Patents

Literature

68results about How to "Guaranteed visual quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

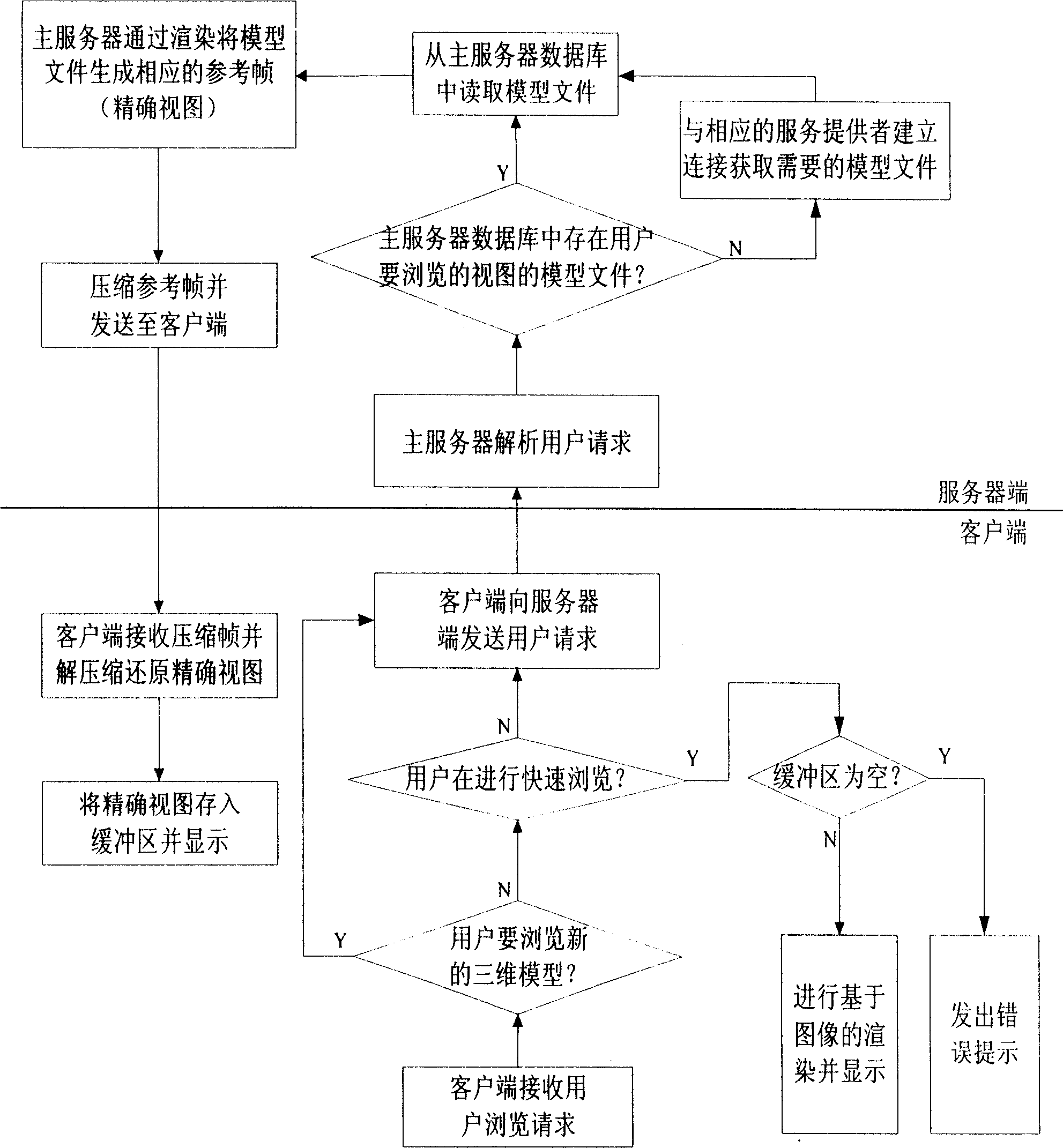

Three-D visual method based on image

InactiveCN1758286AFast Interaction GuaranteedQuality assuranceTransmission3D-image renderingClient-sideThree dimensional model

This invention discloses a 3-D remote visualization method including: 1,the customer end receives an interactive order sent by a user and analyses it, 2, the customer end presents a request for browsing a 3-D model to the server end and the visual position of the user to require to get the accurate views, 3, a primary server analyses the request and judges it to fetch the required model file from the database of the primary server or a server provider or prompt it to the user, 4, the primary server romances the model file to generate an accurate view, 5, the primary server compresses the view color information and depth information, 6, the primary server sends the got compressed file and the visual positions to the customer end, 7, the customer de-compresses the file and positions to store them in a buffer and display the color information.

