Patents

Literature

80results about How to "Small deformation coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel expanded perlite insulation board and preparation method thereof

Provides are a novel expanded perlite insulation board and a preparation method thereof. The novel expanded perlite insulation board is mainly prepared by raw materials of 50%-80% of expanded perlite, 10%-40% of inorganic adhesive and organic adhesive, 0%-10% of fiber and 0%-10% of property-modifying additive. The novel expanded perlite insulation board uses a compression molding process and is high in production efficiency, good in size stability and low in production cost. The novel expanded perlite insulation board has excellent fireproofing safety to overcome shortcomings of poor fireproof performance, ageing resistant and environment pollution; and has excellent waterproofness and low thermal coefficients to overcome a shortcoming that a common inorganic insulation material is large in thermal coefficient and strong in water absorbability. The novel expanded perlite insulation board has excellent heat insulation performance, can achieve thermal insulation performance levels of the organic material, simultaneously has non-ignitable performance of the inorganic material, is good in durability and weather fastness, can achieve same service life of buildings, solves the problem that service life of an organic board is short, and is favorable for energy saving and environmental protection. The service life of the organic board can be asynchronous with the building.

Owner:SHENYANG JIANZHU UNIVERSITY

Plastic wood board with high weather resistance and processing method thereof

ActiveCN101941310AWon't releaseGood physical propertiesRubber layered productsASA-polymerSocial benefits

The invention discloses a plastic wood board with high weather resistance, comprising a plastic wood base board. The plastic wood base board mainly takes wood flour and PVC (Poly Vinyl Chloride) raw material as main raw materials; the surface of the plastic wood base board is provided with an ASA (Acrylonitrile-Styrene-Acrylate) coextrusion layer; and the coverage range of the ASA coextrusion layer is an upper surface of the integral plastic wood board. The plastic wood board with high weather resistance can not only enable the surface of the plastic wood board to be rich in luster and the integral effect to be more attractive by matching with the inherent color of the plastic wood board, but also solve the problem of color fading of the plastic wood board used outdoors and select different models as required and has the advantages of convenient installation, low price and very well social benefit and economic benefit.

