Patents

Literature

294 results about "Phenyl salicylate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phenyl salicylate, or salol, is a chemical substance, introduced c. 1883 by Marceli Nencki of Basel. It is synthesized by heating salicylic acid with phenol. Once used in sunscreens, phenyl salicylate is now used in the manufacture of some polymers, lacquers, adhesives, waxes, and polishes. Commonly it is used in school laboratory demonstrations on how cooling rates affect crystal size in igneous rocks. Can be used to demonstrate seed crystal selectiveness. Salol is also used as an internal antiseptic and as a mild analgesic..

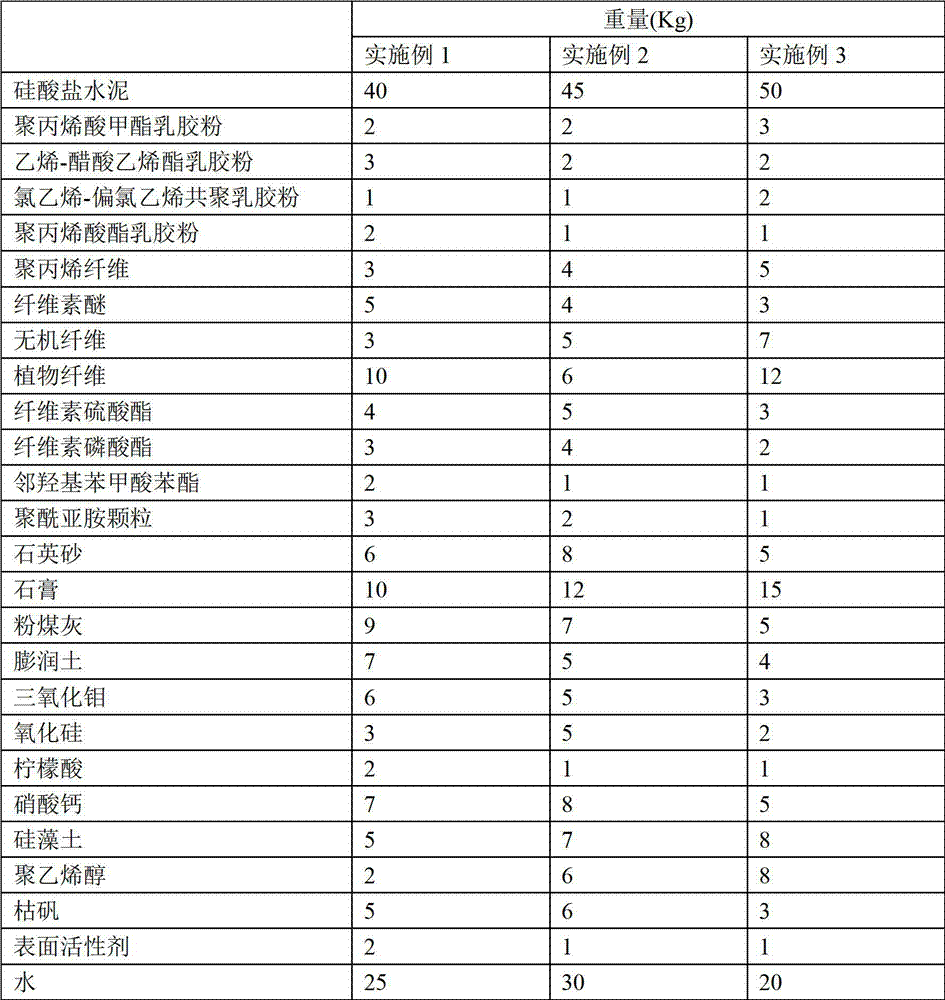

Corrosion-resistant polymer waterproof mortar

The invention provides a corrosion-resistant polymer waterproof mortar, which comprises the following components by weight: 40-50 parts of portland cement, 2-3 parts of polymethyl acrylate latex powder, 2-3 parts of ethylene-vinyl acetate latex powder, 1-2 parts of vinyl chloride-vinylidene chloride copolymerized latex powder, 1-2 parts of polyacrylate latex powder, 3-5 parts of polypropylene fibers, 3-5 parts of cellulose ether, 3-7 parts of inorganic fibers, 6-12 parts of plant fibers, 3-5 parts of cellulose sulfate, 2-4 parts of cellulose phosphate, 1-2 parts of phenyl salicylate, 1-3 parts of polyimide particles, 5-8 parts of quartz sand, 10-15 parts of gypsum, 5-9 parts of fly ash, 4-7 parts of bentonite, 3-6 parts of molybdenum trioxide, 2-5 parts of silicon oxide, 1-2 parts of citric acid, 5-8 parts of calcium nitrate, 5-8 parts of diatomite, 2-8 parts of polyvinyl alcohol, 3-6 parts of dried alum, 1-2 parts of a surfactant, and 20-30 parts of water.

Owner:WUJIANG TIANYUAN PLASTIC

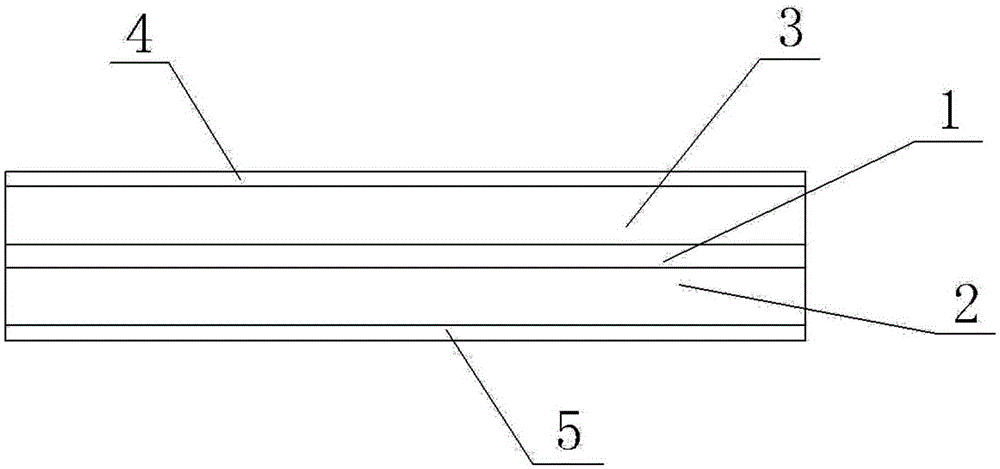

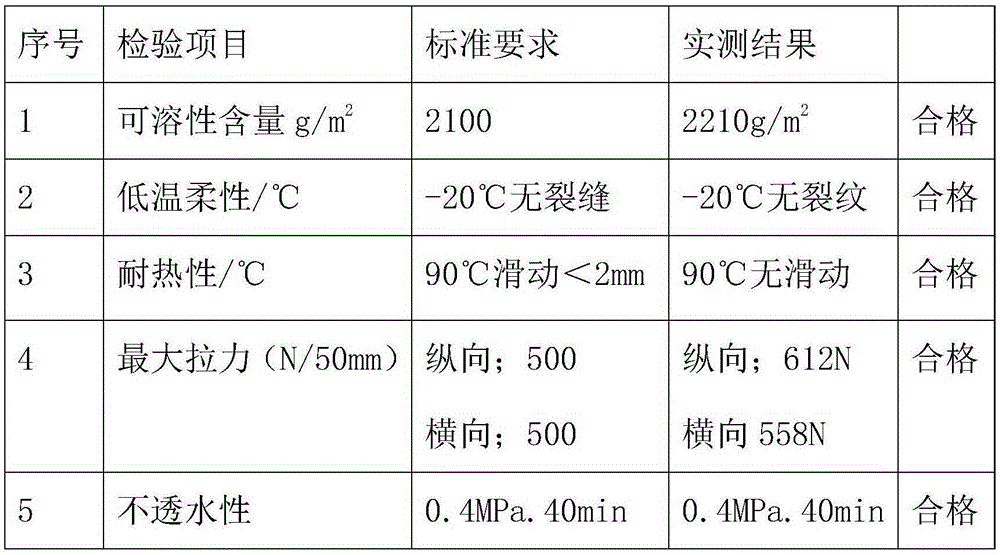

Heat-resistance and saline-alkaline-resistance type elastomer modified bitumen waterproof coil material

