Post-cast strip structure for previously stopping water in basements and construction method thereof

A basement and post-casting technology, which is applied in the field of construction engineering, can solve the problems of post-casting, such as easy leakage, uneven surface, and poor flatness, so as to improve the waterproof and anti-seepage effect, avoid secondary cleaning, and improve waterproofing effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

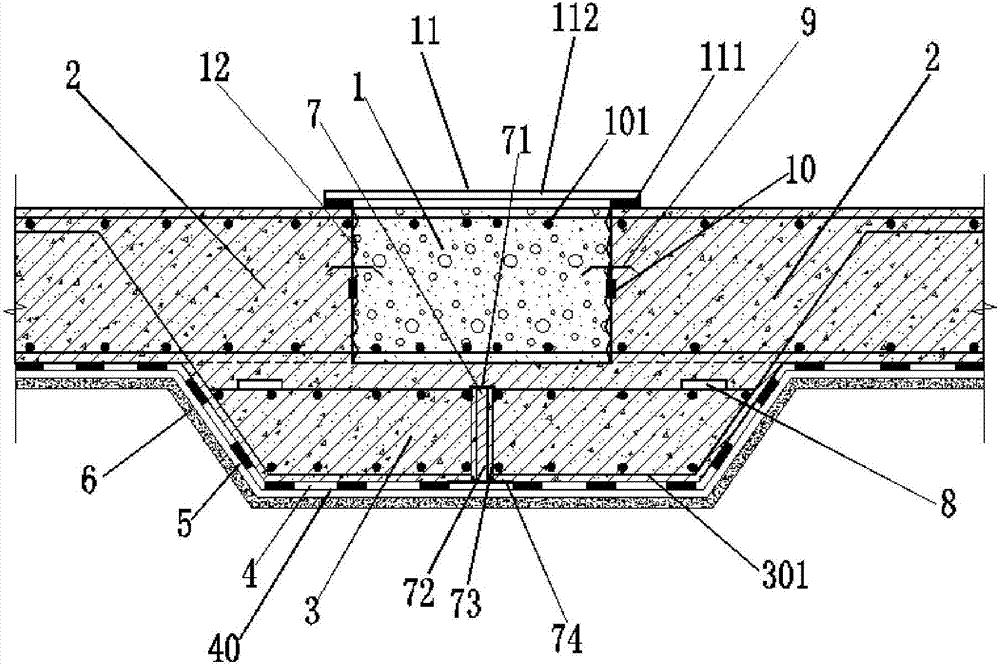

[0038] Such as figure 1 As shown, a basement basement advanced water-stop post-casting belt structure includes left and right basement floors 2 and a middle post-casting belt 1, and also includes a cast-in-place concrete trapezoidal groove structure 3 below the post-casting belt, and the basement floor 2 and the cast-in-place Below the concrete trapezoidal groove structure 3 are the waterproof membrane layer 4 , the waterproof coating layer 40 , the waterproof protective layer 5 and the concrete cushion 6 .

[0039] During specific implementation, the transverse reinforcement 301 of the cast-in-situ concrete trapezoidal groove structure 3 goes deep above the basement floor 2 on the left and right sides, and an expansion joint 7 is arranged in the middle of the trapezoidal groove structure 3, and an expansion joint 7 is provided at the junction end of the expansion joint 7 and the middle post-casting belt 1. U-shaped steel bars 71, with extruded polystyrene boards left inside, ...

Embodiment 2

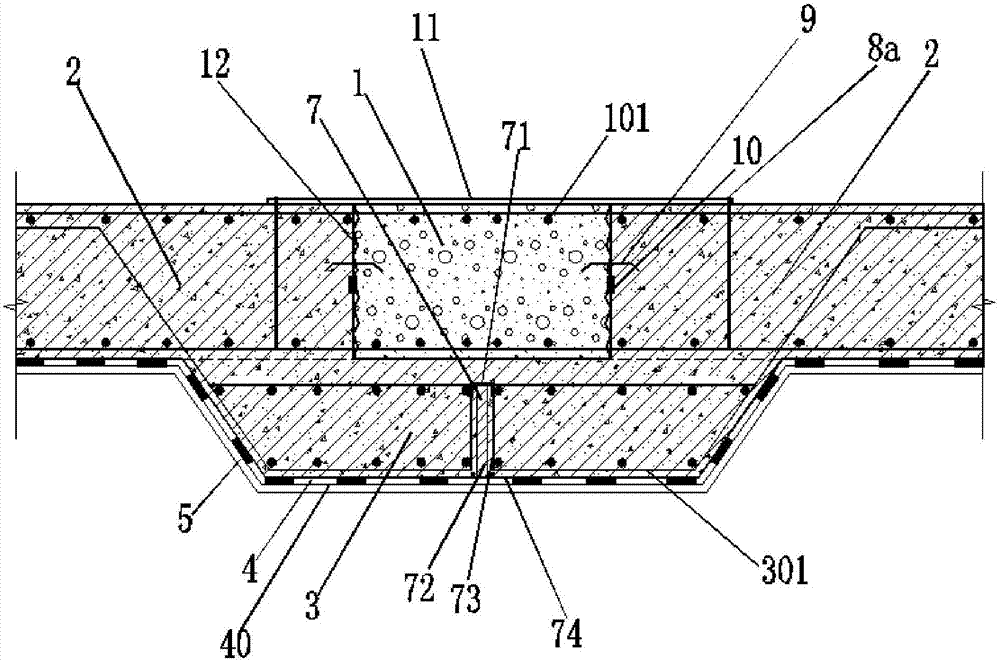

[0055] Such as figure 2 As shown, a basement side wall structure with advanced water-stop and post-casting belt, including left and right basement side walls 2 and a middle post-casting belt 1, also includes a cast-in-situ concrete trapezoidal groove structure 3 arranged under the post-casting belt, basement side wall 2 The outer side of the cast-in-place concrete trapezoidal groove structure 3 is a waterproof coiled material layer 4 , a waterproof coating layer 5 , and a waterproof protective layer 6 .

[0056] During specific implementation, the transverse steel bars 301 of the cast-in-place concrete trapezoidal groove structure 3 go deep into the inner sides of the basement side walls 2 on the left and right sides; There are U-shaped steel bars 71, and extruded polystyrene boards are left inside. After the concrete is poured, the joints are cleared, and then asphalt and linseed 72 are used to fill the joints. Both sides of the expansion joint 7 are equipped with external w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com