Owner:无锡唯景建材科技有限公司

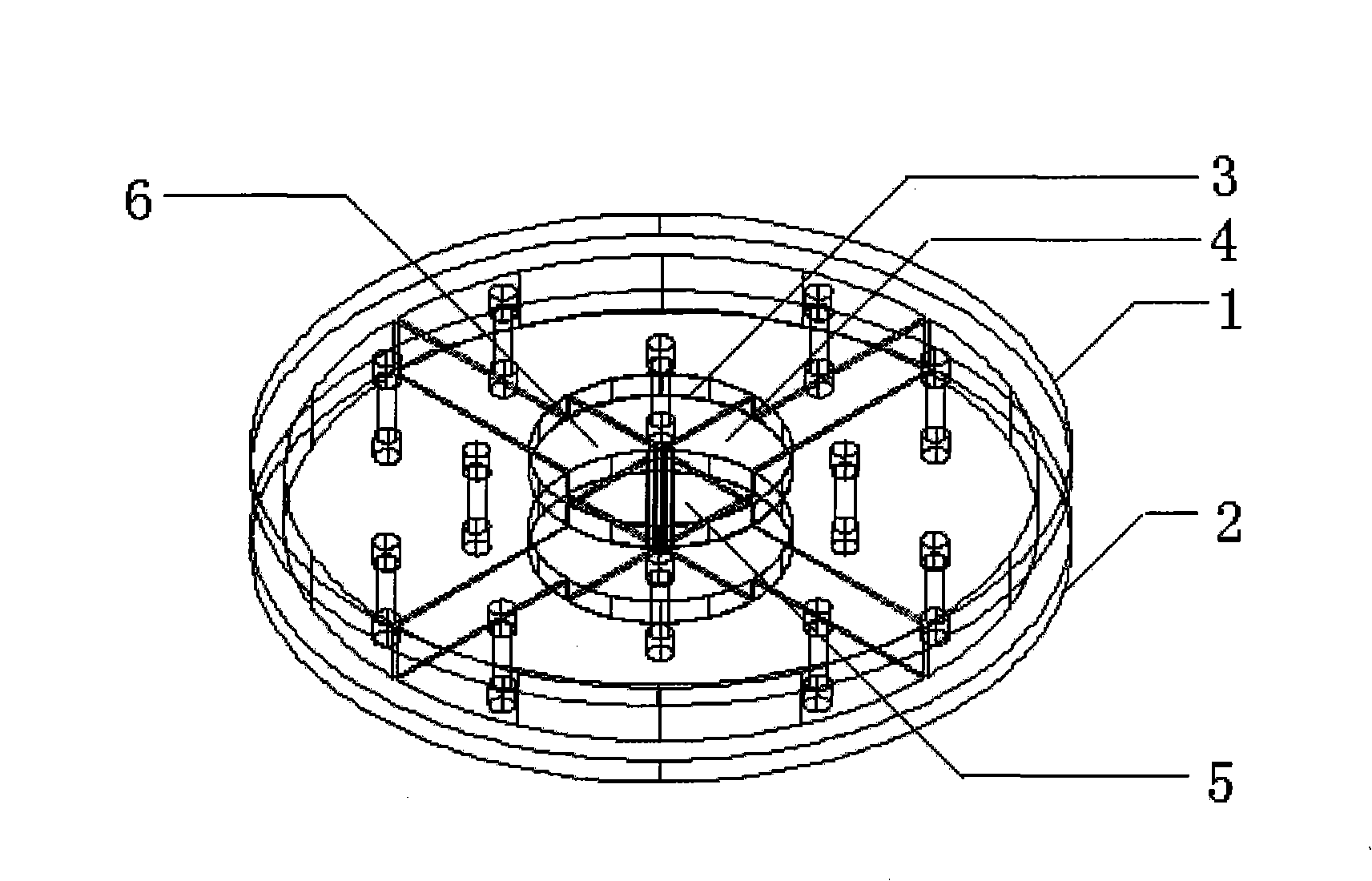

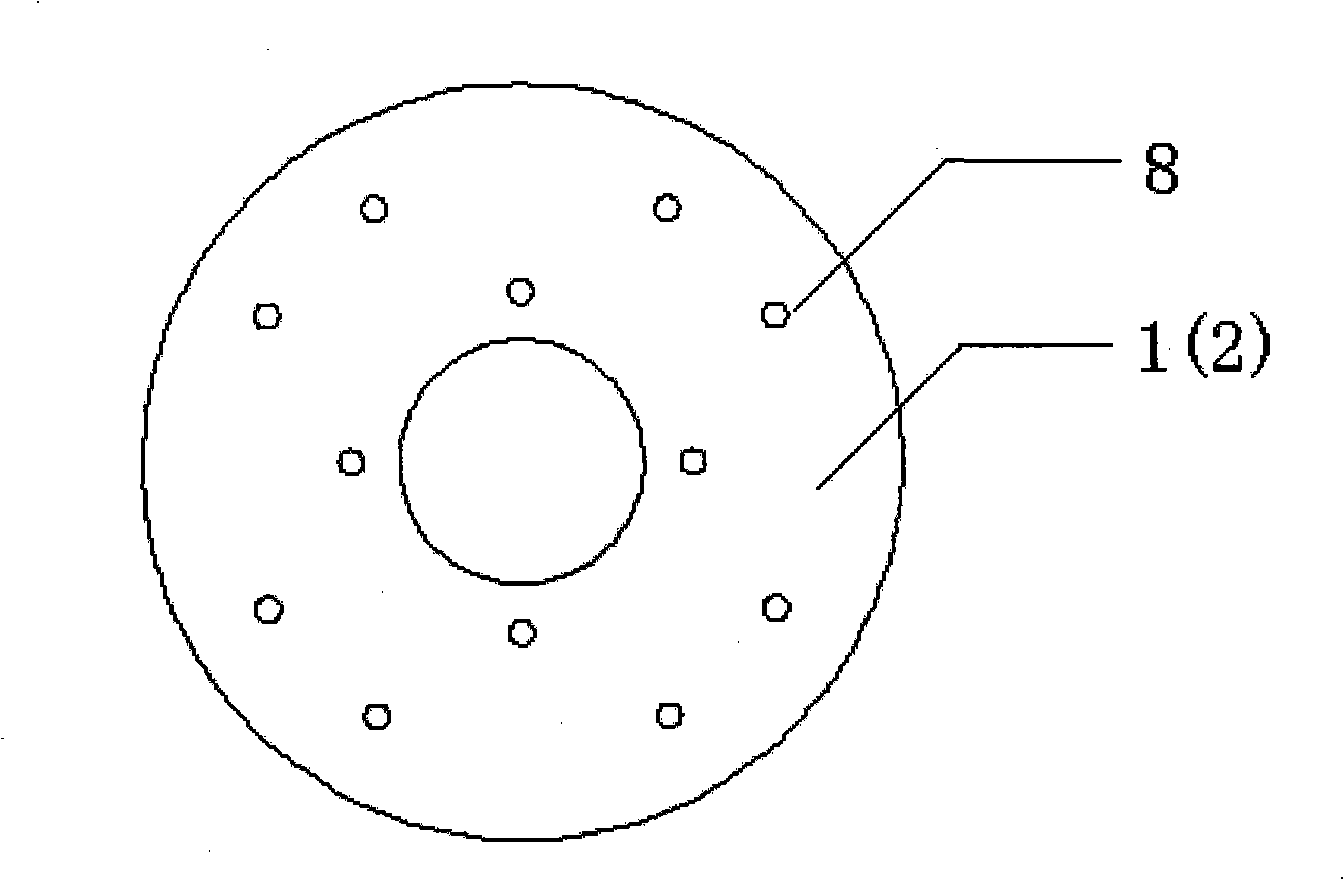

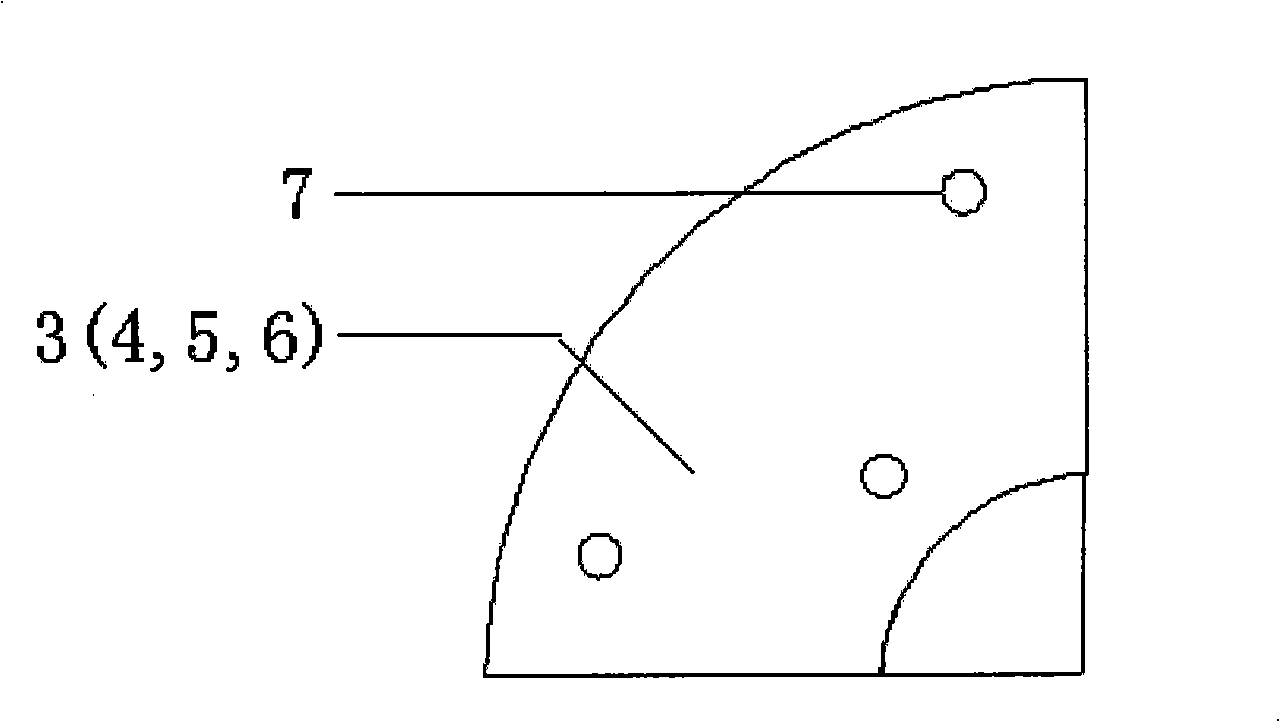

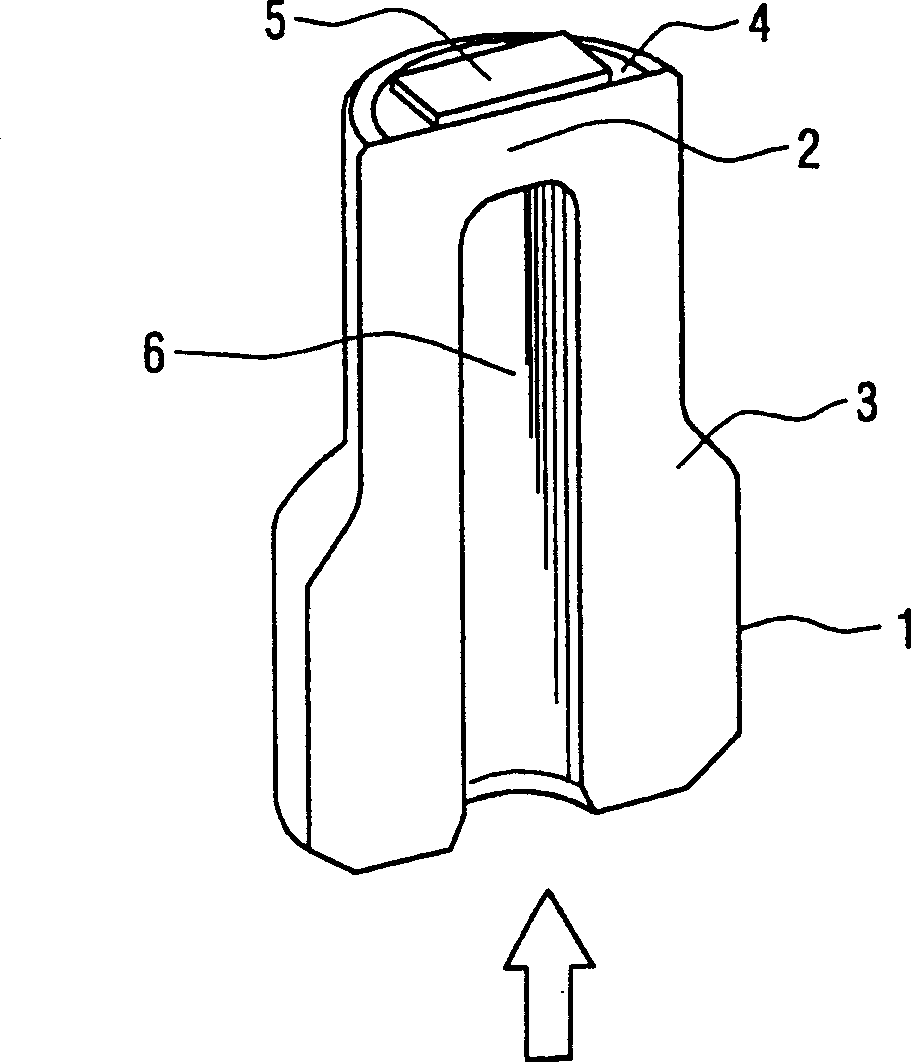

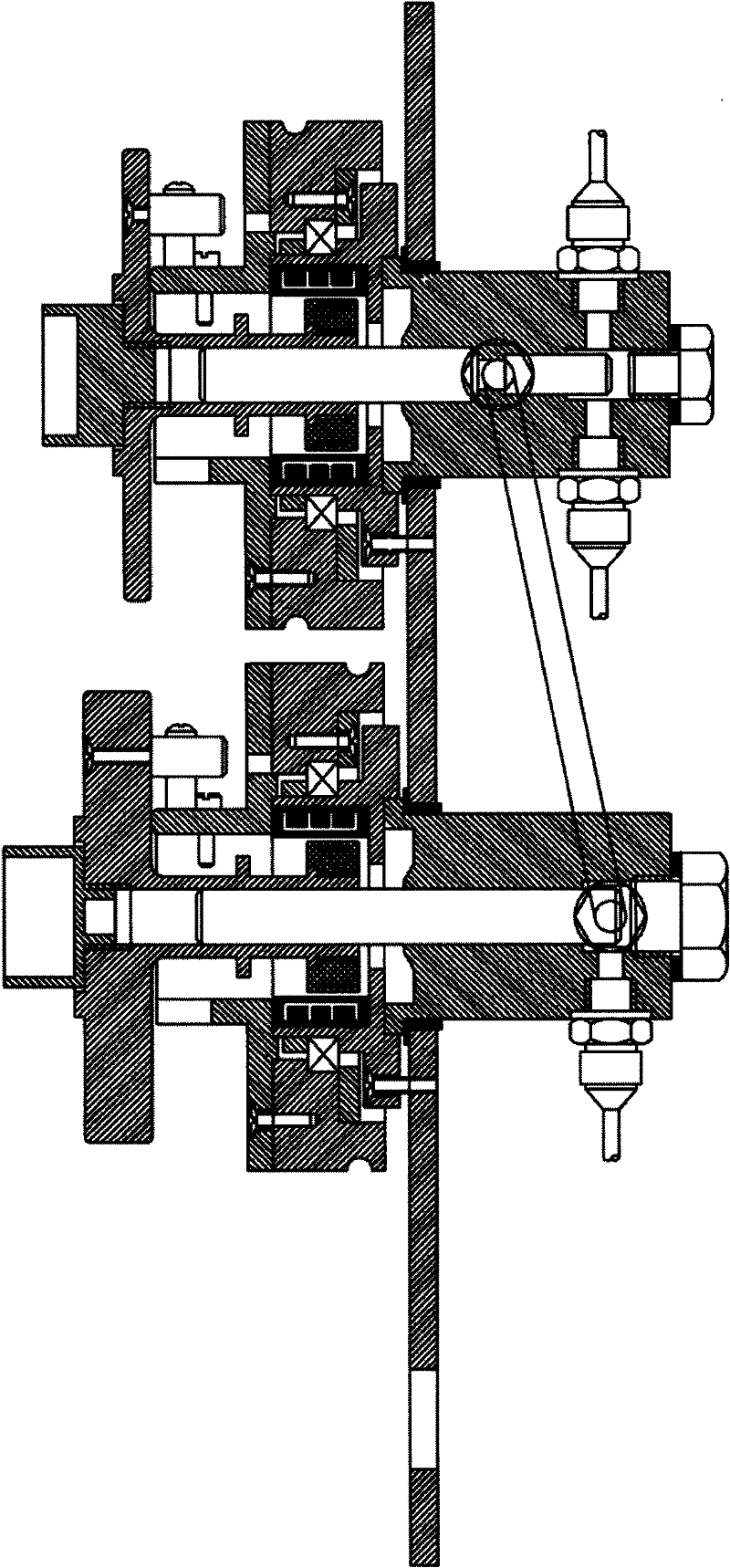

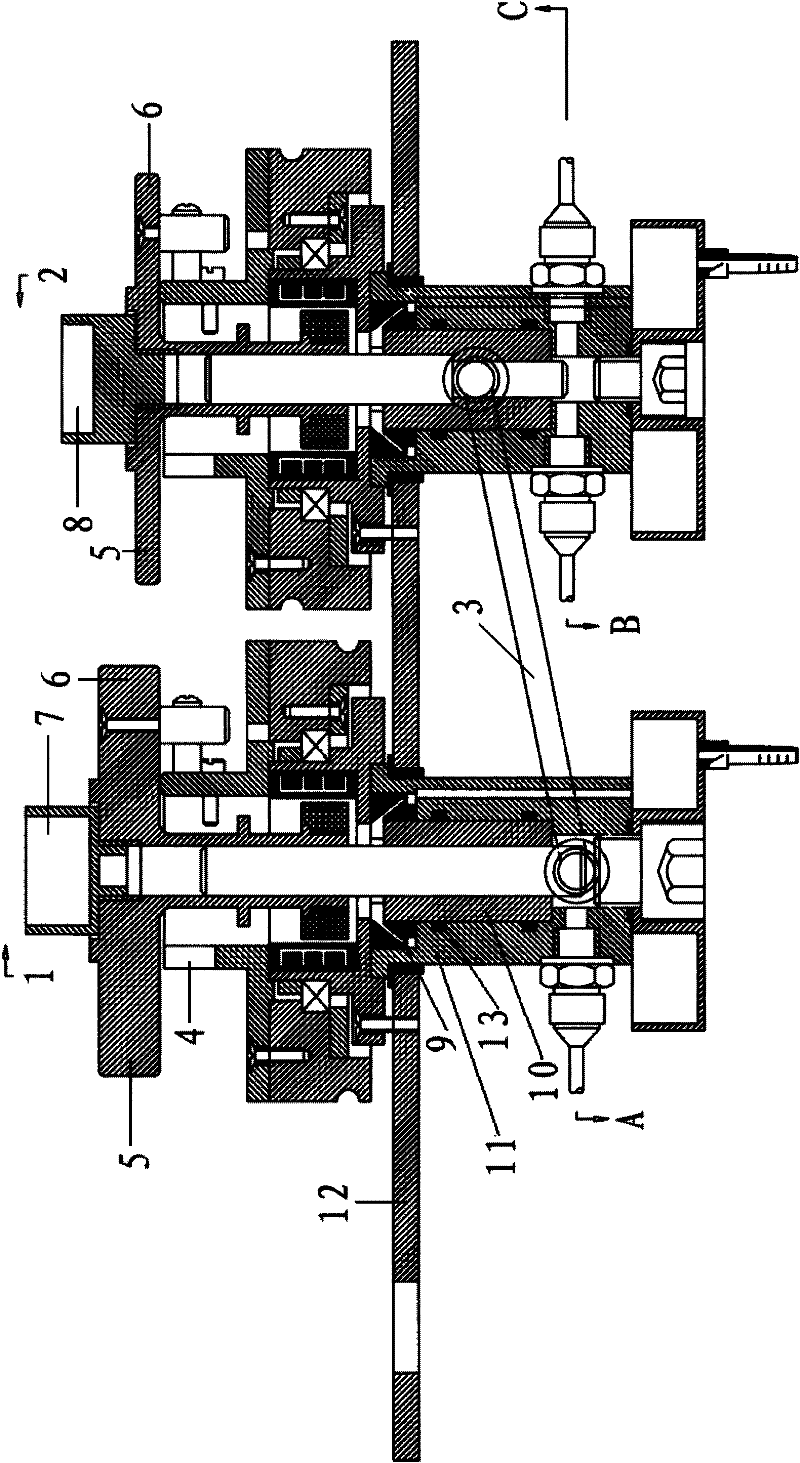

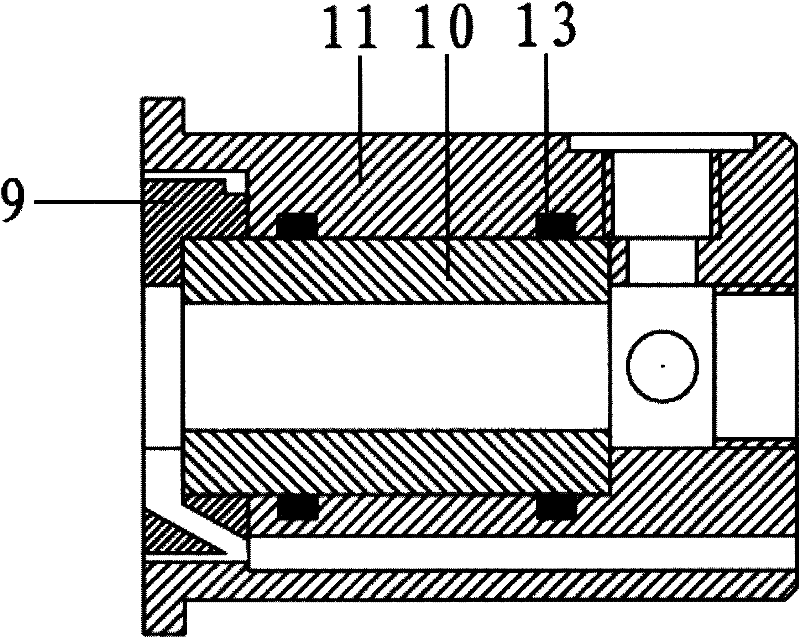

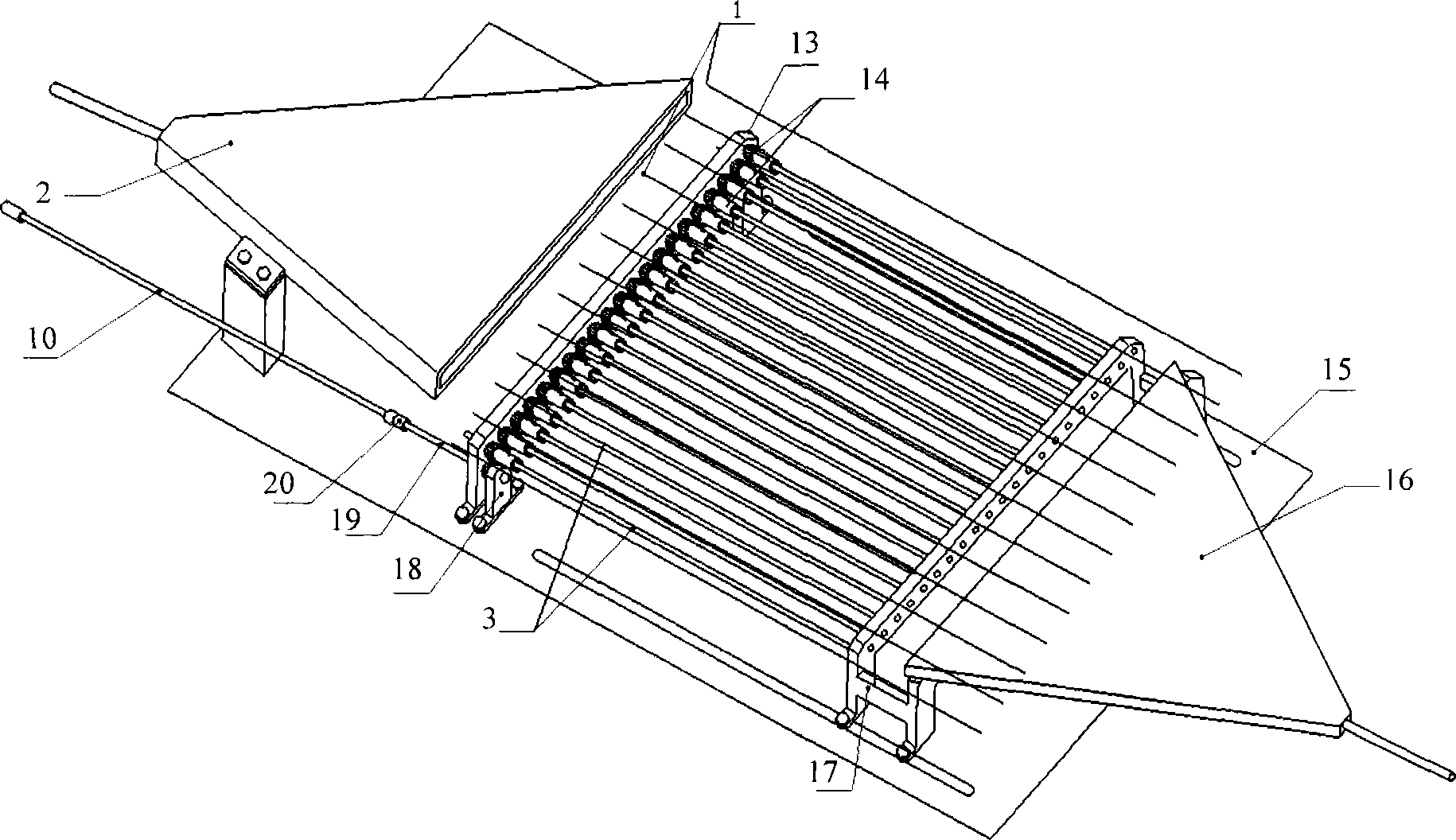

Framework-taking optical fiber ring detaching device of optic fiber gyroscope

InactiveCN101403616AImprove environmental adaptabilityImprove yieldSagnac effect gyrometersCircular discGyroscope

The invention provides a fiber gyroscope non-frame fiber ring disassembly device, comprising two disks with same specifications, a set of fans with same specifications which can form a disk. Each fan is provided with positioning steps and installation holes on the both sides, the center of the disk is provided with a positioning hole, and the surface of the disk is provided with installation holes corresponding to the installation holes of the fans. The disassembly device can overcome the stress influence of the traditional fiber ring winding program due to the existing frame. The disassembly device application of the fiber gyroscope non-frame fiber ring is flexible, and has high adaptable capability to the environment, which can be applicable to a variety of fibers and a variety of fiber technical fields. The parts of the fiber gyroscope non-frame fiber ring disassembly device in the invention have the advantages of simple structure, easy processing, and high yield. Simultaneously, the fiber gyroscope non-frame fiber ring disassembly device in the invention uses hard aluminum alloy, the deformation coefficient is small, the pass rate of the winding fiber ring is high, and the efficiency is high.