Owner:HUAZHONG UNIV OF SCI & TECH

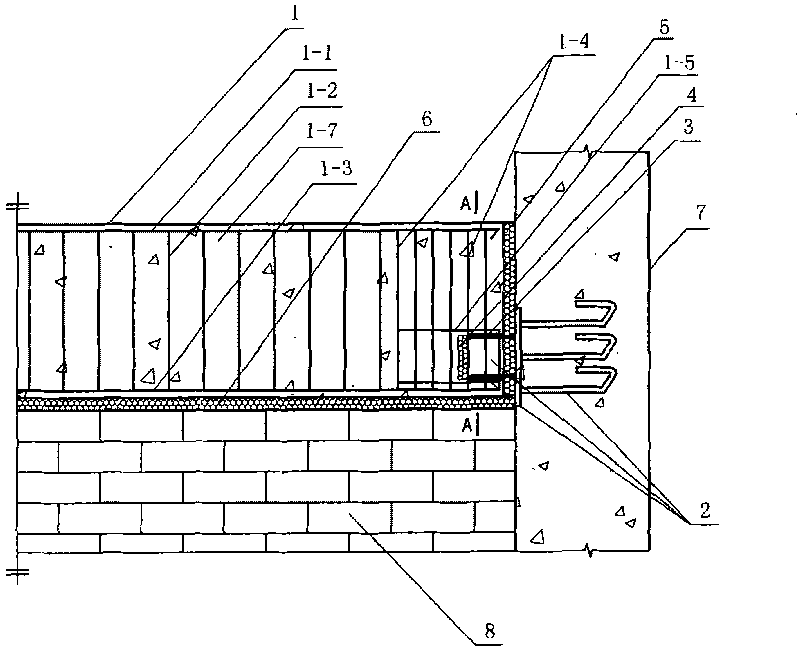

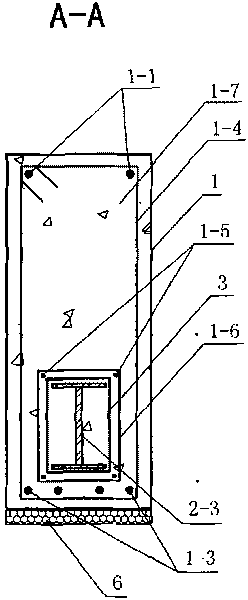

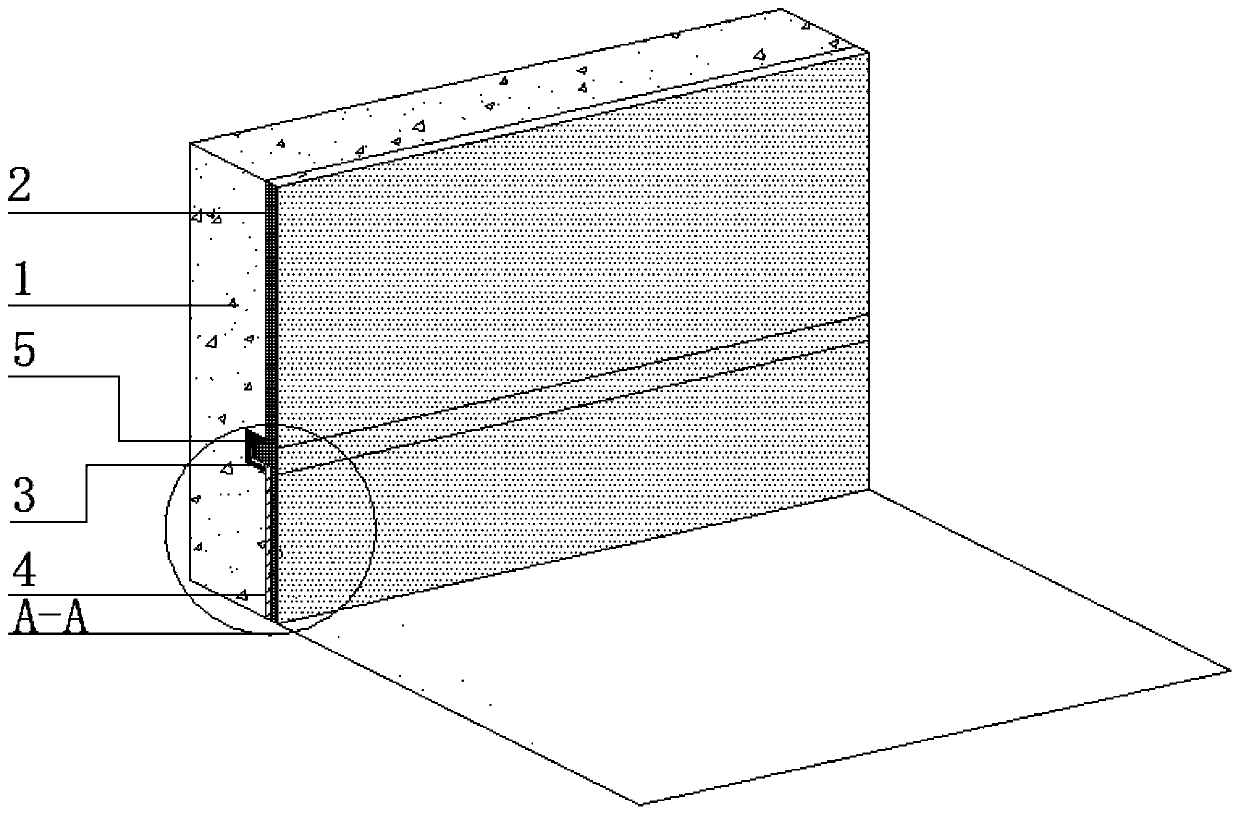

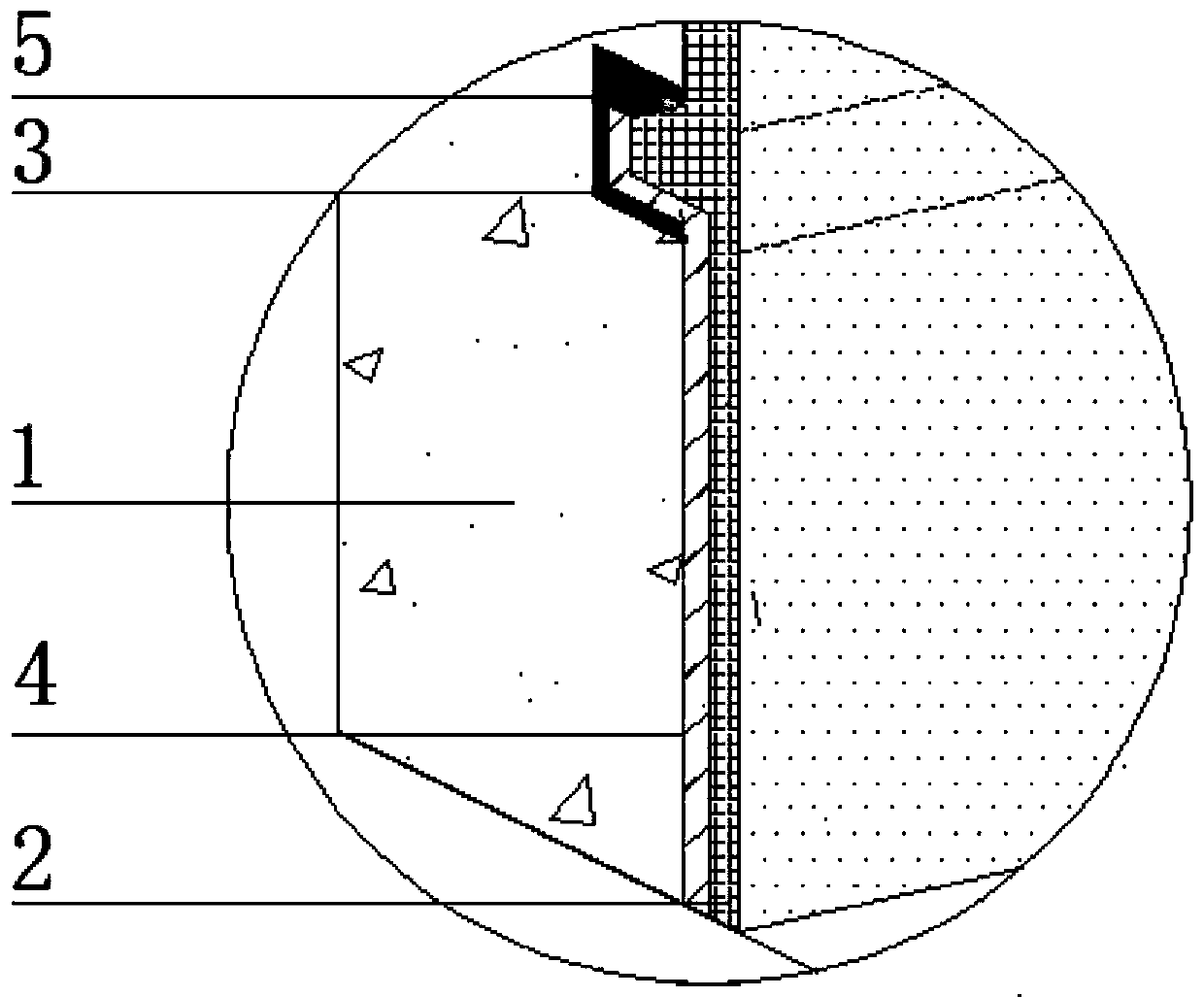

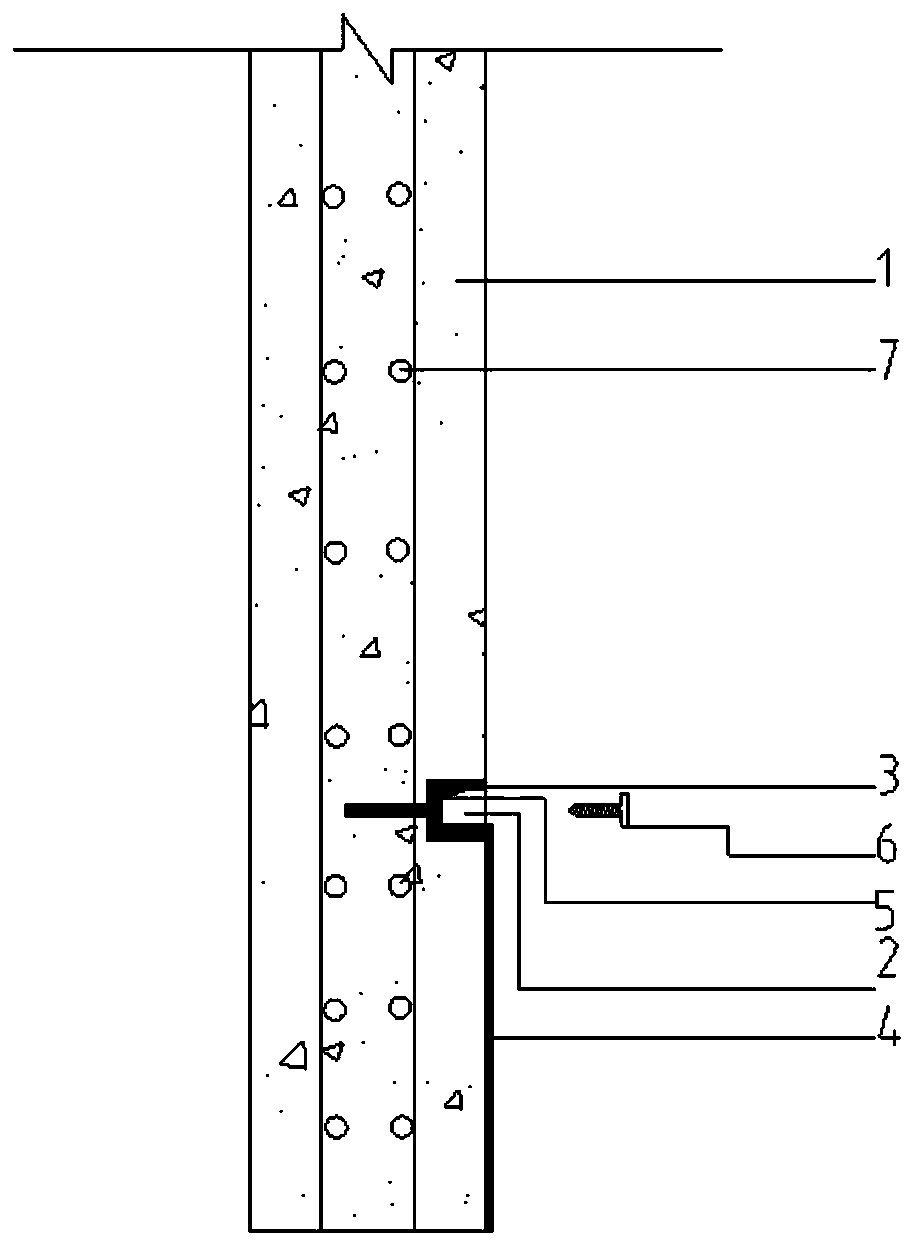

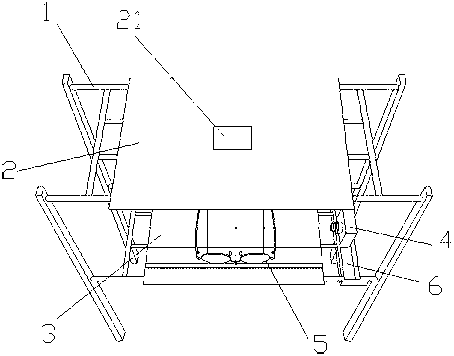

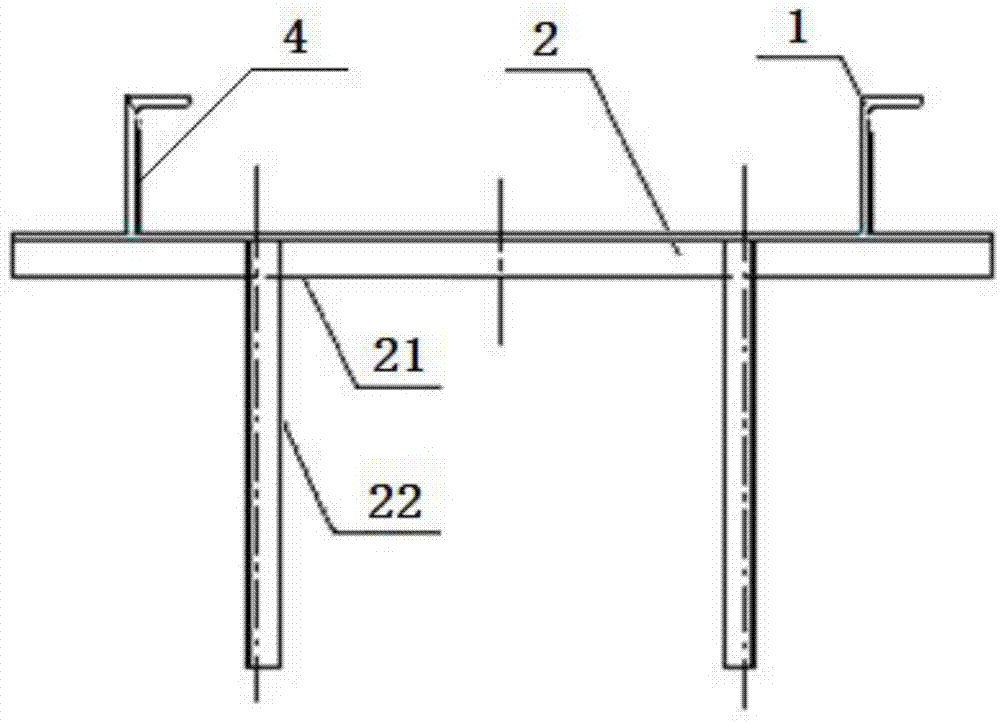

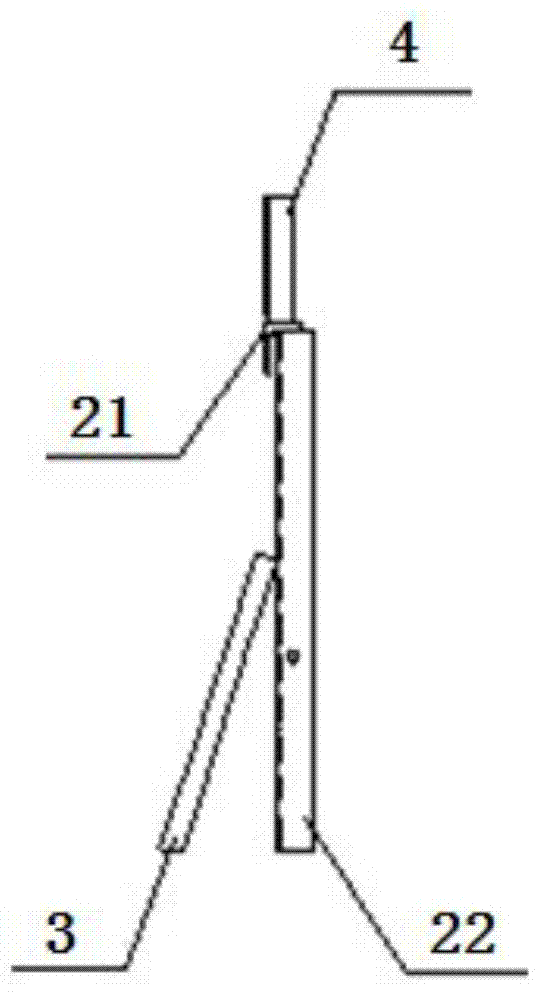

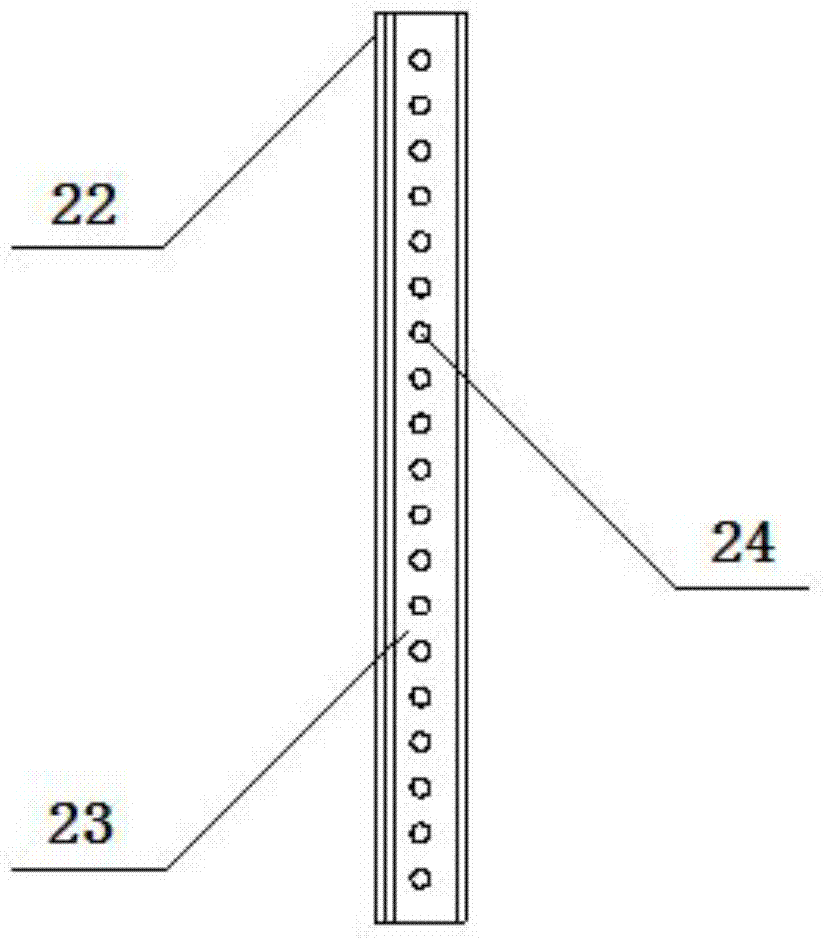

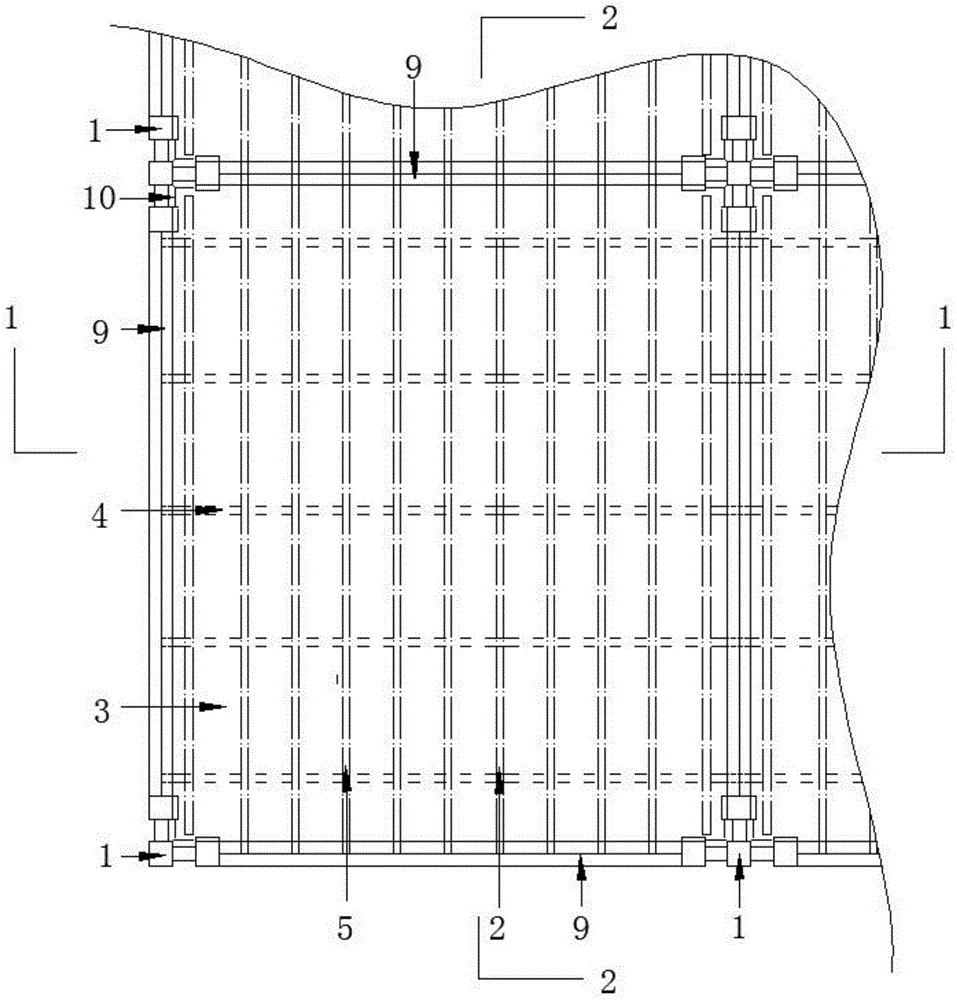

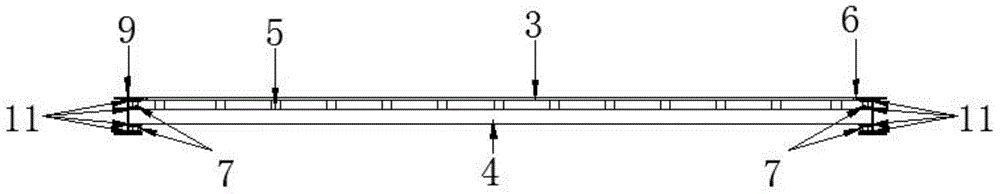

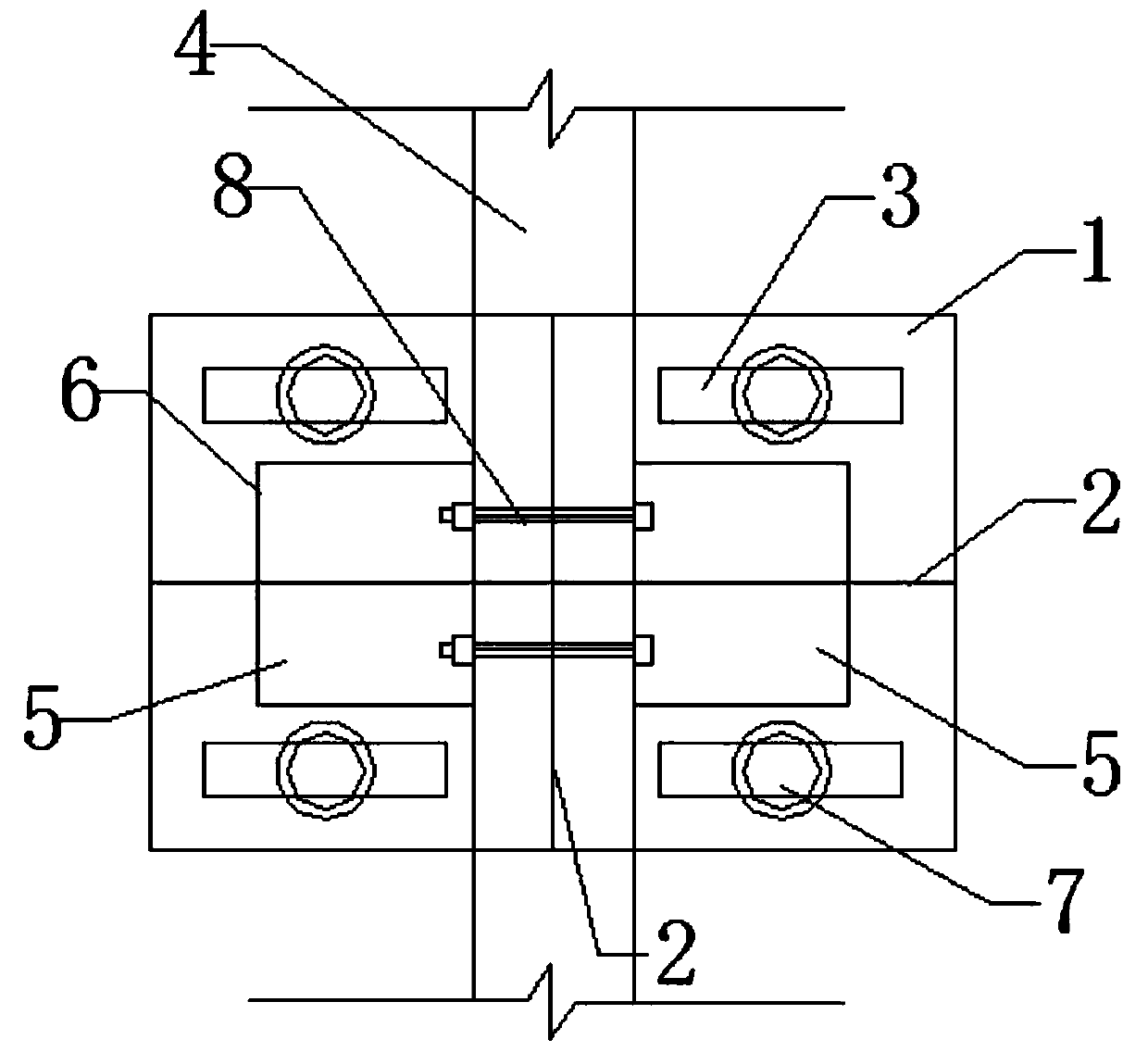

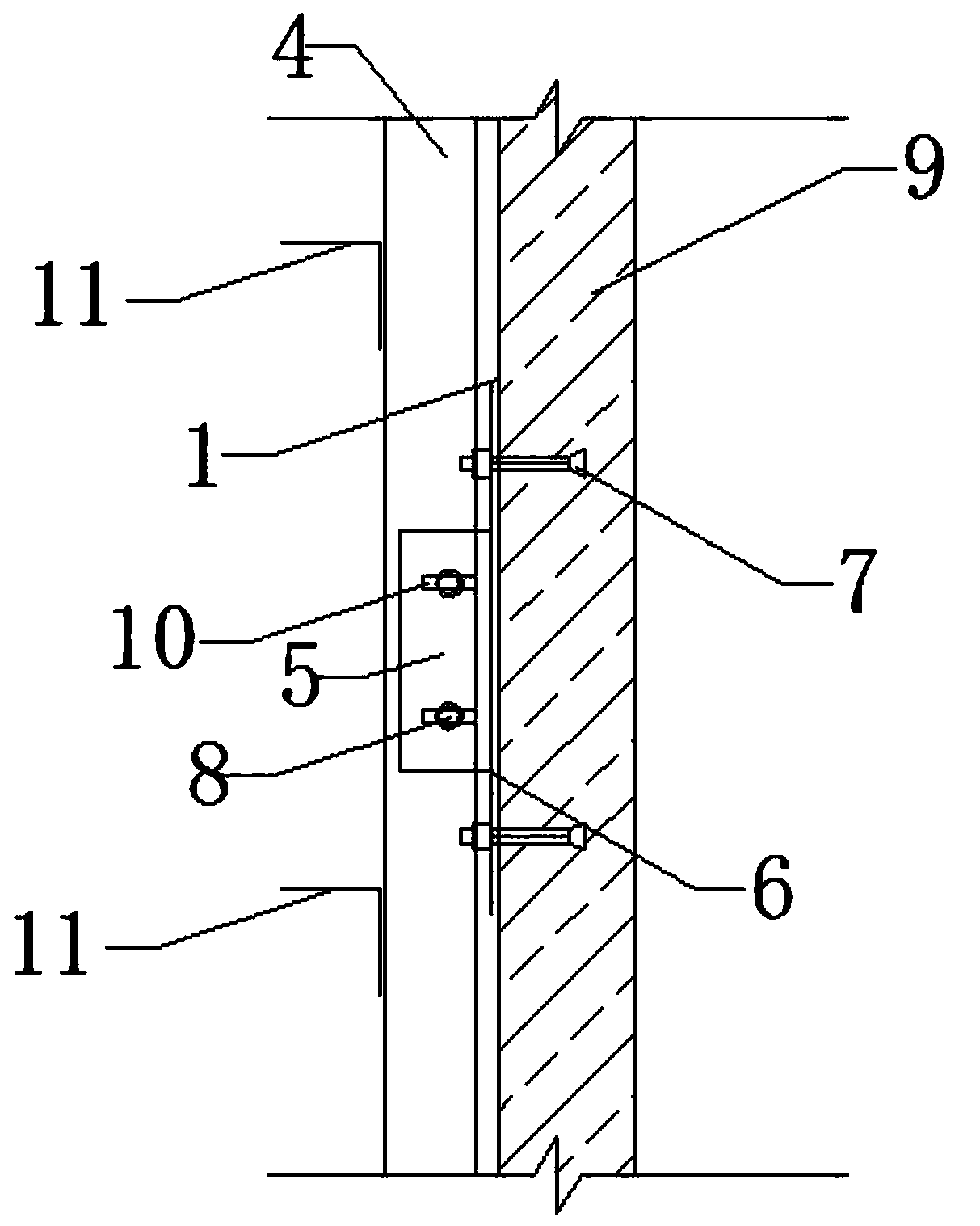

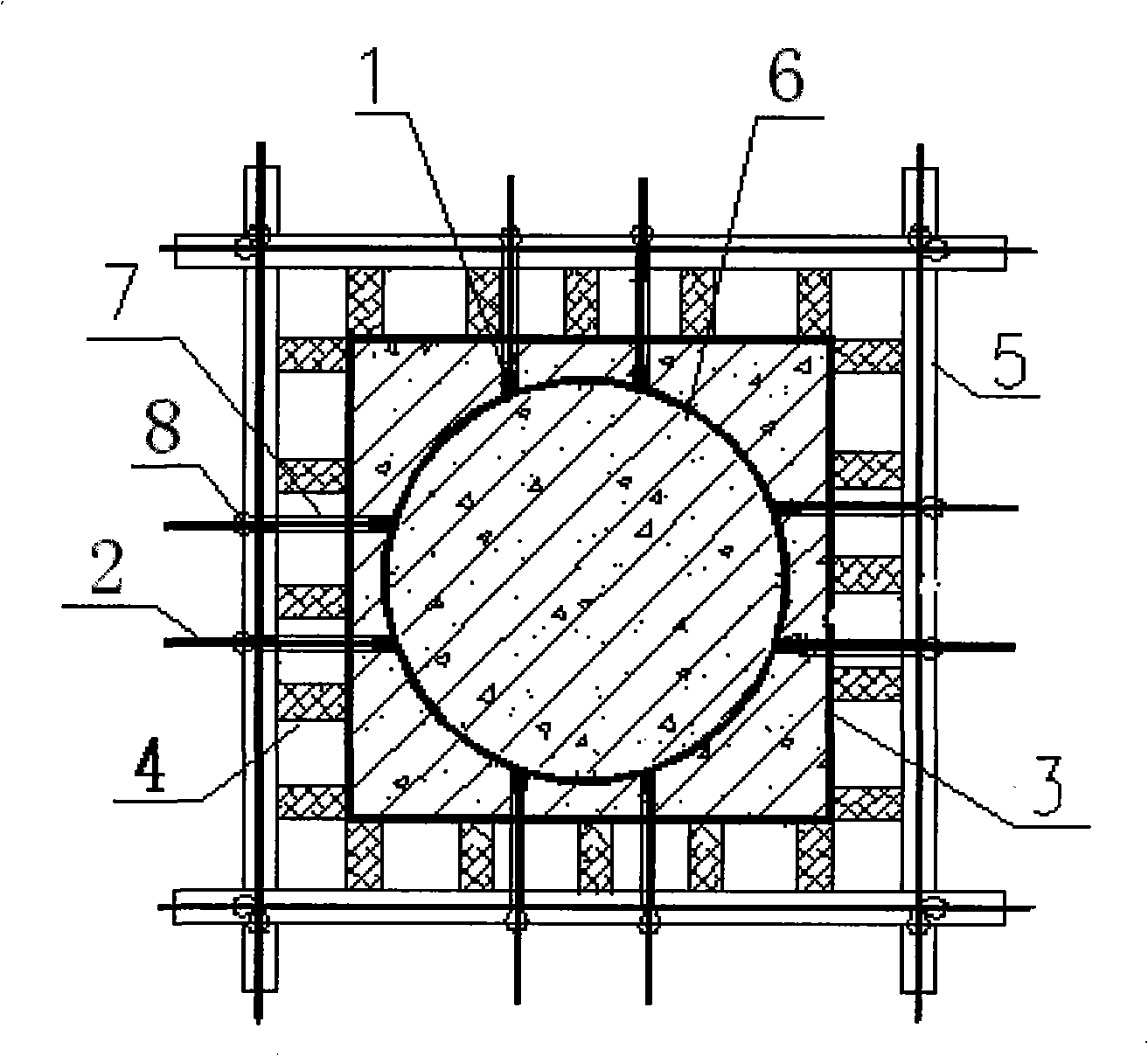

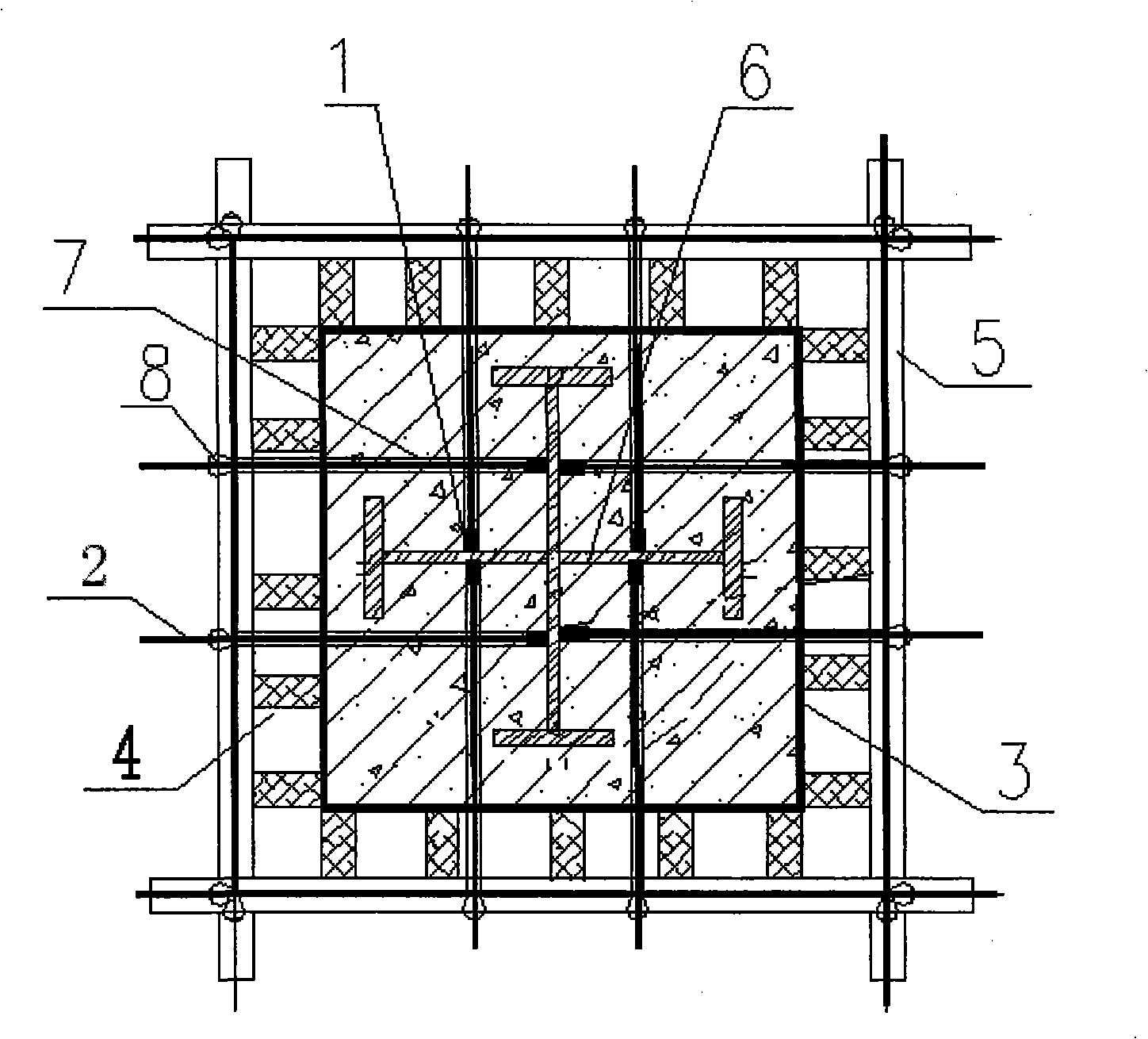

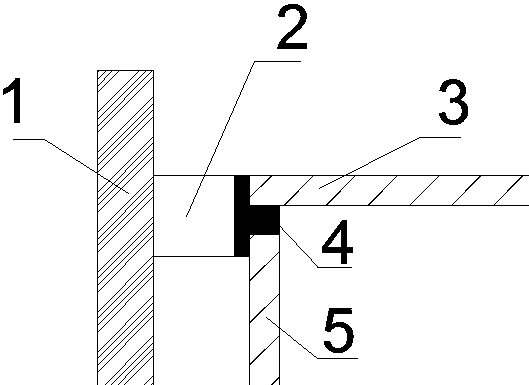

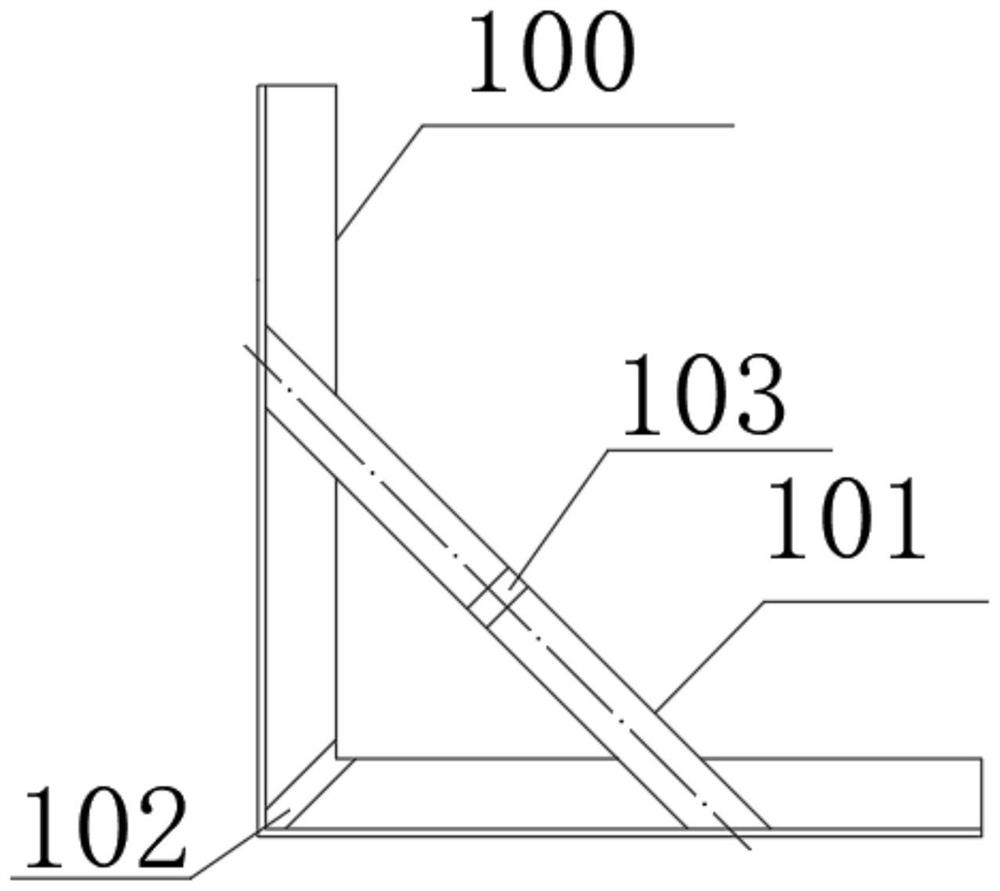

Preset nut type steel-reinforced concrete compound pier template fixing device and construction method thereof

ActiveCN101538939ASolve fixed puzzlesEnsure construction safetyForms/shuttering/falseworksCompound pierReinforced concrete

The invention discloses a preset nut type steel-reinforced concrete compound pier template fixing device and a construction method thereof. The fixing device mainly comprises a template, a nut, a screw rod, a PVC protecting pipe, an inner keel and an outer keel. The nut is welded on a steel column, the template surrounds the periphery of the steel column, the outer keel is arranged around the outer side of the template, the inner keel is arranged between the template and the outer keel, one end of the screw rod is connected with the nut by a thread, the PVC protecting pipe is sleeved on the screw rod, and the other end of the screw rod is fixed on the outer keel by a 3-shaped buckle. The invention has simple structure, low cost, and simple and convenient construction, solves the difficulty of fixing the steel-reinforced concrete compound pier template, is convenient for the field construction operation and lightens the workload and the labor intensity. The inner keel, the outer keel, the template and the screw rod can be repeatedly used so as to save the cost, ensure the construction safety of the template and improve the forming quality of the concrete column; meanwhile, the fixing device adopts common materials, thereby lowering the cost and being convenient for popularization and application.

