Semiconductor mechanical quantity sensor

A technology of sensors and mechanical quantities, applied in semiconductor devices, semiconductor/solid-state device manufacturing, fluid pressure measurement, etc., can solve problems such as stress attenuation, sensor output changes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

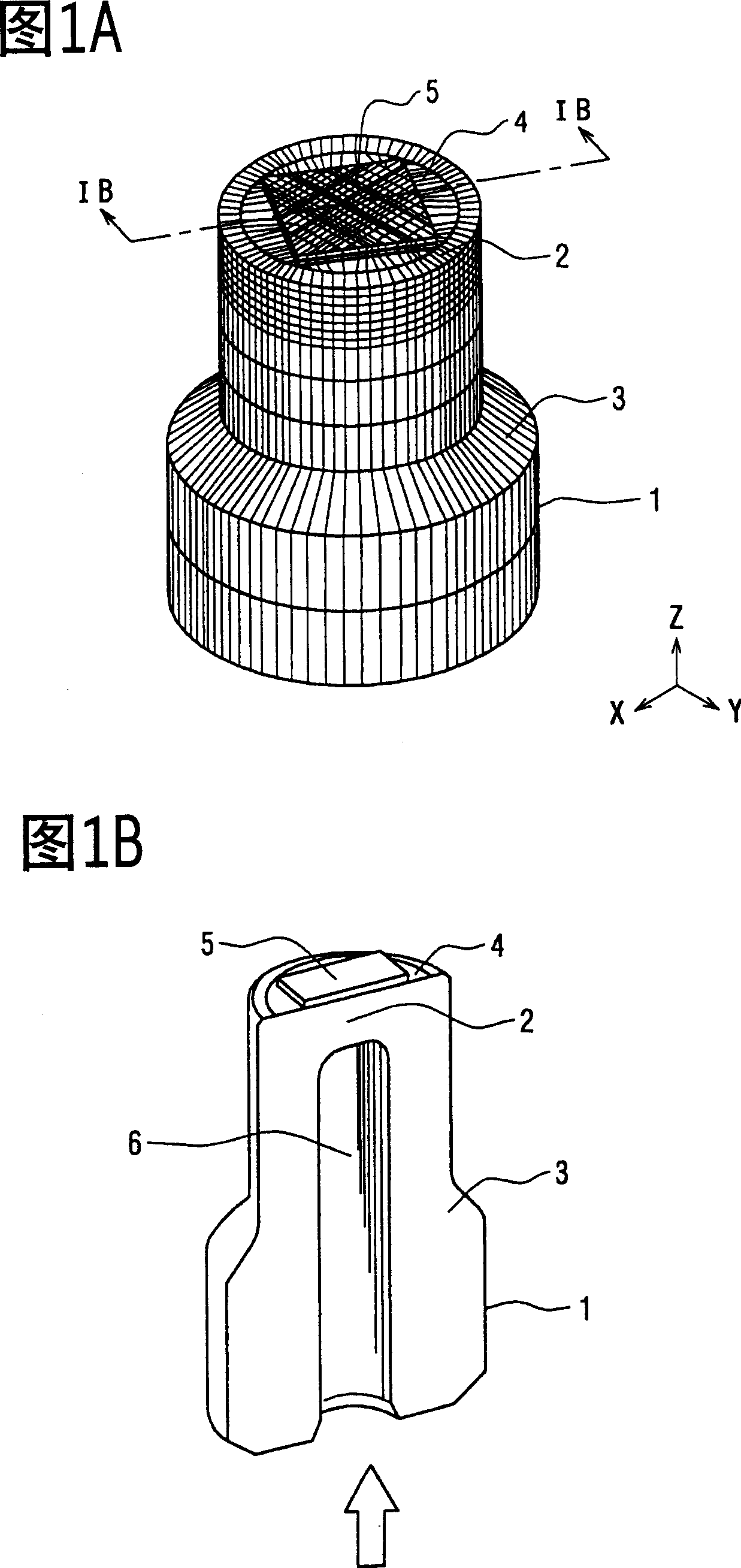

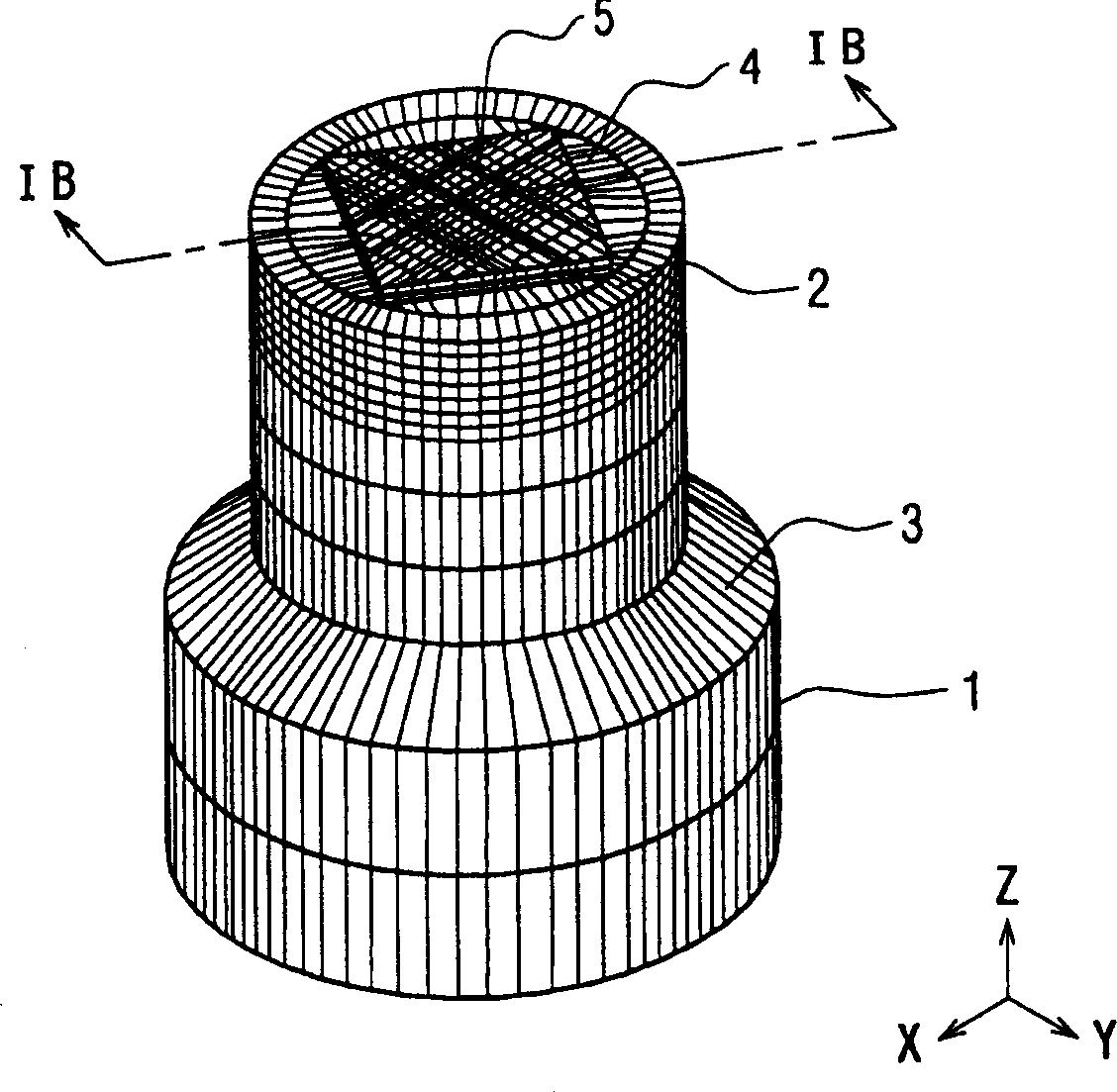

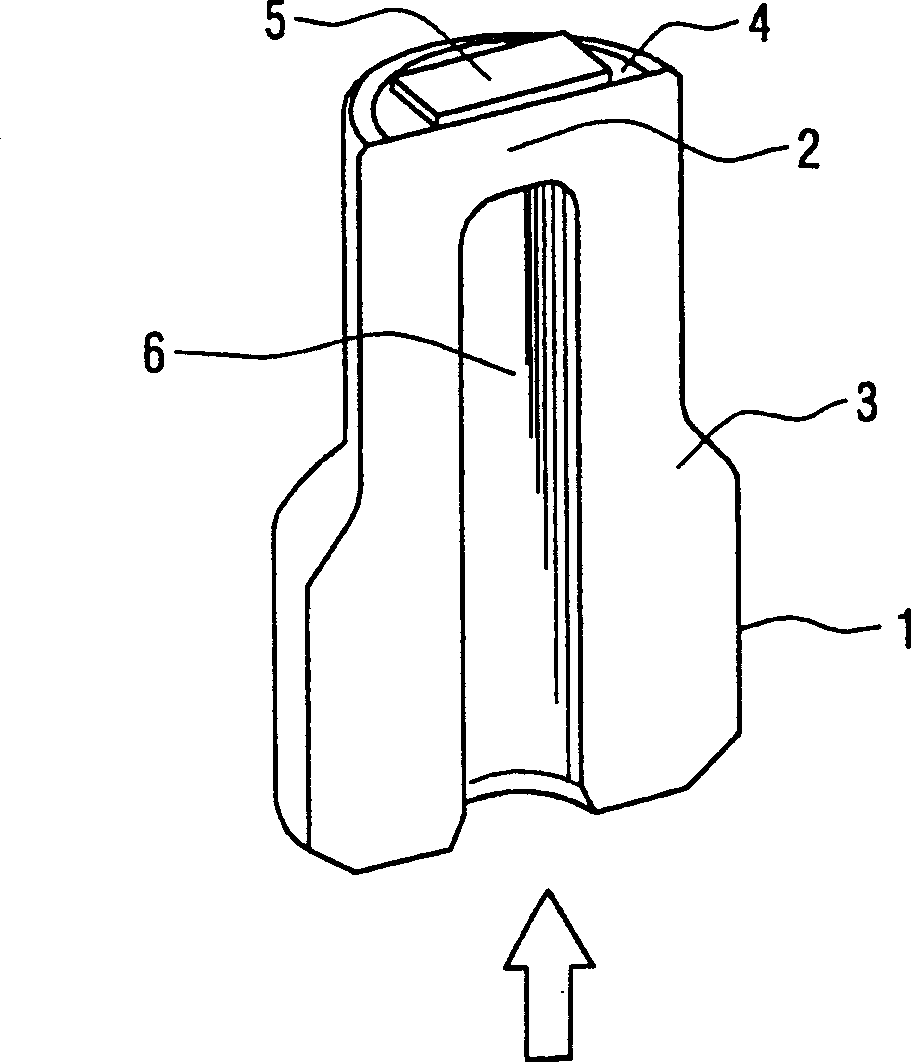

[0015] FIG. 1A is a schematic perspective view of a pressure sensor 1 of an example of the present invention. The pressure sensor 1 as a semiconductor mechanical quantity sensor can be used, for example, to control fuel injection pressure or brake pressure of an engine in a vehicle. The pressure sensor 1 includes a metal rod 3 or a metal step 3 with a disc-shaped metal diaphragm 2 or supporting portion 2 . The pressure sensor 1 also includes an adhesive 4 and a sensor chip 5 . The sensor chip 5 is bonded to the upper surface of the support portion 2 using the adhesive 4 at a predetermined bonding temperature.

[0016] As shown in FIGS. 1A and 1B , the metal rod 3 has a cavity 6 below the upper surface in which the sensor chip 5 is located. A predetermined pressure medium such as a gas and a liquid is introduced into the cavity 6 , and based on the deformation of the bearing 2 and the deformation of the sensor chip 5 , the pressure of the pressure medium is detected.

[0017...

PUM

| Property | Measurement | Unit |

|---|---|---|

| deformation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com