Patents

Literature

91results about How to "Protect the surrounding environment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

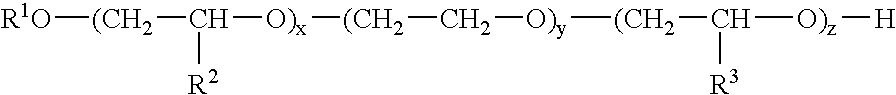

Bleaching product

ActiveUS20060258553A1Minimize interactionMaximize performanceOrganic detergent compounding agentsNon-surface-active detergent compositionsWater solubleNuclear chemistry

Bleaching product in the form of a coated substrate comprising a water-soluble film and a coating comprising a bleaching agent.

Owner:THE PROCTER & GAMBNE CO

Bleaching product comprising a water-soluble film coated with bleaching agents

ActiveUS7517847B2Improve the level ofLarge specific surface areaOrganic detergent compounding agentsNon-surface-active detergent compositionsBleachWater soluble

Bleaching product in the form of a coated substrate comprising a water-soluble film and a coating comprising a bleaching agent.

Owner:THE PROCTER & GAMBLE COMPANY

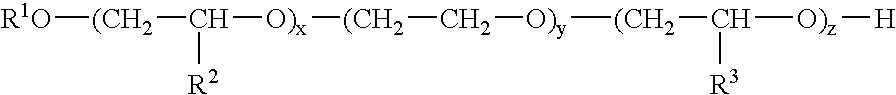

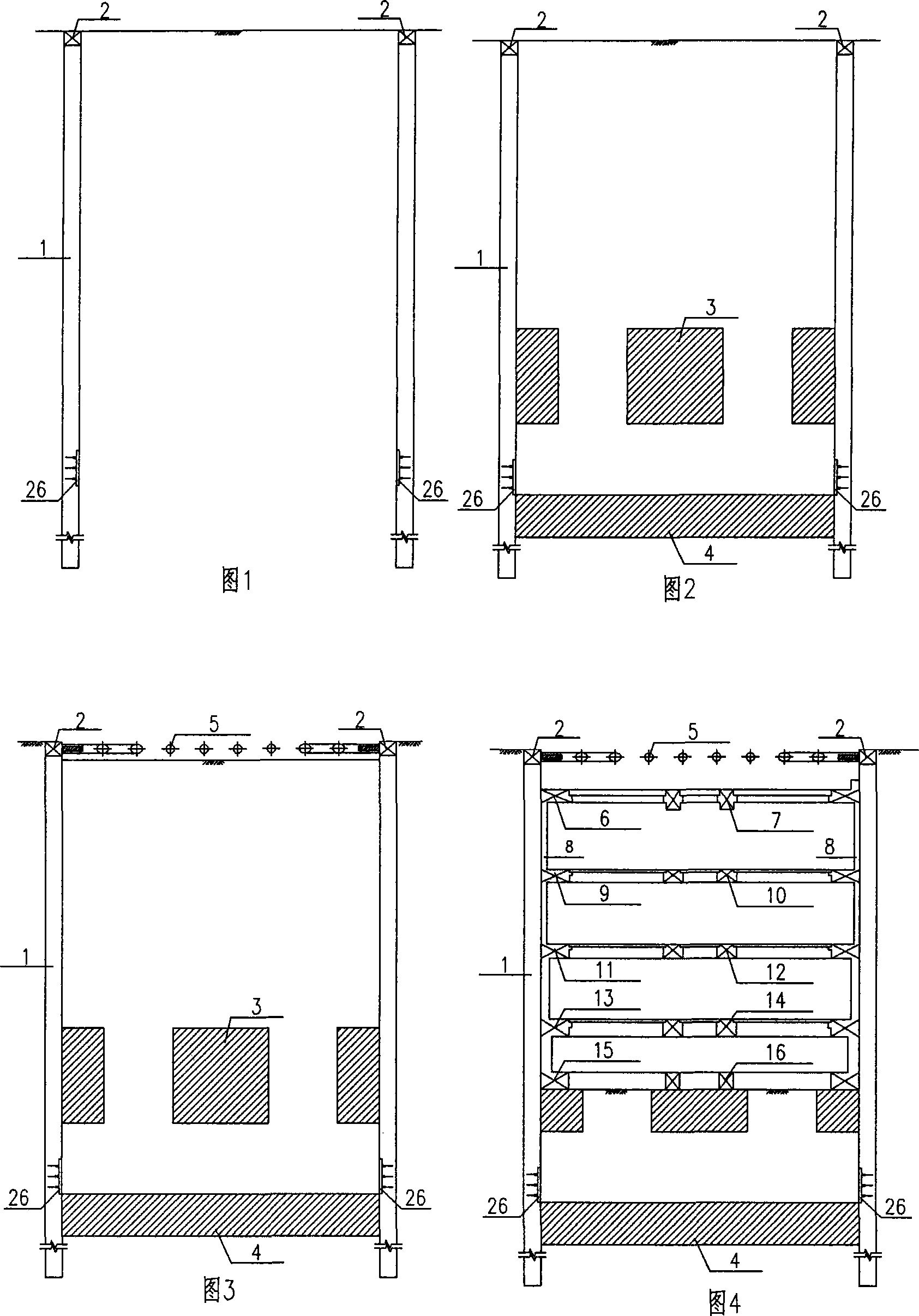

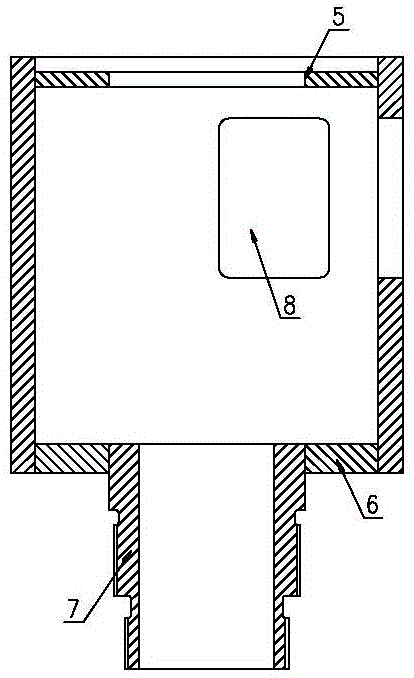

Construction method for high artesian area ultra-deep foundation pit

InactiveCN101139838AProtect the surrounding environmentReduce project costExcavationsPurlinSafety coefficient

The invention relates to track traffic and tunnel categories, in specific to a super-deep foundation pit construction method for high pressure water areas. The method adopts underground continuous walls (or drilling piles, drill biting piles and corresponding waterproof curtains) as enclosure structures and inner supports as support structures; in the premises of complying with pressure water safety factor that is required in specifications, perform open excavation down to a certain elevation; during the course of open excavation method, carry out casting for surrounding purlins, supports and upper side walls; then, add water into the foundation pit, and the water injection height should guarantee the excavation to the bottom can resist pressure water and meet certain safety factors; perform underwater excavation down to the baseplate elevation and overbreak a certain depth for underwater bottom closing concrete cast; then, pump water out of the foundation pit before casting baseplate and back-casting remaining internal structures.