Owner:JIANGSU HUAJIAN CONSTR

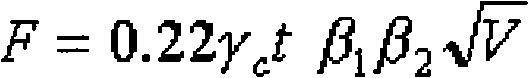

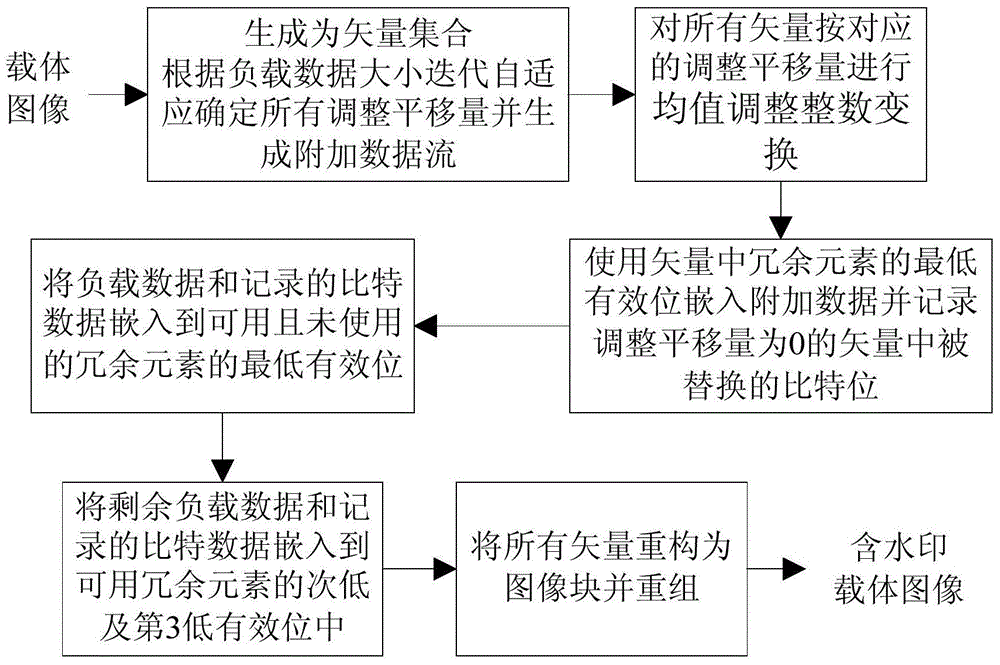

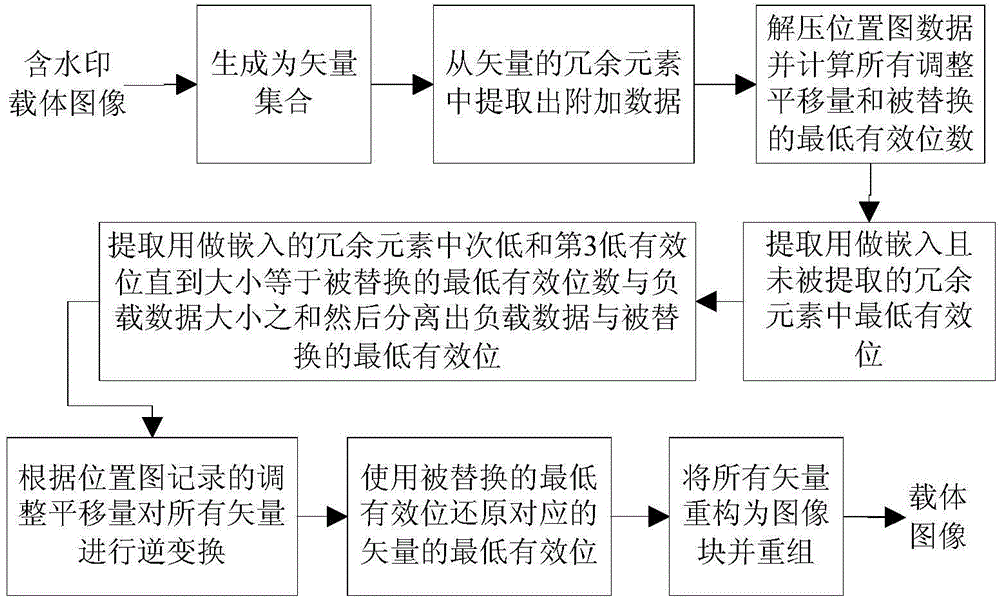

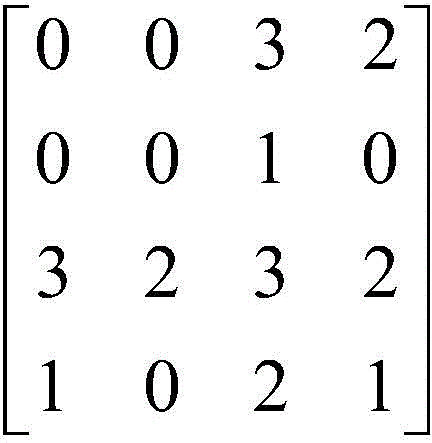

Iterative self-adaptive reversible watermark embedding and extracting method

ActiveCN104835109AIncrease embedding capacityEmbedded Capacity GuaranteeImage data processing detailsAlgorithmWatermark method

The invention provides an iterative self-adaptive reversible watermark embedding and extracting method. The embedding method firstly adopts an iterative self-adaptive method to select an adjustment translation amount to achieve a balance of watermark embedding capacity and embedding carrier visual quality according to influence of the load data size and an integer vector on a peak signal to noise ratio; then a complete location map generation strategy is given according to a principle that neighboring pixel values are close so as to improve location map compression performance; and finally a layered orderly embedding strategy is adopted to embed load data in the lowest, the second lowest and the third lowest significance bits to avoid a circumstance that the capacity is sufficient but embedding cannot be realized. Compared with a conventional mean value adjustment integer transformation reversible watermark, the method provided by the invention can still maintain a large embedding capacity without setting a threshold value in advance, after a watermark is embedded, visual quality of a shelter is better, performance of the location map generation strategy is better than the conventional mean value adjustment integer transformation reversible watermark method and a compressed location map is smaller, thereby indirectly increasing the embedding capacity.

Owner:SHAANXI NORMAL UNIV

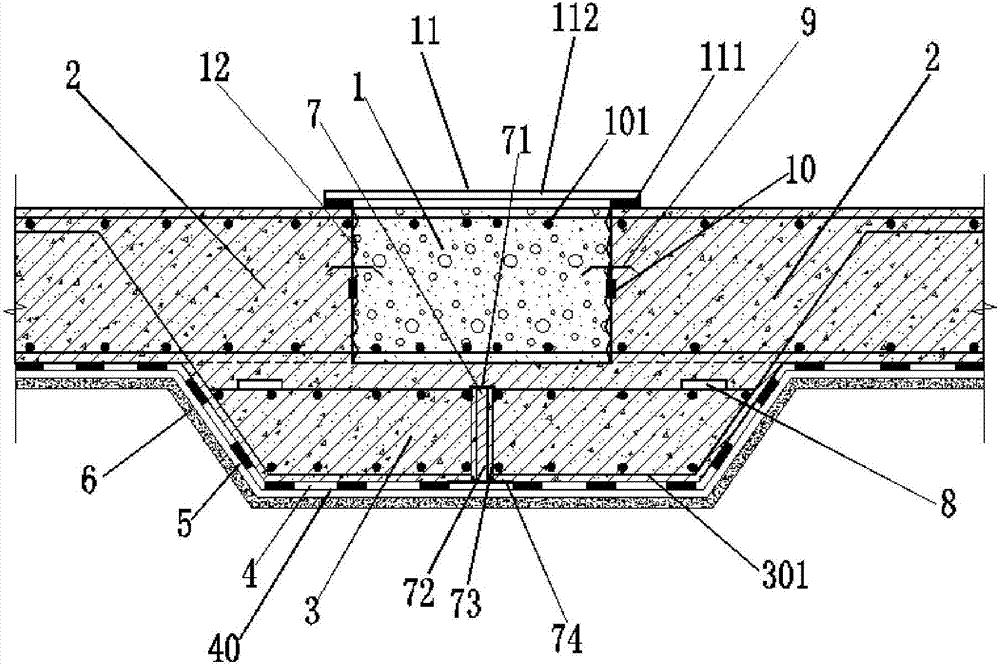

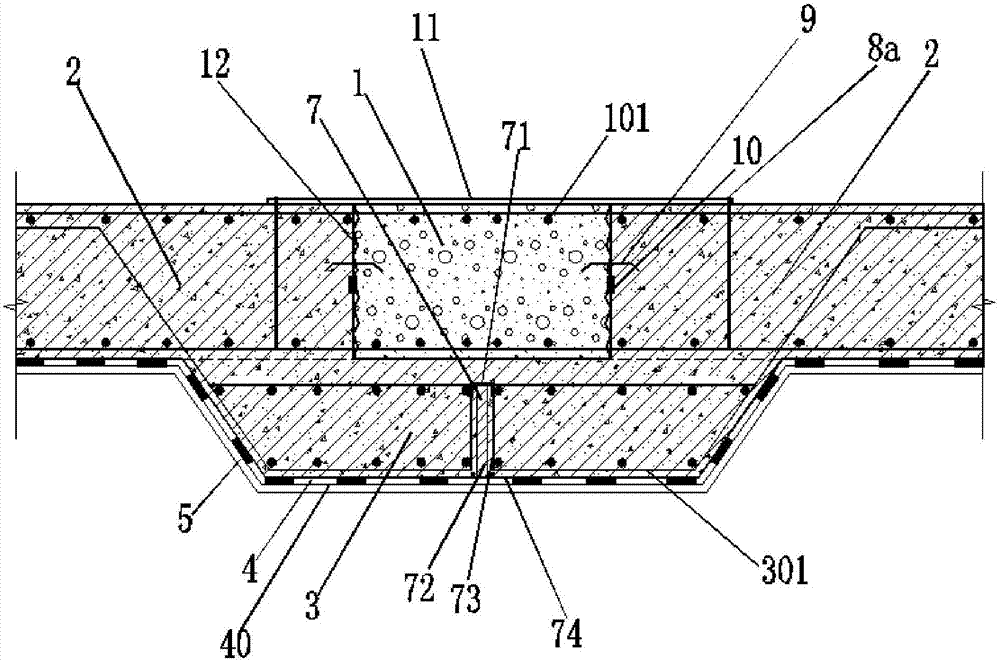

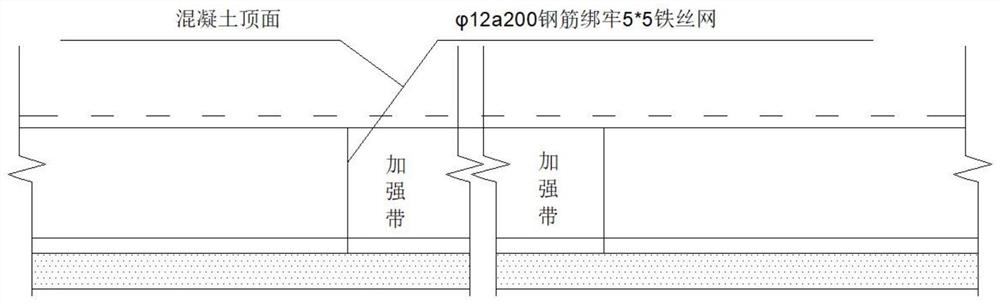

Post-cast strip structure for previously stopping water in basements and construction method thereof

ActiveCN107326940AImprove waterproof performanceImprove waterproof and anti-seepage performanceArtificial islandsUnderwater structuresBasementStructure of the Earth

The invention discloses a post-cast strip structure for previously stopping water in basements and a construction method thereof. The structure comprises a main basement structure on the left and right sides, a post-cast strip area and a cast-in-place trapezoid concrete groove structure which is arranged below the post-cast strip area. A water-proof material rolling layer, a water-proof polyurethane coating film layer, a water-proof protective layer and a concrete cushion layer are sequentially arranged below the main basement structure and the cast-in-place trapezoid concrete groove structure; the post-cast strip structure for previously stopping the water in the basements has the advantages of being excellent in leaking-proof and water-proof effect, simple in structure, high in contraction distortion capability, and capable of effectively preventing sundries and accumulated water from entering the post-cast strip area, avoiding secondary cleaning, providing convenience for construction and effectively accelerating construction progress, and moreover, the undesirable phenomena such as slurry accumulation, water accumulation and the like are unlikely to occur by using the structure, so that the post-cast strip structure for previously stopping the water in the basements is worthy of popularization.

