Patents

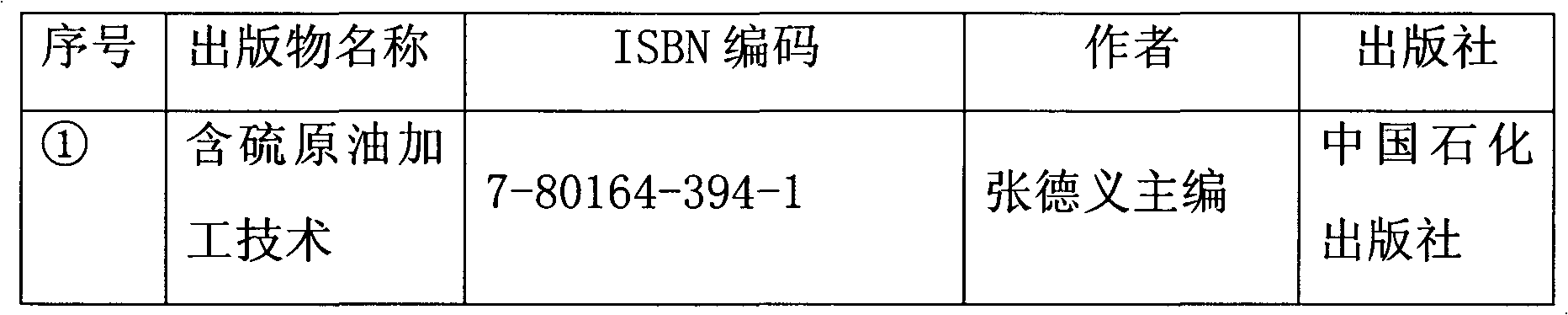

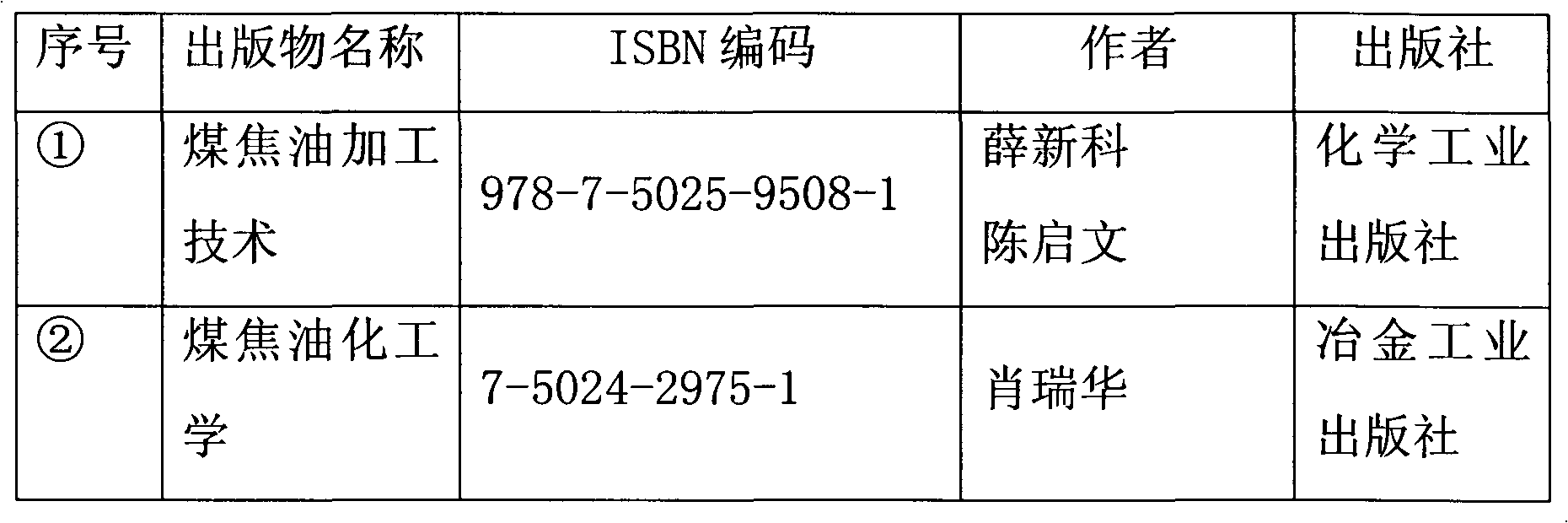

Literature

214 results about "Sodium Phenolate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium phenoxide is an organic compound with the formula NaOC6H5. It is a white crystalline solid. Its anion, phenoxide, also known as phenolate, is the conjugate base of phenol. It is used as a precursor to many other organic compounds, such as aryl ethers.

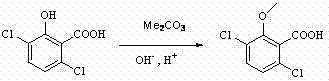

Preparation process of herbicide dicamba

InactiveCN102125035AReduce pollutionHigh reaction yieldBiocideAnimal repellantsMethoxylaricinolic acidSalicylic acid

The invention relates to a preparation process of herbicide dicamba, in particular to a supercritical preparation process. The preparation process of the herbicide dicamba comprises the following steps of: preparing 2,5-dichlorophenol into corresponding sodium phenolate, and then completing carboxylation reaction under a supercritical condition to obtain 3,6-dichlorosalicylic acid; and then completing O-methylation to prepare a product of 3,6-dichloro-2-methoxy salicylic acid, i.e. the dicamba, by taking dimethyl carbonate as a reagent. The invention changes the heterogeneous gas-solid reaction of the traditional process into homogeneous reaction under the supercritical condition, carries out the O-methylation reaction by using the dimethyl carbonate and has the advantages of high reaction yield, good product quality, reduced environmental pollution, lowered energy consumption, and the like.

Owner:上海力智生化科技有限公司

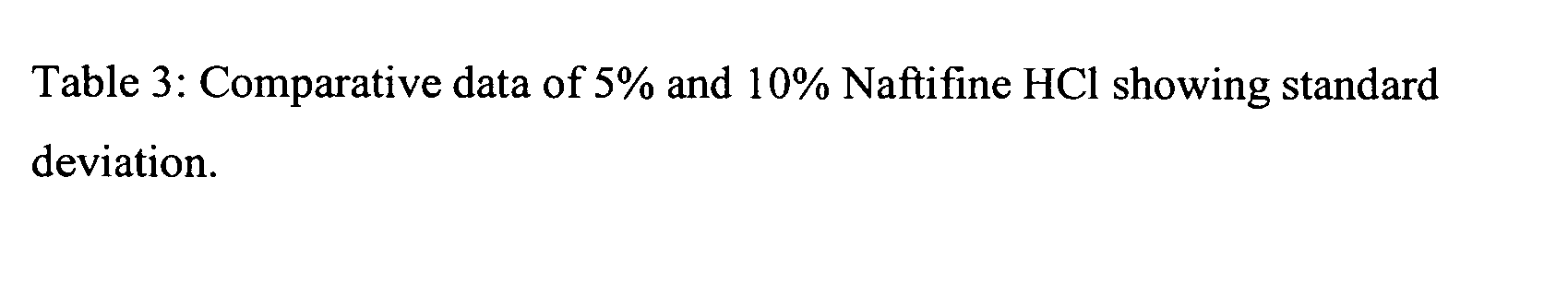

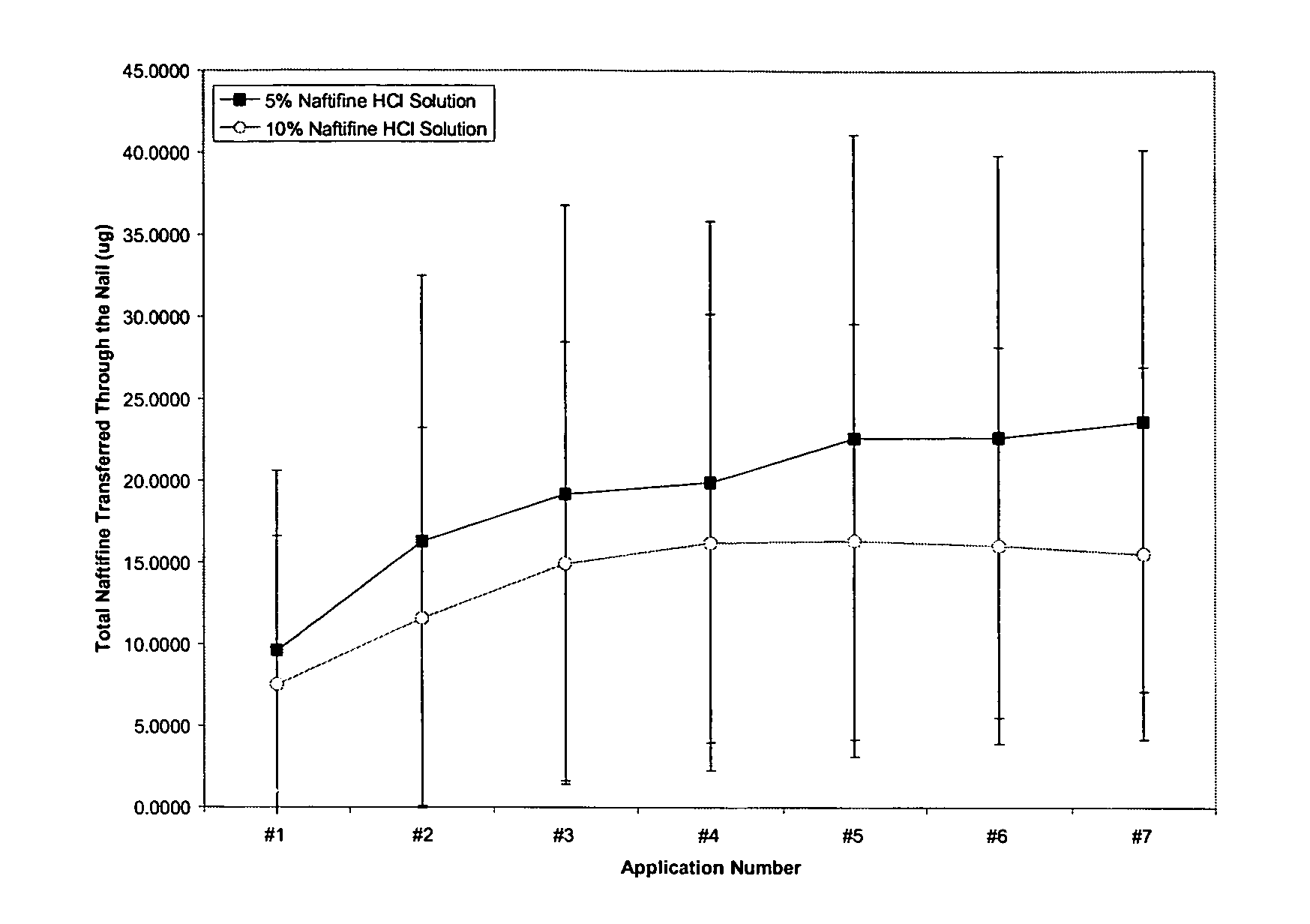

Pharmaceutical composition applicable to body tissue

The present invention provides a non-water soluble, film-forming composition which adheres to body tissue and forms a pharmaceutical carrier to provide localized delivery of an antifungal agent to a treatment site. The composition will typically include: (a) an alkyl cellulose; (b) a hydroxyalkyl cellulose; (c) a pharmaceutically acceptable polar protic solvent; (d) an antifungal agent selected from the group of naftifine, ciclopirox, terbinafine, pharmaceutically acceptable salts thereof, and combinations thereof; (e) an glycol ether; (f) an antipruritic agent selected from the group of camphor, menthol, butamben picrate, metacresol, benzyl alcohol, camphorated metacresol, juniper tar, phenol, phenolate sodium, resorcinol, camphorated metacresol, carbolic acid, and combinations,; and (g) a solubility enhancing agent, a surfactant, a wetting agent, or a combination thereof. The present invention also provides for the use of the composition composition of the present invention, in treating a fungal infection (e.g., nail fungus) in a mammal afflicted with such an infection.