InactiveCN105238084ADefects in preventing water seepage and channelingHigh tensile strengthBuilding insulationsElastomerTectorial membrane

The present invention discloses a heat-resistance and saline-alkaline-resistance type elastomer modified bitumen waterproof coil material, which comprises a tire base, wherein the upper surface and the lower surface of the tire base are respectively provided with a first bitumen layer and a second bitumen layer, the first bitumen layer side away from the tire base is provided with a first protection film, the second bitumen layer side away from the tire base is provided with a second protection film, the first bitumen layer and the second bitumen layer are made from modified bitumen, and the raw materials of the modified bitumen comprise, by weight, 1300 parts of 90# bitumen, 1100 parts of 10# bitumen, 500 parts of 250# heavy oil, 125 parts of a petroleum resin, 300 parts of modified polyurethane, 500 parts of naphthenic oil, 90 parts of a thermoplastic styrene-butadiene rubber, 300 parts of polyisobutylene, 1100 parts of tire rubber powder, 1650 parts of talc powder, 300 parts of a composite flame-retardant agent, 175 parts of a SBS modifier, 100 parts of phenyl salicylate, 60 parts of an anti-aging agent, and 500 parts of a solvent. According to the present invention, the obtained heat-resistance and saline-alkaline-resistance type elastomer modified bitumen waterproof coil material has characteristics of excellent heat resistance and excellent saline-alkaline resistance.

Owner:天长市金牛防水防腐材料有限公司

Antimicrobial moldproof agent for silk fabrics

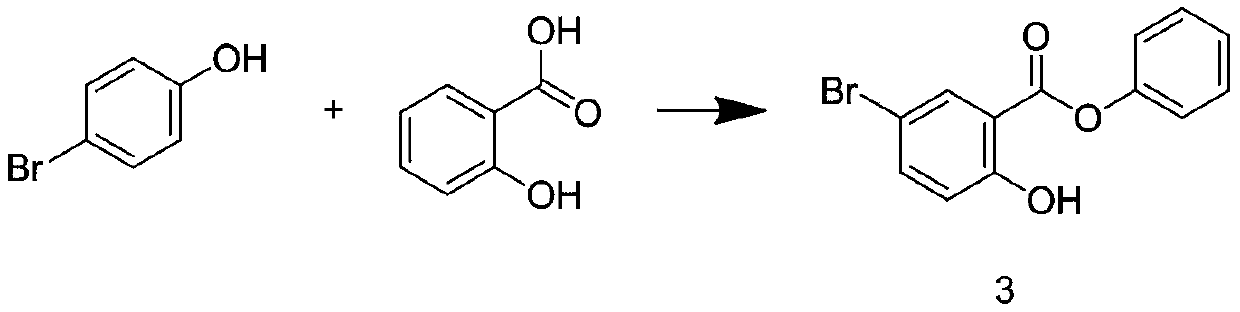

ActiveCN103757893AWon't breakHas antibacterial and antifungal effectsAnimal fibresFiberPhosphoric acid

The invention discloses an antimicrobial moldproof agent for silk fabrics, which is prepared from the following components in parts by weight: 8-12 parts of citric acid, 7-11 parts of polyoxyethylene trimethyl ammonium chloride, 6-10 parts of vinyl siloxane, 5-9 parts of chitosan quaternary ammonium salt, 4-8 parts of tetrasodium metaphosphate, 3-7 parts of tin tetrachloride, 3-7 parts of potassium oxalate, 3-7 parts of sodium alginate, 5-9 parts of phenyl salicylate and 10-14 parts of amyl acetate. The antimicrobial moldproof agent has favorable antimicrobial and moldproof effects; the finished fabric has favorable washing fastness and soft feeling; and the preparation technique is simple, is nontoxic and harmless to the human body, and can not destroy the cocoon fibers in the silk fabric.

Owner:上海福晏精细化工有限公司

Composite concrete waterproofing agent

InactiveCN102875055AImprove waterproof and anti-seepage performanceImprove compactnessSodium BentonitePolyvinyl alcohol

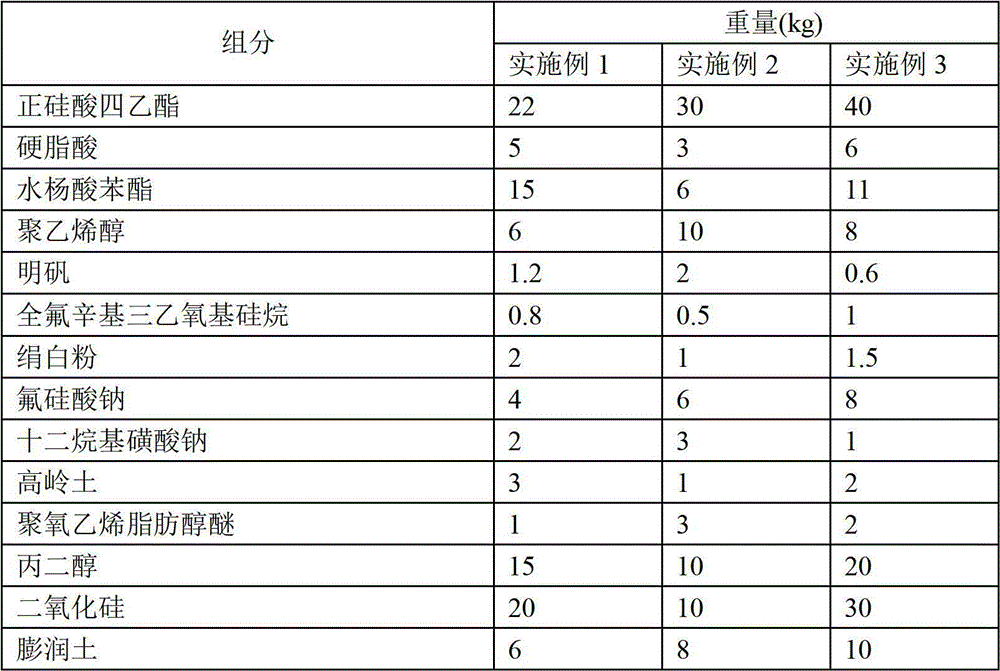

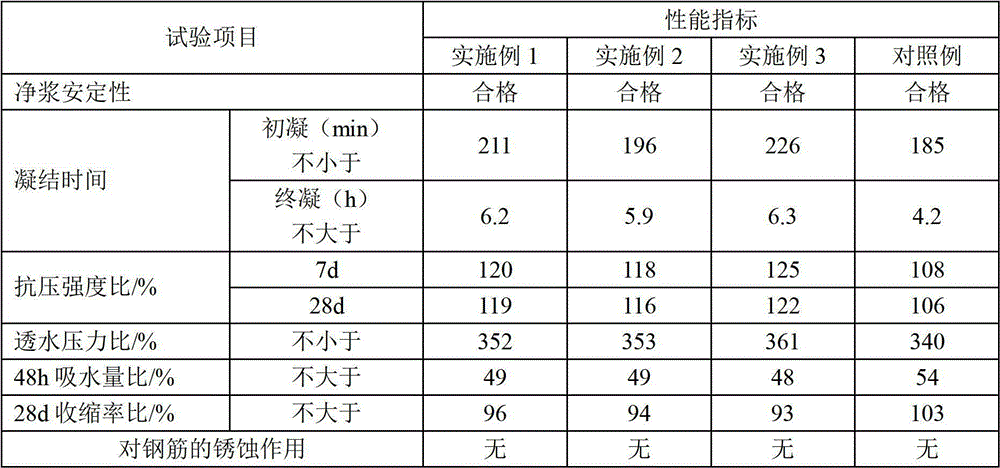

The invention provides a composite concrete waterproofing agent and belongs to the technical field of additives in building materials. The composite concrete waterproofing agent comprises the following components in parts by weight: 20-40 parts of tetraethyl orthosilicate, 3-6 parts of stearic acid, 5-15 parts of phenyl salicylate, 5-10 parts of polyvinyl alcohol, 0.5-2 parts of alum, 0.5-1 part of perfluorinated octyltriethoxysilane, 1-2 parts of silk white powder, 4-8 parts of sodium fluosilicate, 1-3 parts of sodium dodecyl sulfate, 1-3 parts of kaolin, 1-3 parts of polyxyethylated alcohol, 8-20 parts of propanediol, 10-30 parts of silicon dioxide and 4-10 parts of bentonite. According to the composite concrete waterproofing agent disclosed by the invention, the performances of resisting permeability and water can be remarkably improved, the compactness and the pressive strength and the like are improved and the work performance of the concrete is improved. In addition, the composite concrete waterproofing agent has the characteristics of safety, no toxicity and no corrosion.

