Waste foundry sand dry-mixed mortar

A technology of dry-mixed mortar and casting mold, which is applied in the field of waste foundry sand dry-mixed mortar, which can solve the problems of abnormal fluctuations in the quality of the mixed mortar, affecting the quality of buildings, and large dust emissions, so as to prevent the occupation of cultivated land and environmental pollution , the protection of the shape of the river and the surrounding environment, and the unified effect of social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

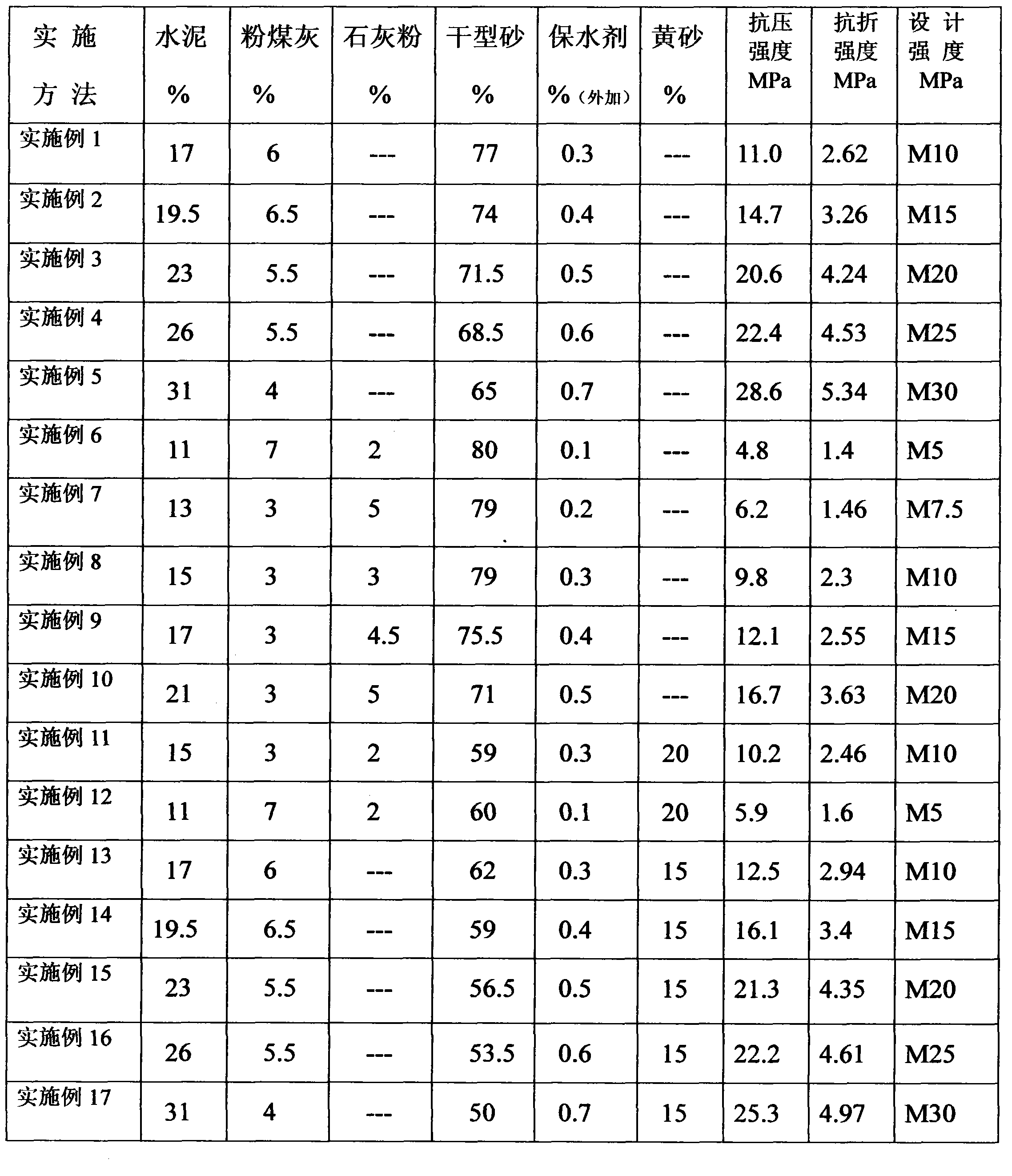

Examples

Embodiment 1

[0027] Quality ratio:

[0028] Dry waste foundry sand 77%;

[0029] Dry fly ash 6%;

[0030] Cement 17%;

[0031] Water retaining agent 0.3%;

[0032] Waste foundry sand is dried waste foundry sand obtained after multiple harmless treatment processes. Its silicon dioxide content is above 92%, the mud content is less than 1%, and its fineness modulus is M X =1.8 or so, belonging to fine sand.

[0033] Dry fly ash is Class II ash.

[0034] The cement is P.042.5 ordinary Portland cement.

[0035] The water retaining agent is cellulose ether, plus.

[0036] The dry-mixed mortar prepared by mixing and stirring has a design compressive strength of M10, the actual measured 7d compressive strength is 11.0MPa, and the 7d flexural strength is 2.62MPa. It meets the requirements of the national standard GB / T25181 "Ready-mixed Mortar".

Embodiment 2

[0038] Quality ratio:

[0039] Dry waste foundry sand 74%;

[0040] Dry fly ash 6.5%;

[0041] Cement 19.5%;

[0042] Water retaining agent 0.4%.

[0043] Waste foundry sand is dried waste foundry sand obtained after multiple harmless treatment processes. Its silicon dioxide content is above 92%, the mud content is less than 1%, and its fineness modulus is M X =1.8 or so, belonging to fine sand.

[0044] Dry fly ash is Class II ash.

[0045] The cement is P.042.5 ordinary Portland cement.

[0046] The water retaining agent is cellulose ether, plus.

[0047] The dry-mixed mortar prepared by mixing and stirring has a design compressive strength of M15, the actual measured 7d compressive strength is 14.7MPa, and the 7d flexural strength is 3.26MPa. It meets the requirements of the national standard GB / T25181 "Ready-mixed Mortar".

Embodiment 3

[0049] Quality ratio:

[0050] Dry waste foundry sand 71.5%;

[0051] Dry fly ash 5.5%;

[0052] Cement 23%;

[0053] Water retaining agent 0.5%.

[0054] Waste foundry sand is dried waste foundry sand obtained after multiple harmless treatment processes. Its silicon dioxide content is above 92%, the mud content is less than 1%, and its fineness modulus is M X =1.8 or so, belonging to fine sand.

[0055] Dry fly ash is Class II ash.

[0056] The cement is P.042.5 ordinary Portland cement.

[0057] The water retaining agent is cellulose ether, plus.

[0058] The dry-mixed mortar prepared by mixing and stirring has a design compressive strength of M20, the actual tested 7d compressive strength is 20.6MPa, and the 7d flexural strength is 4.24MPa. It meets the requirements of the national standard GB / T25181 "Ready-mixed Mortar".

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com