Owner:QLT USA INC

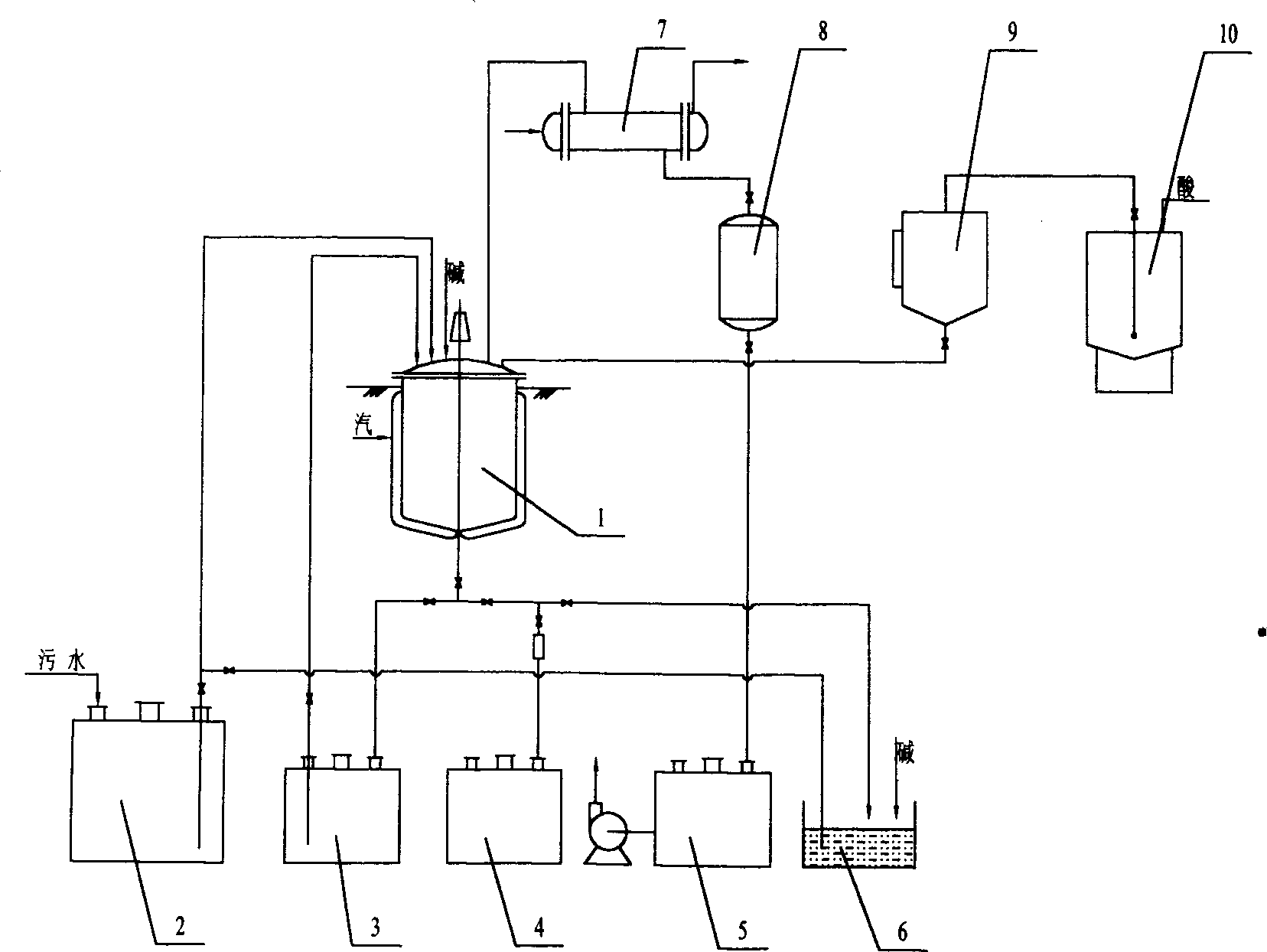

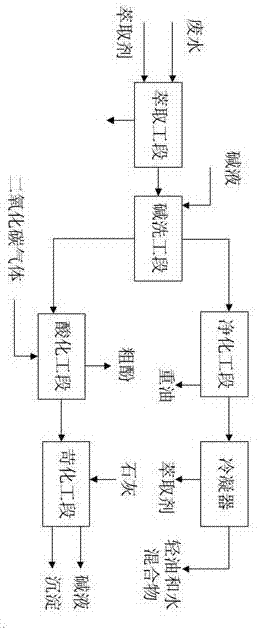

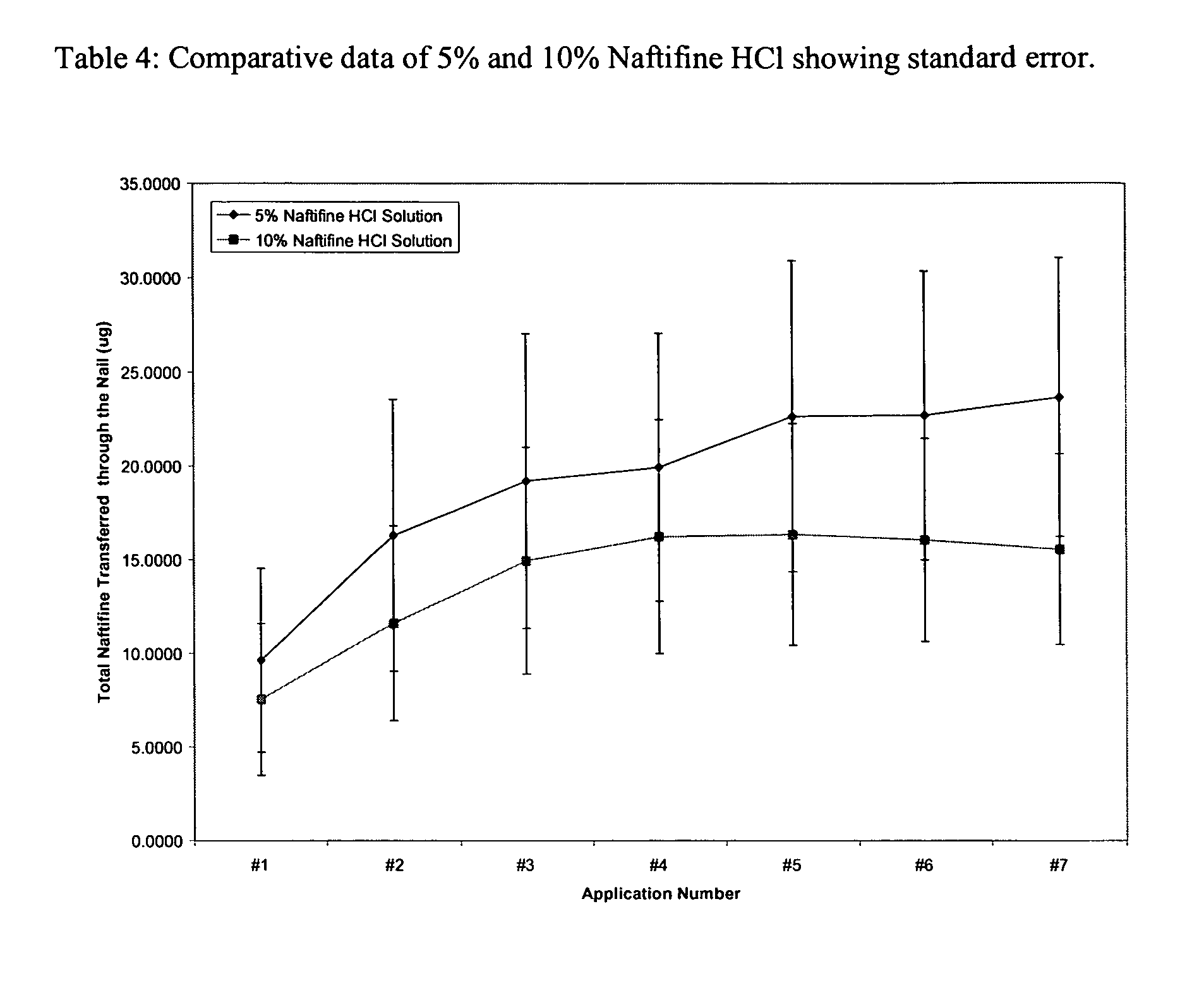

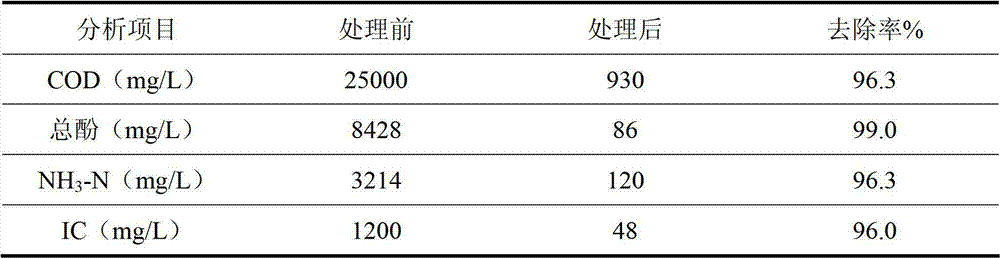

Technological method and device for semi-coke production wastewater resource utilization

ActiveCN104445815AImprove biodegradabilityImprove economic competitivenessOrganic chemistryOrganic compound preparationResource utilizationCoking wastewater

The invention discloses a technological method and device for semi-coke production wastewater resource utilization. The technological method comprises three steps, namely deep oil-water separation, high-efficiency complexing extraction dephenolization and ammonia stilling, to be specific, firstly, separating and recycling a part of coal tar from wastewater when the wastewater passes through an oil partitioning tank, recycling coal tar in a precision filter and an oil-water separator in sequence after discharged water passes through a coarse filter; feeding the oil-removed semi-coke wastewater and an extraction agent into an extraction tower for extraction and dephenolization, feeding the extract phase and a sodium hydroxide solution into a reverse extraction tower for countercurrent contact reverse extraction, feeding an obtained sodium phenolate solution into an acidification kettle, and adding sulfuric acid for acidification to obtain crude phenol; feeding dephenolized wastewater discharged from the bottom of the extraction tower into a wastewater heater, feeding into an ammonia cyanogen separator to be mixed with hot air from an air heater to remove ammonia after being heated by fume from the air heater, and feeding an ammonia-containing mixed gas discharged from the top of the ammonia-cyanogen separator into an ammonia water cooler for cooling to obtain ammonia water. By adopting the method and the device, precious resources such as coal tar, phenol and ammonia can be recycled from the semi-coke production wastewater resource, and the biodegradability of the semi-coke wastewater is improved.

Owner:陕西华祥能源科技集团有限公司

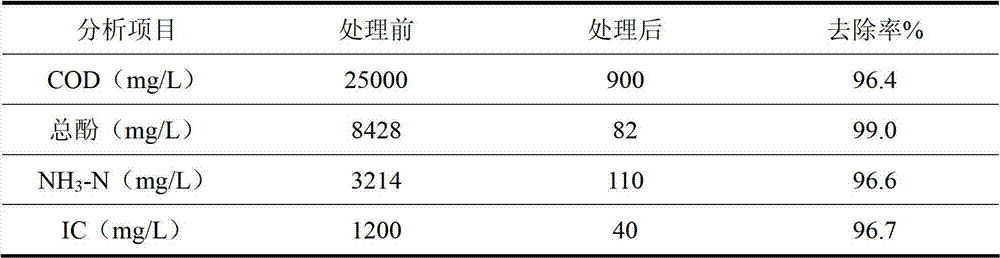

Method for recovery and comprehensive resource treatment of phenol and ammonia in semi-coke waste water

ActiveCN107434335AReduce solubilityPrevent re-evaporationFatty/oily/floating substances removal devicesWater contaminantsSodium saltTreatment system

The invention discloses a method for recovery and comprehensive resource treatment of phenol and ammonia in semi-coke waste water. The method comprises the following steps: performing standing on the semi-coke waste water to realize gravity oil removing and separating recovery, filtering an effluent through a coke filter to remove a solid suspension, and introducing the effluent in an extraction pre-oil removal reactor for deeply removing oil residue, coke powder and tar pollutants in the waste water; performing stripping depickling on the waste water after extraction and pre-oil removal, performing ammonia distilling and performing extraction processing to remove and recover the acidic gas, ammonia and phenol in the waste water, and introducing the processed waste water which reaches the standard in a biochemical treatment system; performing extraction processing to obtain a phenol-rich organic phase, and converting phenols in an extract phase to sodium phenolate through alkali washing processing to realize separation of an extractant and the phenols; and introducing a sodium phenolate solution to an acidifying workshop section for acidifying to prepare crude phenol and sodium salt. The method can realize separation and enrichment of phenols, heavy oil, light oil, ammonia and acidic gas in the semi-coke waste water, realizes resource recovery, at the same time, realizes regeneration and cycle utilization of the extractant and alkali lye, and has good application prospect.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

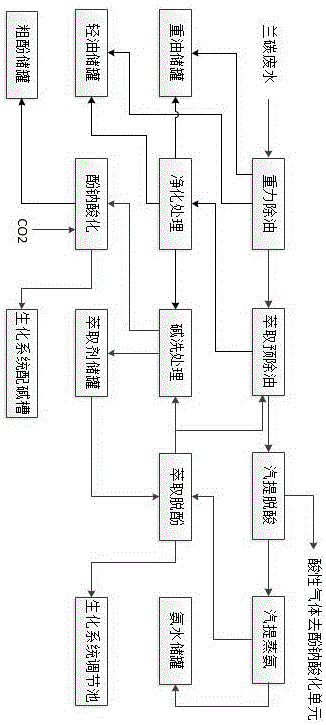

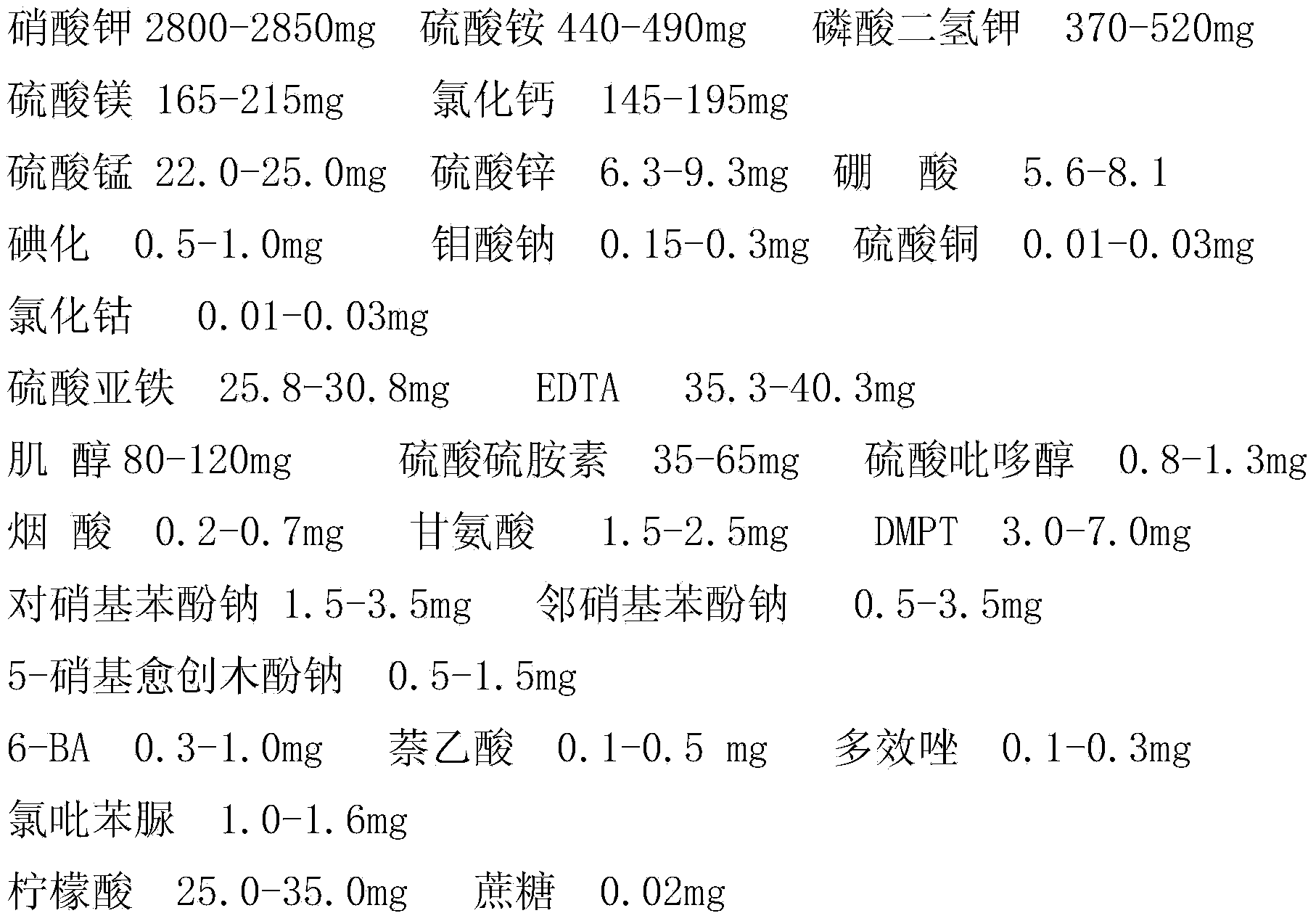

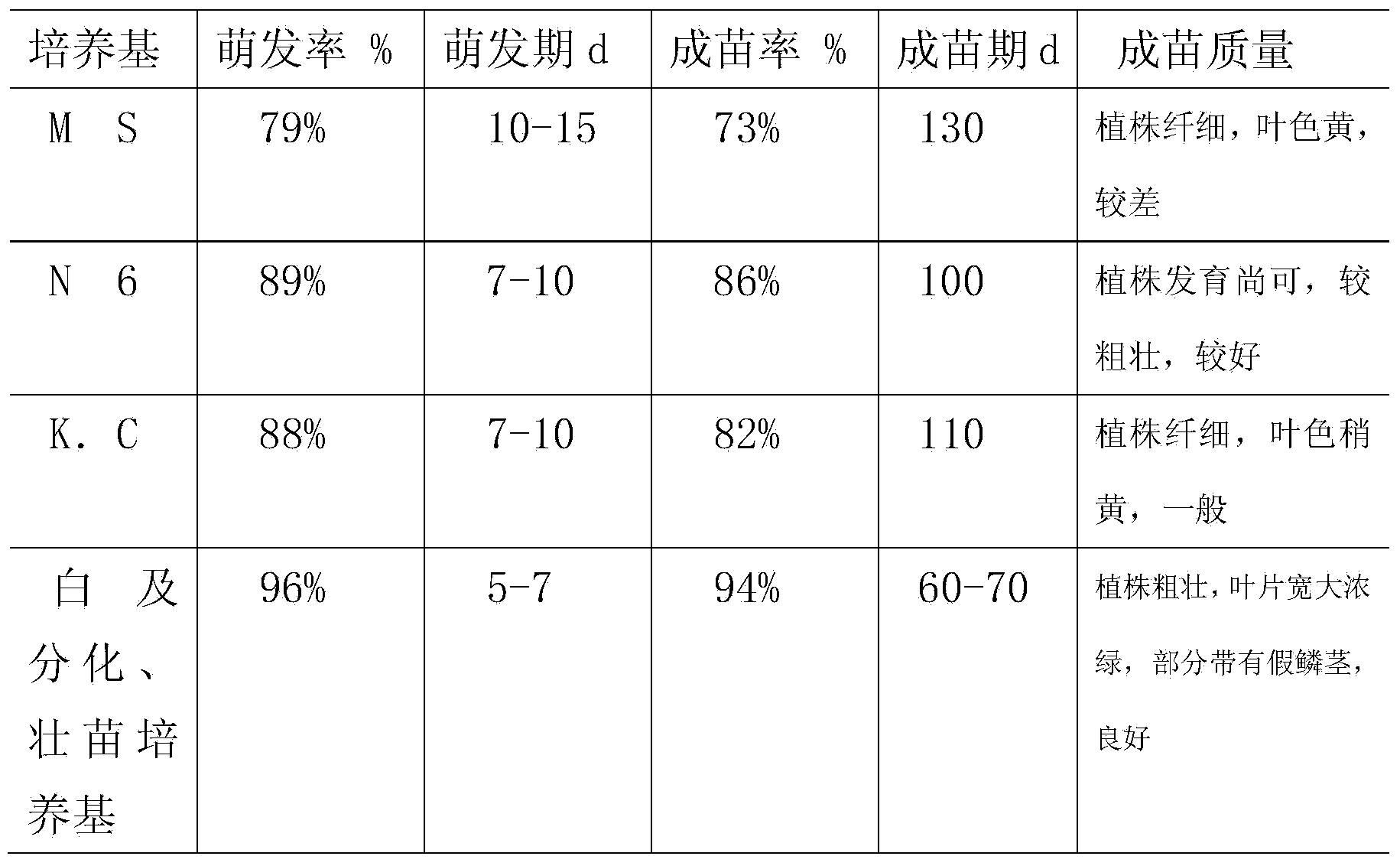

Bletilla striata differentiation and seedling strengthening medium

InactiveCN103651121AStrong differentiation abilityImprove germination ratePlant tissue cultureHorticulture methodsMonopotassium phosphatePotassium iodine

The invention a bletilla striata differentiation and seedling strengthening medium and relates to the technical field of bletilla striata planting and cultivation. The bletilla striata differentiation and seedling strengthening medium is prepared from the following raw materials including potassium nitrate, 440-490mg of ammonium sulfate, monopotassium phosphate, magnesium sulfate, calcium chloride, manganese sulfate, zinc sulfate, boric acid, potassium iodide, sodium molybdate, copper sulfate, cobalt chloride, ferrous sulfate, EDTA (Ethylene Diamine Tetraacetic Acid), phaseomannite, thiamine sulfate, pyridoxine sulfate, nicotinic acid, glycine, DMPT, sodium para-nitrophenolate, sodium ortho-nitrophenol, 5-nitroguaiacol sodium salt, 6-BA, NAA, PP-333, CPPU, citric acid, and cane sugar under a proper pH value condition. The bletilla striata differentiation and seedling strengthening medium can improve the differentiation effects of bletilla striata seeds, and promotes the growth of seedlings and the fast formation of pseudobulb, so that the germination rate of the seeds can be effectively increased, and the growth speed of an embryoid can be increased.

