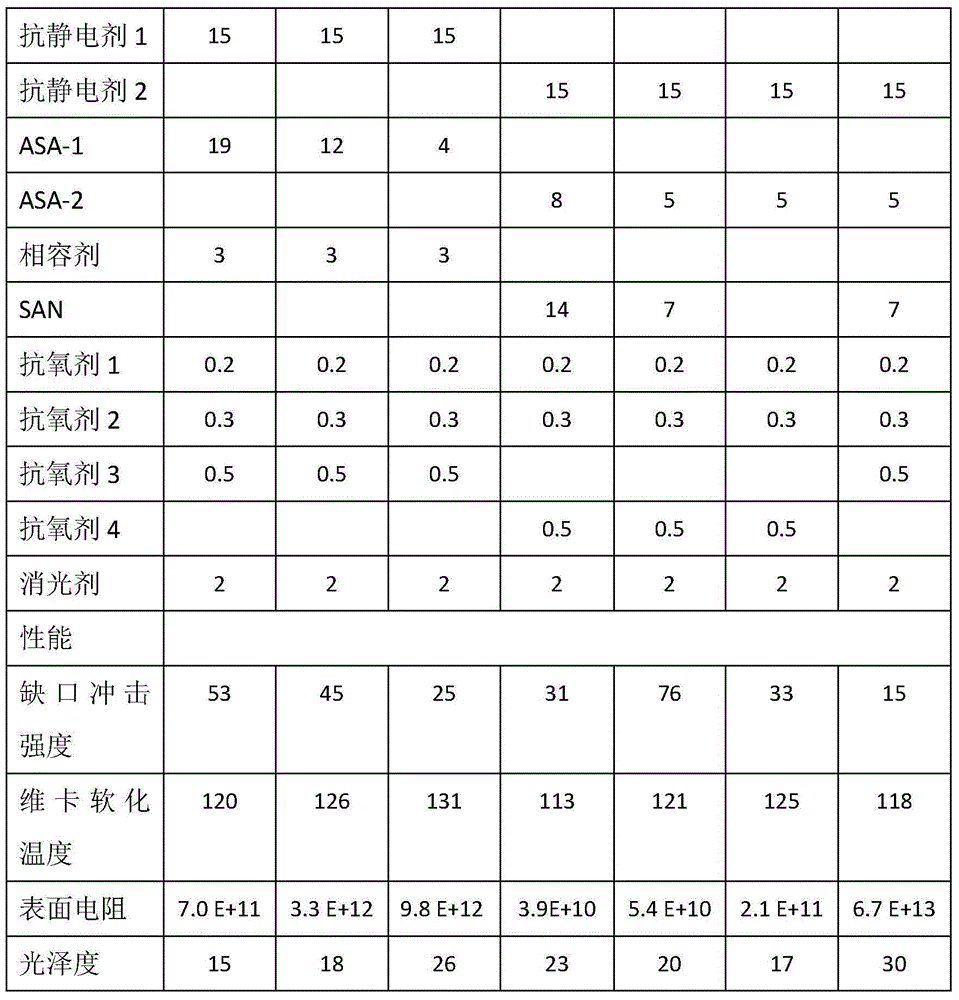

High-heat resistance and low-gloss antistatic PC/ASA alloy material and preparation method thereof

InactiveCN104610719AImprove heat resistanceExcellent permanent antistatic propertiesASA-polymerAntistatic agent

The invention discloses a high-heat resistance and low-gloss antistatic PC / ASA alloy material. The high-heat resistance and low-gloss antistatic PC / ASA alloy material comprises the following components in parts by weight: 60-80 parts of polycarbonate resin, 10-20 parts of an antistatic agent, 0-15 parts of an acrylonitrile-styrene copolymer, 4-20 parts of an acrylonitrile-styrene-acrylate graft copolymer, 0-5 parts of a grafted maleic anhydride compatibilizer, 0-1 part of an antioxidant and 0.1-2 parts of a matting agent. The technical scheme adopted in the invention has the benefits as follows: a polycarbonate / acrylonitrile-styrene-acrylate blending material adopting the technical scheme is excellent in heat resistance, has a permanent anti-static property and a low-gloss characteristic, and can be applied to car interiors.

