Patents

Literature

197results about How to "Solve the problem of resource utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

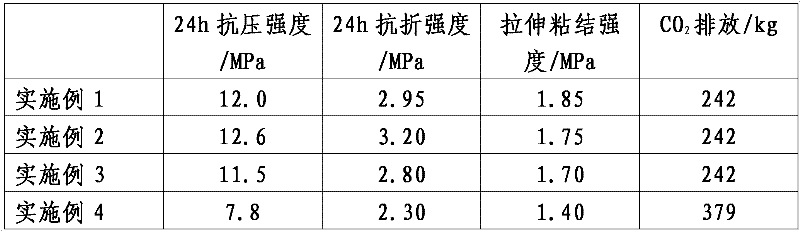

Desulfurization alpha semi-hydrated gypsum self-leveling mortar

The invention belongs to a construction mortar material, and particularly relates to desulfurization alpha semi-hydrated gypsum self-leveling mortar. The conventional cement-based self-leveling motor has the defects of low construction efficiency, low strength, massive cement consumption in mortar and disadvantage to energy conservation and environmental protection. The desulfurization alpha semi-hydrated gypsum self-leveling mortar is prepared by uniformly mixing and stirring the following materials in parts by weight: 40 to 60 parts of desulfurization alpha gypsum, 4 to 6 parts of cement, 20-30 parts of quartz sands of between 40 and 80 meshes, 20 to 30 parts of quartz sands of between 80 and 120 meshes, 0.06 to 0.10 part of retarder, 0.06 to 0.08 part of a water reducing agent, 0.08 to 0.10 part of a water-retaining agent, 0.05 to 0.08 part of a defoaming agent, 2 to 3 parts of re-dispersible gelatin powder, and 22 to 24 parts of water. The desulfurization alpha semi-hydrated gypsum self-leveling mortar has the advantages of high early-stage strength, strong adhesive force with a substrate, no radiation, low emission of CO2, high construction efficiency, and resource utilization of desulfurization gypsum.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD

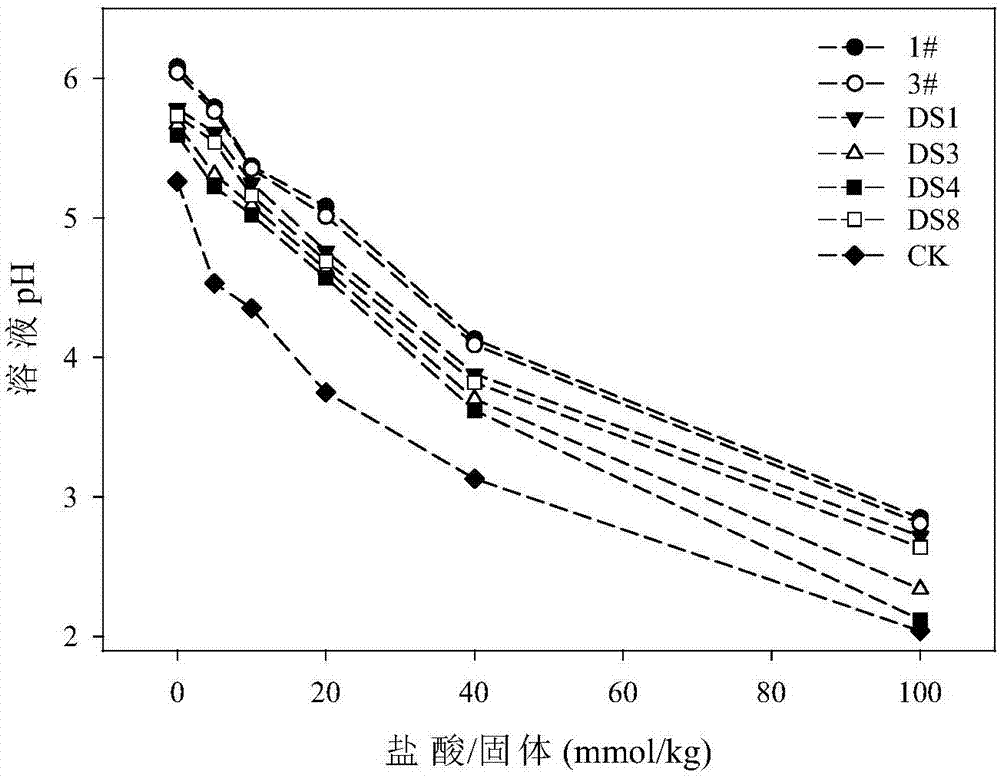

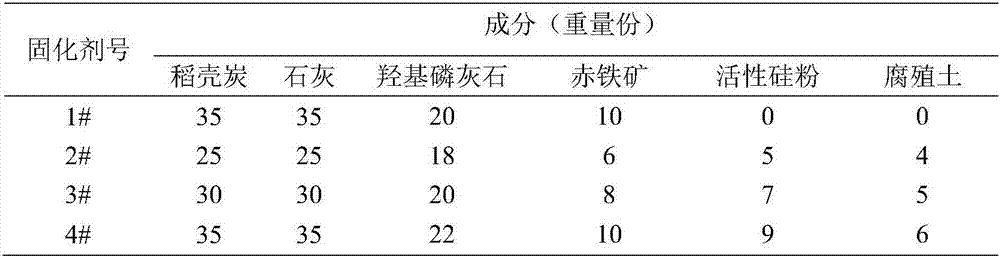

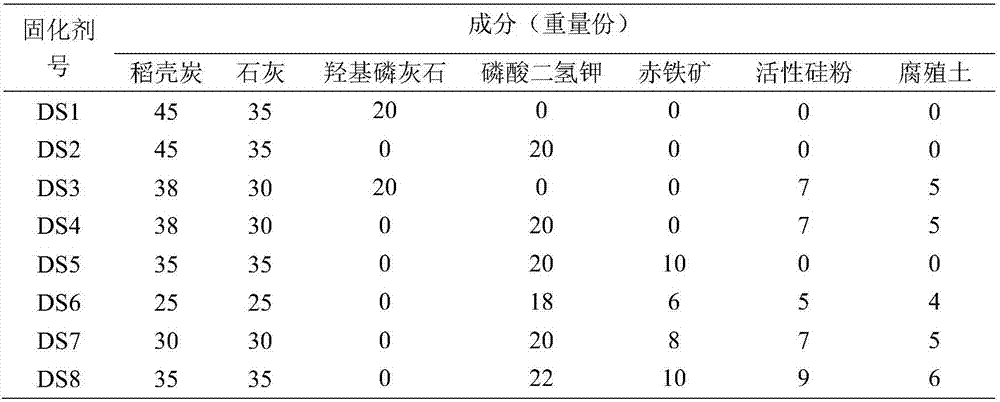

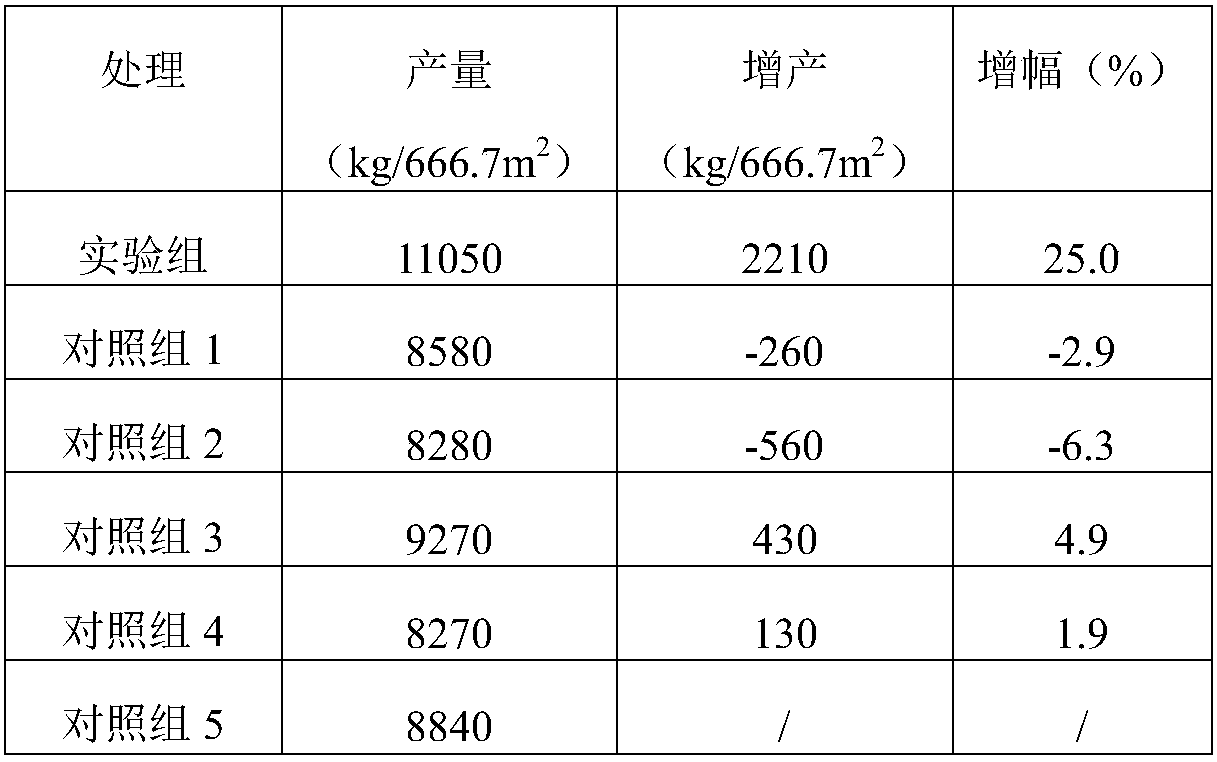

Cadmium (Cd) passivator for acid soil and application thereof

ActiveCN107446589ARaise the pHReduce absorptionAgriculture tools and machinesOther chemical processesEthylic acidBinding state

The invention discloses a cadmium (Cd) passivator for acid soil. The Cd passivator is prepared from the following components of rice hull charcoal, lime, hydroxyapatite and hematite. The Cd passivator for the acid soil, which is provided by the invention, can be used for improving the pH (potential of Hydrogen) of soil and decreasing the content of CaCl2 and ethylic acid extraction state Cd, and is used for promoting the conversion of Cd in the soil from a bioavailable state (an ion exchange state) to a potential available state (a carbonate binding state and a ferromanganese oxide binding state) and an unavailable state (a residue state), reaching the purpose of passivating the activity of the Cd, effectively restoring Cd polluted acid soil, promoting the growth of a plant and decreasing the absorption to the Cd of a crop.

Owner:JIANGXI JIEDI ENVIRONMENTAL TREATMENT & ECOLOGICAL TECH CO LTD

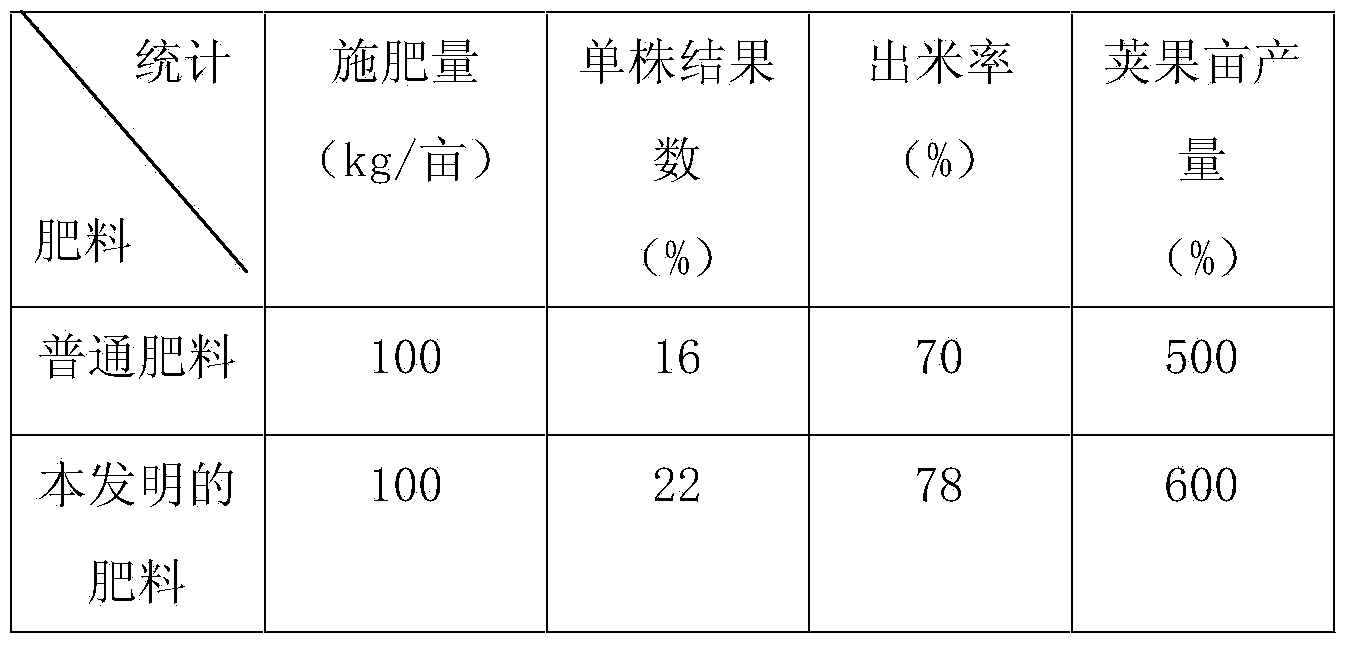

A soil-conditioning type fertilizer and a preparation method thereof

The invention discloses a soil-conditioning type fertilizer. The fertilizer is prepared from following raw materials in parts by weight: 32-36 of rapeseed cake, 22-24 of furfural residue, 20-24 of gypsum, 19-23 of lime, 4-6 of vermiculite, 3-5 of molybdenum tailings, 5-7 of dolomite, 9-11 of diatomite, 7-10 of anthracite, 4-5 of calcium ammonium nitrate, 2-3 of copper sulfate, 1-2 of zinc sulfate, 1-2 of ferrous sulfate, 1-3 of manganese sulfate, 3-6 of a humate, 12-13 of a soil conditioner and a proper amount of water. The rapeseed cake, the furfural residue, and other raw materials are adopted by the soil-conditioning type fertilizer. The raw materials are convenient to take, low in cost and rich in nutrition, and capable of improving the soil structure. The vermiculite has good cation exchange property and absorptivity, and is capable of conditioning the soil structure, enhancing air permeability and water retention of the soil, allowing the acid soil to change into neutral soil, and allowing slow release of the fertilizer in crop growth media. In addition, the vermiculite can provide self-containing K, Mg, Ca and Fe, and trace Mn, Cu, Zn, and other elements for crops. The furfural residue can effectively restore the soil, and overcome pollution of furfural residue solid waste to the environment in the soil restoration process. The furfural residue solid waste is utilized reasonably, thus achieving resource utilization of pollutants. The molybdenum tailings, the dolomite, the diatomite, the anthracite, and other raw materials are added for supplement, thus fully utilizing resources, reducing the production investment and reducing pollution caused by chemical fertilizers.

