A fast-hardening mortar for bonding and caulking of sticker paper bricks

A technology of paper bricks and stickers, which is applied in the field of rapid hardening mortar, can solve the problems of unfilled joints, bricks falling off the facing layer, and mortar not reaching strength, etc., so as to achieve dense and full brick joints, improve filling effect, The effect of high construction efficiency

Active Publication Date: 2017-10-31

奥捷科技股份有限公司

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] 3. While the construction personnel are flushing and wetting, the mortar at this time has not reached a certain strength and cannot withstand the water flushing. It will only cause damage to varying degrees to the caulking that has been torn off the paper next to it, and will The mortar rushes to the brick surface, and finally the mortar is washed away at a seam. The seam is not full, and the brick is washed out of the slurry. You can see the cement slurry, sand and other materials, which greatly reduces the effect of the entire facing layer.

[0006] 4. Although the seam filling measures have been taken after the paper is torn off, there are still a large number of seam filling areas that are not filled. Especially in winter, rainwater penetrates inward through the unfilled areas, and will freeze and expand after low temperature. The entire facing layer Bricks will fall off

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

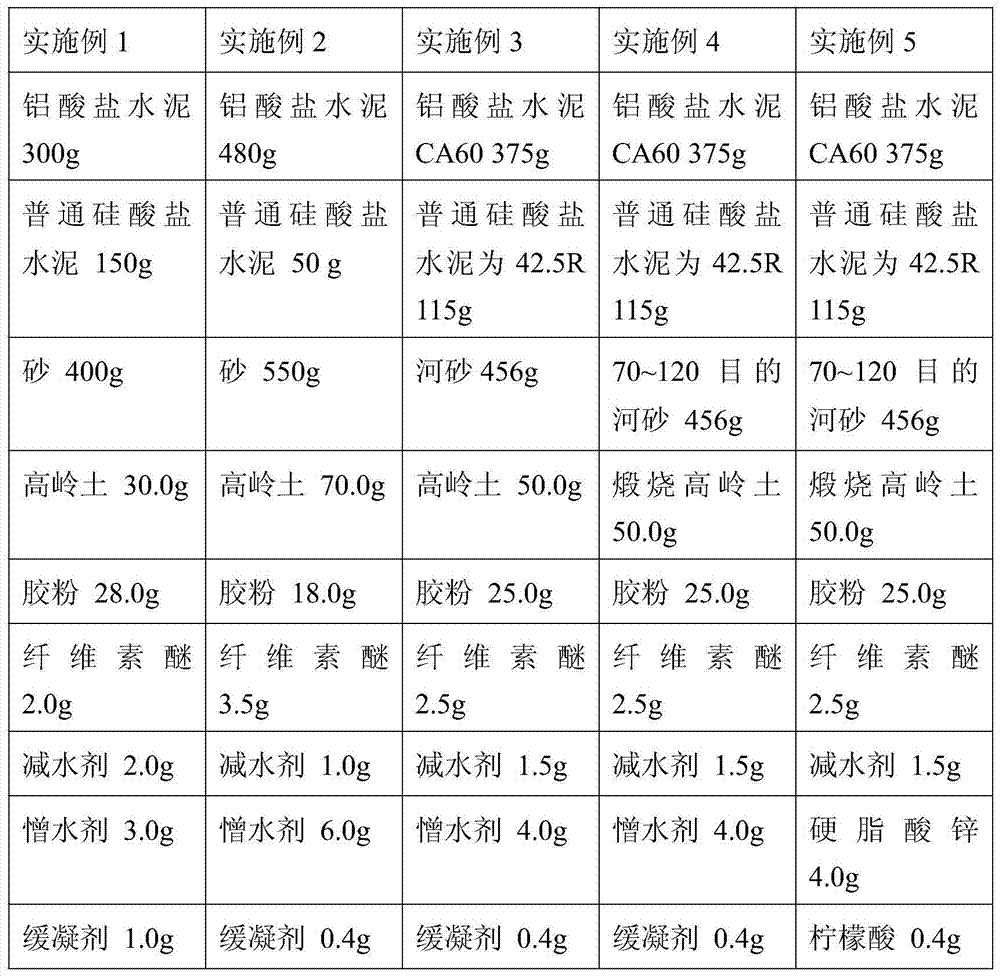

Embodiment 1-5

[0028] Embodiment 1-5, the test items of the joint sealant are tested according to the rapid hardening cement-based joint sealant CG1F in the standard JC / T1004-2006; It can better reflect that the mortar of the present invention can overcome difficulties 3, and especially detect the index of "compressive strength under standard test conditions for 2 hours"; The test results are shown in Table 2.