Owner:SHANGHAI TUNNEL ENGINEERING RAILWAY TRANSPORTATION DESIGN INSTITUTE

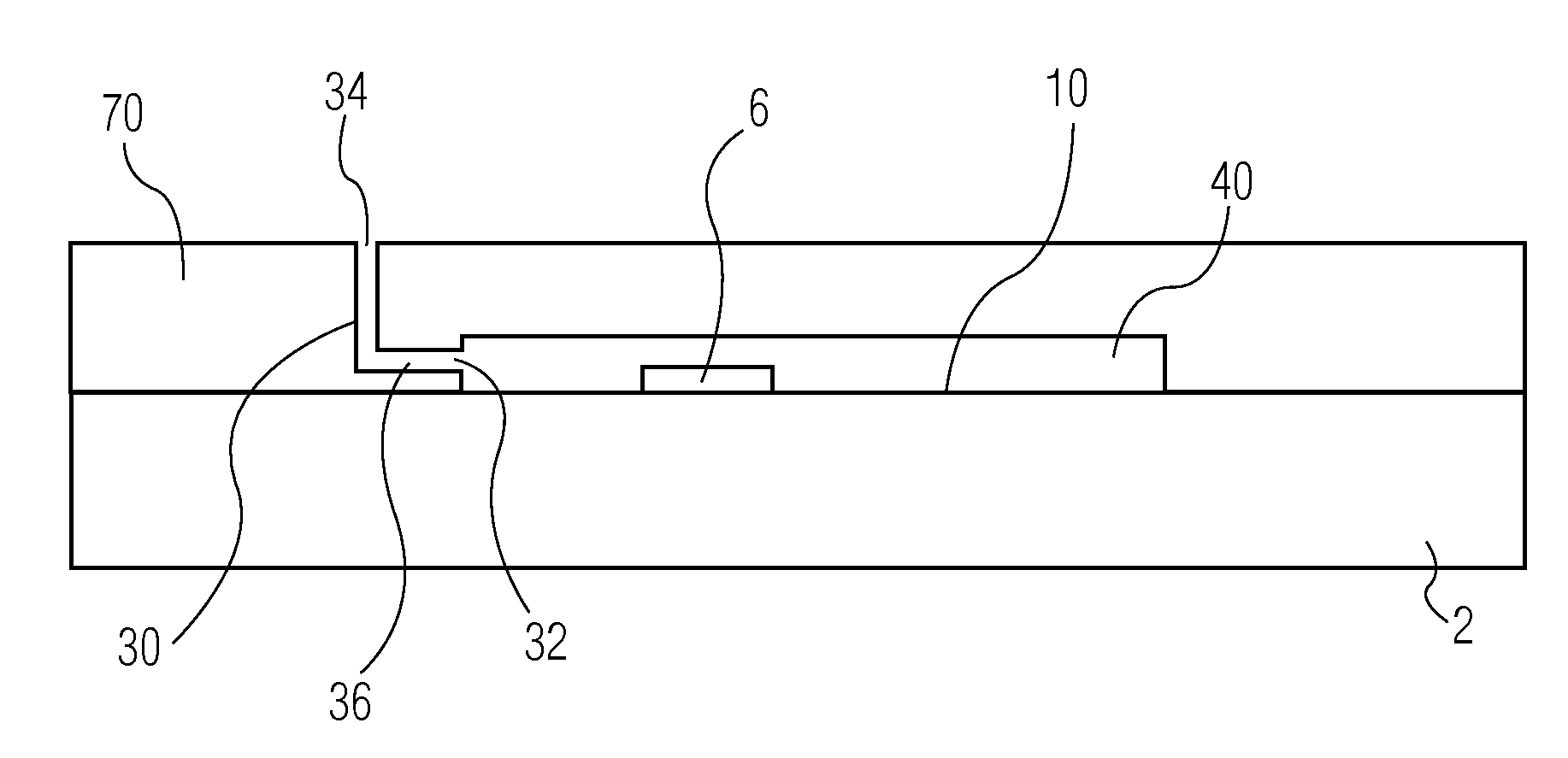

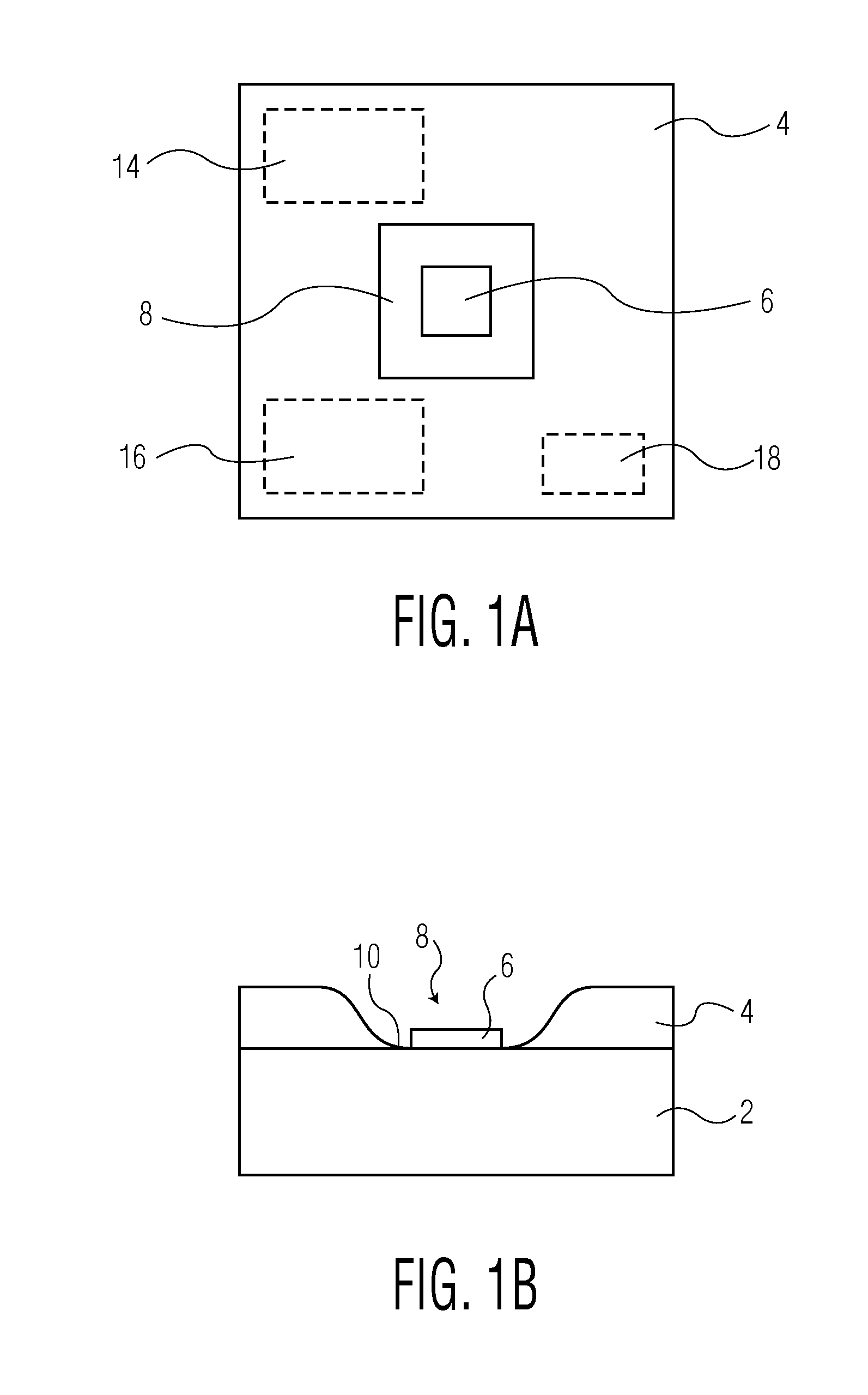

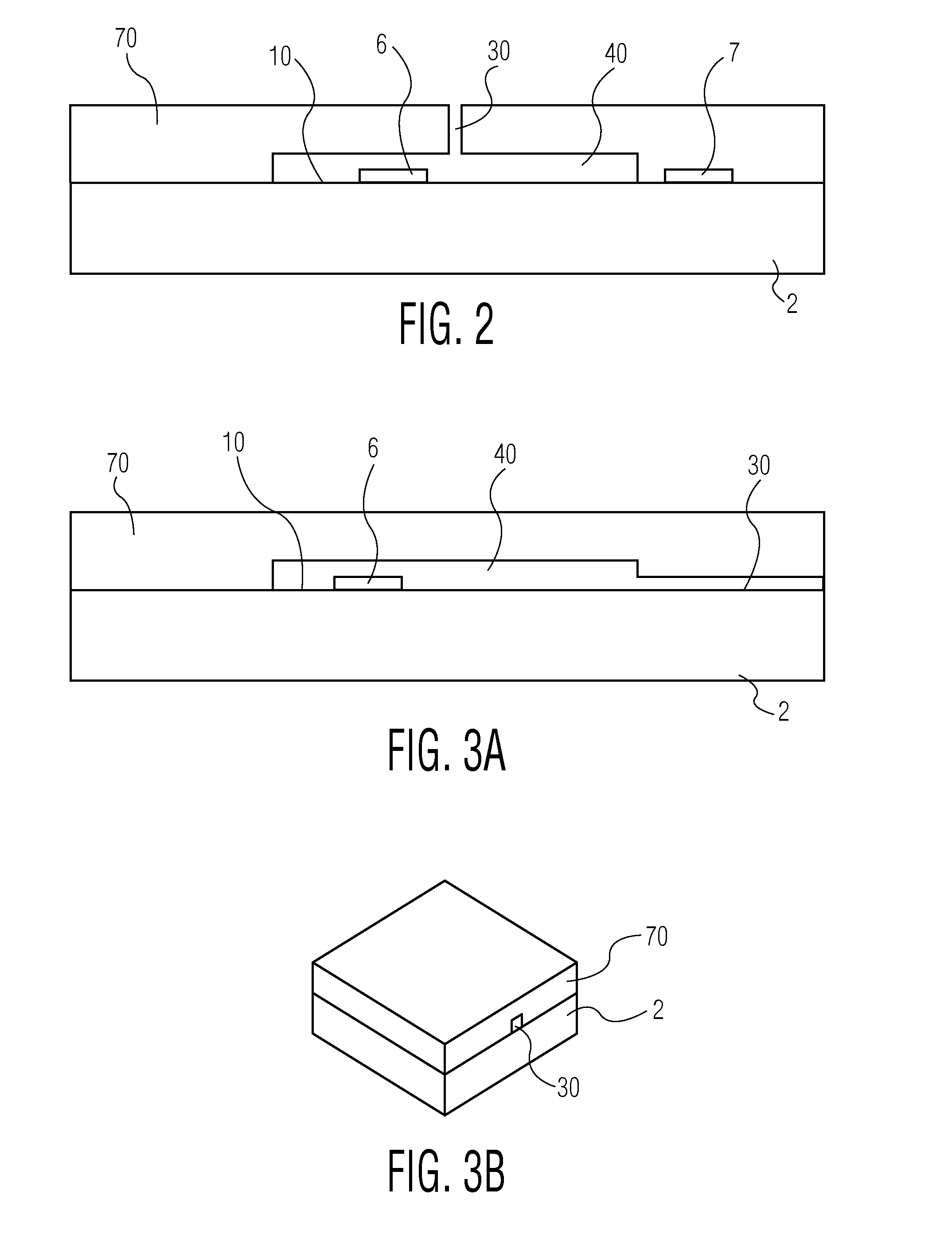

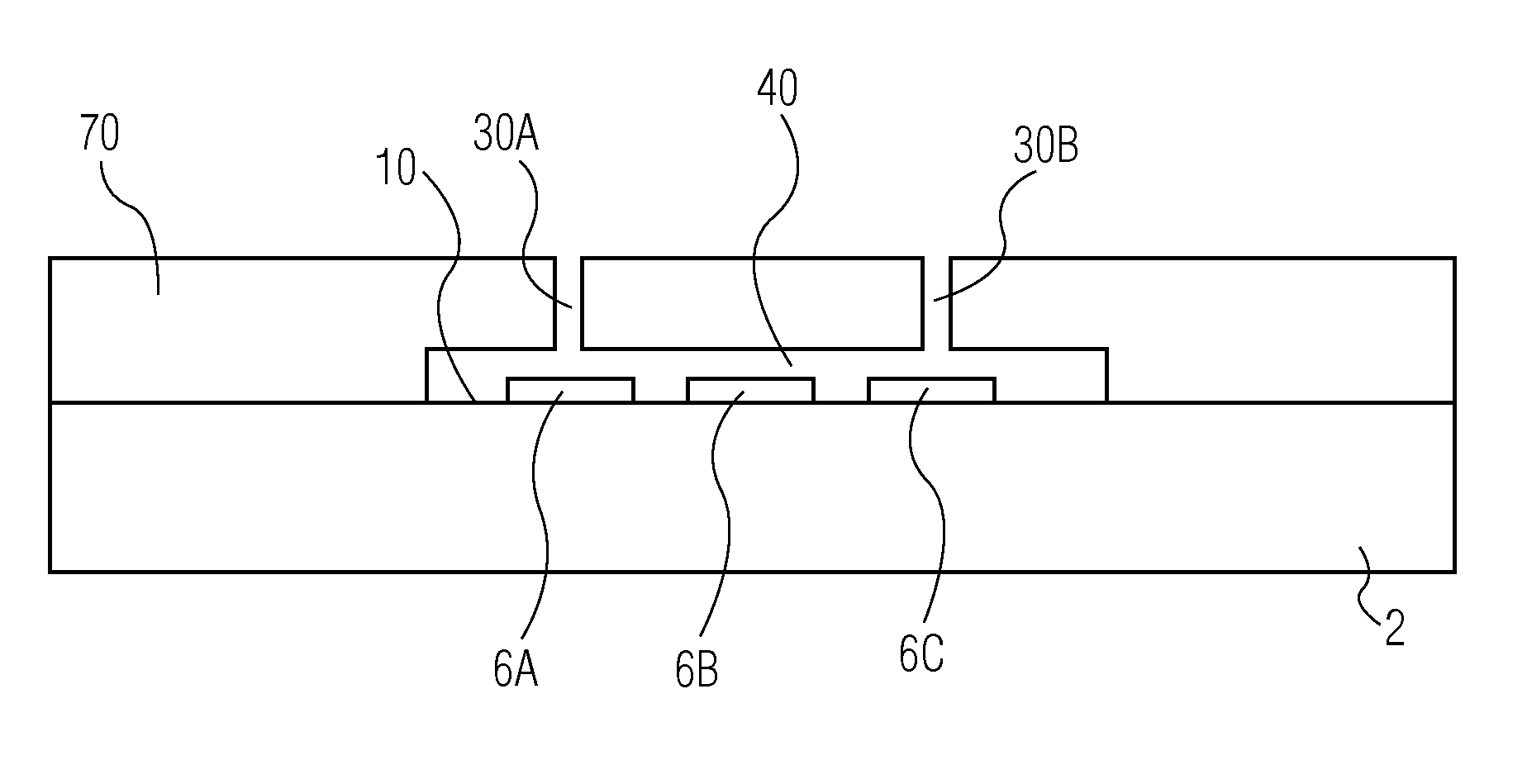

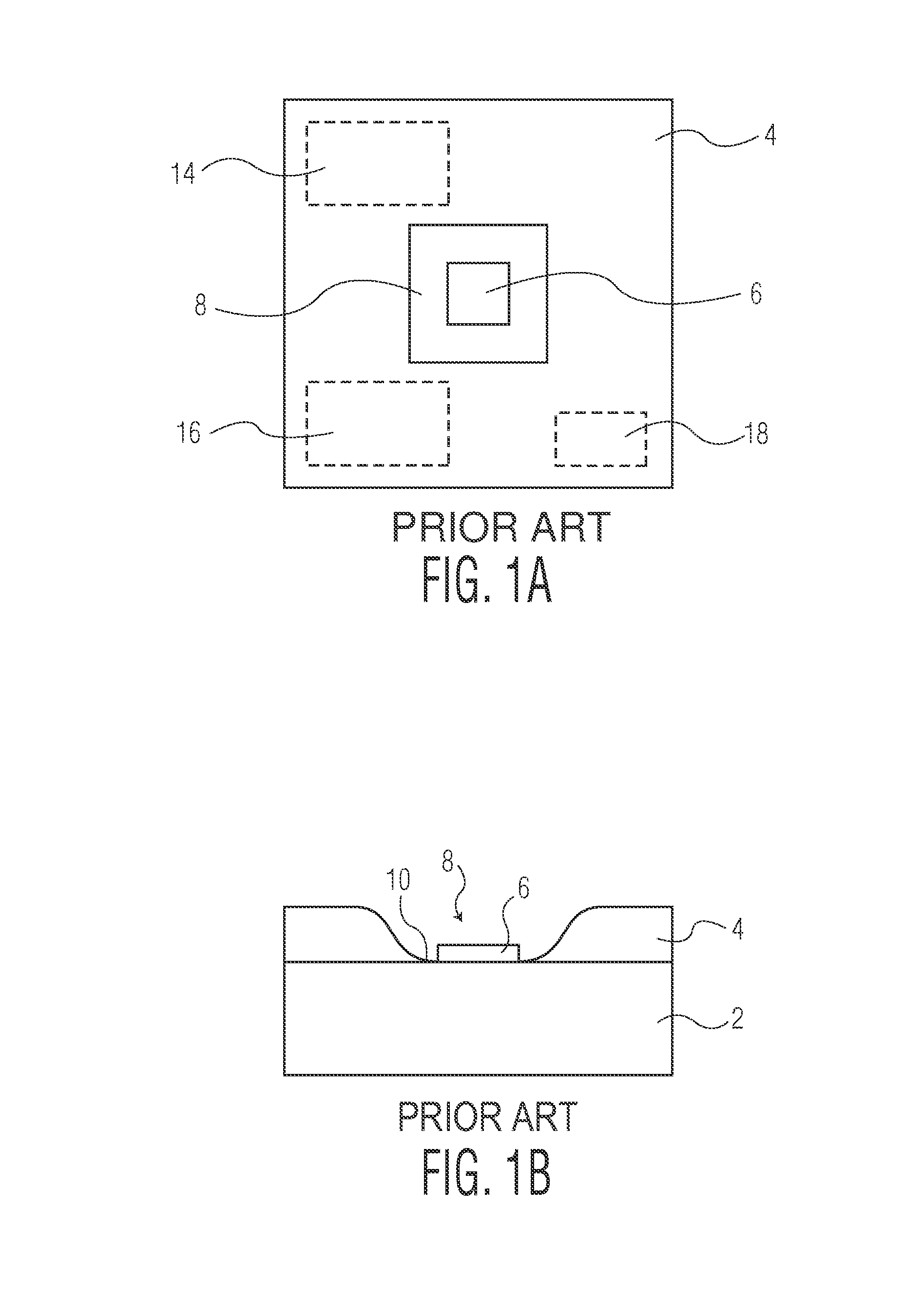

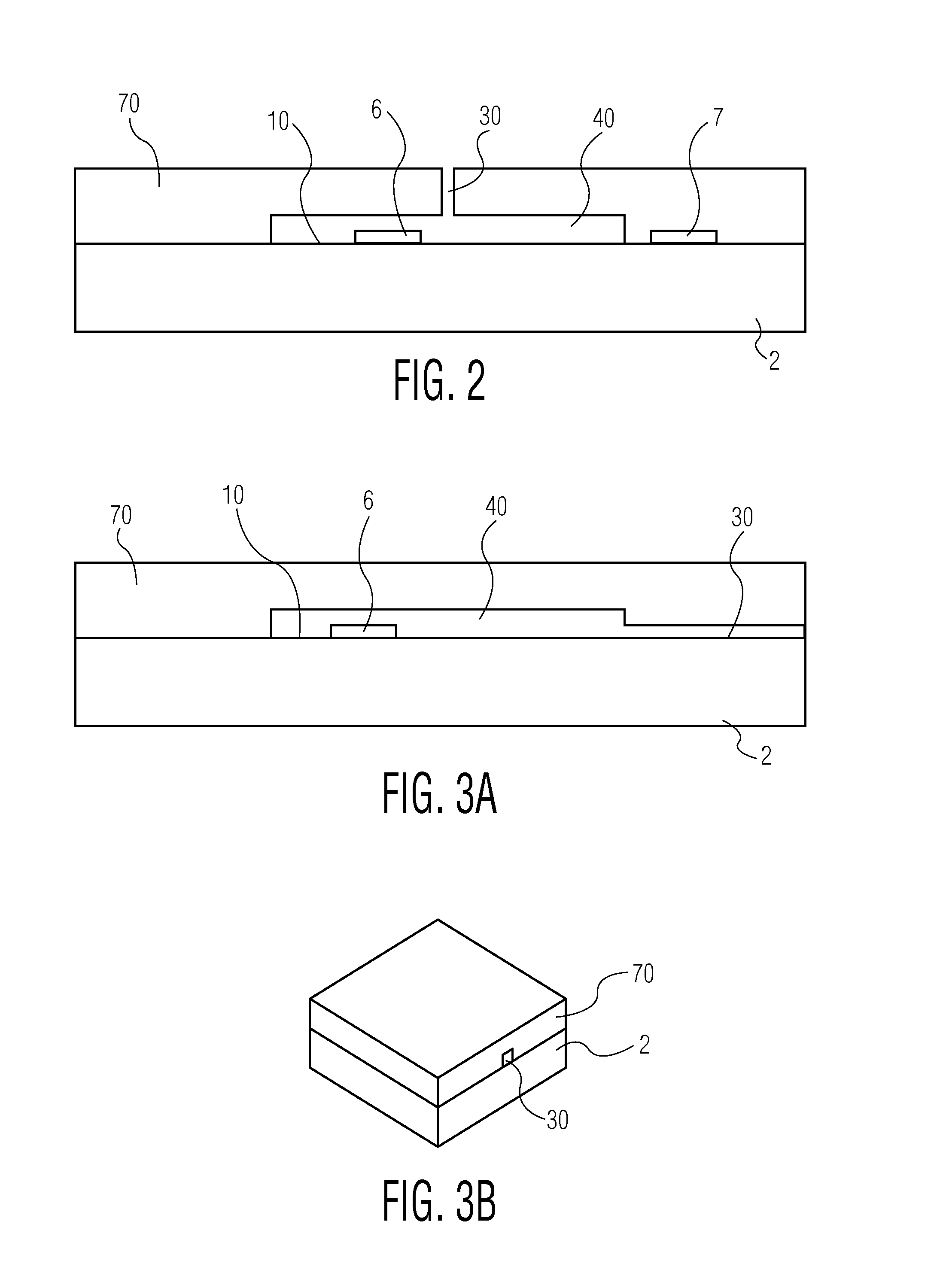

Integrated circuit including an environmental sensor

ActiveUS20140070337A1Improve matchImprove abilitiesSemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor

An integrated circuit and a method of making the same. The integrated circuit includes a semiconductor substrate including at least one environmental sensor. The integrated circuit also includes a cap layer located on a major surface of the substrate. The integrated circuit further includes at least one elongate channel for allowing access of said sensor to an environment surrounding the integrated circuit.

Owner:SCIOSENSE BV

Integrated circuit including an environmental sensor

ActiveUS9105479B2Protect the surrounding environmentHigh degreeSemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor

An integrated circuit and a method of making the same. The integrated circuit includes a semiconductor substrate including at least one environmental sensor. The integrated circuit also includes a cap layer located on a major surface of the substrate. The integrated circuit further includes at least one elongate channel for allowing access of said sensor to an environment surrounding the integrated circuit.

Owner:SCIOSENSE BV

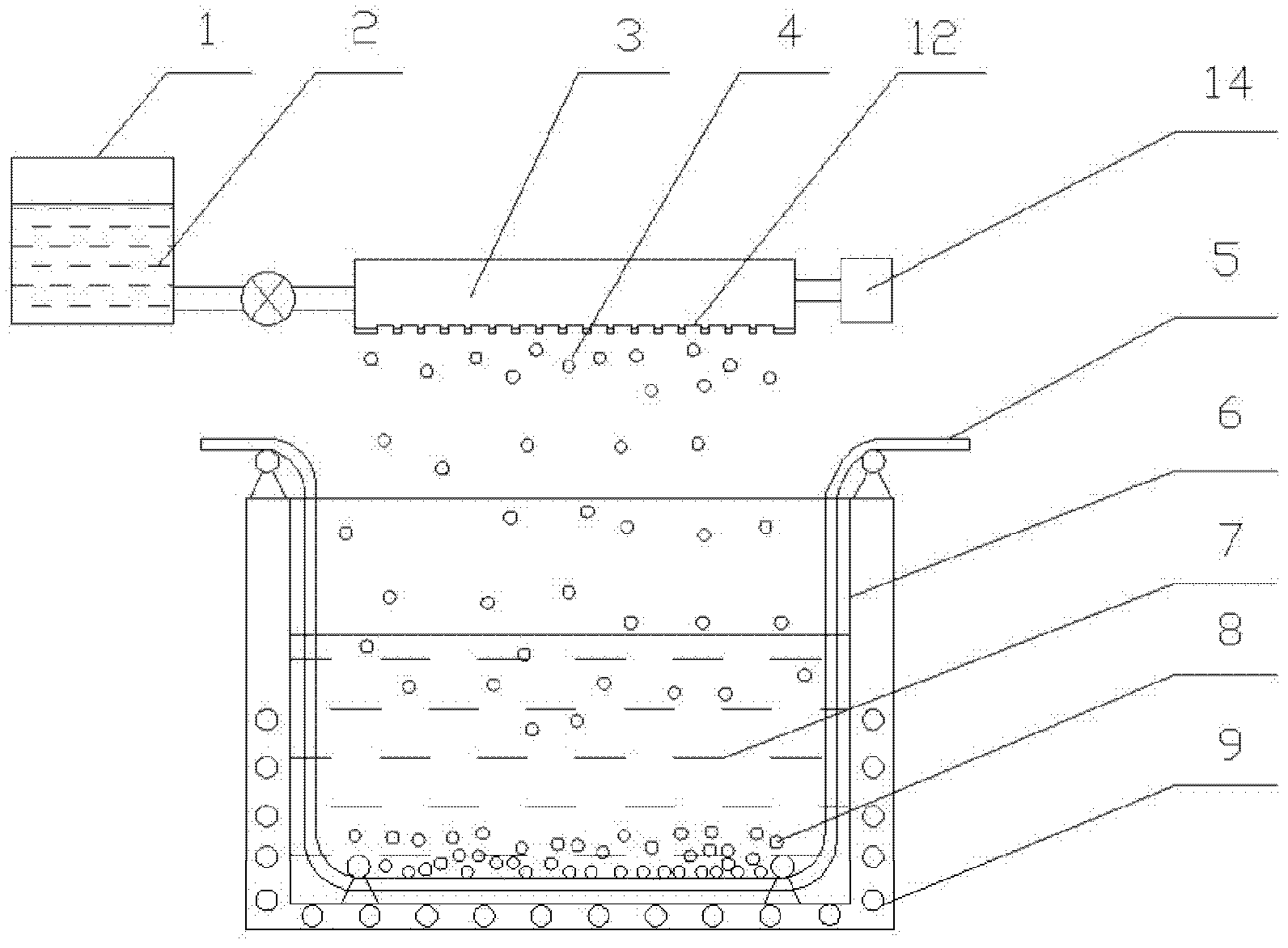

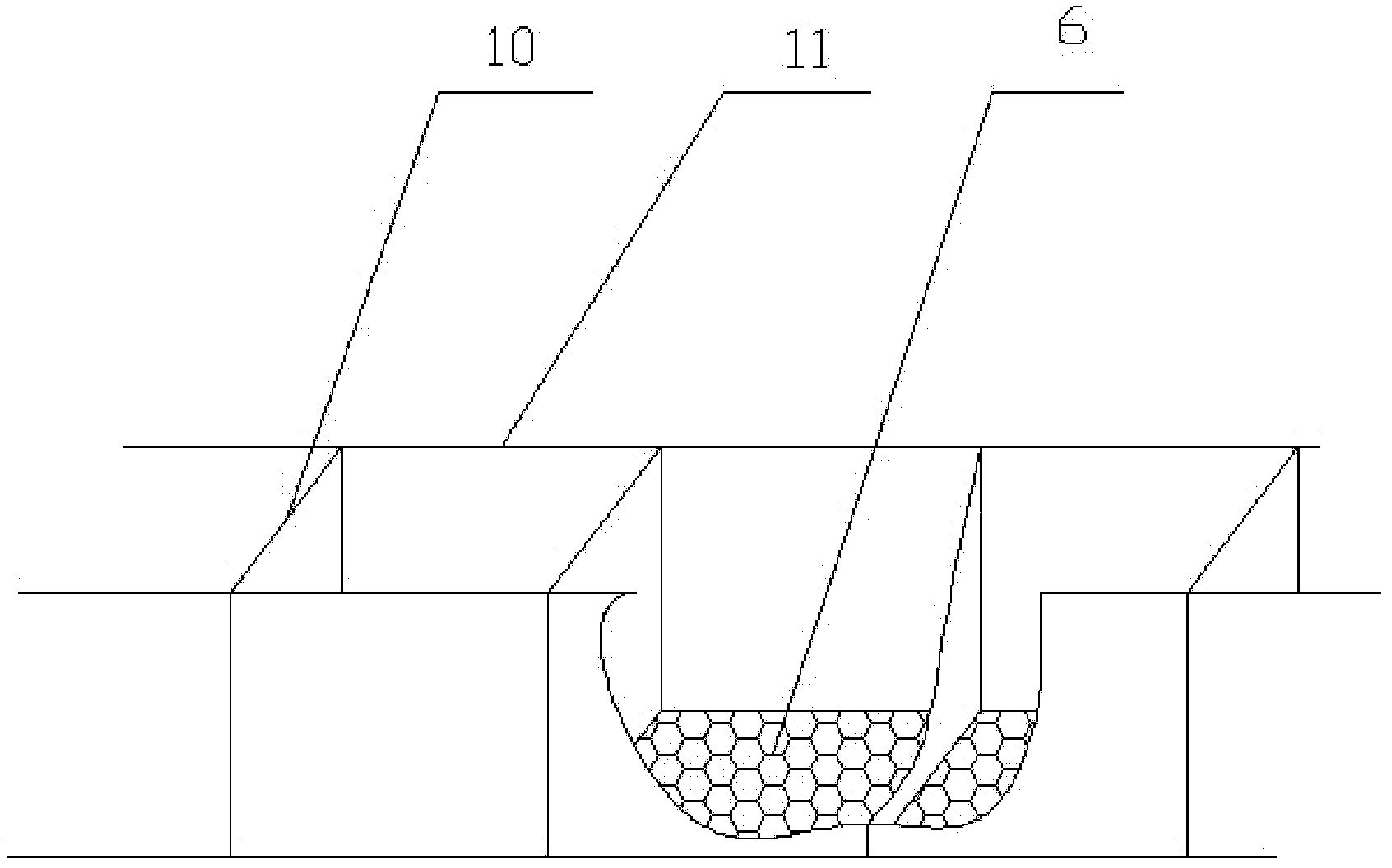

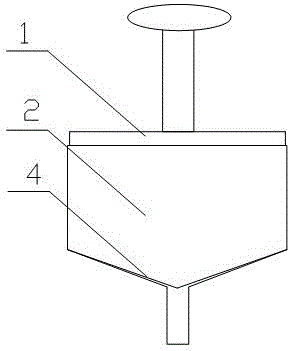

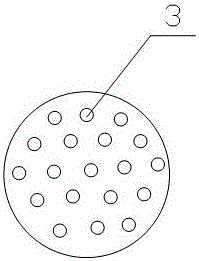

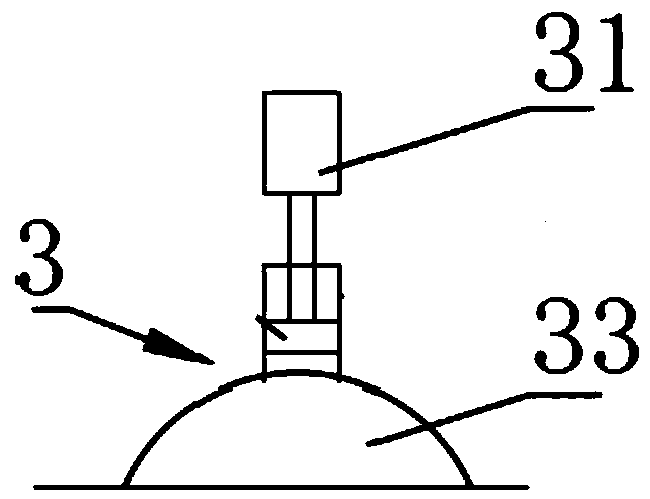

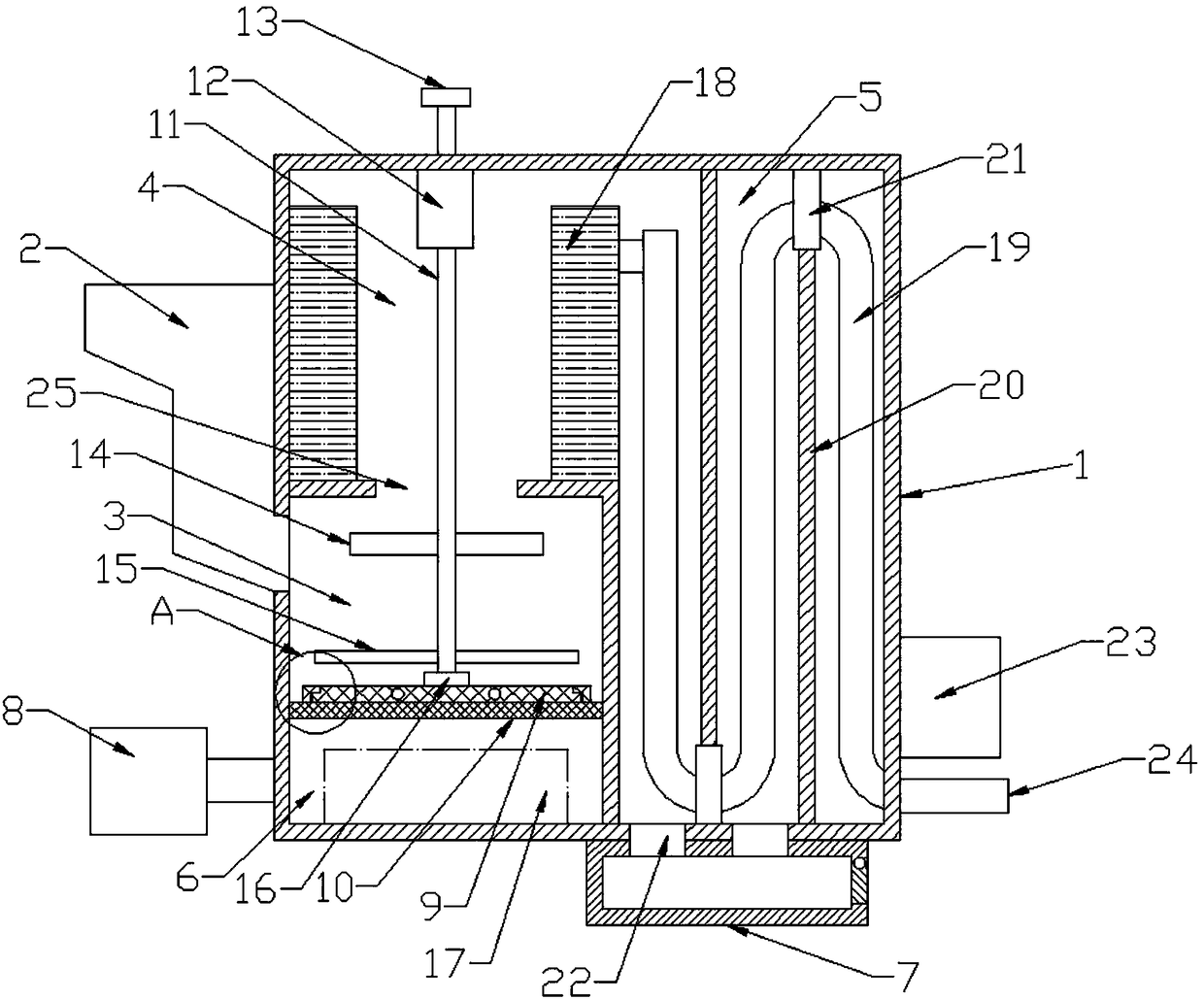

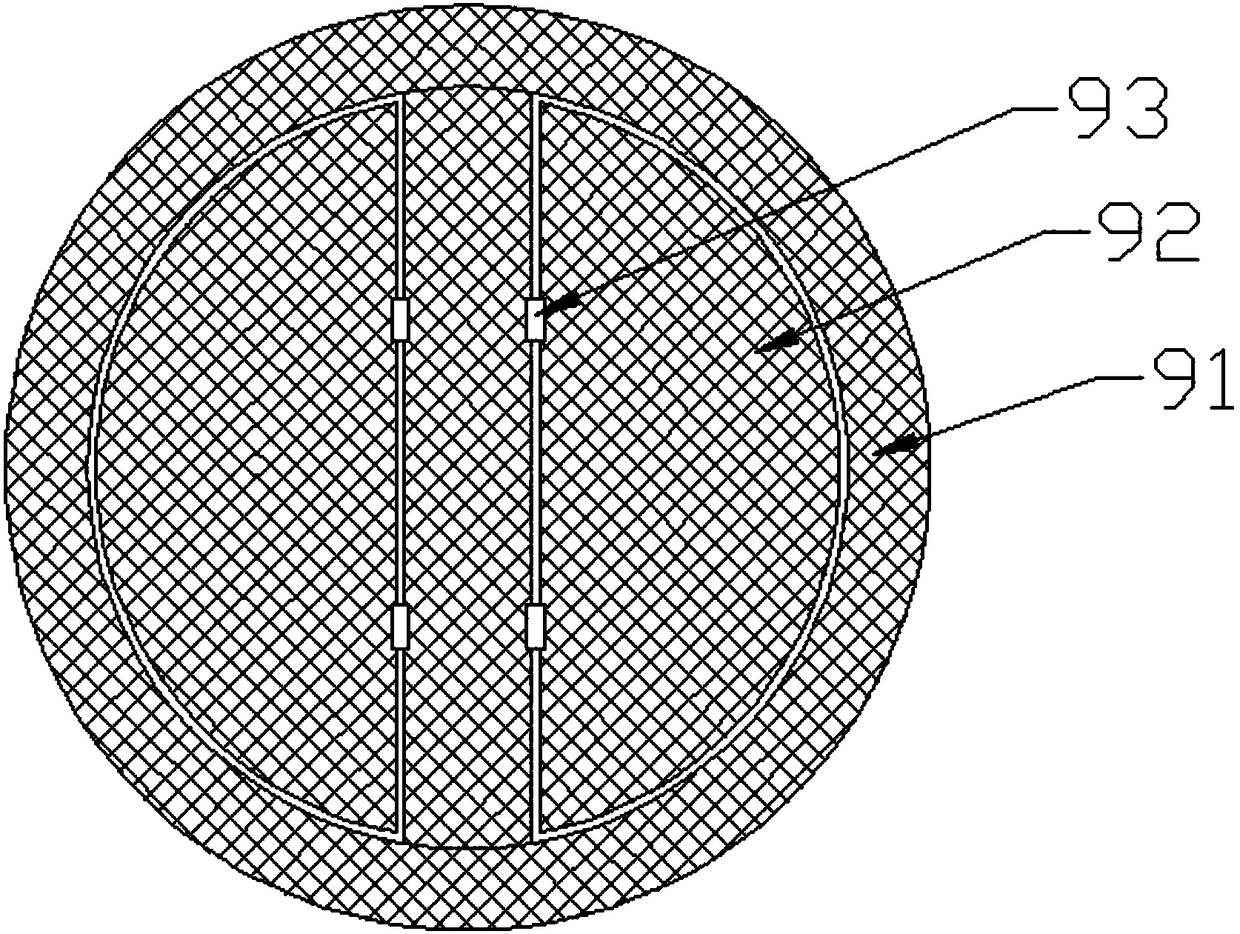

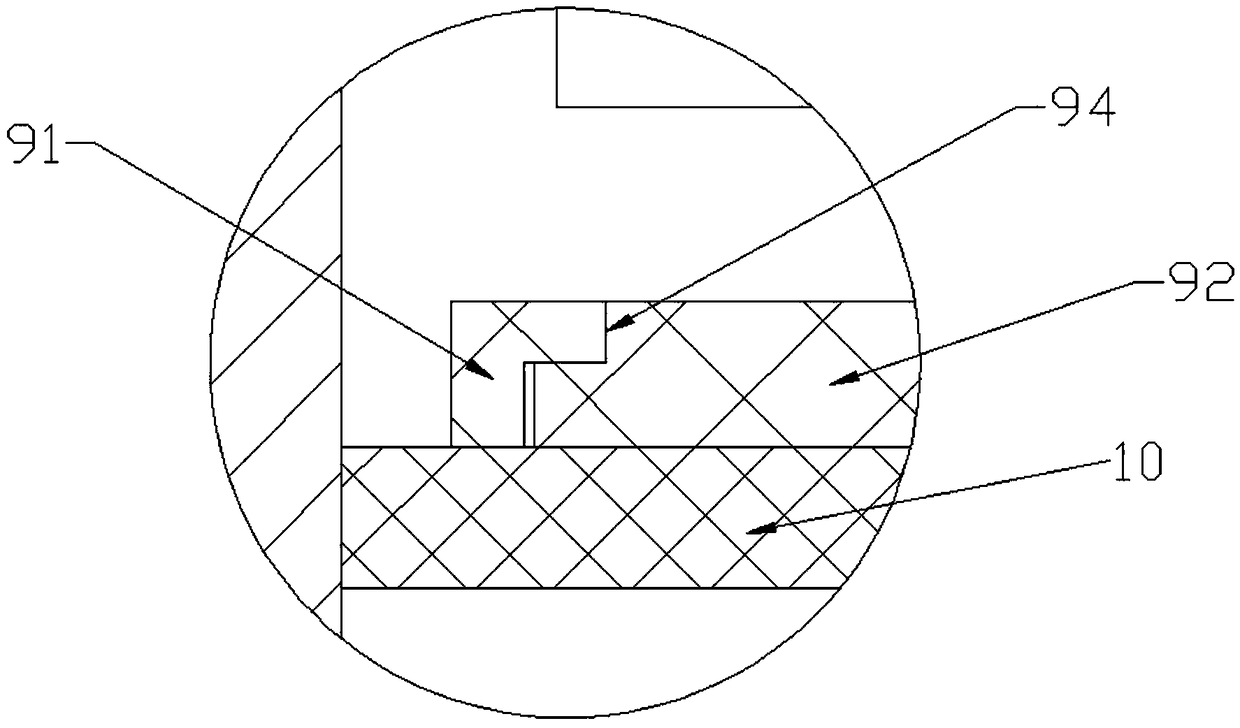

Forming method and device of ceramic micro-bead green body

The invention relates to a forming method and device of a ceramic micro-bead green body, belonging to the technical field of structural ceramics. The forming method of the ceramic micro-bead green body comprises the following steps of: preparing suspended slurry by adopting ammonium citrate and polyacrylic acid, forming liquid beads via a titrator, enabling the liquid beads to drip into hot glycerin in a collecting tank for forming beads, and solidifying to form the micro-bead green body. The forming device of the ceramic micro-bead green body is as follows: a slurry storage tank is connected with the titrator, a titration hole is arranged at the bottom of the titrator, the collecting tank containing the glycerin is arranged below the titrator, the collecting tank is provided with a heating device, and a screen mesh is arranged in the collecting tank. According to the forming method disclosed by the invention, slurry prepared by safe and non-toxic raw and auxiliary materials, and the beads are formed in the hot glycerin and solidified. The forming method and device has the advantages of simple equipment, convenience in operation, good quality of the formed beads, high efficiency and capability of realizing continuous production. The forming method and device which has the benefits of safety, environmental protection, simplicity in operation and high efficiency is provided for forming the ceramic micro-bead green body.