Owner:MAANSHAN KEBANG ECO FERTILIZER

Coated compound fertilizer and preparation thereof

ActiveCN101462907AExcellent nutrient resistance control functionExcellent S-type nutrient dissolution modeFertilizer mixturesLow-density polyethyleneMineral dust

The invention discloses an S type coated compound fertilizer and a preparation method thereof. The S type coated compound fertilizer comprises compound fertilizer granules and a coating wrapped on the surface of the granulated fertilizer; wherein, the material for preparing the coating comprises the substances based on the mass portion ratio: 15-27 portions of polystyrene foam, 24-30 portions of recovered Polypropylene polymers, 7-20 portions of low density polyethylene, 10-45 portions of inorganic mineral dust and 2-9 portions of starch or modified starch. The S type coated compound fertilizer has an excellent S type nutrient dissolving mode, can control the release time and amount of nitrogen, phosphorus and potassium nutrient in an intelligentized way, and meets different needs of agricultural production such as culture of seedling, contact fertilizer application and one-off application.

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES

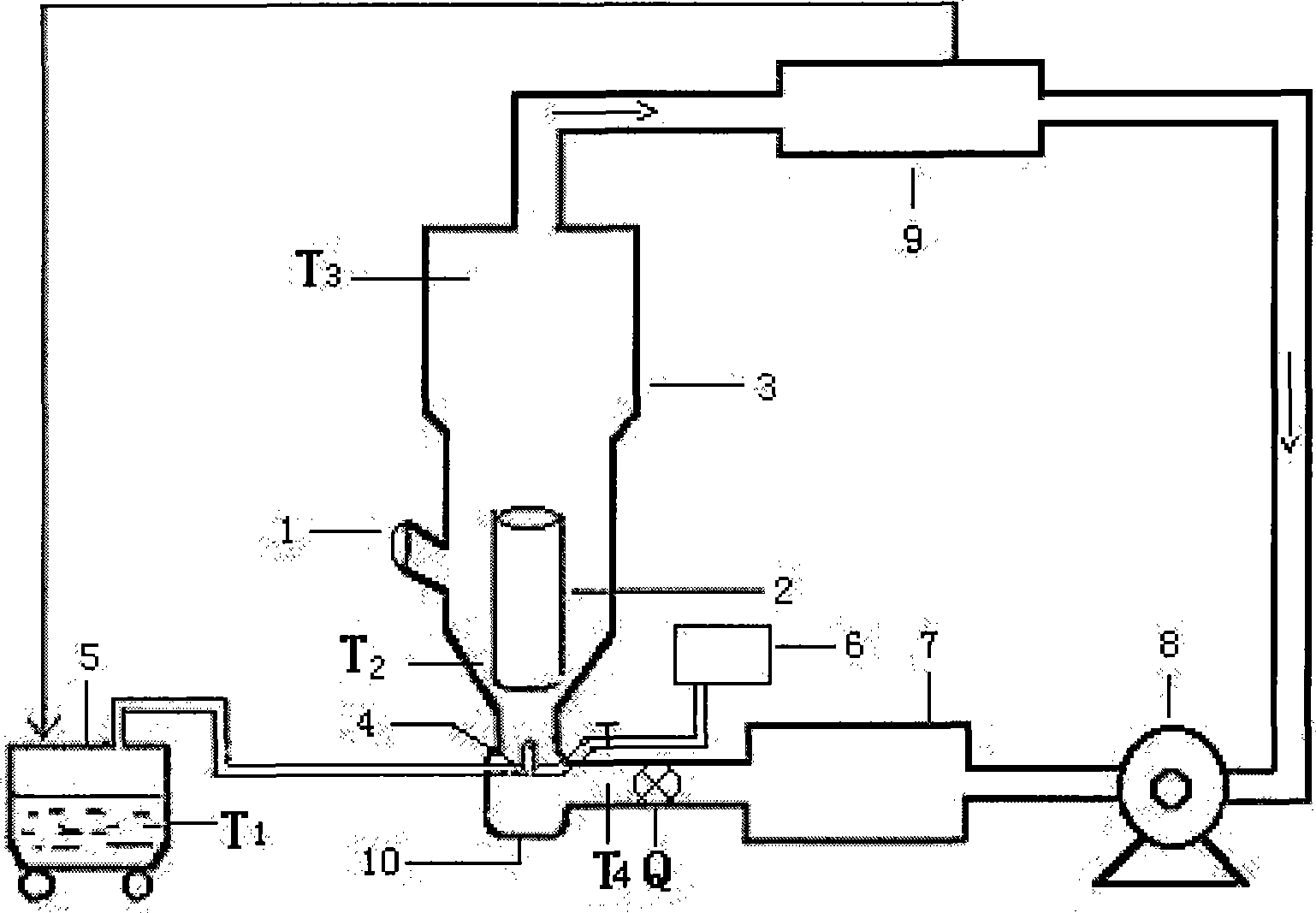

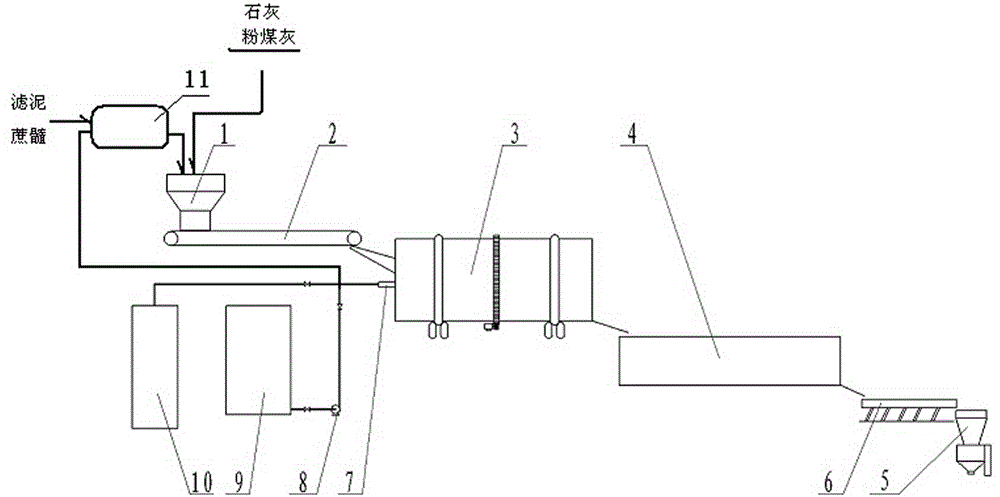

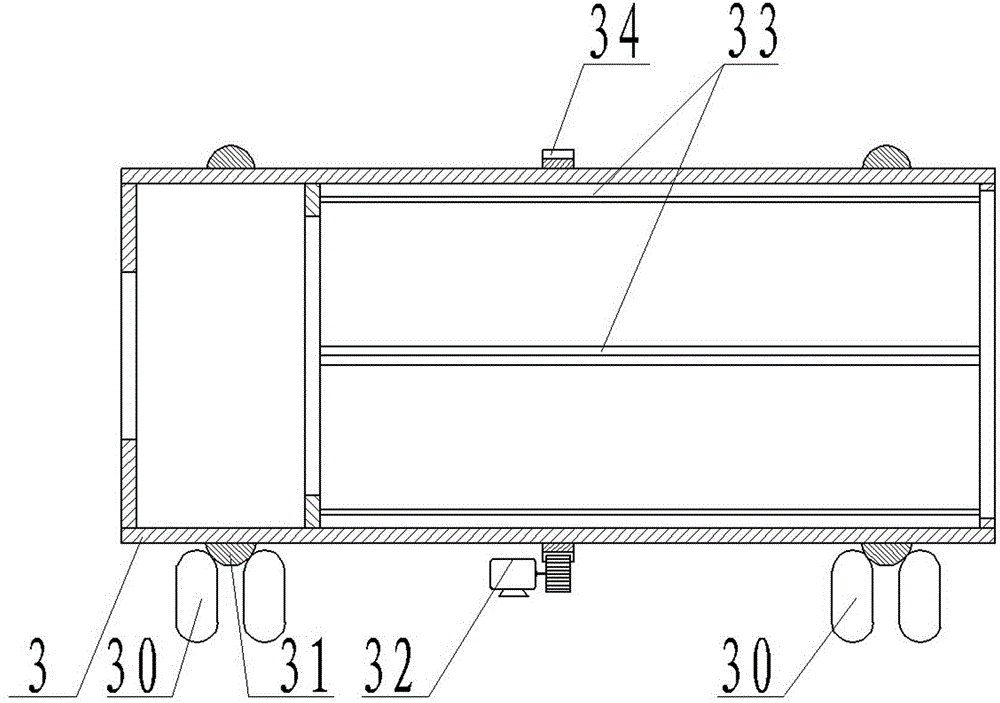

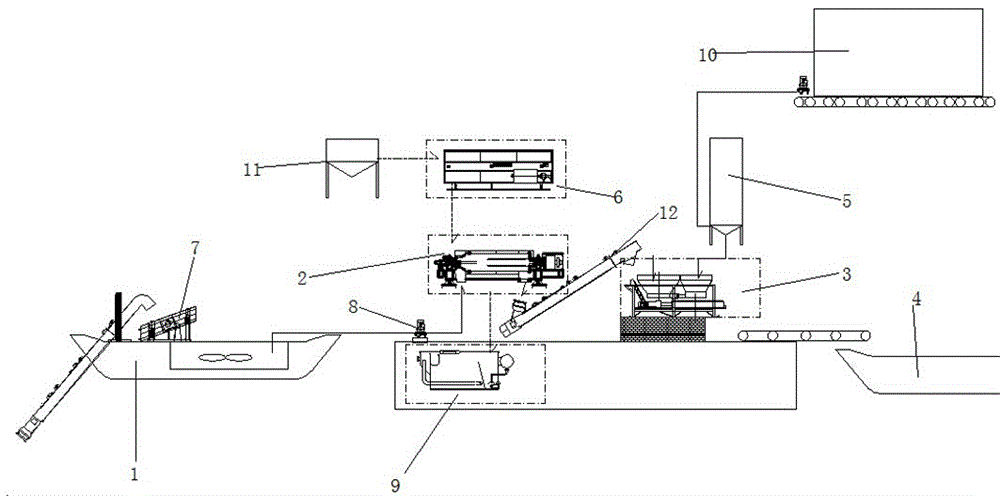

Method and equipment for producing organic mixed fertilizers by comprehensive utilization of wastes in sugar factory

ActiveCN104591869AFertilityRealize cleaner productionCalcareous fertilisersBioloigcal waste fertilisersWater contentScrap

The invention discloses a method and equipment for producing organic mixed fertilizers by comprehensive utilization of wastes in a sugar factory. A method for producing particle fertilizers by utilizing molasses-containing alcohol waste liquid, limes, coal ash, bagasse pith and lime sludge as raw materials comprises the following steps: (1) performing primary mixing on a part of alcohol waste liquid, the lime sludge and the bagasse pith in a pre-mixing device to ensure that the water content is about 50 percent so as to obtain a premix A; (2) putting the premix A, the lime and the coal ash into a feeding hopper to be mixed so as to obtain a premix B; (3) feeding the premix B into a roller-type granulator through a conveyor belt, spraying the molasses-containing alcohol waste liquid by using a spray gun in a rotation process of the roller-type granulator to perform granulation to obtain a granule C; and (4) entering a drying machine to dry at the temperature of 600-800 DEG C, screening after the granule C is dried, and packaging to obtain a product. According to the method and the equipment, the troubled problem of environment pollution caused by alcohol waste liquid in the sugar factory is solved, and the resource utilization purpose in the sugarcane industry is also achieved; the equipment is convenient to operate, low in power consumption and suitable for popularization and utilization in most fertilizer factories; moreover, abundant production cost can be saved for enterprises.

Owner:广西广业贵糖糖业集团有限公司

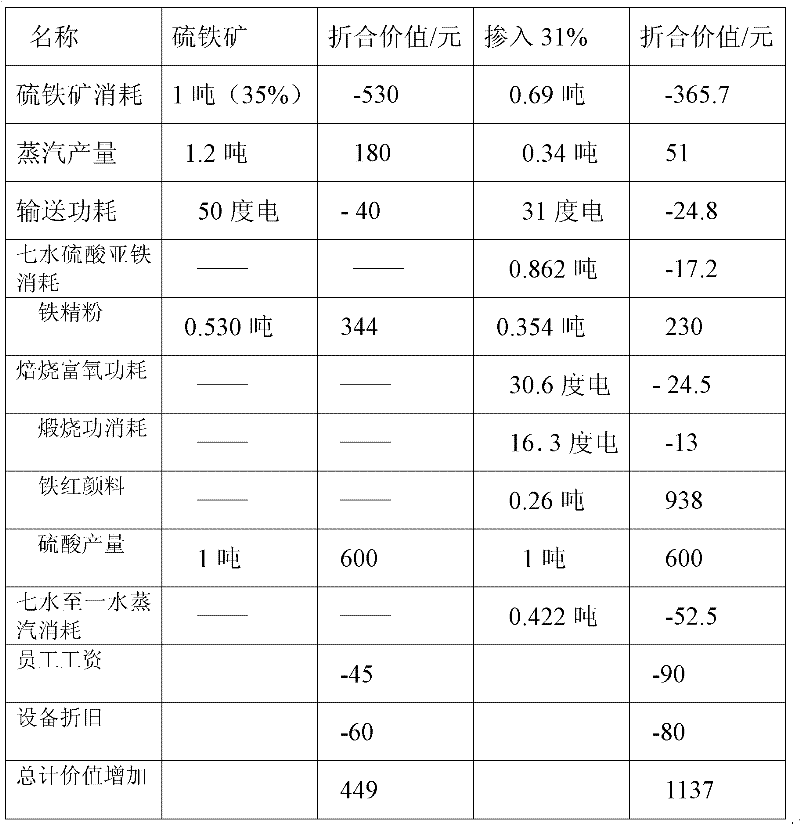

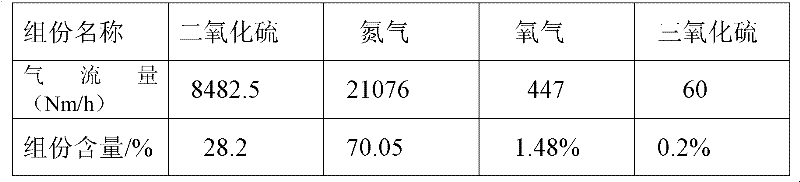

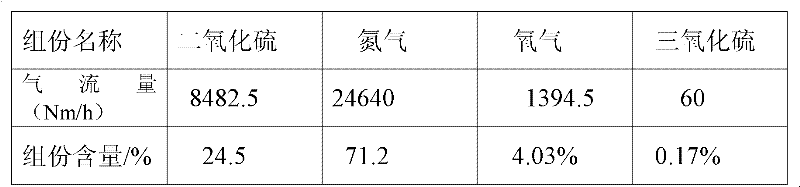

Process for co-producing sulfuric acid, fine iron powder and iron oxide red by ferrous sulfate heptahydrate and pyrite

ActiveCN102344124AIncrease incorporationImprove Pigment PerformanceSulfur compoundsEnergy inputResource utilizationFractionation

The invention provides a process for co-producing sulfuric acid, fine iron powder and iron oxide red by ferrous sulfate heptahydrate and pyrite and relates to the process technology of resource utilization of titanium dioxide byproduct solid waste ferrous sulfate. The process comprises the following steps: adopting titanium dioxide byproduct ferrous sulfate heptahydrate and pyrite as raw materials; increasing the mixing amount of the ferrous sulfate heptahydrate as much as possible through transforming the ferrous sulfate heptahydrate into ferrous sulfate monohydrate, oxygen-enriched roasting, preheating air in front of a furnace, controlling the sulfur content of the pyrite entering the furnace and the moisture and other technical means; and realizing the integrated co-production of the sulfuric acid, the fine iron powder and iron oxide red pigments through cinder fractionation, oxygen-enriched calcining and other process technologies. The process effectively improves the economic value of the heptahydrate ferrous sulfate and has an important significance on efficient and comprehensive utilization of the titanium dioxide byproduct solid waste ferrous sulfate heptahydrate.