Owner:CHONGQNG PRET NEW MATERIAL +2

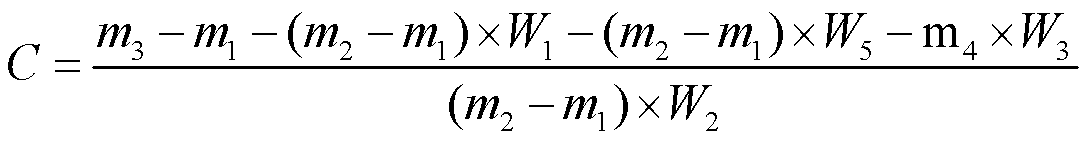

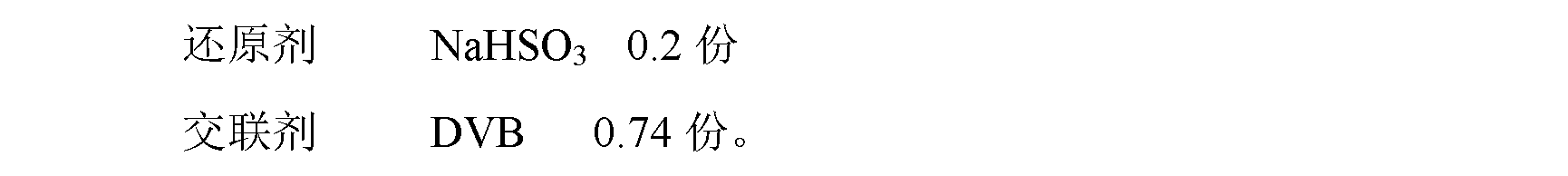

Method for preparing ASA (Acrylonitrile-Styrene-Acrylate) copolymer latex by using water-solubility redox initiator at low temperature

The invention discloses a method for preparing ASA (Acrylonitrile-Styrene-Acrylate) copolymer latex by using a water-solubility redox initiator at low temperature. The method comprises unit processes of preparing polyacrylate seeds, preparing a polyacrylate core, preparing an ASA resin shell and post processing. The water-solubility initiator adopted by the method can initiate polymerization at a lowest temperature of 35 DEG C and reach a high conversion rate. The method has the characteristics of good repeatability, warm reaction condition, low energy consumption, easiness in operation and low price of raw materials, so that the industrial implementation is facilitated.

Owner:HEFEI UNIV OF TECH

Aging-resistant PVC tubular product and preparation method thereof

InactiveCN104140617AGood anti-ultraviolet aging performanceImprove mechanical propertiesPhosphateCadmium Cation

The invention discloses an aging-resistant PVC tubular product and a preparation method thereof. The aging-resistant PVC tubular product is prepared from the following raw materials in parts by weight: 100-150 parts of SG-3 PVC, 30-60 parts of an acrylonitrile-styrene-acrylate copolymer, 2-4 parts of triglycidyl isocyanurate, 10-15 parts of titanium dioxide, 15-20 parts of sericite in powder, 25-45 parts of polyether sulfone, 3-6 parts of polytetrafluoroethylene micropowder, 2-3 parts of tribasic aluminum sulfate, 1.5-2.5 parts of a barium cadmium zinc liquid compound stabilizer, 3-5 parts of erucyl amide, 4-7 parts of Fischer Tropsch wax, 1-2 parts of pyrithione zinc, 1-2 parts of bisphenol A phosphate, 5-10 parts of caustic-burned magnesia powder and 3-4 parts of auxiliaries. The PVC tubular product prepared by the preparation method disclosed by the invention not only has excellent ultraviolet aging resistance and mechanical property, but also has good heat resistance, corrosion resistance, wear resistance, impact resistance, environmental stress crack resistance and the like, and is free from deformation and cracking when being exposed to the sun for a long time and durable.