Owner:GANZHOU KOIN STRUCTURE CERAMICS

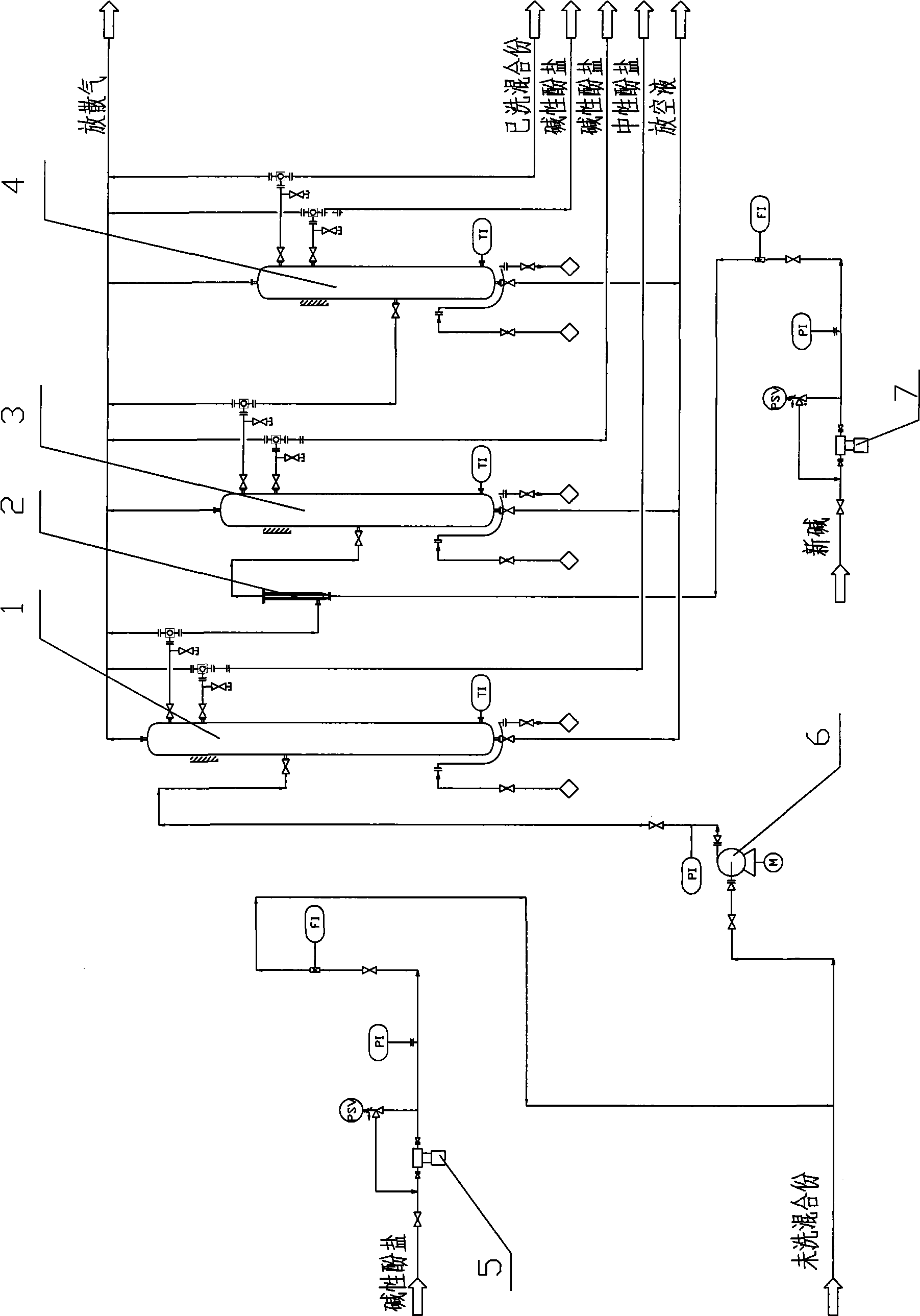

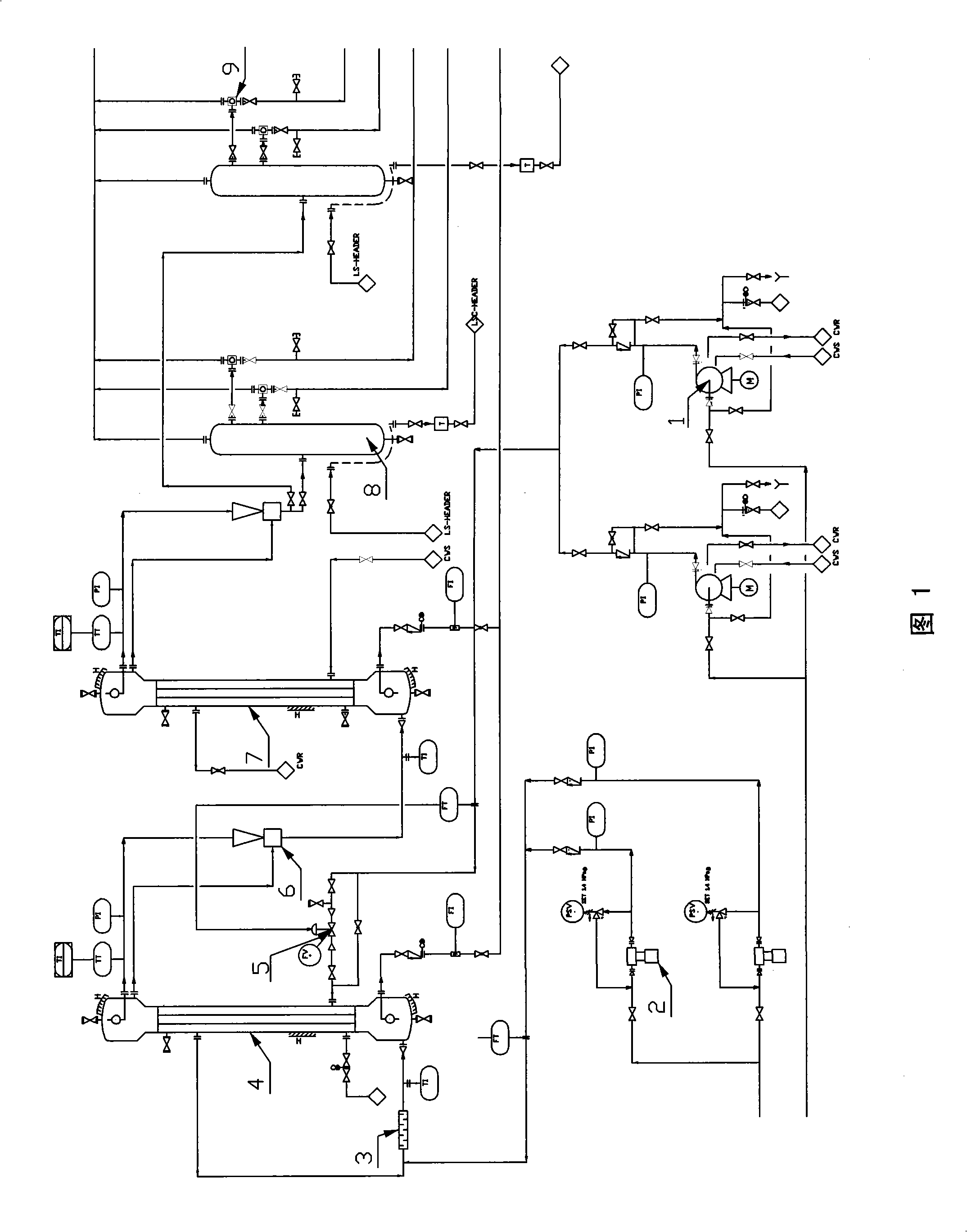

Distillate dephenolizing process and apparatus thereof

The invention relates to a distillate dephenolizing process for the middle production procedure of a coal tar processing device. The technical process comprises the following steps: using a dephenolizing washer pump to pump out the unwashed mixed part which comes from a tar distillation plant so as to be mixed evenly and react with basic phenate together in the dephenolizing washer pump; putting the mixed solution into a primary dephenolizing tower to be kept stand and separated into a mixed part and neutral sodium phenolate, wherein the mixed part enters a secondary dephenolizing tower through a mixing nozzle; and in order to further remove phenols in the mixed part, using 10 to 12 percent diluted alkaline to perform secondary dephenolizing on the mixed solution before the mixed part enters the secondary dephenolizing tower. The mixture is kept stand and separated into the basic phenate and a washed mixed part in the secondary dephenolizing tower, the washed mixed part flows into a phenate removing tower automatically and is kept stand and separated out the residual basic phenate in the phenate removing tower, then the basic phenate flows into a basic phenate groove, and finally the washed mixed part enters a industrial naphthalene distillation plant for further processing. The process can reduce the environmental pollution, save energy resources and improve the efficiency.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

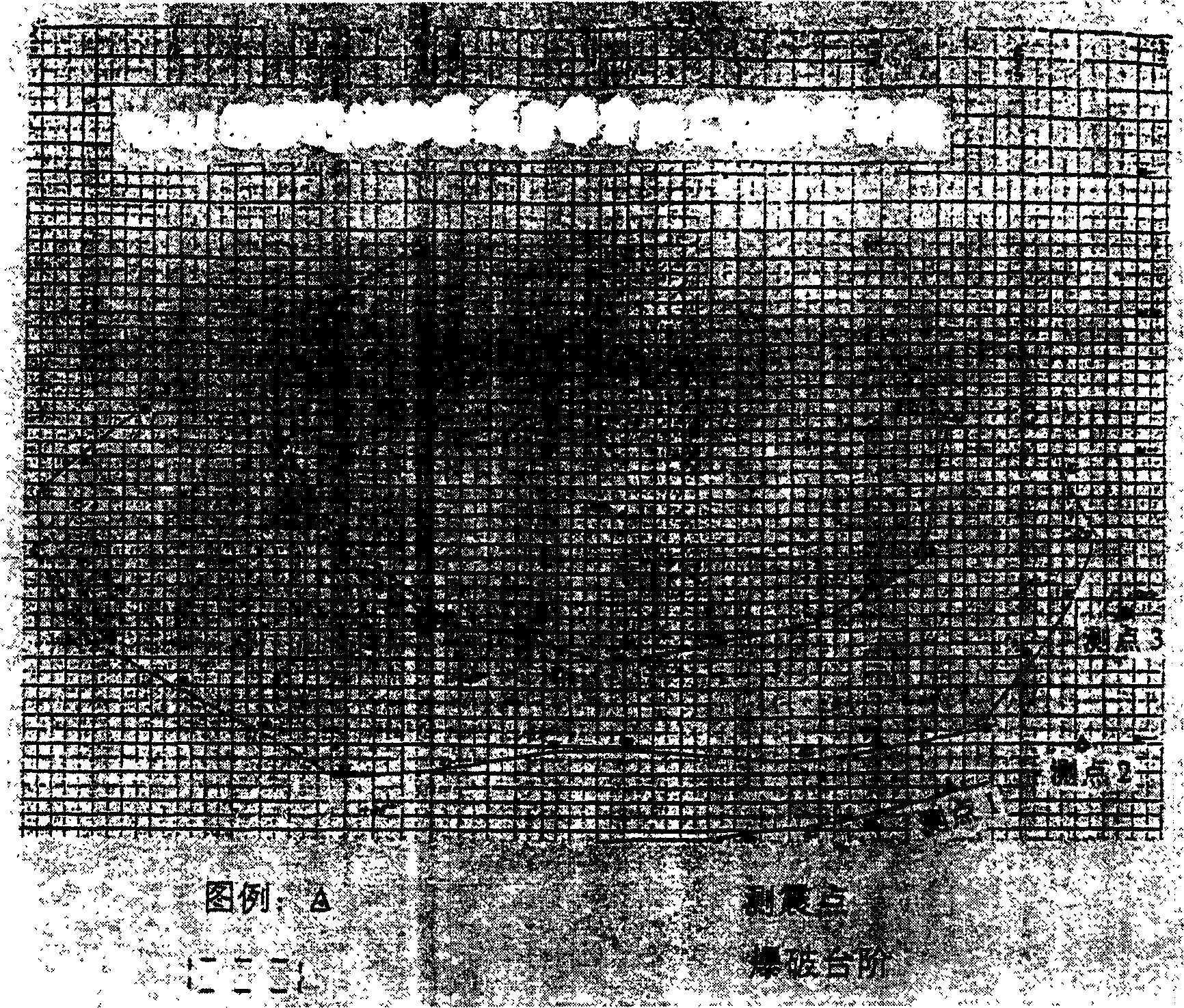

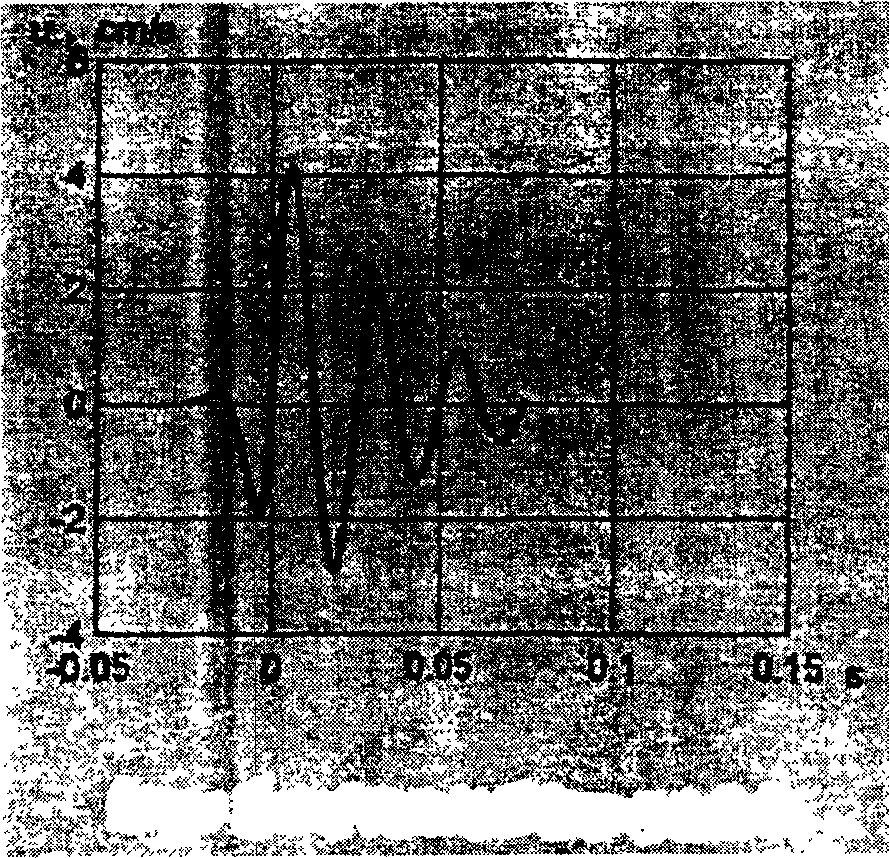

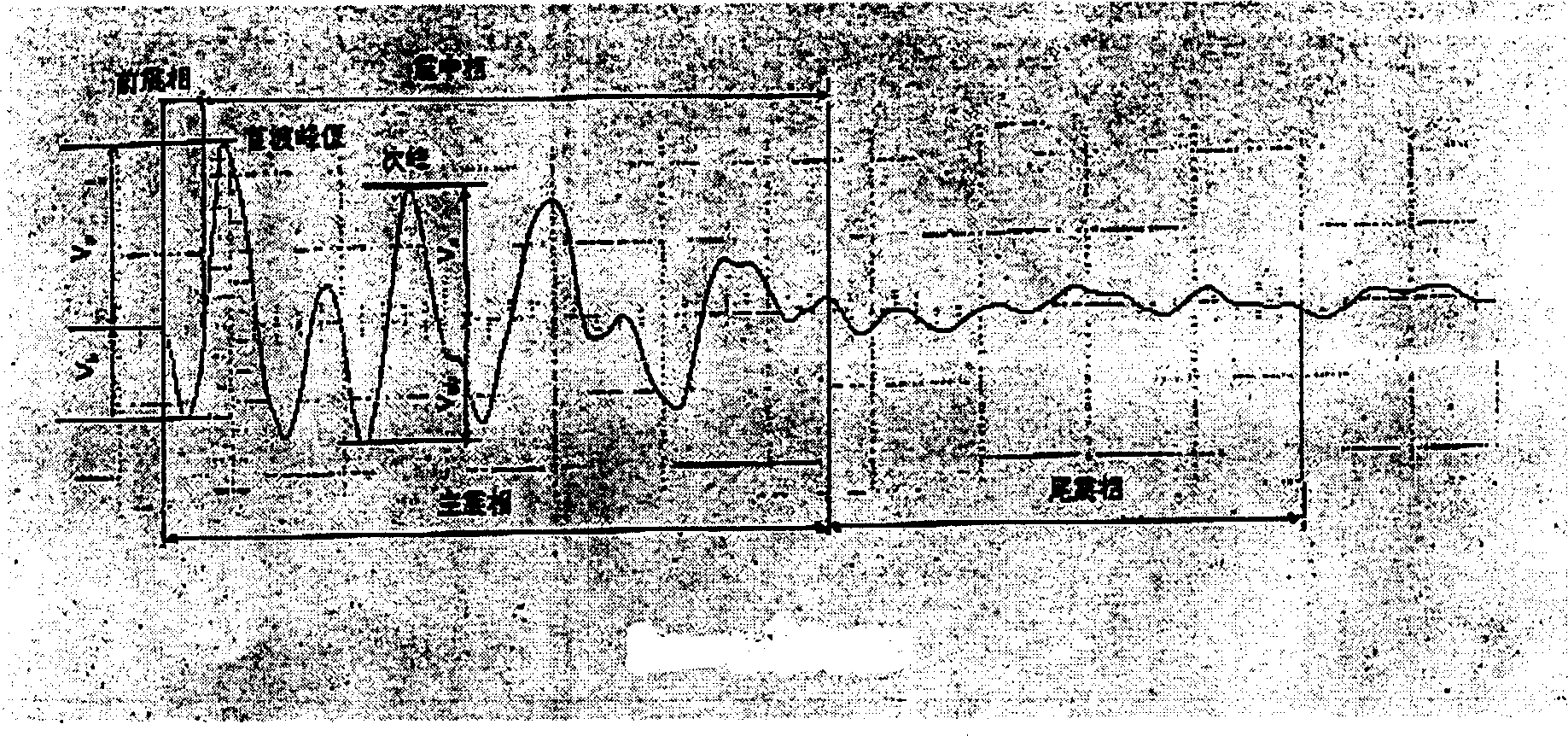

Electric calculating precise time delay interference shock eliminating blasting method

InactiveCN1619254ARelease production capacityAccurate Detonation DelayBlastingElectricityTime delayed

The present invention disclosed an electronically-calculated precision-delayed interference shock-damping blasting method. Said method uses adjacent two blastholes are a group, and utilizes actually-measured blast synthetic wave and composition wave as basic data, and utilizes computer to make precision calculation to obtain accurate delay time for making next blasting, and utilizes the interference to attain the goal of damping shock.