Owner:GUANGZHOU PANYU POLYTECHNIC

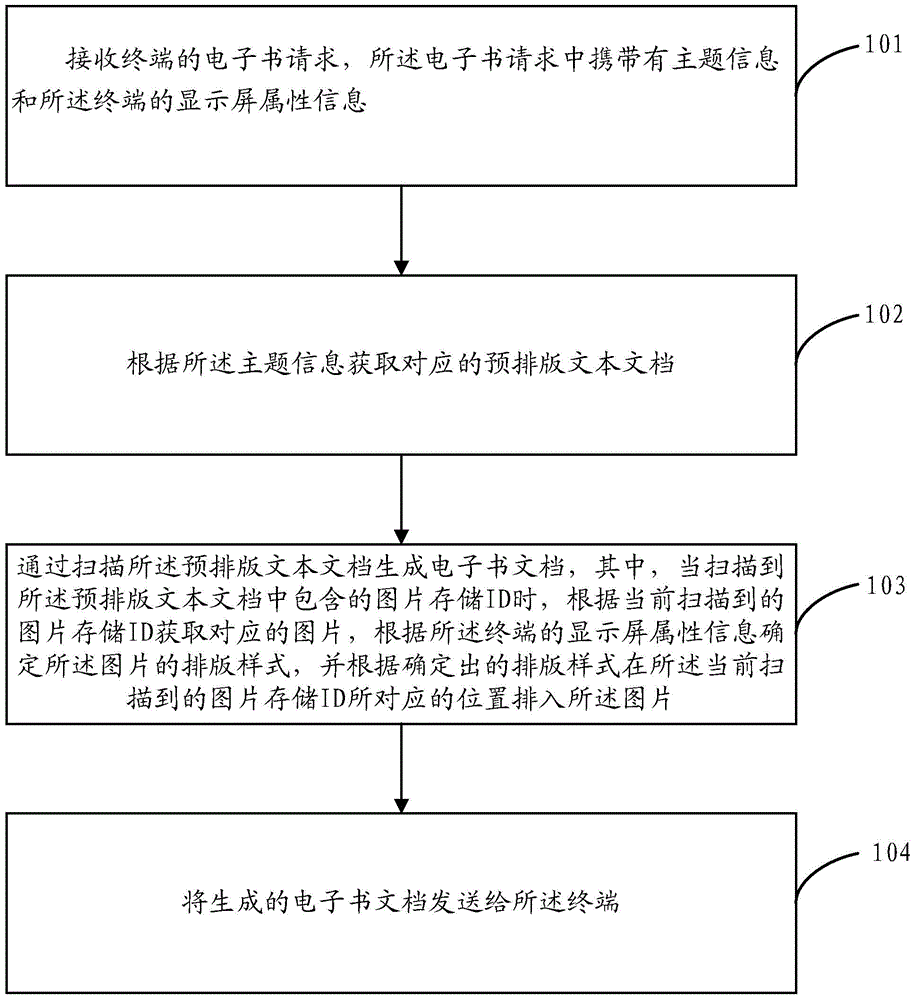

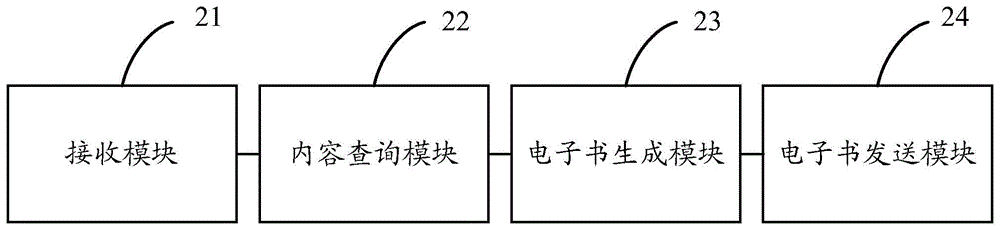

Electronic book sending method and device

InactiveCN104391886AMeet individual needsGuaranteed visual qualityNatural language data processingTransmissionPersonalizationElectronic book

The invention discloses an electronic book sending method and device. The method has the main technical scheme that an electronic book request of a terminal is received, and theme information and display screen attribute information of the terminal are carried in the electronic book request; a corresponding pre-composed file is obtained according to the theme information; an electronic book file is generated through scanning a composing text file, wherein when a picture storage ID (identity) included in the pre-composing text file is scanned, a corresponding picture is obtained according to the currently scanned picture storage ID, the picture composing style is determined according to the display screen attribute information of the terminal, and in addition, the picture is composed into the position corresponding to the currently scanned picture storage ID according to the determined composing style; the generated electronic book file is sent to the terminal. When the technical scheme is adopted, the electronic book sent to a user is enabled to meet the individual needs of a user, and in addition, the visual quality of the reading is ensured.

Owner:WUHAN UNIV

Construction method for special structure layer of cone bottom wheat-immersion

InactiveCN101294420AGuaranteed StrengthGuaranteed stabilitySpecial buildingExtraordinary structuresFalseworkShaped beam

Owner:CHINA CONSTR SIXTH ENG DIV CORP +1

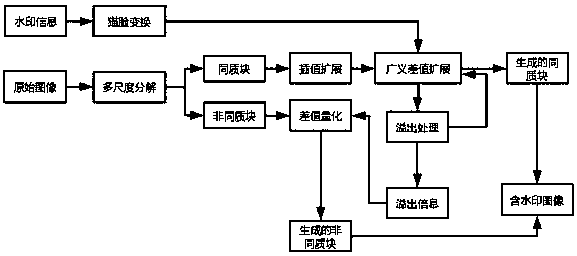

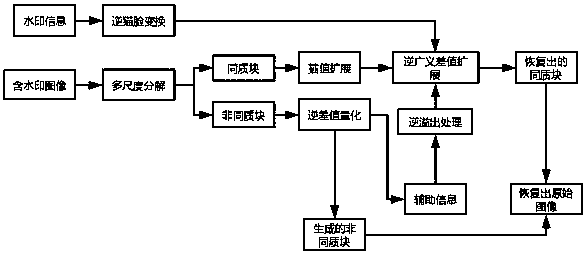

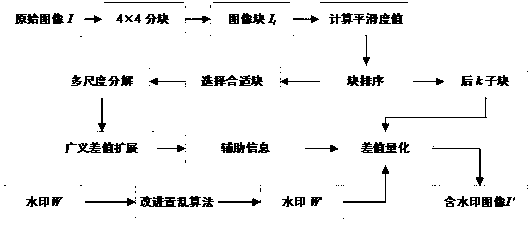

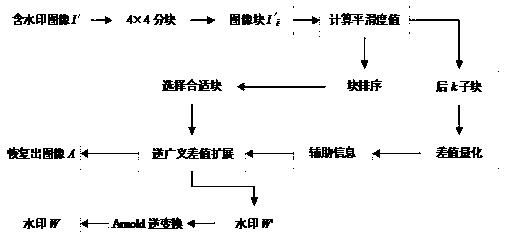

High-capacity reversible image watermarking algorithm with improved difference expansion

ActiveCN110490790ALarge capacityGuaranteed visual qualityImage data processing detailsImaging processingAlgorithm

The invention relates to image processing, the invention relates to the technical field of digital watermarking, and discloses a high-capacity reversible image watermarking algorithm with improved difference expansion. The algorithm comprises the steps of watermark embedding and watermark extraction, watermark embedding of an original image and watermark extraction of an image containing watermarks through cat face scrambling, a generalized difference expansion method, improved gray scale overflow processing and a difference quantification method. Compared with the prior art, the algorithm hasthe advantages that the pixel mean value before and after watermark embedding through a generalized difference expansion method is invariant, so that the smoothness value before and after watermark embedding is invariant, and watermark extraction is facilitated; an improved gray overflow processing method is used, on the premise that certain visual quality is guaranteed, watermark embedding can be conducted multiple times, and the watermark embedding capacity is increased; auxiliary information is embedded through a difference quantization algorithm, so that the method has relatively good imperceptibility and relatively high effective load capacity; and after the watermark is extracted, the original image can be completely recovered, the similarity between the extracted watermark and theoriginal watermark is extremely high, and the error is small.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

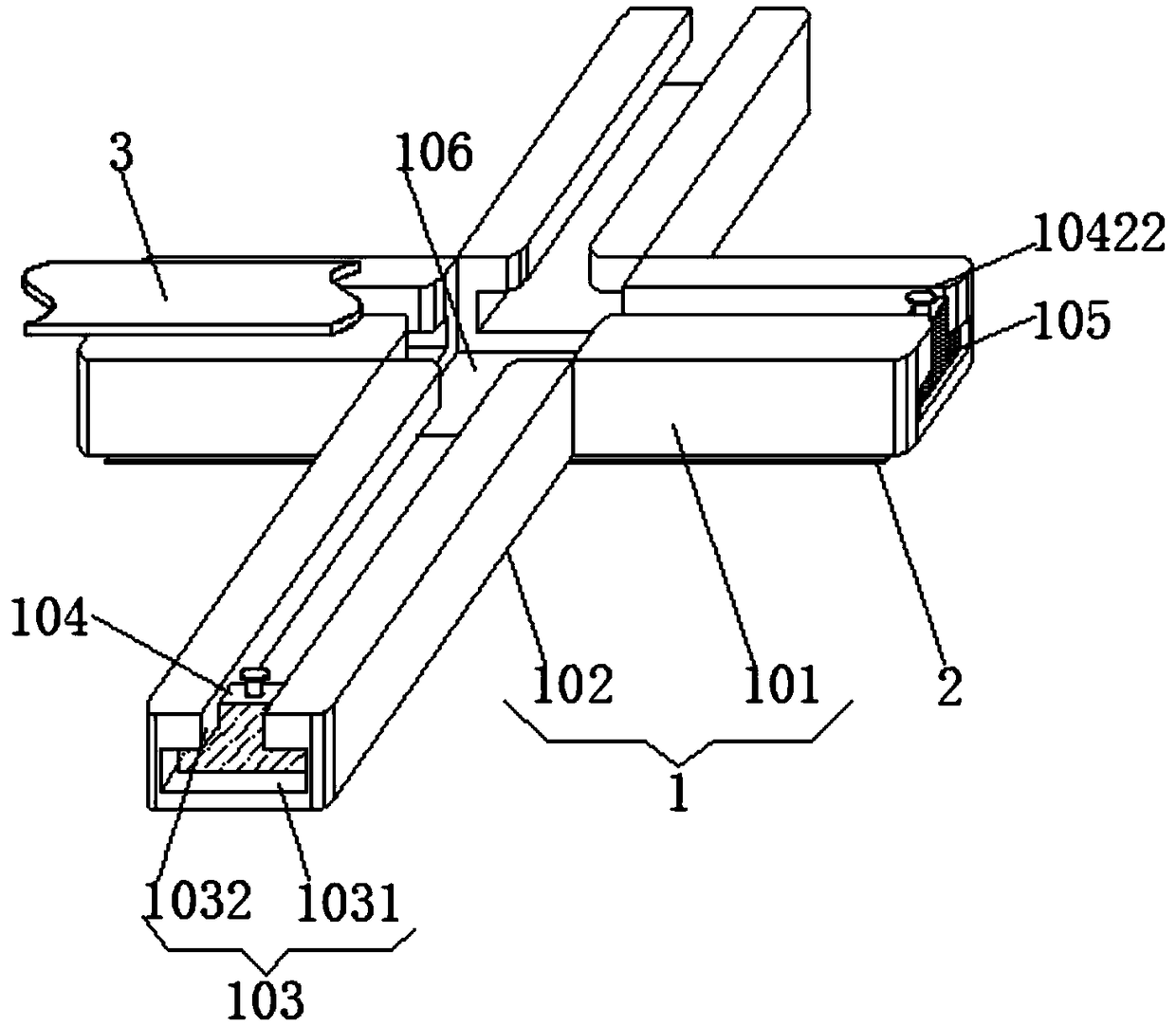

Wall column timber formwork joint seam anti-grout-leakage sealing device and method

InactiveCN107939045AGood stabilityPrevent grout leakage at seamsAuxillary members of forms/shuttering/falseworksStructural stabilityGrout

The invention relates to the field of building formwork joint seam anti-grout-leakage sealing, in particular to a wall column timber formwork joint seam anti-grout-leakage sealing device and method. The wall column timber formwork joint seam anti-grout-leakage sealing device is characterized in that the wall column timber formwork joint seam anti-grout-leakage sealing device comprises channel steel, a batten and a rubber strip; the rubber strip is of a T-shaped section structure, the length of a web of the rubber strip is equal to the thickness of a formwork, the web of the rubber strip is located in a formwork joint seam, and a flange of the rubber strip is located on the outer side of the formwork; and the batten is attached to the flange of the rubber strip, and the channel steel is located on the outer side of the formwork to be used for compressing the batten. According to the wall column timber formwork joint seam anti-grout-leakage sealing device, the structural stability is excellent, grout leakage at the position of the joint seam can be effectively prevented, the concrete appearance quality and the wall column shape are ensured, and the wall column timber formwork joint seam anti-grout-leakage sealing device has the advantages that the structure is simple, and construction is easy and rapid.