Owner:HARBIN ENG UNIV

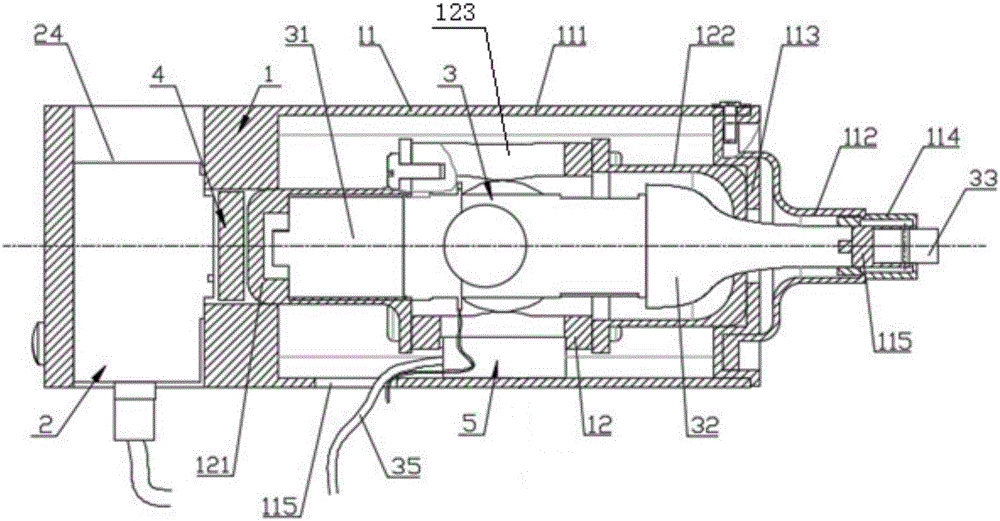

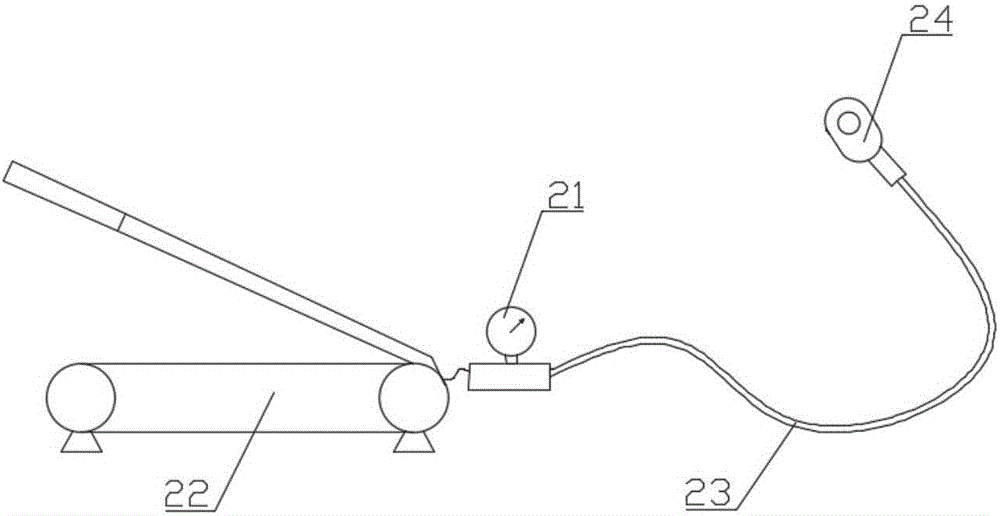

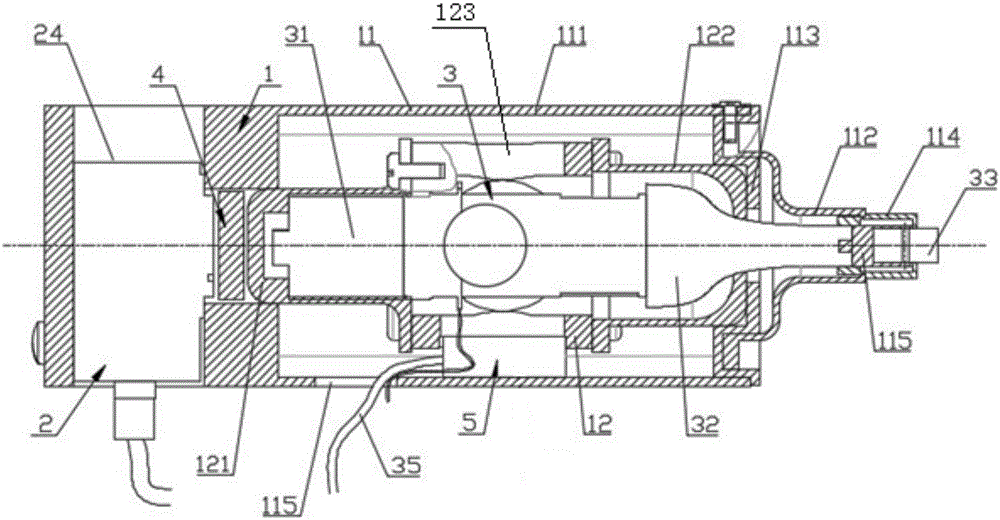

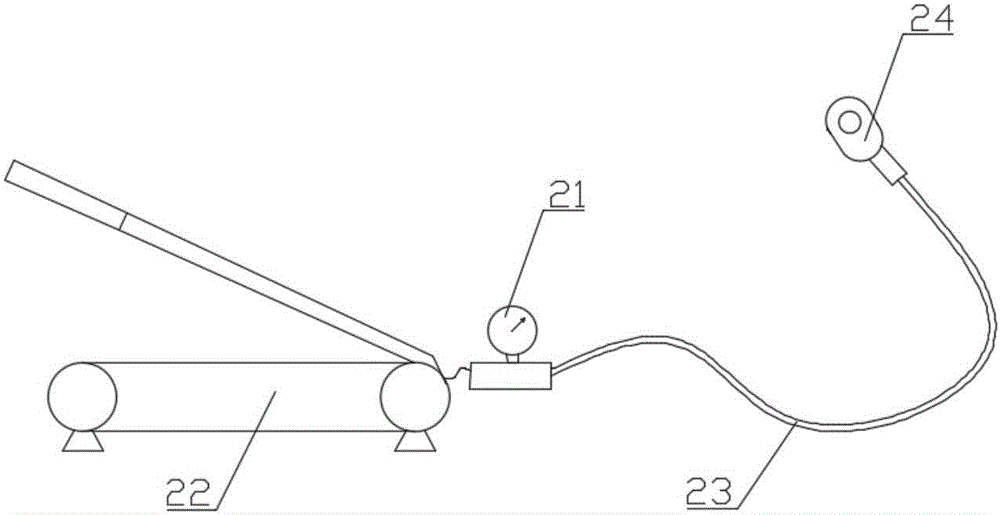

Ultrasonic rolling technique

The invention provides an ultrasonic rolling technique. The ultrasonic rolling technique comprises step as follows: an ultrasonic rolling processing device adaptive to a complicated surface is provided and comprises a casing assembly, a hydraulic assembly and an ultrasonic assembly, wherein the ultrasonic assembly is fixed in the casing assembly and connected with the hydraulic assembly, the ultrasonic assembly comprises a transducer, an amplitude-change pole and a tool head, the transducer is connected with an ultrasonic generator, two edge curves of a radial section of the amplitude-change pole are bezier curves, a first end of the amplitude-change pole is connected to a first end of the transducer, and the tool head is detachably connected to a second end of the amplitude-change pole; the ultrasonic rolling processing device is clamped to a machine tool, and the tool head is arranged in the position in slight contact with a to-be-processed surface of a workpiece; the hydraulic assembly is adjusted to output 100-2,000 N static pressure; the ultrasonic assembly is adjusted, and axial amplitude of an output end of the amplitude-change pole is enabled to be 5-30 mu m; meanwhile, a motion trail of the machine tool is set for ultrasonic rolling processing. The ultrasonic rolling technique has the advantages of high efficiency, low energy loss and the like.

Owner:EAST CHINA UNIV OF SCI & TECH +1

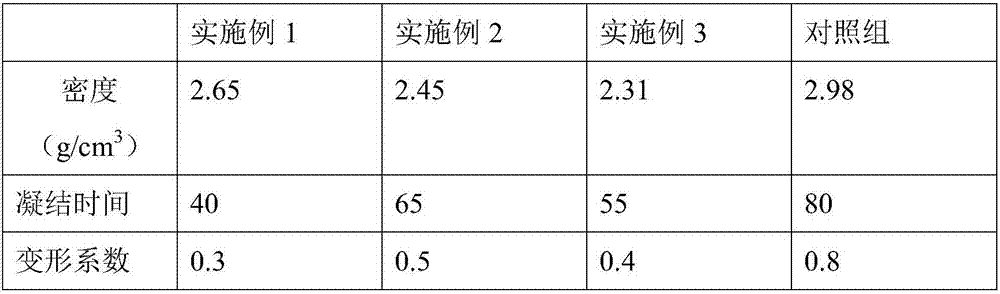

Insulation board made of composite materials and preparation method thereof

The invention discloses an insulation board made of composite materials and a preparation method thereof. The insulation board is made of the following raw materials in parts by weight: 8 to 10 parts of polyphenyl granule, 150 to 200 parts of cement, 20 to 30 parts of fly ash, 5 to 10 parts of sepiolite, 10 to 20 parts of fibrous brucite, 15 to 20 parts of adhesion agent, 0.6 to 1 part of anti-crack fiber, 1 to 2 parts of curing agent, 0.4 to 0.6 part of anti-sliding agent, 0.5 to 0.7 part of hydrophobic agent, 0.4 to 0.6 part of AES, and 100 to 120 parts of water; the preparation method comprises the following steps: proportionally putting the cement, fly ash, sepiolite, fibrous brucite, anti-crack fiber, anti-sliding agent and hydrophobic agent into a stirring machine, and stirring; adding adhesion agent, curing agent and AES into the stirring machine, and stirring; adding polyphenyl granule into the stirring machine so as to obtain thermal mortar; after hardening the thermal mortar, manufacturing the finish product of the insulation board made of the composite materials. The insulation board made of the composite materials, provided by the invention, has excellent heat preservation and heat insulation performance, excellent fireproof performance, high compressive strength and high tensile strength, and is light in weight.

Owner:ANHUI ZHONGRUI DECORATION MATERIALS GRP

Multifunctional graphene superfine fiber multilayer non-woven fabric and preparation method thereof

The invention belongs to the technical field of functional non-woven fabric processing and discloses multifunctional graphene superfine fiber multilayer non-woven fabric and a preparation method thereof. Multifunctional graphene superfine fibers and low-melting-point fibers are opened by a variable-frequency card clothing opener, then sent to a wind power mixer for secondary wind mixing and opening, sent to different cotton boxes, and sent to a zero-wind-pressure cotton web collecting device according to the arrangement mode that the middle layer is the low-melting-point fibers and the upper layer and the lower layer are the multifunctional graphene superfine fibers, so that the fibers uniformly fall onto a collecting row; and the collected fibers are physically rolled and pre-bonded to form a fiber web, and then the fiber web is sent to a thermal bonding machine for shaping to obtain the multifunctional graphene superfine fiber multi-layer non-woven fabric. The multilayer non-woven fabric with a three-dimensional web structure can be obtained by using simple methods of wind mixing and opening, zero-wind-pressure cotton web collection, physical rolling and heat shaping. The multilayer non-woven fabric obtained has the characteristics of being light, soft, warm and sticking.

Owner:GUANGZHOU ZHONGCHENG NEW MATERIALS TECH

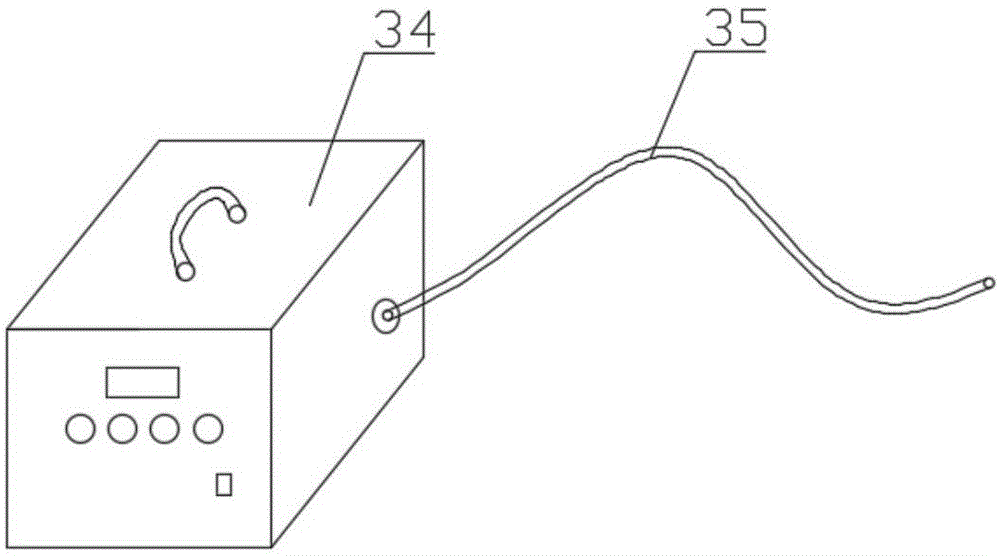

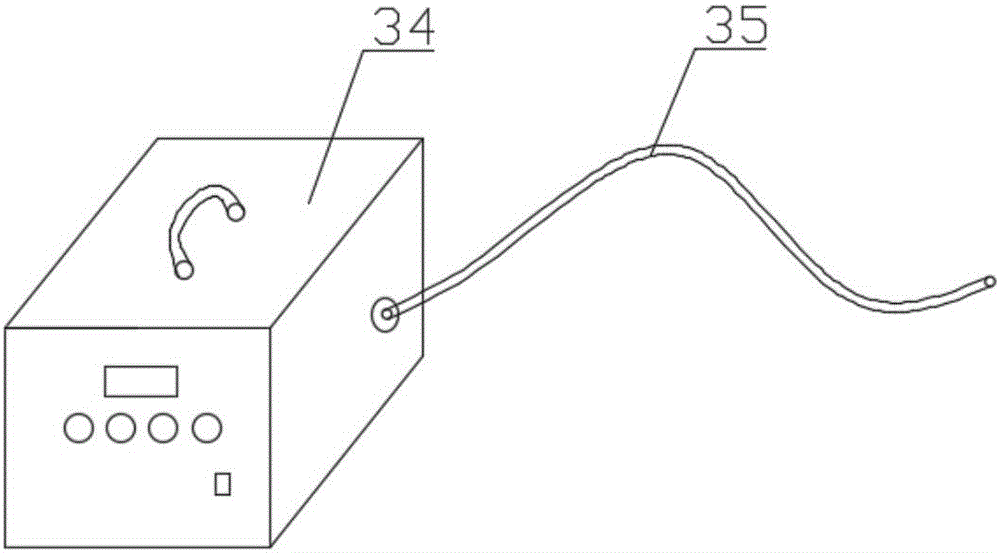

Ultrasonic roll finishing device adaptable to complex surfaces

The invention provides an ultrasonic roll finishing device adaptable to complex surfaces. The ultrasonic roll finishing device adaptable to complex surfaces comprises a shell assembly, a hydraulic assembly and an ultrasonic assembly. The ultrasonic assembly is fixed in the shell assembly and comprises a transducer, an amplitude transformer and a tool head, wherein the transducer is connected with an ultrasonic generator; the first end of the amplitude transformer is connected to the first end of the transducer, and two edge curves of the radial section of the amplitude transformer are Bezier curves; and the tool head is detachably connected to the second end of the amplitude transformer. By adoption of the ultrasonic roll finishing device adaptable to complex surfaces, the probability of movement failures caused by environment changes or self faults can be lowered and even prevented; and the ultrasonic roll finishing device adaptable to complex surfaces has the advantages of being high in efficiency, small in energy loss, small in size, long in service life, good in heat dissipation performance, high in flexibility, good in universality and low in weight.

Owner:EAST CHINA UNIV OF SCI & TECH +1

Fiber insulation board preparation method

The invention relates to a fiber insulation board preparation method. The fiber insulation board preparation method comprises the following steps of (1) evenly mixing first polyester short fibers and fibers A, (2) conducting opening and combing on the mixed fibers to form a fiber net, (3) evenly spraying phosphorous-nitrogen-based flame retardant or phosphorous-based flame retardant which is 2%-10% of the total mass of the fibers on the surface of the fiber net, and (4) obtaining a fiber insulation board after the fiber net processed through the step of (3) is needled, pressed in a rolling mode and set in a heat mode. The fiber insulation board preparation method is simple in technology, no adhesive is added in a production process, physical bonding is only formed through melting and adhesion of raw materials, no pollution is generated to environment, and the board does not release hazard substances under the influence of high temperature and belongs to environment-friendly type materials. In addition, holes exist among fibers, air can be stored in the fibers as insulation materials, and a good insulation effect is achieved. Needling holes are formed in the surface of the fiber board, a sound absorption function is achieved, and interference of environmental noise is effectively reduced.

Owner:JIANGSU BURGEREE NEW TECH MATERIALS

Heat-preservation-decorating-integration plate and manufacturing method thereof

The invention belongs to the field of building and particularly relates to a heat-preservation-decorating-integration plate. A main body of the plate is an inorganic heat preservation plate. A light-weight aggregate concrete layer is fixed on the upper surface of the inorganic heat preservation plate. A decorating face layer coats the outer surface of the light-weight aggregate concrete layer. A silk screen or screen cloth layer is arranged in the middle of the light-weight aggregate concrete layer. A plurality of pre-buried components are arranged on one side, adjacent to the decorating face layer, of the silk screen in the light-weight aggregate concrete layer. Each pre-buried component and a screw rod are fixed. Each screw rod penetrates through the silk screen and the inorganic heat preservation plate and is anchored with a metal keel arranged at the bottom of the inorganic heat preservation plate. The silk screen is arranged on the metal component in a sleeved mode, the silk screen and the metal component are pre-buried in the light-weight aggregate concrete layer together, the effect of impact resistance and cracking resistance of the heat-preservation-decorating-integration plate is achieved, the metal component and the metal keel on the back face of the inorganic heat preservation plate are fixedly connected, so that the heat-preservation-decorating-integration plate forms a firm whole, after the plate is arranged on a wall, a binding-anchoring method is used, and combining with the wall is stable.

Owner:浙江忆赫新材料有限公司

Heat-resisting wear-resisting magnesium alloy and preparation method thereof

The invention relates to the technical field of magnesium alloy materials, in particular to heat-resisting wear-resisting magnesium alloy and a preparation method thereof. By design on the proportion of magnesium alloy components, all magnesium alloy components act on one another, so that while the toughness of the magnesium alloy is improved, the strength of the magnesium alloy is improved, and the wear resisting performance of the magnesium alloy is improved; by definition on magnesium alloy preparation process steps and process parameters, Al-Ni phase is formed in the magnesium alloy, so that the toughness of the magnesium alloy is improved, and the wear resisting performance of the magnesium alloy is improved; in combination with the treatment of an acetone-ethanol mixed liquor, a layer of organic phase is contained on the surface of the magnesium alloy, so that a function of removing impurities on the surface of the magnesium alloy is achieved, a catalytic action is exerted, the wear resisting performance of the magnesium alloy is improved after the magnesium alloy is immersed into a cerium salt conversion solution and an oxygen-carbon-sulfur co-penetrated liquid dissolved with organic silicon in combination with a phosphating solution, the film structure on the surface of the magnesium alloy is strengthened, the heat resisting effect of the film structure is enhanced, and the heat resisting performance of the magnesium alloy is improved.

Owner:贵州航天风华精密设备有限公司

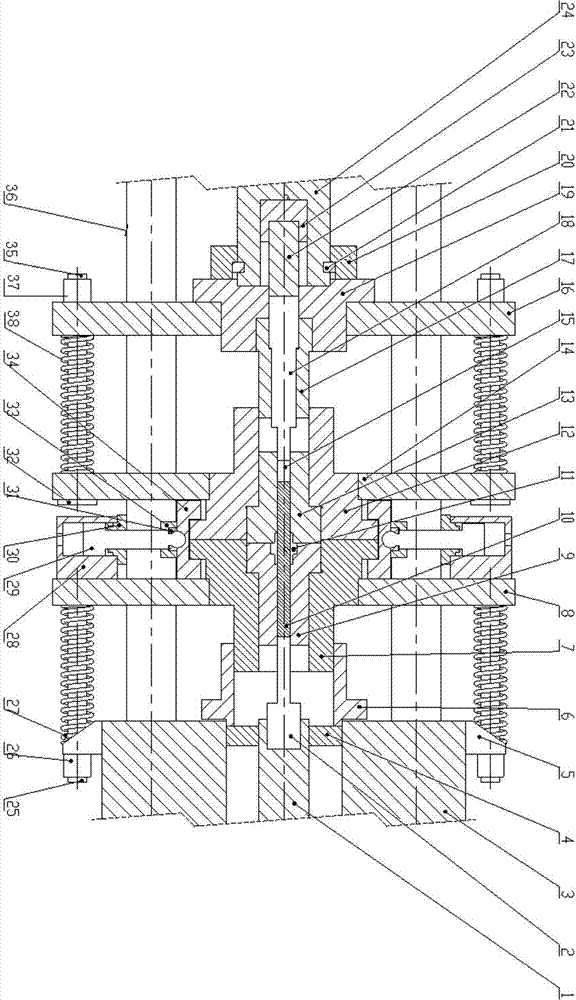

Metal plastic forming device with bidirectional extrusion function

The invention discloses a metal plastic forming device with a bidirectional extrusion function. The metal plastic forming device comprises a main cylinder piston rod in a main operating cylinder, a middle movable plate, an upper punch, a force transfer rod, an upper die core, an upper stress ring, a lower stress ring, a lower die core, a lower movable plate, a lock catch, a lock catch piston rod, a lower crossbeam, a fastening cylinder, a lower punch, an upper movable plate, a first limiting spring, a first limiting rod, a second limiting spring and a second limiting rod. According to the device, only a main operating cylinder and a main cylinder piston rod which corresponds to the main operating cylinder need to serve as power heads, and then blanks can be extruded in up and down directions, so that a machine tool is simple in structure, and the manufacturing cost is greatly reduced; due to bidirectional extrusion, the deformation coefficient of materials is lowered, the possibility of internal cracks of parts is low, and the requirements on energy supply are reduced; and moreover, the device is reliable in operation and convenient to maintain.