Owner:HUNAN HENGGUANG TECH

Vegetable straw microbial organic fertilizer and preparation method thereof

PendingCN107721761AEnsure nutritional needsImprove aggregate structureBio-organic fraction processingGas production bioreactorsMicroorganismMicrobial agent

The invention relates to vegetable straw microbial organic fertilizer. The vegetable straw microbial organic fertilizer comprises the following components in parts by weight: 60 to 90 parts of vegetable straw, 0.1 to 0.2 part of urea, 10 to 20 parts of inoculums, 20 to 30 parts of turfy soil, and 0.5 to 1.0 part of a microbial agent. The vegetable straw is crushed and is then mixed with the urea and inoculums according to certain ratio, and short time high-temperature anaerobic biogas fermentation is performed. The mixture is mixed with the turfy soil after fermentation, and aerobic compostingis performed. The microbial agent is added at the later stage of composting, and composting is performed continuously for a certain time, so that the vegetable straw microbial organic fertilizer is obtained. The vegetable straw microbial organic fertilizer contains various microorganisms helpful for promoting the growth of plants, improving soil, eliminating peculiar smell and restraining harmfulbacteria, and can greatly improves the added value of products. The vegetable straw microbial organic fertilizer takes vegetable straw which is rich in resources in vegetable industry concentration areas and huge in storage as the main material, is clear and intelligible in technical process, does not pollute the environment, is good in product fertilizer efficiency and high in additional value,and can effectively solve the problems of harmless treatment and resource utilization of vegetable straw. The vegetable straw microbial organic fertilizer has a wide popularization prospect in vegetable industry concentration areas, and has good ecological and economic value.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI

Phosphogypsum-based lightweight plastering gypsum product

The invention relates to a phosphogypsum-based lightweight plastering gypsum product. The phosphogypsum-based lightweight plastering gypsum product is prepared from the following components: phosphogypsum powder, an alkaline agent, aggregate, a retarder, a thickner and a water-retaining agent. The phosphogypsum-based lightweight plastering gypsum product provided by the invention has the advantages of light weight and high strength, capability of being firmly bonded with a base layer, no cracking, no hollowing and no odor; the phosphogypsum-based lightweight plastering gypsum product is suitable for indoor plastering construction in winter, has moisture absorption and moisture exhaust functions, and is fireproof and incombustible and the like; the phosphogypsum-based lightweight plasteringgypsum product is an excellent material for indoor plastering and has a good application prospect.

Owner:宁波荣山新型材料有限公司

Gel material for filling worked out section by vanadium-titanium-containing slags

The invention discloses a gel material for filling a worked out section by vanadium-titanium-containing slags. The gel material comprises the following components in percentage by weight: 8-11% of an alkaline excitant, 14-16% of desulfurized gypsum and 71-77% of vanadium-titanium slags. The gel material further can comprise 1-2% of mirabilite as an early strength agent. The invention discloses filling slurry prepared from the gel material, full mill-tailing filler and tap water at the same, wherein the weight ratio of the gel material to the full mill-tailing filler is (1:15)-(1:4), and the percentage by weight of the tap water is 22-32%. The gel material disclosed by the invention realizes resource utilization of vanadium-titanium-containing slags and reduction of stacking of solid residues on the surface, and the filling cost of the worked out section of a mine is greatly reduced. Meanwhile, the filling body prepared has high strength.

Owner:JINCHUAN GROUP LIMITED +1

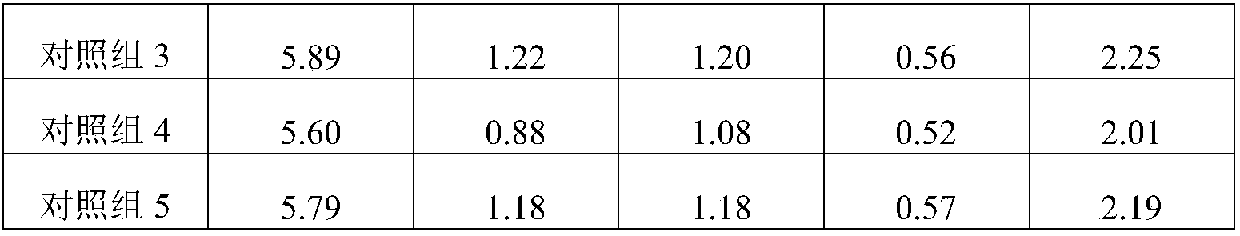

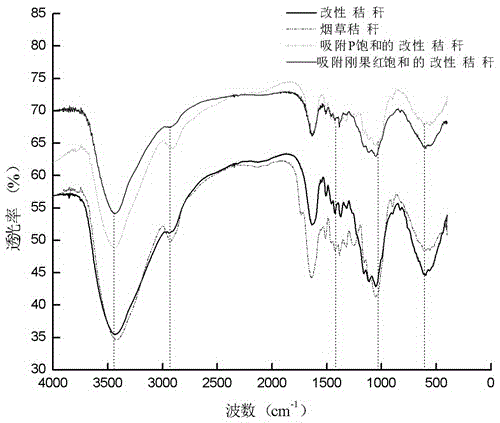

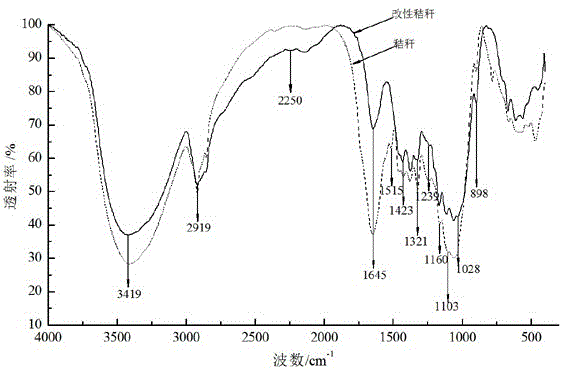

Method for treatment of anionic pollutant containing wastewater with modified tobacco straw

InactiveCN105056902AImprove adsorption capacityImprove abilitiesOther chemical processesWater/sewage treatment by sorptionFiberCellulose

Belonging to the technical field of water treatment in water pollution control, the invention specifically relates to a method for treatment of anionic pollutant containing wastewater with modified tobacco straw. The method includes: employing organic-inorganic cationic monomer graft copolymerization to perform straw fiber modification, firstly pretreating tobacco straw with a sodium hydroxide solution to separate straw cellulose, then under an N2 protection environment, using ceric ammonium nitrate as the initiator, subjecting the pretreated tobacco straw and dimethyl diallyl ammonium chloride, aluminum sulfate to graft copolymerization reaction so as to prepare a novel straw modified material, then using the modified material to remove organic anionic pollutants and inorganic anionic pollutants from water respectively, thus finally realizing treatment of anionic pollutants in wastewater.

Owner:SICHUAN AGRI UNIV

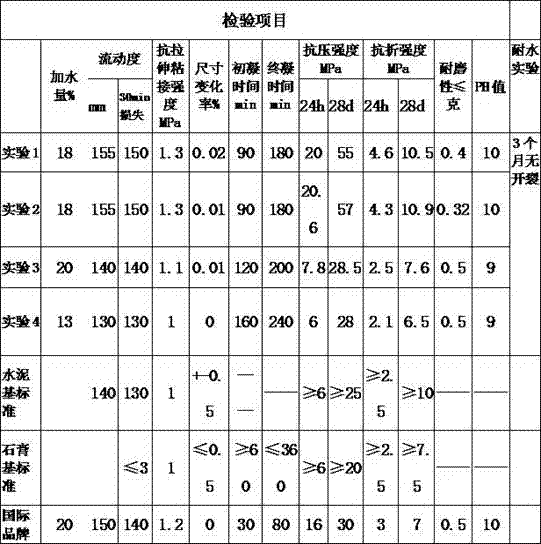

Novel self-leveling mortar and production technology thereof

The invention relates to novel self-leveling mortar and a production technology of the mortar. The mortar comprises the following components in percent by weight: 3-60% of modified cement, 10-66% of modified semi-hydrated gypsum, 0.1-8% of fly ash, 0.07-1.5% of a cement modifier, 0.05-1.5% of a gypsum modifier, 0.04-0.8% of a thickening time control agent, 0.01-0.1% of an anti-swelling agent, 0.01-0.2% of a stabilizer, 0.01-0.2% of a defoaming agent, 0.2-0.4% of toner, 0.05-0.13% of a smoother and 30-86% of aggregates. According to the novel self-leveling mortar, natural semi-hydrated gypsum and industrial solid gypsum are modified, and then subjected to modification and compounding with the fly ash and the cement to form a novel building material; a novel product which is better in production leveling property, higher in tensile strength, higher in compressive strength, adjustable in setting time, higher in construction efficiency, wide in application scope, low in cost and cracking-resistant is realized.

Owner:刘少伟

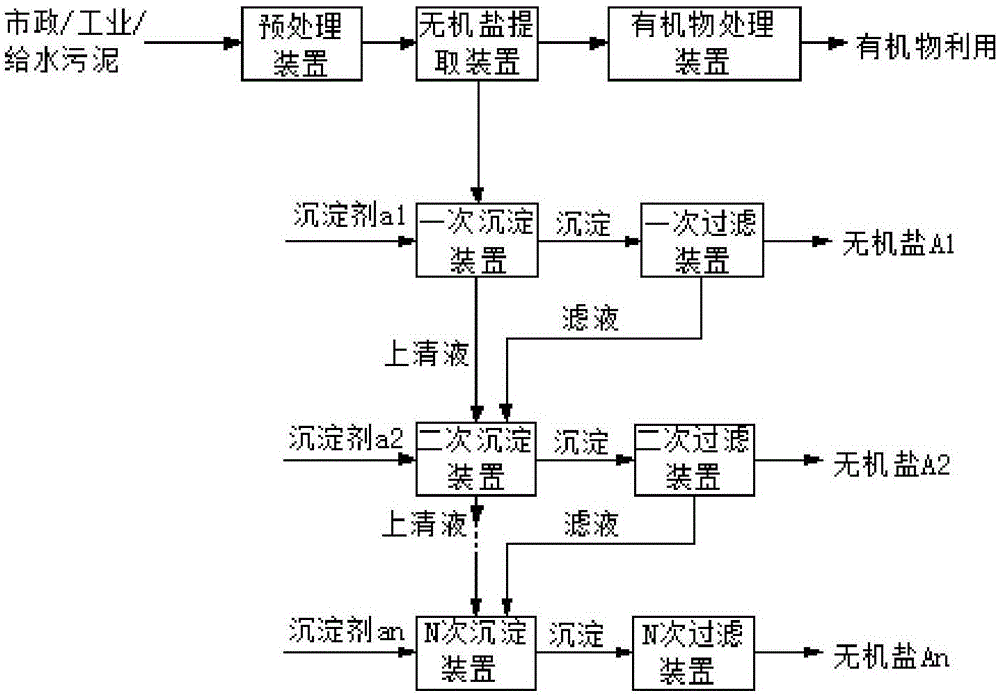

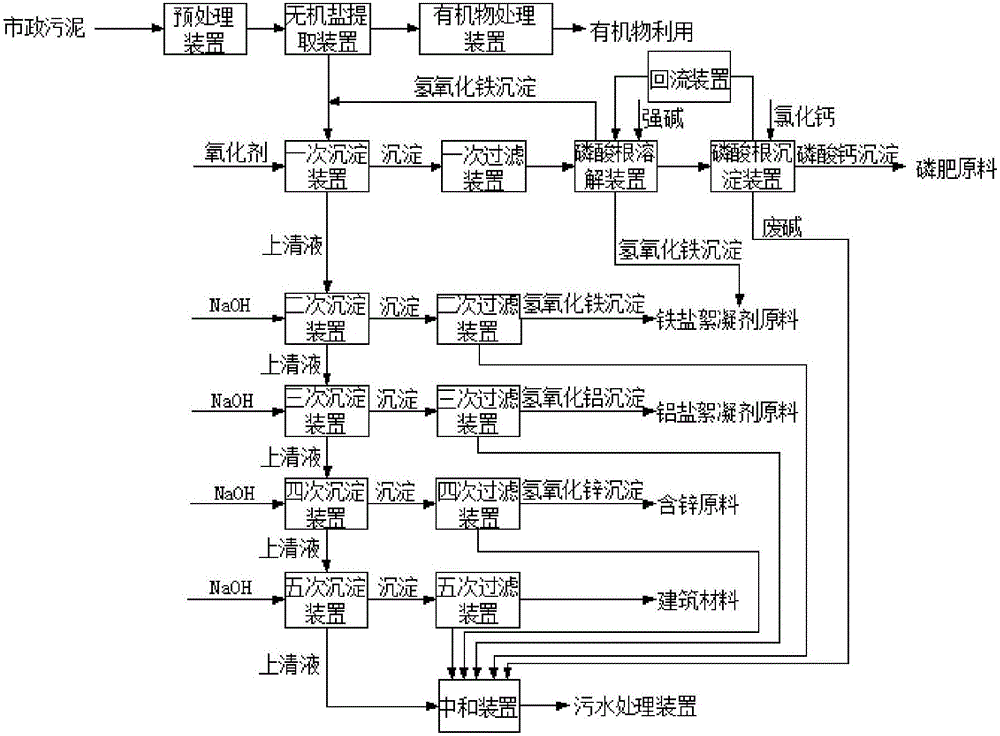

Method and device for respectively extracting and using inorganic matters in sludge

InactiveCN106007292ALow impurity contentHigh puritySludge treatmentLead hydroxidesInorganic saltsResource utilization

The invention provides a method for respectively extracting and using inorganic matters in sludge, and belongs to the technical field of sludge treatment. The method comprises the following steps: (1) pretreating the sludge; (2) extracting inorganic salt from a sludge solution subjected to pretreatment; (3) adding a precipitant a1 into the inorganic salt extracting solution obtained in the step (2) till precipitates are separated, and forming inorganic salt A1 for recycling; (4) adding a precipitant a2 into precipitate-removed supernate in the step (3) till precipitates are separated, and forming inorganic salt A2 for recycling; (5) by parity of reasoning, adding a precipitant an into the precipitate-removed supernate in the former step till precipitates are separated, forming inorganic salt An for recycling. According to the method, the inorganic matters in the sludge are respectively recycled, so that weight reduction for the sludge is realized, and resource utilization of the sludge is also realized; the method is simple in process, high in applicability, simple and convenient to operate, easy to control, low in operating cost, good in treatment effect, wide in application range and easy to popularize and use.