Owner:安徽玉发塑业有限公司

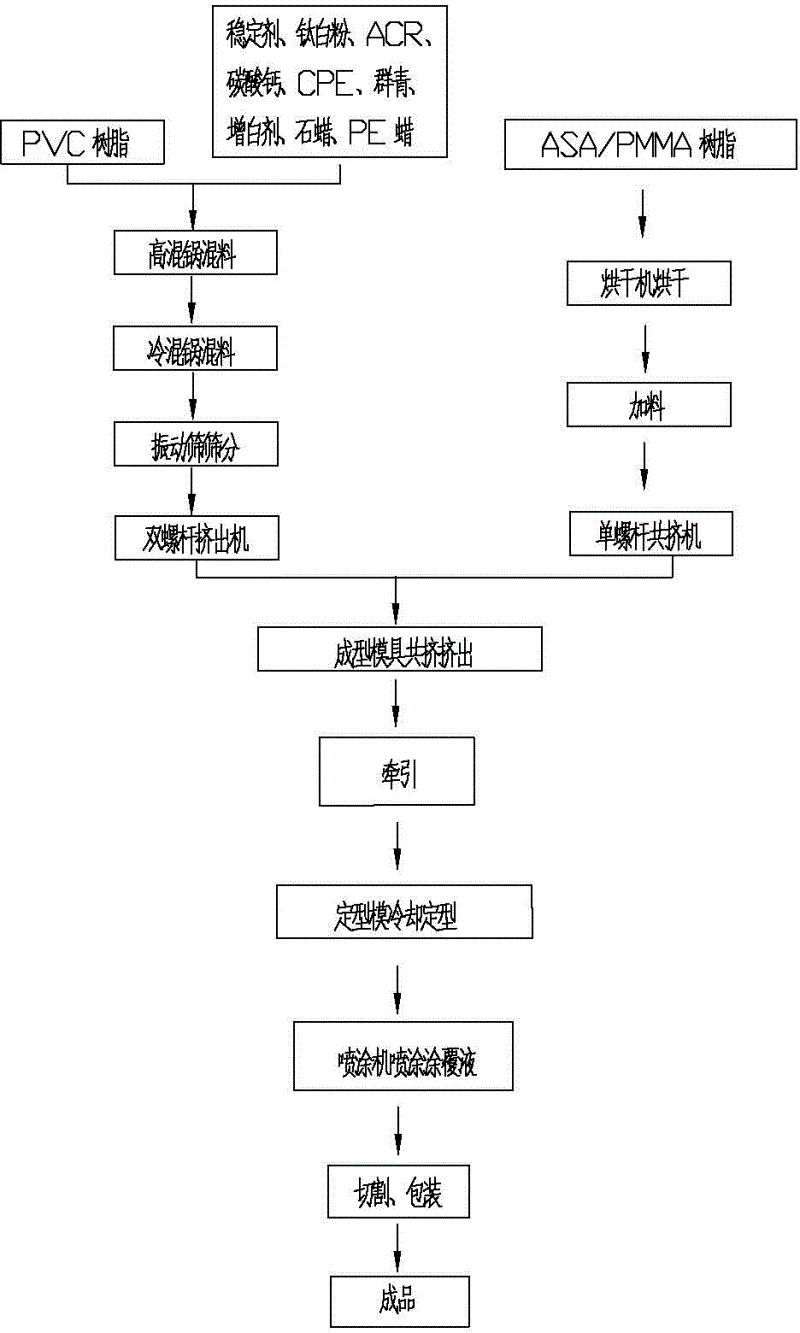

Colored PVC decoration sectional material and production method thereof

The invention relates to the technical field of PVC (polyvinyl chloride) sectional materials, and relates to a colored PVC decoration sectional material and a production method thereof. The colored PVC decoration sectional material is composed of the following components in part by weight: 100 parts of PVC resin, 4-5 parts of stabilizer, 4.5-5 parts of titanium pigment, 1.5-2 parts of ACR (acrylate), 22-26 parts of calcium carbonate, 6.5-7.5 parts of CPE (chlorinated polyethylene), 0.042-1.145 parts of ultramarine, 0.008-0.010 part of brightener, 0.5-0.6 part of paraffin, 0.4-0.5 part of PE (polyethylene) wax, 2-2.5 parts of ASA / PMMA (acrylonitrile styrene acrylate / poly(methyl methacrylate) resin, and 1.5-2.5 parts of micro emulsion. According to the invention, the formula and color of the micro emulsion are adjusted according to the actual demands, so that the decorative effect of the sectional material is improved; and by adopting the process, the surface quality, ultraviolet light resistance and scratch resistance of the PVC colored sectional material are effectively improved, the product quality is improved and the added value of the product is improved.