Owner:龙西新 +2

Processing method for laminated composite cutting die plate

InactiveCN103029412AFlame retardantCorrosion resistantLamination ancillary operationsLaminationGlass fiberWeather resistance

The invention discloses a laser cutting die processing method and particularly discloses a processing method for a laminated composite cutting die plate. The processing method comprises the steps of rotary cutting for obtaining a veneer, grinding the veneer in a beveled way, splicing the veneer in a beveled way, soaking the veneer, soaking a glass fiber cloth, drying, gluing onto PVC, assembling and thermally pressing, reconditioning and the like. Aiming at solving the problems of poor weather resistance, poor corrosion resistance, easy deformation at high temperature and the like existing in a wooden laser cutting die plate, a product obtained through the processing method disclosed by the invention comprises an upper surface layer and a lower surface layer which are both PVC thin layers, a secondary outer layer which is the bevel connection veneer, and other layers which are formed by laminating the glass fiber cloth and wooden layers in a staggered manner. The obtained product by adopting the method provided by the invention has the advantages of light weight, high strength, strong thermal stability, difficulty in deformation and the like and has significant economic benefit and market value.

Owner:郑州兴旺木业有限公司

Modified phenolic resin composite thermal insulation material and preparation method thereof

The invention provides a modified phenolic resin composite thermal insulation material which is prepared from the following raw materials in parts by weight: 30-70 parts of epoxy modified phenolic resin, 30-50 parts of coated expanded perlite, 10-20 parts of straw, 2-5 parts of adhesive, 1-3 parts of water repellent, 0.1-1 part of curing agent, 0.1-1 part of lubricant and 0.1-1 part of toughening agent. A preparation method comprises the following steps of: 1) weighing the phenolic resin, coated expanded perlite, straw, adhesive, water repellent, curing agent, lubricant and toughening agent according to the proportion, mixing and stirring uniformly, and putting into a steel mould; and 2) performing hot compression moulding in the conditions that the compression ratio is 1.6-2.4 and the hot compression moulding temperature is 210-240 DEG C, and preserving pressure for 1.5-2.5h to obtain the modified phenolic resin composite thermal insulation material. The thermal insulation material integrates the advantages of low heat conductivity coefficient of an organic thermal insulation material and high strength and difficulty in combustion of an inorganic thermal insulation material.