Owner:GUANGDONG HONGDA BLASTING

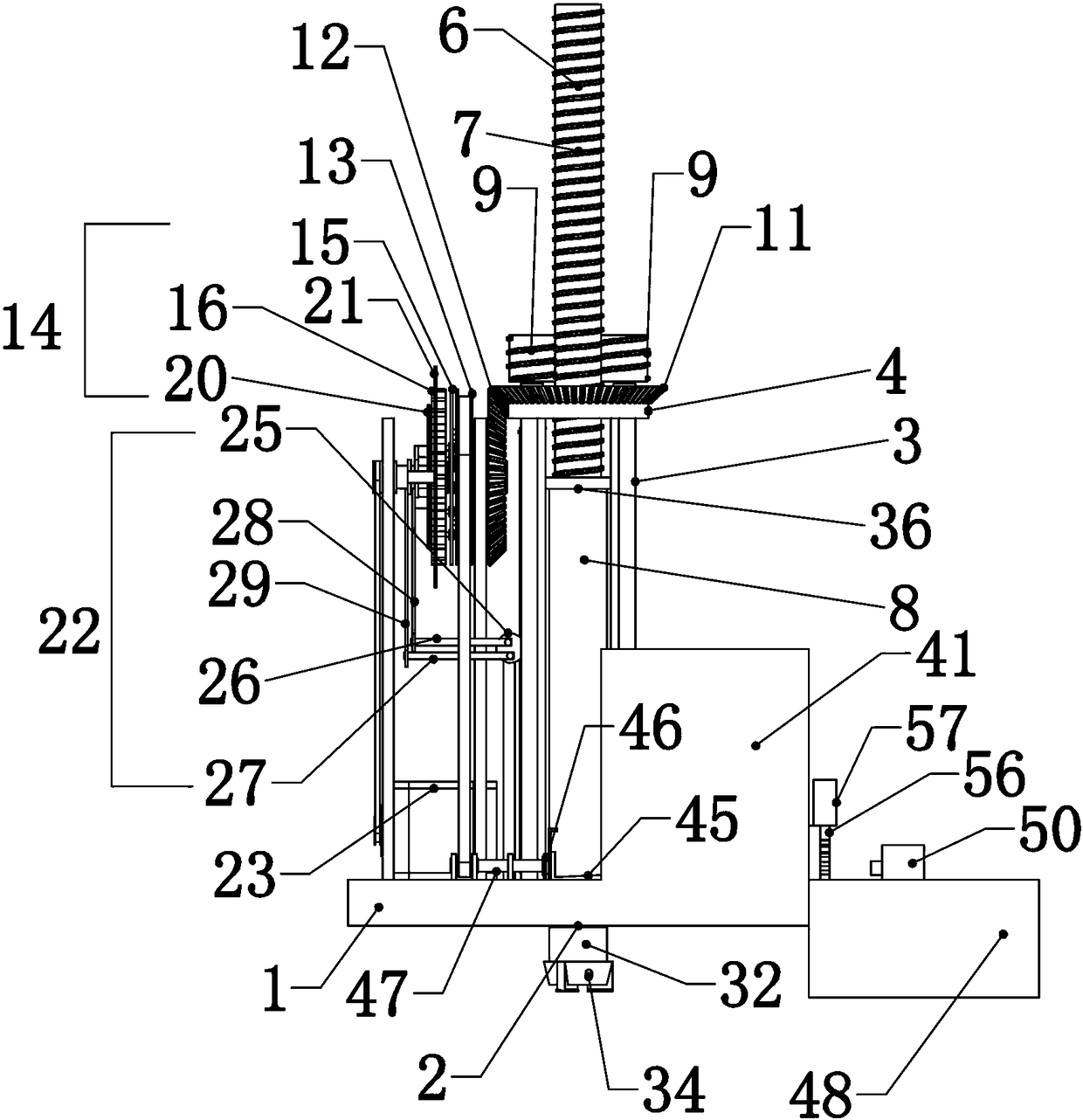

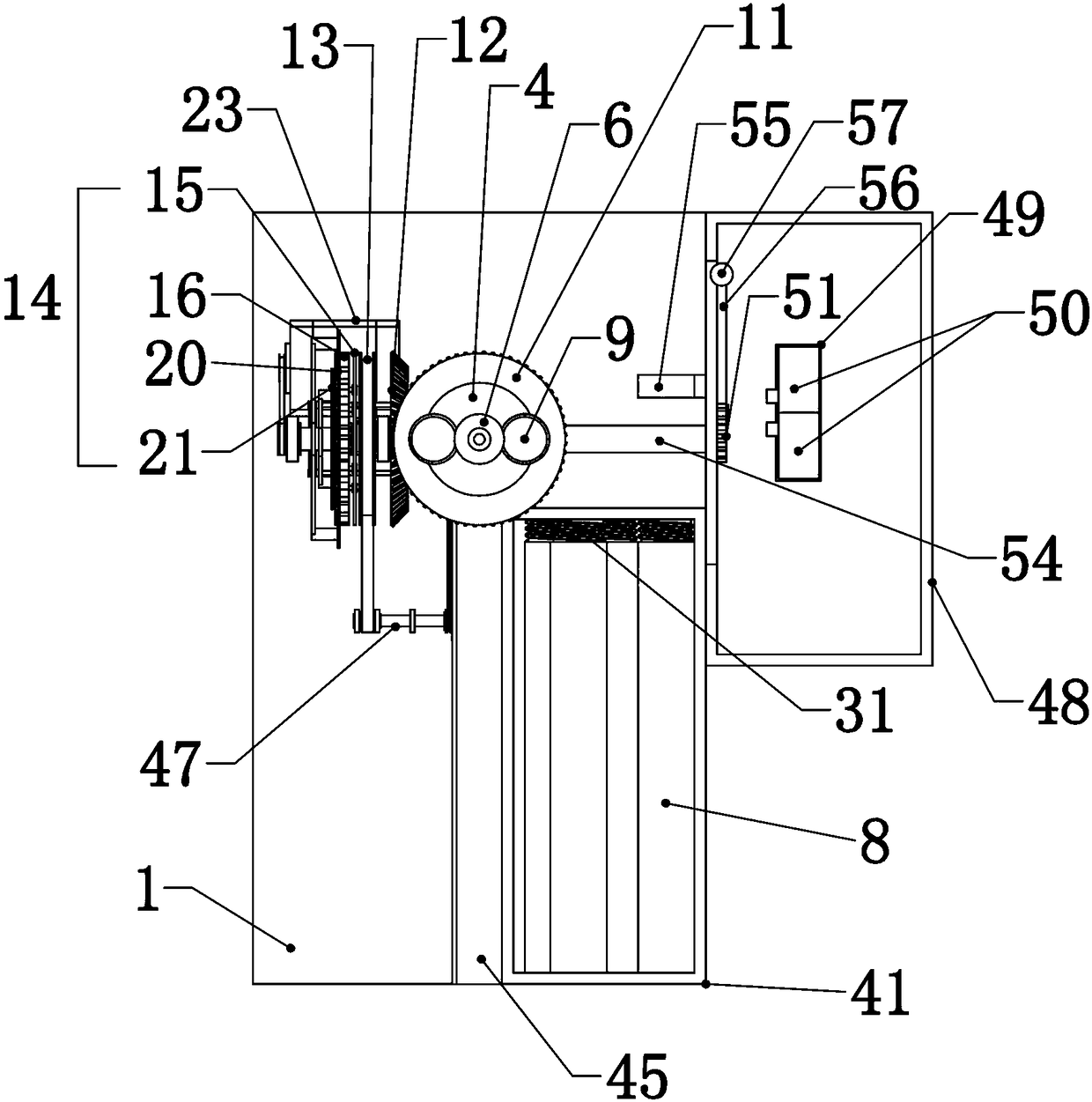

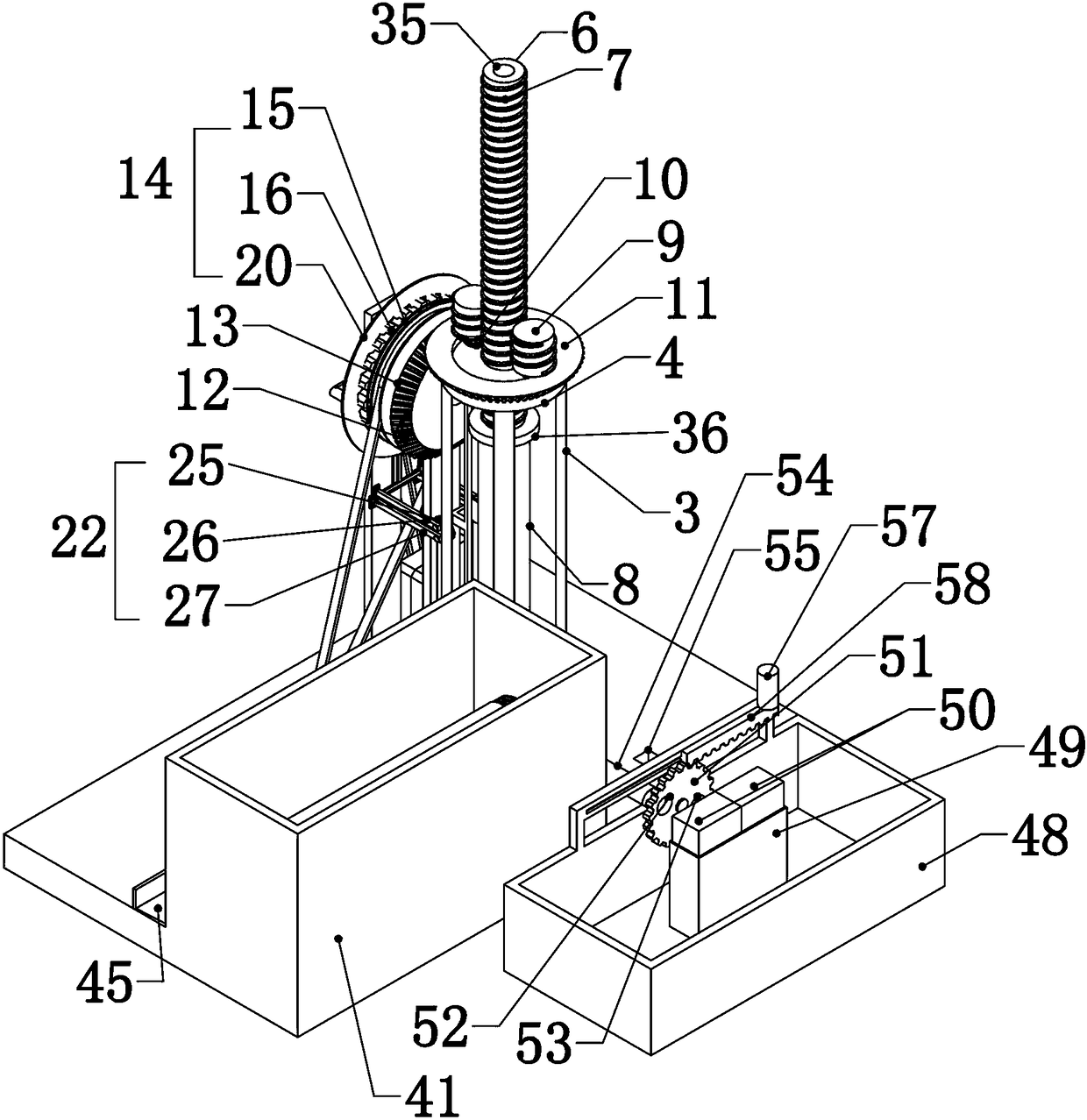

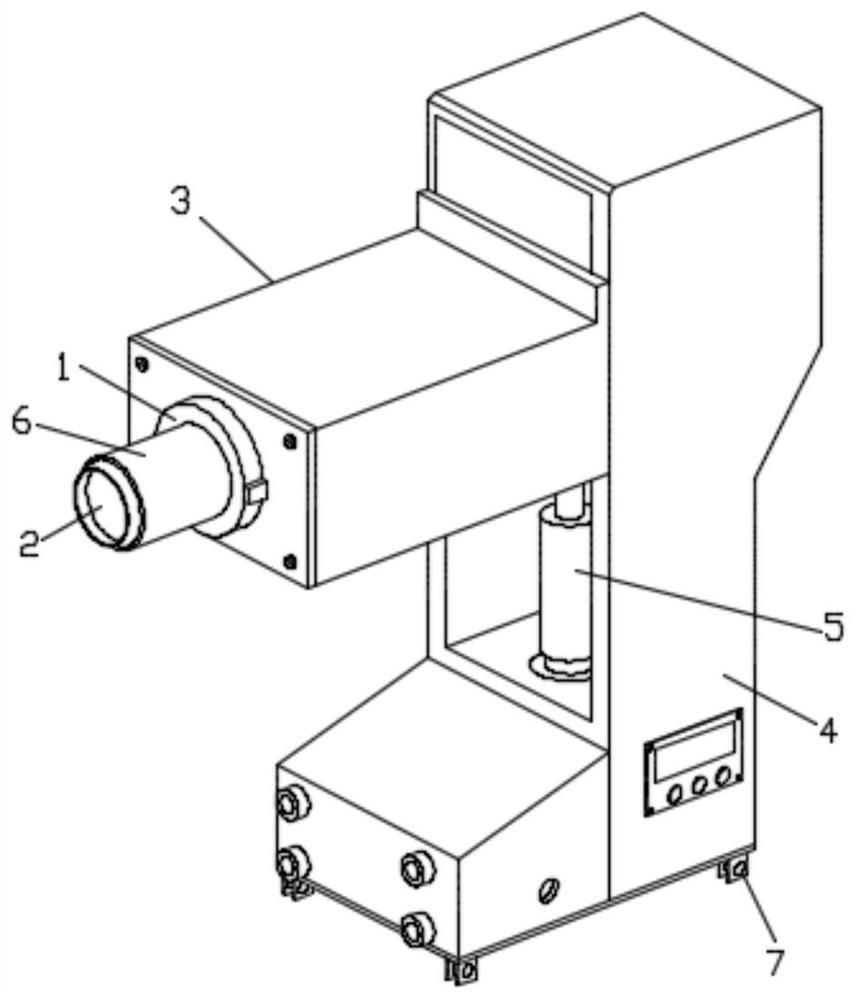

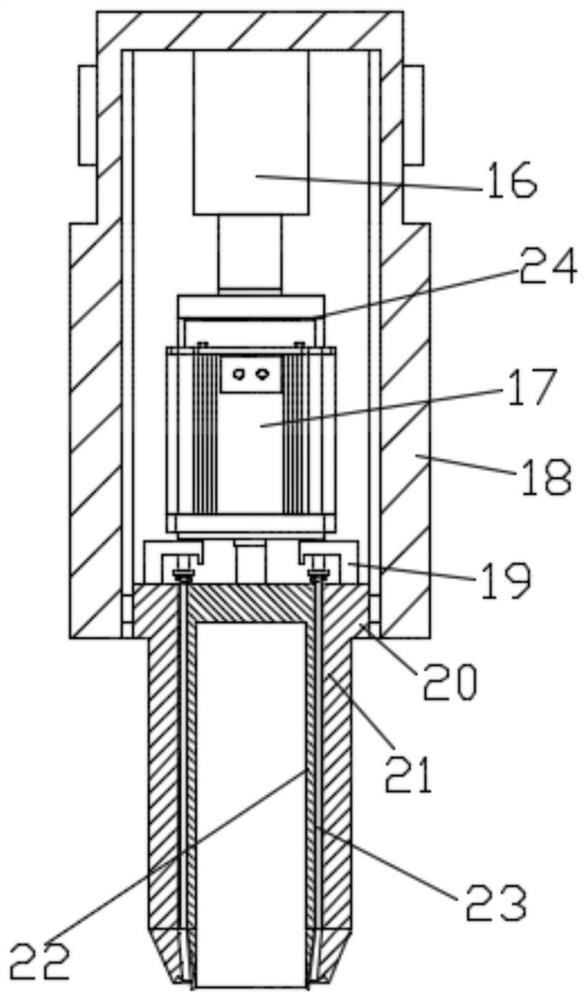

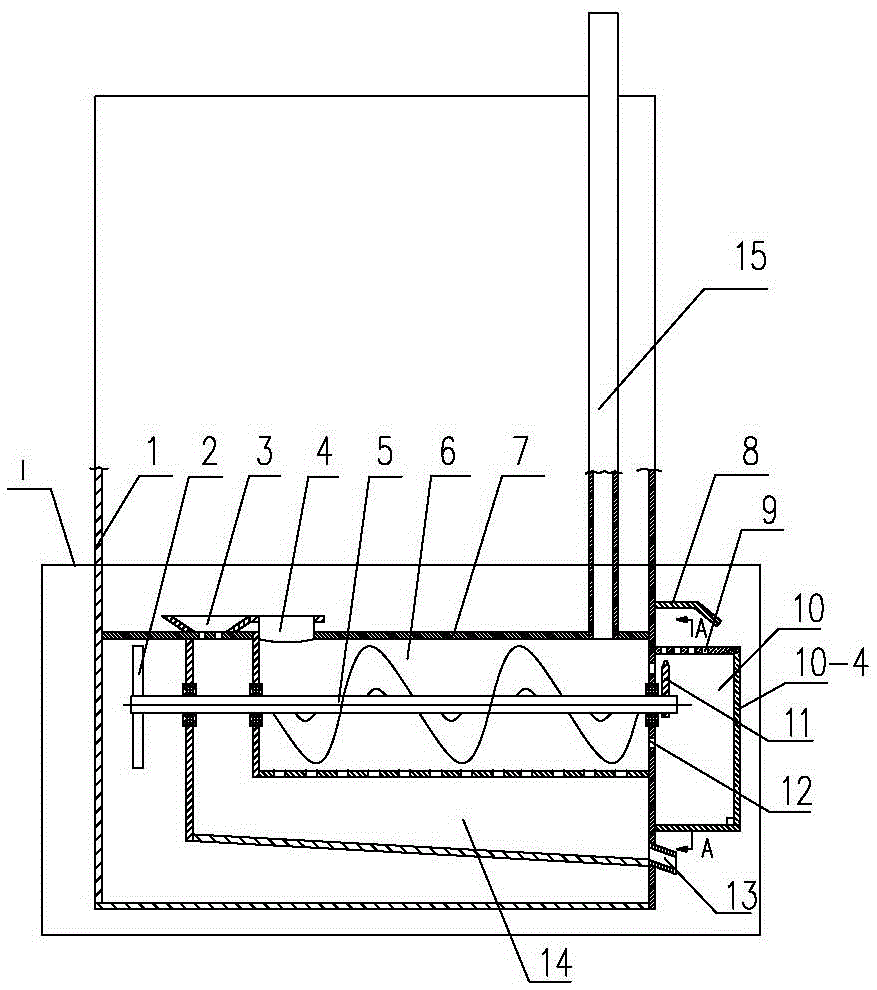

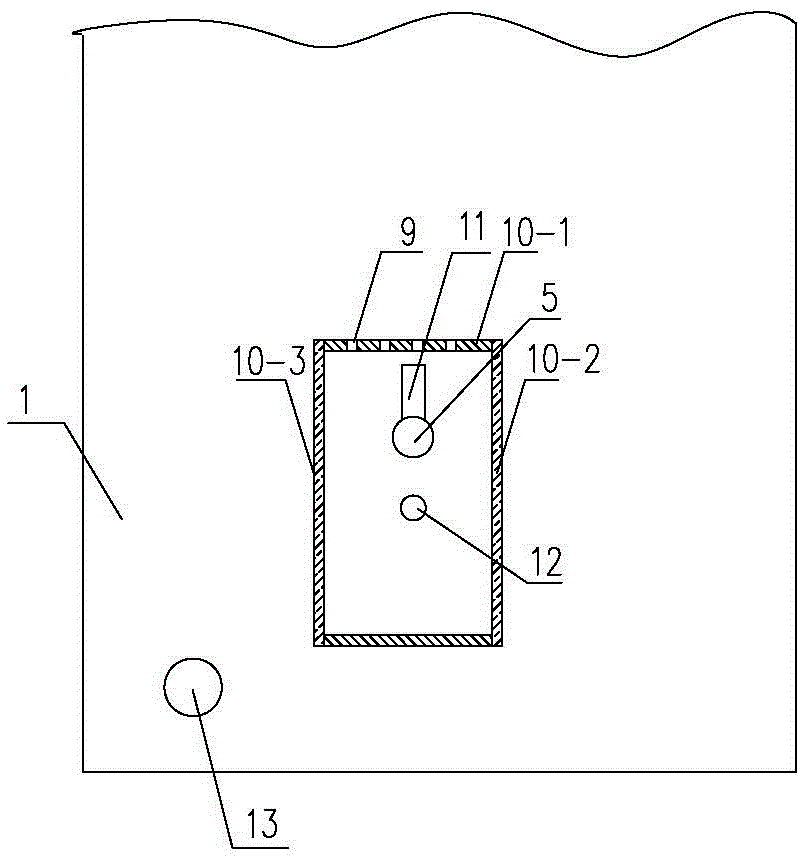

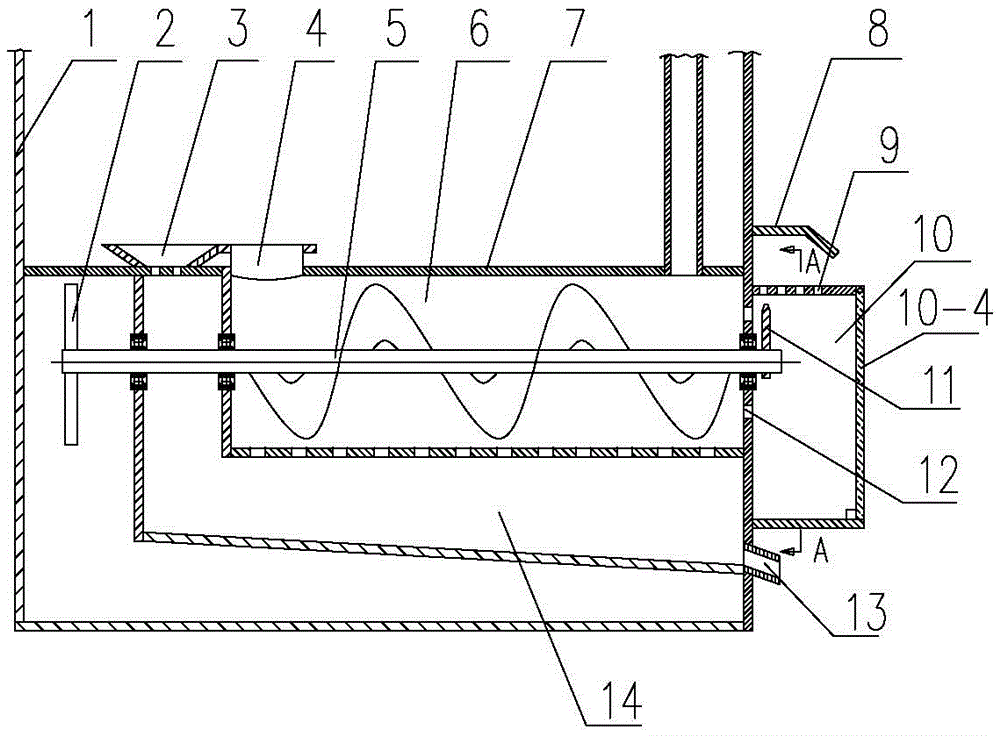

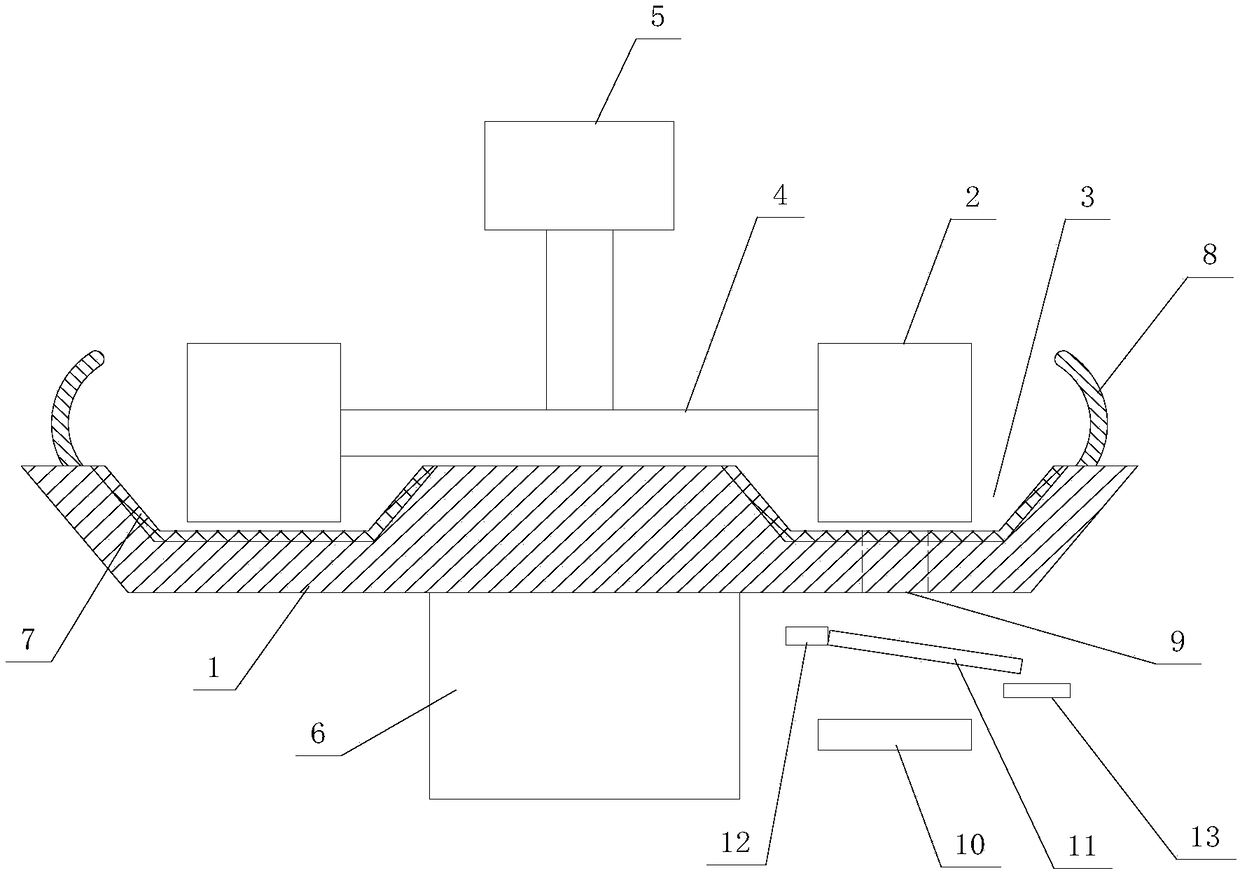

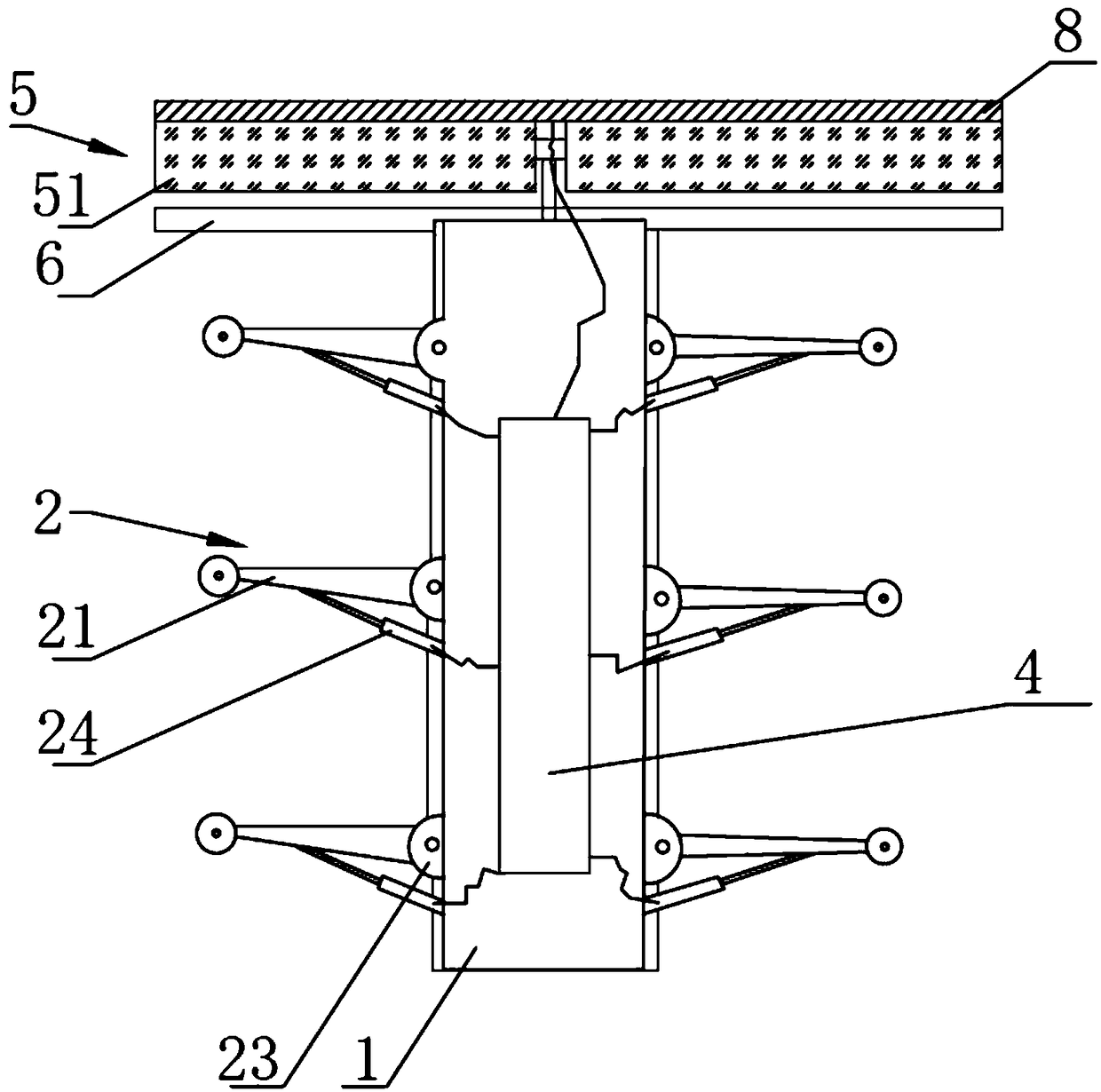

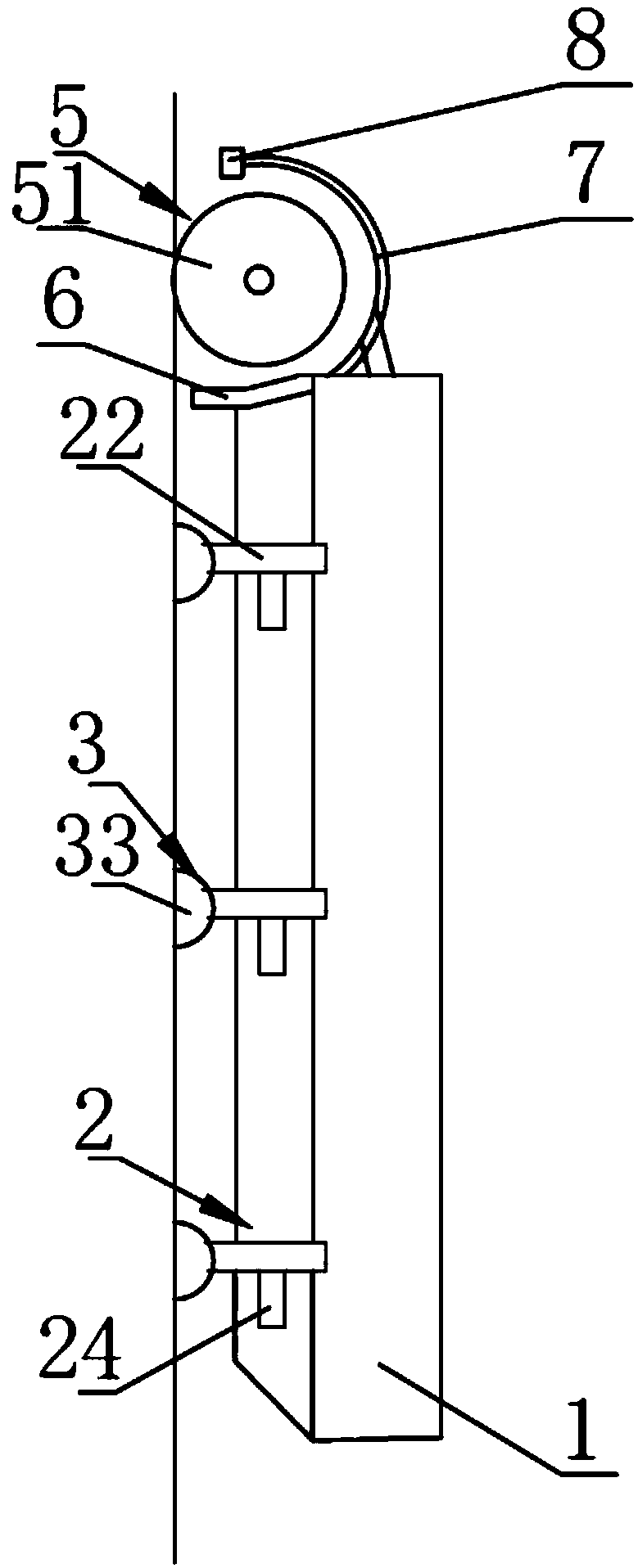

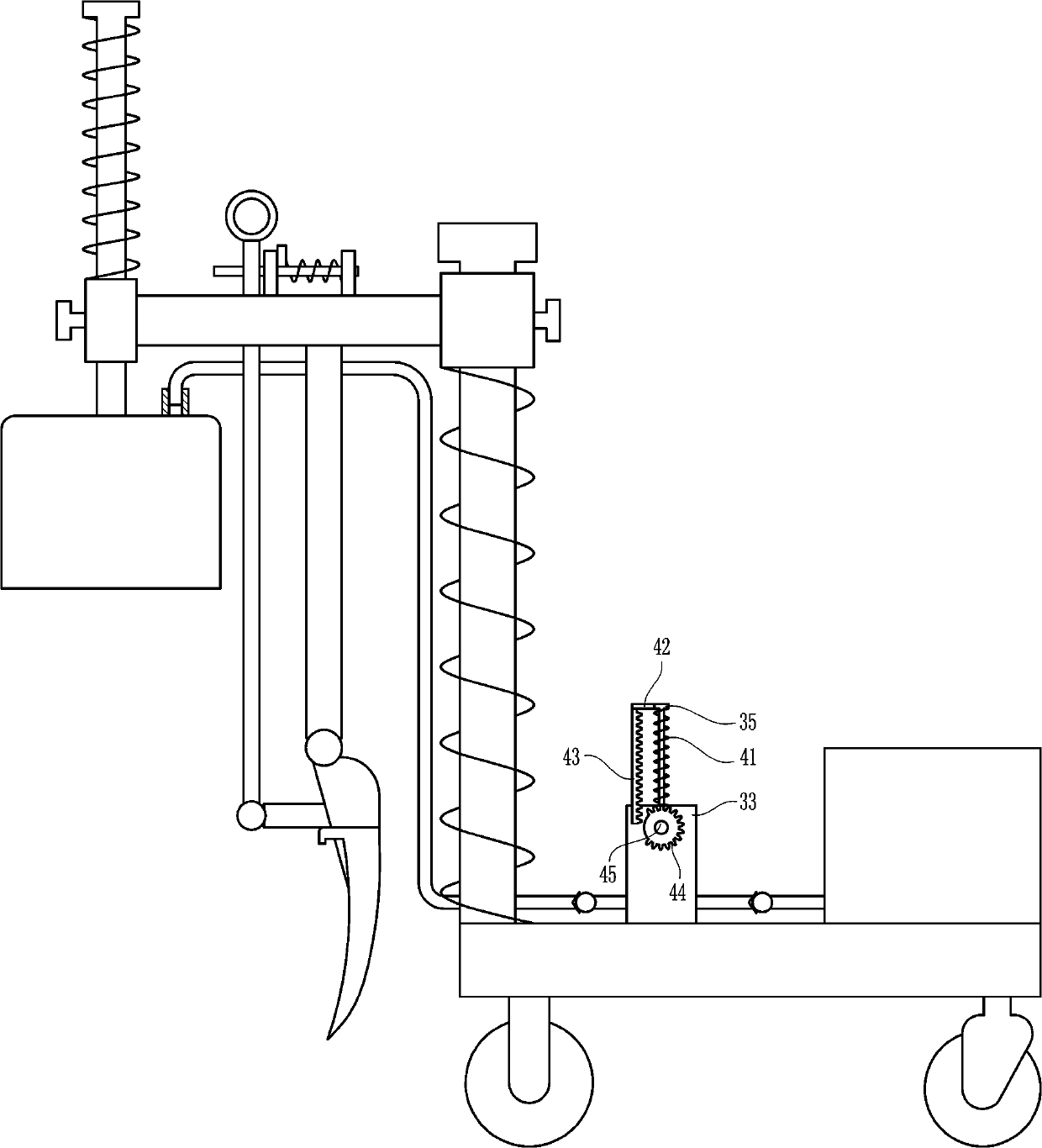

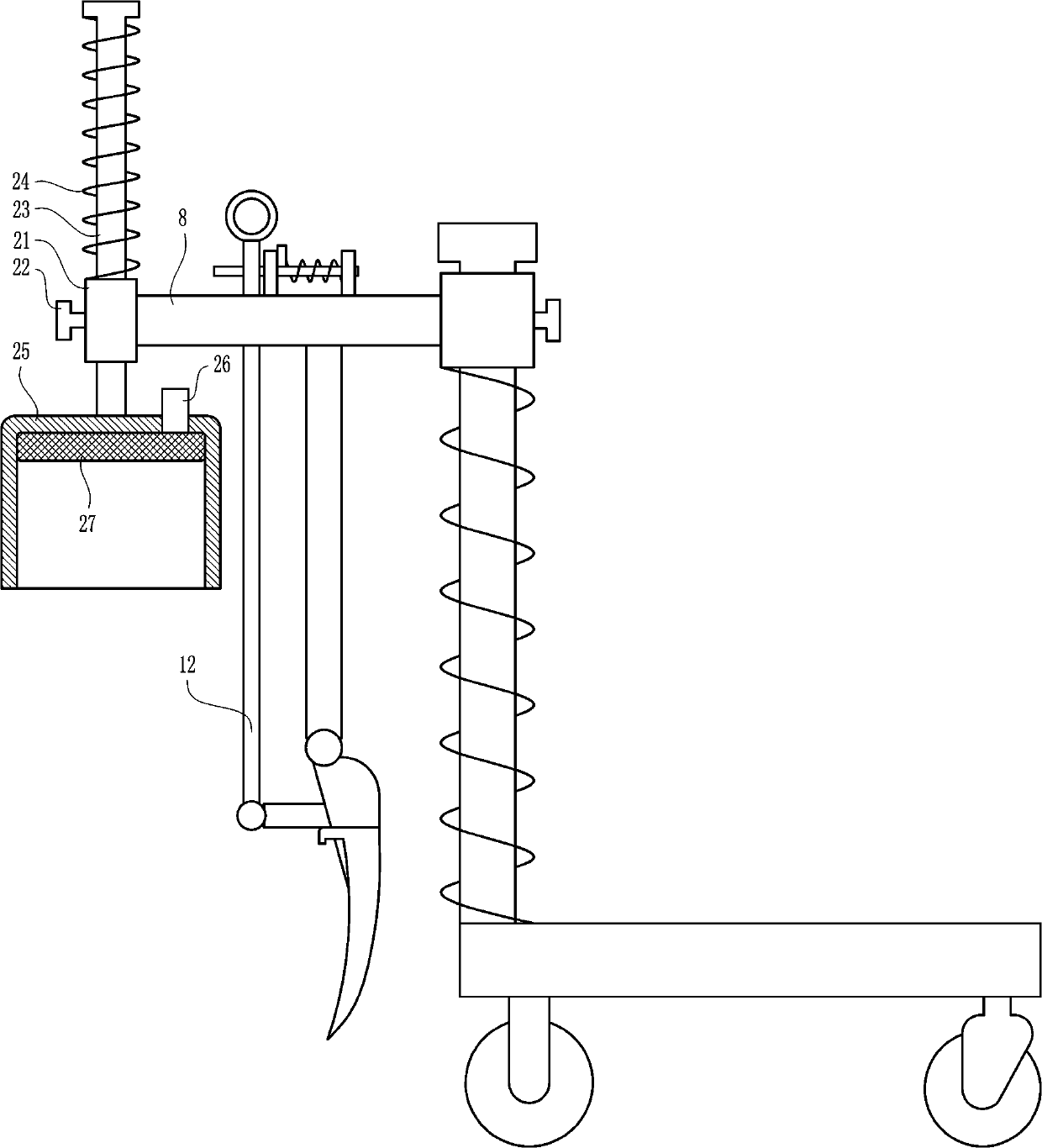

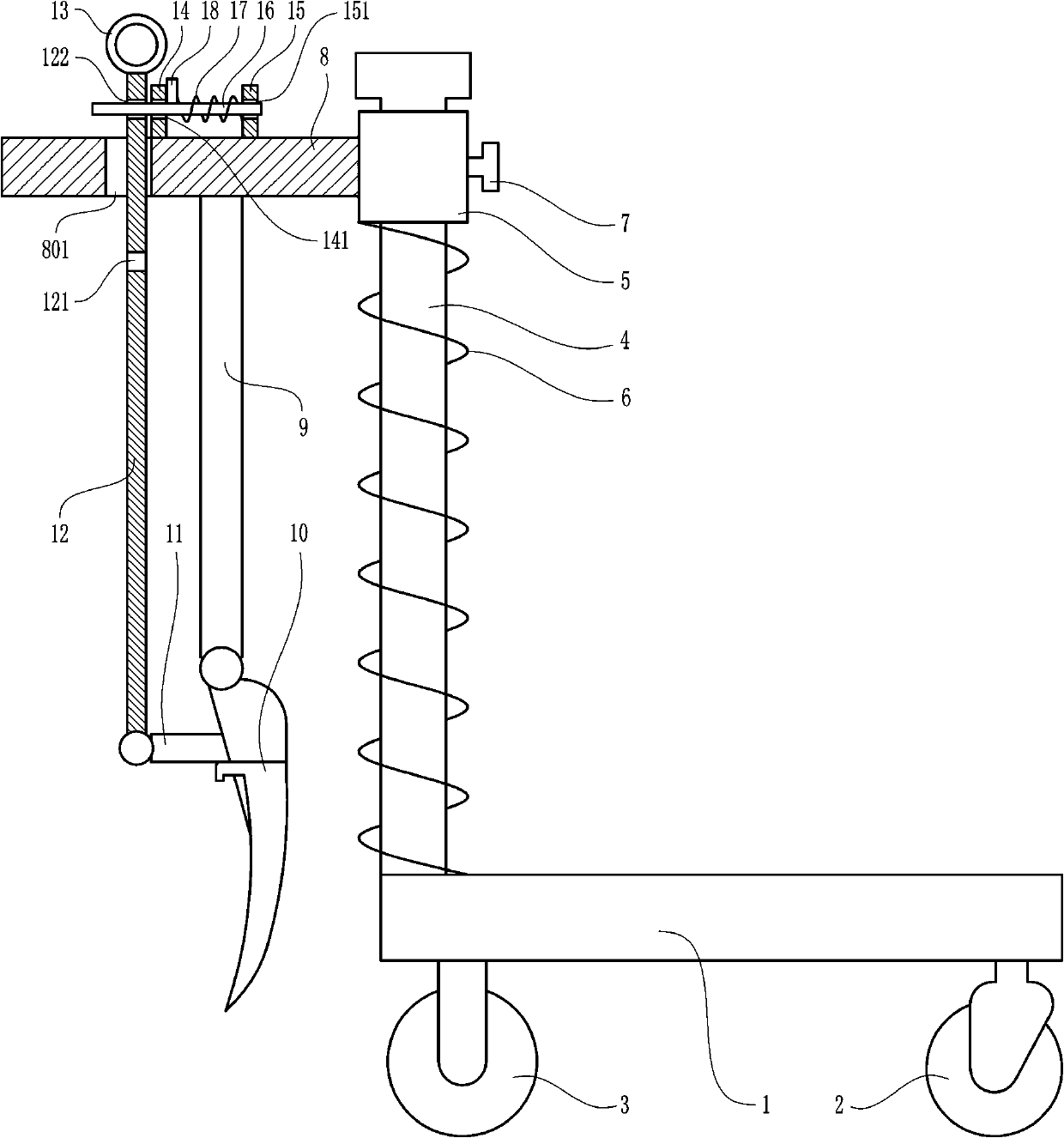

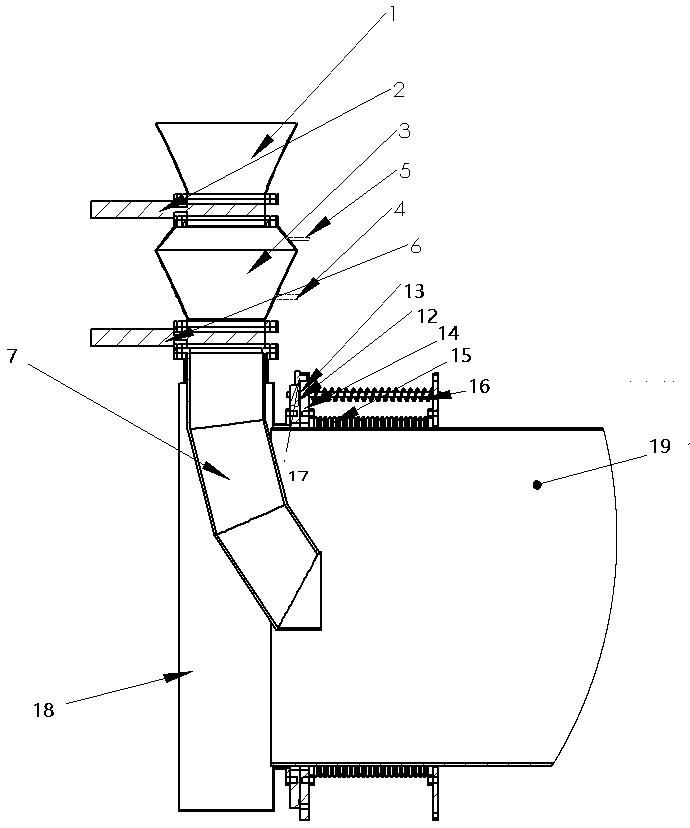

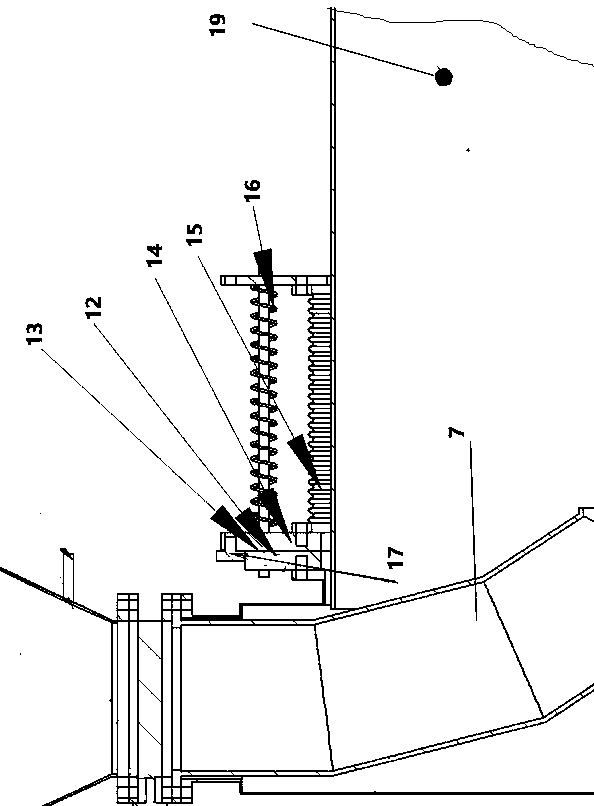

Drilling machine for road construction

ActiveCN108505949AReduce labor intensityFully automatedDrilling rodsConstructionsControl systemEngineering

The invention relates to a drilling machine for road construction. The problem that an existing drilling machine cannot change directions and replace rods automatically is effectively solved. According to the technical scheme, the drilling machine comprises a workbench, a drill hole is formed in the workbench, the workbench is integrally connected with a locating circular ring by a supporting column located near the drill hole, and a locating circular ring thread is arranged on the inner wall of the locating circular ring in a tapping mode. A rotating rod is arranged in the locating circular ring, a rotating rod thread is arranged on the outer wall of the rotating rod in a tapping mode, the rotating rod meshes with the locating circular ring in a threaded mode, and a drill rod is connectedto the lower end of the rotating rod in a threaded mode. A driving screw is arranged next to the drill rod in a threaded and meshing mode, the rotating rod can drive the locating