Owner:ANHUI ZHENYANG AGRI & FORESTRY ECOLOGY DEV

Root promoting agent suitable for camellia chrysantha burgeon cuttage

The rooting agent suitable for stem planting of golden camellia branch consists of 2, 4-dichloro phenoxyacetic acid, 3-indole butyric acid, sodium guaiacol mononitrate, sodium hydroxide and borax. It is diluted before being used for stem planting of golden camellia branch in spring, summer and autumn, and survival rate of golden camellia seedling may reach 93-98 %. The present invention makes it possible to protect, develop and utilize golden camellia via fast industrial seedling growing.

Owner:GUANGXI FUXIN SCI & TECH

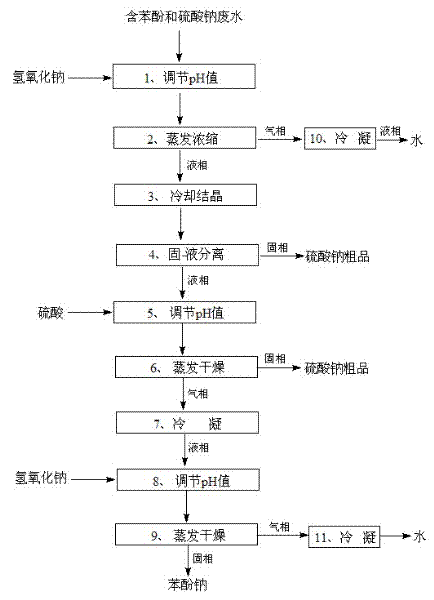

Resource utilization of waste water containing phenol and sodium sulfate and treating method

InactiveCN102351357AReasonable workmanshipSimple methodOrganic chemistryOrganic compound preparationSodium PhenolateWastewater

The invention relates to resource utilization of waste water containing phenol and sodium sulfate and a treating method, and especially to a method of treating waste water containing 0.1% to 2.0% of phenol and 5% to 30% of sodium sulfate and recycling phenol and sodium sulfate. The method comprises the following steps: (1) pH value adjusting; (2) evaporative concentration; (3) cooling and crystallization; (4) solid-liquid separation; (5) pH value adjusting; (6) evaporation and drying; (7) condensation; (8) pH value adjusting; (9) evaporation and drying. The method enables sodium phenolate and a byproduct of sodium sulfate to be obtained simultaneously. The invention has the advantages of a reasonable process, a simple method, environmental protection, energy consumption, low operational cost, good product quality and a high utilization rate of valuable components.

Owner:扬州大学江都高端装备工程技术研究所

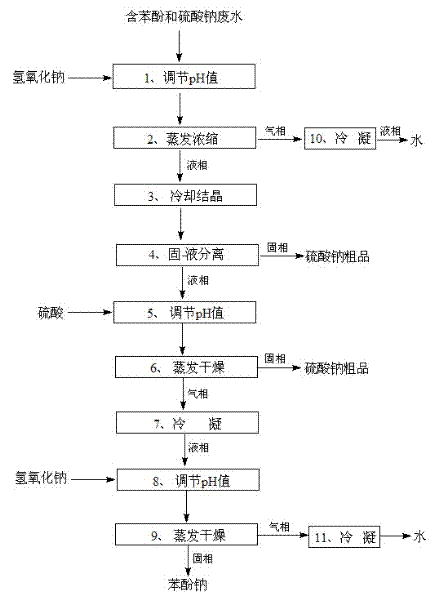

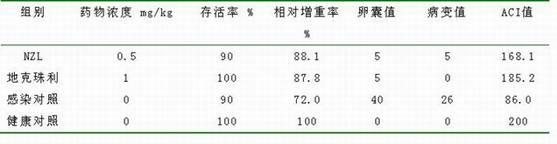

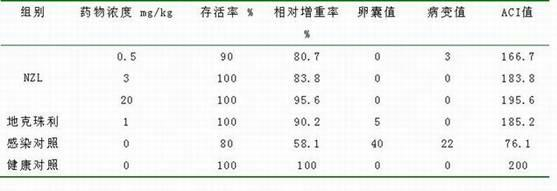

A kind of triazine compound and its application in controlling chicken coccidiosis

ActiveCN102285930AAppropriate physical and chemical propertiesEasy to manufactureOrganic chemistryAnimal feeding stuffDiseaseCoccidiosis

The invention discloses a compound represented by a formula (I) and application thereof to chicken coccidiosis disease control. The compound represented by the formula (I) is obtained by condensation of a compound represented by a formula (II) or sodium phenolate thereof with a compound represented by a formula (III) under the alkaline condition, wherein a substituent group x in the compound represented by the formula (III) is halogen. The compound represented by the formula (I) has the effects of preventing and treating a chicken coccidiosis disease, and has good chicken coccidiosis resisting activity when in concentration of 0.5-20mg / kg.

Owner:SHANGHAI VETERINARY RES INST CHINESE ACAD OF AGRI SCI

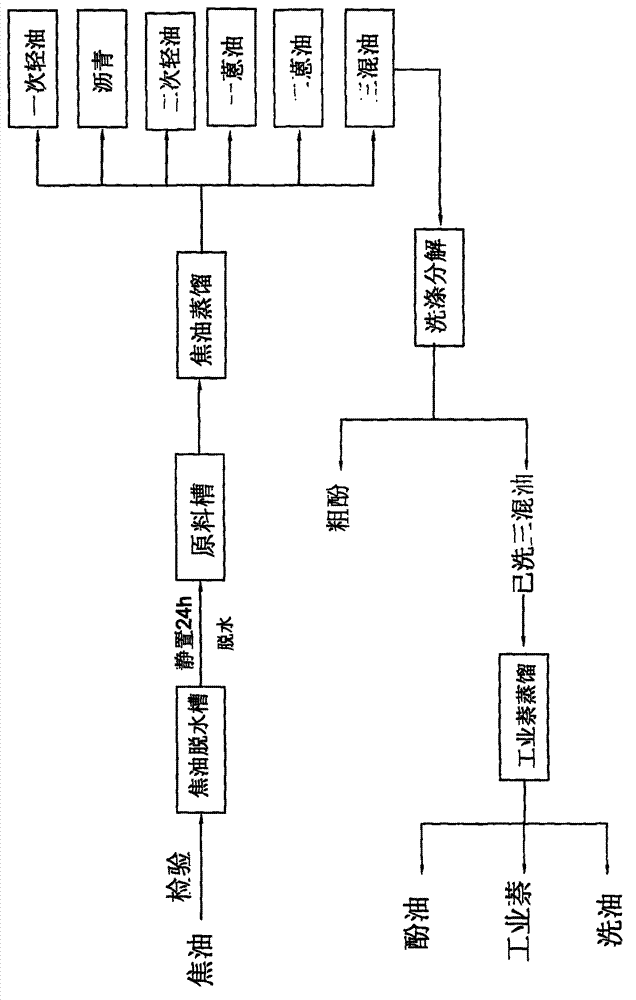

Processing method of coal tar

InactiveCN103242902AAvoid pollutionReduce energy consumptionTreatment with plural serial refining stagesWater insolubleDistillation

The invention relates to a processing method of coal tar. The processing method is characterized by comprising the following steps of: dewatering tar; distilling the tar; sequentially distilling the dewatered tar by adopting continuous type distillation devices, namely a first-stage evaporator and a second-stage evaporator, to respectively obtain light oil, asphalt, anthracene oil II, anthracene oil I, mixed oil III; washing and decomposing: alkalizing the mixed oil III to generate water-soluble phenoxide which can be separated from water-insoluble naphthalene washing distillates so as to provide a raw material for industrial naphthalene; evaporating the separated neutral phenoxide to obtain pure sodium phenolate; decomposing by using sulphuric acid to finally obtain crude phenol of which phenol content is more than or equal to 83%; and distilling industrial naphthalene: dewatering washed mixed distillates, carrying out heat exchange with industrial naphthalene steam to 190-210 DEG C, cutting phenol oil distillates in a primary distillation tower, and cutting the industrial naphthalene and wash oil distillates in a rectifying tower. The process method disclosed by the invention is simple and reasonable in process, reduces the energy consumption and plays an energy conservation role by sufficiently utilizing the afterheat of products in the distillation process of the tar and prevents the flue gas from polluting the environment by arrangement of an exhaust cleaning tower in a washing and decomposing procedure.

Owner:新疆宝鑫炭材料有限公司

Calixarene crown ether bonded silica stationary phase and preparation method and application thereof

InactiveCN102107135AImprove hydrophobicityEasy to identifyIon-exchange process apparatusOther chemical processesBenzoic acidSilanes

Owner:ZHENGZHOU UNIV

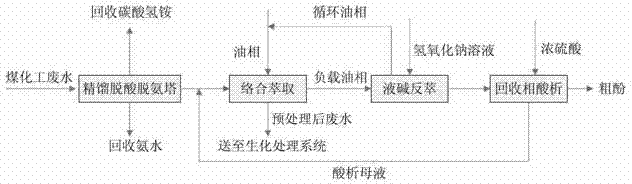

Method for pretreating coal chemical industry production waste water and recycling resources of waste water

ActiveCN102815844AHigh removal rateStable emissionsMultistage water/sewage treatmentRecovery methodGas phase

The invention discloses a method for pretreating coal chemical industry production waste water and recycling resources of the waste water. According to the technical scheme, the method comprises the following steps of: (1) performing rectification, deacidification and deamination, namely feeding the coal chemical industry waste water into a rectification, deacidification and deamination tower, transferring ammonia and carbon dioxide in the waste water from a liquid phase to a gas phase, and respectively recycling 15 to 20 percent of ammonia water and ammonium bicarbonate; and (2) performing complexing extraction and recycling phenolic substances, namely adjusting the pH of the rectified residual solution in a kettle to be less than 3 by acid, adding a prepared oil phase according to a certain proportion, performing complexing extraction, after extraction is balanced, obtaining a load oil phase and pretreated waste water, performing reverse extraction on the load oil phase by sodium hydroxide solution serving as an extraction agent to obtain a concentrated sodium phenolate solution and a regenerated oil phase, acidifying the sodium phenolate to obtain crude phenol, and recycling the regenerated oil phase. Compared with the prior art, the method has the advantages that the technical flow is simple; the equipment investment is small, the energy consumption is low, the efficiency is high, and the phenol recycling rate is high; harmlessness and reclamation of the waste water are realized; and the method is obvious in economical and environmental benefits.

Owner:中国中化股份有限公司 +2

Preparation process of herbicide dicamba

InactiveCN102125035BReduce pollutionHigh reaction yieldBiocideAnimal repellantsSodium PhenolateSolid reaction

The invention relates to a preparation process of herbicide dicamba, in particular to a supercritical preparation process. The preparation process of the herbicide dicamba comprises the following steps of: preparing 2,5-dichlorophenol into corresponding sodium phenolate, and then completing carboxylation reaction under a supercritical condition to obtain 3,6-dichlorosalicylic acid; and then completing O-methylation to prepare a product of 3,6-dichloro-2-methoxy salicylic acid, i.e. the dicamba, by taking dimethyl carbonate as a reagent. The invention changes the heterogeneous gas-solid reaction of the traditional process into homogeneous reaction under the supercritical condition, carries out the O-methylation reaction by using the dimethyl carbonate and has the advantages of high reaction yield, good product quality, reduced environmental pollution, lowered energy consumption, and the like.

