Antistatic PC/ASA (polycarbonate/acrylonitrile styrene acrylate copolymer) alloy plastic for automotive interior trim parts and method for manufacturing antistatic PC/ASA alloy plastic

A technology for automotive interior parts and alloy plastics, which is applied in the field of antistatic PC/ASA alloy plastics for automotive interior parts and its preparation. It can solve the problems of reduced comfort, fading of parts, and cracking of materials, and achieve low product cost. , Excellent antistatic properties, good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

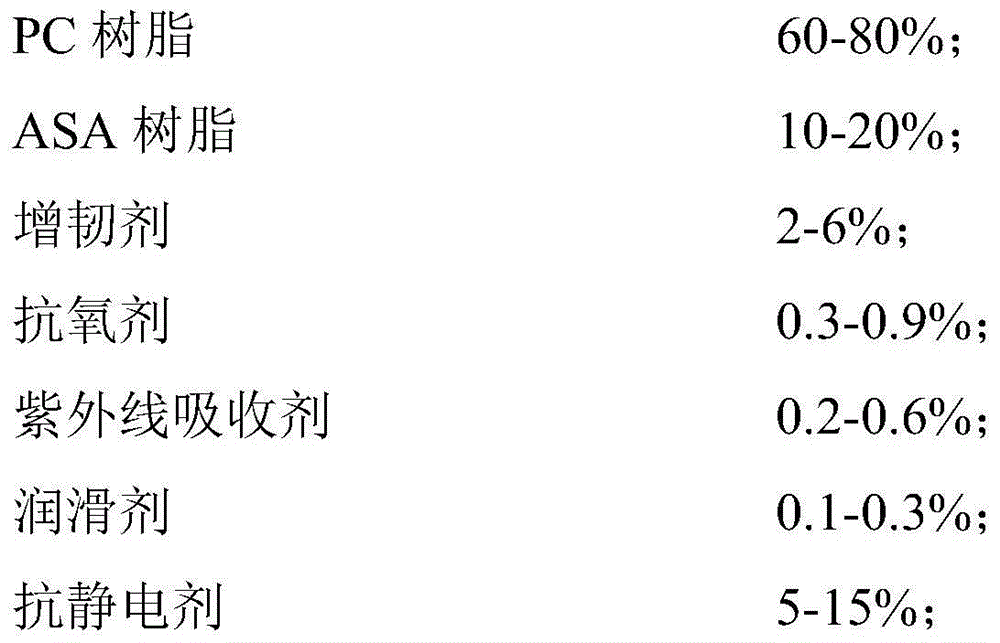

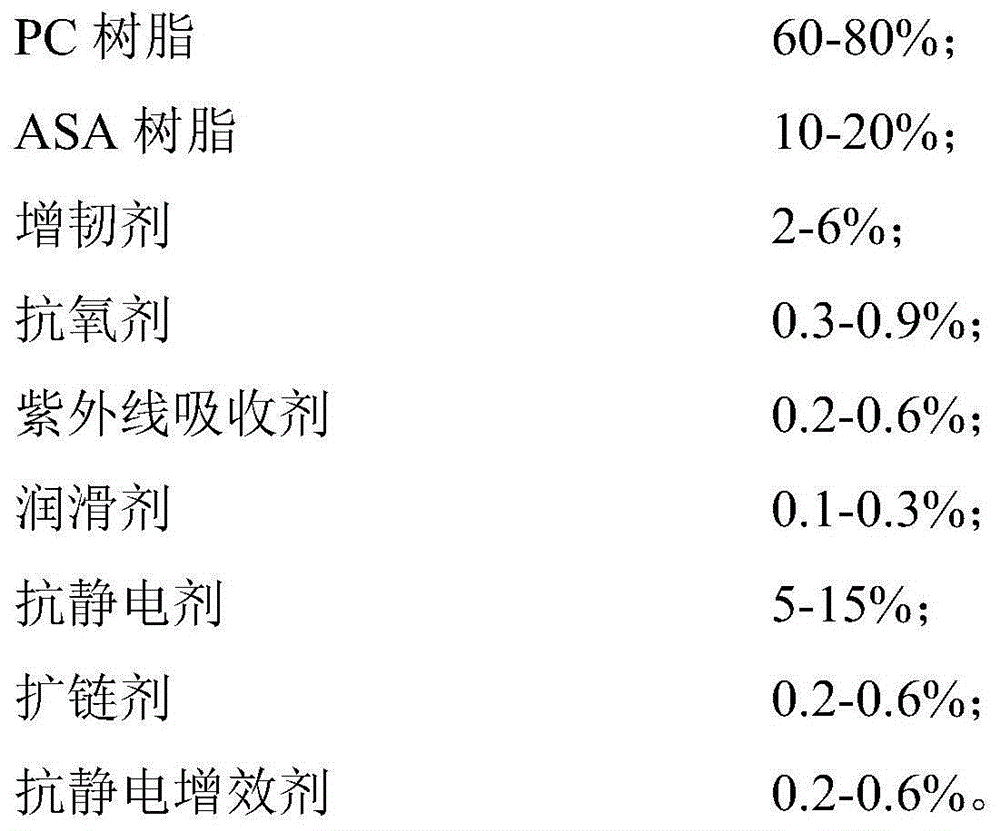

Method used

Image

Examples

Embodiment 1-4

[0040] Each raw material was weighed according to the data corresponding to Examples 1-4 in Table 1.

[0041] In the high-speed mixer, control the speed of the high-speed mixer at 350 rpm at room temperature, mix for 7 minutes, take it out and transfer it to a twin-screw extruder, extrude and granulate at a temperature of 250 ° C, and control the speed of the screw machine at 400 rev / min, namely obtain the antistatic PC / ASA alloy plastics for the automotive interior parts.

[0042] Table 1: Formula table of antistatic PC / ASA alloy plastic (unit: kg)

[0043] raw material

PUM

| Property | Measurement | Unit |

|---|---|---|

| Notched impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com