Owner:TIANJIN ENEW ENVIRONMENTAL PROTECTION ENGCO LTD

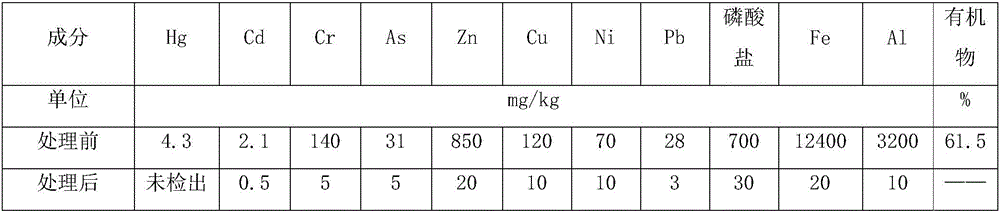

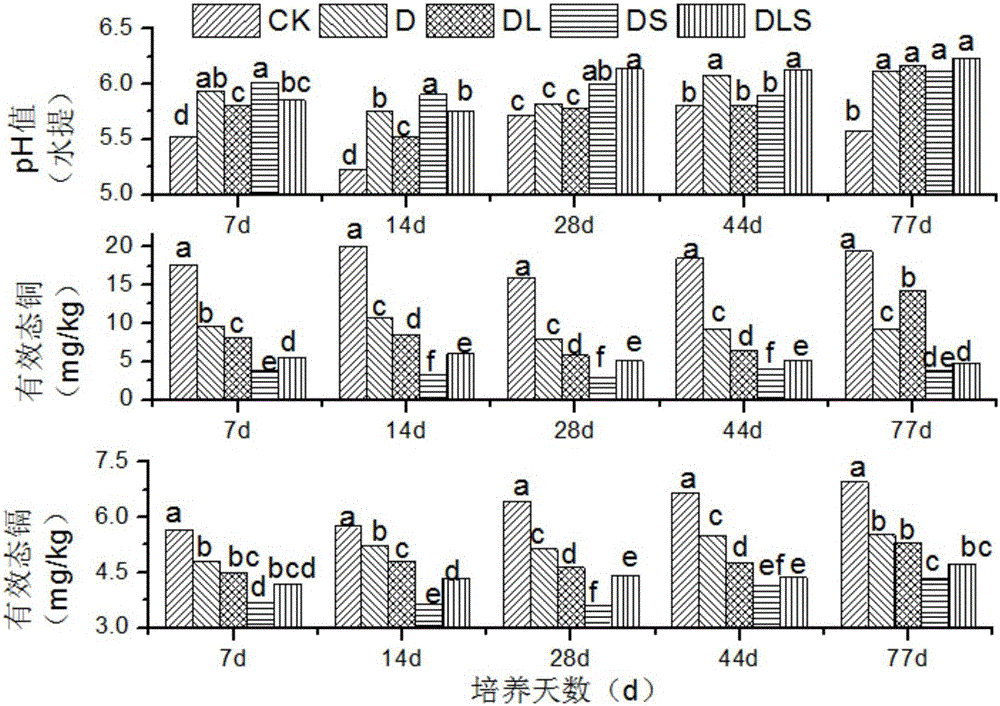

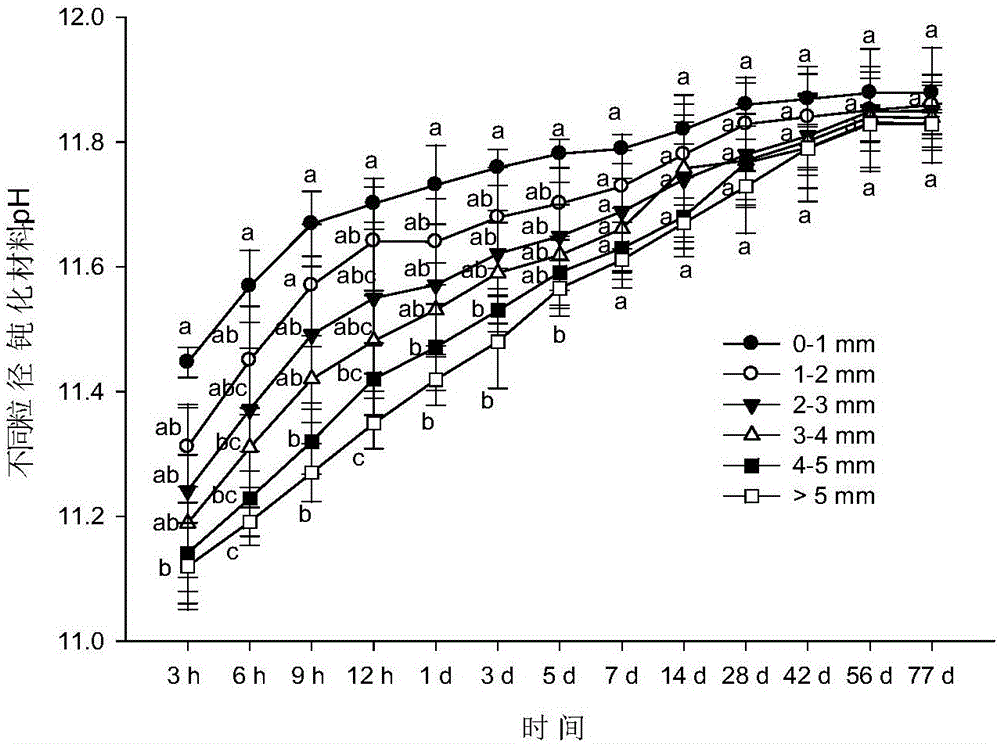

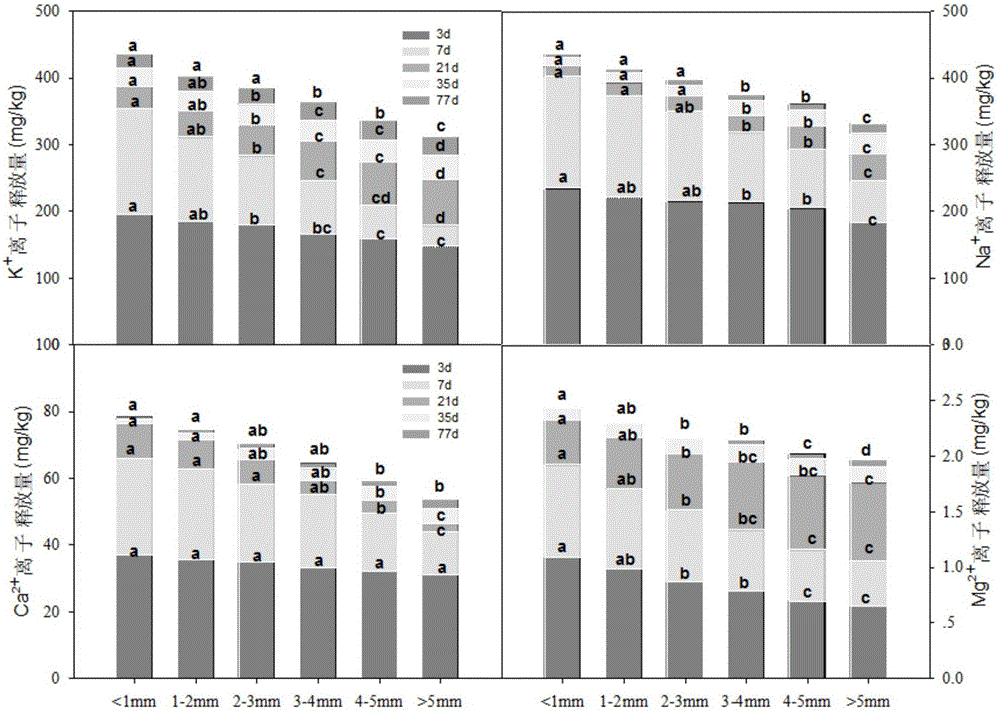

Passivation material capable of repairing cadmium and copper-polluted acidic soil as well as preparation method and application of passivation material

ActiveCN105670636AWide variety of sourcesEasy accessAgriculture tools and machinesOther chemical processesEconomic benefitsColloid

The invention provides a passivation material capable of repairing cadmium and copper-polluted acidic soil as well as a preparation method and application of the passivation material. The pH value of the passivation material is 10 to 13; the passivation material is prepared from the following raw materials in percentage by mass: more than or equal to 60 percent and less than or equal to 85 percent of biomass power plant ash, more than or equal to 10 percent and less than or equal to 25 percent of lime, and more than or equal to 5 percent and less than or equal to 15 percent of phosphorus lime. The passivation material takes the green and cheap biomass power plant ash as the main raw material, the biomass power plant ash is mixed with the lime and the phosphorus lime, any binding agent or a colloid auxiliary material is not added, and spherical grains are prepared; the granulation rate of the raw materials is more than 95 percent and the material returning rate is low. Negative influences of the auxiliary materials including the binding agent and the like can be avoided, and a raw material washing phenomenon is avoided; the application amount of the passivation material is less and only occupies 0.2 percent to 0.6 percent of the mass of soil of a plough layer; a heavy metal passivation effect is remarkable and stable, and the growth of plants is accelerated, so that the aim of efficiently and lastingly repairing the heavy metal cadmium and copper-polluted acidic soil in situ at a low cost is realized, and economic benefits, ecological benefits and a repairing effect are integrated.

Owner:INST OF SOIL SCI CHINESE ACAD OF SCI

Method for preparing soil conditioner from molasses alcohol waste liquor

ActiveCN104449743ASolve pollutionSolve the problem of resource utilizationFungiAgriculture tools and machinesLiquid wasteAlcohol

The invention provides a method for preparing a soil conditioner from molasses alcohol waste liquor. The method comprises steps as follows: Step A: the molasses alcohol waste liquor is concentrated to comprise 38%-51% of organic matters in percentage by mass concentration and comprise 0.84-1.98 g / kg of P, 35.12-90.93 g / kg of K, 5.55-39.90 g / kg of Ca, 1.02-70.31 g / kg of Mg and 16.52-50.40 g / kg of N, wherein the pH ranges from 4.2 to 5.1, and the Brix of the concentrated liquor ranges from 35 to 50; Step B: fermentation strains are screened, that is, bacillus subtilis, streptomyces jingyangensis and saccharomyces cerevisiae are selected; Step C: leaven is produced (for the fermented and concentrated alcohol waste liquor); Step D: the leaven is added to the concentrated molasses alcohol waste liquor for fermentation, and the soil conditioner is obtained. According to the method for preparing the soil conditioner from the molasses alcohol waste liquor, organic waste produced in the sugarcane industry is recycled.