Owner:上海力智生化科技有限公司

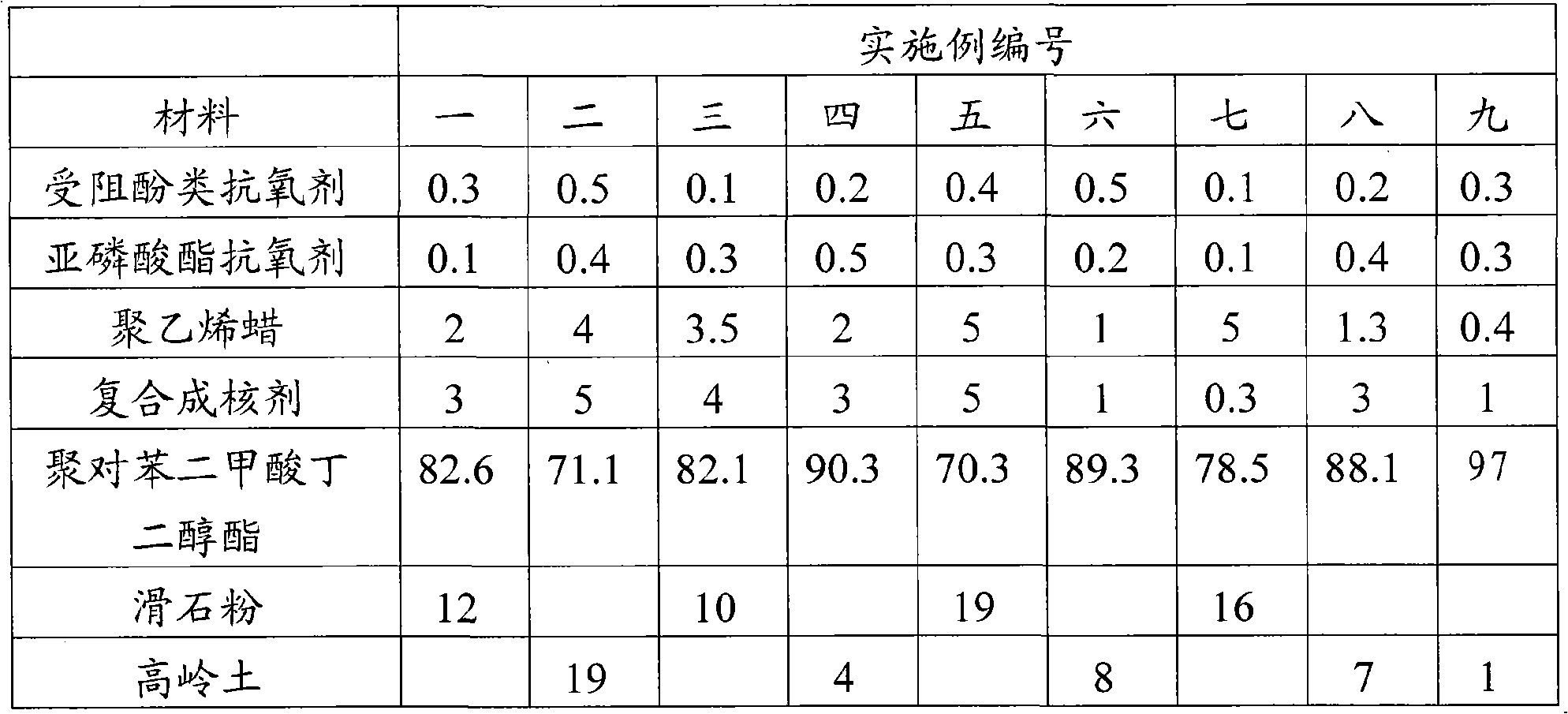

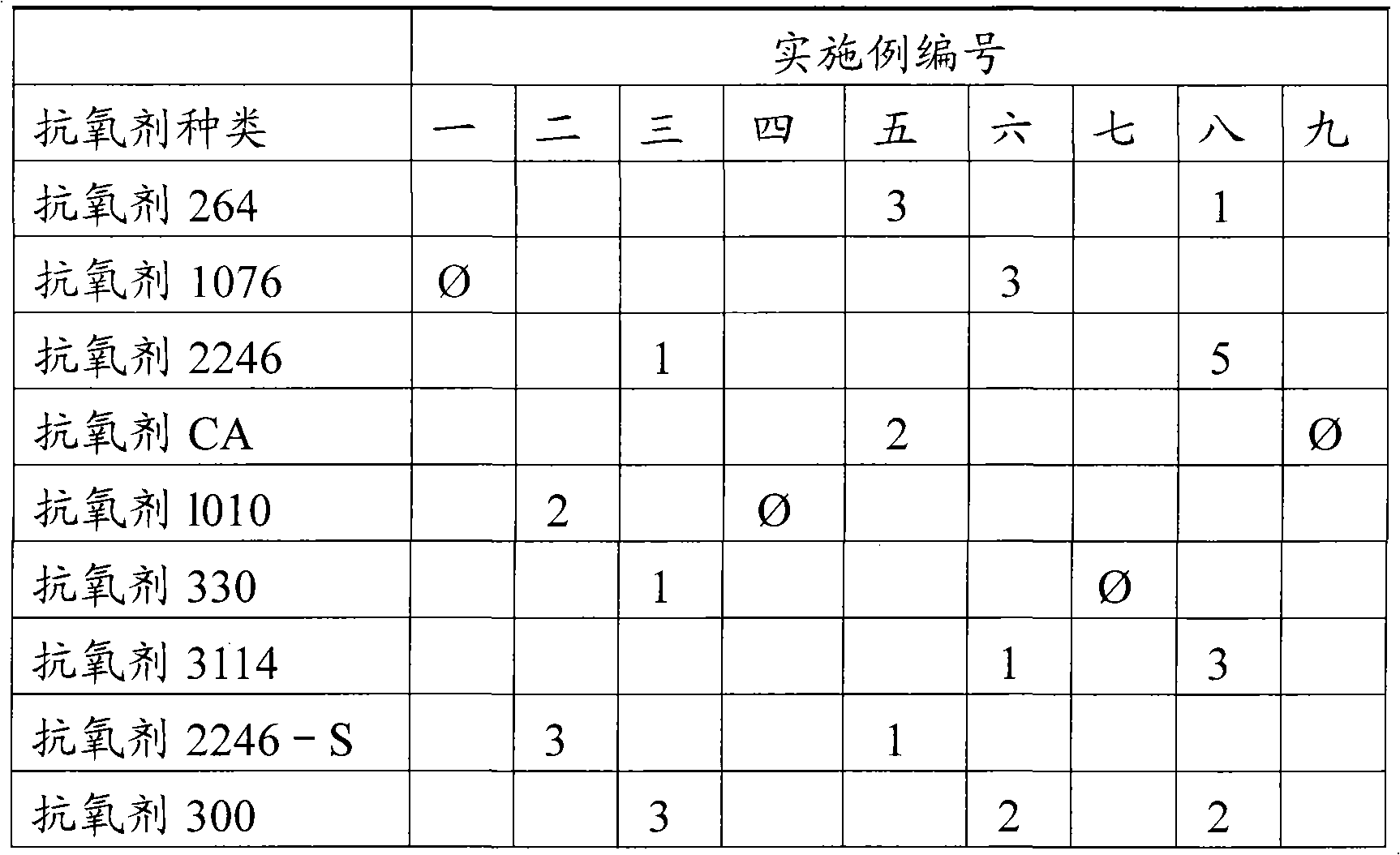

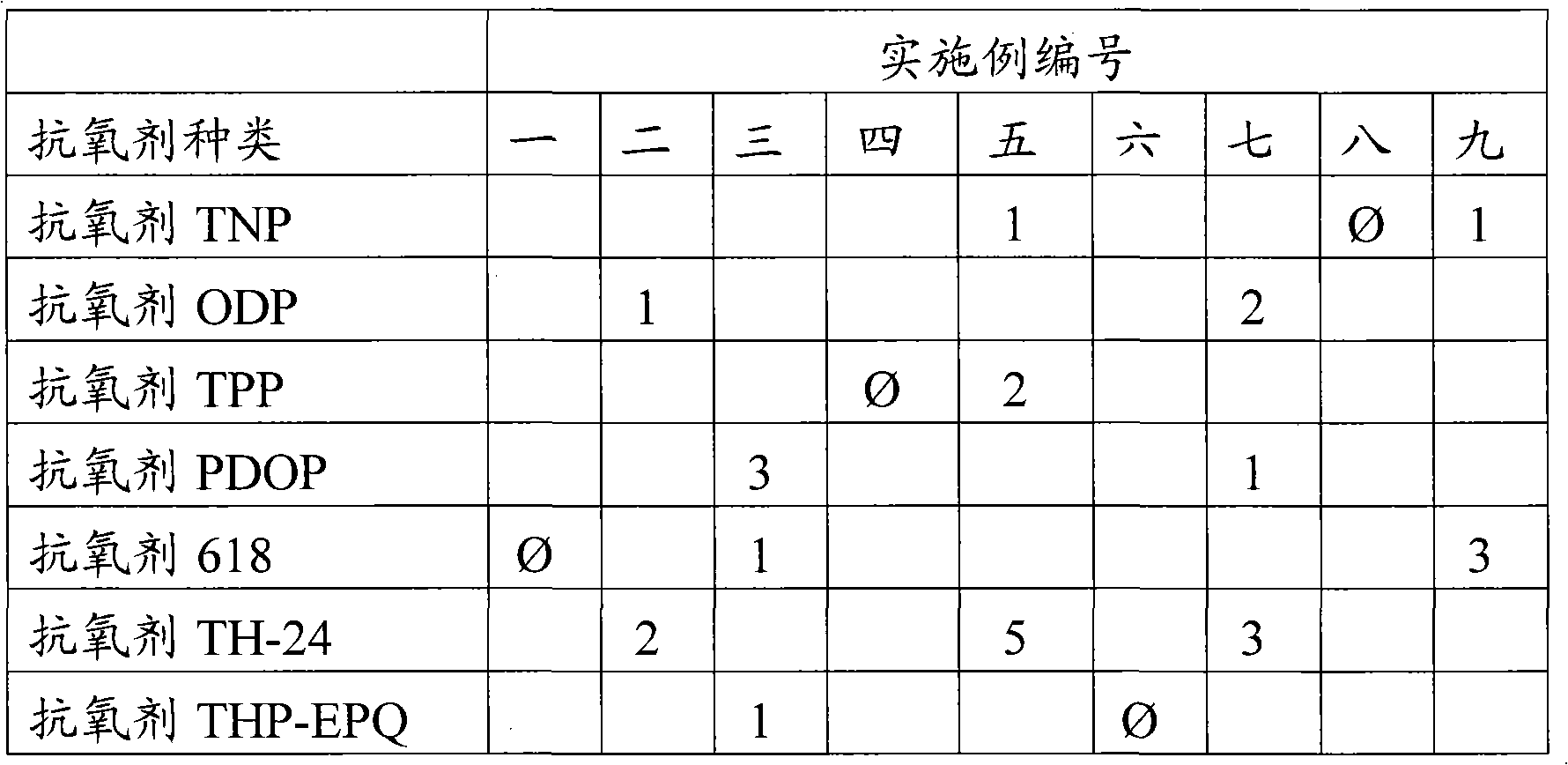

Polybutylene terephthalate material used for decorative ring of vehicle lamp

InactiveCN101550268AGood dimensional stabilityEfficient nucleationSodium acetatePolytetramethylene terephthalate

The invention relates to a polybutylene terephthalate material used for a decorative ring of a vehicle lamp, which consists of the following raw materials by weight percentage: 0.1 to 0.5 percent of hindered phenol antioxidant, 0.1 to 0.5 percent of phosphorous ester antioxidant, 0.1 to 5 percent of polyethylene wax, 0.1 to 5 percent of composite nucleating agent, 69 to 98.6 percent of polybutylene terephthalate and 1 to 20 percent of talcum powder or kaolin; the composite nucleating agent is a complex which consists of at least one of calcium carbonate, silicon dioxide, bentonite, sodium carbonate, potassium carbonate and boron nitride with the particle size of 0.01 to 1 micron and at least one of sodium benzoate of organic nucleating agent, sorbitan dibenzyl, calcium stearate, sodium acetate, para-sodium phenolsulfonate, para-calcium phenolsulfonate and sodium phenolate. The polybutylene terephthalate material improves surface property of the material and saves the procedure of spraying primer in the spraying process, thus reducing labour cost and material cost and reducing defective products due to reduction of one procedure.

Owner:POLYONE POLYMER SUZHOU

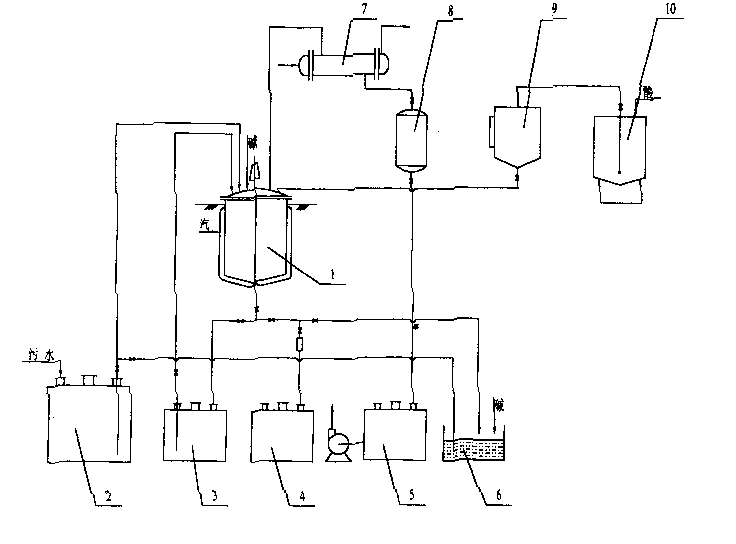

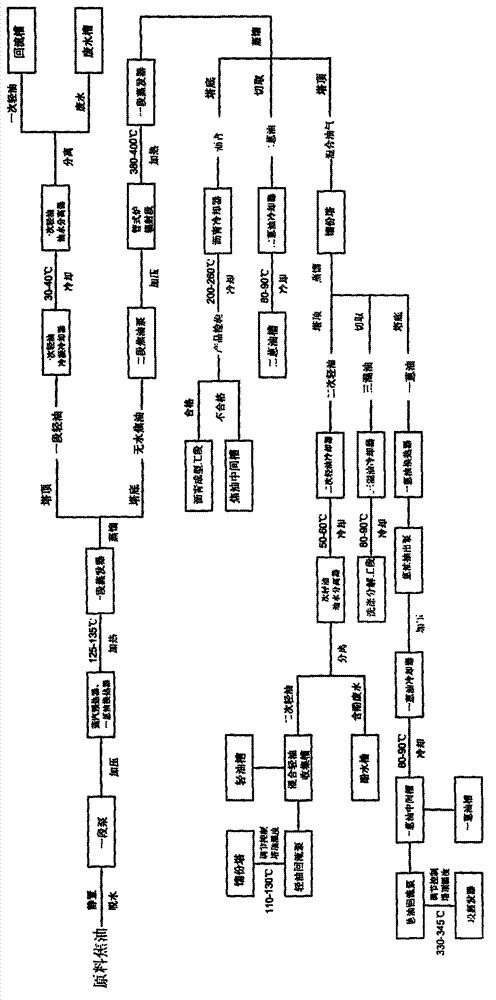

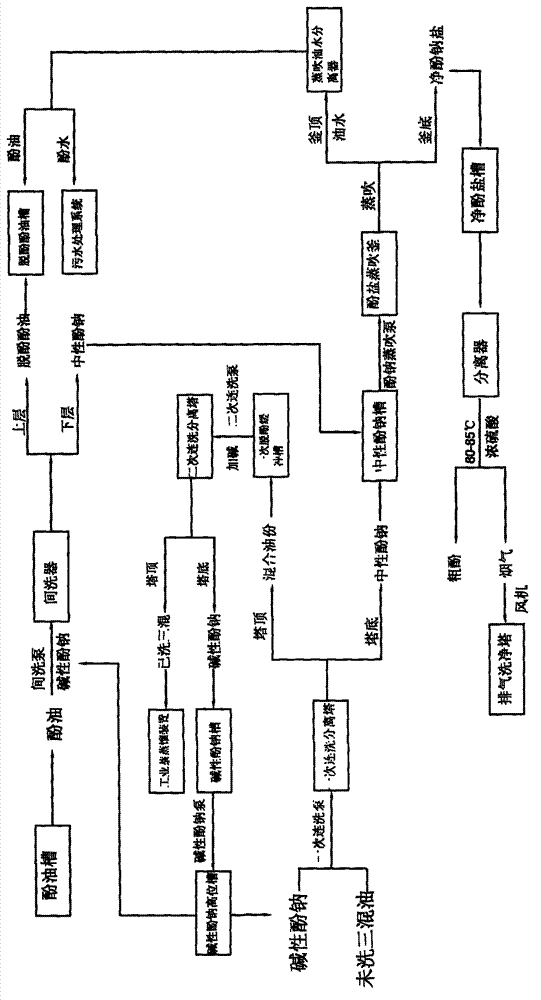

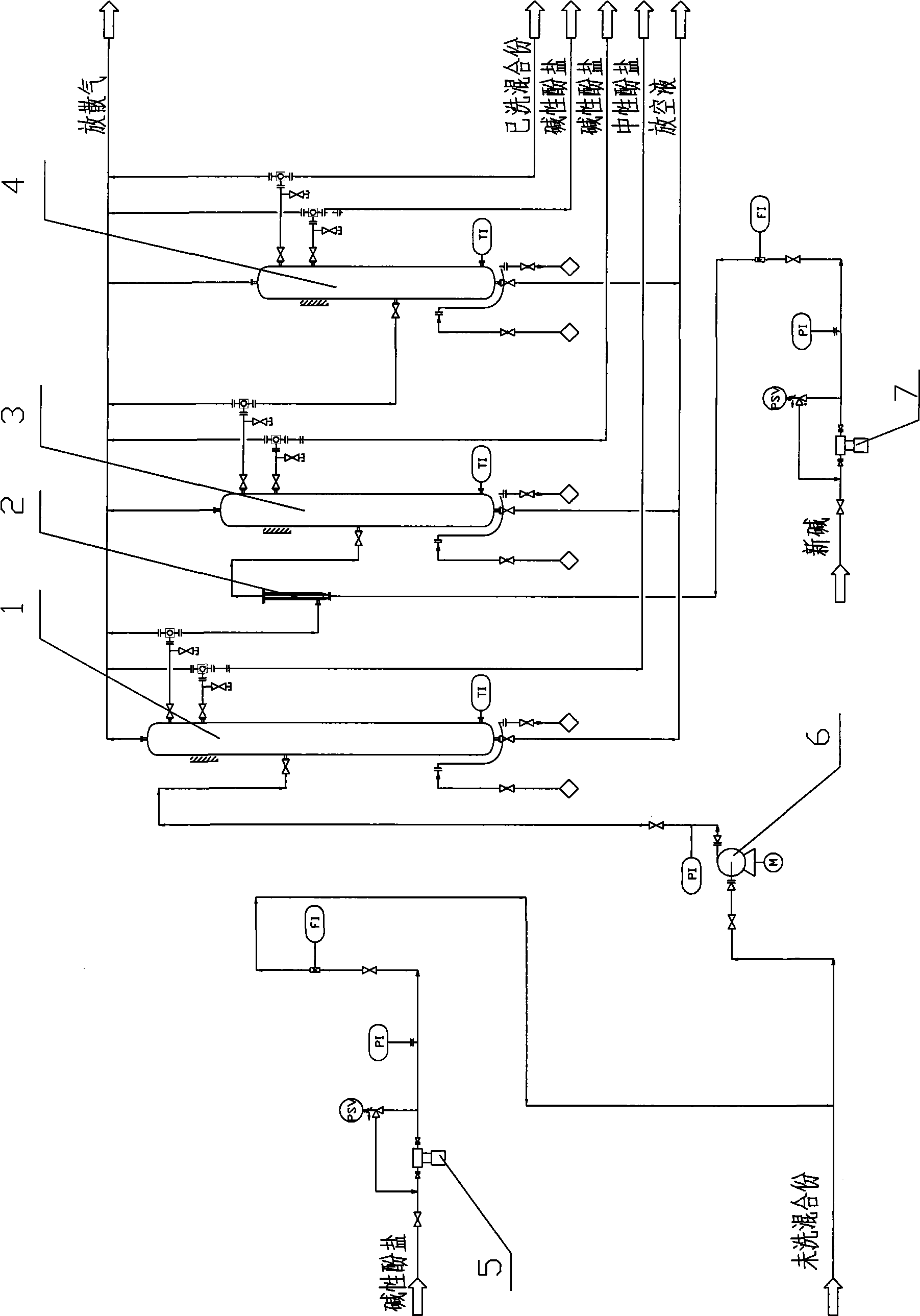

Distillate dephenolizing process and apparatus thereof

The invention relates to a distillate dephenolizing process for the middle production procedure of a coal tar processing device. The technical process comprises the following steps: using a dephenolizing washer pump to pump out the unwashed mixed part which comes from a tar distillation plant so as to be mixed evenly and react with basic phenate together in the dephenolizing washer pump; putting the mixed solution into a primary dephenolizing tower to be kept stand and separated into a mixed part and neutral sodium phenolate, wherein the mixed part enters a secondary dephenolizing tower through a mixing nozzle; and in order to further remove phenols in the mixed part, using 10 to 12 percent diluted alkaline to perform secondary dephenolizing on the mixed solution before the mixed part enters the secondary dephenolizing tower. The mixture is kept stand and separated into the basic phenate and a washed mixed part in the secondary dephenolizing tower, the washed mixed part flows into a phenate removing tower automatically and is kept stand and separated out the residual basic phenate in the phenate removing tower, then the basic phenate flows into a basic phenate groove, and finally the washed mixed part enters a industrial naphthalene distillation plant for further processing. The process can reduce the environmental pollution, save energy resources and improve the efficiency.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