[0029] Table 2

[0030]

[0031]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Login to View More

Abstract

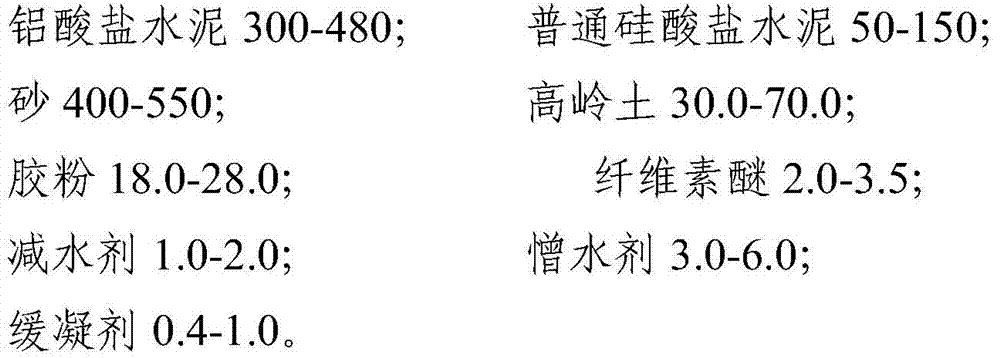

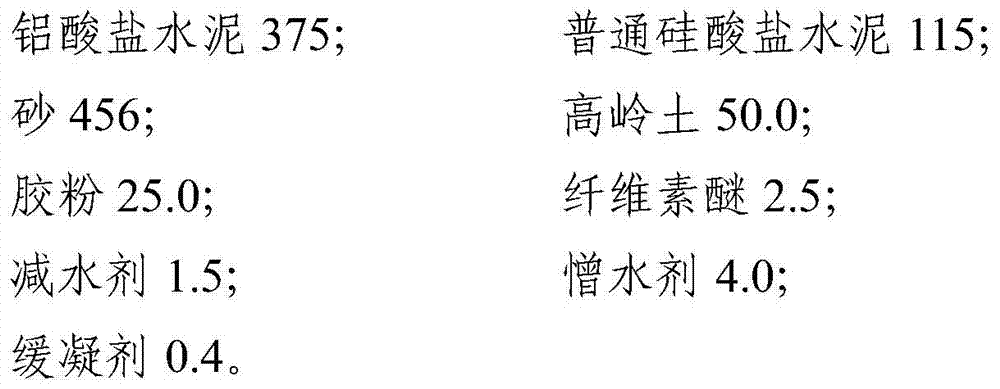

The invention discloses a fast-hardening mortar for bonding and filling joints of sticker paper bricks. The mortar comprises the following components in parts by weight: aluminate cement 300-480; ordinary portland cement 50-150; sand 400‑550; kaolin 30.0‑70.0; rubber powder 18.0‑28.0; cellulose ether 2.0‑3.5; water reducing agent 1.0‑2.0; water repellent 3.0‑6.0; retarder 0.4‑1.0. The rapid-hardening mortar of the present invention has the advantages of high construction efficiency, strong cohesive force, dense and full brick joints, rapid hardening and early strength, etc., and is especially suitable for facing brick veneering projects where sticker paper bricks are used for the veneer.

Description

technical field [0001] The invention relates to a fast-hardening mortar for bonding and filling joints of sticker paper bricks. Background technique [0002] The traditional construction process of sticker paper bricks is to spread the well-mixed wall and floor tile adhesive mortar on the pasting surface of the paper bricks, then stick it on the wall, beat it hard to make it stick to the base wall, and pour the mortar into it. inside the seam. Then fully wet the paper surface with water, observe the filling of the brick joints, and fill the joints where the brick joints are not full. In order to avoid the above-mentioned traditional methods from bringing quality and safety hazards to the entire finishing project, the following four problems must be solved: [0003] 1. In the face brick decoration project, the special mortar for pasting bricks and the special mortar for caulking have their own implementation standards and specific index requirements, and they cannot replace...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C04B28/06

Inventor 张志峰周强詹克志

Owner 奥捷科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com