Lightweight foam concrete for decoration engineering and its preparation method

A lightweight foam and concrete technology, applied in the field of decoration engineering, can solve the problems of slow strength development, long setting time, low strength, etc., and achieve the effects of short setting time, small deformation coefficient and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

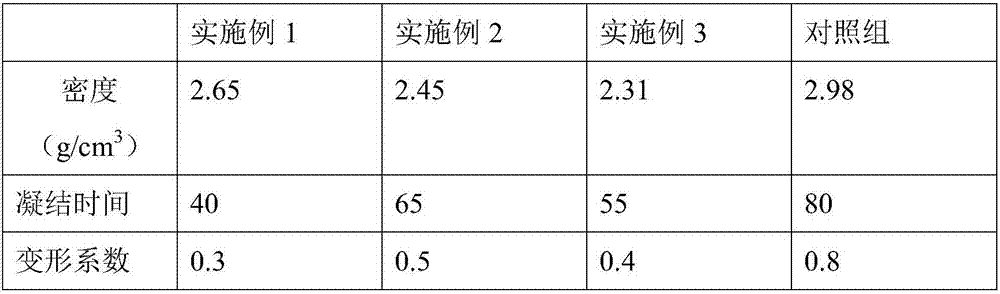

Examples

Embodiment 1

[0020] A kind of lightweight foam concrete for decoration engineering, comprising the following raw materials in parts by weight: 20 parts of cement, 7 parts of fine powder of phosphorous slag, 4 parts of diatom mud, 2 parts of calcium lignosulfonate powder, 1 part of silicon dioxide powder, 6 parts of fiber, 3 parts of dispersible latex powder, 2 parts of modifier, and 1.5 parts of foaming agent.

[0021] The modifier is formed by mixing magnesium oxide and slaked lime at a mass ratio of 2:1, wherein the magnesium oxide is lightly calcined powder, and the calcining temperature is 600°C.

[0022] The fiber is one or more of coconut palm fiber, sisal fiber, ramie fiber and basalt fiber.

[0023] The silica powder is nano silica powder.

[0024] A preparation method of lightweight foamed concrete for decorative engineering, mainly comprising the following steps:

[0025] Step 1: The raw materials are weighed, including the following raw materials in parts by weight: 20 parts o...

Embodiment 2

[0032] A kind of lightweight foamed concrete for decoration engineering, comprising the following raw materials in parts by weight: 30 parts of cement, 10 parts of phosphorus slag micropowder, 7 parts of diatom mud, 8 parts of calcium lignosulfonate powder, 7 parts of silicon dioxide powder, 8 parts of fiber, 6 parts of dispersible latex powder, 4 parts of modifier, and 2.5 parts of foaming agent.

[0033] The modifier is formed by mixing magnesium oxide and slaked lime at a mass ratio of 3:1, wherein magnesium oxide is lightly calcined powder, and the calcining temperature is 700°C.

[0034] The fiber is one or more of coconut palm fiber, sisal fiber, ramie fiber and basalt fiber.

[0035] The silica powder is nano silica powder.

[0036] A preparation method of lightweight foamed concrete for decorative engineering, mainly comprising the following steps:

[0037] Step 1: The raw materials are weighed, including the following raw materials in parts by weight: 30 parts of ce...

Embodiment 3

[0044] A kind of lightweight foamed concrete for decorative engineering, comprising the following raw materials in parts by weight: 40 parts of cement, 15 parts of phosphorus slag micropowder, 10 parts of diatom mud, 10 parts of calcium lignosulfonate powder, 10 parts of silicon dioxide powder, 10 parts of fiber, 9 parts of dispersible latex powder, 5 parts of modifier, and 3.5 parts of foaming agent.

[0045] The modifier is made by mixing magnesium oxide and slaked lime at a mass ratio of 4:1, wherein the magnesium oxide is lightly calcined powder, and the calcining temperature is 850°C.

[0046] The fiber is one or more of coconut palm fiber, sisal fiber, ramie fiber and basalt fiber.

[0047] The silica powder is nano silica powder.

[0048] A preparation method of lightweight foamed concrete for decorative engineering, mainly comprising the following steps:

[0049] Step 1: The raw materials are weighed, including the following raw materials in parts by weight: 40 parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com