Owner:CHINA FIRST METALLURGICAL GROUP

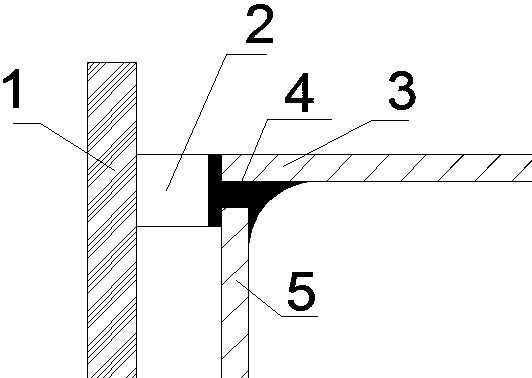

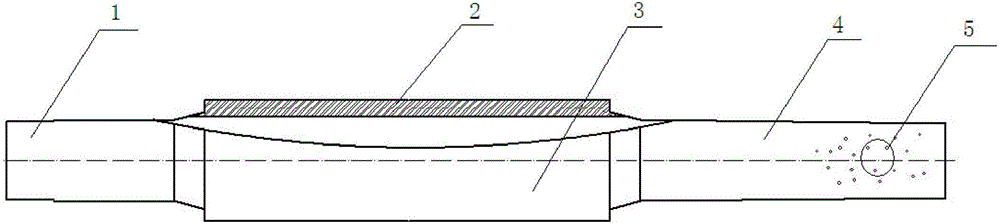

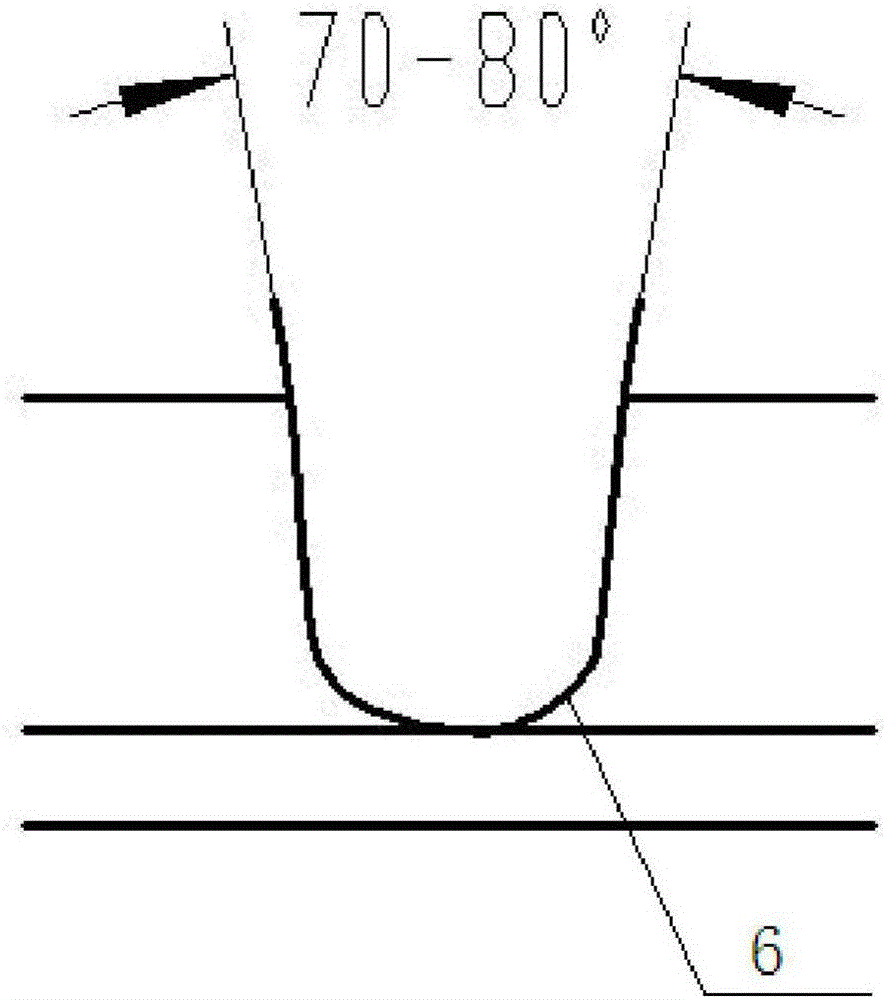

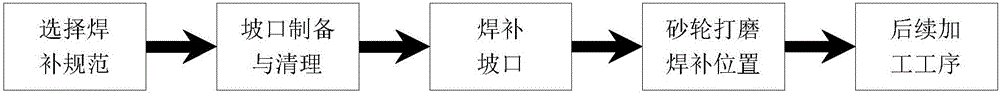

Welding repair method for surface defects of centrifugal composite roller

InactiveCN106270935AReduce surface defectsGuaranteed processing effectArc welding apparatusQuality levelAssisting procedures

Provided is a welding repair method for surface defects of a centrifugal composite roller. The method specifically comprises the following steps that (1) welding repair specifications are selected; (2) a groove is ground and cleaned; (3) welding repair is carried out on the groove; and (4) the welding repair positions are ground. Damaged portions of a workpiece are subjected to welding repair recovery through electric arc heating and welding rod melting. The specifications of short sections, the intermittent mode, dispersed welding and multi-layer and multi-pass welding are followed in the welding process. Compared with the prior art, the welding repair method has the beneficial effects that pores, slag inclusion, shrinkage and other defects of the centrifugal composite roller are repaired through a cold welding method. The method has the advantages that neither preheating before welding nor thermal treatment after welding is needed, the deformation of welded products is small, the welding operation is easy, the number of assisting procedures before welding is small, the labor intensity of welders is relieved, and the welding environment is improved. The method is suitable for welding repair and recovery of various positions, mechanical cutting is easily carried out after welding is completed, and the quality level of finished products is greatly improved.

Owner:ANSTEEL HEAVY MACHINERY CO LTD

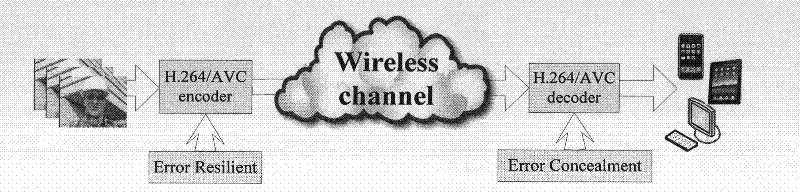

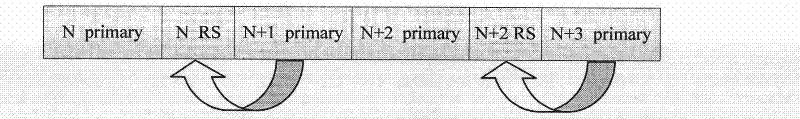

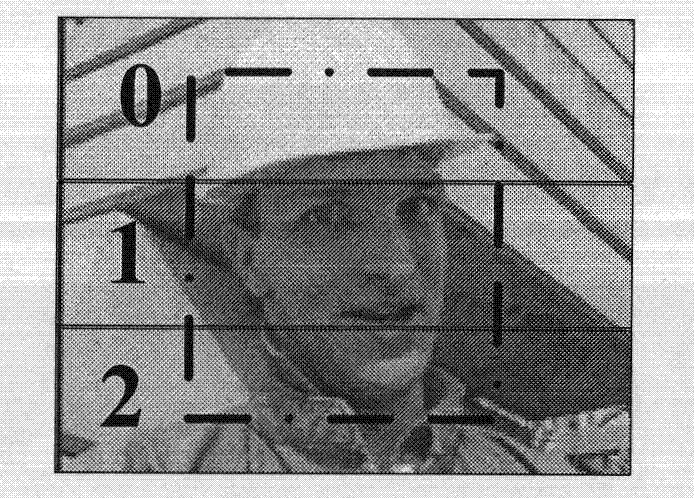

A Video Error Tolerant Coding Method Based on Reversible Information Hiding and Redundancy Technology

InactiveCN102300098AEasy to embedNo damageTelevision systemsDigital video signal modificationFault tolerancePacket loss

A video fault tolerance coding method based on reversible information hiding and a redundancy technology is disclosed. The method comprises two steps: coding terminal information embedding and decoding terminal information extraction. The step of the coding terminal information embedding is characterized in that: redundant slice is adaptively added to odd numbered frame of a video sequence and the RS is not added to even numbered frame; a motion vector of the even numbered frame in a key area is extracted and converted into a bit sequence; a scheme for easily expanding bilateral reversible information hiding is provided, a motion vector distribution function in the RS is calculated and information of the even numbered frame is embedded in the motion vector of the RS in a previous frame. The step of the decoding terminal information extraction is characterized by: extracting the embedded information according to an extraction algorithm of the decoding terminal and a distribution function characteristic of the RS motion vector and converting into the motion vector which can be used by error concealment; according to a network state, if a packet loss phenomenon happens to the odd numbered frame, starting using the RS; if motion vector loss happens to the even numbered frame, using the extracted motion vector information to carry out error concealment. In the invention, the video fault tolerance coding solution scheme with a gradable character, a large capacity and a low bit rate expansion is provided.

Owner:UNIV OF SCI & TECH OF CHINA

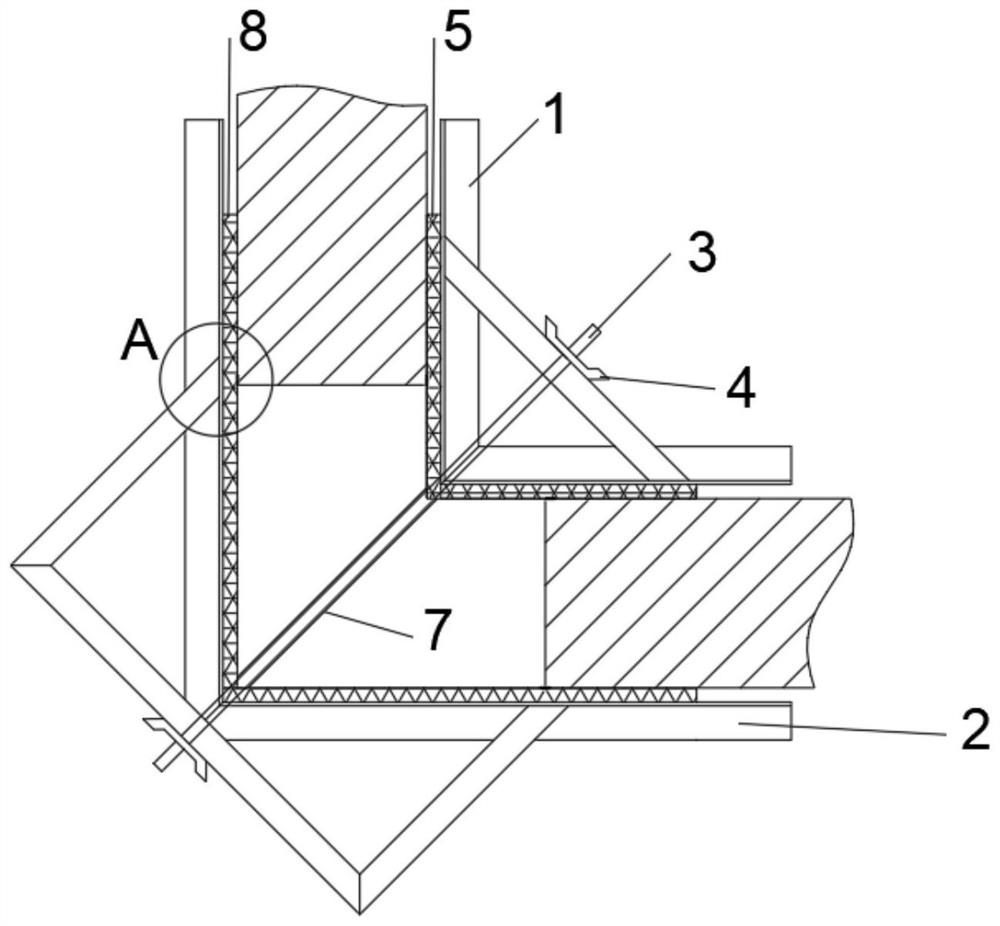

Brickwork corner constructional column formwork shaping and reinforcing device and construction method

PendingCN112796514AAvoid destructionGuaranteed visual qualityForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksArchitectural engineeringStructural engineering

The invention provides a brickwork corner constructional column formwork shaping and reinforcing device. The brickwork corner constructional column formwork shaping and reinforcing device comprises an external corner reinforcing part, an internal corner reinforcing part and a connecting part, wherein the connecting part is connected with the external corner reinforcing part and the internal corner reinforcing part; the external corner reinforcing part and the internal corner reinforcing part are arranged in parallel; the external corner reinforcing part comprises an external corner positioning part and an external corner supporting part; the two ends of the external corner supporting part are connected with the external corner positioning part; the external corner supporting part supports the external corner positioning part; the internal corner reinforcing part comprises an internal corner positioning part and an internal corner supporting part; the two ends of the internal corner supporting part are connected with the internal corner positioning part; and the internal corner supporting part supports the internal corner positioning part. The brickwork corner constructional column formwork shaping and reinforcing device has the beneficial effects that damage to brickwork is avoided, finished brickwork protection is facilitated, the appearance quality of the brickwork is guaranteed, and the maintenance workload of the brickwork is reduced; and main components are formed by welding angle steel and square steel and are made of leftover materials of a construction site, manufacturing is convenient, meanwhile, the brickwork corner constructional column formwork shaping and reinforcing device can be repeatedly used, and the construction cost is saved to a certain degree.