Owner:苏州市德莱尔建材科技有限公司

Polyester adhesive

InactiveCN102994033AImprove performanceLow shrinkageNon-macromolecular adhesive additivesDibutyl tin dilauratePhenyl salicylate

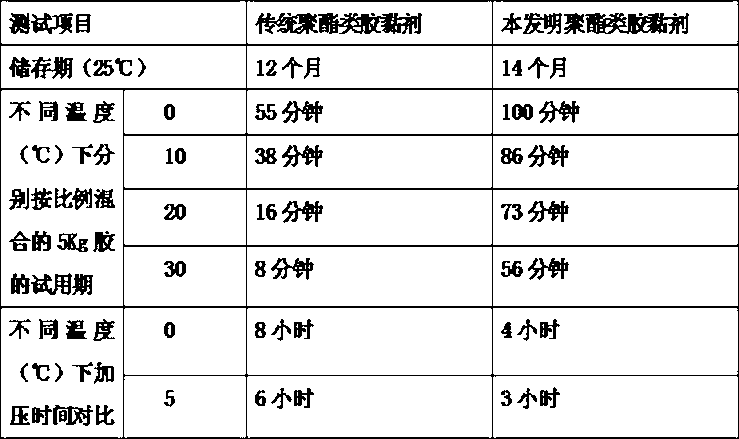

The invention discloses a polyester adhesive which is composed of components A and B, wherein the component A is composed of the following raw materials: n-butyl alcohol, 307 unsaturated polyester, talcum powder, aluminium powder, calcium carbonate, triethylene tetramine and chlorobenzene; the component B is composed of the following raw materials: propylene glycol, toluene diisocynate, dibutyltin dilaurate, phenyl salicylate and modified nanometer argil; and the polyester adhesive is formed by mixing and uniformly stirring the components A and B in the mass ratio of 1:5. According to the invention, by using the modified nanometer argil, the produced polyester adhesive has various good performances of traditional adhesives and has the advantages of low shrinkage rate, high adhesive strength, stable size, good electrical performance, chemical medium resistance, simpleness in preparation and process, little damage, no environmental pollution and the like; and the polyester adhesive disclosed by the invention has the beneficial effects of long storage time, benefit of the reduction of waste products, longer working life, higher curing speed, convenience for customer operation and capability of reducing the glue waste and finally increasing the overall quality of the product.

Owner:ANHUI DONGFANGJINHE PRECISION MACHINERY MFG +1

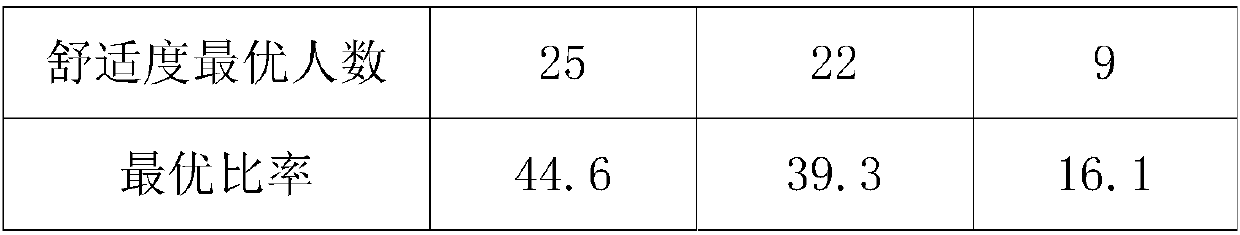

Method for producing laminated shell fabric of full window blind

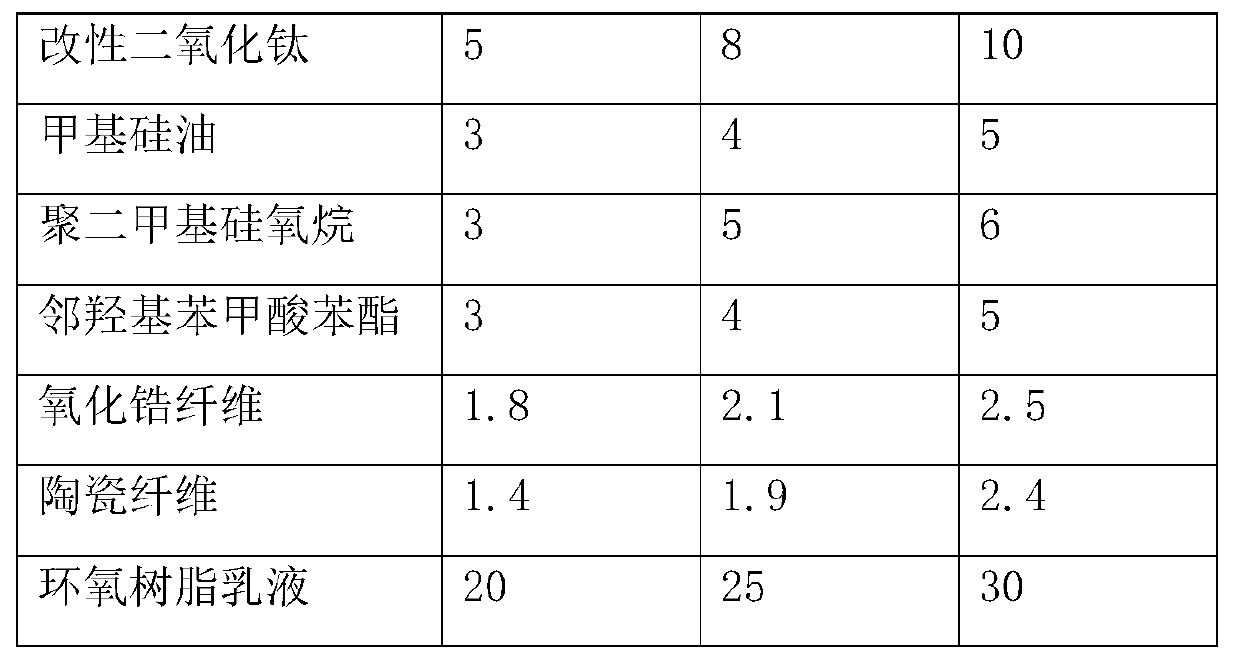

InactiveCN110802898AImproves UV resistanceGood anti-aging performanceLamination ancillary operationsDomestic upholsteryBlow moldingPolymer science

