Causticized alkali liquor efficient separation method

A separation method and technology of caustic lye, applied in chemical instruments and methods, inorganic chemistry, alkali metal compounds, etc., can solve the problems of inconvenient transportation, low concentration of lye, unfavorable for storage, etc., to eliminate environmental and personal The effect of hidden safety hazards, great economic benefits, and good social and environmental benefits

Active Publication Date: 2010-08-25

QUJING ZHONGYI FINE CHEMICAL INDUSTRY CO LTD

View PDF0 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The more mature process is to use a vacuum filter to filter and clean with water to recover as much sodium hydroxide (NaOH) as possible, which leads to low concentration of sodium hydroxide (NaOH) lye, and supplements caustic soda (solid hydrogen) Sodium oxide, the content is about 95%), and the method of increasing the concentration produces the inexhaustible total lye and discharges it, which not only causes waste, but also pollutes the environment, and forms a pressure on the wastewater treatment process

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

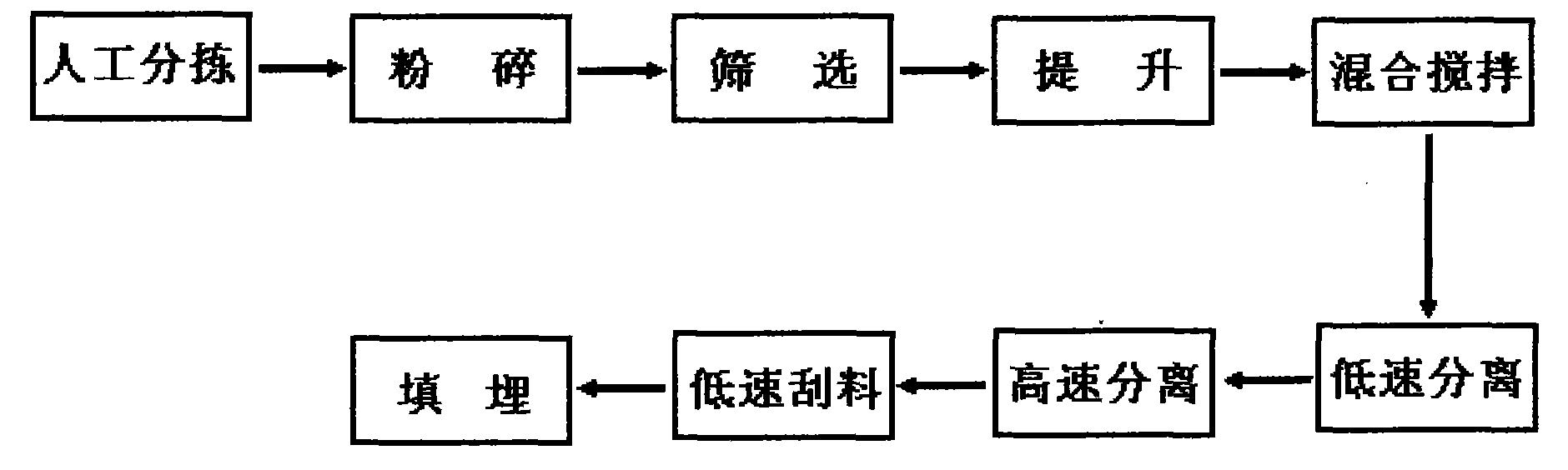

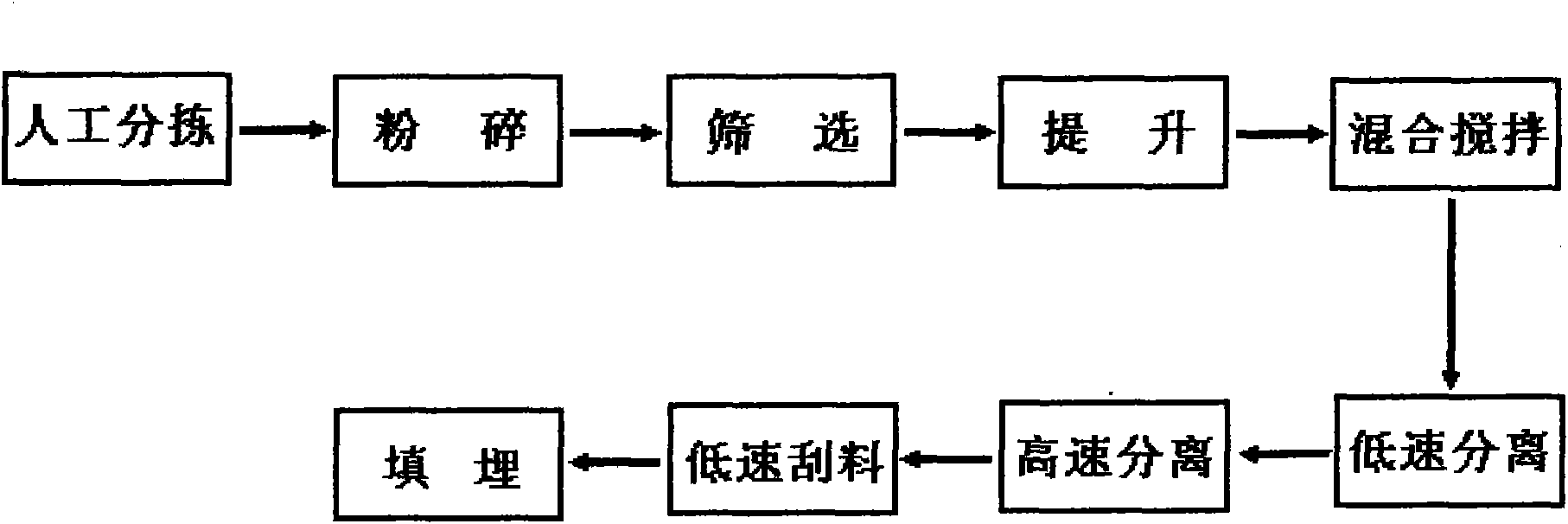

The invention discloses a causticized alkali liquor efficient separation method, including the following procedures: A, quick lime is subject to pre-treatment, smashing and screening are carried out to remove massive stone and dross, so as to obtain quick lime powder; B, the quick lime powder is hoisted into a causticization tank for carrying out causticization under the action of mechanical stirring; C, after causticization is completed, material is gradually fed into centrifugal separation equipment under the stirring condition, low speed separation is carried out firstly, material filter cake is formed at filter screen interface, material feeding is stopped when the thickness of the filter cake reaches specified value, and high speed