Owner:新疆蓝山屯河型材有限公司 +1

High-impact resistance and high-brightness acrylonitrile-styrene-acrylate copolymer (ASA) alloy material

The invention discloses a high-impact resistance and high-brightness acrylonitrile-styrene-acrylate copolymer (ASA) alloy material and a preparation method thereof. The preparation method is characterized in that main raw materials of 30 to 90 parts of ASA, 0 to 50 parts of polycarbonate (PC) and 0 to 20 parts of polymethyl methacrylate (PMMA) is added with a dispersant, a lubricant, an anti-oxidant, a ultraviolet ray absorber and color pigment, and the mixture is subjected to mixing extrusion in a double-screw extruder to form the ASA alloy material. The ASA alloy material retains excellent ultraviolet ray resistance, excellent weatherability, high rigid, good chemical stability, good stainability and good chemical resistance of ASA resin, has high toughness, high brightness, excellent comprehensive properties, a low cost, good co-extrusion compatibility with polyvinyl chloride (PVC) and stable co-extruded layer thickness, does not produce distortion, layering and warping under a large temperature difference condition, can be utilized for preparation of uniform and stable profiles having different colors, and can be widely utilized for the building fields of plastic doors and windows.

Owner:HEILONGJIANG XINDA ENTERPRISE GRP

Low-shrinkage high-weatherproofness polypropylene composite material for shell of electric tool

The invention discloses a low-shrinkage high-weatherproofness polypropylene composite material for a shell of an electric tool. The polypropylene composite material is prepared from the following components in parts by weight: 45 to 85 parts of co-polypropylene, 10 to 50 parts of enhancer, 1 to 15 parts of flexibilizer, 0.1 to 0.5 part of coupling agent, 0.1 to 0.5 part of antioxidant, 0.1 to 0.5 part of light stabilizer and 0 to 5 parts of other additives. According to the polypropylene composite material disclosed by the invention, the shrinkage rate of a matrix resin is decreased, so that the dimensional stability of the material is improved; meanwhile, the dimensional stability of the material is improved, so that the polypropylene composite material is capable of replacing ASA (Acrylonitrile Styrene Acrylate Copolymer) to be used for producing the shell of the electric tool.