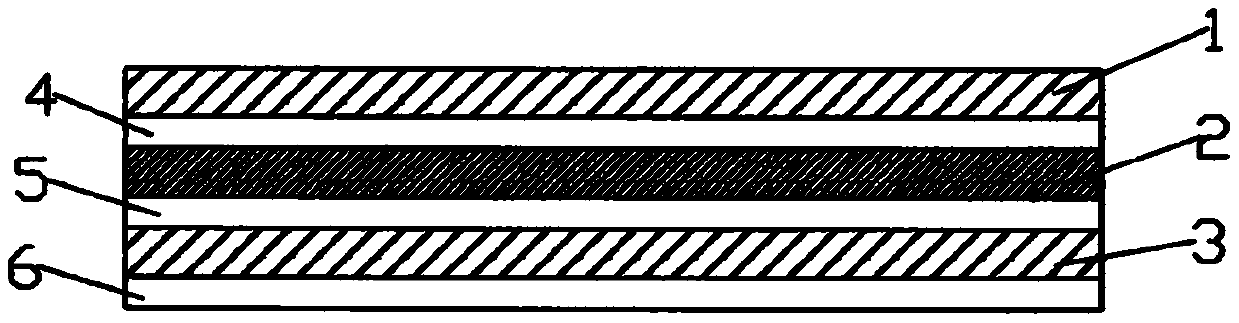

The invention discloses a method for producing a laminated shell fabric of a full window blind. The laminated shell fabric of the full window blind comprises a first base fabric layer, a first adhesive layer, a TPU black shading film, a second adhesive layer and a second base fabric layer, wherein surfaces of both the first base fabric layer and the second base fabric layer have patterns formed through embossing. The laminated shell fabric of the full window blind is produced according to the following steps: base fabric treating, TPU black shading film preparing, first-step hot-pressing laminating and second-step hot-pressing laminating. According to the method for producing the laminated shell fabric of the full window blind, disclosed by the invention, the TPU black shading film is produced by using an extruding blow molding method, then, is subjected to hot-pressing laminating with the first base fabric layer subjected to degreasing and cleaning treatment and then is subjected to hot-pressing laminating with the second base fabric layer, and thus, the whole production process is environmentally friendly and pollution-free. Phenyl salicylate and titanium dioxide are employed inthe TPU black shading film, so that the laminated shell fabric has good ultraviolet resistance and aging resistance. Furthermore, the laminated shell fabric also has good heat and sound insulating effects.

Owner:HAINING SANLIAN TEXTILE CO LTD

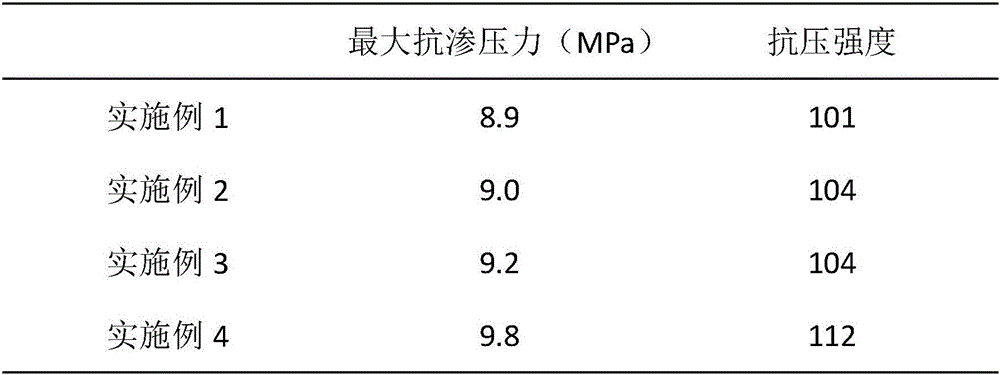

High-strength waterproof concrete

The invention provides a high-strength waterproof concrete. The concrete comprises the following components in parts by weight: 100-120 parts of cement, 80-85 parts of coarse aggregate, 90-100 parts of fine aggregate, 20-25 parts of bentonite, 20-25 parts of asphalt powder, 2-5 parts of alkyl sodium sulfonate, 2-3 parts of copper sulfate, 10-12 parts of basalt fiber, 5-8 parts of polypropylene fiber, 2-3 parts of Grace fiber, 0.2-0.5 part of sodium perfluorooctylsulfonate, 0.1-0.2 part of coconut oil diethanolamide, 0.5-1 part of bisphenol A epoxy resin, 0.1-0.2 part of styrylphenol polyoxyethylene ether, 3-5 parts of iron chloride, 0.2-0.5 part of phenyl salicylate, 2-5 parts of aluminum potassium sulfate, 0.1-0.2 part of 1,6-hexamethylene diisocyanate and a right amount of water. The invention also discloses a method for preparing the concrete. According to the invention, the concrete has favorable impermeability, and the maximum impermeability pressure can be up to 9.8 MPa; and the obtained concrete has high compression strength, and the maximum compression strength can be up to 112 MPa.

Owner:SICHUAN UNIV

Three-in-one plastic sports ground, and preparation method thereof

InactiveCN105713269ALow costLong lasting bright colorsGround pavingsPolyurea/polyurethane coatingsEpoxyAdhesive

The invention discloses a three-in-one plastic sports ground. The three-in-one plastic sports ground is prepared from, by weight, 1.5 to 2.5 parts of epoxy resin, 70 to 90 parts of regenerated rubber, 10 to 14 parts of an adhesive, 1.5 to 2.5 parts of titanium dioxide, 0.1 to 0.3 part of a reinforcing agent, 1.5 to 2.5 parts of a coloring material containing inorganic pigments, 7 to 9 parts of quartz sand, 2.5 to 3.5 parts of a colorant, and 6 to 8 parts of polyurethane; the coloring material comprises 2 parts of a pigment powder, 0.21 part of titanium dioxide, 0.15 part of antioxidant 1010, 0.18 part of an anti-ultraviolet agent, and 0.15 part of a fortifier; the regenerated rubber is recycled waste rubber; the adhesive contains trimethylolpropane and hexamethylene diisocyanate; the anti-ultraviolet agent is phenyl salicylate; and the reinforcing agent is silicon dioxide. The invention also provides a preparation method of the three-in-one plastic sports ground. The preparation method comprises following steps: smearing of a water-proof layer, laying of an elastic layer, gap filling, and spraying of a wear-resistant layer. The cost of the three-in-one plastic sports ground is lower than that of conventional runways; the three-in-one plastic sports ground possesses permeability; and problems such as bulking, cracking, peeling, and discoloration are not caused.

Owner:梁意昌

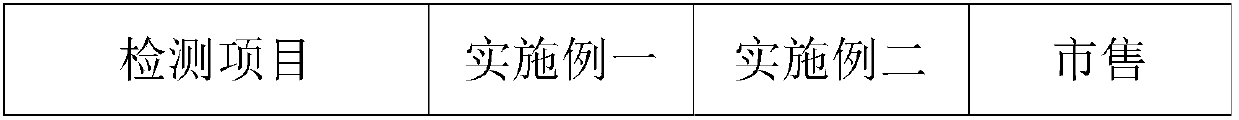

Production method of natural latex mattress

InactiveCN108034092AReduce dosageGuaranteed comfortStuffed mattressesSpring mattressesEpoxyFar infrared

The invention discloses a production method of a natural latex mattress. The method comprises the following steps: S1, preparing raw materials of the natural latex mattress; S2, ultrasonically dispersing benzotriazole, phenyl salicylate, far infrared ceramic powder and sericite powder into alcohol, an adding a traditional Chinese medicine extract to obtain a mixture A; S3, heating natural latex, adding a polyurethane elastomer, epoxy resin and liquid silicone rubber into the natural latex, uniformly mixing, then adding a vulcanizing agent, an anti-yellowing agent, a heat stabilizer, a thickening agent and a foaming agent, uniformly mixing, adding the mixture A and uniformly mixing to obtain a mixture B; S4, foaming, pre-setting and setting the mixture B to obtain a semi-finished natural latex mattress; and S5, washing and drying the semi-finished natural latex mattress to produce the natural latex mattress. The production method of the natural latex mattress is simple to operate and low in production cost; the produced mattress is high in comfort degree, high in elasticity and long in service life, is capable of improving the sleep quality, and has wear resistance and ageing resistance.

Owner:安徽情暖家具有限公司

Anti-ultraviolet treating agent for fabric

InactiveCN102851958AImproves UV resistanceSimple preparation processFibre treatmentCellulosePolyvinyl alcohol

The invention discloses an anti-ultraviolet treating agent for fabric, which is composed of the following components in parts by weight: 10-20 parts of phenyl salicylate, 3-5 parts of 2,4-dihydroxy benzophenone, 1-3 parts of methylol cellulose, 10-20 parts of polyvinyl alcohol, 10-20 parts of ethanol, 3-5 parts of ammonium sulfate, 3-5 parts of acrylic acid, 4-8 parts of acetic acid and 400-600 parts of water. Compared with the prior art, the anti-ultraviolet treating agent disclosed by the invention has the following beneficial effects: (1) a layer of film can be formed on the surface of the fabric treated by the treating agent, thereby achieving a great anti-ultraviolet effect; (2) the dyeing effect can not be influenced, and the fabric treated by the treating agent can resist high temperature and water washing; and (3) the preparation process is simple, and the anti-ultraviolet treating agent is nontoxic and harmless to human bodies.