Owner:滦县盛泽保温科技有限公司

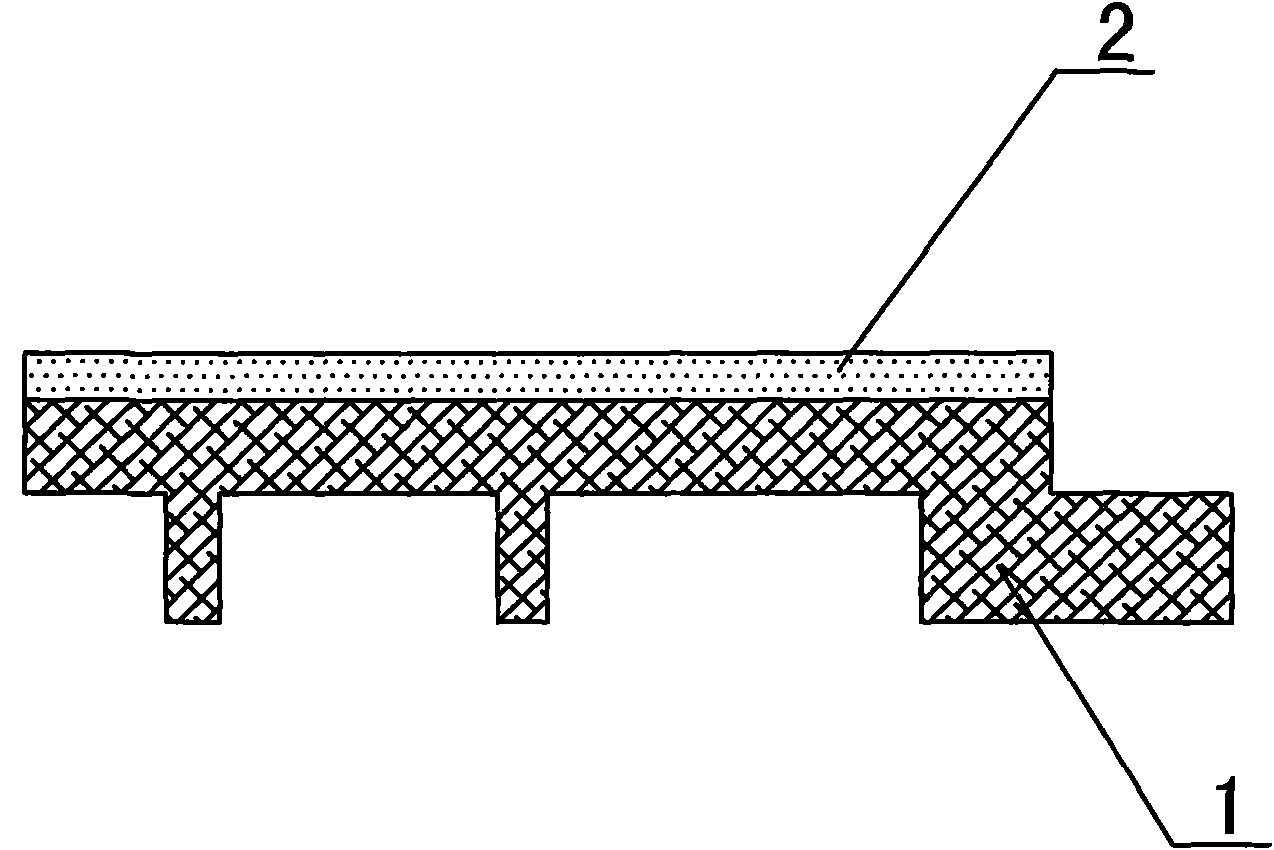

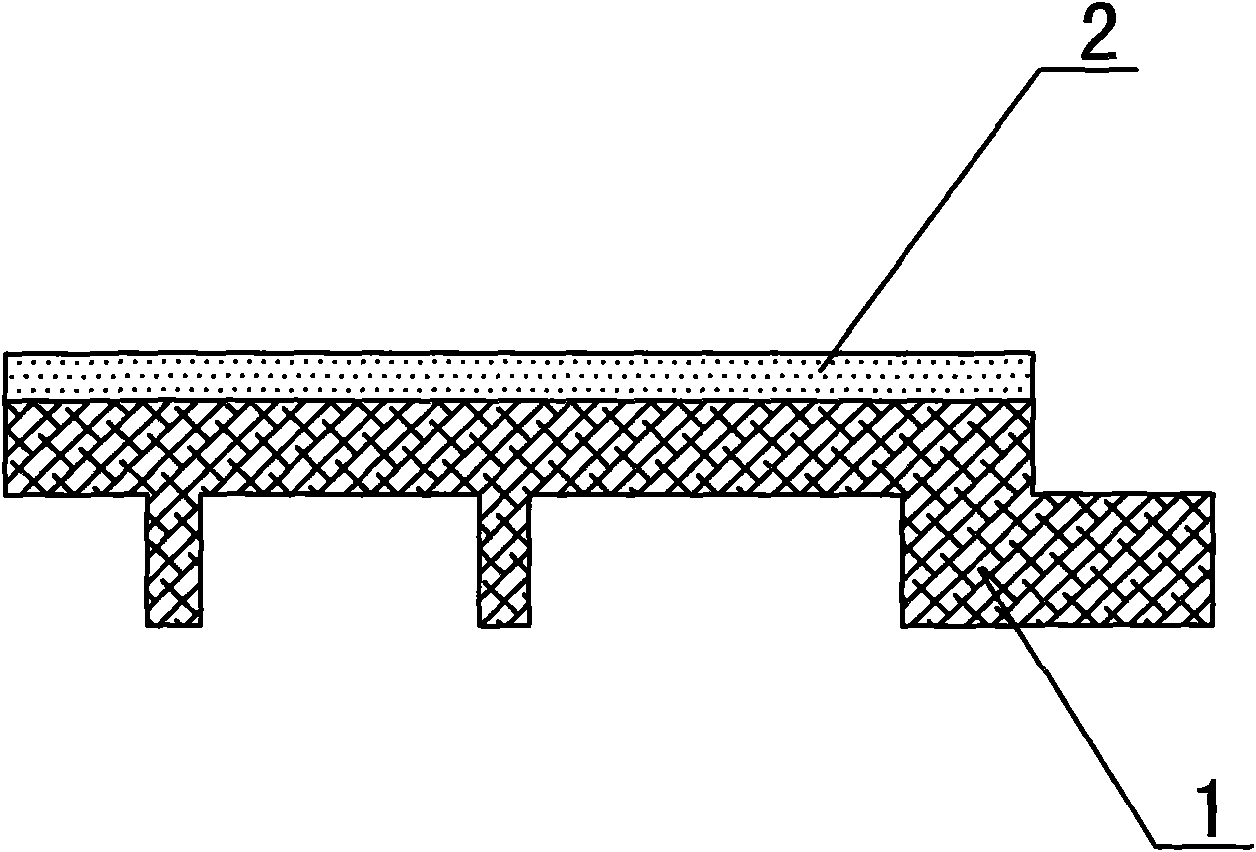

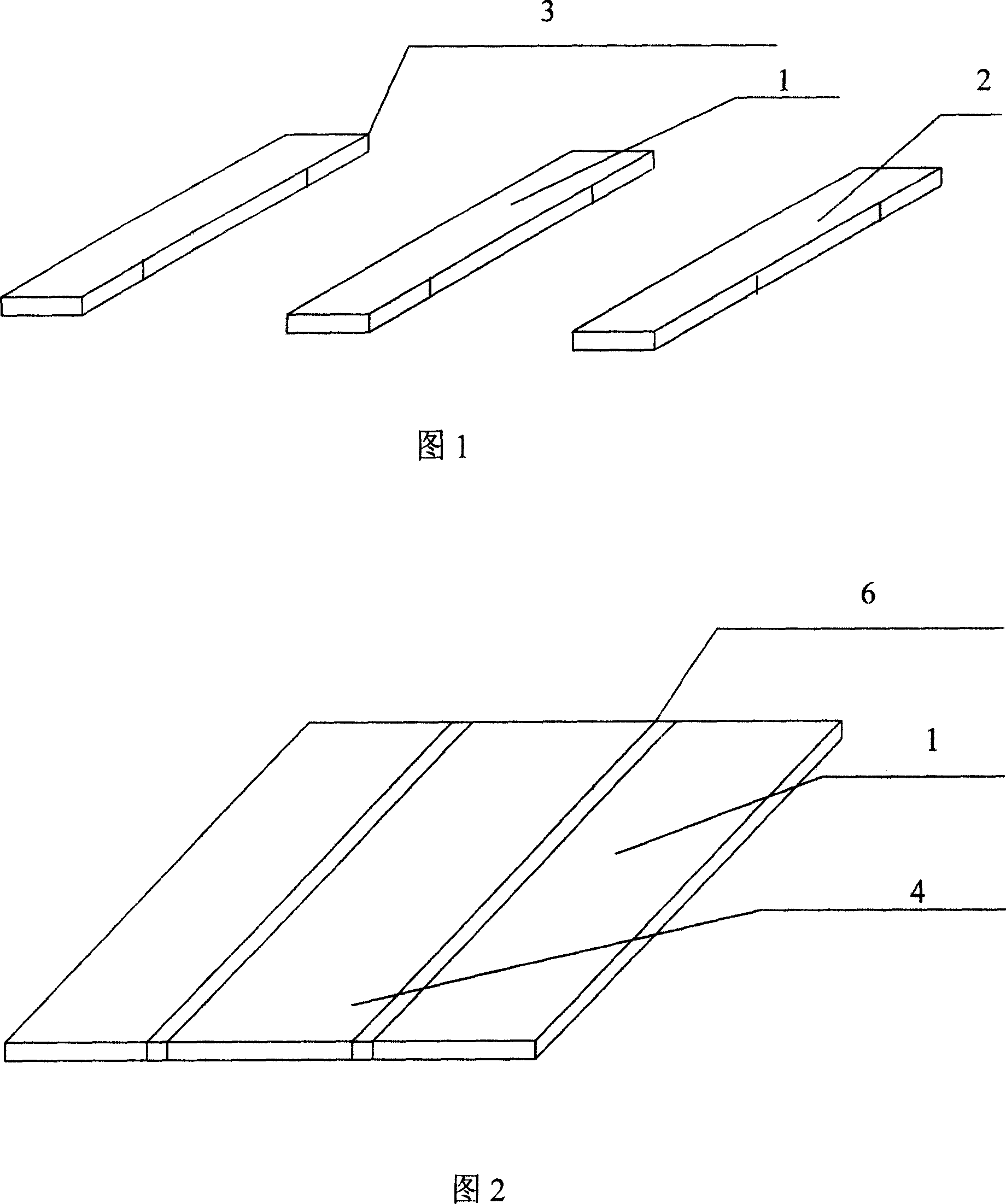

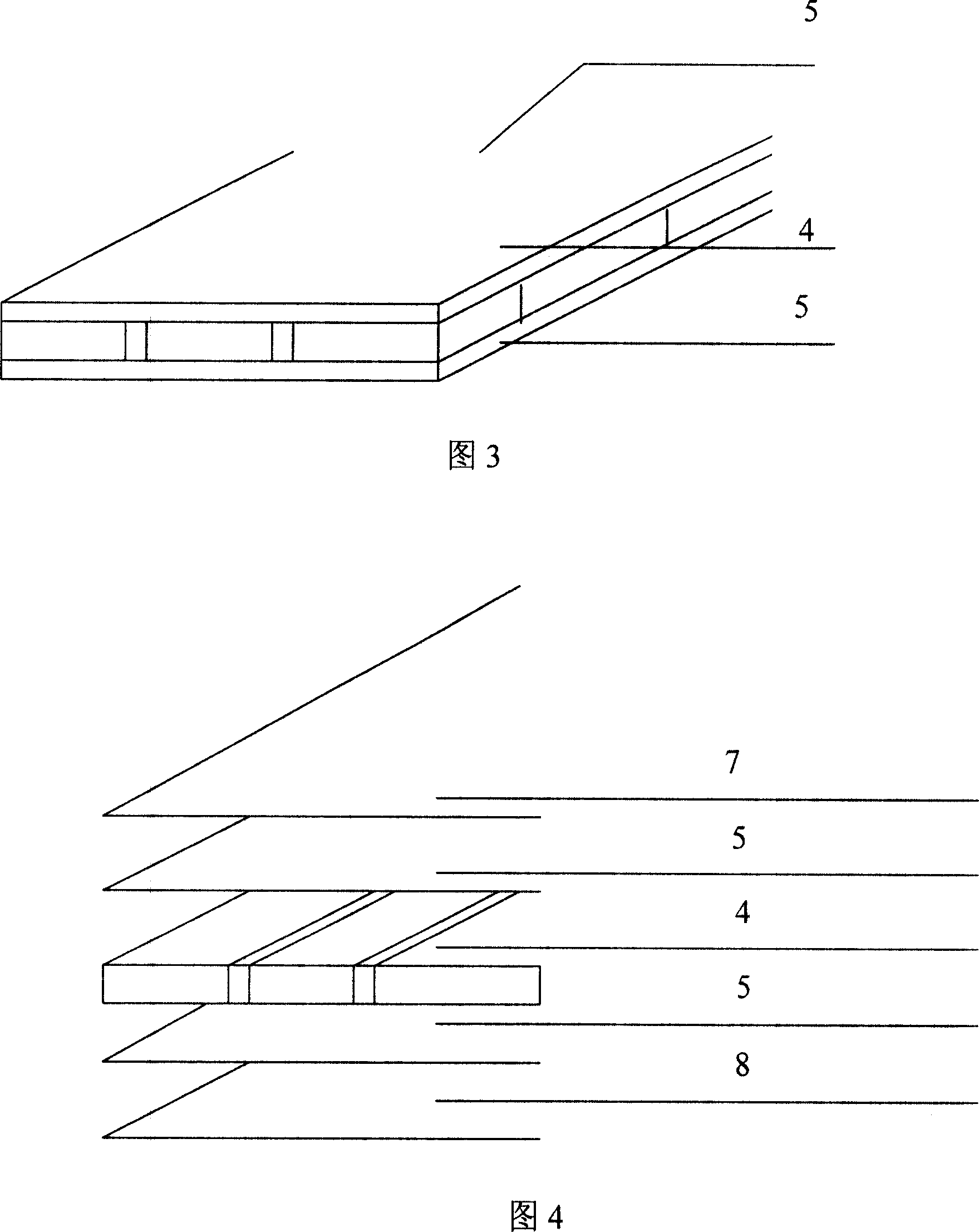

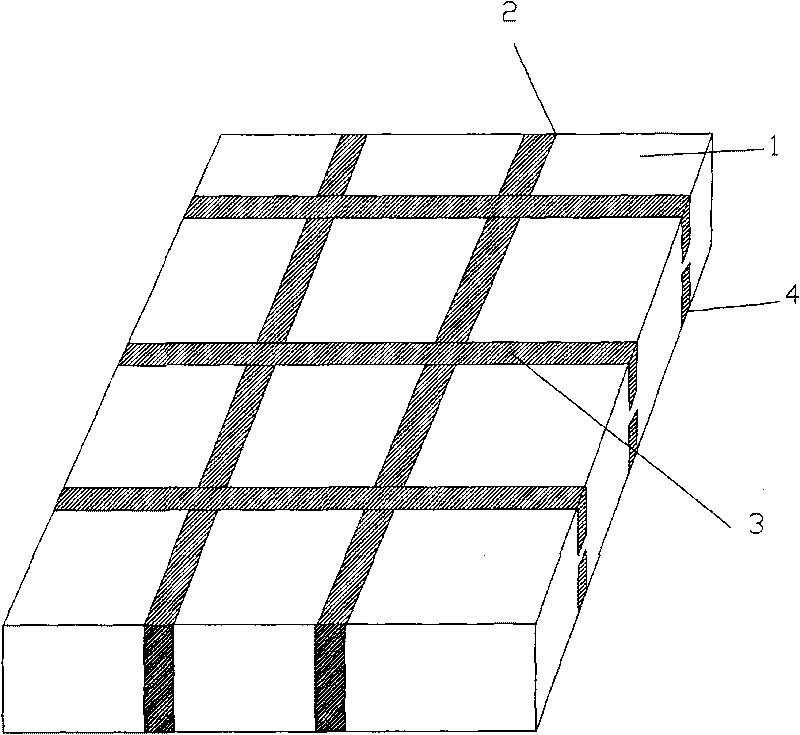

Wood composite floor and production method therefor

ActiveCN101016799AChange stressSmall deformation coefficientWood working apparatusWood layered productsSolid woodBrick

A recombination solid wood floor with its production method relates to a recombination construction art within three-ply boards, wherein a middle board layer comprises rectangular wood bricks in direct processing art which are connected to be a base block board, and at least one side of the base block board is recombined with a -shaped wood board of different fiber orientation, while the base block board is recombined with at least two rectangular wood bricks via bars between the every two rectangular wood bricks. The method comprises processing the rectangular wood bricks to be a base layer of floor in direct processing art, making the rectangular wood bricks to be base block boards, and recombining the connected base block boards with the wood boards of different fiber orientation, thereby making the block board of floor to be -shaped. The method has advantages of simple structure, easy processing art, good quality, low cost, convenience assembling, and good using effect.

Owner:DER FUTURE SCI & TECH HLDG GRP CO LTD

Graphene multifunctional superfine fiber multilayer non-woven fabric and preparation method thereof

The invention belongs to the technical field of functional non-woven fabric processing, and discloses a graphene multifunctional superfine fiber multilayer non-woven fabric and a preparation method thereof. Graphene multifunctional superfine fiber and low-melting-point fiber are respectively opened through a variable-frequency card clothing opener, are then sent to a wind power mixer to be subjected to secondary wind mixing opening, are next conveyed into different cotton boxes, and are then conveyed into a zero-wind-pressure cotton net collecting device in a distribution mode that a middle layer is the low-melting point fiber and upper and lower layers are the graphene multifunctional superfine fiber, so that the fiber uniformly falls onto a collecting bar; the collected fiber is subjected to physical milling and pre-adhesion to form a fiber net; then, the fiber net is conveyed to a thermal binding machine to be shaped; and the graphene multifunctional superfine fiber multilayer non-woven fabric is obtained. The multilayer non-woven fabric of a three-dimensional reticular structure can be obtained by using a simple method of wind mixer opening, zero-wind-pressure cotton net collection, physical milling and thermal shaping. The multilayer non-woven fabric has the characteristics of light weight, softness, warmness and closed-fit performance.

Owner:GUANGZHOU ZHONGCHENG NEW MATERIALS TECH

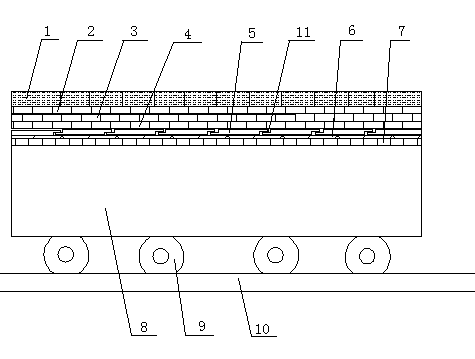

Bogie hearth for bogie hearth type resistance furnace

The invention provides a bogie hearth for a bogie hearth type resistance furnace. The bogie hearth for the bogie hearth type resistance furnace is formed by cast iron which is used for bearing workpieces, a fire-proof layer, a first thermal insulation layer, a second thermal insulation layer, a base plate layer, a heating element, a thermal preservation brick and a bogie hearth body which are arranged from top to bottom sequentially; the base plate layer is formed by a plurality of strip-shaped furnace bottom plates in a splicing mode; the furnace bottom plates are made of heat resisting steel; splicing positions of the adjacent furnace bottom plates are in hasp modes; splicing positions of the furnace bottom plates are provided with thermal expanded and cold contracted gaps; the heating element is bent to be in a wave band shape through belts; the heating element is fixed on the thermal preservation brick. The bogie hearth for the bogie hearth type resistance furnace has the advantages of guaranteeing the furnace bottom temperature; improving the surficial area of the heating element, reducing the surface load of the heating element and prolonging the service life of the heating element due to the fact that the heating element is arranged on bogie hearth; meanwhile avoiding short circuit due to the fact that oxidized iron sheets fall on the heating element and improving the production safety due to the furnace bottom plates.

Owner:徐州东创重工机械有限公司

Structural finger-jointed sheet material and manufacturing process

InactiveCN101691903AHigh strengthIncrease elasticityWood working apparatusSheets/panelsPlastic materialsFinger joint

The invention relates to a structural finger-jointed sheet material and a manufacturing process. The structural finger-jointed sheet material comprises at least two finger-jointed battens serving as the main bodies. The two finger-jointed battens are spliced by a bamboo splicing strip or a plastic splicing strip to form a flat sheet material. At least two run-through insertion grooves which correspond to each other up and down and run through both sides along the direction vertical with the bamboo splicing strip or the plastic splicing strip are milled on the upper and lower surfaces of the flat sheet material respectively. Bamboo insertion strips or plastic insertion strips, which are parallel and lever with the surface of the flat sheet material, are inserted in the run-through insertion grooves. The manufacturing process is that: the finger-jointed battens used as the main bodies are separated by bamboo materials or plastic materials and then are spliced into the sheet material of required specifications by using a finger-jointed splicing board process and after splicing is completed, the width direction of the sheet material is milled with the corresponding grooves up and down and the grooves run through the sheet width; and after the process is completed, the bamboo materials or the plastic materials are coated with glue, then are inserted into the grooves, are subjected to heat pressing by using a hot press to complete solidification, and then reach the required thickness by using a contact calibrating machine to complete producing the finger-jointed sheet material. The structural finger-jointed sheet material has the characteristics of simple production process, low deformation coefficient, elasticity and strength increase, low cost, simple structure, convenient and reliable use, capacity of industrial scale production and the like.

Owner:DER FUTURE SCI & TECH HLDG GRP CO LTD

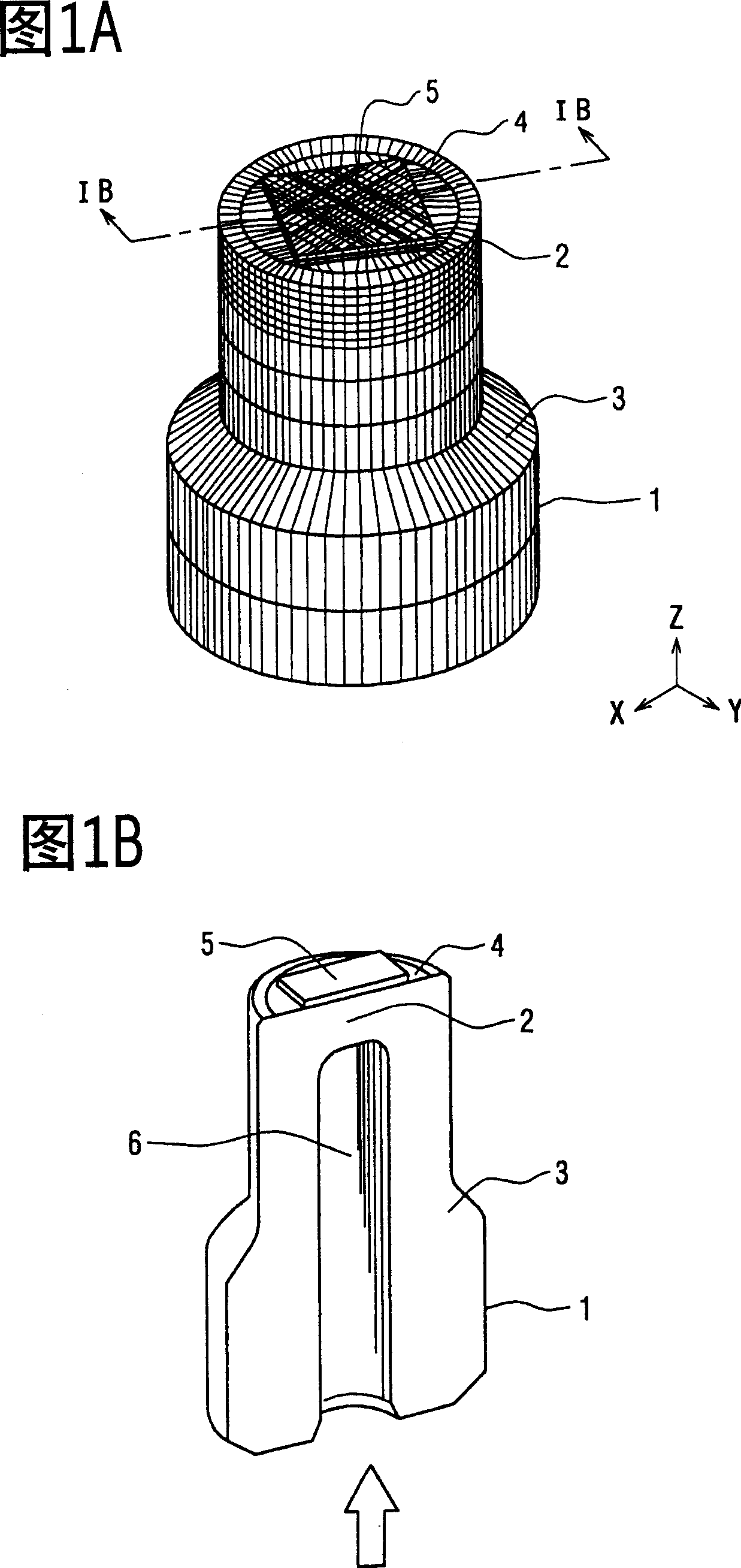

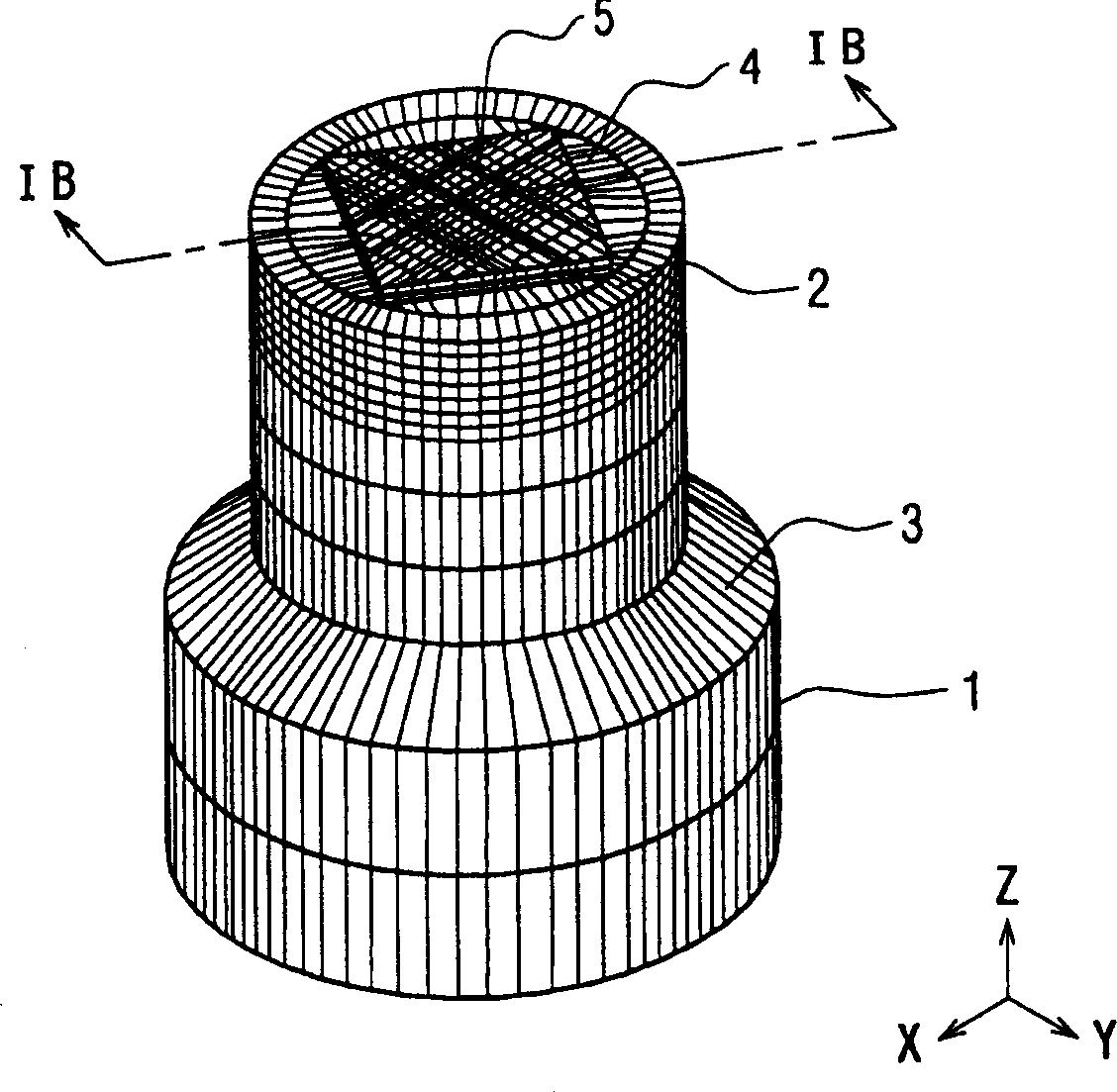

Semiconductor mechanical quantity sensor

InactiveCN1470857ASmall deformation coefficientReduce stressFluid pressure measurement using ohmic-resistance variationSemiconductor/solid-state device manufacturingAdhesiveSemiconductor

A semiconductor dynamic quantity sensor includes a supporting portion, an adhesive, and a sensor chip. The adhesive is located on a surface of the supporting portion. The sensor chip is located on the adhesive. The sensor chip and the supporting portion have been bonded together by heating the adhesive. The adhesive has a deformation factor of 0.5% or smaller at the temperature at which the adhesive is heated for bonding the sensor chip and the supporting portion together in order to reduce the stress caused by the hardening shrinkage of the adhesive.

Owner:DENSO CORP

Process for preparing waterproof foam concrete

InactiveCN101955376AStrong waterproof and heat preservation performanceImprove fire and flame retardant performanceCeramicwareFoam concreteFoaming agent

The invention relates to a process for preparing waterproof foam concrete. The waterproof foam concrete comprises the specific components of water, cement, sand, coal ash, a reinforcing agent and a foaming agent, wherein the mass ratio of the water to the foaming agent is 1:30, the mass ratio of the cement to the reinforcing agent is 100:1-0.8, and the mass ratio of the cement to the coal ash to the sand is 5:3:2; the coal ash is required not containing large particles and cakes, and ordinary Portland cement NO.42.5 is suitably used as cement. The process comprises the following steps of: mixing all proportioned materials, fully stirring uniformly, pouring, molding, keeping wet and maintaining. The foam concrete prepared by the process has strong waterproofing and heat-insulating properties, flame retardance, small deformation coefficient, light volume weight, strong earthquake resistant property, good endurance, low production cost, low elasticity and excellent shock-absorbing property.