Owner:HEFEI GENIUS NEW MATERIALS

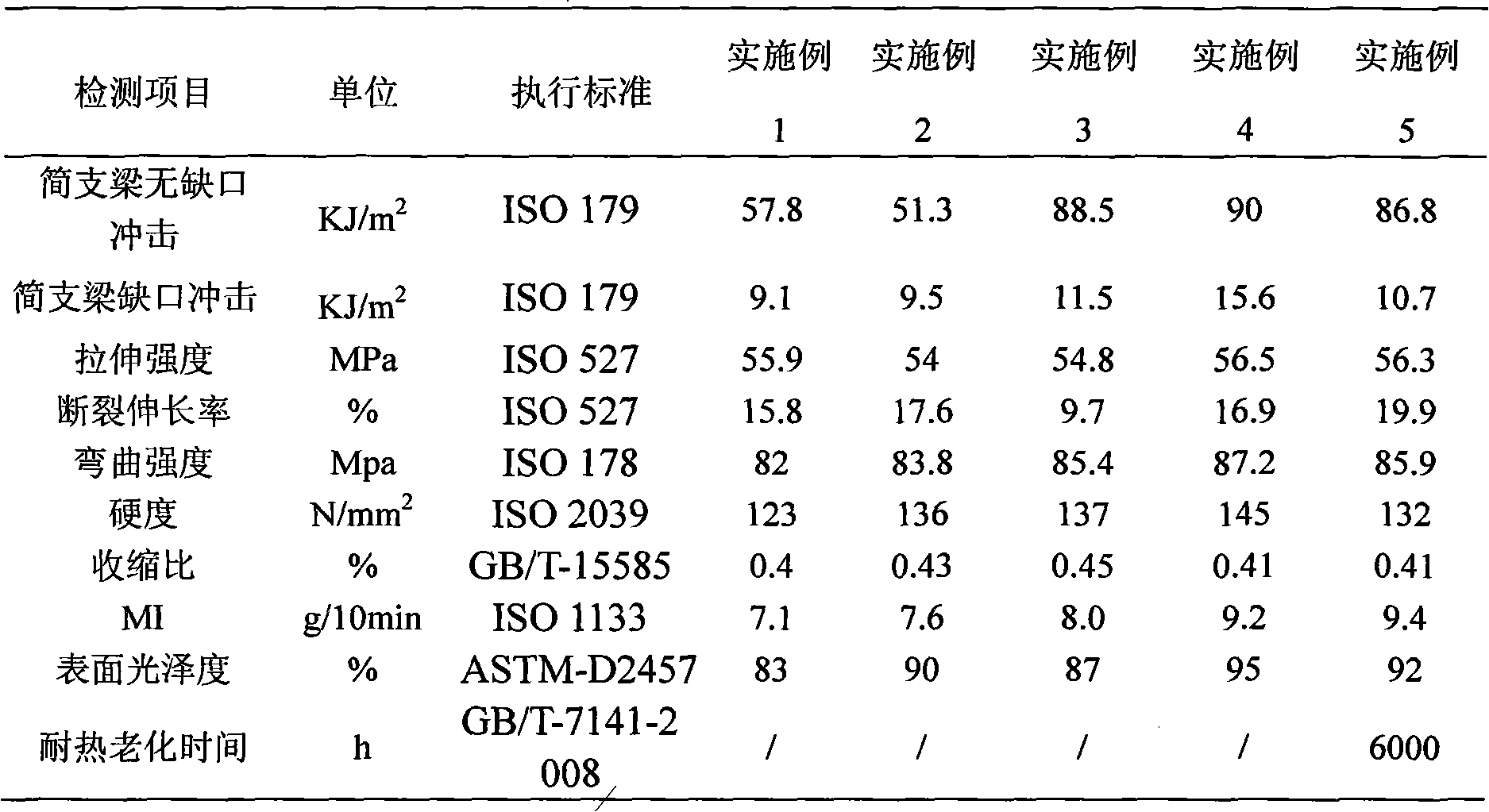

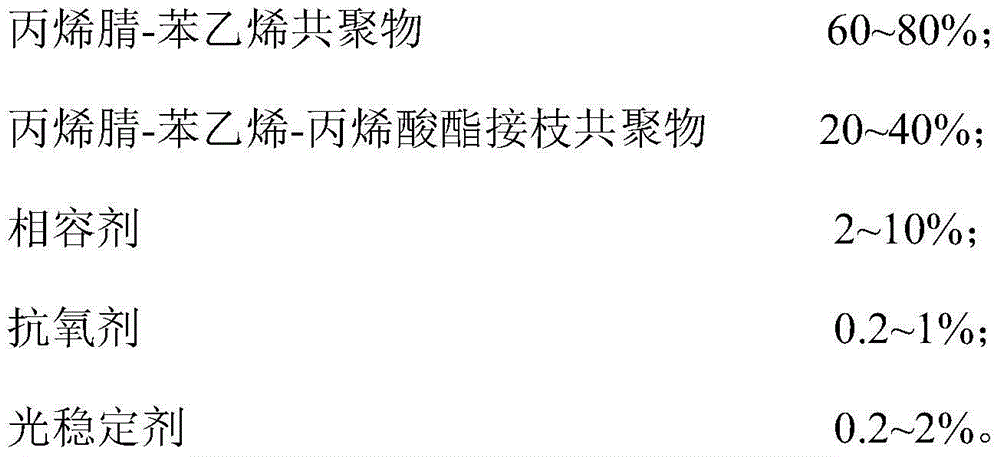

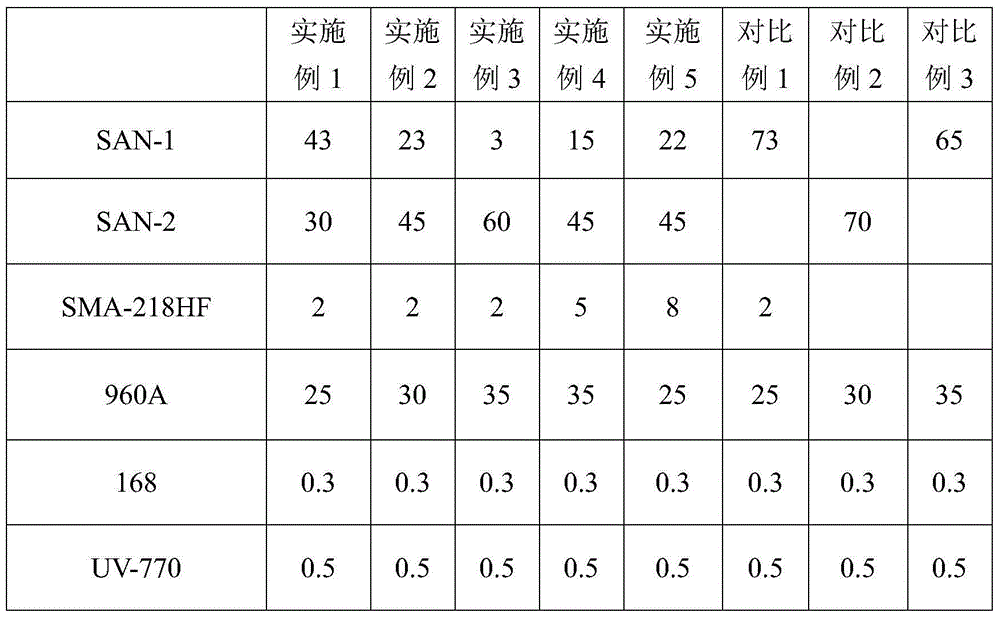

High- fluidity and high-impact ASA material and preparation method thereof

The invention discloses a high-fluidity and high-impact ASA material and a preparation method thereof and belongs to the field of polymer composite materials. The ASA material comprises the following raw materials in percentage by weight: 60-80% of an acrylonitrile-styrene copolymer, 20-40% of an acrylonitrile-styrene-acrylate graft copolymer, 2-10% of a compatibilizer, 0.2-1% of an antioxidant and 0.2-2% of a light stabilizer. The ASA material prepared by the preparation method has high impact performance and good processing fluidity, is easy to fill molded large-size abrasive tools and can be widely applied to interior and exterior decorative parts of automobiles and parts of electronic electric appliances.