Owner:WUJIANG YISHENG TEXTILE

Composite cloth for curtain roller shutter and preparation method of composite cloth

ActiveCN109397806AWaterproof and breathableReduce tensionSynthetic resin layered productsLow-density polyethyleneUltraviolet protection

The invention discloses a composite cloth for a curtain roller shutter and a preparation method of the composite cloth. The composite cloth comprises a plasma-treated base cloth and a polyurethane TPUfilm attached to the base cloth, wherein the polyurethane TPU film is prepared by the following method that 70-80 parts of polyurethane TPU, 4-6 parts of low-density polyethylene (LDPE), 4-6 parts ofcarbon black, 4-6 parts of titanium oxide, 4-6 parts of nano glass micro-beads and 4-6 parts of phenyl salicylate are mixed evenly, then extruded and subjected to tape casting to form the film. By modifying the polyurethane TPU, the obtained composite cloth is soft and comfortable in hand feeling, environmental protection, shading, strong light irradiation resisting, ultraviolet protection, washing and dry-cleaning resisting and aging resistance are achieved, excellent light resistance and aging resistance are achieved, the adhesion fastness of a product is high, and the quality-guarantee service life is ten years or above. After the surface of the base cloth is activated, the modified polyurethane TPU film is composited in a hot-pressed mode, glue is not used, and thus real energy savingand environmental protection are achieved.

Owner:浙江鸿圣纺织科技有限公司

Antimicrobial mothproof finishing agent for silk fabrics

The invention discloses an antimicrobial mothproof finishing agent for silk fabrics, which is prepared from the following components in parts by weight: 7-15 parts of Fructus Caryophylli powder, 7-14 parts of pomegranate rind powder, 5-9 parts of silicone oil, 2-7 parts of beeswax, 3-9 parts of alkylolamide, 2-6 parts of polyvinylpyrrolidone, 4-7 parts of potassium xylenesulfonate, 2-7 parts of lactose, 3-7 parts of starch, 20-24 parts of alcohol, 5-9 parts of phenyl salicylate and 5-9 parts of sorbitan stearate. The antimicrobial mothproof finishing agent for silk fabrics has favorable antimicrobial and mothproof effects; the finished fabric has favorable washing fastness and soft feeling; and the preparation technique is simple, is nontoxic and harmless to the human body, and can not destroy the cocoon fibers in the silk fabric.

Owner:苏州市奕鸣织造有限公司

Antibacterial and mildew-proof treatment liquid of digital printing real-silk silk painting and antibacterial and mildew-proof post-treatment process

InactiveCN105421049AGood antibacterial and antifungal effectDoes not damage the structureBiochemical fibre treatmentAnimal fibresProtein structure2-Phenylphenol

The invention discloses components and a preparation method of antibacterial and mildew-proof treatment liquid of a digital printing real-silk silk painting and an antibacterial and mildew-proof post-treatment process. The treatment liquid is prepared from 2.00%-6.00% of phenyl salicylate, 0.10%-0.70% of dichlorophenol, 0.10%-0.40% of 2-phenylphenol, 0.10%-0.70% of N-octylisothiazolinone, 2.00%-6.00% of sodium alginate, 30.00%-45.00% of ethanol and 41.20%-65.70% of de-ionized water. All the components of the treatment liquid are added into a mixed solution of the ethanol and the de-ionized water and are stirred to be sufficiently dissolved; and the obtained liquid can be used for post-treatment process steps of starching a real-silk white blank of the digital printing real-silk silk painting, drying, drawing by spraying, steaming, washing with water, and impregnating by the antibacterial and mildew-proof treatment liquid and the like. The antibacterial and mildew-proof treatment liquid has a simple and convenient preparation process, has no toxicity and damages to human bodies and no any toxic side effect on the environment, does not damage a silk protein structure in a silk fabric and does not influence the real effect of the digital printing real-silk silk painting; and the difficulties that various bacteria are easily bred on the real-silk silk painting and the real-silk silk painting has mildew, so that the quality and service life of the painting are influenced are overcome.

Owner:SUZHOU SILKCUBE TEXTILE

Butyl rubber waterproof sealing adhesive tape substrate

InactiveCN103497433AHigh tensile strengthGood extensibilityFilm/foil adhesivesSuccinic acidButadiene-styrene rubber

The invention discloses a butyl rubber waterproof sealing adhesive tape substrate. The substrate comprises butyl rubber, an anti-impact modifier, a preservative, a weather-proof agent, a dispersing agent and a stabilizer, wherein the anti-impact modifier is a styrene-butadiene copolymer, the preservative is alkenyl succinic acid, the weather-proof agent is phenyl salicylate, the dispersing agent is glycerol tristearate, and the stabilizer is organic silicon resin. The product is prepared from the butyl rubber and multiple additives; the prepared adhesive tape substrate has the advantages of high tensile strength, good elasticity and extensibility, excellent chemical resistance, weather resistance and corrosion resistance, good waterproof property, sealing property and low temperature resistance and stable product quality.

Owner:SUZHOU HUAZHOU TAPE

Non-cured rubber asphalt waterproof coating material

InactiveCN105238269AImprove flame retardant performanceImprove high temperature resistanceFireproof paintsReclaimed rubber coatingsEpoxyStearic acid

The present invention discloses a non-cured rubber asphalt waterproof coating material, wherein the raw materials comprise, by weight, 25-35 parts of modified asphalt, 3-5 parts of styrene-butadiene rubber, 18-24 parts of methyl acrylate, 3-5 parts of a 120* solvent oil, 8-15 parts of regeneration glue powder, 23-26 parts of light calcium carbonate, 5-7 parts of carbon black, 4-9 parts of a rosin resin, 0.5-2.5 parts of an epoxy resin, 2-4 parts of calcium stearate, 3-5 parts of epoxyfuroic-oleic butyl, 2-3 parts of dihydroquinoline, 0.5-0.7 part of a light stabilizer 994, 0.6-0.8 part of phenyl salicylate, 0.5-1 part of PE-g-TS, 1-3 parts of diethylene triamine, 0.1-0.5 part of stearic acid, 0.05-0.1 part of zinc oxide, and 3-5 parts of vinyl triethoxysilane. The non-cured rubber asphalt waterproof coating material of the present invention has characteristics of good waterproof performance, good fire-retardant property, and high mechanical property.

Owner:天长市金牛防水防腐材料有限公司

Improved concrete waterproofer

An improved concrete waterproofer is prepared by raw materials in parts by weight as follows: 6-10 parts of polyamide, 3-10 parts of aluminum hydroxide, 6-8 parts of epoxy resin, 7-11 parts of kaolin, 5-10 parts of dibutyl phthalate, 1-5 parts of calcium carbonate, 3-5 parts of an antifoaming agent, 6-8 parts of tetraethyl orthosilicate, 1-4 parts of silicon dioxide, 7-10 parts of polyvinyl alcohol, 6-8 parts of phenyl salicytate, 2-4 parts of oleic acid and 1-5 parts of emulsified oil. The improved concrete waterproofer has the benefits of good waterproofing and seepage-proofing functions, good compatibility, wide application range and low probability of deterioration.

Owner:QINGDAO LAOXIANG TEA PROD

Anti-ultraviolet finishing agent for silk fabrics

InactiveCN103741464AAntibacterial and anti-ultraviolet effectGood effectAnimal fibresFiberUltraviolet

The invention discloses an anti-ultraviolet finishing agent for silk fabrics, which is prepared from the following components in parts by weight: 10-16 parts of phenyl salicylate, 8-12 parts of alcohol ether carboxylate, 10-14 parts of coconut oil acetal amide, 6-9 parts of urea, 6-9 parts of fatty alcohol polyethenoxy ether, 4-10 parts of ethyl acrylate, 2-7 parts of sodium alginate, 3-8 parts of dimethyl terephthalate and 3-6 parts of sorbitan stearate. The anti-ultraviolet finishing agent for silk fabrics has favorable antimicrobial and anti-ultraviolet effects; the finished fabric has favorable washing fastness and soft feeling; and the preparation technique is simple, is nontoxic and harmless to the human body, and can not destroy the cocoon fibers in the silk fabric.