separation is carried out; D, moisture percentage of material lime mud after high speed separation is controlled to be less than 5%, and the material lime mud is buried after meeting security landfill requirement. The invention solves the technical problem in the industry and eliminates potential safety hazard to environment and person. The quick lime mud obtained by separation can be calcined to produce lime, and the produced CO2 gas can be used for industrial production such as sodium phenolate decomposition air source. By implementing the invention, not only economic benefit of enterprise is good, but also social benefit is good, the invention has better environment protection and economic significance and is a practical technical method in which resource can be recycled and clean production can be realized.

Description

High-efficiency separation method of caustic lye technical field The invention belongs to the technical field of chemical production, and in particular relates to an efficient separation method for caustic lye in industrial naphthalene production. Background technique In the coal tar deep processing industry in the field of coal chemistry, in order to achieve the maximum comprehensive profit, the mixed fraction is first dephenolized with lye sodium hydroxide and then deep processed to extract primary products such as phenol oil, naphthalene oil and washing oil fraction. After dephenolization, sodium salt of phenol must reduce phenol, and the raffinate is sodium carbonate (Na2CO3) and sodium bicarbonate (NaHCO3). In order to realize the optimization of industrial production cost, the raffinate is converted into sodium hydroxide ( NaOH) is used as the raw material for dephenolization to realize the recycling of raw materials, which is equivalent to only using cheap and easy-...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C01D1/28

Inventor 熊柱松罗国林

Owner QUJING ZHONGYI FINE CHEMICAL INDUSTRY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com