Owner:SUGARCANE RES INST GUANGXI ACADEMY OF AGRI SCI

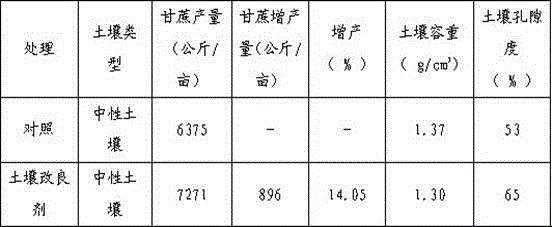

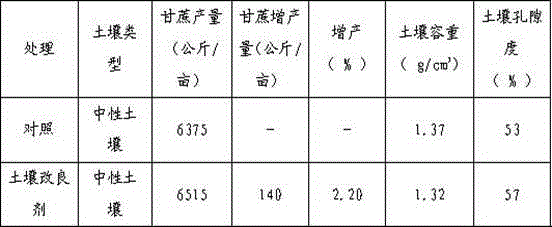

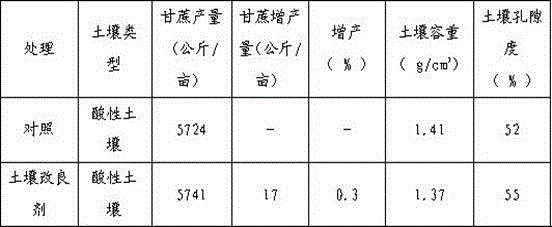

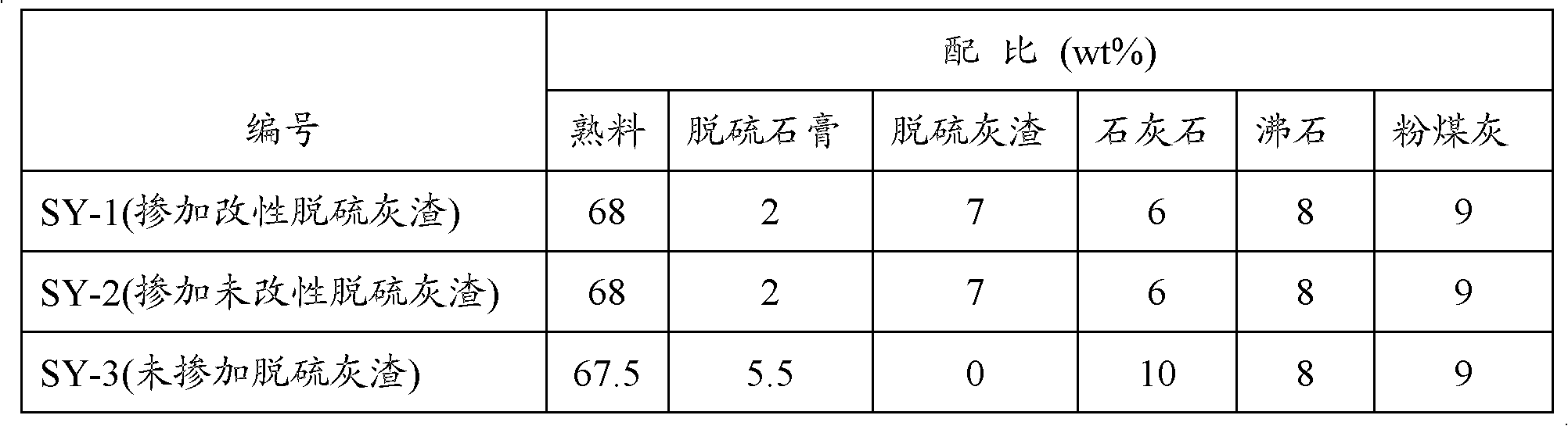

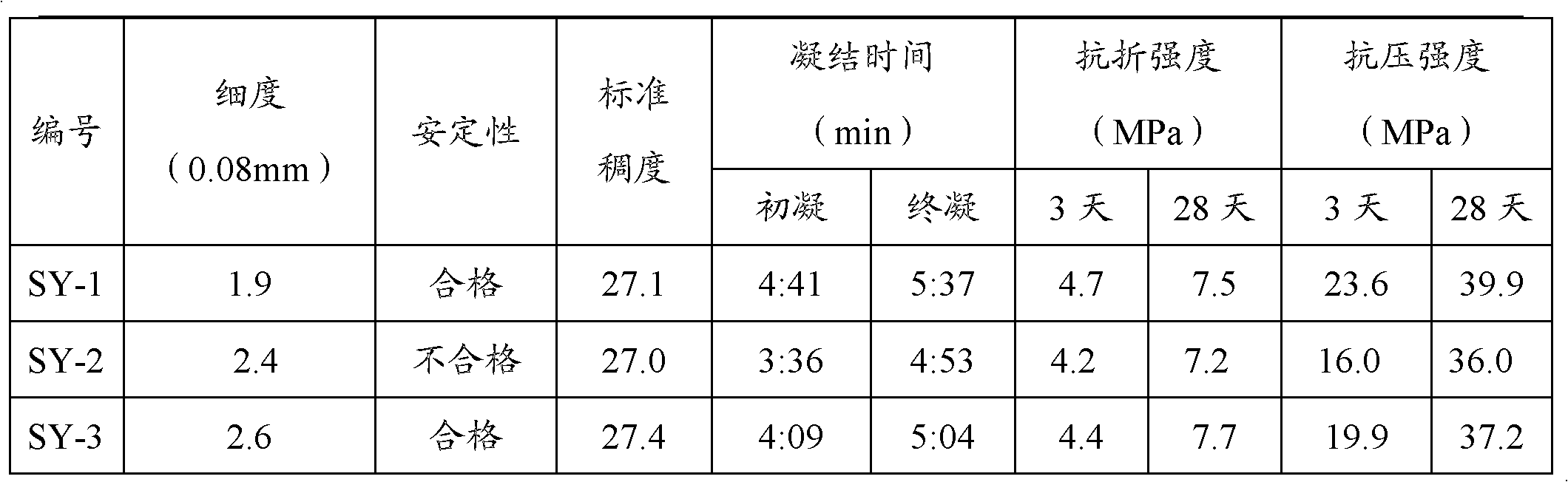

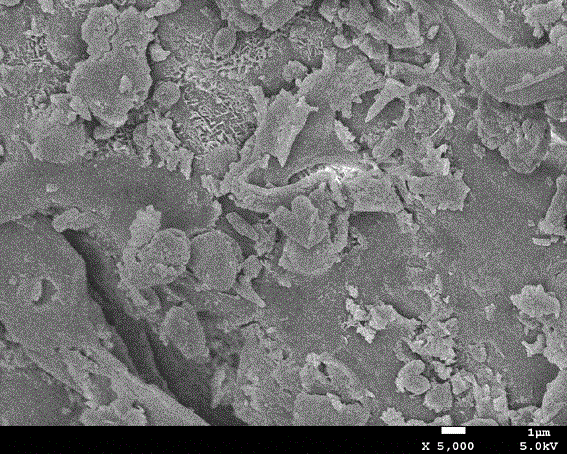

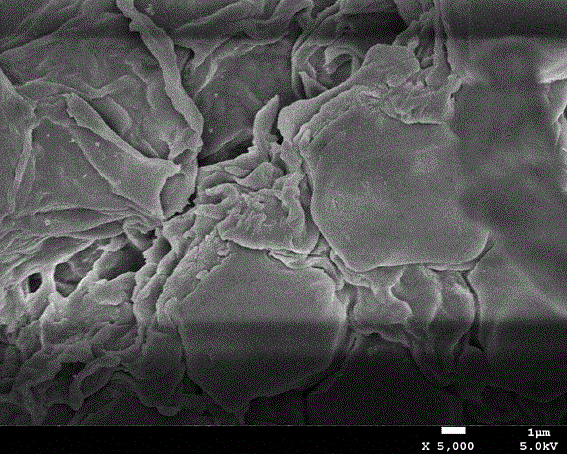

Method for preparing modified desulphurized ash

InactiveCN102153301ASolve the problem of resource utilizationEliminate the problem of bad stabilitySolid waste managementResource utilizationRoom temperature

The invention discloses a method for preparing a modified desulphurized ash. The method comprises the steps of first adding water to the desulphurized ash to be sufficiently mixed so that the water content of the desulphurized ash reaches 20-40 wt%; and placing the desulphurized ash for 20-40 days at a room temperature and at a humidity of 70-100% so as to obtain the modified desulphurized ash, wherein the content of free carbon oxide in the modified desulphurized ash is less than 5%. In the invention, the desulphurized ash is first pre-treated and modified and then the modified desulphurized ash is applied to cement production to eliminate the problem of bad cement soundness brought by doping the dry desulphurized ash into the cement, and thus the preparation method effectively solves the resource utilization difficulty of the desulphurized ash at present, reduces clinker consumption and production cost, saves energy and reduces emission.

Owner:广州市越堡水泥有限公司

A method of treating dye wastewater by using modified straw

InactiveCN104310559BImprove cohesionStrong decolorization abilityWaste water treatment from textile industryWater/sewage treatment by flocculation/precipitationDyeing wastewaterPre treatment

The invention belongs to the technical field of water treatment in water pollution prevention and control, and relates to the treatment of dye wastewater, in particular to a method for treating dye wastewater by utilizing modified straws. The method comprises the following steps of performing straw modification by virtue of a two-step method, namely pre-treating rice straws by virtue of sodium hydroxide, and performing modification reaction on the pre-treated rice straws and tetradecyl trimethyl ammonium chloride; removing orange yellow II, methylene blue and eriochrome black T dyes from a water body to finally realize the treatment of the dye wastewater by virtue of the modified straws. The modified rice straws and tetradecyl trimethyl ammonium chloride are subjected to mixed reaction according to a mass ratio of 1:1 to 1:1.5; the content of sodium hydroxide is 10 to 30 mass percent. According to the technical scheme, the good coagulation effects, high decolorization capability and convenience in use are achieved, and the cost is lowered; agricultural straws can be recycled, and meanwhile, the dye wastewater can be decolored.

Owner:SICHUAN AGRI UNIV

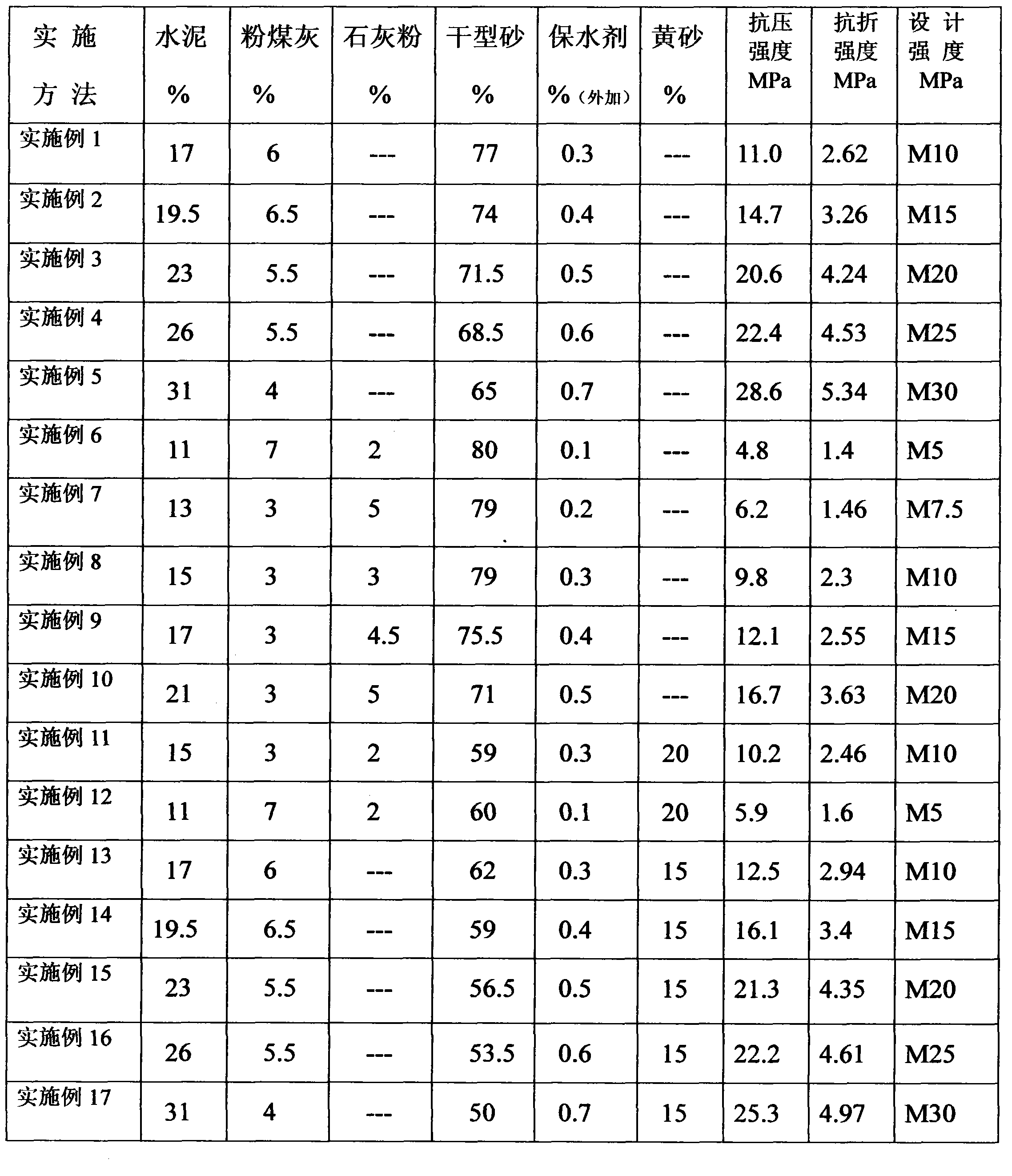

Waste foundry sand dry-mixed mortar

The invention relates to a waste foundry sand dry-mixed mortar, belonging to the technical field of circular economy and building material mortar. The waste foundry sand dry-mixed mortar is characterized in that the production raw materials of the dry-mixed mortar are based on waste foundry sand with the following mass ratio: 11-31% of cement, 3-7% of dry coal ash, 0-5% of dry lime powder, 50-80% of dry waste foundry sand, 0-20% of yellow sand (with particle diameter between 2.36mm and 1.18mm), and 0.1-0.6% of water retaining agent (additionally added). The varieties of the dry-mixed mortar prepared according to the invention comprise various types of dry-mixed masonry mortar, dry-mixed plastering mortar, dry-mixed terrace mortar and the like which all meet the requirements of national standard GB / T25181 Ready Mixed Mortar. The waste foundry sand dry-mixed mortar is beneficial for the harmless treatment and resource utilization of the waste foundry sand, and opens up a brand-new resource regeneration way of the waste foundry sand.

Owner:秦大春

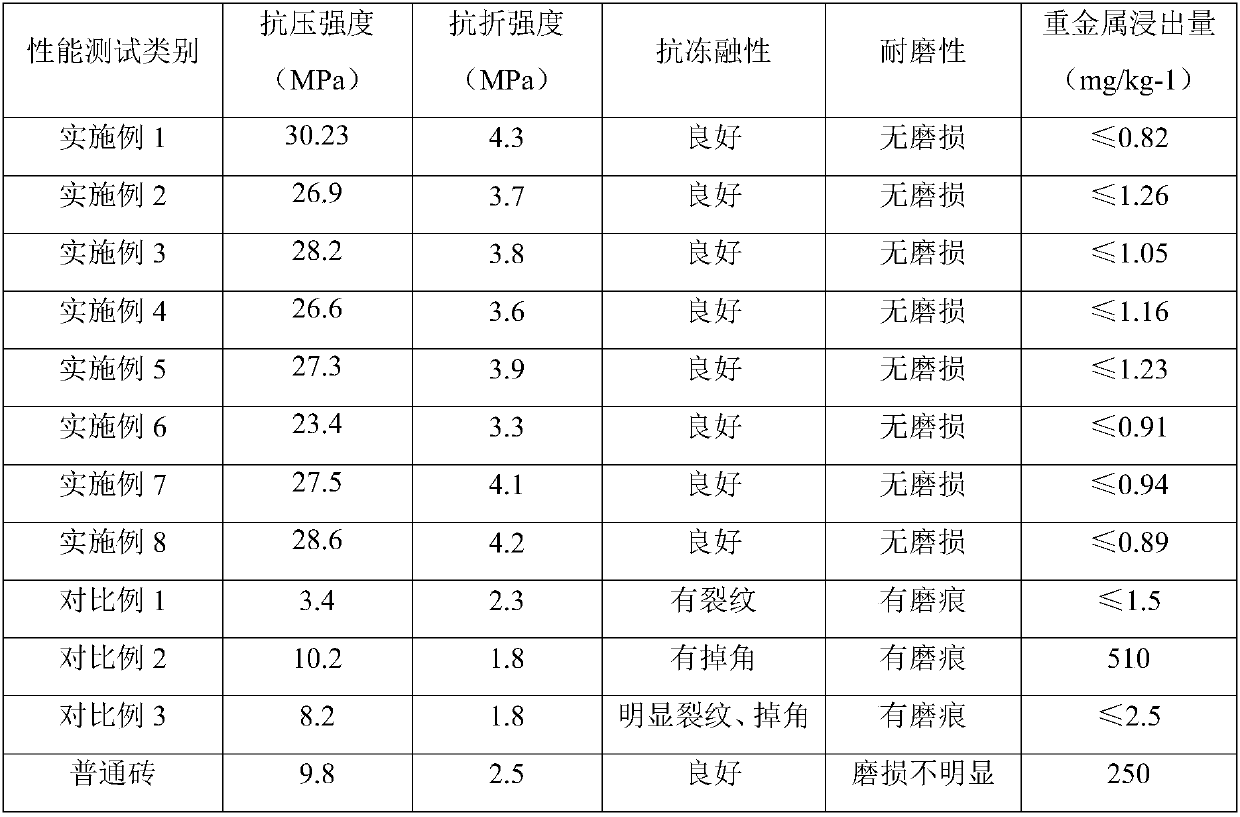

Sludge/mud environment-friendly type baking-free bricks and preparation method thereof