circular ring to move rotatably up and down in the locating circular ring, a driven small gear is integrally and coaxially connected to the lower end of the driving screw, and a driving gear ring is arranged outside thedriven small gear in a meshing mode. A helical tooth is arranged outside the driving gear ring, a driven helical gear is arranged next to the driving gear ring in a meshing mode, a driven belt pulleyis integrally connected to the driven helical gear, a planetary gear train is in pin joint with the driven belt pulley, and the planetary gear train is controlled by a control system. The drilling machine for the road construction improves the efficiency of construction work.

Owner:刘国胜

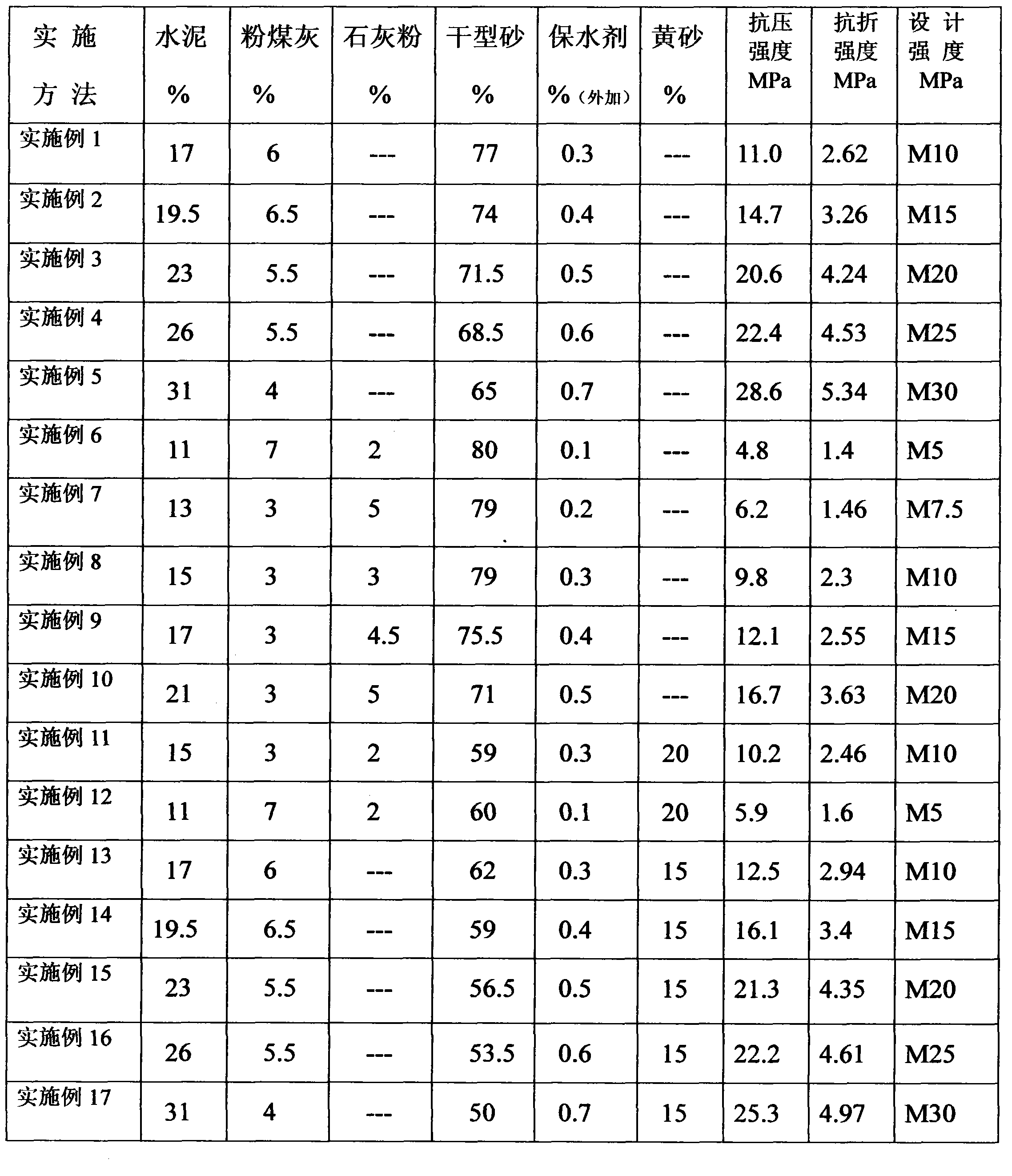

Waste foundry sand dry-mixed mortar

The invention relates to a waste foundry sand dry-mixed mortar, belonging to the technical field of circular economy and building material mortar. The waste foundry sand dry-mixed mortar is characterized in that the production raw materials of the dry-mixed mortar are based on waste foundry sand with the following mass ratio: 11-31% of cement, 3-7% of dry coal ash, 0-5% of dry lime powder, 50-80% of dry waste foundry sand, 0-20% of yellow sand (with particle diameter between 2.36mm and 1.18mm), and 0.1-0.6% of water retaining agent (additionally added). The varieties of the dry-mixed mortar prepared according to the invention comprise various types of dry-mixed masonry mortar, dry-mixed plastering mortar, dry-mixed terrace mortar and the like which all meet the requirements of national standard GB / T25181 Ready Mixed Mortar. The waste foundry sand dry-mixed mortar is beneficial for the harmless treatment and resource utilization of the waste foundry sand, and opens up a brand-new resource regeneration way of the waste foundry sand.