Owner:SHANGHAI PRET COMPOSITES +2

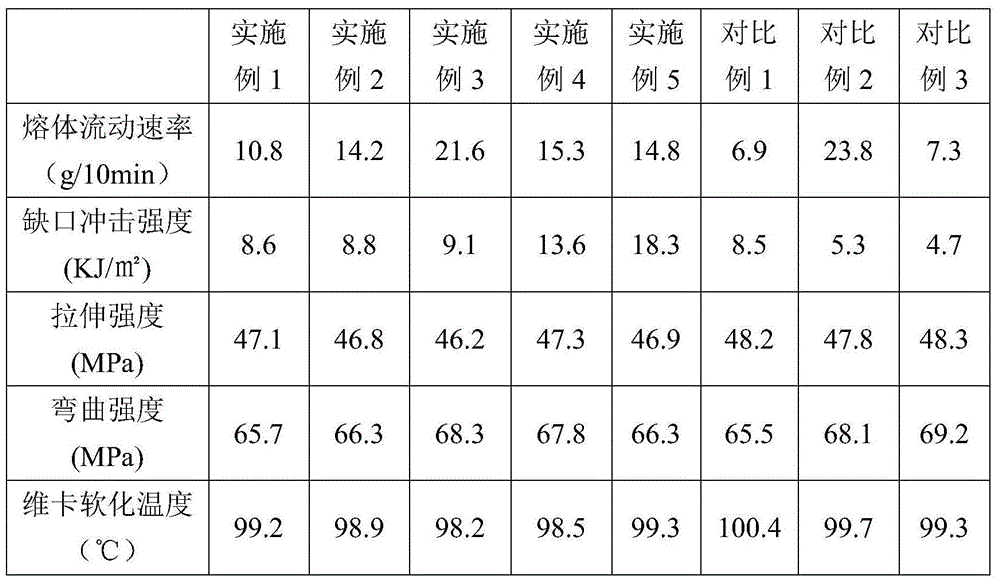

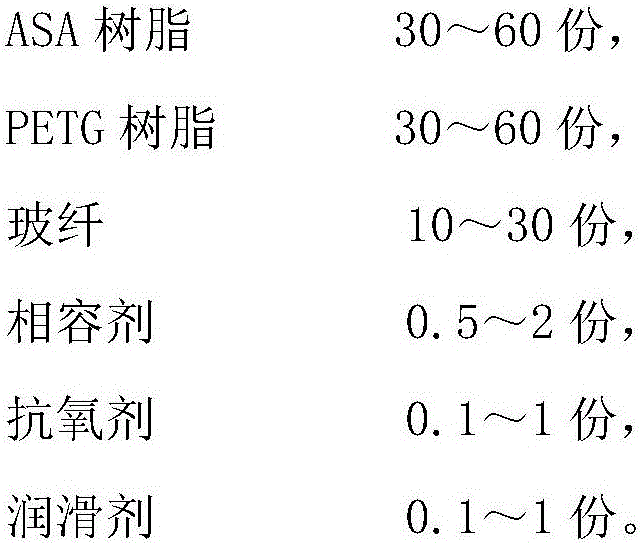

Glass fiber reinforced ASA (acrylonitrile-styrene-acrylate copolymer)/PETG (polyethylene terephthalate glycol) alloy material and preparation method thereof