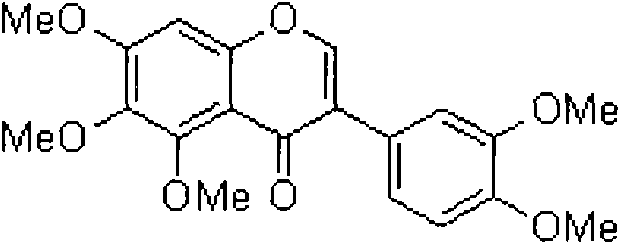

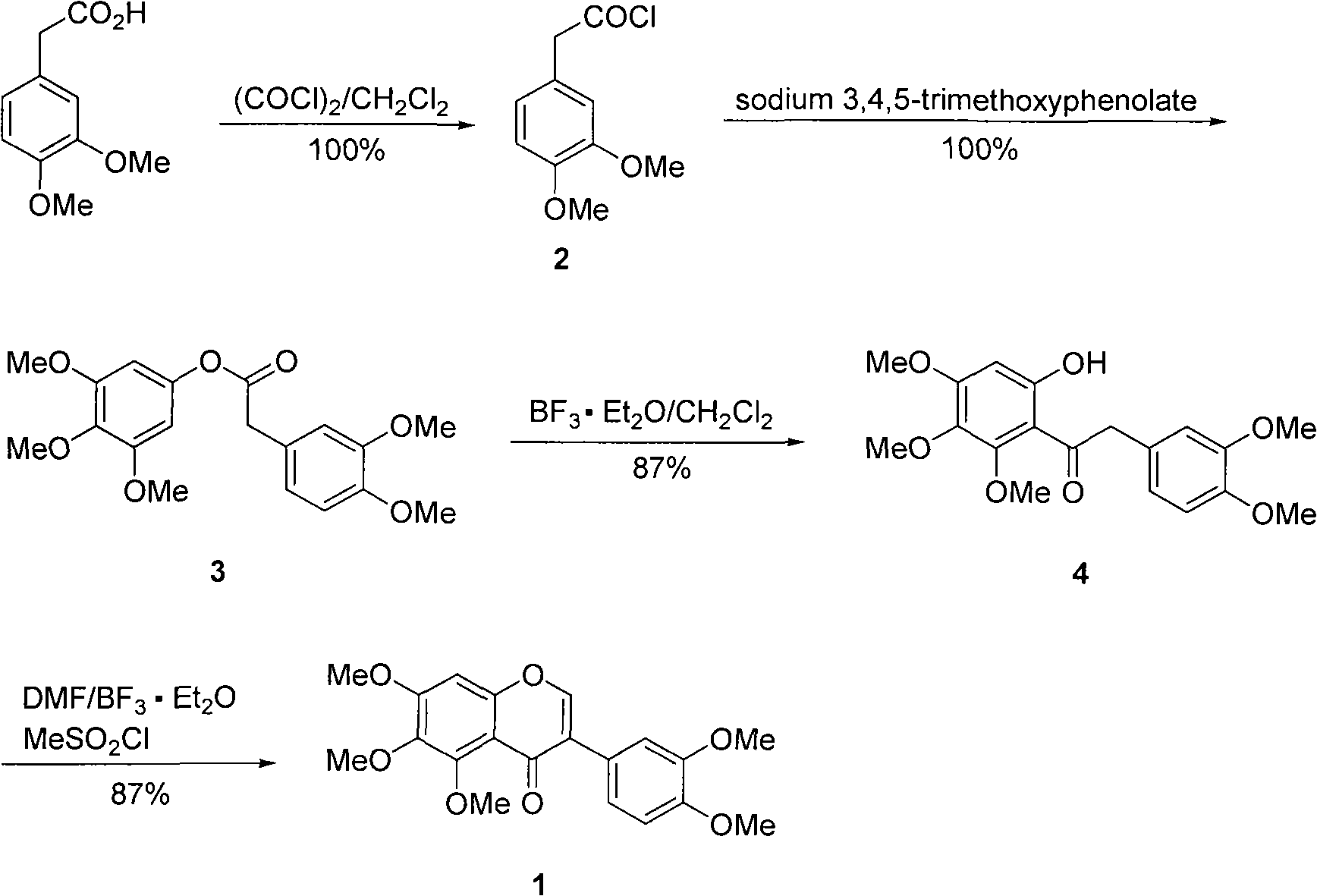

Preparation method of COMT inhibitor 5, 6, 7, 3', 4'-pentamethoxyl isoflavone

InactiveCN101643465AEasy to operateShort reaction timeOrganic active ingredientsOrganic chemistrySulfonyl chlorideFormylation reaction

The invention relates to a preparation method for COMT inhibitor 5, 6, 7, 3', 4'-pentamethoxyl isoflavone, comprising the following steps: mixing 3, 4-dimethoxyphenylacetic acid and oxalyl chloride indichloromethane solution to carry out reflux reaction for 2 to 3 h, and cooling to room temperature; adding 3, 4, 5-trimethoxy sodium phenolate to carry out esterification reaction to carry out Friesrearrangement reaction under the catalysis of Lewis acid boron trifluoride ether; and finally carrying out reaction with DMF with the existence of the Lewis acid boron trifluoride ether; and adding methane sulfonyl chloride to promote Vilsmeier-Haack formylation reaction and subsequent cyclization reaction to obtain light yellow crystals 5, 6, 7, 3', 4'-pentamethoxyl isoflavone. The preparation method has simple and easily available raw materials, simple operation, short reaction time, mild reaction condition, environment protection and high yield of 76 %, and is suitable for industrial production.

Owner:DONGHUA UNIV

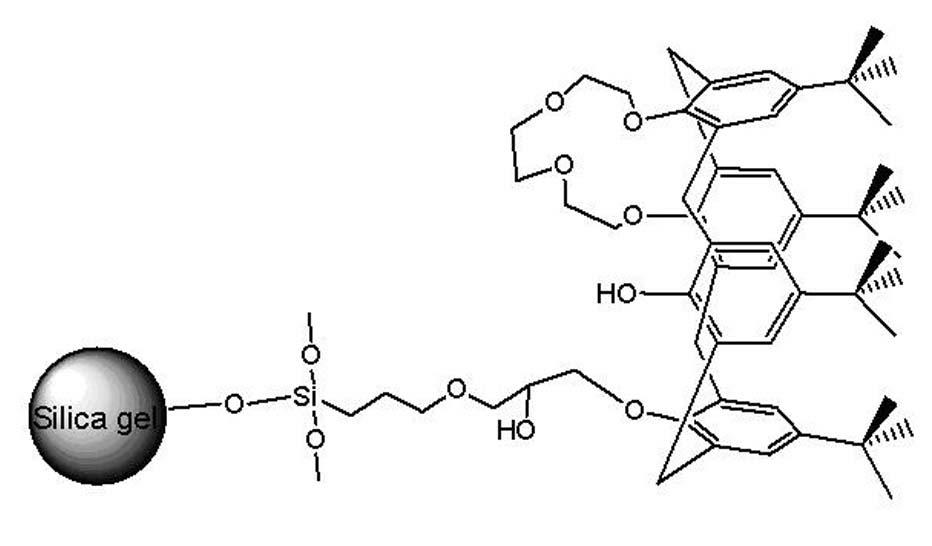

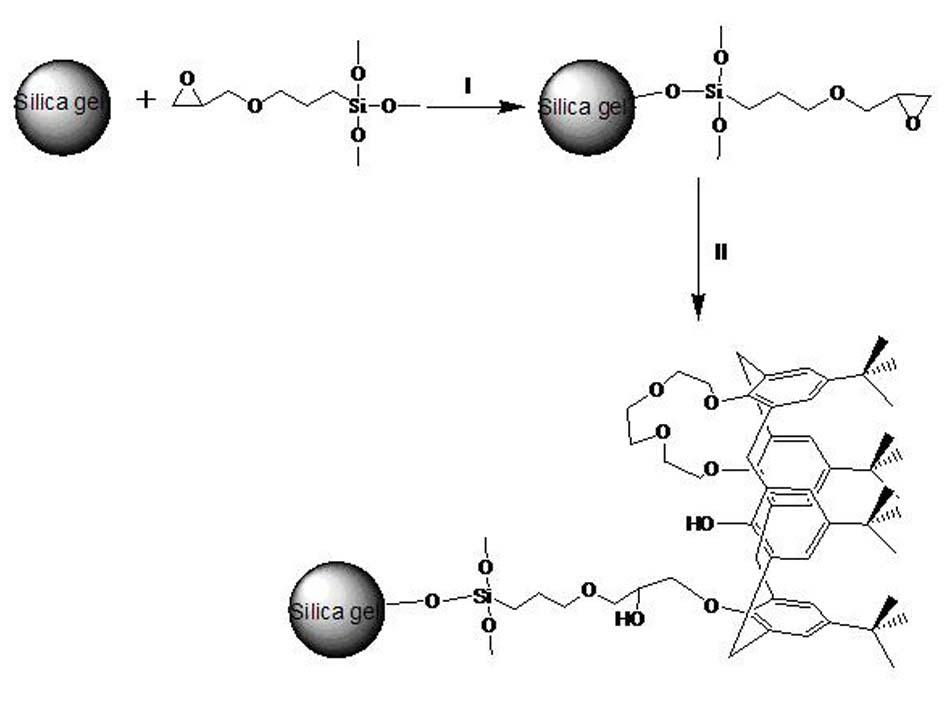

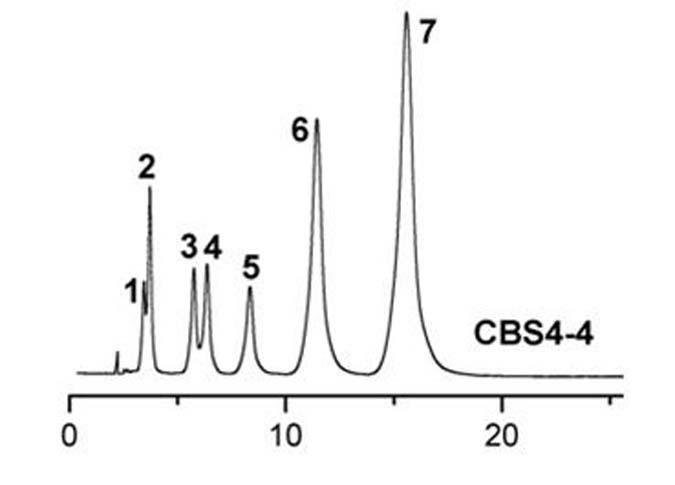

25,27-di(3-methyl-thio-ethoxy thiadiazole) calix[4]arene stationary phase, preparation method and application thereof

ActiveCN102091597AHigh bonding capacitySynthetic method is simpleIon-exchange process apparatusOther chemical processesThio-Silica gel

The invention discloses a 25,27-di(3-methyl-thio-ethoxy thiadiazole) calix[4]arene stationary phase which is low in cost, high in content of compounded calixarene bonded stationary phase bonded amount, and stable in stability bonding layer, and is prepared by the following steps of: under the action of phase transfer catalyst ammonium tetrabutyl bromide, carrying out nitrogen protection to gamma-glycidol ether bonded silica gel and calixarene derivative sodium phenolate, and preparing the object calixarene stationary phase at 80 DEG C. The calixarene stationary phase compounded by the method in the invention is high in bonded amount, stable in boned layer, simple and easy in compounding method, low in cost, free of pollution in the compounding process and the like. The stationary phase not only has traditional ODS (Octadecylsilyl) reversion phase chromatography performance, and has containing complexing action, pi-pi action, hydrogen bonding action and dipole-dipole action because of many action sites; in a certain degree, the stationary phase in the invention has special separation performance comparing with the traditional ODS column.

Owner:ZHENGZHOU UNIV

Combination treatment method of 2-naphthol production wastewater

ActiveCN102603101AAchieve recyclingRealize resource utilizationWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentHigh concentrationChemical oxygen demand

The invention discloses a combination treatment method of 2-naphthol production wastewater, belonging to the technical field of wastewater treatment. The method comprises the steps of: respectively treating the 2-naphthol production wastewater through complexing extraction and liquid membrane separation technologies to ensure that the wastewater is easily subjected to biochemical treatment; and respectively carrying out alkali washing and demulsification on a load extraction agent and a load emulsion to ensure that the extraction agent and a liquid membrane oil phase are regenerated, wherein a concentrated solution contains high-concentration sodium phenolate and sodium naphthalene sulphonic and can be reused in production sections. The treatment method of the 2-naphthol production wastewater has the advantages that the COD (Chemical Oxygen Demand) in the wastewater is reduced from about 100000mg / L to about 3000mg / L; nonbiodegradable organic pollutants in the wastewater are greatly decreased; the biodegradability of the wastewater is increased; reduction and resource utilization of the pollutants in the 2-naphthol production wastewater can be realized at the same time; and a certain economic benefit is provided.

Owner:中国中化股份有限公司 +2

Phenolic resin sewage treatment method

InactiveCN1371871ANo pollutionReliable technologyWater/sewage treatment by neutralisationWater/sewage treatment by heatingSteam pressureDecomposition

The method for treating sewage product from production of phenolic resin includes the procedures of alkaline salt-forming reaction, vacu9um evaporation concentration, decomposition reaction and evaporatino crystallization. In the sewage the alkali is added until the pH value of sewage is 11-12, the they are stirred at normal temp., the sodium phenolate salt aqueous solution can be obtained, underthe conditions of that its vacuum is 0.01-0.015 Mpa, and heated steam pressure is 0.15-0.3 Mpa the above-mentioned solution is concentrated, and its phenol content is 25-30%, then the dilute acid is added in the concentrate until its pH value is 1-3, reacted and stood still, the phenol and residue can be separated and recovered, the residue can be naturally evaporated, and the sodium sulfate can be separated, crystallized and recovered.

Owner:ANSHAN KAITE ENVIRONMENT PROTECTION ENG TECH

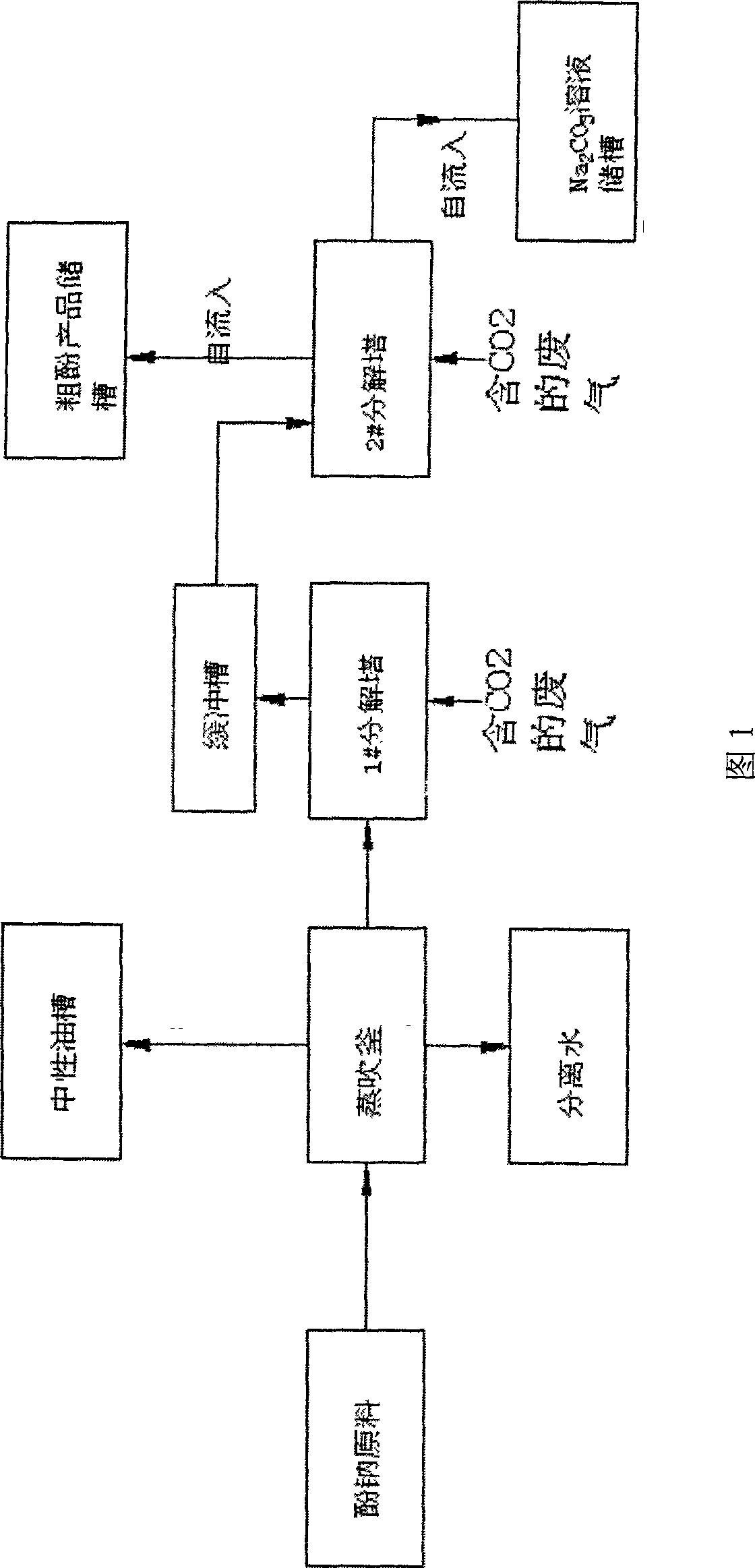

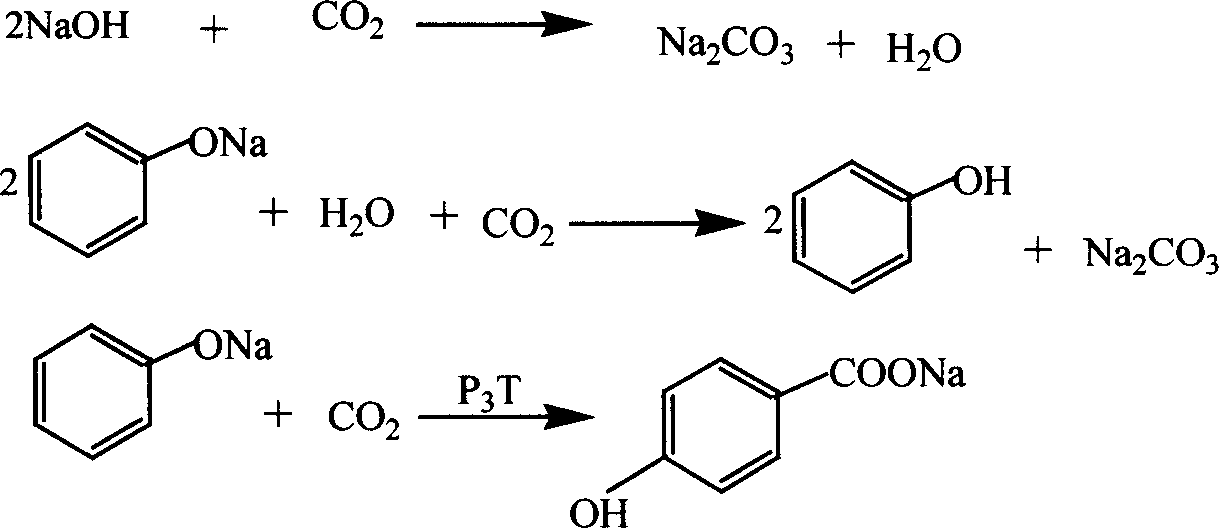

Method for decomposing sodium phenolate using low CO2-content exhaust gas

ActiveCN101381284AEmission reductionProtection advantageOrganic chemistryOrganic compound preparationForeign matterCO2 content