Owner:重庆市潼南区久平服装厂

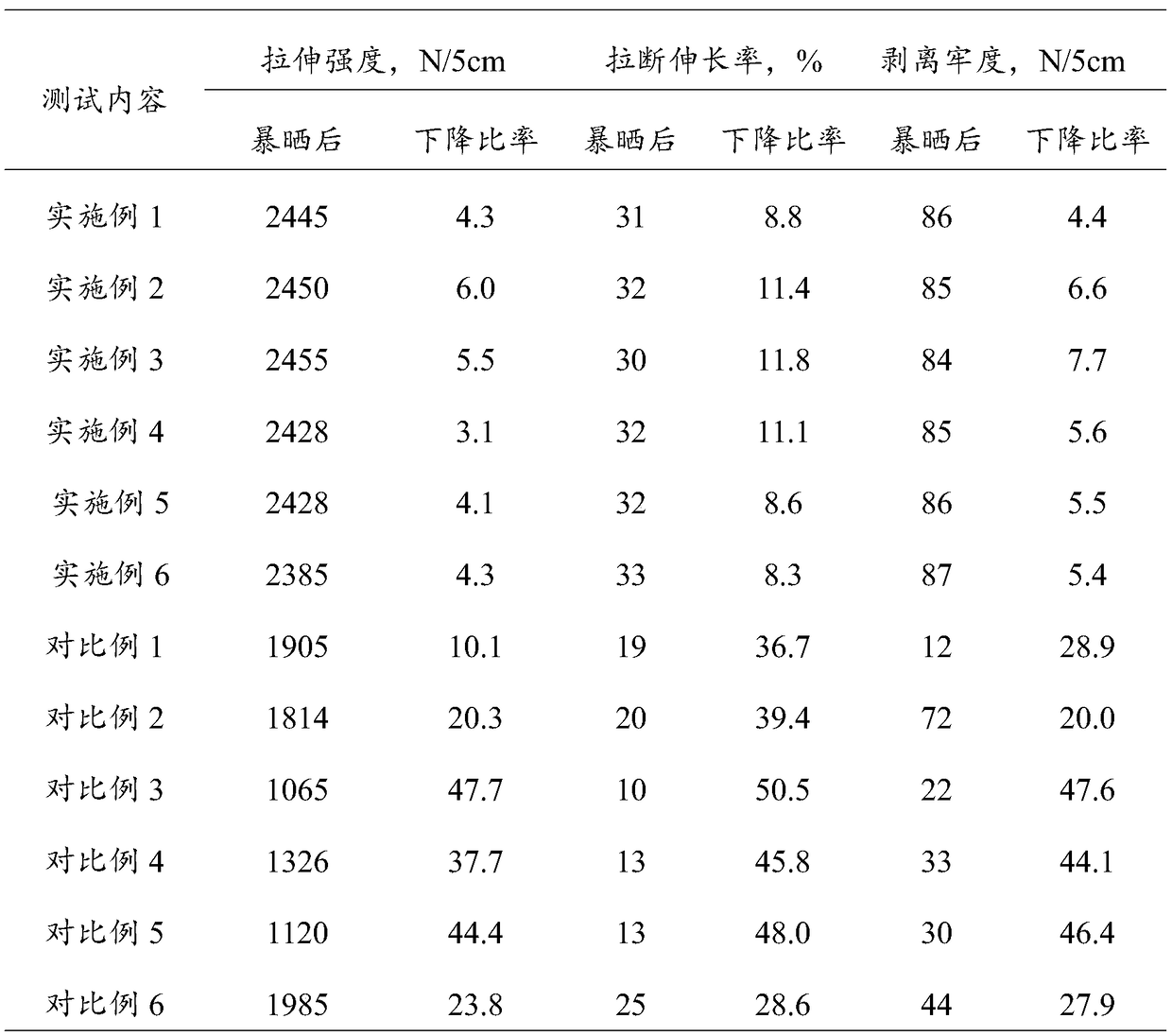

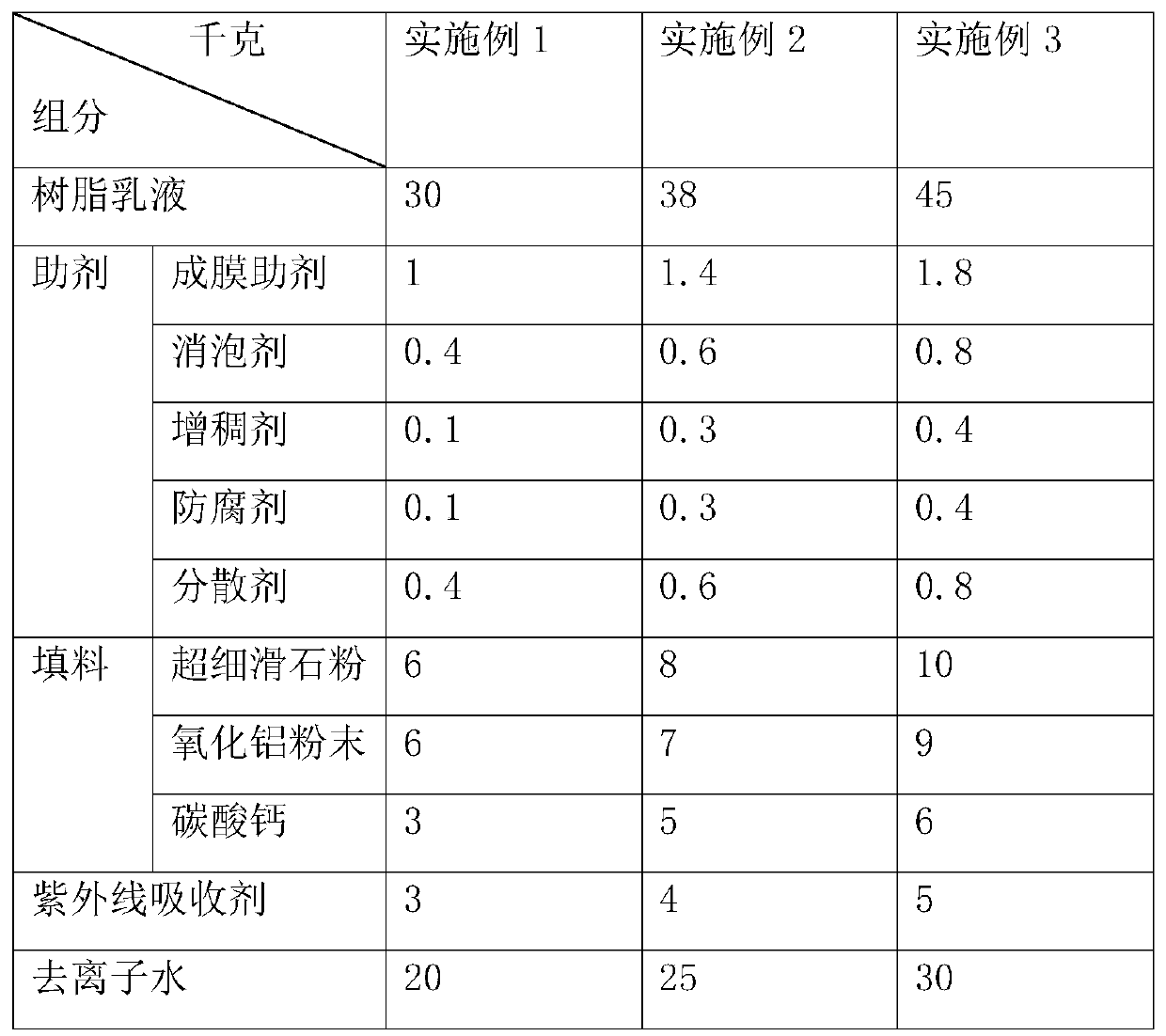

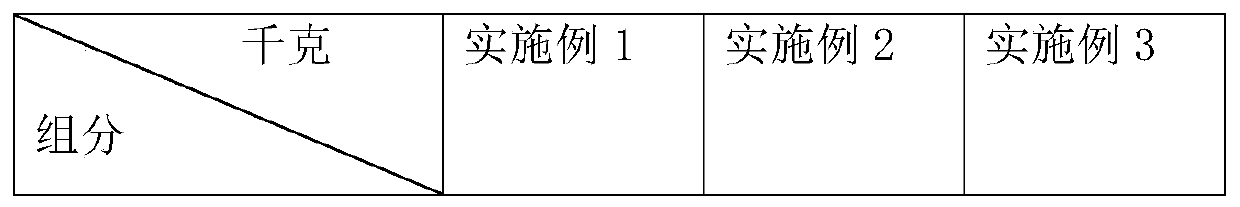

Anti-ultraviolet paint for cosmetic packing bottles and preparation method and application technique thereof