Owner:刘士权

Production method of acid-resistant, alkali-resistant and high-temperature-resistant foamed ceramic heat-insulation lining used in chimney

The invention discloses a production method of an acid-resistant, alkali-resistant and high-temperature-resistant foamed ceramic heat-insulation lining used in a chimney. The heat-insulation lining is prepared from following raw materials, according to certain weight part ratios, clay, bentonite, calcite, dolomite, sandstone, talcum, silicon carbide and a peptizing agent. The production method includes following steps: 1) crushing the raw materials into granular materials being less than 10 mm; 2) stirring and homogenizing the granular materials in a ball mill and wet-milling the granular materials into slurry material in 250 meshes; 3) feeding the slurry material into a drying column, increasing the temperature to 320 DEG C to dry and pelletize the slurry material to obtain pellets; 4) placing the pellets in a kiln car and sintering the pellets in a tunnel kiln at 1200-1250 DEG C; and 5) decreasing the temperature to normal temperature and moving the sintered product after the pellets remains at the sintering temperature zone for 3-10 h, and cutting the sintered product into building blocks according to requirement. The close-pore ceramic heat-insulation material, which is formed through high-temperature roasting to the raw materials blended according to certain weight part ratios and is high in porosity, has the characters of being fire-proofing and flame-retarding, being less in deformation coefficient, is anti-aging, is stable in performance and is toxic-free and environment-friendly. The material is good in compatibility with a wall base layer and a plaster layer, is good in safety and stability, has the same service life of a building, and provides guarantee to heat insulation and high temperature resistance of various chimney buildings.

Owner:ZHENGZHOU ZHENDONG TECH

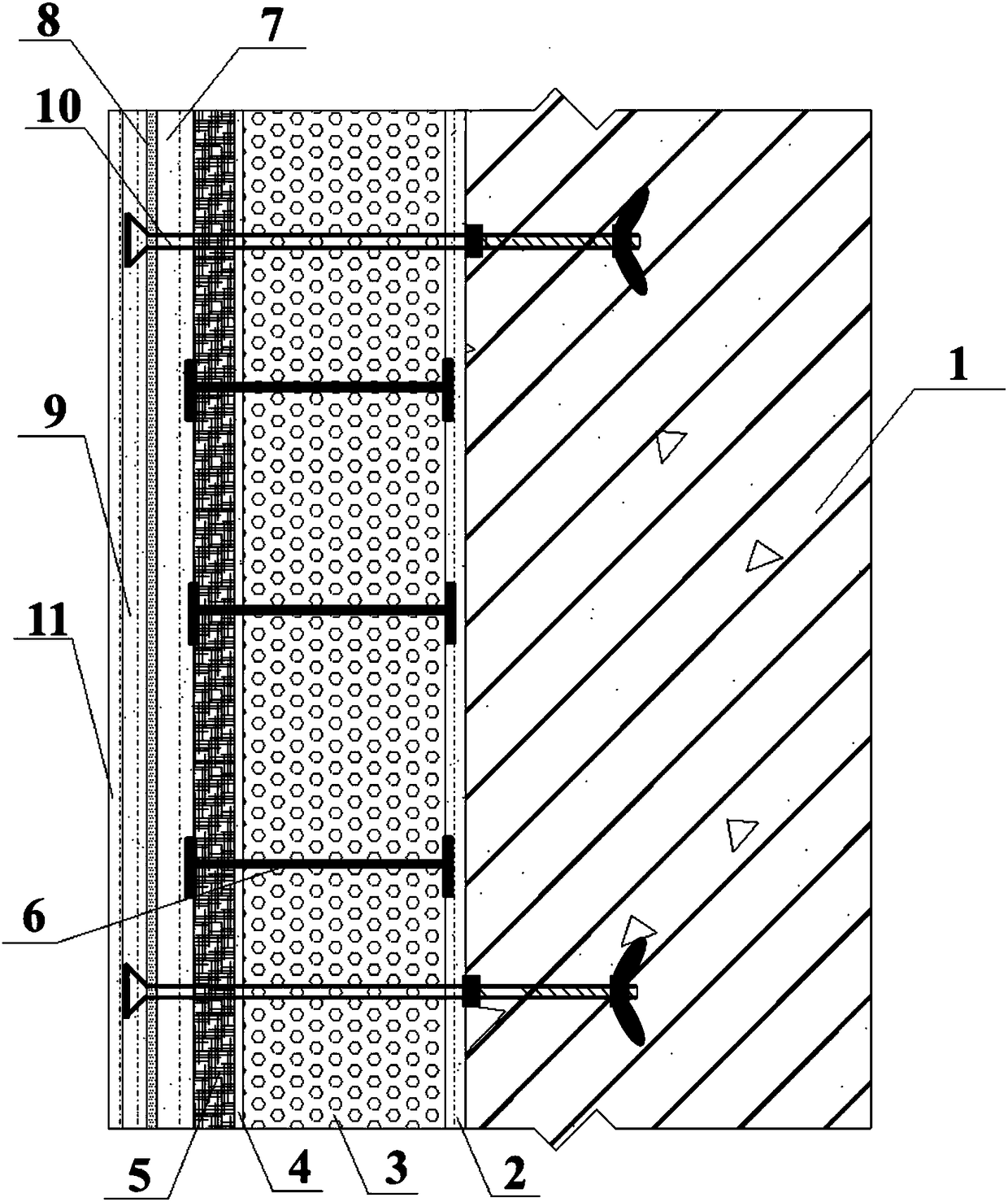

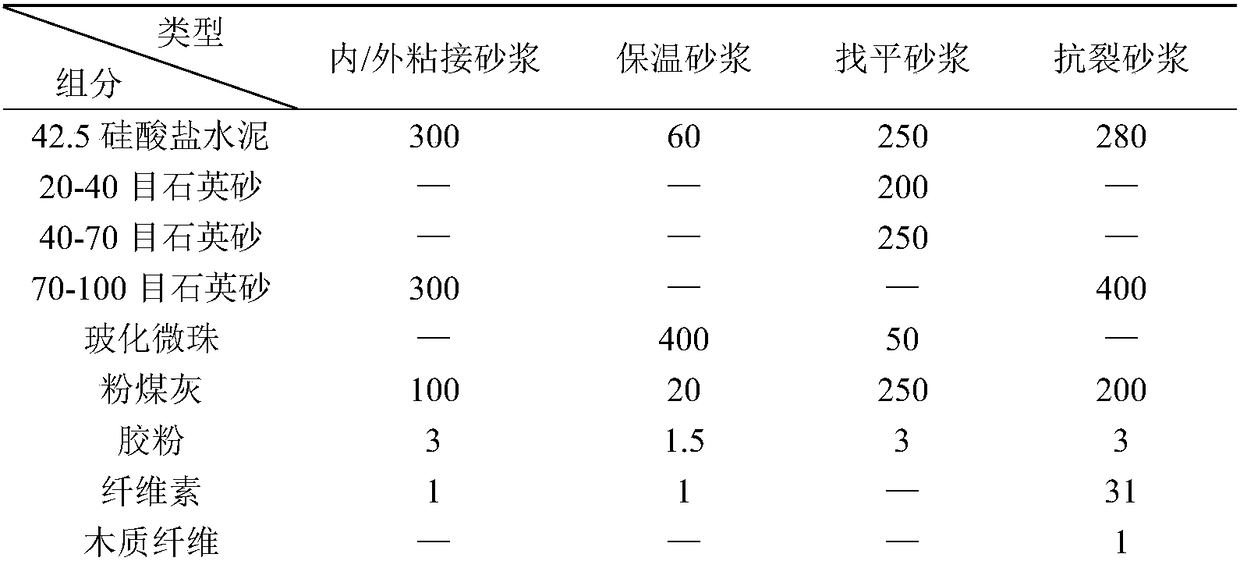

Compound insulation formwork for building external wall and construction method of compound insulation formwork

PendingCN108571162AImprove fire performanceTightly boundClimate change adaptationInsulation improvementInsulation layerQuality safety

The invention discloses a compound insulation formwork for building external wall and a construction method of the compound insulation formwork. The compound insulation formwork comprises an inner bonded mortar layer, a silicified polyphenyl insulation plate, an outer bonded mortar layer, an aerogel fibrofelt layer, an insulation mortar layer, a waterproof layer, a leveling mortar layer and an anti-crack mortar layer which are fixed and attached to an external wall base in sequence. The compound insulation formwork has the advantages of being good in heat insulation and fire prevention performance, safe and reliable in quality, high in wind resisting load, small in deformation coefficient, high in structure stability and the like, the compound insulation formwork and concrete can be pouredand constructed at the same time, an insulation layer and a structural body can be completed at the same time, and the construction period is greatly shortened. Meanwhile, due to the fact that the silicified polyphenyl insulation plate layer and the aerogel fibrofelt layer are connected through insulation nails, the elasticity modulus between the silicified polyphenyl insulation plate layer, theaerogel fibrofelt layer and the insulation mortar layer achieves gradient changing, the layers are tightly combined, the overall deformation coefficient is small, and the structure is more stable.

Owner:天津市华利杰科技发展有限公司

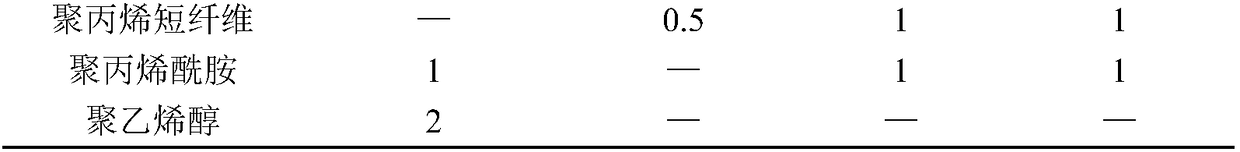

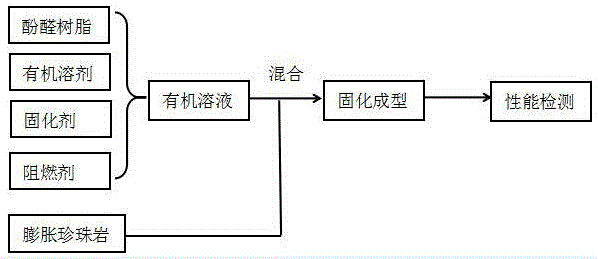

Organic/inorganic compound thermal insulation material and preparation method

InactiveCN106084632AOvercome strengthOvercoming poor aging resistanceThermal insulationInorganic compound

The invention belongs to the field of a thermal insulation material and preparation thereof. The invention discloses a compound thermal insulation material taking phenolic resin and expanded perlite as main raw materials and a preparation method of the compound thermal insulation material. The preparation method comprises the following steps: uniformly mixing phenolic resin, expanded perlite and fire retardant; filling into a mould; solidifying and forming at a certain temperature for a period of time. Thermoset phenolic resin is selected as the phenolic resin and the dosage is 20wt%-70wt%; perlite in bulk density of 90-120kg / m3 is selected as the expanded perlite and the dosage is 30wt%-80wt%; half-dry pressing is performed under the forming temperature of 100 DEG C for forming time of 2h; the apparent density of the sample is 200-360Kg / m3, the compressive strength is 0.8-1.2MPa, the breaking strength is 0.4-0.7MPa and the combustion performance is B1 level; the overall performance of the material is between the organic and inorganic thermal insulation materials at present. The compound thermal insulation material provided by the invention has the advantages of low heat conductivity coefficient of organic thermal insulation materials and high strength and difficulty in burning of the inorganic thermal insulation material.

Owner:UNIV OF JINAN

Double piston type pressure vacuum gauge

InactiveCN102221438ASmall deformation coefficientSmall temperature linear expansion coefficientFluid pressure measurement using pistonsVacuum gauge using compression chambersPiston cylinderPallet

The invention relates to a double piston type pressure vacuum gauge which comprises a simple piston, a differential piston and an oil pipe connecting the simple piston and the differential piston. The simple piston and the differential piston are fixed on a piston cylinder seat board. The upper parts of the simple piston and the differential piston are provided with pallet seat frames, pallets and counterweight pallets. The pallets are respectively on the corresponding pallet seat frame. The counterweight pallets are respectively on the corresponding pallets. The lower parts of the simple piston and the differential piston are provided with cylinder combination members. The cylinder combination members comprise piston cylinders, piston cylinder seats and cylinder caps. The piston cylinders of the simple piston and the differential piston are fixed on piston cylinder seats through cylinder caps. Through an improvement design of pistons, piston cylinder structure and material of a present double piston type pressure vacuum gauge, the piston and piston cylinder in the invention has the advantages of good wearability, long service life and convenient cleaning. And the accuracy control of double piston rods in working is ensured.