The invention relates to a production method for decomposing sodium phenolate by using low-content CO2 waste gas. The method comprises the following steps: the low-content CO2 waste gas is used, the temperature of the CO2 waste gas is reduced to between 40 and 60 DEG C through a cooling device, vapor and foreign matters in the CO2 waste gas are cleared away, and then the CO2 waste gas is pumped to a decomposing tower and an acidifying tower through a fan; the sodium phenolate is warmed up by steam and then is put into the decomposing tower to contact the low-content CO2 waste gas, and the temperature in the decomposing tower is between 40 and 60 DEG C; under the action of internal parts of the decomposing tower, thermal transfer and mass transfer are realized to decompose the sodium phenolate into crude carbolic acid and sodium carbonate; and the sodium phenolate is sprayed from the top of the decomposing tower to contact reverse current of the low-content CO2 waste gas so that the sodium phenolate is decomposed into the crude carbolic acid and the sodium carbonate which are separated to obtain a crude carbolic acid product and sodium carbonate solution after being kept stand, wherein the sodium carbonate solution is causticized into sodium hydroxide solution through calcium oxide, and the sodium hydroxide solution is used as a raw material for distillate washing to perform circulation. The production method makes full use of the characteristics of distillate processing and the prior resources of deep-processing enterprises to realize the standard emission of the waste gas to be emptied.

Owner:QUJING ZHONGYI FINE CHEMICAL INDUSTRY CO LTD

Technology for treating waste water containing phenol in synthetic process of p-hydroxy-phenyl-hydantoin

InactiveCN101591083AReduce pressure on environmental protectionMultistage water/sewage treatmentNature of treatment waterInorganic saltsIndustrial waste water

The invention provides a method for treating waste water containing phenol in a synthetic process of p-hydroxy-phenyl-hydantoin, which belongs to the technical field of the treatment of organic chemical industrial waste water. The method comprises the following step: synthetic waste water is distilled and pretreated, wherein the treatment of the synthetic waste water comprises the processes that acidizing pretreatment is firstly carried out on the synthetic waste water, and then the collected waste water containing phenol is adsorbed by macroporous resin. Because the method removes phenol-containing substances in the waste water in advance, the difficulty of the recovery processing of inorganic salt subsequent can be greatly improved, and recovered sodium phenolate can be reused for a synthetic working process of the p-hydroxy-phenyl-hydantoin. The method has stable and reliable treatment effect, low treatment cost, convenient and easy operation and easy realization of industrialized application.

Owner:HENAN NEWLAND PHARMA +2

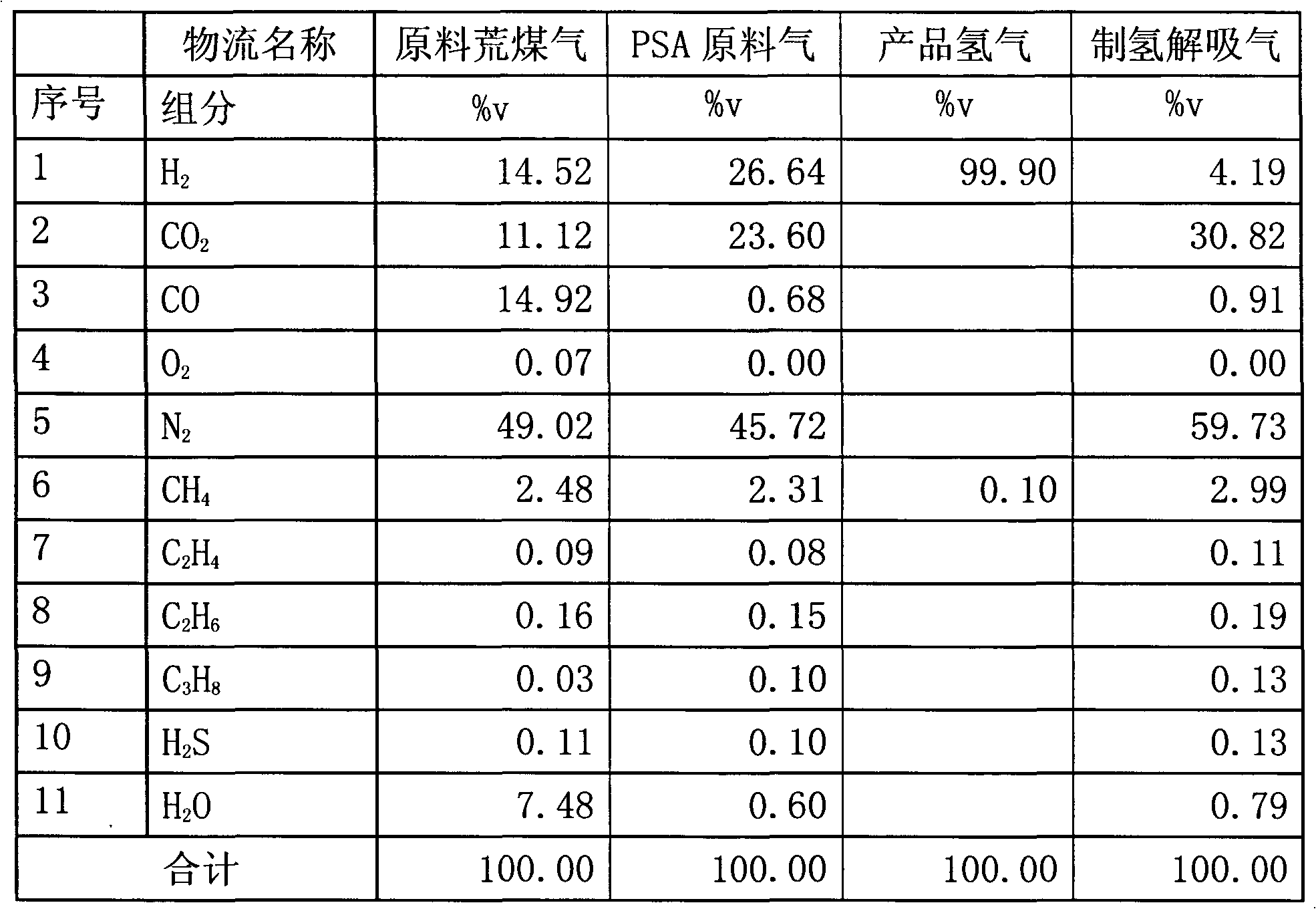

Two-step pressure swing adsorption separation method of multicomponent gas containing hydrogen and hydrogen sulfide

A two-step pressure swing adsorption separation method of multicomponent gas containing hydrogen and hydrogen sulfide is adopted to divided raw gas into a hydrogen sulfide-rich first adsorbent bed regenerative vent gas (which is easy for further desulfhydrylation), a second purified gas composed of high-purity hydrogen and a second adsorbent bed regenerative vent gas containing low concentration of hydrogen sulfide, high concentration of carbon dioxide and inflammable gas (suitable for serving as carbon dioxide gas source or fuel gas in the crude phenol preparation process by sodium phenolate decomposition). The invention can realize large-range integrated combination technology with the combination of hydrogen production, desulphurization and tail gas utilization processes by conversion of raw gas into produced gas and processes of low medium temperature coal tar fractionation, crude phenol preparation by carbon dioxide decomposition method, coal tar distillate oil hydrogenation modification and its gas stream desulfhydrylation and the like, and can build complete resource comprehensive utilization industrial chain.

Owner:何巨堂

Resourceful treatment method for coal gasification wastewater

InactiveCN107473311AImprove efficiencyGuaranteed uptimeWater contaminantsWater/sewage treatment by extractionCoal gasification wastewaterSodium Phenolate

The invention provides a resourceful treatment method for coal gasification wastewater. According to the method, the coal gasification wastewater subjected to deacidification, deamination and oil pre-removal is extracted and dephenolized, the dephenolized wastewater treated to reach the standard reaches the standard, and enters a coal chemical wastewater biochemical treatment process, and phenols in an extraction phase are converted into sodium phenolate by a phenol-rich organic phase through an alkali cleaning section, so that the aims of an extracting agent and phenol separation are fulfilled; a sodium phenolate solution enters an acidification section, and is acidified to prepare crude phenol and sodium salt; sodium hydroxide is recycled from the sodium salt obtained by separation by causticization reaction, and is recycled for the alkali cleaning section; a dephenolization extracting agent obtained by the alkali cleaning section is subjected to purification treatment to regenerate the extracting agent. According to the method, separation and enrichment of the phenols, heavy oil, light oil and the like in the coal gasification wastewater can be realized to realize recycling of resources, and meanwhile, the extracting agent and alkali liquor can be recycled.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

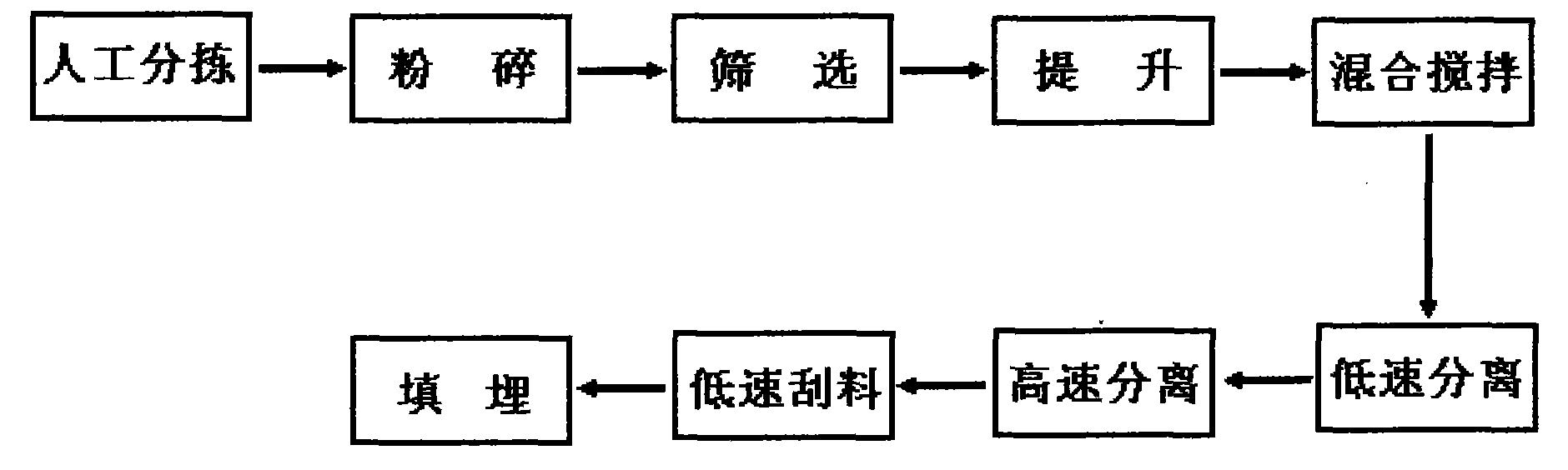

Causticized alkali liquor efficient separation method

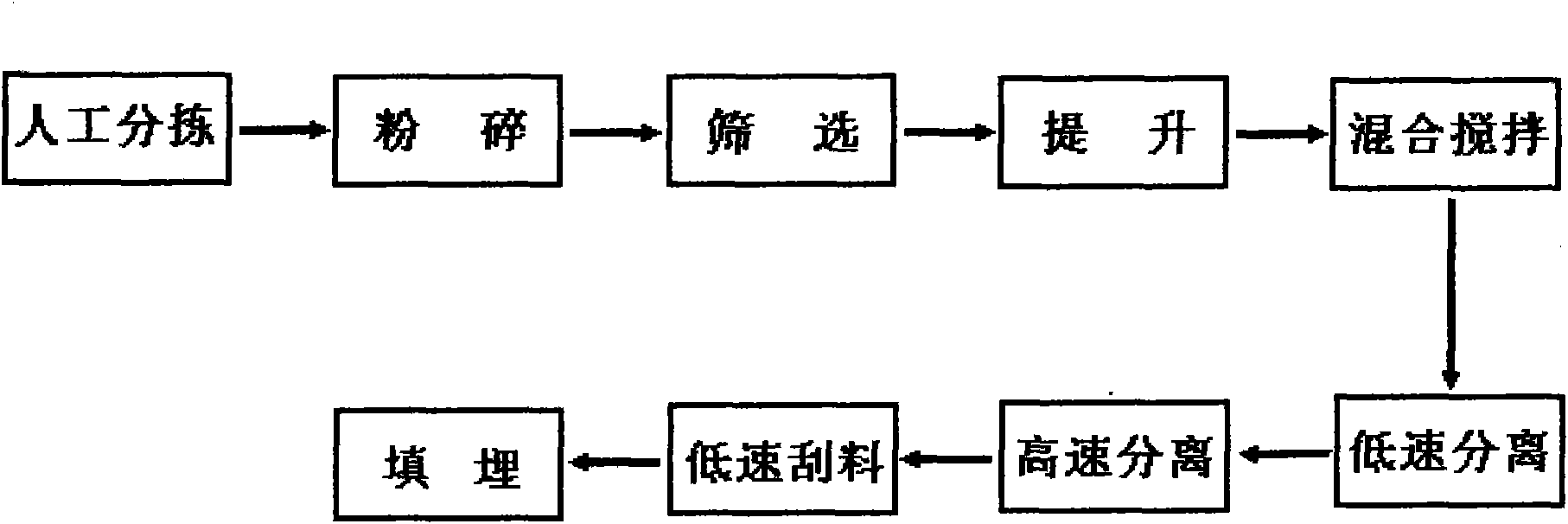

ActiveCN101811706ASolve technical problemsGood social and environmental benefitsAlkali metal oxides/hydroxidesLow speedDecomposition

The invention discloses a causticized alkali liquor efficient separation method, including the following procedures: A, quick lime is subject to pre-treatment, smashing and screening are carried out to remove massive stone and dross, so as to obtain quick lime powder; B, the quick lime powder is hoisted into a causticization tank for carrying out causticization under the action of mechanical stirring; C, after causticization is completed, material is gradually fed into centrifugal separation equipment under the stirring condition, low speed separation is carried out firstly, material filter cake is formed at filter screen interface, material feeding is stopped when the thickness of the filter cake reaches specified value, and high speed separation is carried out; D, moisture percentage of material lime mud after high speed separation is controlled to be less than 5%, and the material lime mud is buried after meeting security landfill requirement. The invention solves the technical problem in the industry and eliminates potential safety hazard to environment and person. The quick lime mud obtained by separation can be calcined to produce lime, and the produced CO2 gas can be used for industrial production such as sodium phenolate decomposition air source. By implementing the invention, not only economic benefit of enterprise is good, but also social benefit is good, the invention has better environment protection and economic significance and is a practical technical method in which resource can be recycled and clean production can be realized.

