Two-step pressure swing adsorption separation method of multicomponent gas containing hydrogen and hydrogen sulfide

A pressure swing adsorption, hydrogen sulfide technology, used in separation methods, chemical instruments and methods, dispersed particle separation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

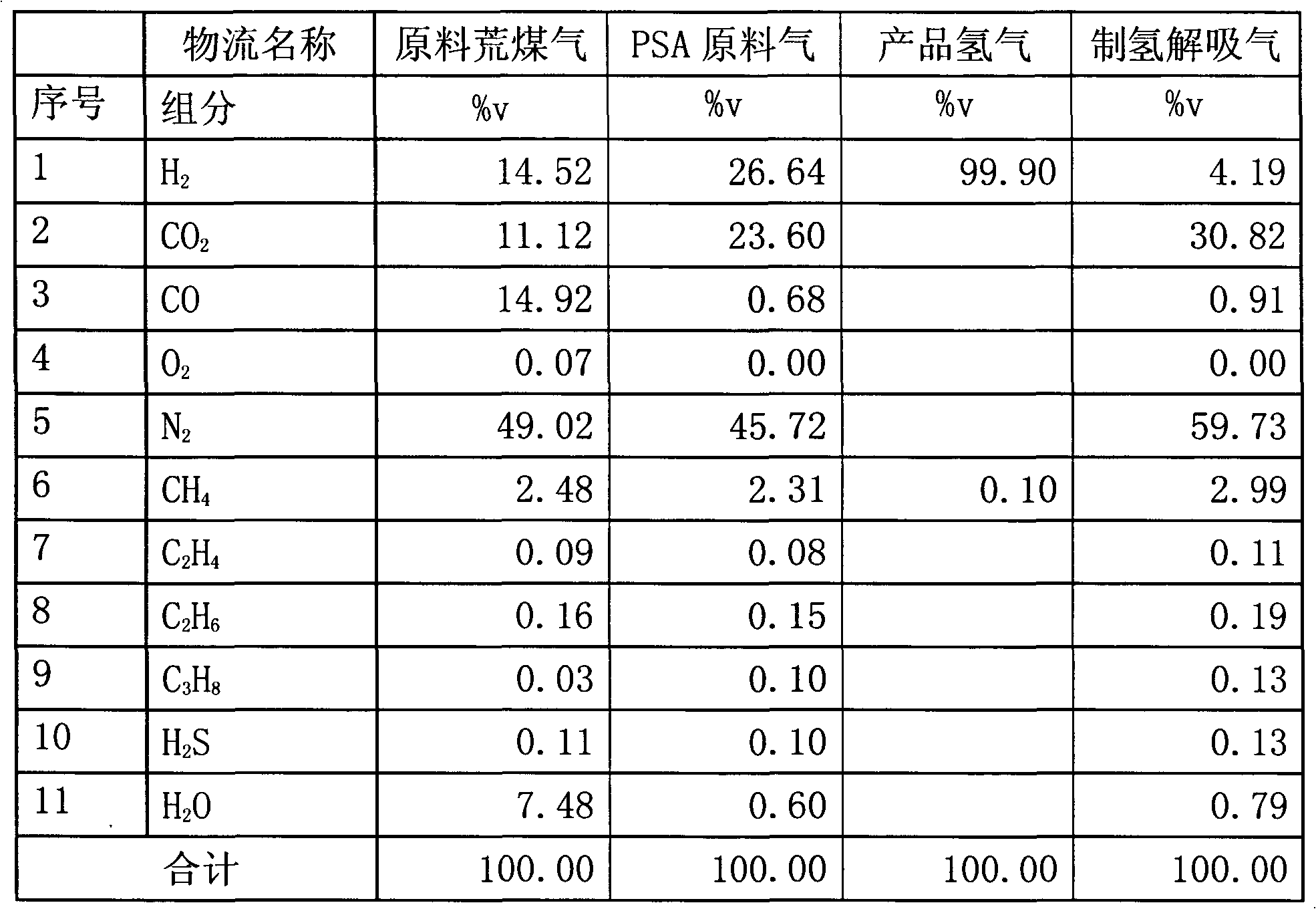

[0114] The No. 1 raw coal gas whose composition is shown in Table 1 completed the expected deoxygenation reaction and carbon monoxide shift reaction, and the shift gas obtained was used as a raw material gas for the hydrogen production process by pressure swing adsorption.

[0115] Since No. 1 raw coal gas contains tar and other impurities, in order to prolong the life of the conversion catalyst and improve the efficiency of the PSA pressure swing adsorption hydrogen extraction adsorbent, etc., the tar and other impurities are removed before entering the reactor of the conversion process. The method adopted is For pressure swing adsorption separation, activated carbon adsorbents are usually used to absorb impurities such as tar. The desorption method is a combination of decompression desorption, heating desorption and flushing desorption. The flushing gas comes from the exhaust gas generated during the regeneration process of the second pressure swing adsorption part.

[0116] ...

Embodiment 2

[0140] Based on Example 1, the raw coal gas produced by the same carbonization device is divided into two parts, the first part of raw coal gas GF is used as the gas source of the raw material gas F described in step 1, and the second part of raw coal gas GFF is produced through the hydrogen sulfide removal process DS to produce low sulfur Hydrogen fuel gas, the first adsorbent bed regeneration exhaust gas PG1 completes the removal of hydrogen sulfide through the dehydrogen sulfide process DS. The hydrogen sulfide removal process DS of raw gas GFF adopts the "PDS+extraction" method, and the hydrogen sulfide is finally converted into sulfur paste.

[0141] The crude gas from the semi-coke device enters the lower part of the turbulent ball raw gas desulfurization tower and contacts with the desulfurization liquid sprayed from the top of the tower. The polypropylene balls in the washing tower are constantly turbulent to increase the contact area and improve the desulfurization eff...

Embodiment 3

[0143] Based on Example 1, step ② hydrogen is used as the raw material hydrogen gas of HP in the hydroconversion process of medium and low temperature coal tar LF distillate oil, and the hydrogen sulfide-containing gas produced in the hydrogenation conversion process HP is removed through the hydrogen sulfide removal process HPDS, step ① The regeneration exhaust gas PG1 of the first adsorbent bed is removed through the hydrogen sulfide removal process HPDS to complete the removal of hydrogen sulfide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com