Phenolic wastewater treatment system and phenolic wastewater treatment technology

A treatment system and treatment process technology, applied in the phenol-containing wastewater treatment system and its process field, can solve the problems of large loss of extractant, low stage efficiency, easy occurrence of back-mixing, etc., and achieve low loss of extractant and high level Efficiency improvement and waste water treatment cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

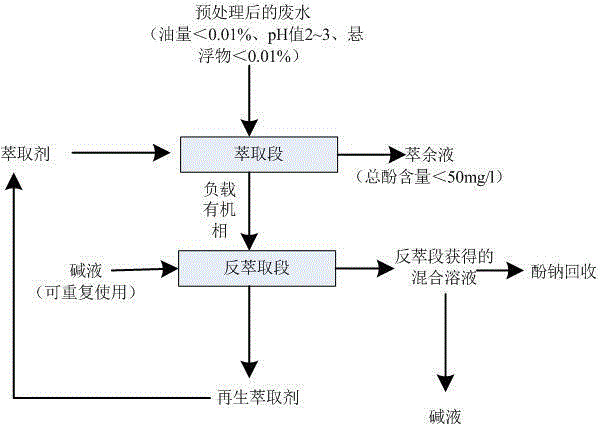

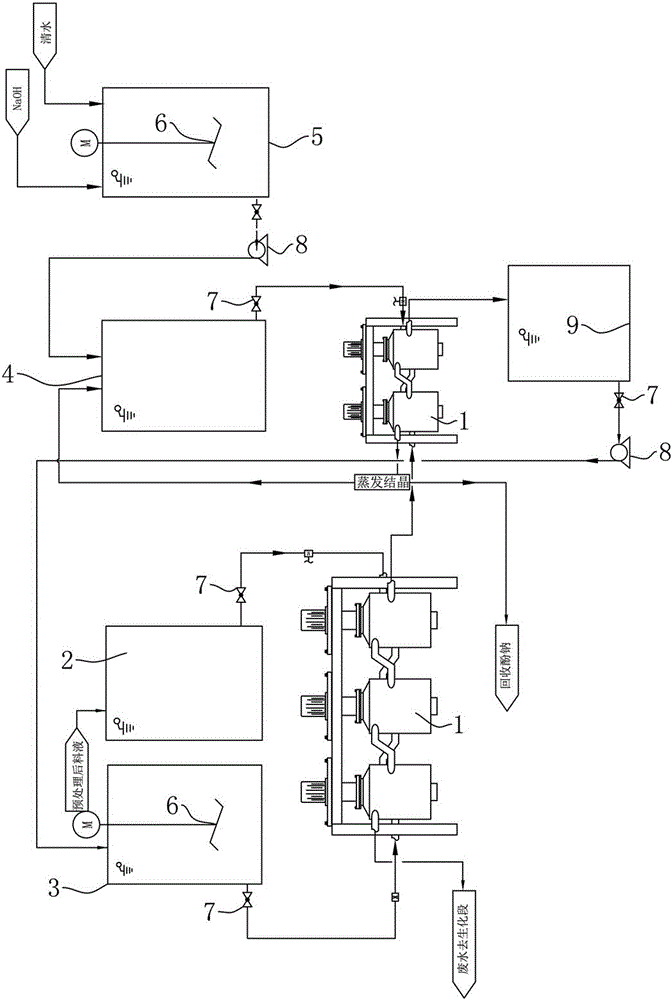

[0020] Such as figure 1 As shown in the phenol-containing wastewater treatment system, the extraction section is composed of three stages of centrifugal extractors 1 arranged in series, the light phase inlet pipeline of the extraction section is connected to the extraction agent configuration tank 3, and the heavy phase inlet of the extraction section is connected to the wastewater storage tank 2, A structure for countercurrent extraction of phenol-containing wastewater is formed. After the wastewater is filtered to remove impurities, it enters the wastewater storage tank 2. The wastewater storage tank 2 is used to store the wastewater to be entered into the extraction section. The extraction agent configuration tank 3 is used to store the wastewater to be extracted. The extraction agent of section, this part extraction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com