Plastic wood board with high weather resistance and processing method thereof

A processing method and weather resistance technology, applied in the high weather resistance plastic board and its processing field, can solve the problems of poor weather resistance, easy fading and high maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

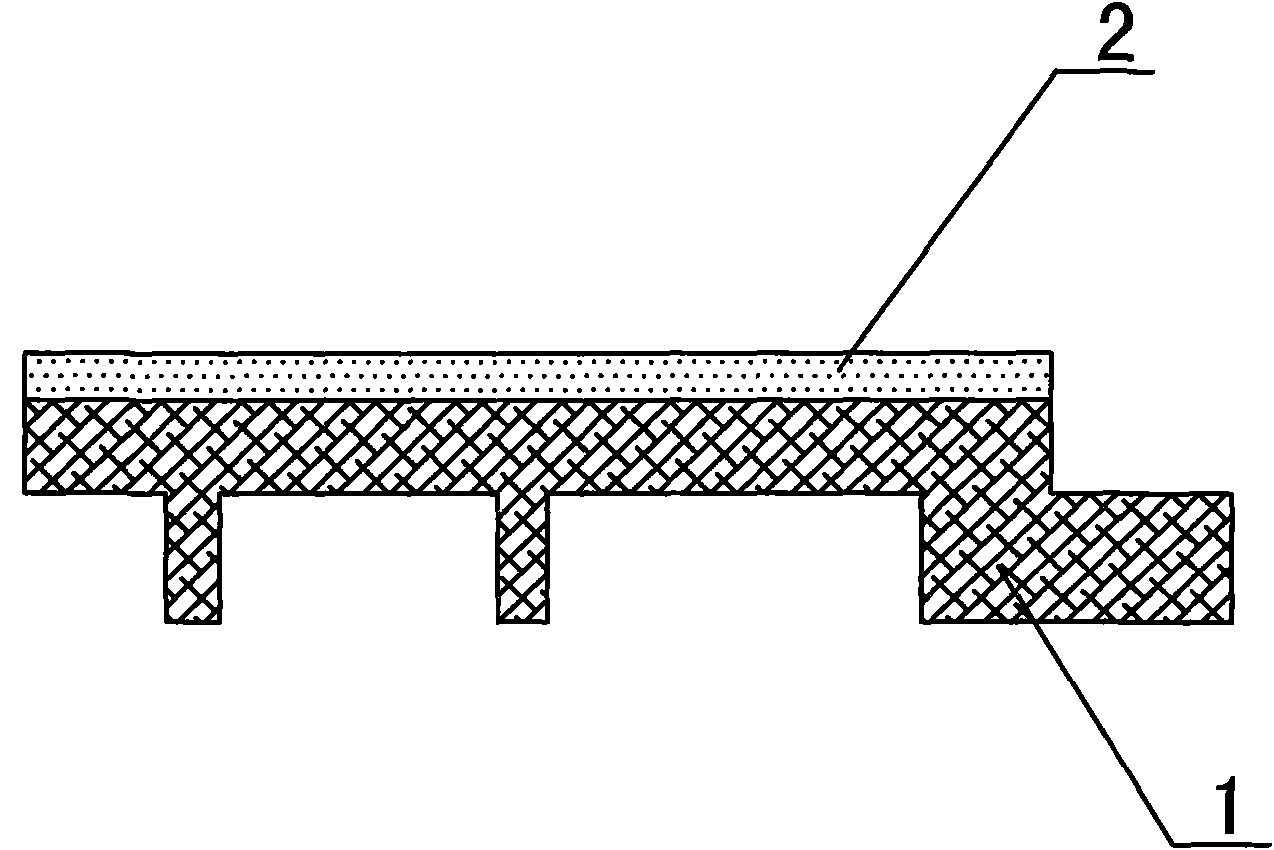

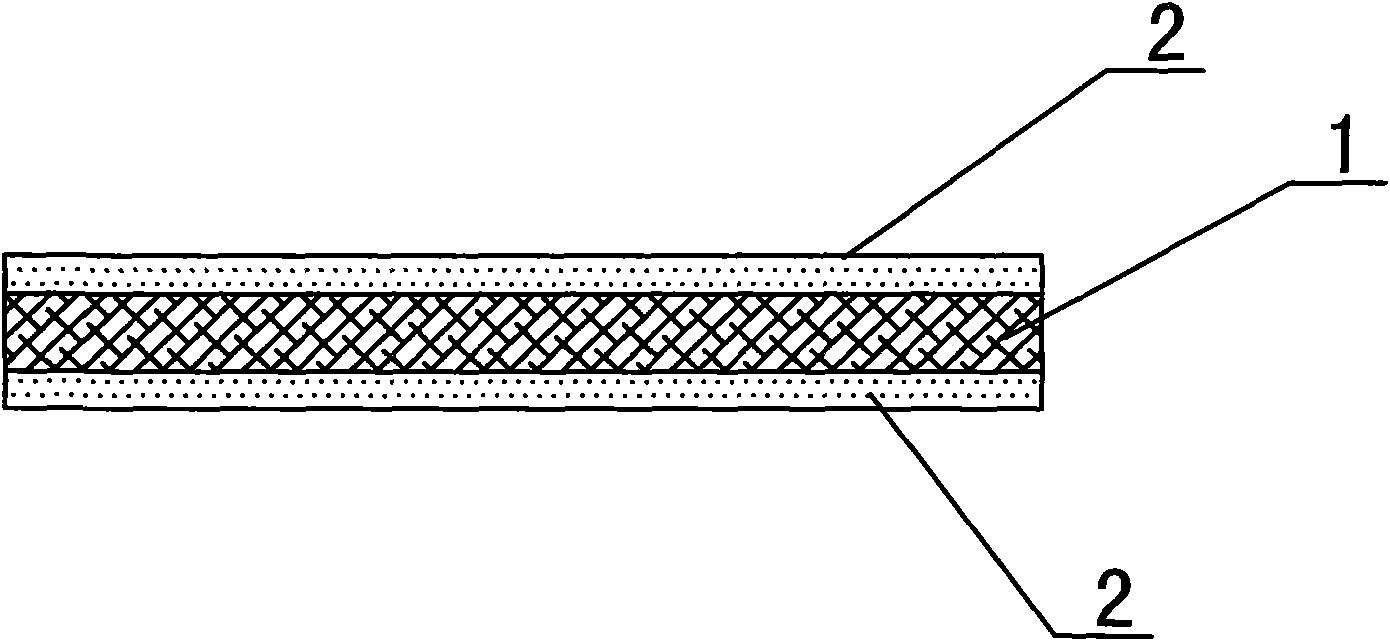

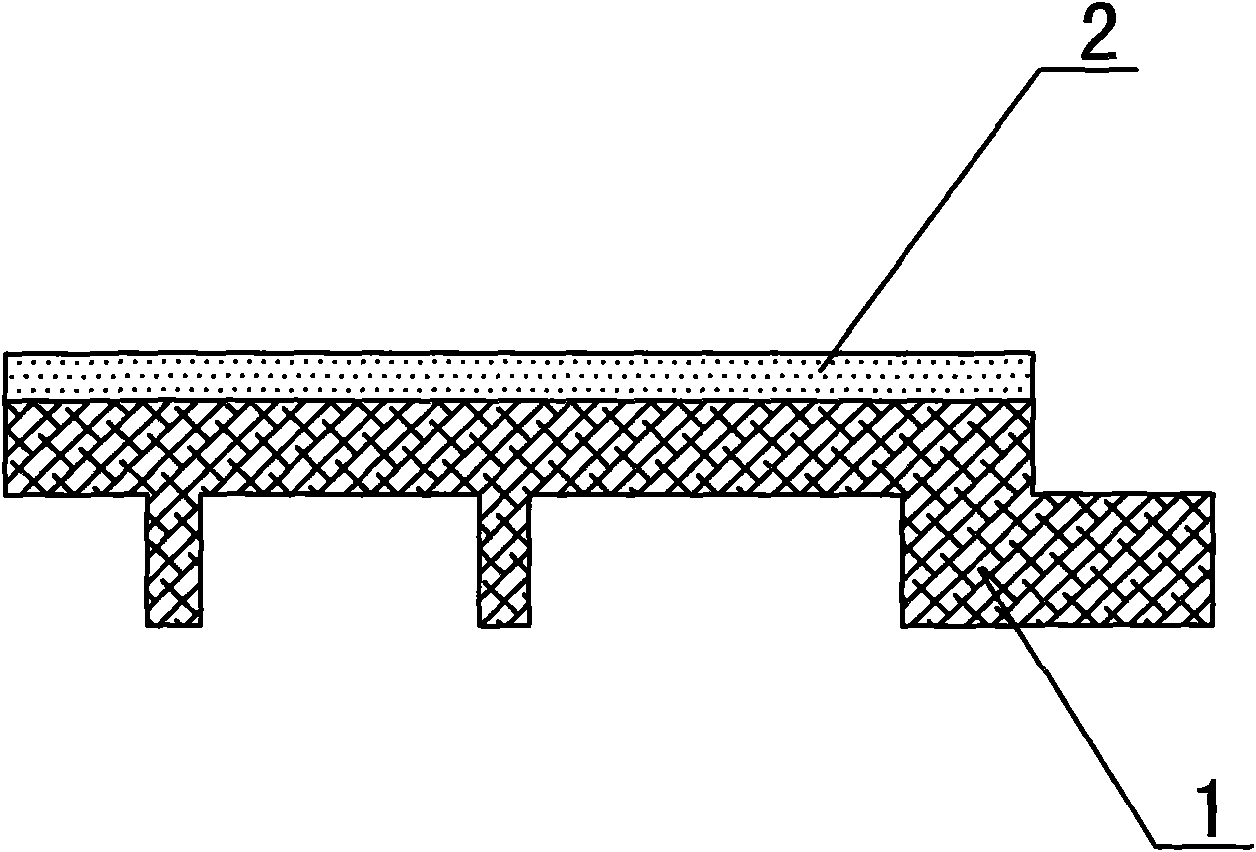

[0025] Please refer to figure 1 as shown, figure 1 It is a schematic structural view of the high weather resistance plastic wood board of the present invention. In this embodiment, a high weather resistance plastic wood board includes a plastic wood substrate 1, and the plastic wood substrate 1 is mainly composed of: plastic: PVC (polyvinyl chloride) , Natural fibers: wood flour, calcium carbonate CaCO 3 , ACR, CPE, stabilizer, ADC, P530, PE wax, 1801, epoxidized soybean oil, baking soda, H200, the weight ratio of various components is: PVC: 100, wood flour: 40-60, carbonic acid Calcium: 20-50, ACR: 1-3, CPE: 2-8, Stabilizer: 4-10, ADC: 1-2, P530: 6-10, PE wax: 0.5-1, 1801: 0.5-1, Epoxidized soybean oil: 1-2, baking soda: 0.5-1, baking soda: 0.5-1.5, H200: 0.5-1, ASA, the upper surface of the wood-plastic substrate 1 is provided with an ASA co-extrusion layer 2, the The ASA co-extruded layer 2 evenly covers the entire upper surface of the wood-plastic substrate 1. The above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com