ActiveCN107602041AReduce manufacturing costImprove production efficiencySolid waste managementCoal gangueBrown iron oxide

The invention discloses sludge / mud environment-friendly type baking-free bricks. The sludge / mud environment-friendly type baking-free bricks are prepared from the following raw materials in percentageby weight: 30 percent to 60 percent of waste mud, 5 percent to 25 percent of rough sand, 5 percent to 25 percent of silicon aluminum calcium iron oxide, 2 percent to 20 percent of mountain flour, 2 percent to 20 percent of quicklime and 2 percent to 20 percent of gypsum, wherein the waste mud is sludge or / and mud; the silicon aluminum calcium iron oxide is one or a mixture of more of fly ash, fine coal slag, mineral slag powder and coal gangue. According to the sludge / mud environment-friendly type baking-free bricks disclosed by the invention, resource utilization of the sludge / mud can be realized; the raw material composition is simple and the cost is low; the product has the characteristics of high bending strength and compressive strength, good wearing resistance, strong freezing and thawing resisting capability and the like through the optimization of the raw material ratio; the leaching rate of heavy metal in the baking-free bricks is relatively low, and the baking-free bricks have no odor and are environmentally friendly and safe, so that large-scale batch production is easy to realize; the baking-free bricks can be applied to the fields of engineering construction includingmunicipal plaza pavement, sidewalk pavement, hydraulic engineering protection slopes and the like.

Owner:武汉鹏森环境科技有限公司

Nano cellulose extracted from shuck of xanthoceras sorbifolia and extraction method

ActiveCN103821021ASolve the problem of resource utilizationEfficient use ofPaper material treatmentWax removalHydrogen peroxide

The invention relates to a method for extracting nano cellulose from shuck of xanthoceras sorbifolia, which comprises the steps of alkali treatment, wax removal treatment, lignin removal treatment and hydrolysis. The method comprises the following steps: immersing the crushed shuck of xanthoceras sorbifolia, washing to neutrality and drying; immersing the product in a mixed solution of toluene and ethanol, heating and keeping for a while, cleaning the residues by ethanol and drying; placing in a mixed solution of hydrogen peroxide and acetic acid, stirring and keeping for a while under heating condition, flushing the residues after a reaction is finished, pumping filtration until a filtrate presents neutral; heating the product in a sodium hydroxide solution, heating and reacting, pumping filtration and flushing until the filtrate presents neutral and then drying; adding in a sulfate solution, stirring and keeping for a while under heating condition, adding deionized water in a reaction container; placing the obtained fluid suspension in a high speed centrifuge for multitime separation, adding an aqueous alkali drop by drop for neutralizing if the fluid suspension is acidic, and finally drying through a freezing mode to obtain the nano cellulose powder extracted from shuck of xanthoceras sorbifolia.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

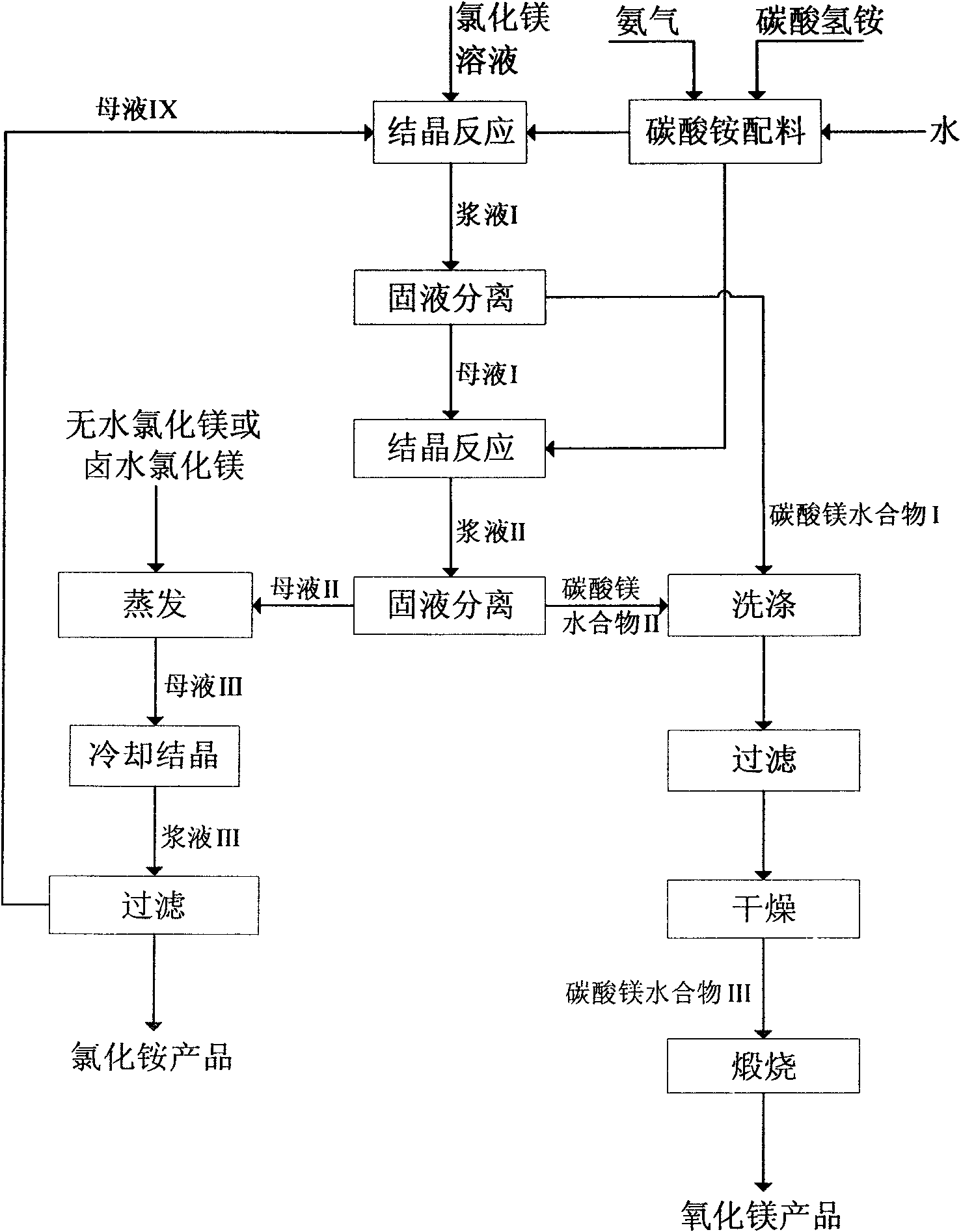

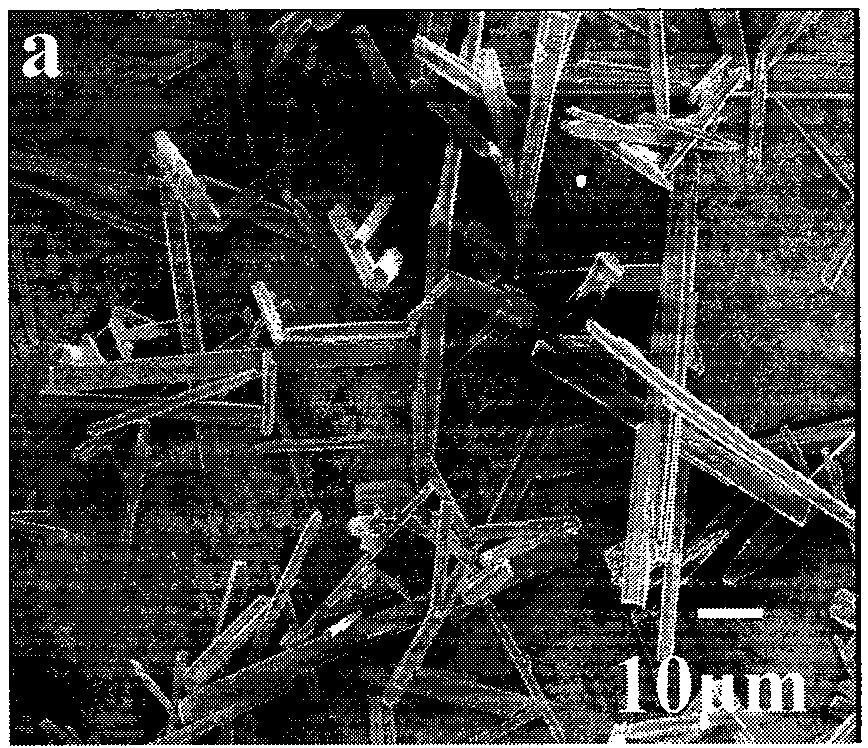

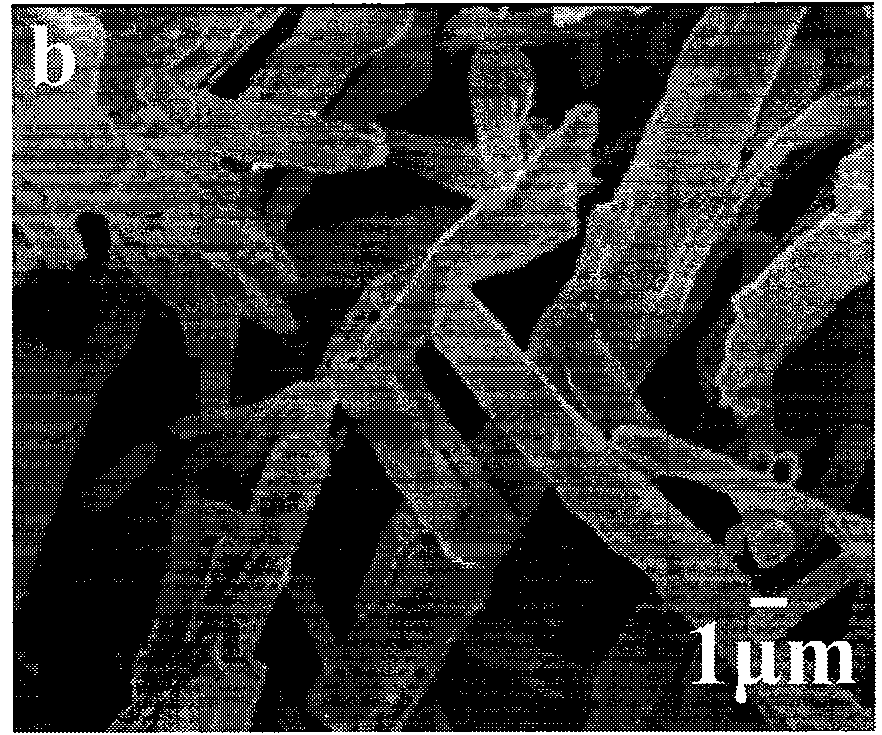

Method for producing magnesium oxide with co-production of ammonium chloride by taking magnesium carbonate hydrate as intermediate

InactiveCN101993097AHigh purityGood filtration propertiesMagnesium carbonatesAmmonium halidesMagnesium saltSeawater

The invention belongs to the field of inorganic salt chemical industry and fertilizer production, particularly relates to a method for producing magnesium oxide with co-production of ammonium chloride by taking magnesium carbonate hydrate as an intermediate. The method comprises the following steps of: with anhydrous magnesium chloride or bittern magnesium chloride as a raw material and with ammonia and ammonium bicarbonate as precipitating agents, obtaining the magnesium carbonate hydrate intermediate (the purity reaches 97-99 percent) with favorable crystal form by controlling process conditions; calcining the obtained magnesium carbonate hydrate intermediate to prepare magnesium oxide (the purity reaches 95-99 percent); adding salt to mother liquor enriched with ammonium salts and evaporating, salting out and cooling to separate out ammonium chloride, and filtering to obtain the ammonium chloride, wherein the mother liquor is circularly taken as a raw material. The method aims at producing needle-shaped or spherical magnesium carbonate hydrate by utilizing rich magnesium chloride brine from salt lakes, or magnesium chloride brine from seawater, or anhydrous magnesium chloride used for producing titanium sponge by-products, and other magnesium salt materials, thereby preparing high-purity magnesium oxide with the simultaneous co-production of ammonium chloride fertilizer. The method of the invention has strong maneuverability and is easy to realize industrialization.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

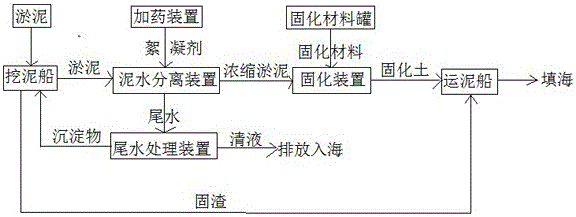

Sea dredged silt dewatering and solidifying treatment integrated device and method

InactiveCN105731758ASolving Disposal ProblemsGood dehydration and curing effectSludge treatment by de-watering/drying/thickeningFixation/solidifcation sludge treatmentPollutionTreatment costs

The invention relates to a sea dredged silt dewatering and solidifying treatment integrated device and method.Dredged silt is sucked onto a dredger, the dredged silt is conveyed into a silt-water separating device after the dredger arrives at a sea treatment platform, centrifugal dewatering is carried out on the dredged silt through the silt-water separating device, tail water generated after dewatering is conveyed to a tail water treatment device to be treated, concentrated silt is conveyed to a solidifying device, a solidifying material in a solidifying material tank is conveyed to the solidifying device together with the concentrated silt, the concentrated silt and the solidifying material are fully stirred to obtain solidified soil, and the solidified soil is transported to a reclamation area through a silt transporting boat for reclamation.The sea dredged silt dewatering and solidifying treatment integrated device and method are good in dewatering and solidifying effect, high in dredged silt treatment efficiency, low in dredged silt treatment cost and high in automation degree; besides, the silt does not fall to the ground, no stock dump is needed and no secondary pollution is caused in the whole working process, the treated dredged silt reaches the standard and can be directly applied to engineering backfill, no secondary argillization happens, and disposal and efficient reutilization of the dredged silt are effectively achieved.