Owner:QUJING ZHONGYI FINE CHEMICAL INDUSTRY CO LTD

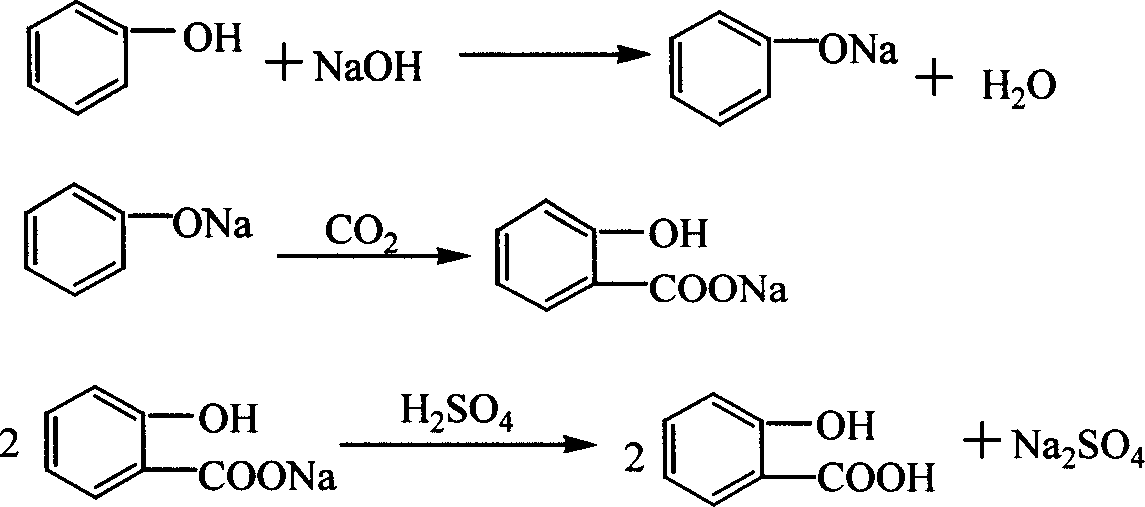

Novel supercritical phase salicylic acid synthesis process

InactiveCN1733684ANo recycling issuesEnhanced mass transferOrganic compound preparationCarboxylic compound preparationKolbe–Schmitt reactionSalicylic acid synthesis

Disclosed is a novel supercritical phase salicylic acid synthesis process, which comprises making sodium phenolate through neutralizing phenol with NaOH aqueous solution, drying and grinding to obtain solid sodium phenolate, subjecting the sodium phenolate and carbon dioxide to supercritical homogeneous phase carboxylation reaction (Kolbe-Schmitt reaction) in heavy pressure reaction kettle, obtaining sodium salicylate, acidifying to prepare the salicylic acid.

Owner:QILU UNIV OF TECH

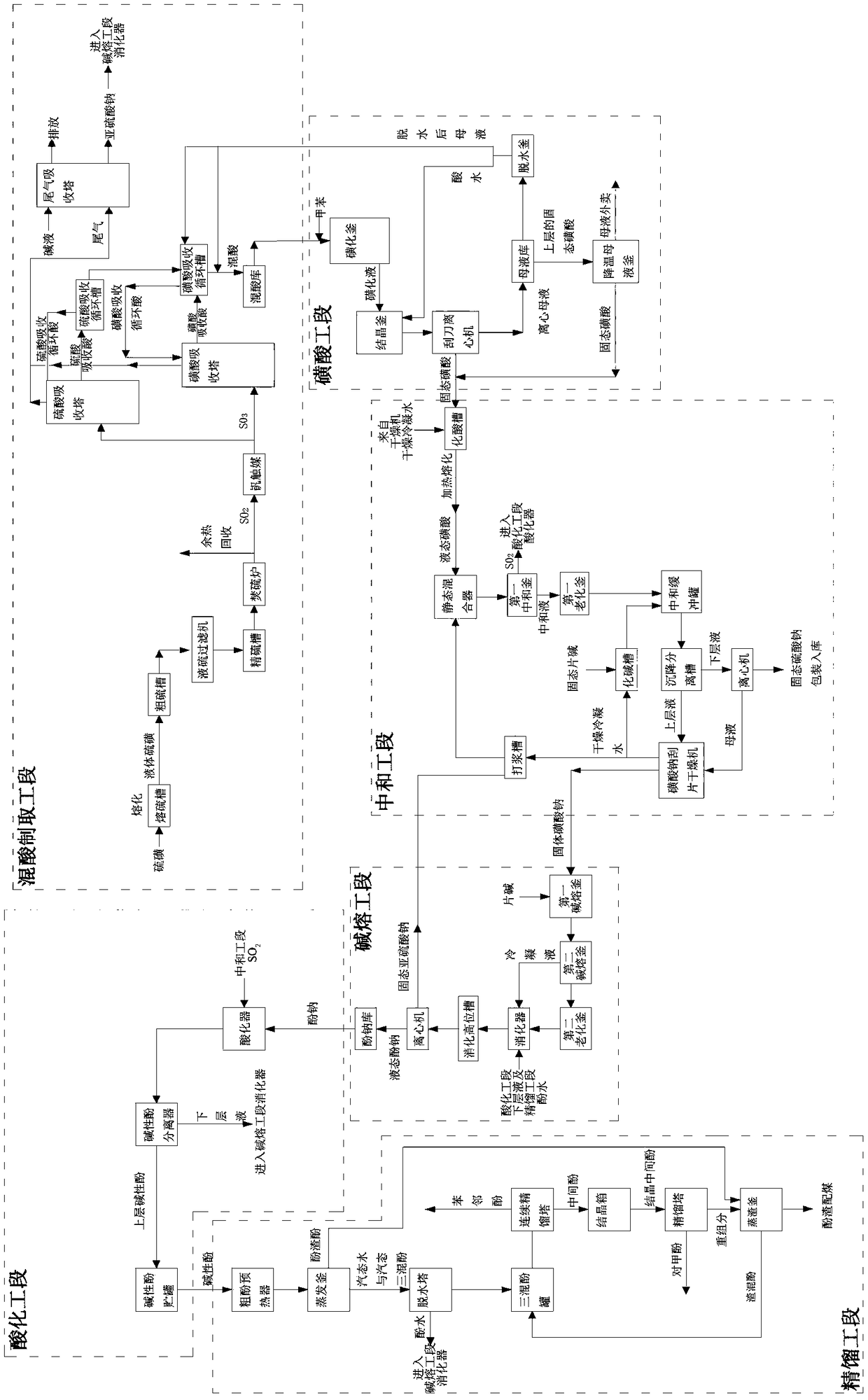

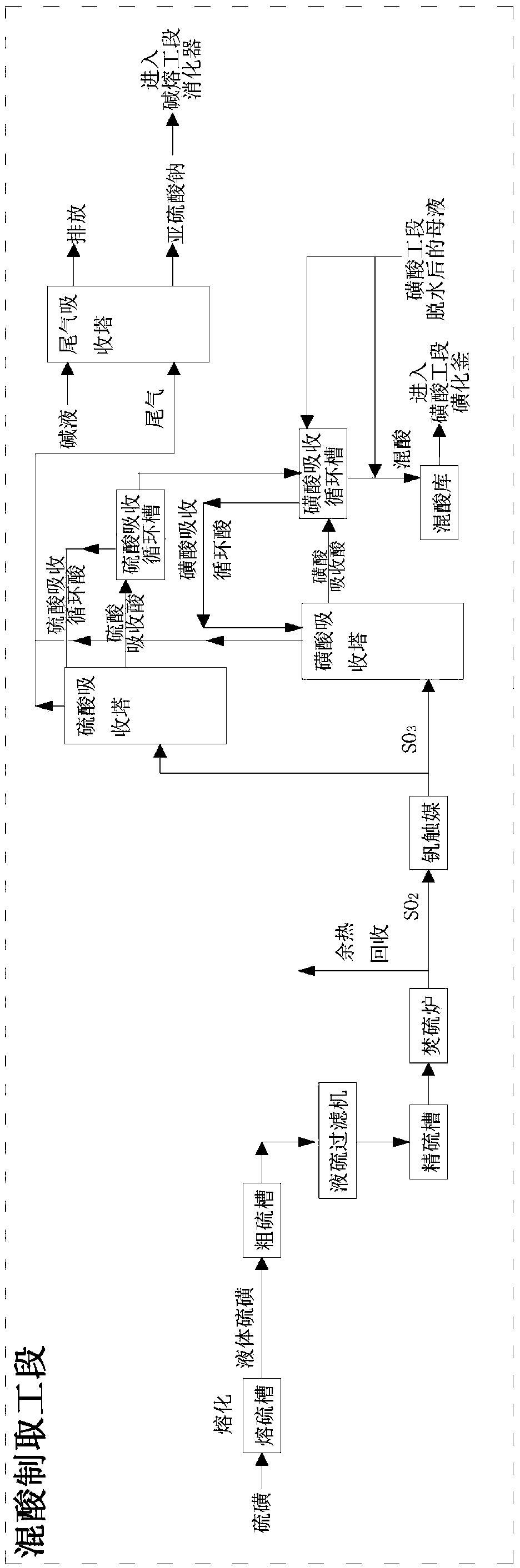

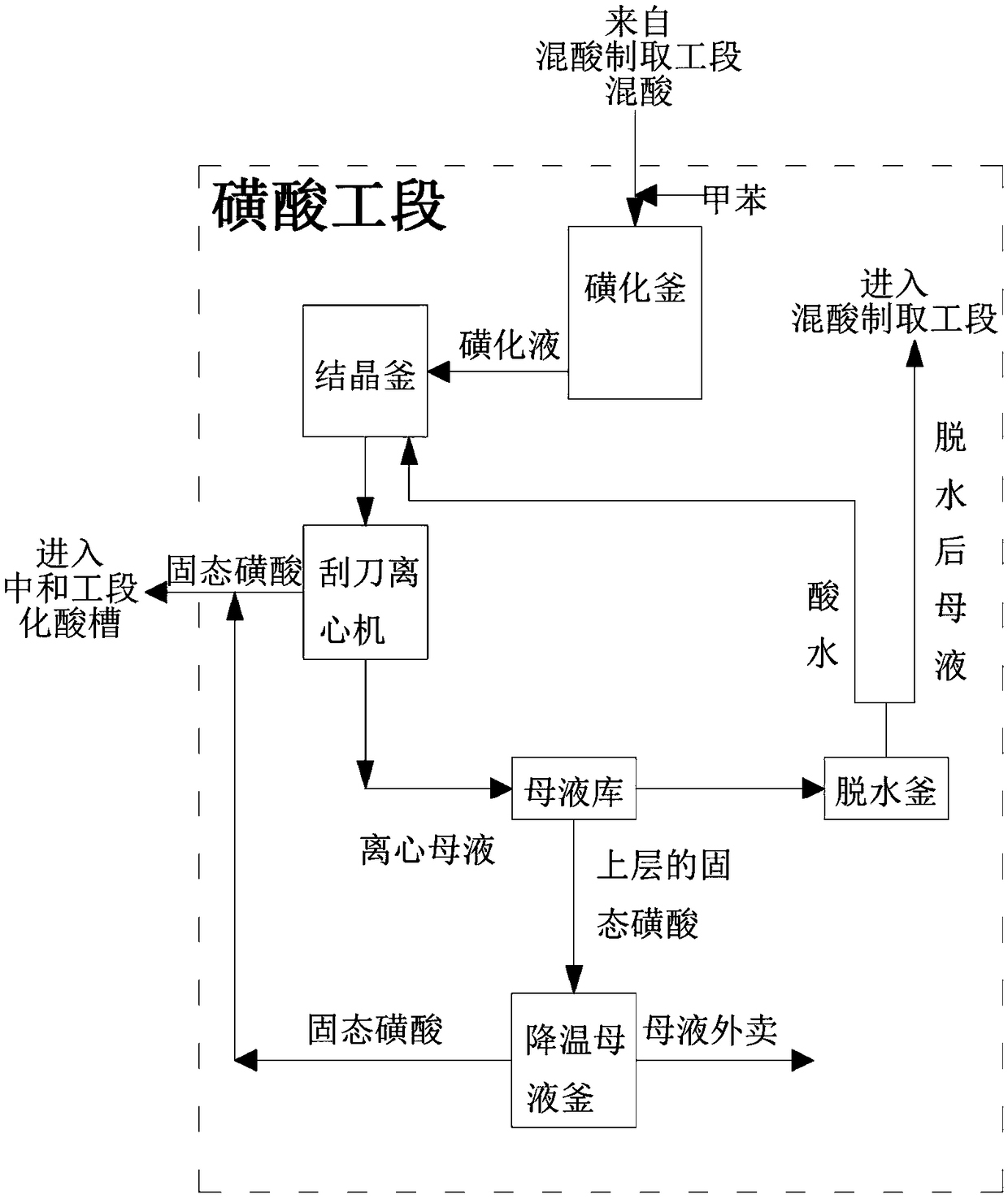

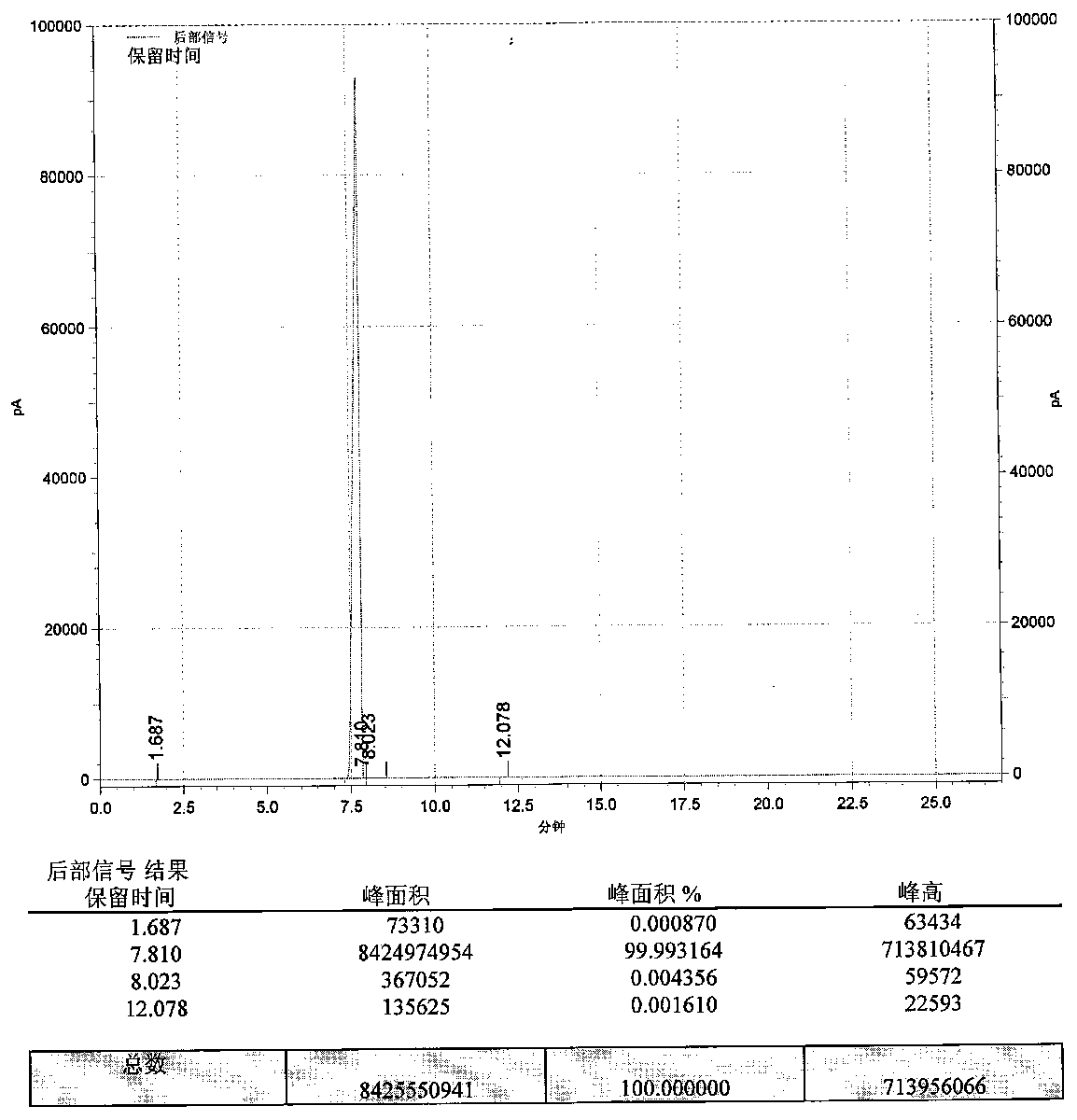

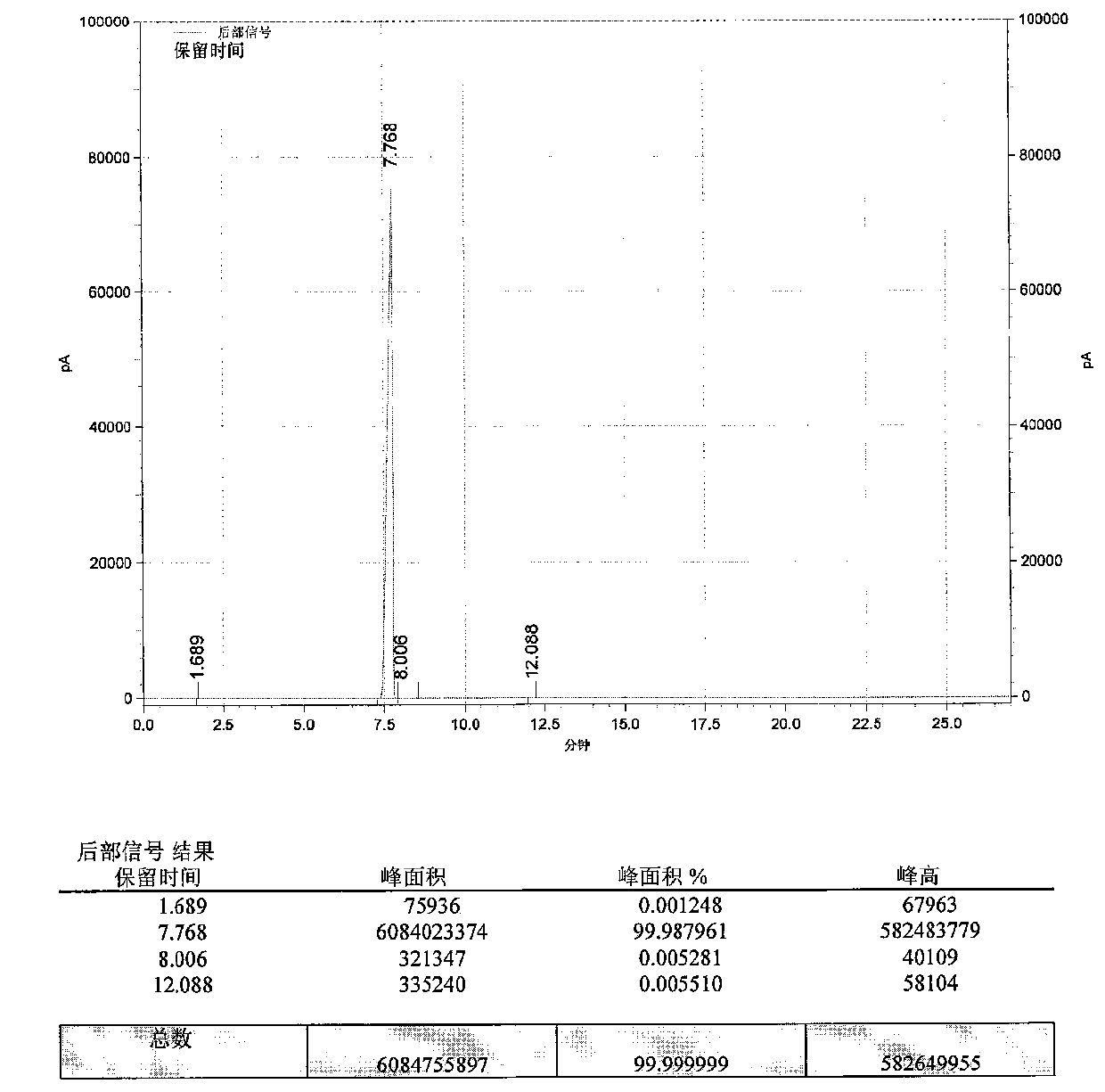

Preparation method and device for p-cresol

ActiveCN109400446ALow running costImprove environmental performanceOrganic compound preparationSulfonic acids salts preparationSulfite saltSlurry

