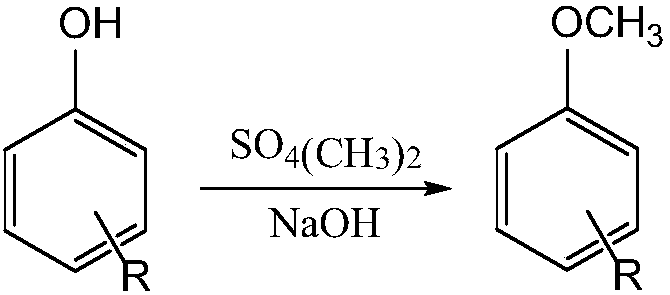

Microreaction system and method for synthesis of anisole and derivatives thereof

A synthesis method and micro-reaction technology, which is applied in the field of micro-reaction systems for synthesizing anisole and its derivatives, can solve problems such as energy consumption and low production efficiency, and achieve the goals of increasing utilization, increasing production efficiency, and reducing energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

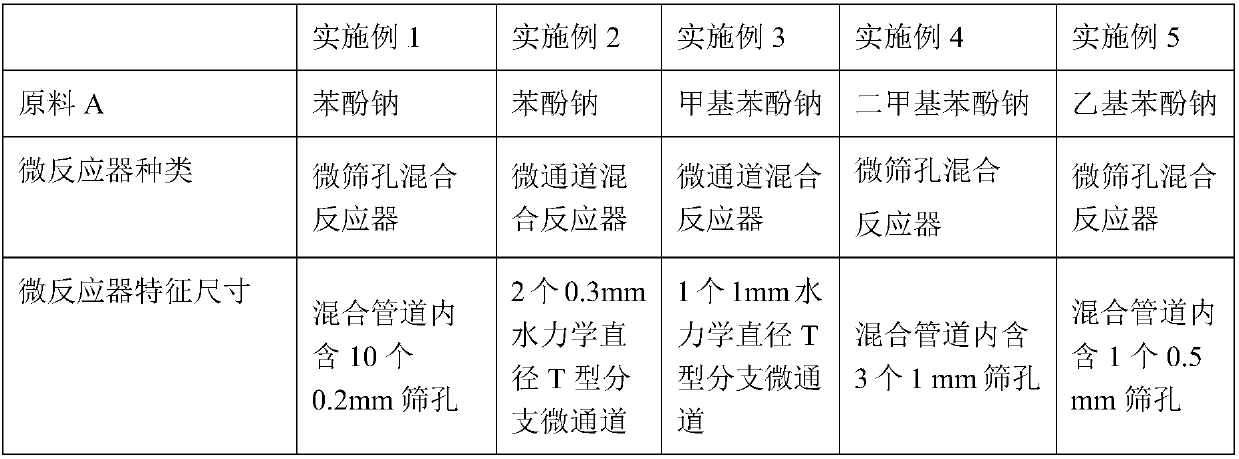

[0026] Embodiment 1: the synthesis of anisole

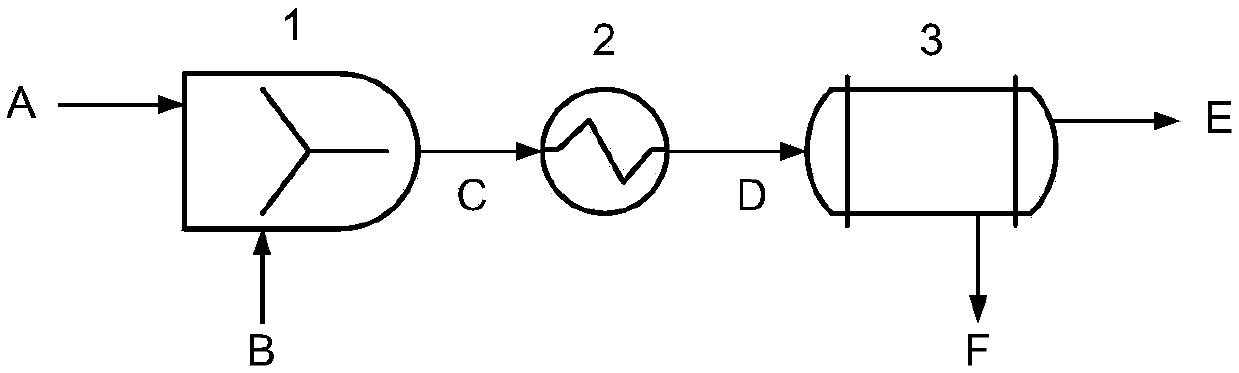

[0027] The micro-reaction system in this embodiment consists of a micro-sieve mixing reactor, a tubular heat exchanger and a clarification tank in series. The synthetic steps of anisole are as follows:

[0028] (1) Use a metering pump to transport the reaction raw materials sodium phenate and dimethyl sulfate to the micro-sieve mixing reactor, monitor the temperature of the key position of the reaction (reaction raw material and the outlet of the heat exchanger) in real time, and mix the raw materials to initiate the reaction to form a high-temperature reaction Liquid C;

[0029] (2) After the high-temperature reaction liquid C flows out from the micro-sieve mixing reactor, the temperature of the product is controlled through a tubular heat exchanger to form a low-temperature reaction liquid D;

[0030] (3) After the low-temperature reaction solution D flows out from the heat exchanger, it is separated through a phase separator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com