Owner:秦大春

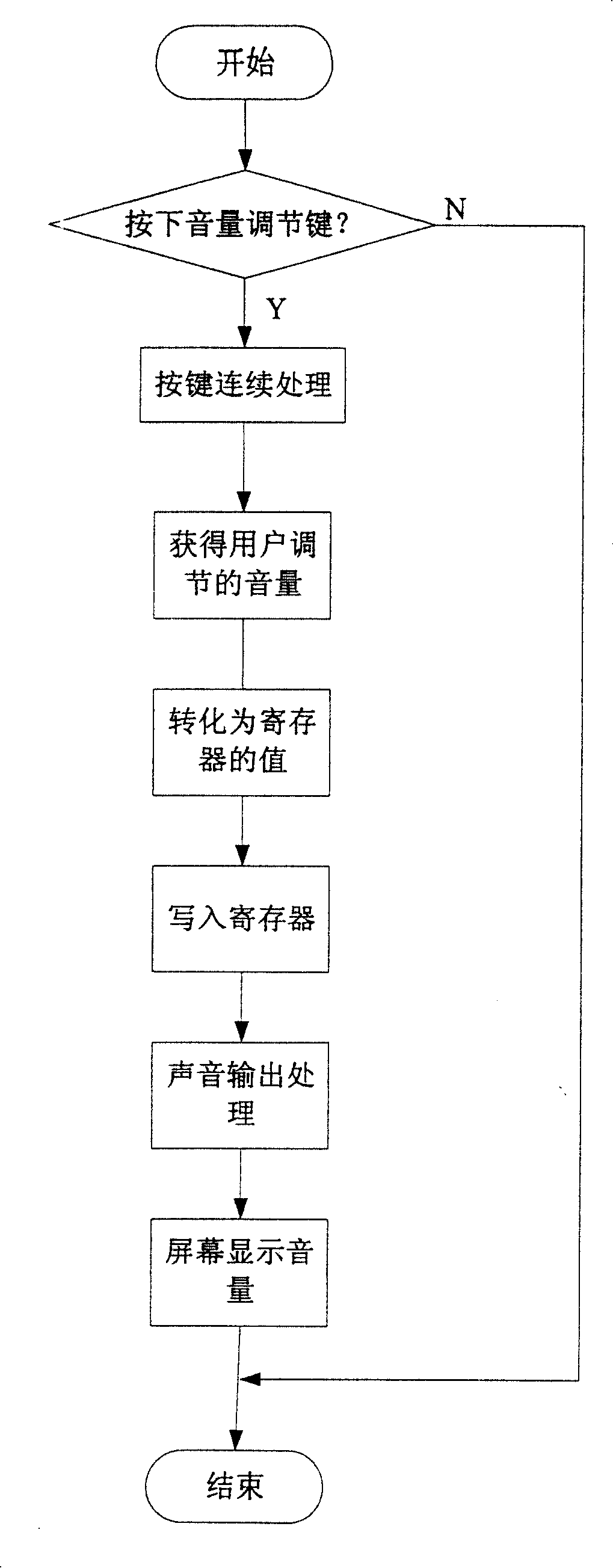

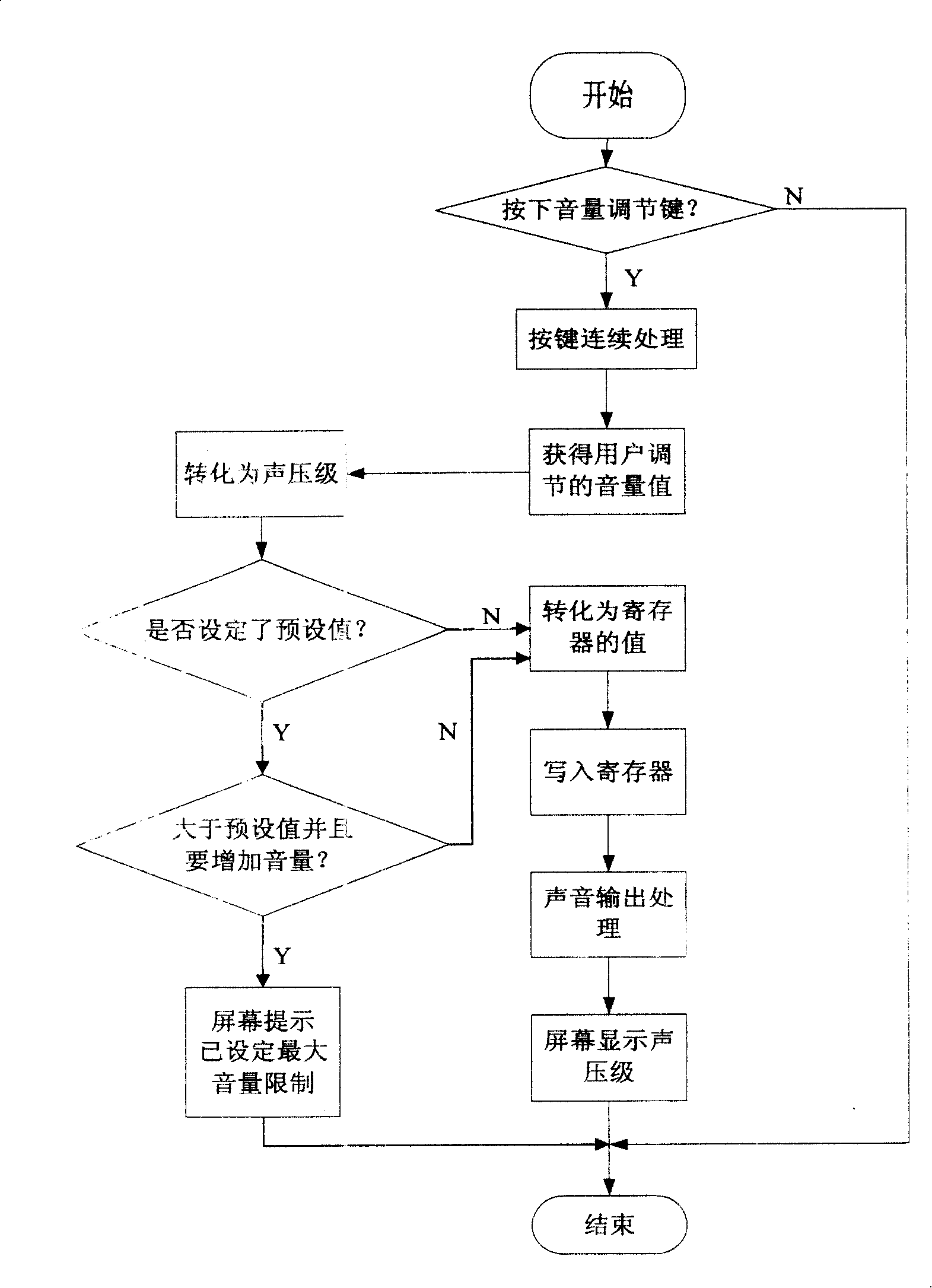

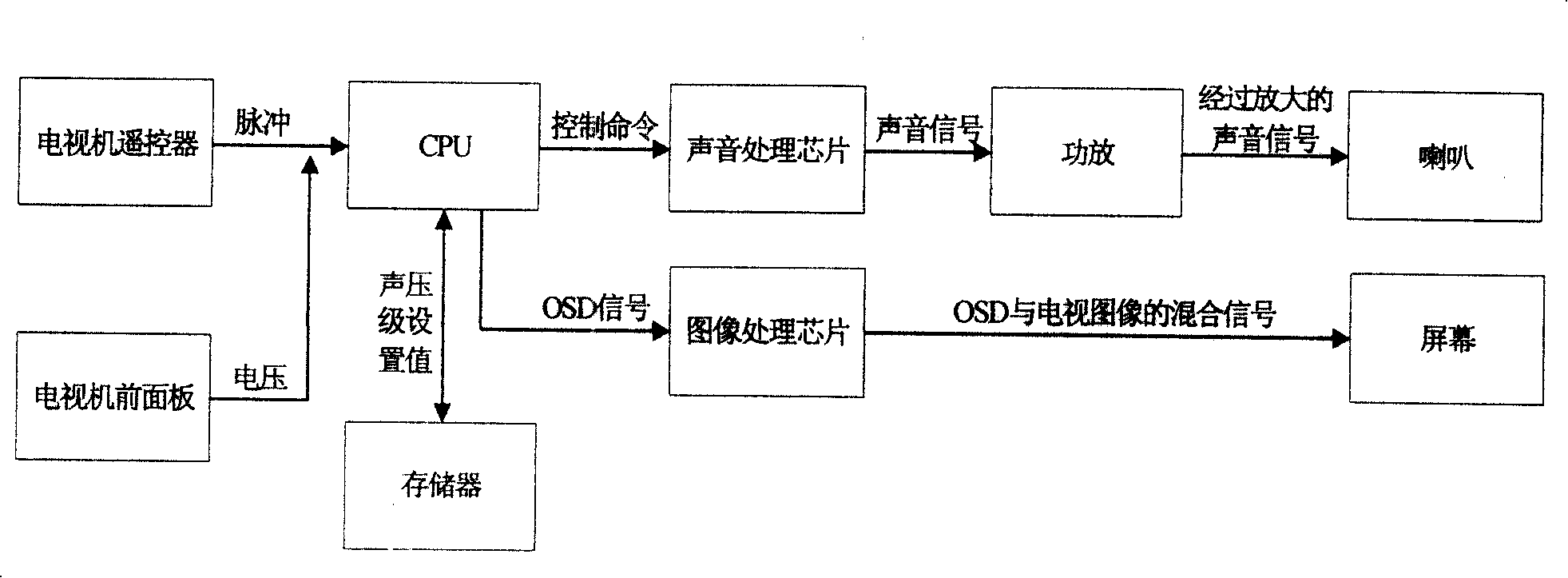

Method and apparatus for setting actual volume of television set

ActiveCN101163215AHearing protectionProtect the surrounding environmentTelevision system detailsColor television detailsProcessor registerTelevision screen

A setting method and device for actual volume of a television comprises a collecting element of actual volume of a television and a memory device. The memory device is used for memorizing preset maximum of actual volume of television and memorizing a correspondent relation table of actual volume and actual acoustic pressure level. The invention includes the following procedures that: a. user presses on the volume-increasing button, thus obtaining needed volume value; b. the television transforms received volume into acoustic volume levels; c. with comparison between the acoustic pressure level and the system-preset volume maximum, if the acoustic pressure level is bigger than the preset volume maximum, operation requesting volume increase will not work, or, d. writing the volume into memory device; e. implementing sound output processing; f. volume is displayed on the television screen. The invention and device can not only enable users know the sound of television and the actual sound pressure, but also protect the hearing of user and surrounding environment by limiting over high sound pressure.

Owner:KONKA GROUP

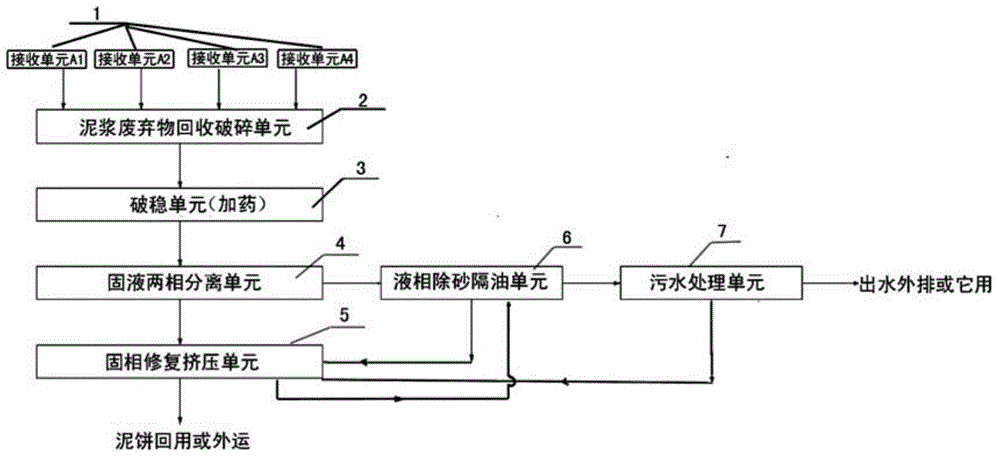

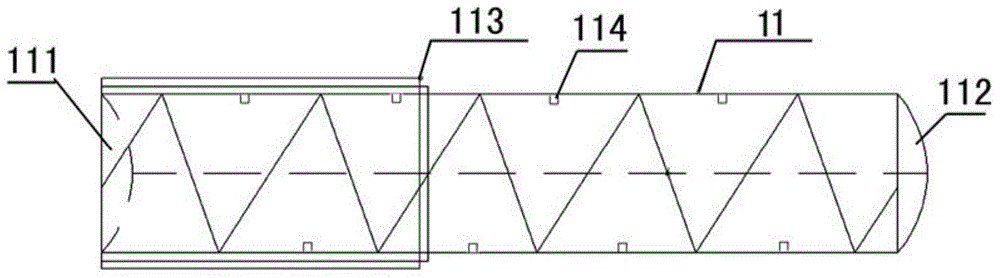

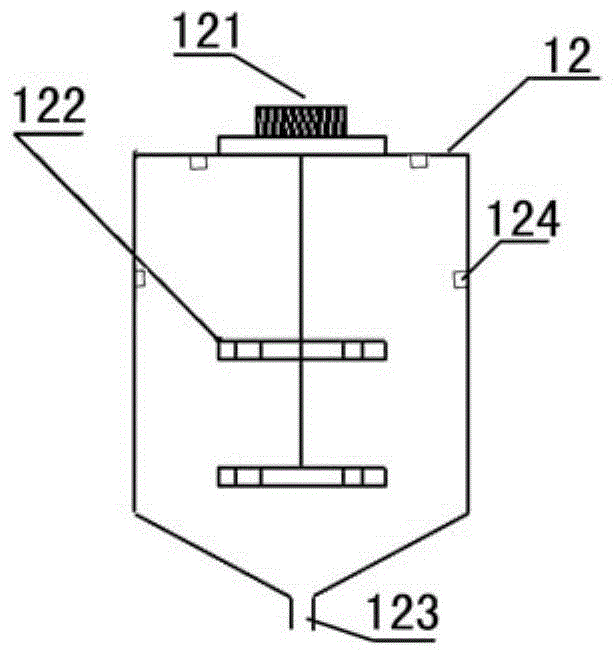

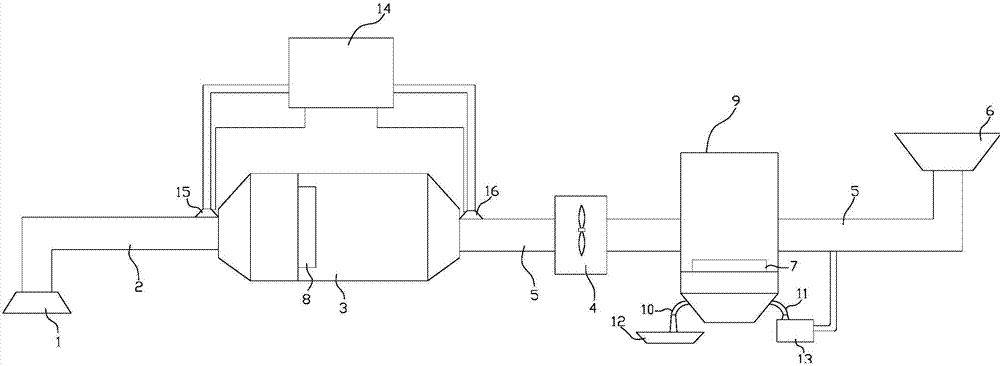

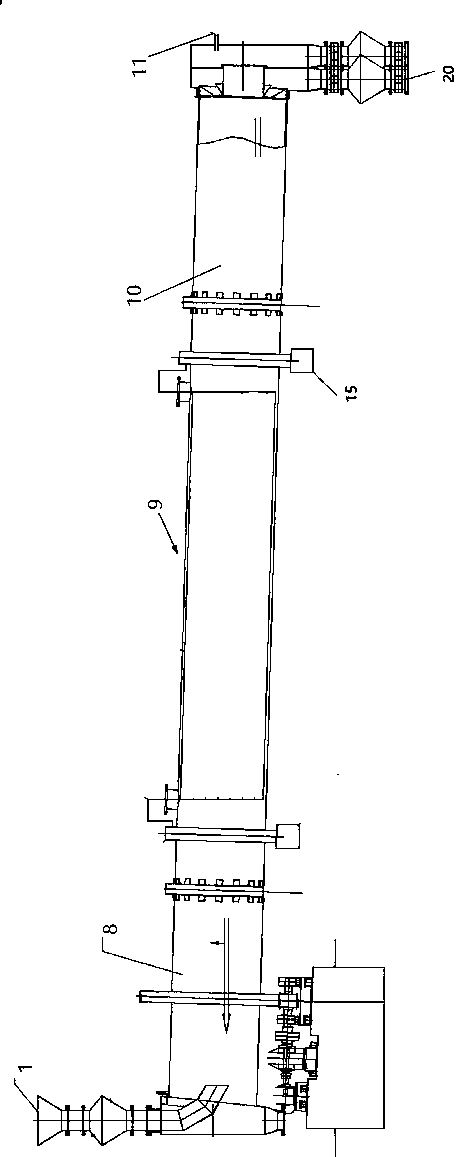

Oil and gas field drilling fluid waste treatment-while-drilling system

ActiveCN104829070AEnable reuseGuaranteed not to fallSludge treatmentMultistage water/sewage treatmentOil phaseWaste treatment

The invention discloses an oil and gas field drilling fluid waste treatment-while-drilling system. The system comprises a fluid waste receiving unit, a fluid waste recovery and fragmentation unit, a stability breaking unit, a solid-liquid two phase separation unit, a solid phase restoration extrusion unit, a liquid phase desanding oil-isolation unit and a sewage treatment unit, and the above units are orderly connected. An inlet of the solid phase restoration extrusion unit is connected to an oil phase and solid phase impurity outlet of the liquid phase desanding oil-isolation unit. An inlet of the liquid phase desanding oil-isolation unit is connected to a liquid phase outlet of the solid phase restoration extrusion unit. The inlet of the solid phase restoration extrusion unit is connected to a flocculate outlet of the sewage treatment unit. Through multiple treatment by the multiple units, solids and liquid in the waste are respectively subjected to harmless treatment so that waste recycle is realized. The system prevents fluid waste landing, protects an environment around a drilling operation place and is convenient for scheduling arrangement of equipment used in a drilling site.

Owner:李磊

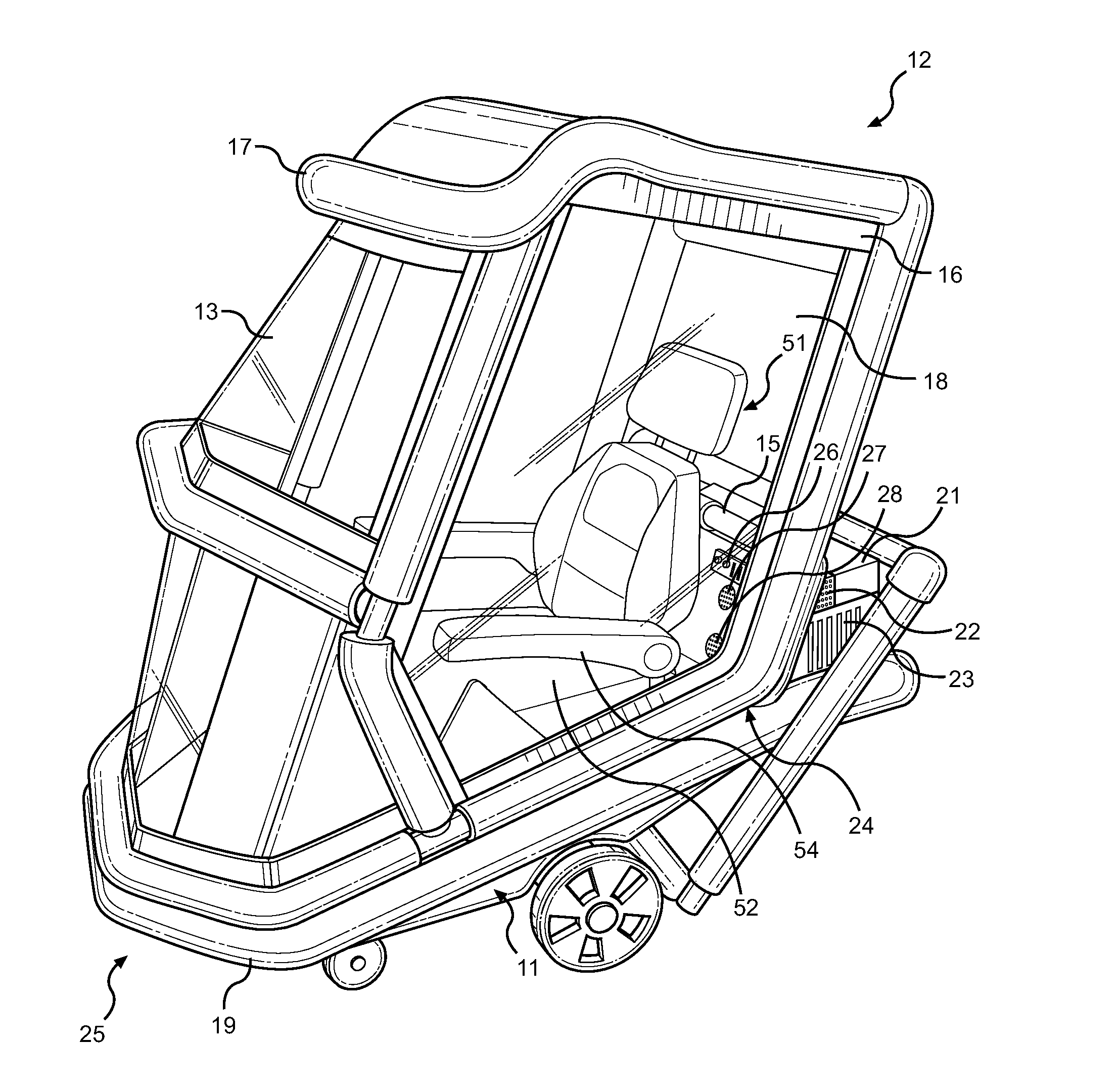

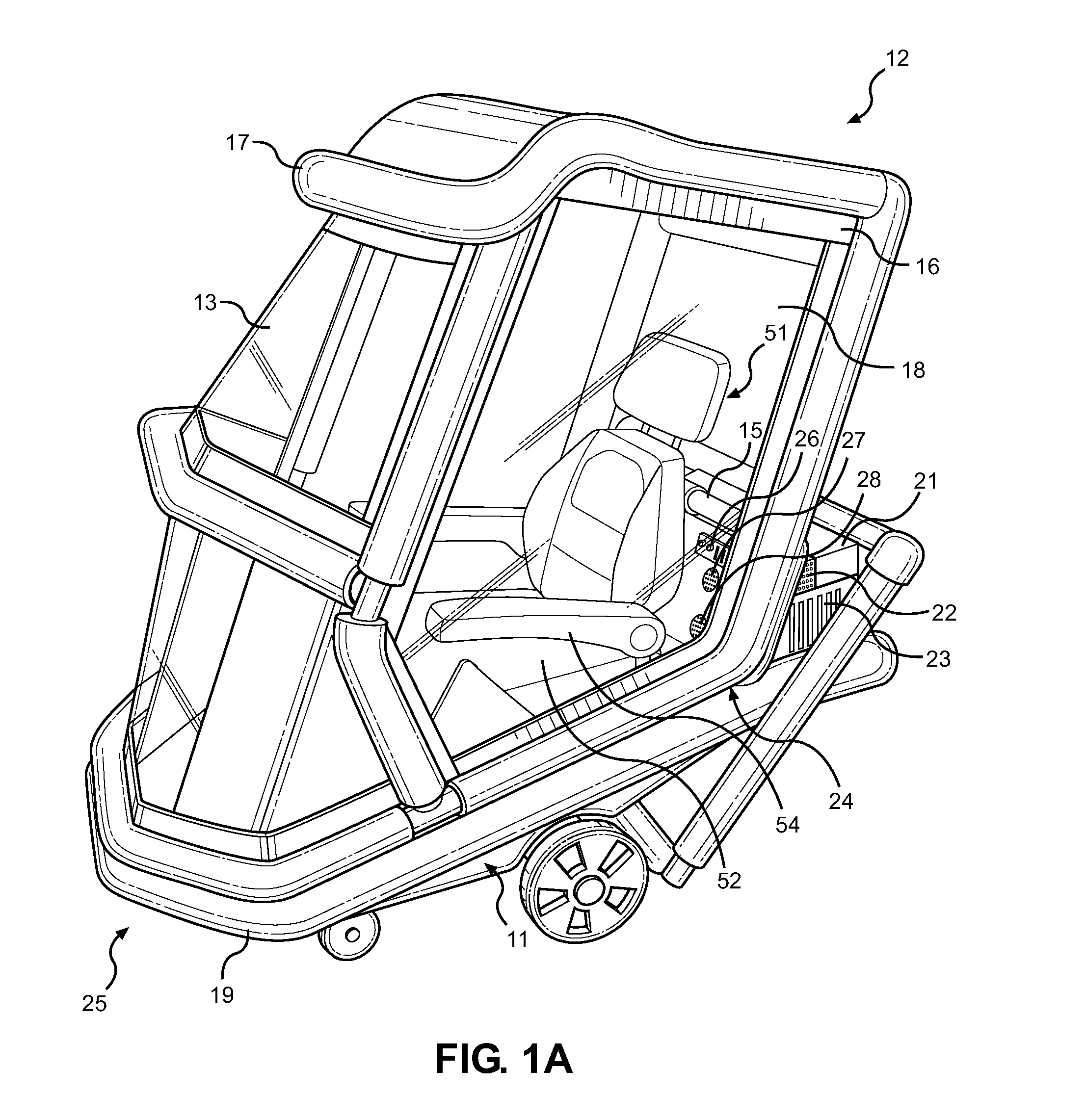

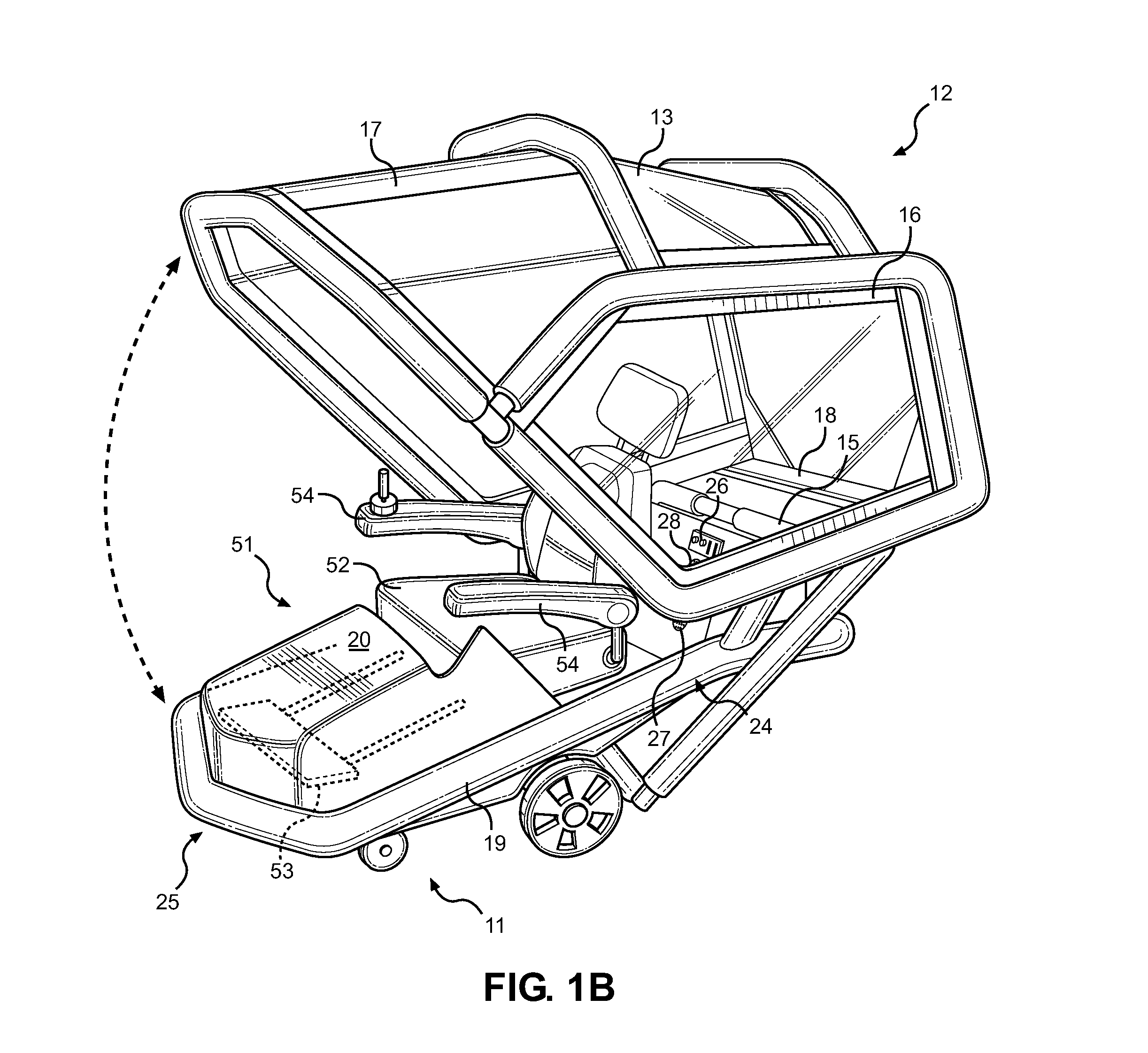

Temperature-Controlled Personal Mobility Device Enclosure

InactiveUS20150137557A1Protect the surrounding environmentEasy to makeCyclesVehicle seatsTemperature controlWheelchair

A temperature-controlled enclosure that is attachable to a personal mobility device. The present invention comprises a frame that is attachable to a wheelchair, scooter, or other personal mobility device via welding, fasteners, or any other such method of attachment. The frame supports a hingedly attached cover, a power source, a heating unit, and a cooling unit. When users are excessively hot or cold, they can pull the cover down and activate either the heating unit or the cooling unit, as desired. When the cover is in its closed position, the cover and the frame create an enclosed space around the seat of the personal mobility device, trapping the heated or cooled air therein and thus providing relief to users from the surrounding environmental conditions.