The invention provides preparation method and device for p-cresol. The method includes: performing a reaction to toluene and sulfuric acid to prepare sulfonic acid; performing a reaction on the sulfonic acid with slurry to prepare sodium sulfonate, the slurry being prepared from solid sodium sulfite, in an alkali fusion section, with dry condensed water; treating the sodium sulfonate under alkaline conditions to generate sodium phenolate; treating the sodium phenolate under acidic conditions to generate the p-cresol. The method shortens process of the p-cresol and reduces equipment investment,greatly reduces the unit consumption of raw materials, energy and water, can completely solve the problems of high treatment difficulty and cost on waste water and waste gas in a p-cresol productionprocess in the prior art, can improve automation level of equipment by changing most of batch production into continuous production, and improves work environment.

Owner:JINNENG SCI & TECH

Benzodioxole preparation method

ActiveCN110590732AReduce ammonia nitrogen contentReduce pollutionOrganic chemistrySodium PhenolateOrganic synthesis

The invention provides a benzodioxole preparation method, and belongs to the technical field of organic synthesis. The preparation method comprises: mixing catechol, sodium hydroxide, water and dimethyl silicone oil, and carrying out a first reaction to obtain a sodium catechol solution; and mixing the sodium catechol solution, tetrabutylammonium chloride and dichloromethane, and carrying out a condensation reaction to obtain the benzodioxole. According to the present invention, during the preparation of the sodium phenolate solution, dimethyl silicone oil is added, so that the sodium phenolate solution is protected from being oxidized so as to improve the yield of subsequent product; by using tetrabutylammonium chloride as the catalyst, the yield of the benzodioxole is increased comparedwith the use of tetrabutylammonium bromide as the catalyst; and the data of the embodiments show that the preparation method can achieve the molar yield of the benzodioxole of 92-95% and the purity ofthe benzodioxole of greater than 99.9%.

Owner:HEBEI HAILI FRAGRANCES CO LTD

Method for treating phenol-containing wastewater in gas generator

InactiveCN104163524AReduce consumptionImprove mass transfer efficiencyOrganic chemistryOrganic compound preparationLiquid wasteThree level

The invention discloses a method for treating phenol-containing wastewater in a gas generator and relates to the technical field of wastewater treatment. The treatment method comprises the following steps: slowly dropwise adding 98 percent concentrated sulfuric acid into wastewater, and regulating the pH value of the wastewater; filtering the acidified wastewater, pumping the wastewater into a liquid collector, and removing suspended solids and tar; metering the wastewater liquor and a QH-1 complexing extraction agent, and pumping the liquor and extraction agent into extraction equipment for performing multistage countercurrent extraction phenol removal; performing five-level countercurrent extraction on the wastewater liquor, allowing the wastewater subjected to phenol removal to enter a production process for recycling or to enter the next-level biochemical treatment process; and performing three-level countercurrent reverse extraction on a load extraction agent subjected to the five-level countercurrent extraction, recycling a solvent subjected to reverse extraction in a solvent tank, and collecting and storing the sodium phenolate liquid removed by reverse extraction. A phenomenon that the product yield is influenced due to abnormal production of a cracking furnace caused by instable air supply as well as brought safety and environmental protection risks can be eliminated. Meanwhile, industrial effluent is greatly reduced, and the economic benefits are good.

Owner:JIANGSU TIANCHENG BIOCHEM PROD

Technology for treating phenol-contained wastewater in synthetic process of L-(+)-D-p-hydroxyphenylglycine

InactiveCN101759268AWater contaminantsMultistage water/sewage treatmentDistillationTherapeutic effect

The invention relates to a technology for treating phenol-contained wastewater in the synthetic process of L-(+)-D-p-hydroxyphenylglycine, which belongs to the technical field of the treatment of organic chemical wastewater. In the method, after the distillation pretreatment is carried out on synthesized wastewater, the macroporous resin adsorption treatment is carried out on the collected phenol-contained wastewater, wherein the pretreatment comprises the step of carrying out acidized pretreatment on the synthesized wastewater. In the method, because a phenol-contained substance in the wastewater is removed in advance, the recycling and processing difficulty of the subsequent inorganic salt can be greatly improved. The recycled sodium phenolate can be charged back to the synthesizing section of p-hydroxyphenylglycine. The method has stable and reliable treatment effect, low treatment cost and simple, convenient and easily-applied operation and is easy to realize industrialized application.

Owner:HENAN NEWLAND PHARMA

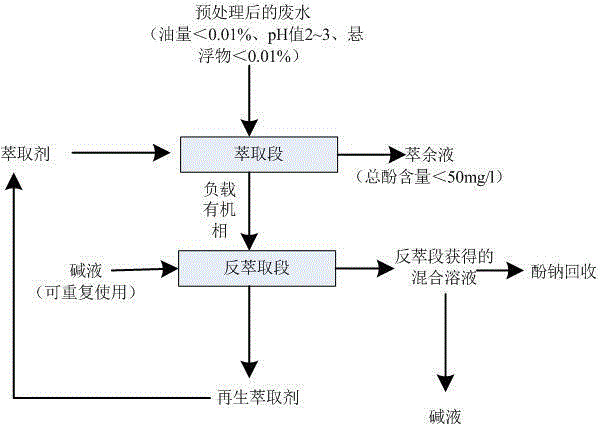

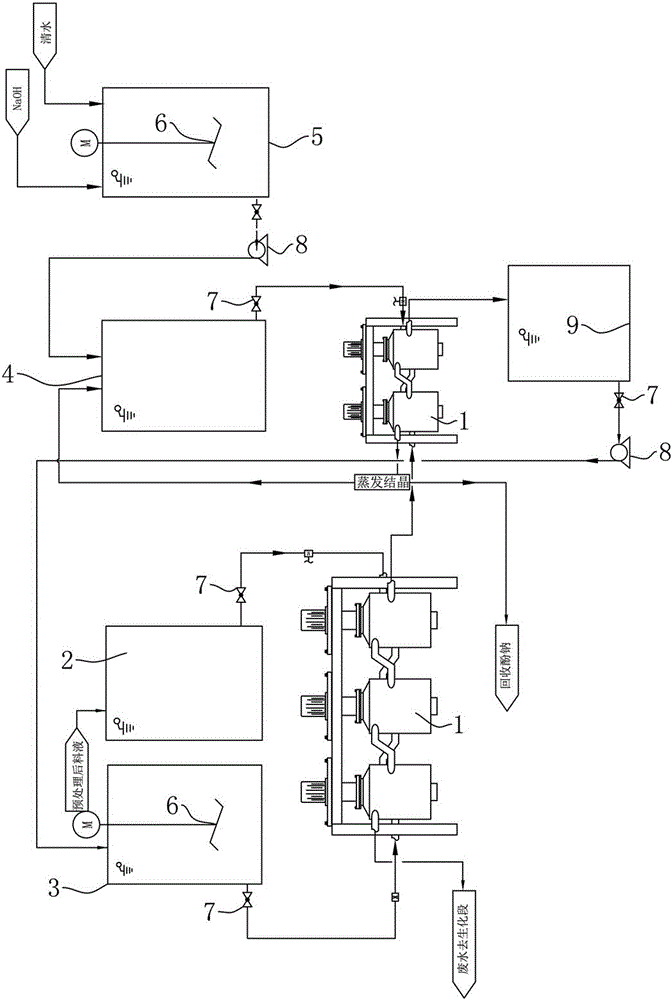

Phenolic wastewater treatment system and phenolic wastewater treatment technology

InactiveCN105923833AReduce lossesReduce processing costsWater contaminantsTreatment involving filtrationSodium PhenolateWater treatment system

The invention provides a phenolic wastewater treatment system and a phenolic wastewater treatment technology, aiming at solving the problems of high energy consumption, proneness to causing secondary pollutants and backmixing, poor stage efficiency, difficulty in extraction agent recovery and large extraction agent loss quantity of a traditional phenolic wastewater treatment method. The phenolic wastewater treatment system comprises an extraction section and a reverse extraction section. The phenolic wastewater treatment technology includes regulating a pH value of phenolic wastewater prior to counter-current extraction, and adding alkali liquor into a loaded organic phase so as to recover the alkali liquor and an extraction agent. The phenolic wastewater treatment technology has the advantages that energy consumption in the technology is only as high as one fifth of that of the traditional technology, secondary pollutants are avoided and stage efficiency is improved remarkably; reverse extraction used for recycling the extraction agent in the technology is more energy saving than a distillation method for recycling the extraction agent and is little in extraction agent loss, sodium phenolate products are recovered in the extraction section, and the alkali liquor is returned to the reverse extraction section to be reused, so that wastewater treatment cost is reduced greatly.

Owner:ZHENGZHOU TIANYI EXTRACTION TECH

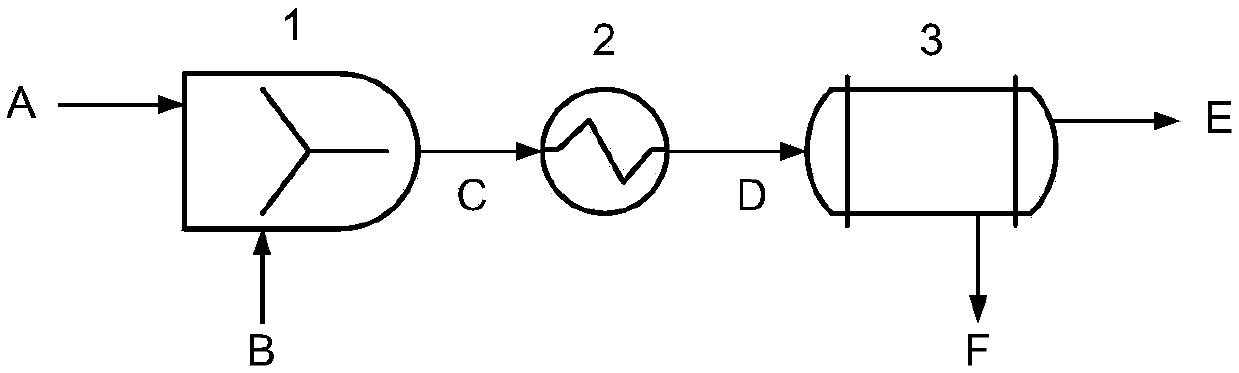

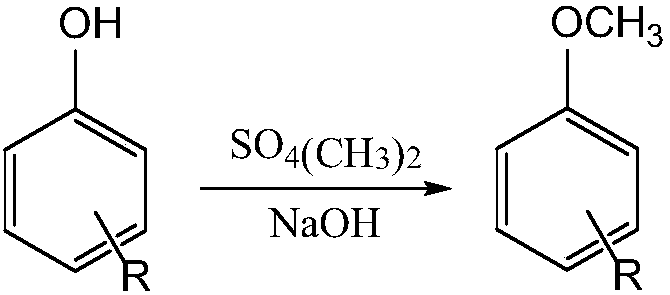

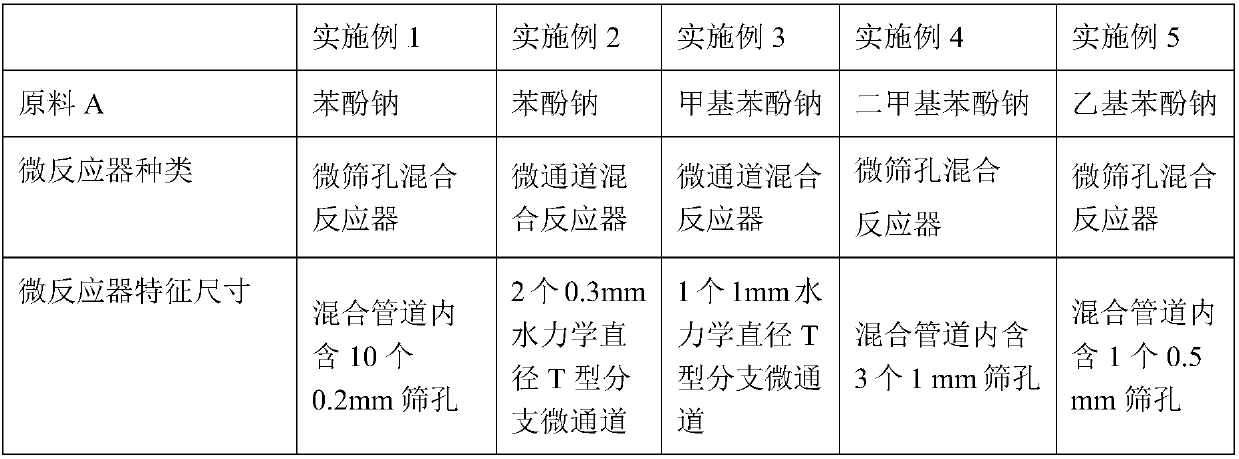

Microreaction system and method for synthesis of anisole and derivatives thereof

ActiveCN107628931AIncrease profitSolve the problem of rapid hydrolysisEther separation/purificationEther preparation by ester reactionsSynthesis methodsChemical products

Belonging to technical field of chemical product synthesis, the invention discloses a microreaction system and method for synthesis of anisole and derivatives thereof. The system is formed by connection of a microreactor, a heat exchanger and a phase separator in series successively. The synthesis method includes: mixing a sodium salt water solution of phenol or its derivatives and dimethyl sulfate in the microreactor and initiating reaction, controlling the product temperature by the heat exchanger, and performing separation by the phase separator to obtain anisole and derivatives thereof. The system and method provided by the invention can realize low-energy consumption and continuous production of anisole and its derivatives, improve the utilization rate of dimethyl sulfate, and can achieve a sodium phenolate conversion rate of 98% or more under the condition of a dimethyl sulfate / sodium phenolate mole ratio of slightly larger than 1.0, and the product purity reaches 99% or more.

Owner:TSINGHUA UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![25,27-di(3-methyl-thio-ethoxy thiadiazole) calix[4]arene stationary phase, preparation method and application thereof 25,27-di(3-methyl-thio-ethoxy thiadiazole) calix[4]arene stationary phase, preparation method and application thereof](https://images-eureka.patsnap.com/patent_img/2a9667a6-fabd-4686-9d48-92cc51198479/110107150052.PNG)

![25,27-di(3-methyl-thio-ethoxy thiadiazole) calix[4]arene stationary phase, preparation method and application thereof 25,27-di(3-methyl-thio-ethoxy thiadiazole) calix[4]arene stationary phase, preparation method and application thereof](https://images-eureka.patsnap.com/patent_img/2a9667a6-fabd-4686-9d48-92cc51198479/110107150445.PNG)

![25,27-di(3-methyl-thio-ethoxy thiadiazole) calix[4]arene stationary phase, preparation method and application thereof 25,27-di(3-methyl-thio-ethoxy thiadiazole) calix[4]arene stationary phase, preparation method and application thereof](https://images-eureka.patsnap.com/patent_img/2a9667a6-fabd-4686-9d48-92cc51198479/DEST_PATH_HDA0000046831350000011.PNG)