Owner:SHANGHAI JIANZHOU MACHINERY EQUIP

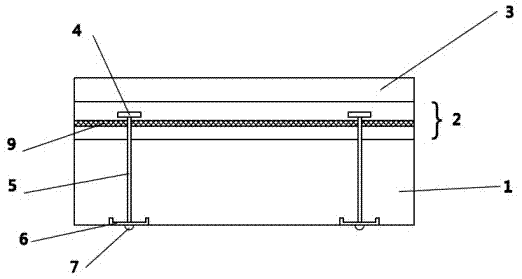

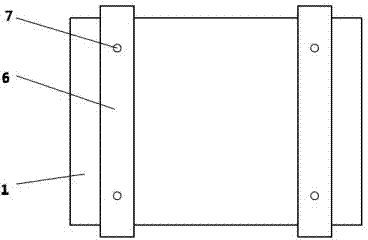

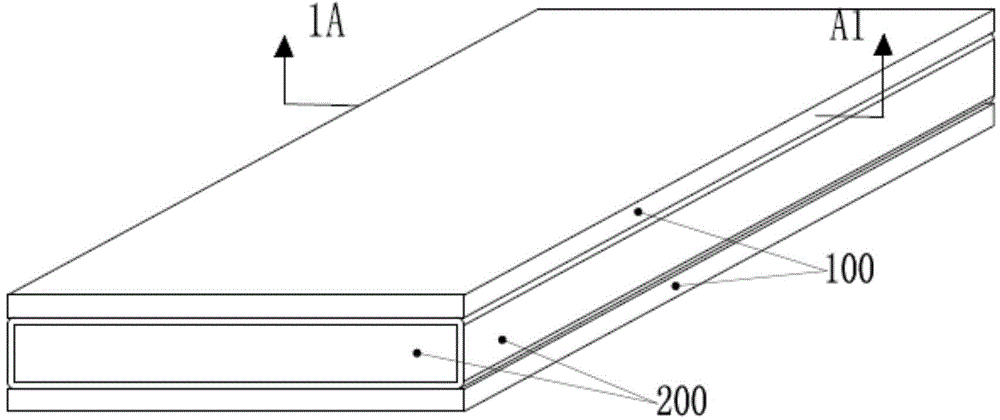

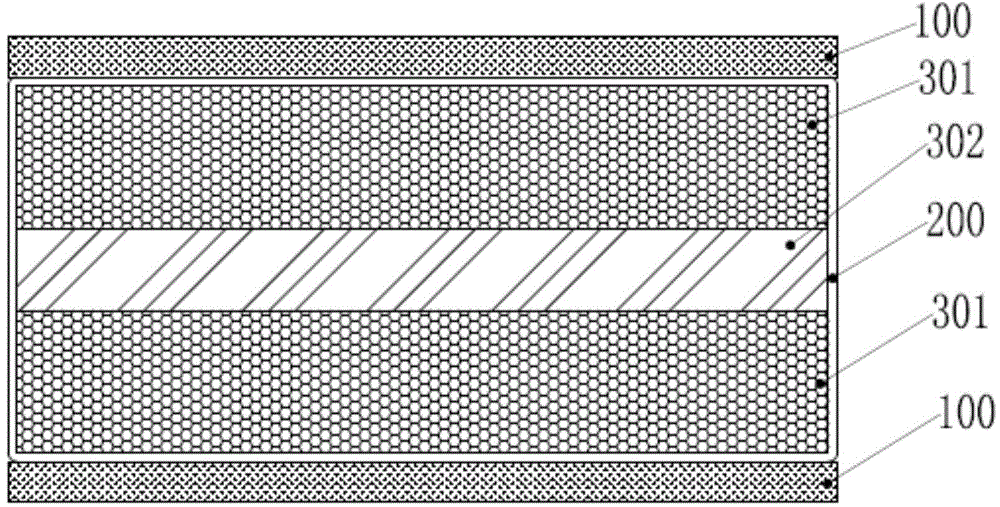

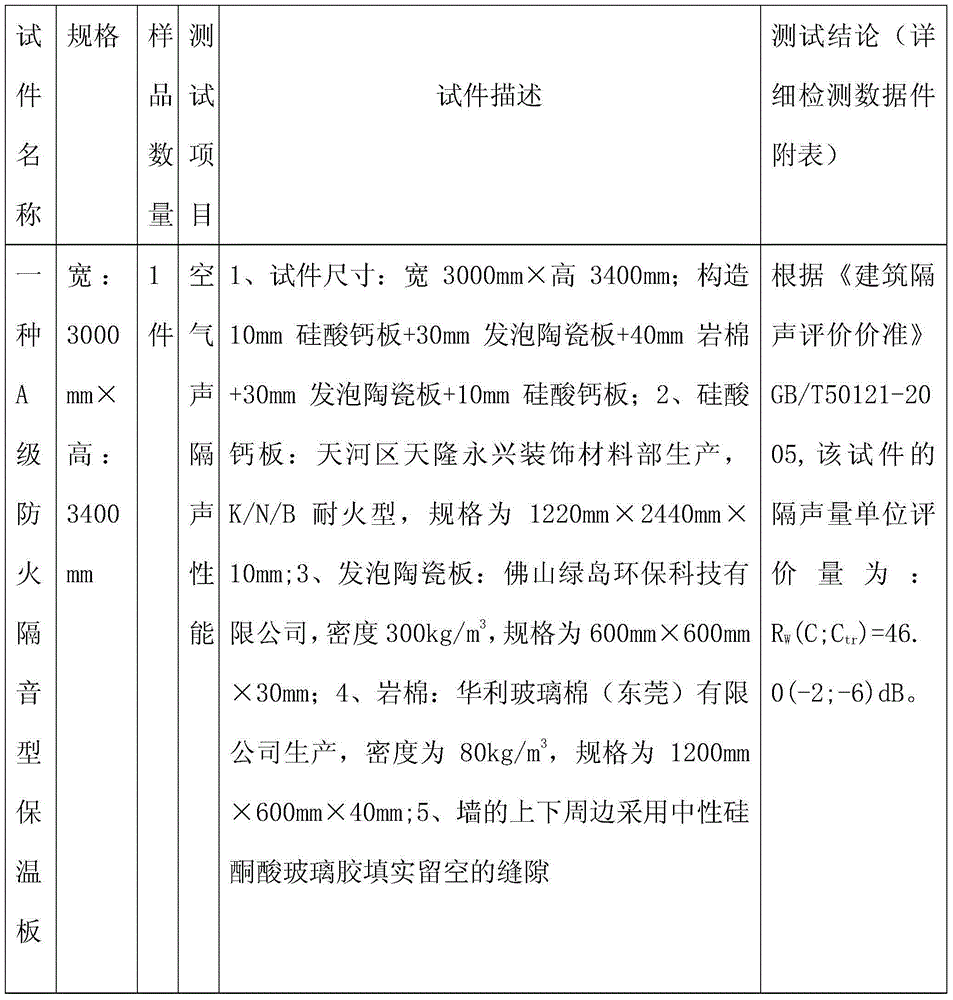

A-level fireproof-soundproof-heat-preservation wall board

InactiveCN104533009AImprove sound insulationImprove insulation effectBuilding componentsKeelTwo layer

The invention relates to the field of building materials and particularly relates to an A-level fireproof-soundproof-heat-preservation wall board. The A-level fireproof-soundproof-heat-preservation wall board comprises two light refractory heat-preservation layers and a supporting keel layer, wherein the supporting keel layer is positioned between the two light refractory heat-preservation layers and consists of two layers of foamed ceramic plates wrapped by metal plates and an inorganic heat-preservation cotton arranged between the foamed ceramic plates. The A-level fireproof-soundproof-heat-preservation wall board has the advantages that according to the structure, the supporting keel layer is adopted to completely wrap and protect the supporting keel layer with main functions, and by adoption of the mode of additionally arranging the light refractory heat-preservation layers outside the supporting keel layer to play roles in protecting the metal plates in the wall board, improving the performance of the wall board and decorating the wall board, the A-level fireproof-soundproof-heat-preservation wall board has the characteristics of relatively stable and firm structure, long service life, and good fireproof, soundproof and heat-preservation effects.

Owner:佛山绿岛盈嘉装饰科技有限公司

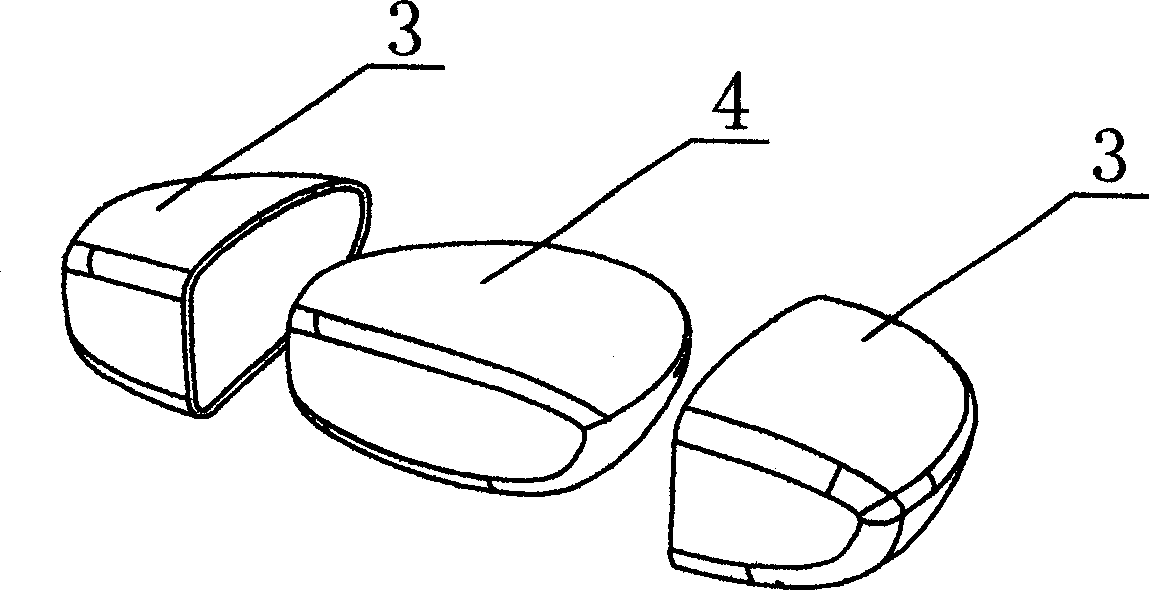

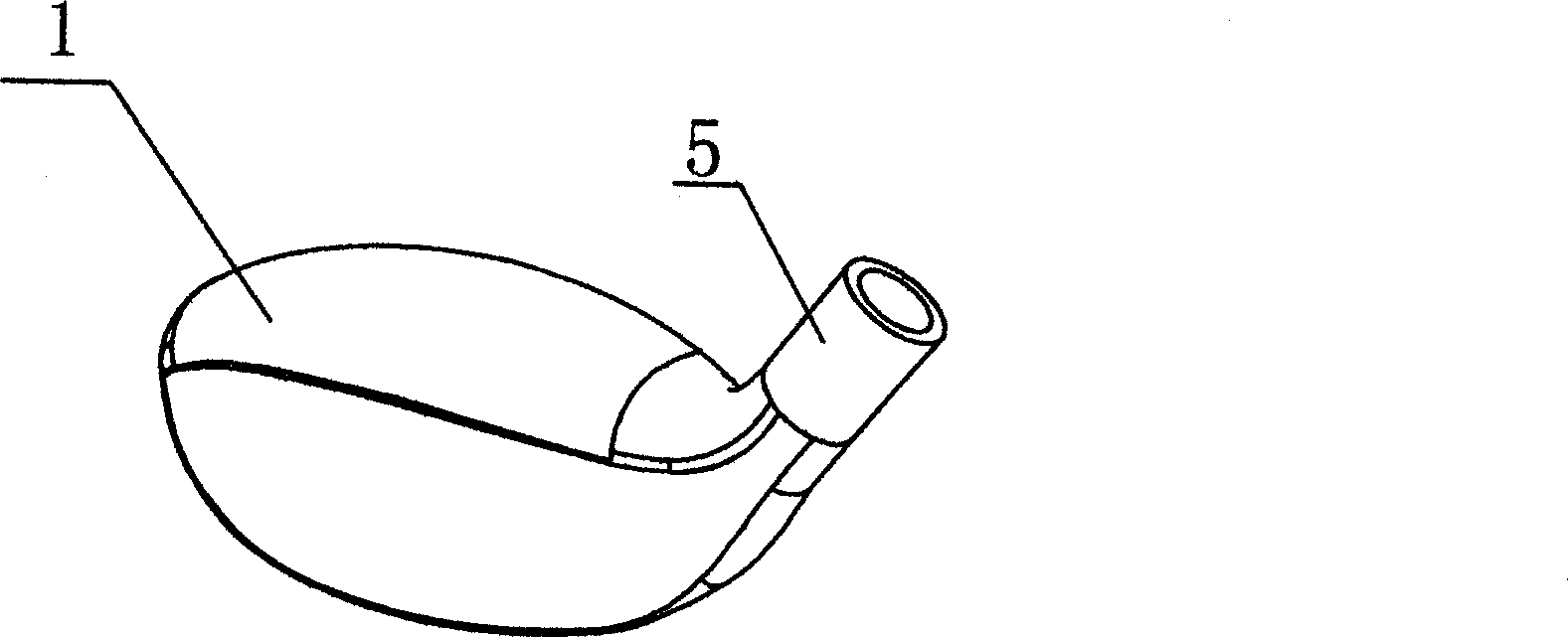

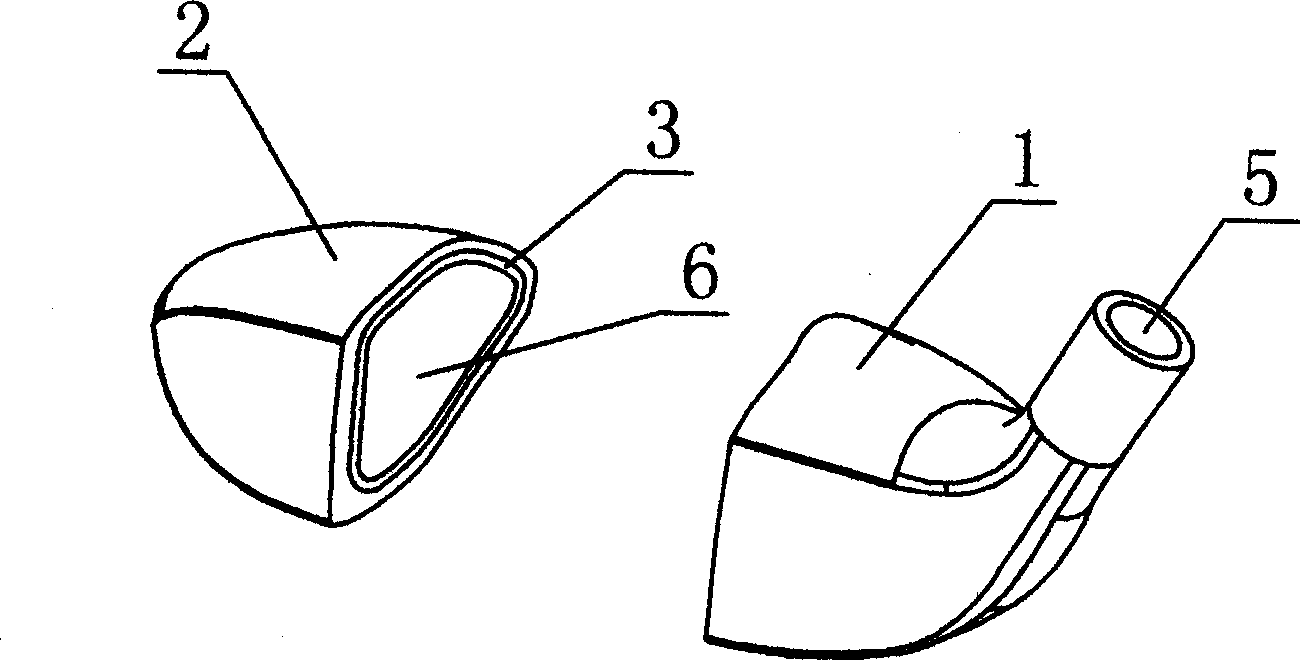

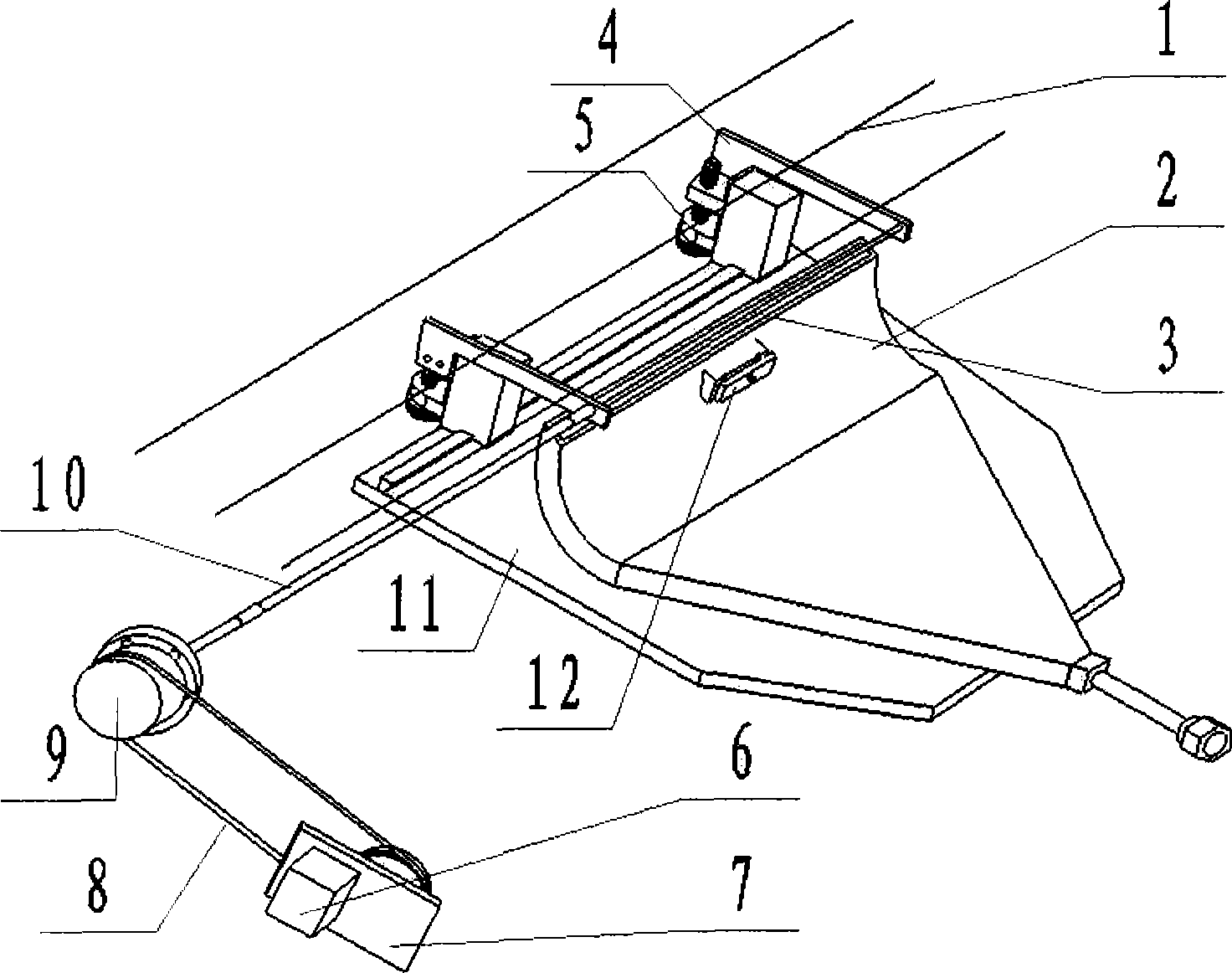

Improved manufacture method of one-piece golf bar head and products thereof

InactiveCN101362197AReduce distortionReduce consumptionFoundry mouldsFoundry coresMetallic materialsGolf club

The invention discloses a manufacturing method for improving an integral golf club head, which includes the following steps: (1) precasting an internal sleeve, the outer contour of which is the same with the shape of an inner cavity of the golf club head, and at least one opening is arranged in the internal sleeve; (2) preparing granular filling materials for the internal sleeve and placing the filling materials into the inner cavity of the internal sleeve through the opening; (3) precasting a die-casting die of the club head; (4) fixing the entity of the internal sleeve in the die-casting die; (5) casting metal liquid, the casting melting point of which is not higher than the melting point of the metal material of the internal sleeve, into the die, and the die is cast and formed; (6) preparing a club head embryo which consists of a shell layer, an internal sleeve layer and filling materials after die de-molding; (7) drilling a bore hole which permeates the shell layer and the internal sleeve layer on the embryo club head; and (8) manufacturing the golf club head by arranging the opening of the bore hole downward to cause the filling materials to flow out automatically from the bore hole. The method also discloses a product made by adopting the method.

