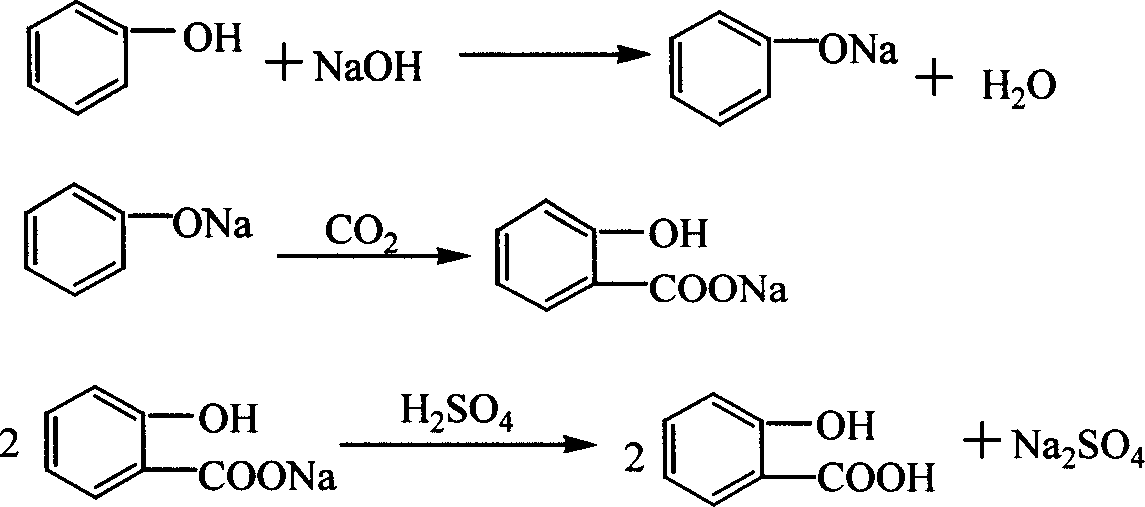

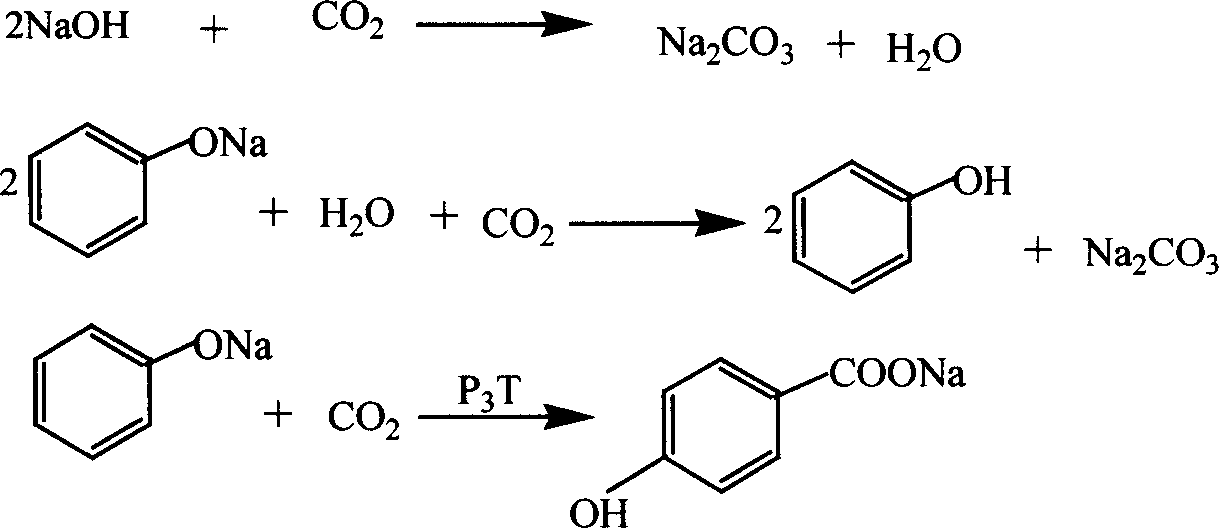

Novel supercritical phase salicylic acid synthesis process

A supercritical phase, salicylic acid technology, applied in the preparation of carboxylate, the preparation of organic compounds, the production of bulk chemicals, etc., can solve the problems of poor mass transfer and heat transfer performance, small phase contact area, and complicated process control. , to achieve the effect of lowering operating temperature, good reaction selectivity and avoiding side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Accurately weigh 60.40 g (1.51 mol) of sodium hydroxide, prepare a 50% solution with distilled water, and cool. Accurately weigh 141.165 g (1.5 mol) of phenol, heat the solid phenol to a liquid state, and add the phenol liquid into the sodium hydroxide solution under stirring. After stirring the mixture for 15 minutes, heat up and distill water under reduced pressure. When the solution becomes viscous, it is transferred to a vacuum oven for the first drying under reduced pressure. Control the vacuum degree to 0.085MPa-0.095MPa, and the temperature is at 160°C-170°C. When there is less water, cool down. Take out the solid sodium phenate, grind it into a fine powder in a mortar, and then perform a second drying at a temperature of 135°C-145°C and a vacuum degree of 0.090MPa-0.095MPa. Cool down until no water comes out. Take out the solid sodium phenate and transfer it to a volume of 500ml in an autoclave equipped with electromagnetic stirring and automatic temperature ...

Embodiment 2

[0026]Accurately weigh 410.00 g (10.25 mol) of sodium hydroxide, prepare a 50% solution with distilled water, and cool. Accurately weigh 941.10 g (10.0 mol) of phenol, heat the solid phenol to a liquid state, and add the phenol liquid into the sodium hydroxide solution under stirring. After stirring the mixture for 15 minutes, heat up and distill water under reduced pressure. When the solution becomes viscous, it is transferred to a vacuum oven for the first drying under reduced pressure. Control the vacuum degree to 0.085MPa-0.095MPa, and the temperature at 160°C-170°C. When less water comes out, cool down. Take out the solid sodium phenate, grind it into a fine powder in a mortar, and then dry it for the second time at a temperature of 130°C-145°C and a vacuum of 0.090MPa-0.095MPa, and cool down until no water comes out. Take out the solid sodium phenate and transfer it to a volume of 5000ml in an autoclave equipped with electromagnetic stirring and an automatic temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com