Owner:THOMAS BRANDON

Novel process flow and apparatus for decomposing phenate

InactiveCN101407725ASmall footprintLess investmentOrganic chemistryOrganic compound preparationLow speedAtmospheric air

The invention relates to the technique field of coal tar processing in the metallurgical carbonization industry, in particular to a new technological process and equipment for phenolate decomposition in the middle production procedures in coal tar processing devices. The technological process comprises the following steps: clean phenolate and 40%-98% of sulfuric acid in a weight proportion of 1:0.6-1.2 are introduced into a mixer at low speed; the mixing liquid enters a reactor 1# at high speed; the produced gas phase and liquid phase enter a reactor 2# through a jet; the reaction solution enters a separator so that corresponding products, crude phenol and waste sodium sulfate solution are separated; waste gas produced in the separator and a production tank is cleaned with new base or clean phenolate in a Venturi tube and then exhausted into the atmosphere. The equipment includes a clean sodium phenolate tank, a gas-liquid mixer, a product tank, transport pipelines for various raw materials and products, valves and pipe peep mirrors arranged in the pipelines, the reactor 1#, the reactor 2# and a product separator. The invention is applicable to technology renovation and establishment projects in coal tar processing industry and can reduce environment pollution, save energy and increase effect.

Owner:UNIV OF SCI & TECH LIAONING

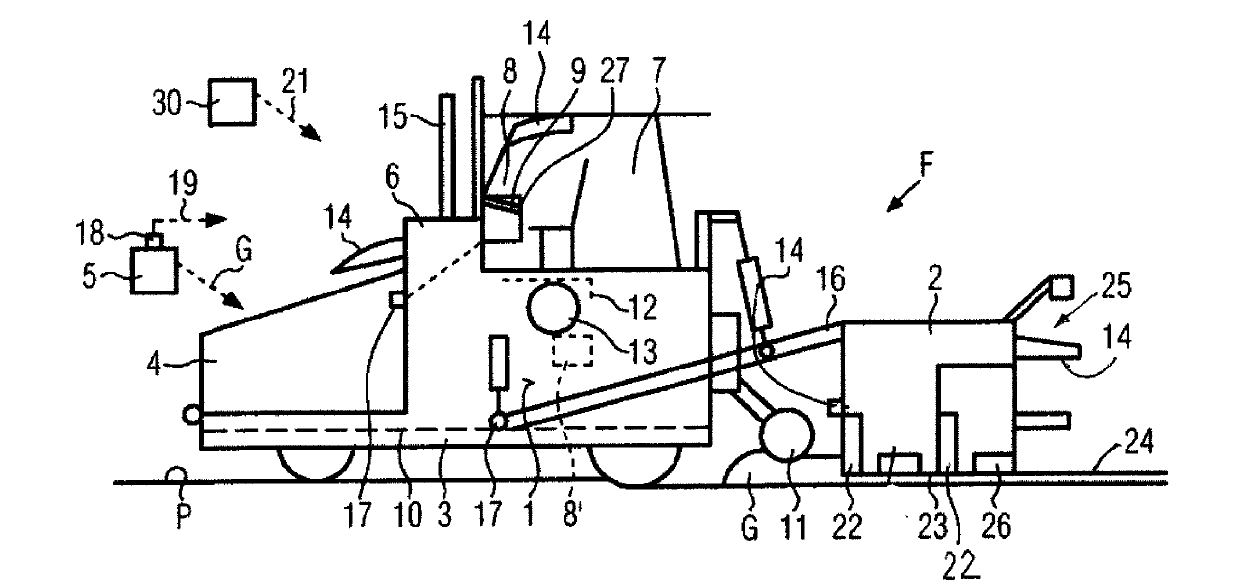

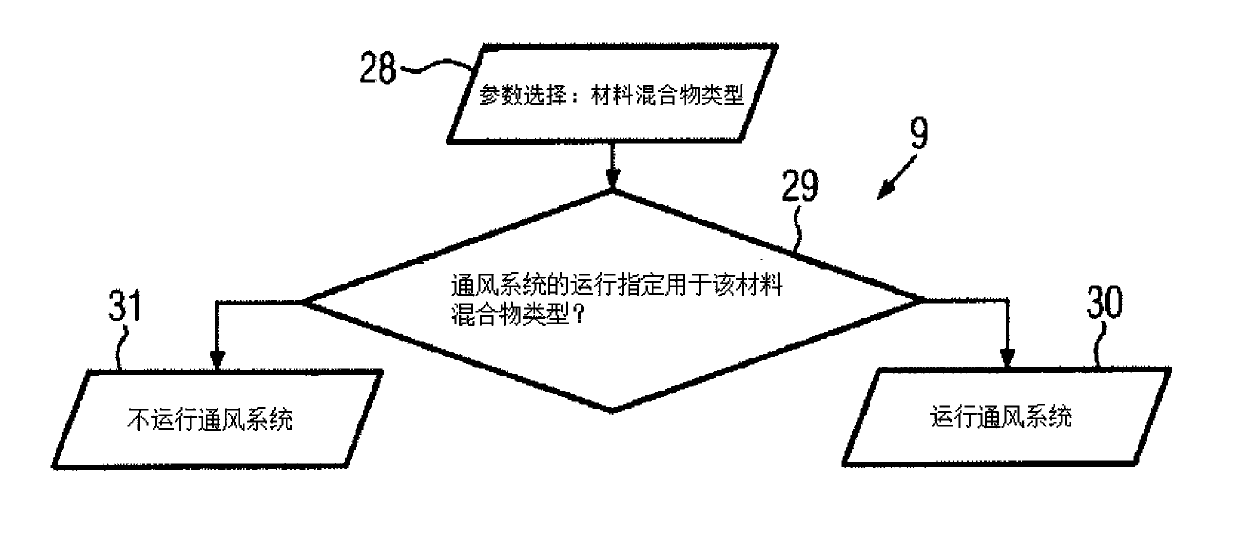

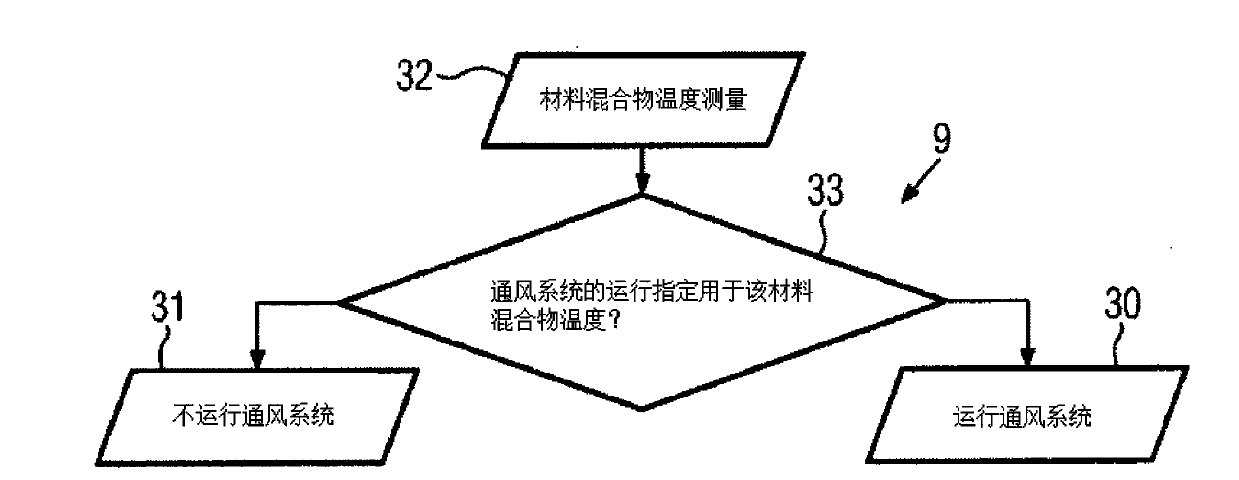

Road finishing machine and method for laying mixed material with a road finishing machine

ActiveCN103469721AImprove working conditionsImprove energy balanceRoads maintainenceScreedPower control

In a road finishing machine (F) comprising at least one screed (2), a machine control (8), and a ventilation system (12) including a fan (13), the fan (13) can be switched on or off via the machine control (8) automatically independent of the operator and exclusively depending on demand. According to the invention, before or during the laying operation, a defined demand for the operation of the ventilation system (12) is determined, and during or for the laying operation, the ventilation system (12) is operated independent of the operator and automatically, and optionally power-controlled, upon determination of the defined demand.

Owner:JOSEPH VOEGELE AG

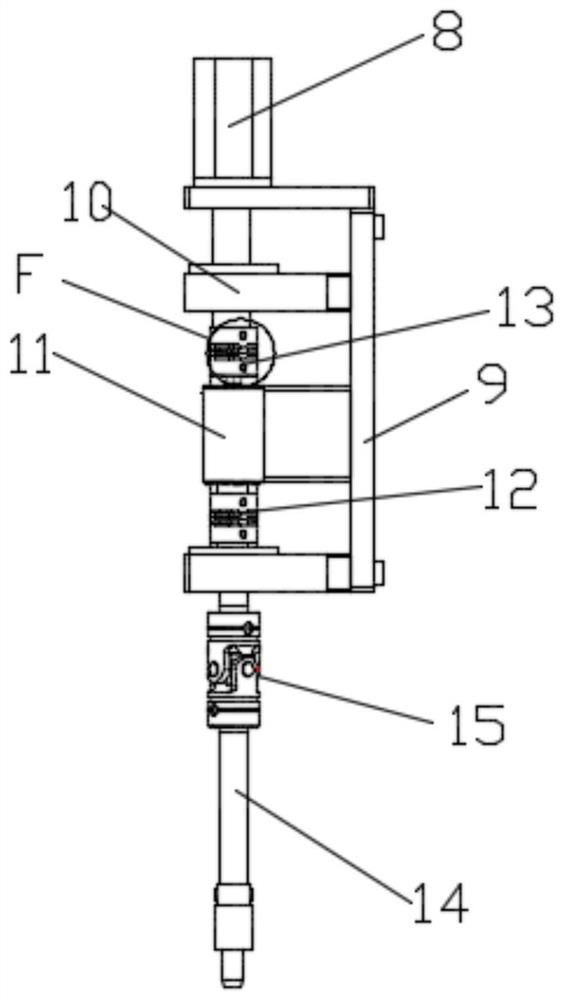

Overall-sampling device for sectional rock stratums of biological fossils

ActiveCN111827912AReduce vibrationAvoid crackingDrill bitsDrilling rodsMining engineeringDrive motor

The invention discloses an overall-sampling device for sectional rock stratums of biological fossils. A drilling mechanism is arranged to comprise an outer drill barrel, an inner drill barrel, an outer drill barrel drive motor and an inner drill barrel drive motor; drilling edges are arranged at the front ends of the outer drill barrel and the inner drill barrel; the drilling edge of the outer drill barrel is shorter than the drilling edge of the inner drill barrel, so that the drilling edge of the inner drill barrel is forwards protruded out of the drilling edge of the outer drill barrel; when drilling a slot hole, the inner drill barrel can firstly drill, and the outer drill barrel is then adopted for chambering, so that the vibration during drilling is reduced, the fossils are preventedfrom being cracked; and a buffer mechanism is further arranged, so that the vibration generated by drilling can be further reduced through a buffer effect of the buffer mechanism, and the fossils areprevented from being damaged.

Owner:HENAN POLYTECHNIC UNIV

Country scenic region waterless toilet capable of performing comprehensive sterilization treatment on excrement

InactiveCN105686739AReduce emissionProtect the surrounding environmentSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesFertilizerUrine

The invention discloses a country scenic region waterless toilet capable of performing comprehensive sterilization treatment on excrement and belongs to the technical field of pit toilets. The country scenic region waterless toilet comprises an excrement pool. The country scenic region waterless toilet is characterized by further comprising an outer cover, a floor is arranged in a space encircled by the outer cover and divides the space into an upper part and a lower part, a closet pan is arranged above the floor, an excrement pool is arranged below the floor, and the closet pan is communicated with the excrement pool. A urine collecting pool is arranged below or on one side of the excrement pool and can be communicated with the excrement pool. An excrement processing device is arranged in the excrement pool, one side of the excrement pool is further connected with a dry excrement box, and the dry excrement box is located outside the outer cover and made of a transmitting material or a material conducting heat easily. After the excrement is crushed and processed into grains, the surface area is increased equivalently, and the weathering drying speed is especially quick. The excrement does not need flushing and is free of other impurities such as water, nutritional high fidelity of the excrement is guaranteed, and the excrement can be used as an agricultural production fertilizer.

Owner:淄博正邦知识产权企划有限公司

Complete discharging wet grinding machine

Owner:成都鼎信致远科技有限公司

Filter pressing device for producing amino acid

InactiveCN105999834AWill not cause overflowSmall particle diameterFiltration circuitsFilter pressMachining process

The invention discloses a filter pressing device for producing amino acid. The filter pressing device comprises a pressing head and a funnel; the inner diameter of the funnel is matched with the outer diameter of the pressing head; the pressing head can be pressed into the funnel; and one group of counter bores are uniformly formed in the bottom of the pressing head. Compared with the prior art, a whole filter pressing process has a certain air pressure gap all the time through the design of the pressing head and the counter bores on the funnel in the aspect of manufacturing; the overflowing, even splashing of an intermediate are not caused and the production efficiency of filter pressing can also be effectively controlled, so that the peripheral environment of a filter pressing field is protected; and meanwhile, a biological film is matched with the filter pressing in the design so that the grain diameter of the intermediate subjected to filter pressing is reduced, a foundation is laid for rapidly entering a next path of fine machining process and the quality of products is also ensured.

Owner:宜兴市前成生物有限公司

Robot with cleaning function

PendingCN108814402AReduce cleaning costsReduce labor intensityCarpet cleanersFloor cleanersUltimate tensile strengthControl theory

The invention provides a robot with a cleaning function, which comprises a frame, a plurality of pairs of mechanical legs, a plurality of fastening devices, a controller and a cleaning device, whereinone end of the plurality of pairs of the mechanical legs is symmetrically arranged on two sides of the frame respectively with respect to the frame, The cleaning device is arranged at one end of theframe, the controller is arranged on the frame, the controller is connected with the cleaning device, the fastening device is arranged at the other end of the mechanical legs, and the fastening deviceis buckled with the surface of an object to be cleaned. Through the special combination of the fastening device and the mechanical legs, the robot can adsorb and walk on the end surface of a glass curtain wall, by arranging the cleaning device, the robot can clean the glass curtain wall, the labor intensity of a user is reduced and the working efficiency is improved, the cleaning cost of the glass curtain wall is reduced.

Owner:柏秋

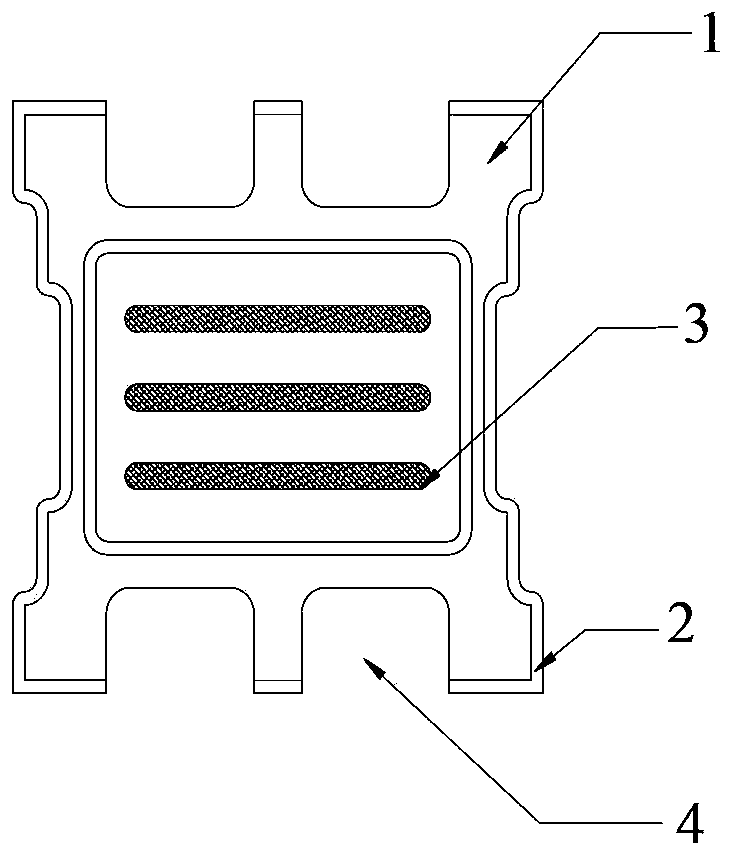

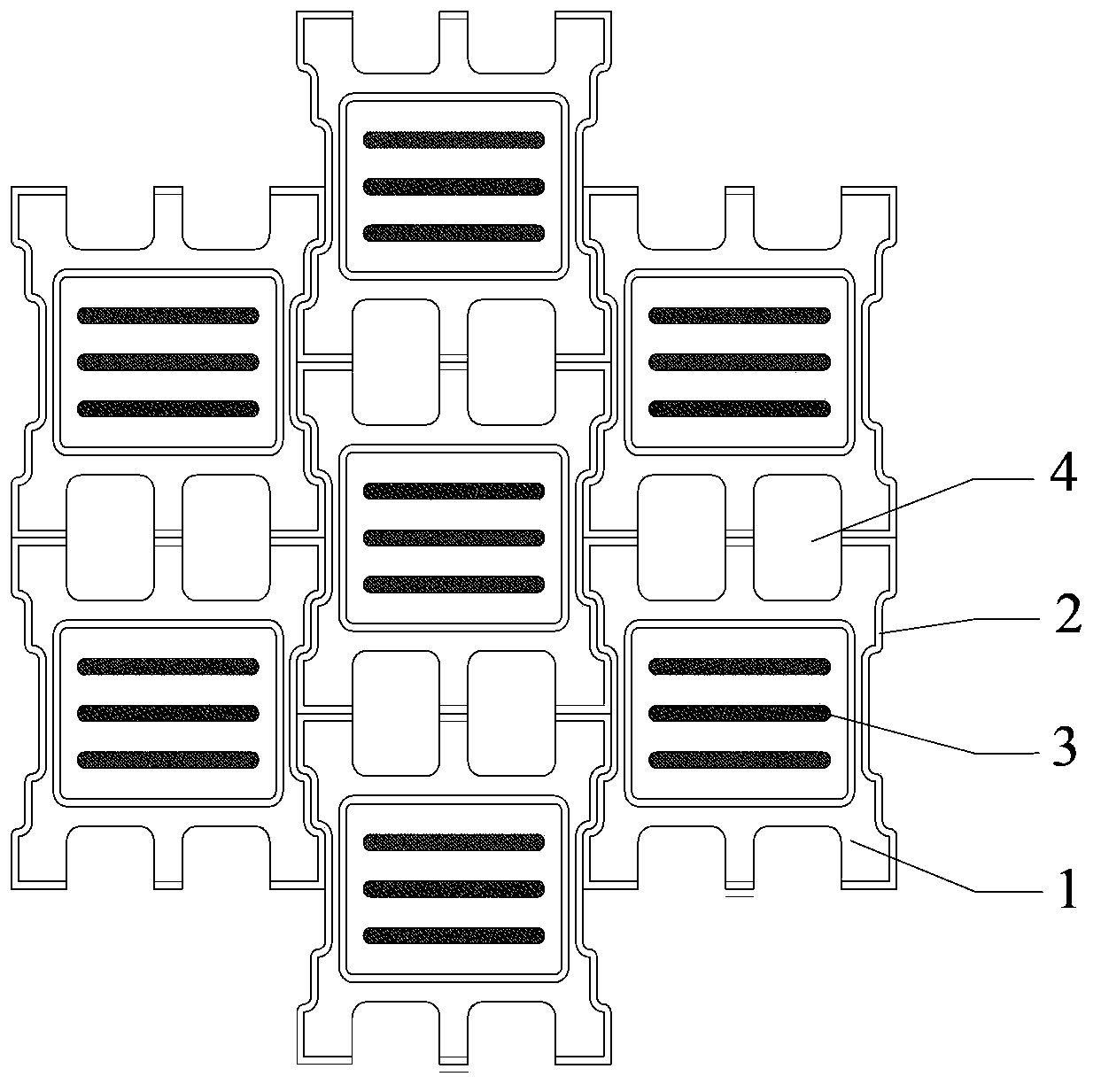

Ecological slope protection building block with strong skid-resistance capability

InactiveCN104047265AImprove securityStrong skid resistanceCoastlines protectionExcavationsVegetationEngineering

The invention relates to an ecological slope protection building block with the strong skid-resistance capability. The building block comprises a concrete bed body, a protection frame and convex strips, wherein two side edges of the concrete bed body are symmetrically provided with planting slots; the protection frame is arranged on the periphery of the concrete bed body; the convex strips are arranged on the upper surface of the concrete bed body. Compared with the prior art, the ecological slope protection building block with the strong skid-resistance capability has the advantages of higher safety coefficient, convenience in overhauling and wider use range, and the perfect environment is provided for vegetation by the tapping type slope protection building block.

