Composite concrete waterproofing agent

A technology of concrete waterproofing agent and bentonite, which is applied in the field of concrete composite waterproofing agent and building material additives. It can solve the problems of not being able to compensate for concrete shrinkage cracks, adverse effects on concrete strength, and affecting concrete waterproofing performance, so as to improve impermeability and waterproofing performance. Compactness and compressive strength, the effect of improving frost resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

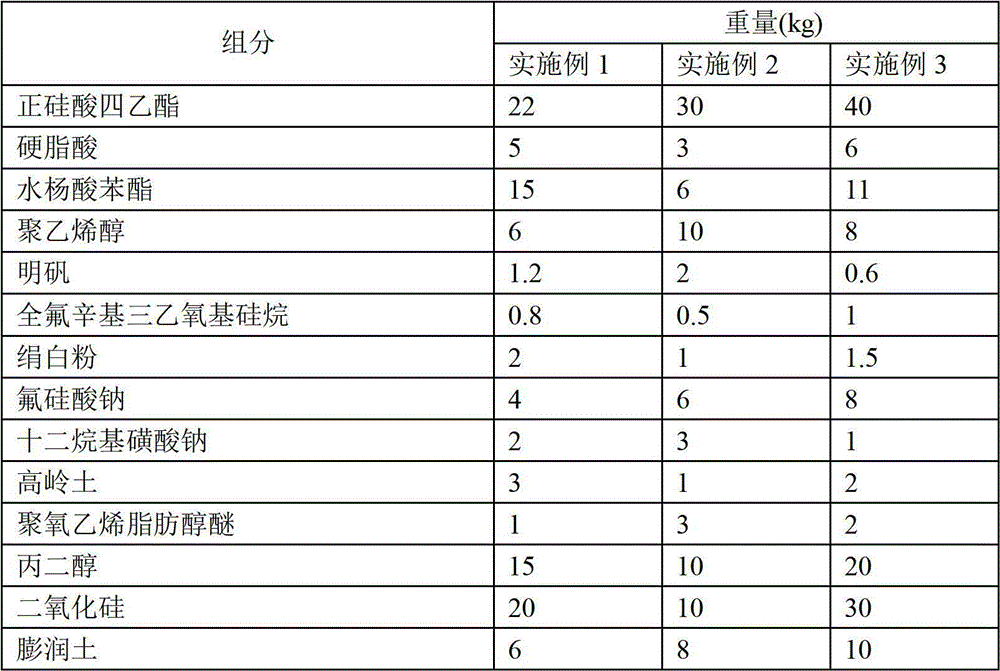

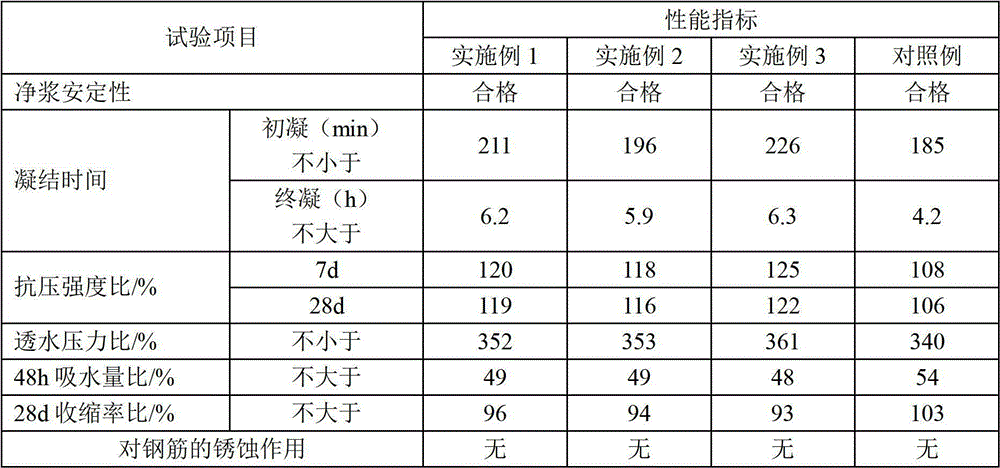

[0014] The weight proportion of table 1 embodiment 1-embodiment 3

[0015]

[0016] The above-mentioned polyvinyl alcohol is polyvinyl alcohol 1799, and its purity is technical grade.

[0017] The particle size range of the above-mentioned silica particles is 200-500 mesh.

[0018] The particle size of the above-mentioned bentonite particles is greater than 50 mesh.

[0019] The preparation method of each embodiment is:

[0020] S1 Add tetraethyl orthosilicate, stearic acid, phenyl salicylate, polyvinyl alcohol, and alum into the reaction kettle, control the temperature at 60~70°C and stir for 0.5 hours to make the mixture uniform;

[0021] S2 Continue to add propylene glycol, silicon dioxide, bentonite, sodium fluorosilicate, and sodium dodecylsulfonate to the mixture obtained in S1, control the temperature at 50±2°C, and stir for 1 to 2 hours.

[0022] S3 Add perfluorooctyltriethoxysilane, silk white powder, and polyoxyethylene fatty alcohol ether to the mixture obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com