Owner:LONGHUI SPORTS GOODS +1

Graphene modified slurry insulation material and preparation method thereof

The invention provides a graphene modified slurry insulation material, prepared from the following raw materials in parts by weight: 5-10 parts of polystyrene particles, 20-40 parts of epoxy modified phenolic resin, 10-15 parts of encapsulated expanded perlite, 5-10 parts of graphene, 3-5 parts of methoxyphenyl methoxyl silicon oil, 1-3 parts of stablizer and 0.1-1 part of flexibilizer. The preparation method comprises the following steps: (1) according to the proportion, weighing the polystyrene particles, encapsulated expanded perlite and graphene, stirring and mixing to obtain mixture A; (2) heating the mixture obtained in step (1) to 70-90DEG C, then adding the epoxy modified phenolic resin and methoxyphenyl methoxyl silicon oil and stirring to obtain mixture B; and (3) placing the mixture B under a vacuum condition, then adding the stablizer and flexibilizer and stirring uniformly, and cooling to room temperature. The insulation material has folding strength of over 12MPa, low water absorptivity and low thermal conductivity.

Owner:陕西墨氏石墨烯科技有限公司

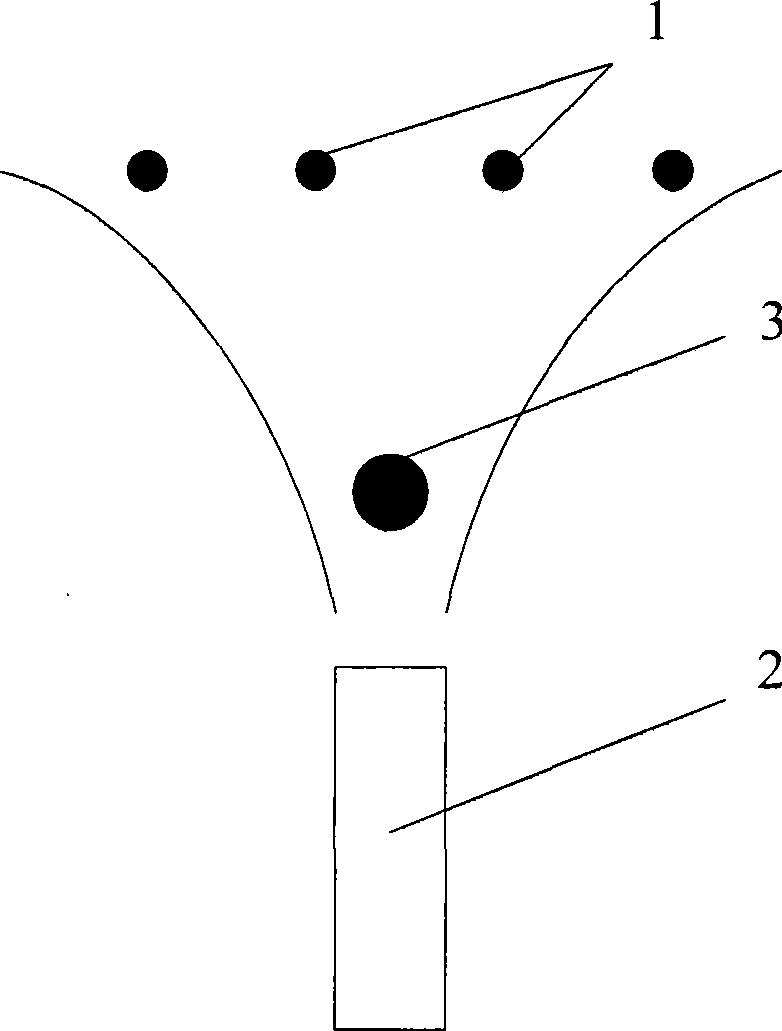

Apparatus for preparing CVD diamond film for linear sample

InactiveCN101503796AIncrease growth rateIncrease profitChemical vapor deposition coatingProduct gasEngineering

The invention discloses a device for preparing a CVD diamond film through a linear sample. The device comprises a vacuum reaction chamber, a gas cracking hot wire, a gas expelling device and a basal body support used for placing a linear substrate, wherein the gas cracking hot wire, the gas expelling device and the basal body support are arranged inside the reaction chamber. The device is characterized in that: the gas expelling device is a gas collector with a narrow slit aeration cavity; the gas collector also has a V-shaped cross section; and the gas cracking hot wire, the linear substrate and an inlet of the gas collector are arranged in turn from top to bottom so as to achieve the aim of collecting gas within a smaller area which is matched with the gas cracking hot wire and the linear substrate to improve the proportion of cracked gas and the utilization ratio of the gas. The device makes an air flow field distributed in the form of the V-shaped cross section, thereby improving the utilization ratio of mixed gas and the growth rate of a diamond crystal, and ensuring that a diamond film evenly deposit on the surface of the substrate.

Owner:CENT SOUTH UNIV

Lightweight foam concrete for decoration engineering and its preparation method

The invention discloses a lightweight foam concrete for decorative engineering, which comprises the following raw materials according to parts by weight: 20-40 parts of cement, 7-15 parts of phosphorus slag micropowder, 4-10 parts of diatom mud, calcium lignosulfonate powder 2~10 parts, silica powder 1~10 parts, fiber 6~10 parts, dispersible latex powder 3~9 parts, modifier 2~5 parts, foaming agent 1.5~3.5 parts. The invention provides a lightweight foamed concrete for decorative engineering and a preparation method thereof. The industrial solid waste phosphorus slag micropowder is mainly used as a cementitious material, and its potential activity is stimulated by calcium lignosulfonate powder and a modifier. The prepared concrete has the characteristics of fast hardening and early strength, which solves the problems of long setting time and easy collapse of ordinary Portland cement, short setting time, small deformation coefficient, low density and light weight, which is suitable for indoor and outdoor. For decoration, it has good social application value.

Owner:HEFEI XINYADA INTELLIGENT TECH CO LTD

Outer wall vacuum inorganic foam insulation plate and manufacturing method thereof

InactiveCN102808460AImprove thermal conductivityLow thermal conductivityClimate change adaptationInsulation improvementAging resistanceThermal insulation

The invention relates to an outer wall vacuum inorganic foam insulation plate and a manufacturing method thereof. The insulation plate is made of a vacuum packaging bag and a foam insulation core plate mounted in the bag; the foam insulation core plate is one of a foam cement plate or a foam glass plate or a foam ceramic plate; the vacuum packaging bag adopts an aluminum foil vacuum packaging bag; construction mounting edges of 15-30 mm are pressed on the two sides or the periphery of the aluminum foil vacuum packaging bag; and the aluminum foil vacuum packaging bag adopts a single-layer aluminum foil vacuum packaging bag or a dual-layer aluminum foil vacuum packaging bag. Due to the insulation plate, the thickness of the outer wall insulation plate can be reduced, the thermal insulation and insulating performance of the insulation plate can be enhanced, the phenomenon of expanded deformation, aging, cracking, damage and the like can be also eliminated, and the service life of a wall body is greatly prolonged. The insulation plate has the advantages of light weight, low heat conducting coefficient, excellent insulation performance, high strength, aging resistance and good fireproofing flame retardant effect.

Owner:信阳天意节能技术股份有限公司

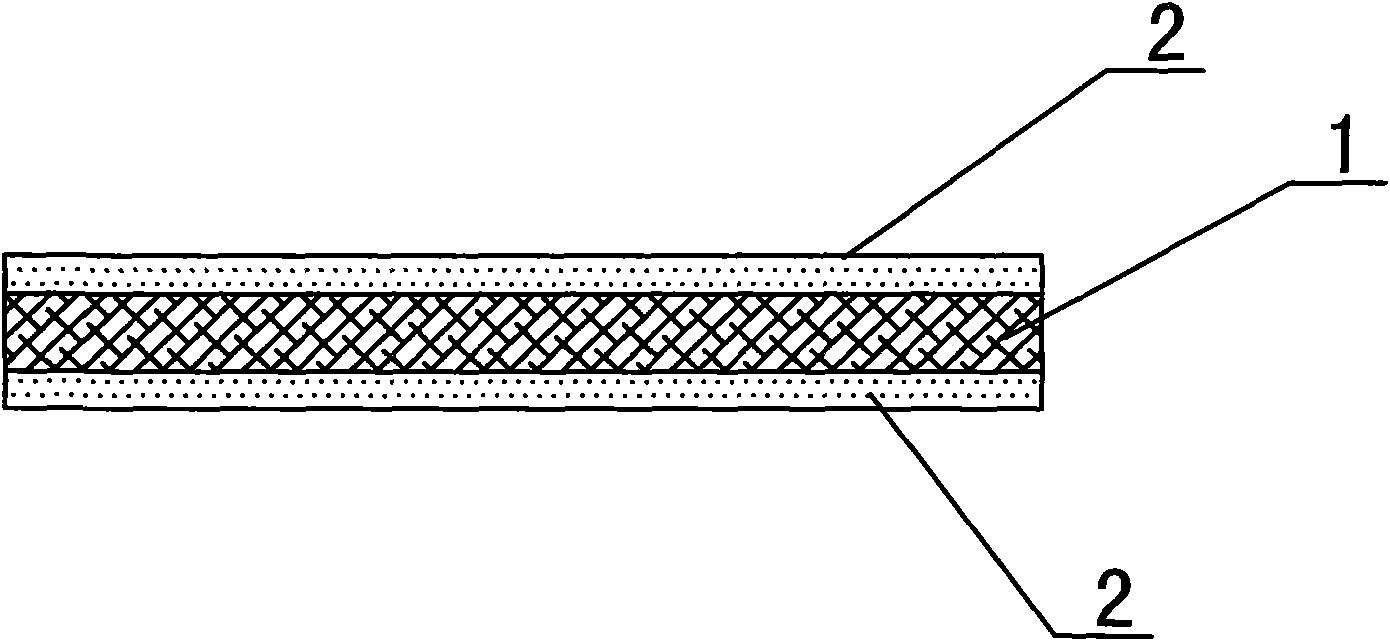

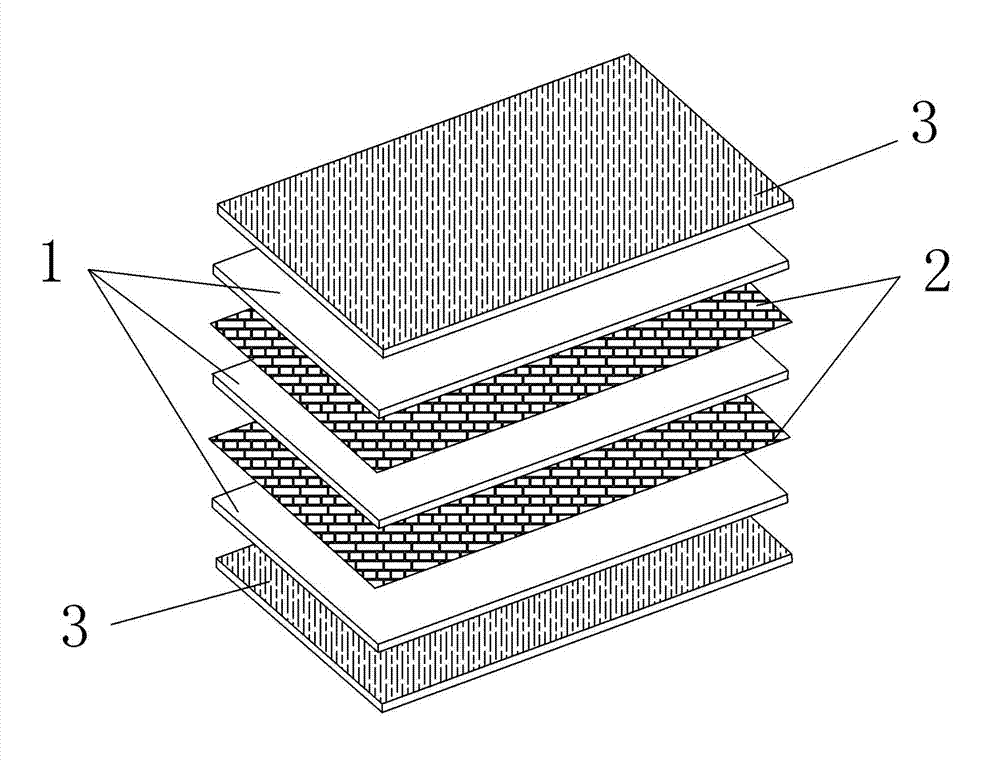

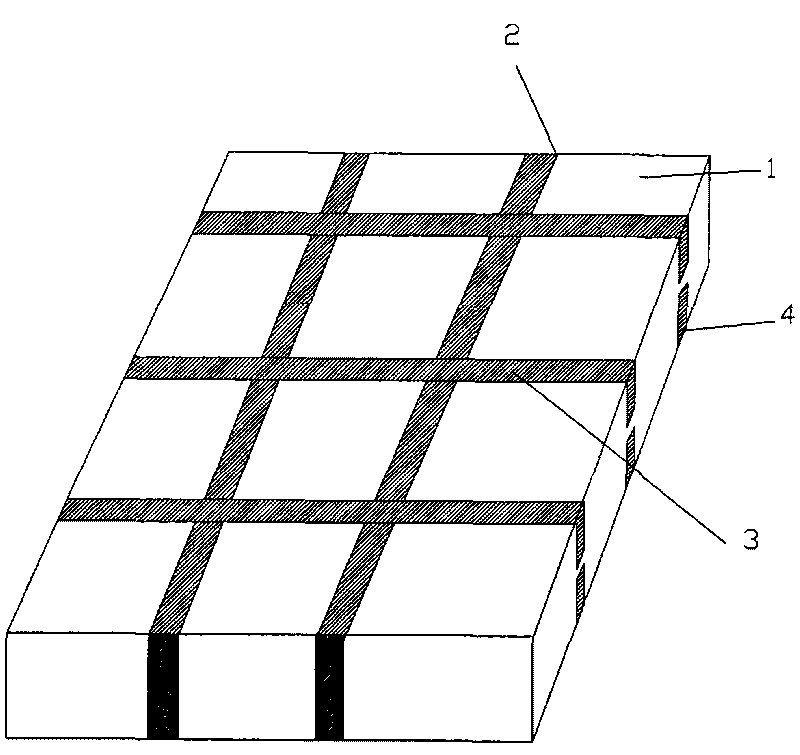

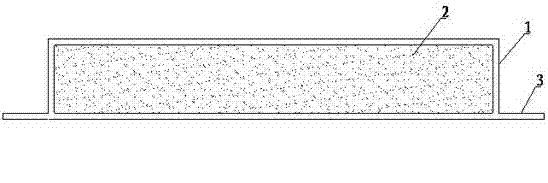

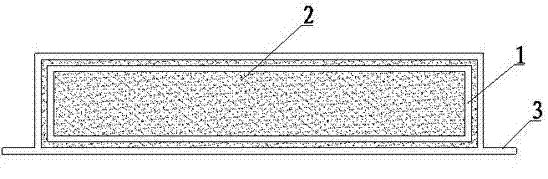

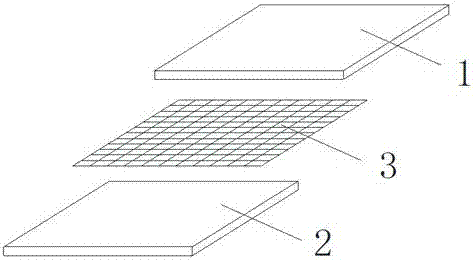

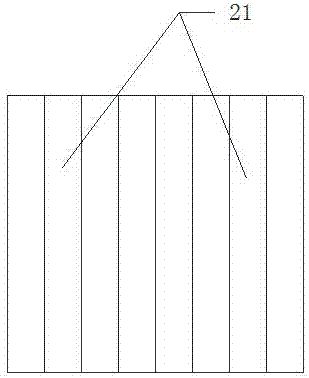

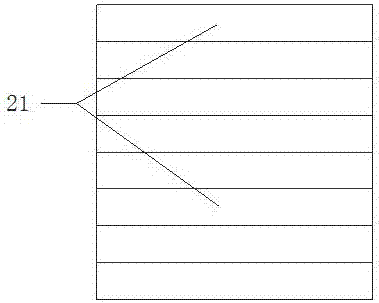

Solid wood composite plate of fiber reinforced structure and preparation method of solid wood composite plate

InactiveCN107116628AImprove performanceSmall deformation coefficientPlywood pressesVeneer manufactureSolid woodMaterials preparation

The invention discloses a solid wood composite plate of a fiber reinforced structure and a preparation method of the solid wood composite plate. The solid wood composite plate comprises a face plate (1) and a bottom plate (2) which are overlaid up and down. A reinforcing layer (3) is arranged between the face plate (1) and the bottom plate (2). The face plate (1), the bottom plate (2) and the reinforcing layer (3) are adhesively connected through PUR glue. The preparation method comprises the first step of face plate material preparation, the second step of bottom plate preparation and the third step of pressing. Compared with the prior art, the formaldehyde-free production technology is adopted, the technology is simple, the rate of finished products is high, the solid wood composite plate is environmentally friendly and free of pollution, meets the requirement for healthy life and accords with the concept of environmental protection, the reinforcing structure is adopted, the plate performance is stable, the deformation coefficient is low, the composite plate with the large width size can be manufactured, and the solid wood composite plate can be used as a furniture material and a decoration material.

Owner:江苏双奇地板有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com