Phenolic resin sewage treatment method

A sewage treatment method and phenolic resin technology, applied in the direction of heating water/sewage treatment, neutralizing water/sewage treatment, etc., can solve the problems of high technical requirements, low extraction rate, large investment, etc., and achieve no pollution to the environment and good treatment effect Good, high economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

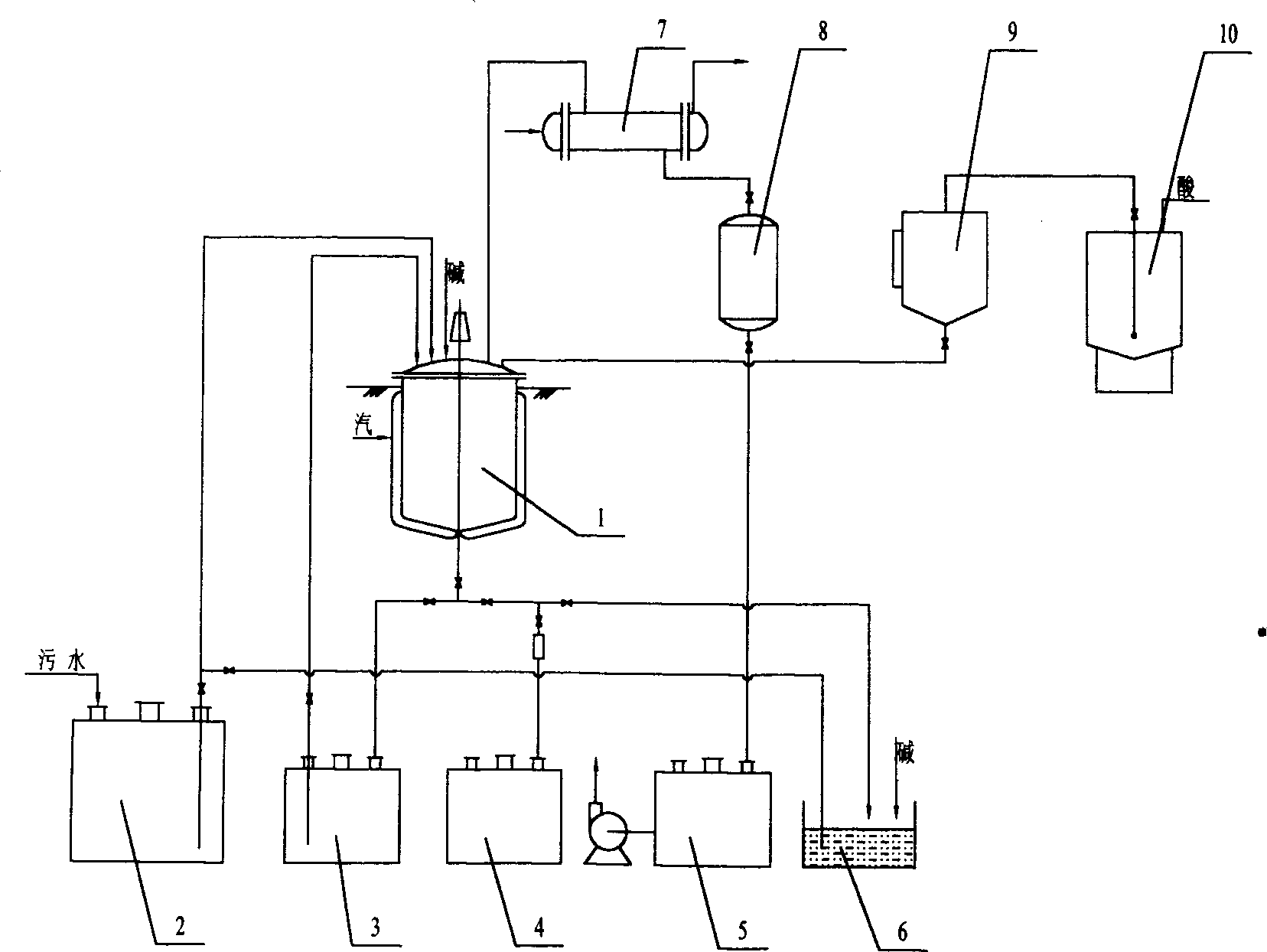

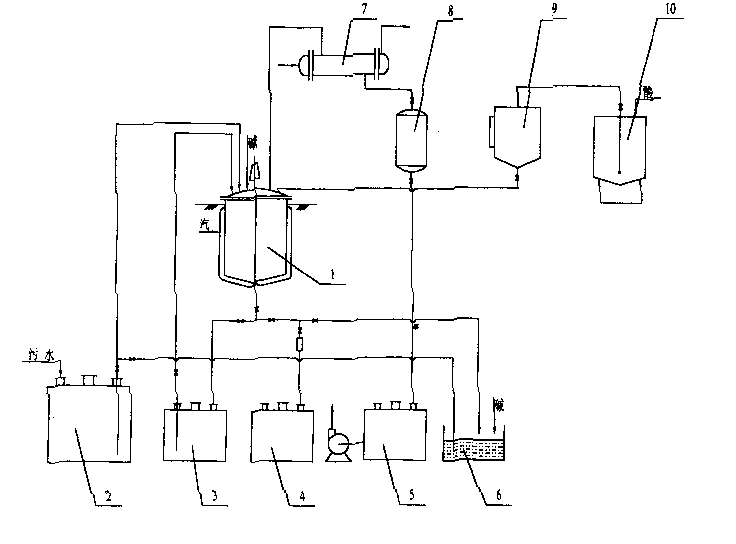

[0016] The technical features, operating principle and process of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0017] In the accompanying drawings, 1 main reaction kettle, 2 raw water storage tanks, 3 concentrated liquid tanks, 4 phenol storage tanks, 5 condensed water tanks, 6 crystallization tanks, 7 condensers, 8 condensed water receiving tanks, 9 phenol metering tanks, 10 acid storage tanks Can

[0018] As shown in the accompanying drawing, the phenolic resin sewage is introduced from the raw water storage tank 2 into the main reactor 1, and then solid alkali sodium hydroxide is added until the pH value of the sewage after the reaction is 11-12. Stir at a speed of 90 rev / min for 20-30 minutes, so that the phenol and sodium hydroxide in the phenolic resin sewage react to form a phenol sodium salt solution. Under the condition that the vacuum degree of the main reactor 1 is 0.01~0.015Mpa, and the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com