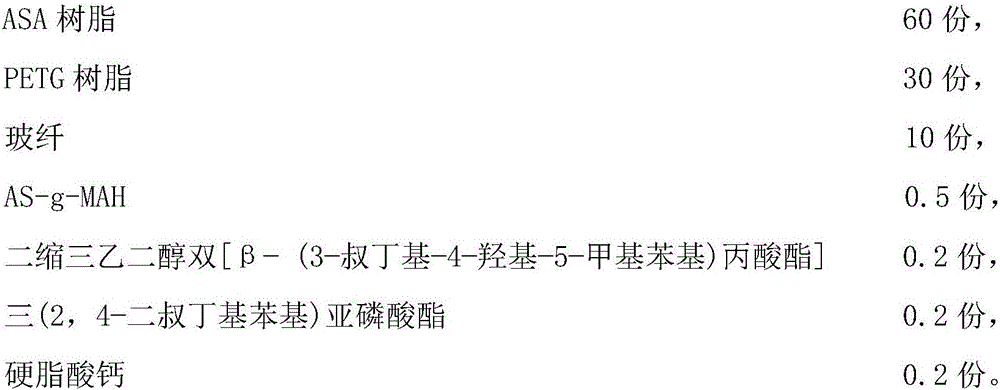

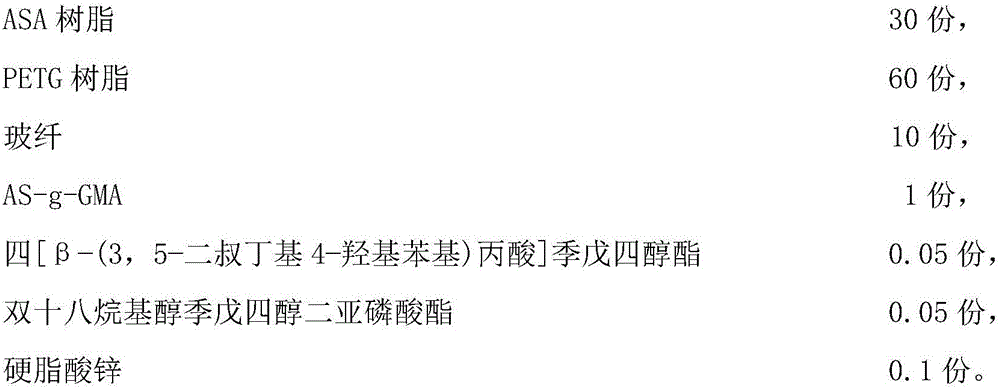

The invention relates to a glass fiber reinforced ASA (acrylonitrile-styrene-acrylate copolymer) / PETG (polyethylene terephthalate glycol) alloy material and a preparation method thereof. The ASA / PETG alloy material is prepared from, by weight, 30-60 parts of ASA resin, 30-60 parts of PETG resin, 10-30 parts of glass fibers, 0.5-2 parts of a compatilizer, 0.1-1 part of an antioxidant and 0.1-1 part of a lubricant. The preparation method includes steps: (a) adding the ASA resin, the PETG resin, the compatilizer, the antioxidant and the lubricant into a mixer to realize mixing; (b) after side feeding of the glass fibers and main feeding of a mixture obtained at the step through a double-screw extruder, blending and granulating to obtain the material. The method is simple and feasible; by the compatilizer, the ASA, the PETG and the glass fibers are combined more steadily, and the glass fiber reinforced ASA / PETG alloy material has excellent mechanical properties, fluidity and dimensional stability and suitable for automotive complex structural interior decoration parts such as speaker covers and defogging grilles.

Owner:SHANGHAI KUMHOSUNNY JINSHAN PLASTICS CO LTD

PMMA/ASA alloy material for PVC profile coextrusion surface layer and preparation thereof

The invention discloses a PMMA / ASA alloy material for a PVC profile coextrusion surface layer and preparation thereof. The PMMA / ASA alloy material is prepared from the following raw materials in percentage by ,mass: 0.5 to 3 percent of chain extender, 0 to 5 percent of inorganic nano particle, coupling agent accounting for 0 to 3 percent of the mass of the inorganic nano particle, and the balanceof PMMA resin and ASA resin, wherein the mass ratio of the PMMA resin to the ASA resin is 1:0.25-4; the PMMA resin is polymethylmethacrylate resin; the ASA resin is acrylonitrile-styrene-acrylate grafted copolymer; and the chain extender contains groups which can react with the carboxyl. The PMMA / ASA alloy material has excellent performance such as high intensity, high toughness, high glossiness,friction and abrasion resistance, and the like.

Owner:ZHEJIANG UNIV OF TECH

Highly weather-proof PBT (polybutylene terephthalate)/ASA (acrylonitrile styrene acrylate) wire for 3D printing and preparation method of PBT/ASA wire

ActiveCN105440596AReduce thermo-oxidative degradationAvoid damageAdditive manufacturing apparatusASA-polymerWeather resistance

The invention discloses a highly weather-proof PBT (polybutylene terephthalate) / ASA (acrylonitrile styrene acrylate) wire for 3D printing and a preparation method of the PBT / ASA wire, relates to a printing material and aims to provide a 3D printing polymer material with better toughness and higher weather resistance. The technical scheme is that the formula comprises components in percentage by weight as follows: 50%-93% of PBT, 4%-90% of ASA, 0.5%-10% of a compatilizer, 0.1%-2% of a heat stabilizer, 0.1%-1% of an ultraviolet absorber, 0.1%-5% of an ultraviolet screening agent, 0.01%-0.1% of an antioxidant and 0.1%-1% of while oil. The weather-proof ASA is adopted to serve as a toughener of PBT, other weather-proof assistants are added, and the printing wire applied to a 3D printing product and used in outdoor intensive ultraviolet, damp, rain and light environments is provided.

Owner:FUJIAN NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com