InactiveCN110054982AGood dispersionImprove adhesionLiquid surface applicatorsAnti-corrosive paintsEpoxyFiber

The invention discloses an anti-ultraviolet paint for cosmetic packing bottles and a preparation method and application technique thereof. The anti-ultraviolet paint is made from, by weight, 30-45 parts of resin emulsion, 4-8 parts of an aid, 6-10 parts of a filling material, 3-5 parts of an ultraviolet absorbent, and 20-30 parts of deionized water. The resin emulsion is made by mixing a silica-modified acrylate, polyurethane acrylate and hollow glass beads in a mass ratio of 1:(0.8-1):(0.5-0.8); the ultraviolet absorbent comprises, by weight, 5-10 parts of modified titania, 3-5 parts of methyl silicone oil, 3-6 parts of polydimethylsiloxane, 3-5 parts of phenyl salicylate, 1.8-2.5 parts of zirconia fiber, 1.4-2.4 parts of ceramic fiber, and 20-30 parts of epoxy resin emulsion. The anti-ultraviolet paint for cosmetic packing bottles has good heat insulation effect and high ultraviolet resistance.

Owner:广州澳盈日化包装用品有限公司

Fiber-reinforced polylactic-acid composite material and preparation method thereof

The invention discloses a fiber-reinforced polylactic-acid composite material. The fiber-reinforced polylactic-acid composite material is prepared from the ingredients in parts by weight: polylactic-acid resin, kapok fibers, Shengma fibers, nano cellulose, silicon carbide powder, nano zinc phosphate, epoxy resin E44, epoxy chloropropane, lithium chloride, phenyl salicylate, isophorone diamine, polyamide wax, a coupling agent, 0.5mol / L potassium hydroxide, sodium dithionite and barium stearate. The prepared fiber-reinforced polylactic-acid composite material has the breaking elongation of 243.5 percent to 301.4 percent, the tensile strength of 48.2MPa to 53.4MPa and the notch impact strength of 149.2J / m to 201.7J / m, and the comprehensive mechanical properties are good, so that the problem of the traditional composite materials that the rupture strength and ductility are poor due to poor interface compatibility between polylactic acid and fibers is solved, and the needs of actual applications are met.

Owner:顺达塑胶制品(深圳)有限公司

Concrete waterproof agent

A concrete waterproof agent is prepared from the following raw materials in parts by weight: 15-20 parts of calcium lignosulfonate powder, 7-9 parts of alunite, 5-8 parts of fatty alcohol polyoxyethylene ether, 4-8 parts of nanometer silicon dioxide, 9-16 parts of sodium fluosilicate, 5-8 parts of sodium alkylbenzene sulfonate , 5-10 parts of sericite powder, 4-10 parts of sodium polyacrylate, 20-30 parts of sodium methyl silicate, 5-12 parts of chrome oxide, 7-12 parts of molasses, 10-18 parts of sulfur trioxide, 8-19 parts of calcium phosphate, 21-27 parts of tetraethyl orthosilicate, 10-14 parts of phenyl salicylate, 10-18 parts of calcium hydroxide and 3-7 parts of 1H,1H,2H,2H-perfluorooctyltriethoxysilane. The provided concrete waterproof agent is superior in waterproof performance, strong in permeability and strong in frost resisting.

Owner:QINGDAO CHENQING INFORMATION TECH

Wall paint with radiation protection and corrosion resistance

InactiveCN108624222AImprove radiation protection performanceEasy to integrateAnti-corrosive paintsPolyurea/polyurethane coatingsWater basedUltraviolet

The invention relates to the technical field of building paint, in particular to wall paint with radiation protection and corrosion resistance. The wall paint comprises the following ingredients: water-based polyurethane-acrylate emulsion, organic silicon resin, titanium dioxide, enveloped metal micropowder, graphene, a pigment, a wetting dispersing agent, a silane coupling agent, an isocyanate curing agent, dimethythiotoluene diamine, a defoaming agent, a film formation assistant and an ultraviolet absorber. The wetting dispersing agent is an ammonium polyacrylate dispersing agent or a polyhydroxy acid ammonium dispersing agent; the defoaming agent is an organosilicon defoaming agent; the film formation assistant is texanol; and the ultraviolet absorber is phenyl salicylate or 2-hydroxyl-4-methoxy benzophenone. The paint has relatively excellent radiation protection performance and very excellent corrosion resistance and water resistance.

Owner:合肥展游软件开发有限公司

Concrete pumping agent with stable performances

A concrete pumping agent with stable performances is prepared from the following raw materials, by weight, 6-9 parts of triethanolamine, 5-7 parts of urea, 4-9 parts of bentonite, 1-4 parts of ultrafine fly ash, 6-9 parts of polyacrylamide, 4-9 parts of an acrylic copolymer, 5-10 parts of hydroxypropyl methylcellulose, 3-8 parts of re-dispersible latex powder, 5-7 parts of chrome oxide, 6-11 parts of phenyl salicylate, 4-10 parts of polyoxyethylene alcohol ether, 2-6 parts of sodium methyl silicate, 1-5 parts of triterpenoid saponin, 2-5 parts of monoethanolamine, 2-8 parts of sodium lauryl sulfate, 6-10 parts of p-hydroxy N-methylcyclohexylamine and 1-5 parts of a polycarboxylate water reducer. The concrete pumping agent with stable performances has the advantages of stable chemical properties, very good safety, low temperature resistance, strong applicability to cement, and wide range.

Owner:QINGDAO LAOXIANG TEA PROD

Anti-corrosive efficient waterproof agent

A disclosed anti-corrosive efficient waterproof agent is prepared from the following raw materials in parts by weight: 33-53 parts of deionized water, 2-7 parts of nanometer silicon dioxide, 2-6 parts of sodium alkyl sulfate, 3-6 parts of sodium polyacrylate, 2-5 parts of ethyl silicate, 4-8 parts of chrome oxide, 3-6 parts of an ethanolamine, 10-20 parts of sulfur trioxide, 5-10 parts of n-butyl benzoate, 15-25 parts of tetraethyl orthosilicate, 2-6 parts of a benzoate and 6-14 parts of phenyl salicylate. The provided anti-corrosive efficient waterproof agent is good in weatherability, high in caking ability and substantial in waterproof and anticorrosion effects, is especially applicable to ocean engineering, and does not contain substances harmful to human body.

Owner:QINGDAO CHENQING INFORMATION TECH

Plant sunscald controlling agent

InactiveCN102812958AEffective controlEffective sunburnBiocidePlant growth regulatorsPhenyl salicylateSURFACTANT BLEND

The invention discloses a plant sunscald controlling agent which comprises, by weight, 15-25 parts of dodecyl mercaptan, 0.1-5 parts of ultraviolet absorbents, 3-10 parts of difenoconazole, 5-10 parts of surfactants and 50-70 parts of dimethylbenzene. When the plant sunscald controlling agent is manufactured, dimethylbenzene, dodecyl mercaptan, phenyl salicylate, difenoconazole and the surfactants are evenly mixed. The plant sunscald controlling agent has the advantage of being capable of effectively controlling plant sunscald. Tests prove that the sunscald occurrence rate is below 6%.