Owner:国家海洋局南海规划与环境研究院

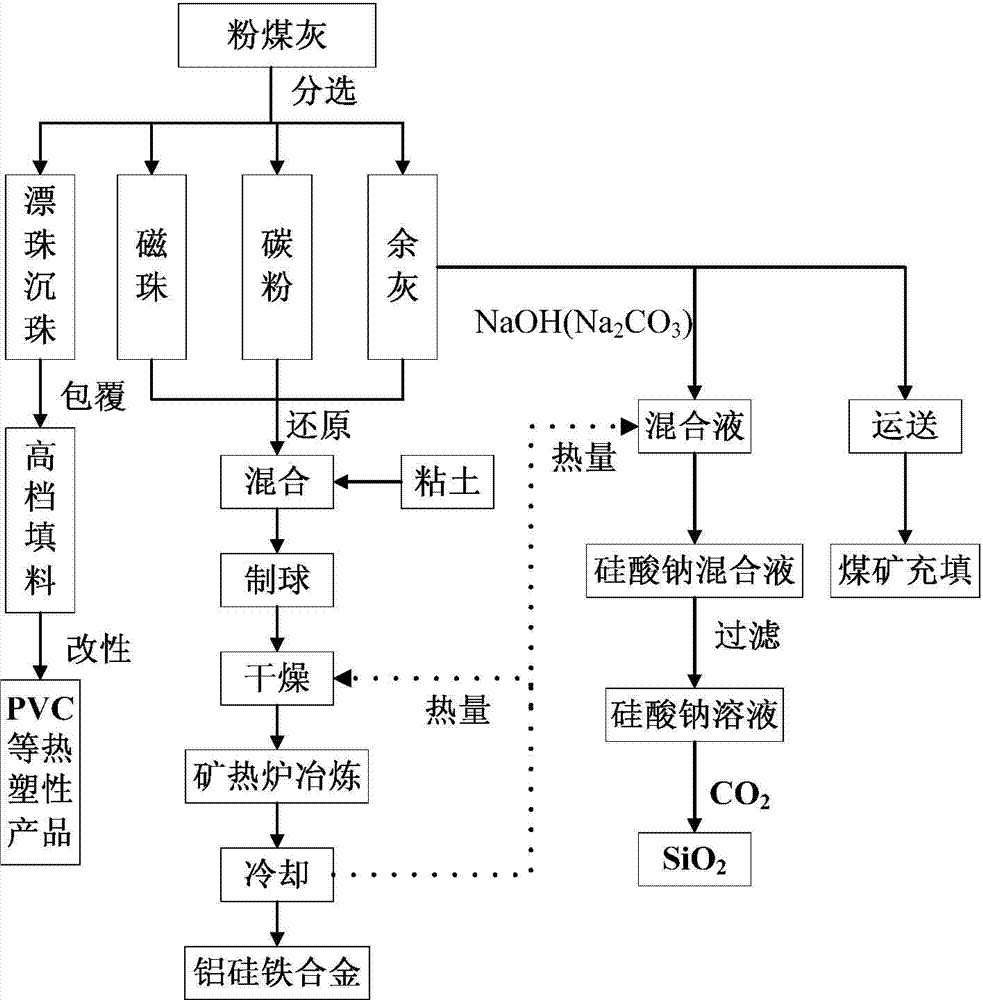

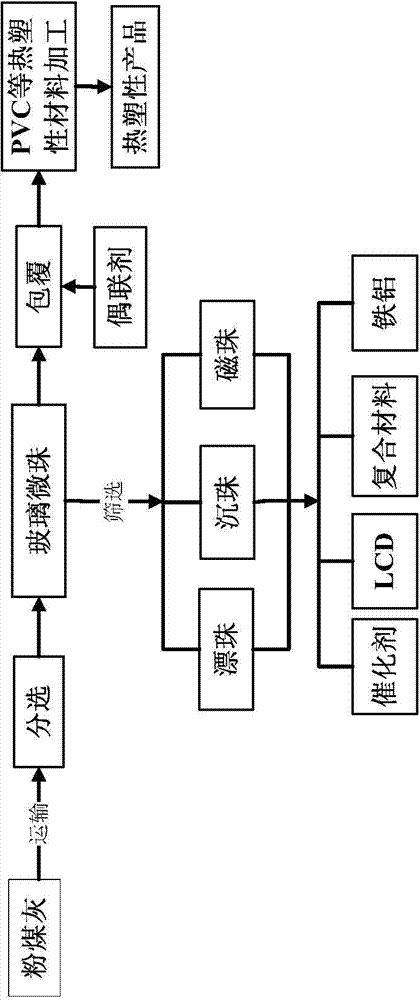

Method for simultaneously extracting glass microbeads from fly ash and coproducing aluminum-silicon-iron alloy and white carbon black

InactiveCN102826776AAchieving zero emissionsRealize comprehensive utilizationSilicaSolid waste managementPolyvinyl chlorideSodium silicate

The invention provides a method for simultaneously extracting glass microsbeads from fly ash and coproducing aluminum-silicon-iron alloy and white carbon black, relating to the technical field of cyclic utilization of waste resources. The method comprises the following steps: separating power plant fly ash to obtain floating beads, settling beads, magnetic beads, carbon powder and residual ash, wherein the floating beads and settling beads can be treated to be used as a high-grade filler which can be added into PVC (polyvinyl chloride) and other thermoplastic materials; adding clay and water into the magnetic beads, carbon powder and residual ash, mixing, granulating, drying, and smelting in a submerged arc furnace to obtain the aluminum-silicon-iron alloy; dipping the residual ash in alkali to obtain a sodium silicate mixed solution, and introducing CO2 to obtain the white carbon black; and sending the rest of residual ash into a coal mine goaf to carry out filling. The invention comprehensively utilizes high-value resources in the fly ash, and fully utilizes the energy; and the invention lowers the cost of the plastic products, lowers the energy consumption, reduces the emission of CO2, and implements zero discharge of waste, thereby having significant economic benefit and environmental value.

Owner:ELION RESOURCE GROUP

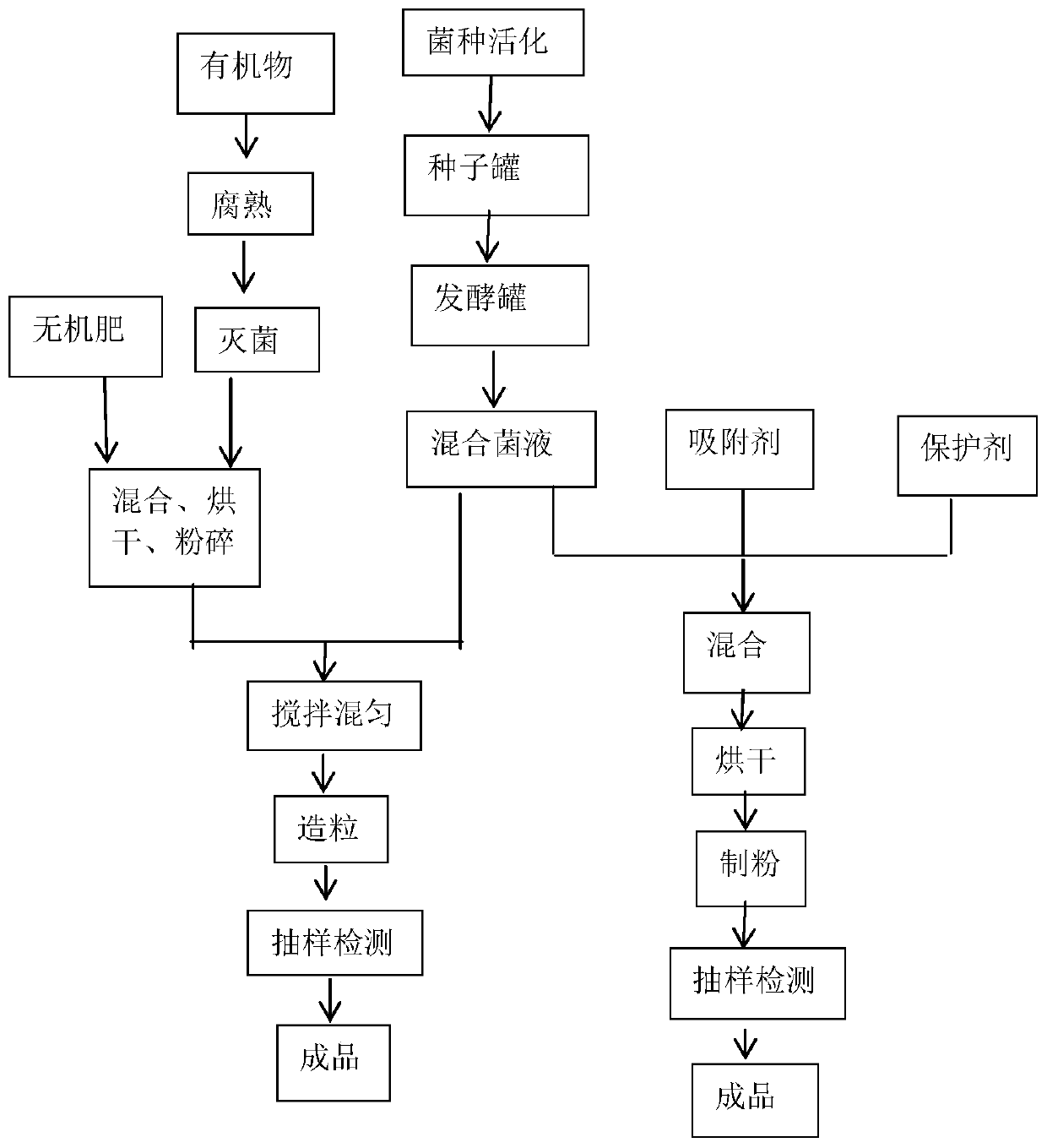

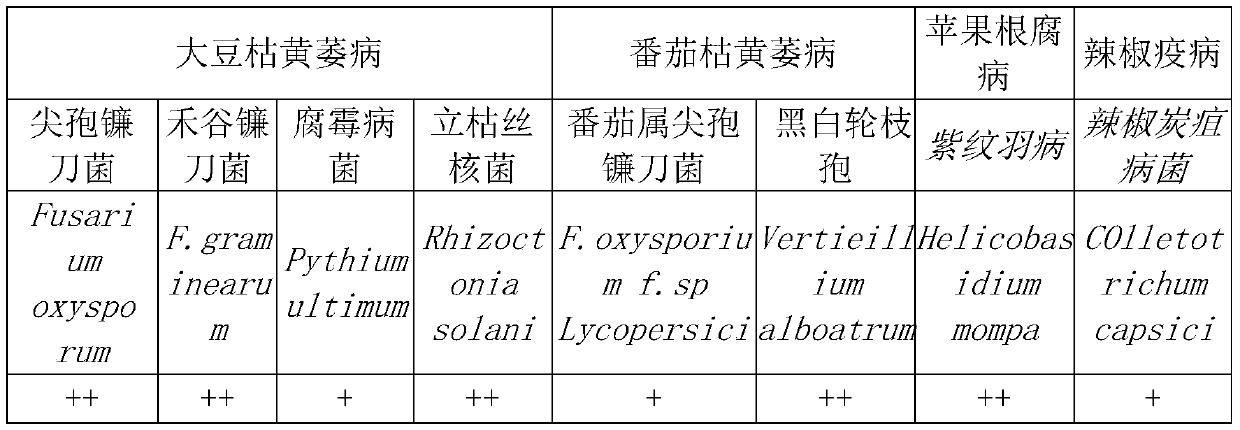

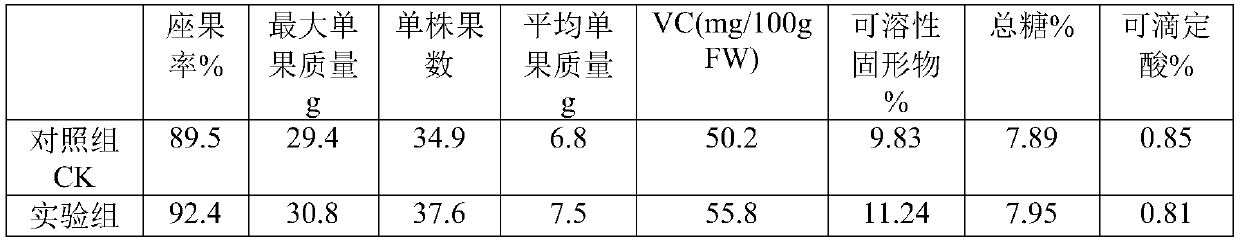

Preparation and application of composite microbial agent and biological organic compound fertilizer

The invention relates to preparation and application of a composite microbial agent and biological organic compound fertilizer. Bacillus, saccharomycetes, photosynthetic bacteria and the like are combined with various organic matters and inorganic matters through a scientific formula to form the composite microbial agent and biological organic compound fertilizer. The composite microbial agent andbiological organic compound fertilizer has effects of improving the ecological system and the nutrient environment of crop rhizosphere soil through interaction of microorganisms, improving the absorption capacity of crops, promoting growth of crops and increasing yield and income. The composite microbial agent and biological organic compound fertilizer has effects of improving soil, controlling soil-borne diseases and insect pests, degrading harmful residues such as heavy metals and pesticides, promoting plant growth, improving crop stress resistance and increasing crop quality, and has the characteristics of high efficiency, quick effect and sustained effect.