Owner:FUJIAN HENGRUI NEW BUILDING MATERIAL

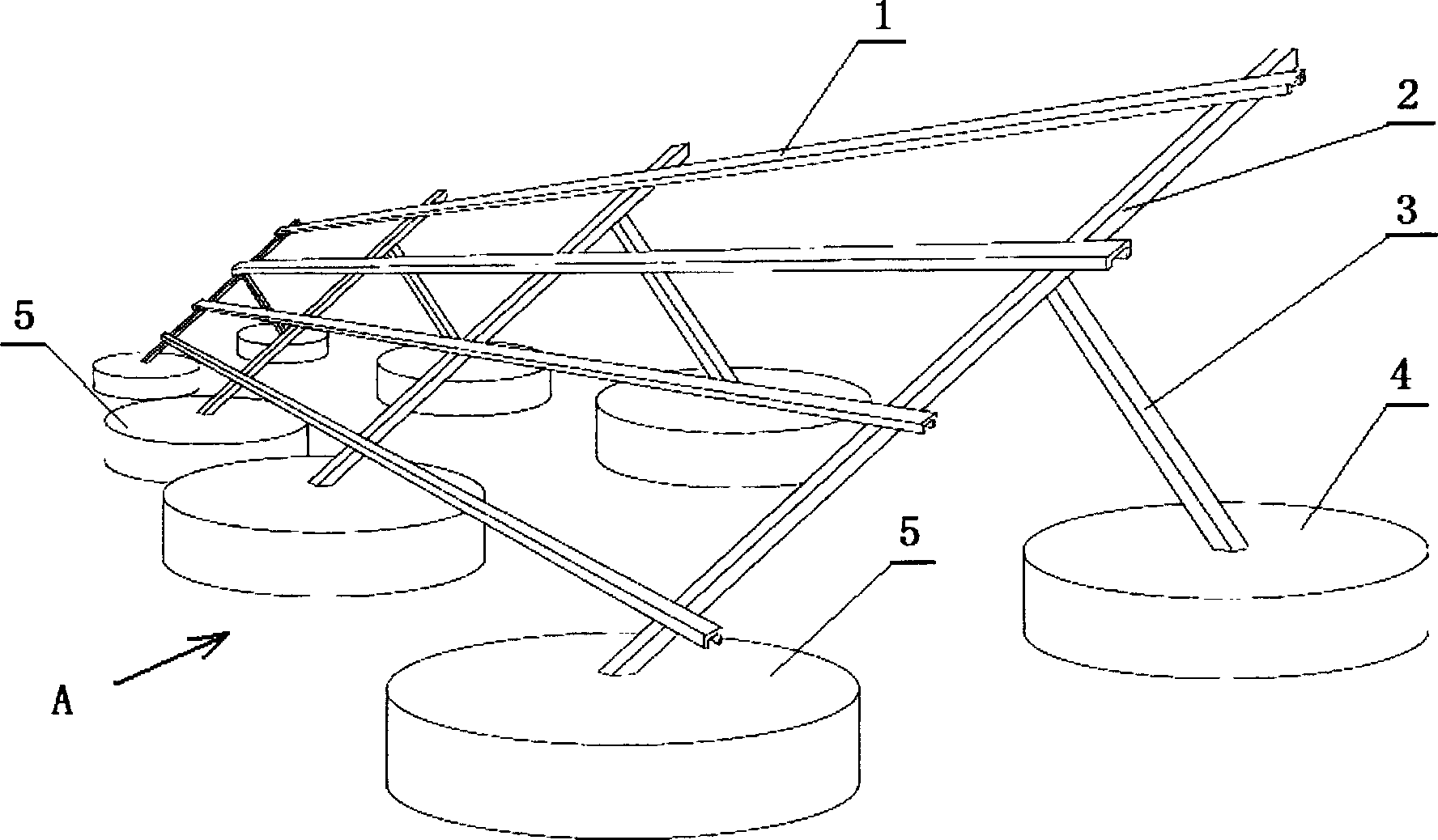

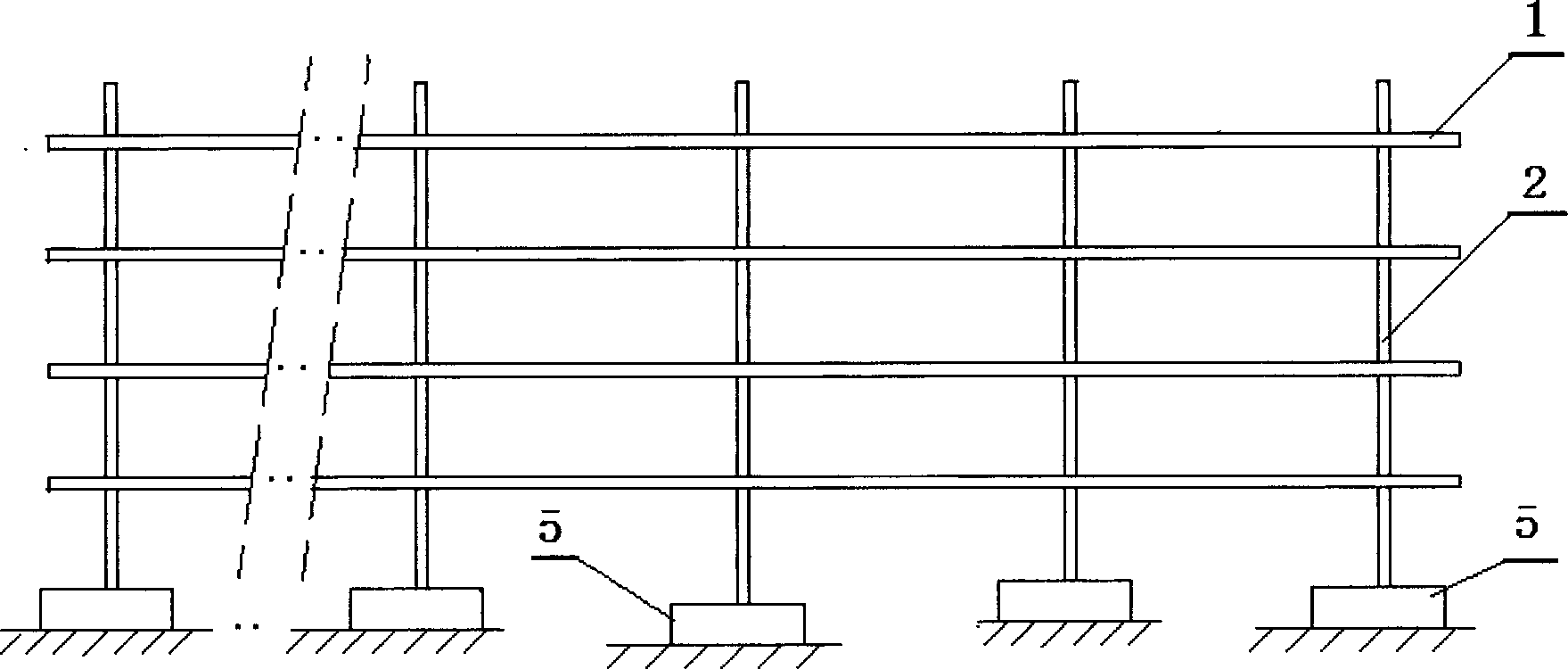

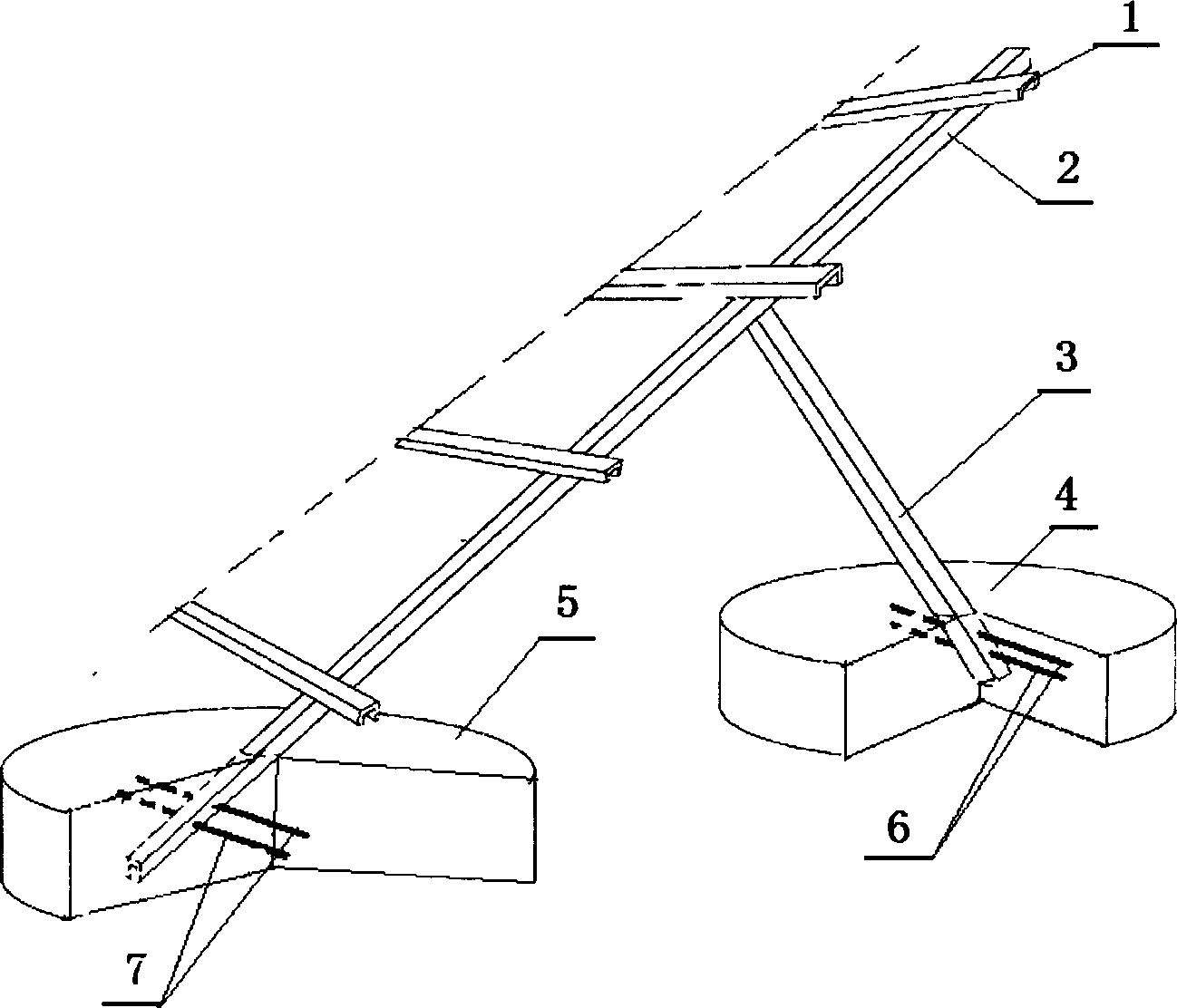

Method for installing integrated photovoltaic support of solar panel

InactiveCN103633927AEnsure stabilitySimplify complex processesPhotovoltaic supportsPhotovoltaic energy generationRebarWeed

The invention discloses a method for installing an integrated photovoltaic support of a solar panel, and belongs to the technical field of installation of solar photovoltaic components. The method is characterized by comprising the following steps: (1) clearing weeds and surface soil at the support installation place in the installation site; (2) connecting longitudinal beams, cross beams and support diagonal beams, wherein the lengths of the longitudinal beams and the support diagonal beams are determined according to the situation of the installation position; (3) installing horizontal reinforced bars at the installation root parts of the longitudinal beams and the support diagonal beams; (4) placing the support at the support installation position and adjusting the position and the installation angle of the support; and (5) pouring concrete to the installation root parts of the longitudinal beams and the support diagonal beams for fixing, thereby installing the integrated photovoltaic support. The construction process is simple, and the construction cost is saved; the installation speed is high, and the construction cycle is short; the natural feature and the peripheral environment are protected, and the construction process has an environment protection effect.

Owner:吴加林

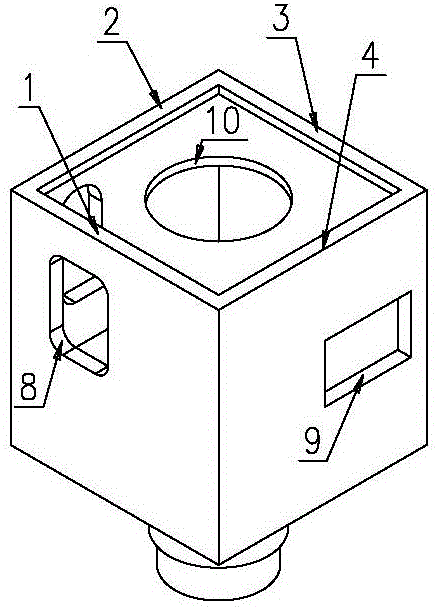

Integrated house corner fitting specially used for water drainage

InactiveCN106049770AImprove integrity and aestheticsReasonable structural designRoof drainageEngineeringDrainage tubes

The invention relates to an integrated house corner fitting specially used for water drainage. The problems that water drainage devices of existing integrated house roofs are not reasonably arranged in corner fittings, only scattered water drainage can be achieved, and pollution is brought to wall enveloping systems can be effectively solved through the integrated house corner fitting specially used for water drainage. According to the technical scheme, the integrated house corner fitting specially used for water drainage comprises a hollow square tube, a positioning plate and a hollow tube, rectangular holes are formed in a first side plate and a second side plate of the hollow square tube, and a water groove hole is formed in a third side plate or a fourth side plate of the hollow square tube; and the positioning plate is arranged at the upper end of the hollow square tube, and an end plate is arranged at the lower end of the hollow square tube and connected with the hollow tube. In the using process, the corner fitting is used for water drainage, so that the walls of an integrated house are protected, and the surrounding environment of the integrated house can be protected; a water drainage tube is hidden in the corner fitting and a stand column thereof, so that the integrality and attractiveness of the housing are improved; and the structural design is reasonable, the number of dismounting times of the integrated house is improved, the service life of the integrated housing is prolonged, the using effect is good, and the integrated house corner fitting is an innovation on the integrated house.

Owner:ZHENGZHOU NO 9 METALLURGICAL SANWEI CHEM MACHINERY

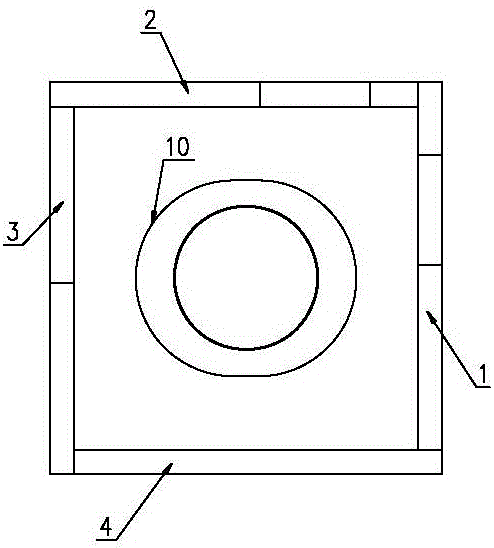

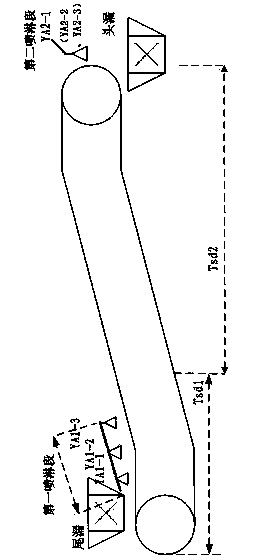

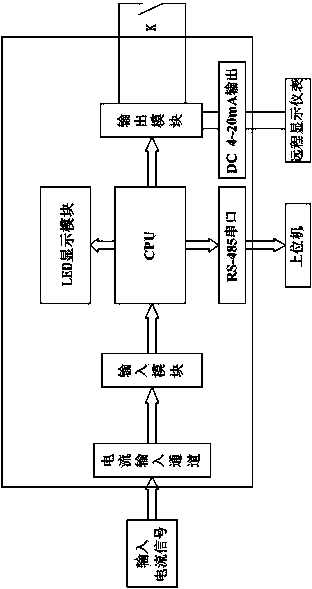

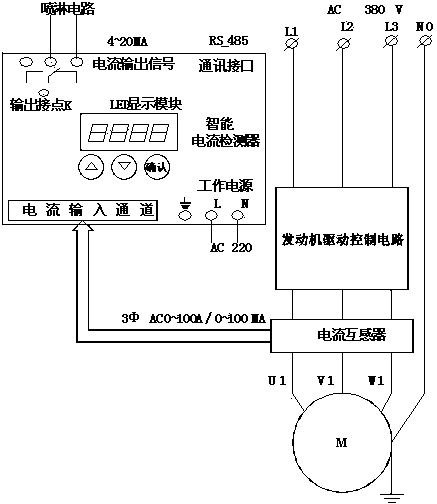

Belt conveyor intelligent current detection spraying system and control method

ActiveCN104229422AImprove intelligenceProtect the surrounding environmentControl devices for conveyorsAutomotive engineeringDrive motor

The invention relates to a belt conveyor intelligent current detection spraying system and a control method. Through a current transformator or a frequency converter I / O (input / output) board, a standard current signal reflecting an actual load of a driving motor is accessed into an intelligent current detector, the intelligent current detector uses the difference between the idle load current and the load current of the driving motor to determine a current set value Isd, through calculation, when the actual load current I is greater than or equal to the Isd, the intelligent current detector switches on a spraying circuit for implementing the spraying in a time delay manner through an output module, the time delay time is delta T, the actual current detected by the intelligent current detector needs to continuously meet the requirement that I is greater than or equal to the Isd in the time of the delta T, when the actual load current I is smaller than the Isd, the intelligent current detector switches off the spraying circuit through the output module, and the spraying operation is stopped. The application range is wide, the advantages of low investment, good effect, high practicability, high intelligence and water resource saving are achieved, the surrounding environment is effectively protected, the occurrence rate of anthracosis is reduced, and the safe and civilized production is ensured.

Owner:ANSTEEL GRP MINING CO LTD

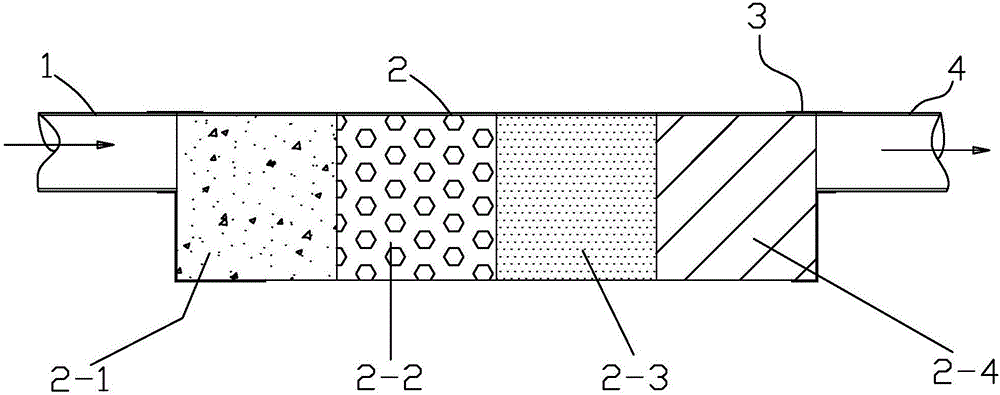

Building construction process domestic sewage treatment ground filtering device and filtering method

InactiveCN106621494AImprove water qualityProtect the surrounding environmentTreatment involving filtrationLoose filtering material filtersPipingSewage treatment

The invention relates to a building construction process domestic sewage treatment ground filtering device and a filtering method. The device comprises a filtering pipe, a water inlet pipe is arranged at one end of the filtering pipe, a water outlet pipe is arranged at the other end of the filtering pipe, and four filtering layers are arranged in the filtering pipe and are sequentially gravel, ceramsite, fine sand and sponge from one end of the water inlet pipe to one end of the water outlet pipe. Domestic sewage primarily treated by a septic tank is secondarily filtered by the four filtering layers including the gravel, the ceramsite, the fine sand and the sponge, water quality is further improved to meet secondary pollution exhaust criteria, and produced sewage in the whole engineering construction period is controlled, so that surrounding environments are protected.

Owner:GUANGXI METALLURGICAL CONSTR

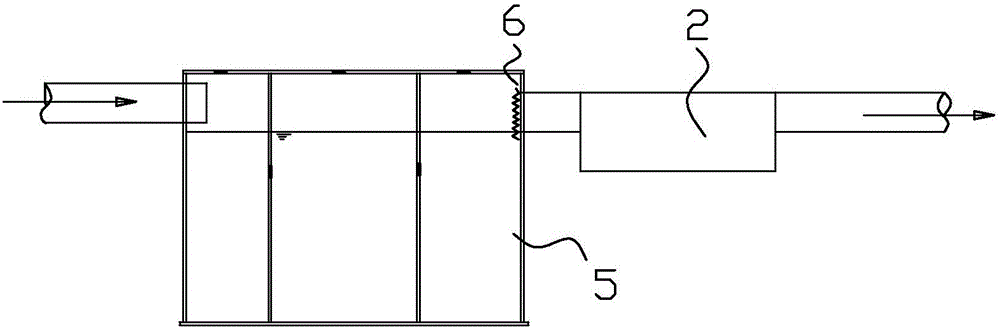

Concentrated feed waste gas treatment device

PendingCN107469619ASolve pollutionInhibited DiffusionGas treatmentDispersed particle separationSpray nozzleWaste collection

The invention relates to a concentrated feed waste gas treatment device. The device comprises a gas collecting pipe, an air inlet pipe, a purifying device, an air outlet pipe and an exhaust opening which are arranged in sequence, wherein a booster fan and a treatment chamber are arranged on the air outlet pipe, and the booster fan is positioned above the treatment chamber; the discharge opening of the treatment chamber is provided with a solid outlet and a gas outlet, a waste collection tank is connected with the lower side of the solid outlet, and the gas outlet is connected with a dust collector; the outlet of the dust collector is connected to the air outlet pipe under the treatment chamber; a catalyzing device is arranged in the purifying device, a liquid spray tank is formed in the side of the purifying device and comprises a first spray nozzle connected with the tail end of the air inlet pipe and a second spray nozzle connected to the front end of the air outlet pipe; pressure sensors are arranged on the first and second spray nozzles; sensitive signals of the pressure sensors are conducted to a controller of the liquid spray tank; and the controller is used for controlling start and close and openness of the first and second spray nozzles.

Owner:ANHUI TIANLONG FEED

Environment-friendly digging device for agriculture

InactiveCN109566005AProtect the surrounding environmentReduce labor intensityPlantingFurrow making/coveringAgricultureEngineering

The invention relates to a digging device for agriculture, in particular to an environment-friendly digging device for agriculture. The environment-friendly digging device for agriculture achieves thetechnical purposes that pollutant discharge cannot be caused and the surrounding environment can be protected. According to the technical scheme, the environment-friendly digging device for agriculture comprises a base, a universal wheel, a rolling wheel, a first guiding rod, a first guiding sleeve, a first large spring, a first screw, a lifting plate, a connecting rod, an iron hoe, a connectingblock and the like; the universal wheel is connected to the right side of the bottom of the base, the rolling wheel is connected to the left side of the bottom of the base, and the first guiding rod is connected to the left end of the top of the base. The environment-friendly digging device for agriculture has the advantages that in the digging process, the pollutant discharge cannot be caused, the surrounding environment can be protected, and the labor intensity is low; in the digging process, flying dust can be avoided, the time and labor are saved, and the production and life of people arefacilitated.

Owner:刘晨

Heating boiler with lifting pressing plate for crushing furnace slag

ActiveCN108061305AAvoid burnsProtection securityLighting and heating apparatusCombustion chamberSlag

The invention discloses a heating boiler with a lifting pressing plate for crushing furnace slag. The heating boiler comprises a shell, a feeding hopper, a combustion chamber, a heating chamber and afurnace slag collecting cavity, the shell is internally partitioned into the combustion chamber, the heating chamber, the furnace slag collecting cavity and a smoke channel, and a bearing is fixed toa center shaft of a pressing plate. A vertical operating rod is fixedly inserted into the bearing, the pressing plate comprises a fixed mesh plate, an open-close mesh plate, hinges and clamp protrusions, and a horizontal shifting rod is fixed to the operating rod. A horizontal limiting rod is further fixed to a guiding sleeve, a water sleeve is fixed into the heating chamber, and two partition plates are fixed into the smoke channel. A heat exchange pipe is arranged in the smoke channel in a penetrating mode. According to the heating boiler, through the arranged pressing plate, the generated furnace slag can be crushed to be refined and then falls at the bottom from holes of a furnace grill to be collected, people do not need to hold a tool by hands to stretch into the heating chamber to conduct clearing, operation is convenient, personnel are prevented from being burned, and personnel safety is achieved.

Owner:FUYANG ANGU BOILER PRESSURE VESSEL MFG

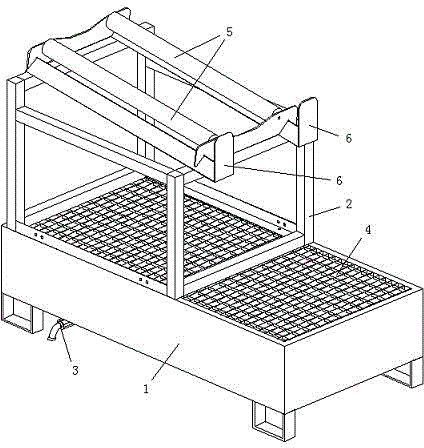

Oil drum storage rack

The invention discloses an oil drum storage rack, relates to the technical field of goods shelves, and aims to solve the problem of inconvenience in oil taking. The storage rack comprises an oil receiving disk, a roller frame and an oil discharging valve, wherein the oil receiving disk is a box body which is upwards opened in the single direction; an opening part in the upper end of the oil receiving disk is covered by a latticed grating; an oil discharging opening is formed in the bottom of the oil receiving disk; the oil discharging valve is fixed on the outer wall of the oil receiving disk; an oil inlet of the oil discharging valve is connected to an oil discharging opening of the oil receiving disk; the roller frame is mounted on the oil receiving disk; two rotatable rollers are arranged at the top of the roller frame and are positioned right above the oil receiving disk; the two rollers are parallel to each and are downwards inclined from back to front; the inclination angles of the two rollers are smaller than 45 degrees; two baffles are fixed on the roller frame, are distributed at an interval and are positioned in front of the two rollers; the front ends of the two rollers are lower than the top edges of the two baffles and are higher than the bottom edges of the two baffles. The storage rack provided by the invention is suitable for placing an oil drum.

Owner:SHANGHAI POWERWAY LOGISTICS EQUIP

Full-closed metallurgy rotary kiln

The invention discloses a full-closed metallurgy rotary kiln and belongs to metallurgy ichor. The full-closed metallurgy rotary kiln comprises a kiln head, a kiln cylinder and a kiln tail of the rotary kiln and further comprises a kiln head box, wherein the sides, opposite to the kiln head and the kiln tail, of the kiln head box are connected with the ends of the kiln cylinder. The kiln head box and the kiln cylinder are rotataby connected, and a cleaning sealing bin is arranged at the kiln head and the kiln tail; a material outlet and inlet are formed in the cleaning sealing bin, and the outlet and the inlet are each provided with a plug board sealing valve; the cleaning sealing bin is further provided with an air inlet and an air outlet, and during feeding and discharging, the first plugboard sealing valve and the second plug board sealing valve which are arranged at the outlet and the inlet of the cleaning sealing bin are opened and closed alternately, so that the interior of the kiln cylinder is isolated from the outside; full sealing of the metallurgy rotary kiln can be achieved from the links such as material in and out, circumferential sealing and end face dynamic sealing,strict isolation is achieved between the kiln interior atmosphere and the atmosphere, and the purpose that metallurgy materials are protected through the production atmosphere is achieved.

Owner:ANYANG YUQIANXIN METALLURGY REFRACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com