Owner:张军防

High-performance anti-rutting modified asphalt

A high-performance anti-rutting modified asphalt, which is made of the following raw materials in parts by weight: 16-27 parts of asphalt, 0.2-0.4 parts of defoamer, 0.2-0.6 parts of cationic emulsified asphalt powder, and 7-9 parts of rubber powder 1-4 parts of glycidyl methacrylate, 0.6-1.5 parts of dioctyl sulfosuccinate sodium, 0.4-1.5 parts of azobisisobutyronitrile, 3-7 parts of guar gum, 4 parts of zirconium dioxide ‑5 parts, 12‑18 parts of atactic polypropylene, 1‑2 parts of magnesium alkyl ether sulfonate, 1.5‑3.6 parts of phenyl salicylate, 4‑7 parts of stearic acid, 3‑5 parts of diatomaceous earth, Silicon carbide whiskers 4‑7 parts, talcum powder 12‑16 parts. The beneficial effects of the present invention are: the high-performance anti-rutting modified asphalt of the present invention can prevent the formation of ruts and torsion damage, increase the high-temperature shear resistance of asphalt, greatly improve the anti-skid property and wear resistance of the road surface, and have simple process and low cost Low.

Owner:青岛千帆高新技术有限公司

Efficient antirust mechanical oil cleaning agent

InactiveCN104877819AImprove rust resistanceEasy to cleanSurface-active non-soap compounds and soap mixture detergentsSalicylic acidChloramine

The invention discloses an efficient antirust mechanical oil cleaning agent which is prepared from the following raw materials in parts by weight: 5-9 parts of a pickling agent, 3-5 parts of monoethanolamine, 1-1.5 parts of a vitrification agent, 2-5 parts of phenyl salicylate, 5-10 parts of nano calcium carbonate, 2-4 parts of molybdenum disulfide, 7-14 parts of an antirust agent, 2-4 parts of glycerol monostearate, 5-8 parts of ferrous chloride, 6-8 parts of sodium dodecyl benzene sulfonate, 3-7 parts of magnesium nitrate, 4-6.5 parts of chloramine, 3-6 parts of kieselguhr, 4-15 parts of magnesium sulfate and 2-6 parts of dimethyl bis(isooctyl thioglycolate) tin. The efficient antirust mechanical oil cleaning agent has the beneficial effects of good cleaning performance and low cost; and the antirust capability is improved.

Owner:QINGDAO WENSHENG AUTOMOBILE COMPONENTS & PARTS

Concrete waterproofing agent

The invention discloses a concrete waterproofing agent, which is prepared from the following raw materials in parts by weight: 15-20 parts of calcium lignosulphonate powder, 7-9 parts of alunite, 5-8parts of polyoxyethylene fatty alcohol ether, 4-8 parts of nano silica, 9-16 parts of sodium fluorosilicate, 5-8 parts of sodium alkylbenzenesulfonate, 5-10 parts of lassolatite powder, 4-10 parts ofsodium polyacrylate, 20-30 parts of sodium methyl silicate, 5-12 parts of chromium oxide, 7-12 parts of molasses, 10-18 parts of sulfur trioxide, 8-19 parts of calcium phosphate, 21-27 parts of tetraethyl orthosilicate, 10-14 parts of phenyl salicylate, 10-18 parts of calcium hydroxide, 3-7 parts of perfluorooctyltriethoxysilane, 10-20 parts of stearic acid and 1-3 parts of potassium hydroxide. The concrete waterproofing agent has a good waterproof effect as well as very good water reducing and leakage resisting effects; by determining all the components and content ranges thereof, all the components are enabled to achieve a more excellent synergistic effect; the concrete waterproofing agent can effectively improve the capillary pore structure of concrete, block the capillary pore channelinside the concrete, significantly improve the anti-seepage and waterproof functions, and has the effects of reinforcing, reducing water, resisting crack, and the like.

Owner:徐州巨龙新材料科技有限公司

Preparation process for high-strength PVC power pipe

InactiveCN110724354AIncrease the relative molecular massIncrease forceOrganic compound preparationGroup 5/15 element organic compoundsPlasticizerPolyvinyl chloride

The invention discloses a preparation process for a high-strength PVC power pipe. The high-strength PVC power pipe is prepared from the following raw materials in parts by weight: 20-25 parts of polyvinyl chloride resin, 8-10 parts of a modified tricresyl phosphate flame retardant, 8-10 parts of a modified phenyl salicylate light stabilizer, 8-10 parts of an impact modifier, 5.5-7 parts of a lubricant, 3.5-5 parts of a heat stabilizer, and 6.5-8 parts of a plasticizer. In the preparation process of the high-strength PVC power pipe, the modified tricresyl phosphate flame retardant and the modified phenyl salicylate light stabilizer are prepared, so that the original flame retardancy of the PVC power pipe is further improved, and the effective time of the flame retardant substance is ensured; and the added light stabilizer ensures that in the construction process, the PVC power pipe does not undergo a photochemical reaction due to illumination to make the surface of the PVC power pipe turns yellow, color and brittle, and the service life of the PVC power pipe is further improved.

Owner:安徽瑞琦塑胶科技有限公司

Medical dialyzing paper

InactiveCN105970719AHigh strengthGood antibacterialCoatings with pigmentsPaper/cardboardPolyesterAntioxidant

The invention relates to a medical dialysis paper, which comprises a paper base layer and a hot-melt adhesive layer coated on the upper and lower surfaces of the paper base layer. The paper base layer contains 60-65 parts by weight of hardwood raw materials and 30-35 parts by weight of softwood wood materials. , 7 to 10 parts by weight of bamboo charcoal fiber, 3 to 5 parts by weight of polyester staple fiber, the length of the bamboo charcoal fiber is 1 to 2mm, the length of the polyester staple fiber is 2.5 to 3mm, and the hot melt adhesive The layer contains the following raw materials in parts by weight: 60-75 parts of ethylene-vinyl acetate copolymer, 15-25 parts of polyamide resin, 1-2 parts of paraffin, 1.5-2 parts of antioxidant, 5-8 parts of bamboo charcoal fiber powder, hard 2-3 parts of barium fatty acid, 8-15 parts of hydrogenated rosin, 1-1.5 parts of fluorinated graphite, 0.2-0.4 parts of phenyl o-hydroxybenzoate, and the particle diameter of the bamboo charcoal fiber is less than 0.3 mm.

Owner:福建希源纸业有限公司

Nano calcium carbonate modified polytetrafluoroethylene composite material for sealing valve

The invention discloses a nano calcium carbonate modified polytetrafluoroethylene composite material for sealing a valve and relates to the technical field of valve sealing materials. The nano calcium carbonate modified polytetrafluoroethylene composite material is prepared from the following raw materials in parts by weight: 75-80 parts of polytetrafluoroethylene, 15-20 parts of nano calcium carbonate, 12-16 parts of sodium carboxymethylcellulose, 10-13 parts of glycerol, 8-10 parts of linear phenolic resin, 5-8 parts of bentonite, 5-8 parts of talc powder, 3-5 parts of phosphite ester, 3-5 parts of dibutyl phthalate, 3-4 parts of phenyl salicylate, 2-3 parts of graphite powder, 2-3 parts of stearic acid, 1-2 parts of polyester and 1-2 parts of agar. According to the nano calcium carbonate modified polytetrafluoroethylene composite material disclosed by the invention, nano calcium carbonate modified polytetrafluoroethylene is adopted, an appropriate amount of an auxiliary agent is added, the prepared composite material has the characteristics of good plasticity, high-temperature resistance, ageing resistance and corrosion resistance, can be processed into various shapes and is low in friction coefficient, and the use temperature is -136-420 DEG C, so that the composite material can be used as a sealing material to improve the sealing performance of the valve.

Owner:HEXIAN KEJIA VALVE CASTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com