Owner:沈阳华生生物科技开发有限公司

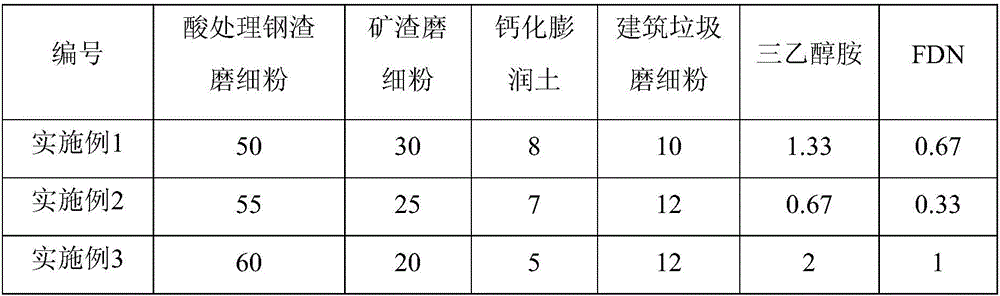

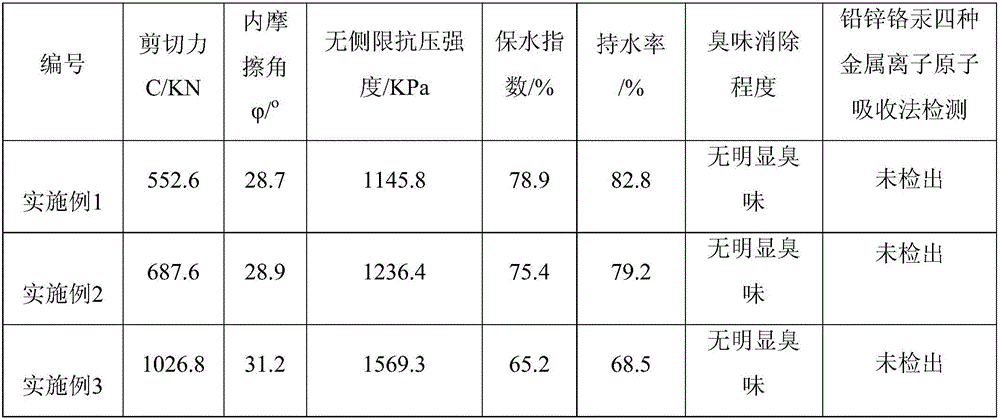

An environmental friendly soil ecology modifying agent and a preparing method thereof

InactiveCN105837370AIncrease nutritionEasy to optimizeFertilizer mixturesSodium BentoniteSoil ecology

An environmental friendly soil ecology modifying agent is disclosed. The modifying agent comprises 5-10% by mass of calcium bentonite, 50-60% by mass of acid-treated steel slag pulverized powder, 10-20% by mass of building waste pulverized powder, 20-30% by mass of ground mineral slag powder, 0.5-3% by mass of triethanolamine and 0.5-1.5% of FDN. The calcium bentonite is adopted as a component preserving water and nutrients, and the acid-treated steel slag pulverized powder and the building waste pulverized powder are used as main cementing materials. The prepared modifying agent is used for ecological remediation of polluted bottom mud of lakes and the like, has characteristics of good soil modifying effects, a low production cost and high engineering usability, and is low in requirements on production device. The prepared modifying agent can effectively overcome the demand of treating black and odorous bottom mud and a problem of resource utilization of industrial wastes, has important environment and economic benefit and is suitable for popularization and application.

Owner:WUHAN UNIV OF TECH

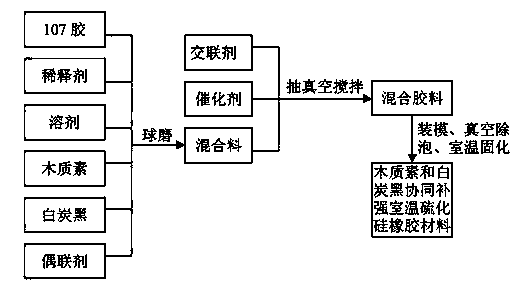

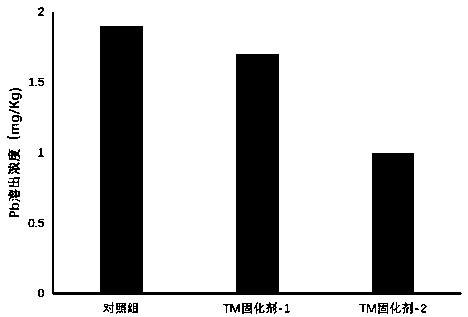

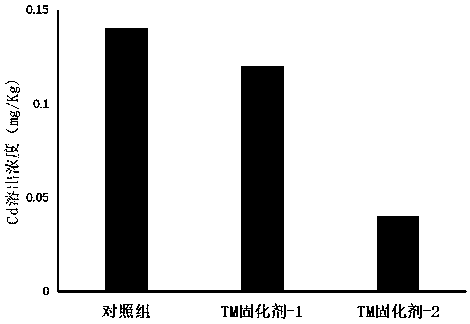

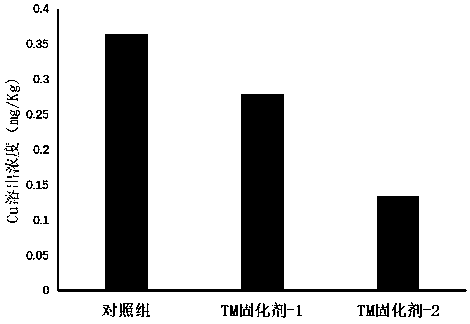

Preparation method of room temperature sulfurated silicon rubber material co-enhanced by lignin and white black carbon

A preparation method of a room temperature sulfurated silicon rubber material co-enhanced by lignin and white black carbon comprises the following steps: (1) preparing the following raw materials in parts by weight: 100 parts of alpha,omega-dihydroxypolydimethylsiloxane (107 glue), 0 to 10 parts of lignin, 0 to 10 parts of white carbon black, 0.1 to 0.5 part of coupling agent, 1 to 10 parts of diluent, 50 to 100 parts of solvent, 4 to 10 parts of coupling agent, and 1 part of catalyst; (2) adding the 107 glue, diluent, solvent, lignin, white carbon black and coupling agent into a high-performance ball grinder, grinding for 2 hours, then adding the coupling agent and catalyst, vacuumizing and stirring for 10 minutes, pouring the mixture into a mould, eliminating the bubbles in vacuum environment, and allowing the mixture to carry out curing reactions for 24 hours at a room temperature so as to obtain the room temperature sulfurated silicon rubber material co-enhanced by lignin and white black carbon. Low cost lignin is cooperatively used with white black carbon as an enhancing agent for the room temperature sulfurated silicon rubber material, the enhancing agent can prominently improve the mechanical property of the room temperature sulfurated silicon rubber material, at the same time, the lignin resource is effectively utilized, and the manufacture cost for room temperature sulfurated silicon rubber material is reduced.

Owner:NANCHANG HANGKONG UNIVERSITY

Iron-manganese oxide based heavy metal curing agent and preparation method and applications thereof

InactiveCN110257078AStrong curing and stabilizing abilityMild preparation conditionsOrganic fertilisersSoil conditioning compositionsManganese oxideHumus

The invention belongs to the technical field of environment protection, and specifically relates to an iron-manganese oxide based heavy metal curing agent, which comprises following components in percentage by weight: 10 to 20% of tailings of manganese ores and iron ores, 5 to 10% of a pH adjuster, 30 to 40% of humus, 15 to 25% of chitosan, and 10 to 20% of straw ash. The preparation method of the heavy metal curing agent comprises following steps: individually grinding tailings of manganese ores and iron ores, a pH adjuster, humus, chitosan, and straw ash, sieving the powder by a 100-150 mesh sieve, and evenly mixing. Then the heavy metal curing agent is applied to heavy metal polluted soil, and the heavy metal curing agent accounts for 10 to 20% of the weight of the soil. Tailings of manganese ores and iron ores are taken as the raw materials; the preparation conditions are mild; the heavy metal chelating effect of the heavy metal curing agent is good, the heavy metal curing and stabilizing performance is strong, multiple heavy metal ions can be immobilized and stabilized at the same time, and the problem that manganese tailing is difficult to utilize is solved.

Owner:CHINA CITY ENVIRONMENT PROTECTION ENGINEERING LIMITED COMPANY

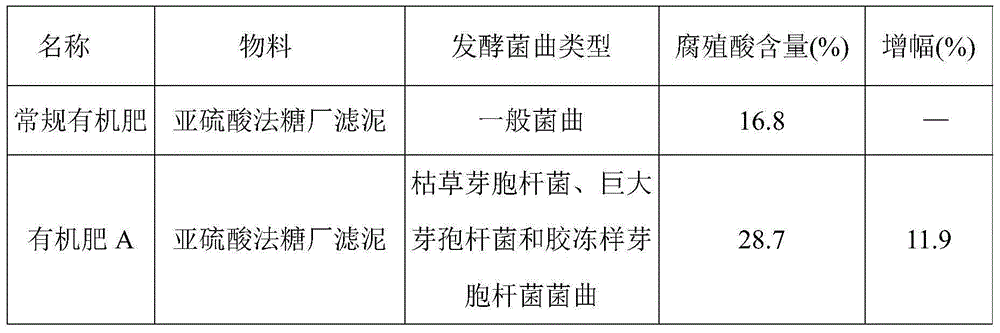

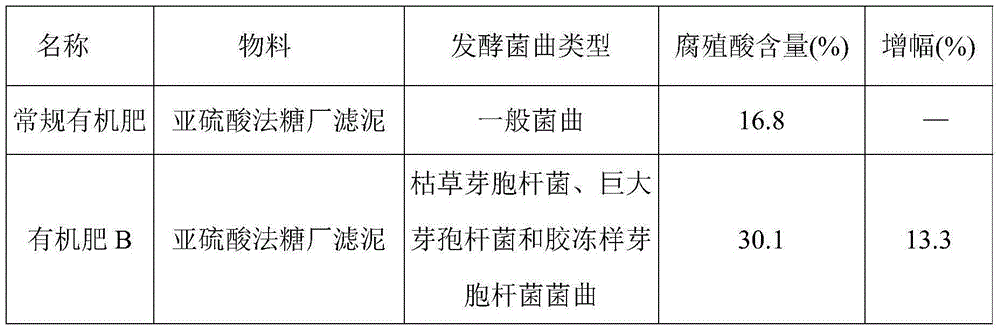

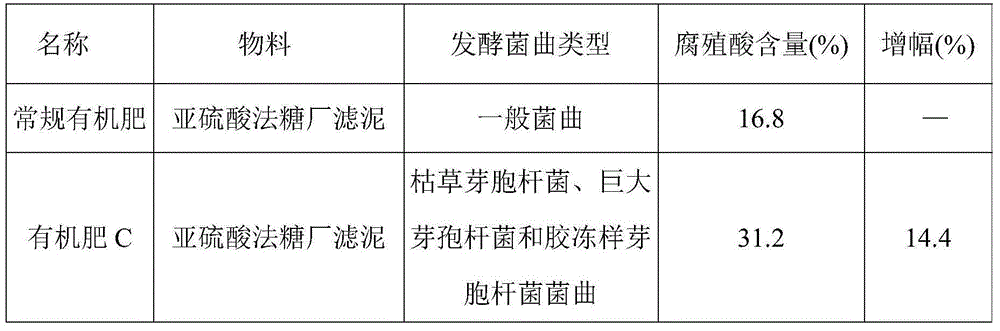

Organic fertilizer with high humic acid content and preparation method thereof

ActiveCN105084948AHigh humic acid conversion rateHigh in humic acidBio-organic fraction processingClimate change adaptationFiltrationMicrobial agent

The invention provides an organic fertilizer with high humic acid content and a preparation method thereof. The preparation method of the organic fertilizer with high humic acid content includes the following steps: preparing fermentative bacteria, wherein the fermentative bacteria include bacillus subtilis, bacillus megaterium and bacillus mucilaginosus; making the fermentative bacteria into fermentation microbial agent; filtering mud in a sugarhouse through a sulfurous method, and mixing with the fermentation microbial agent for fermentation to obtain the organic fertilizer with high humic acid content. Compared with the conventional organic fertilizer, the organic fertilizer obtained through the technical scheme provided by the invention is higher in humic acid conversion rate and humic acid content; the sulfurous method is fully utilized to filter mud in the sugarhouse, and resource utilization is realized in the cane sugar industry, and the problem of environment pollution troubling the sugarhouse, caused by the mud filtration with the sulfurous method in the sugarhouse is solved; wastes are turned to treasures, soil productivity is increased, the sugar yield is increased, cleaner production is realized, the environment is protected, and the sustainable development of the sugar industry is promoted.

Owner:东莞市益田生物科技有限公司

Treatment method for double-salt crystals during manganese electrolysis

InactiveCN108396158ARealize resource utilizationRealize the development of circular economyElectrolysis componentsPhotography auxillary processesElectrolysisResource utilization

The invention belongs to the technical field of chemical engineering, and relates to a treatment method for double-salt crystals generated during manganese electrolysis. The method includes the stepsthat 1, the double-salt crystals generated during manganese electrolysis are dissolved into a saturated solution with water at 40 DEG C; 2, the pH value is regulated to 6.5-8.5 with ammonium hydroxide; 3, filtering is carried out, and filter liquor is reacted with CO2 gas to generate settled manganese carbonate; 4, solid-liquid separation is carried out on the settled manganese carbonate, and filter residues are washed by water till the content of manganese carbonate is greater than 92%; 5, magnesium oxide is added into filter liquor obtained after washing to react to generate magnesium sulfate and ammonium hydroxide; 6, reaction products are conveyed to a deamination tower, and ammonium hydroxide is turned into gas to be removed; and 7, a solution obtained after deamination is subjected to crystal separation to obtain magnesium sulfate crystals. By means of the method, resource utilization of the double-salt crystals generated during manganese electrolysis is realized, circular economy development of manganese electrolysis is realized, the clearing and stacking cost is saved, land occupation and environment pollution are reduced, and good social and economical benefits are achieved.

Owner:NINGXIA TIANYUAN MANGANESE LIMITED

Excess sludge deep dehydration conditioner

InactiveCN104926075AGood effectReduce usageSludge treatment by de-watering/drying/thickeningResource utilizationEngineering

The invention discloses an excess sludge deep dehydration conditioner, and belongs to the technical field of sludge treatment. Rice hull powder is adopted as the sludge dehydration conditioner, so that the defects that at present, FeCl3 and CaO can corrode incineration facilities, and incineration is influenced along with the reduction of organic matters are overcome; compared with a manner that chemical conditioners or wood chips are used, the effect of rice hull powder is better, the raw materials source is wide, the price is low, and the problem of how to realize waste resource utilization of rice hull powder in the prior art can also be solved.

Owner:JIANGNAN UNIV

Organic cultivation medium produced from chicken manure residues and sludge compost and production method of organic cultivation medium

InactiveCN103242067ALight weightIncrease fine poresBio-organic fraction processingOrganic fertiliser preparationNutrientDecomposition

The invention relates to an organic cultivation medium produced from chicken manure residues and sludge compost and a production method of the organic cultivation medium. The production method of the organic cultivation medium comprises the steps of material preparation, heap building for fermentation, crushing and mixing. The organic cultivation medium takes the chicken manure residues and the sludge compost as main raw materials, wherein the chicken manure residues are solid chicken manure residues obtained by separating flushing sewage of a large-scale chicken farm through a solid-liquid separator; and the sludge compost is obtained by mixing urban living sludge and edible fungi residue cultivation waste residues and carrying out fermentation for thorough decomposition. According to the organic cultivation medium, the materials are convenient to obtain, the cost is low, and the produced organic cultivation medium has excellent physical and chemical properties including low salinity, high organic content, moderate nutrients and the like, and can meet requirements for solid medium cultivation of crops so as to realize the resource utilization of wastes.

Owner:INST OF AGRI ENG TECH FUJIAN ACAD OF AGRI SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com