Owner:TIANJIN 20 CONSTR

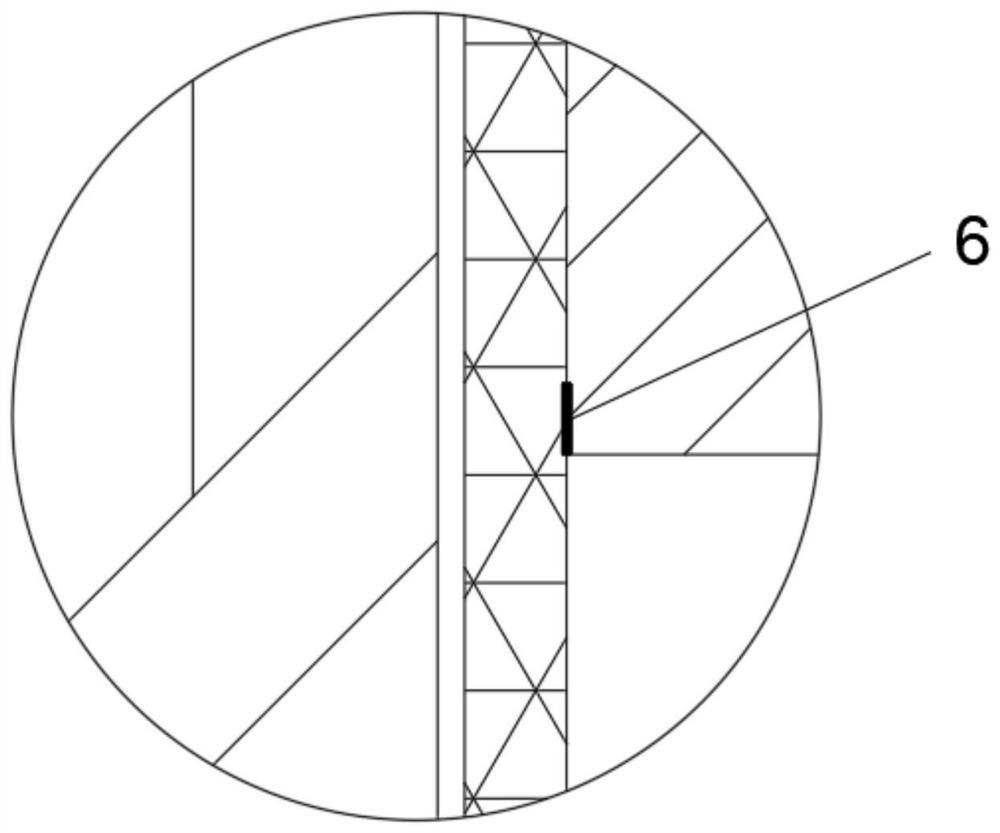

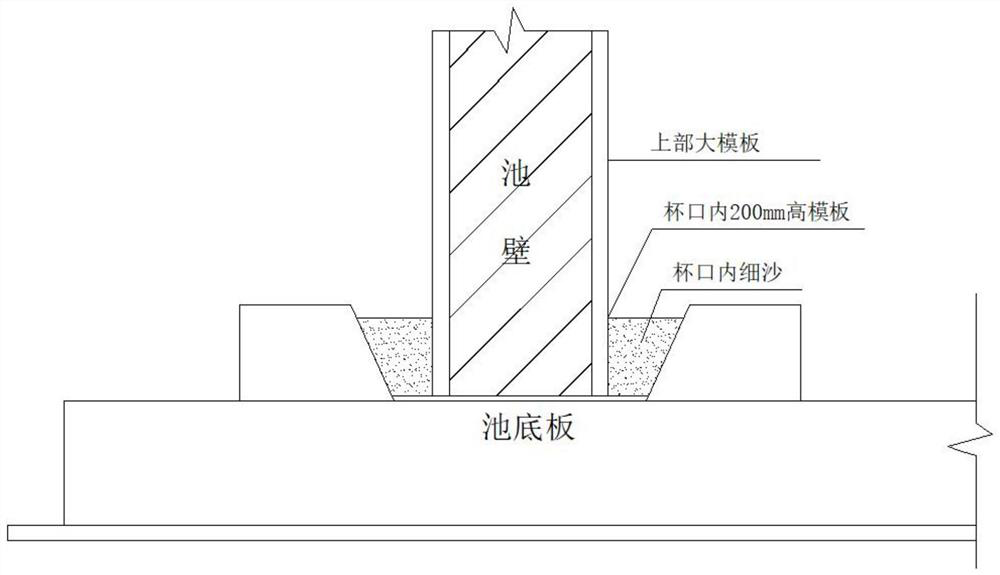

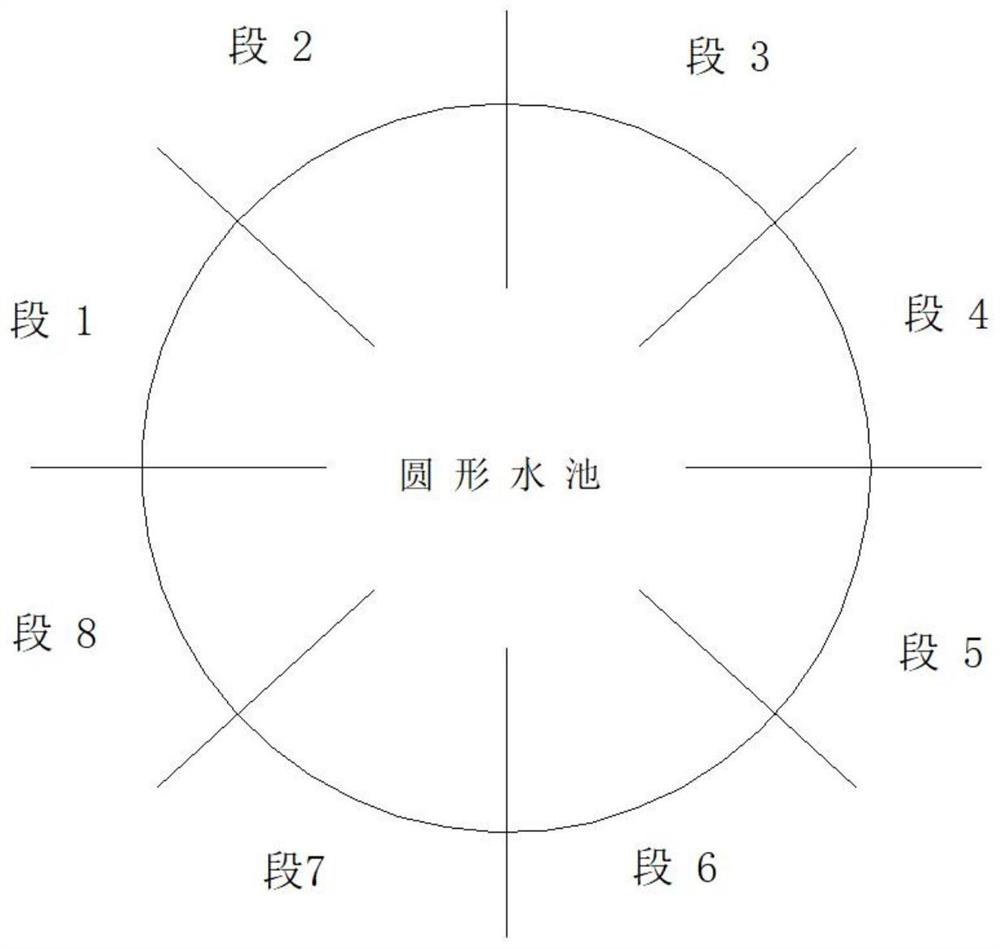

Construction method of unbonded prestressed large-diameter reinforced concrete thin-wall circular pool

ActiveCN112663774AGuaranteed visual qualityReduce deformation constraintsSewerage structuresBuilding material handlingReinforced concretePre stress

The invention discloses a construction method of an unbonded prestressed large-diameter reinforced concrete thin-wall circular pool. The construction method sequentially comprises the following steps that surveying and setting out are conducted on a construction site according to the design requirements of the pool; earth excavation is conducted according to surveying and setting out; a foundation cushion layer of the pool is constructed; pool bottom plate steel bars are bound, and formworks are erected; pool bottom plate concrete is poured; the formworks are erected on the pool wall, and steel bars of the pool wall are bound; unbonded prestressed steel bars of the pool wall are laid and bound; pool wall concrete is poured and maintained; the unbonded prestressed steel bars of the pool wall are tensioned in a prestressed mode; the anchoring ends of the unbonded prestressed steel bars of the pool wall are blocked; waterproof sealing treatment is conducted on a cup opening of a bottom plate of the pool; and a full water test is conducted on the pool. According to the construction method, during construction of the circular pool, the wall thickness of the pool can be effectively decreased on the premise that the circular pool meets the design and use functions, the construction cost of the pool is reduced, and meanwhile the construction difficulty is lowered.

Owner:CHINA RAILWAY NO 8 ENG GRP CO LTD

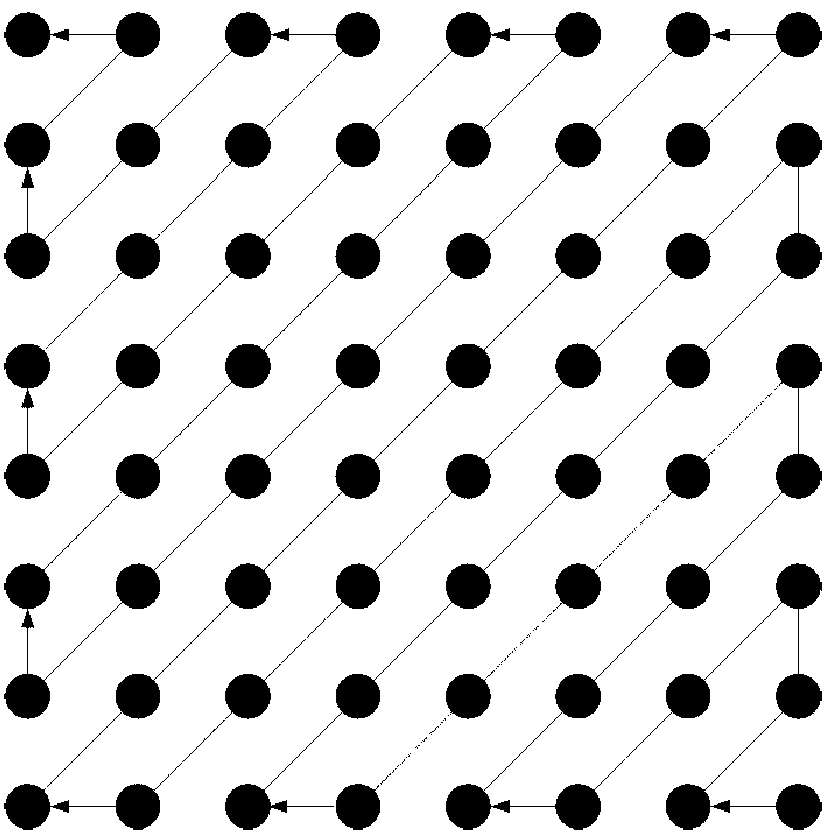

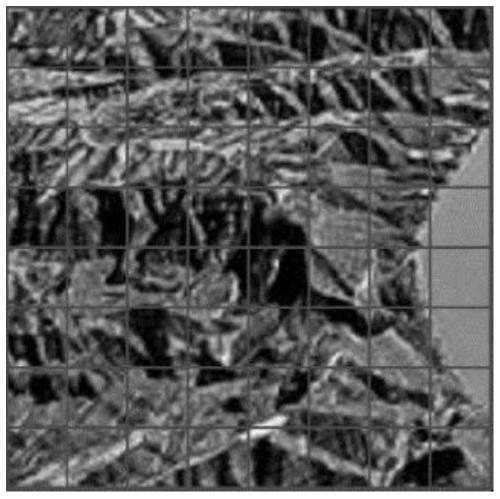

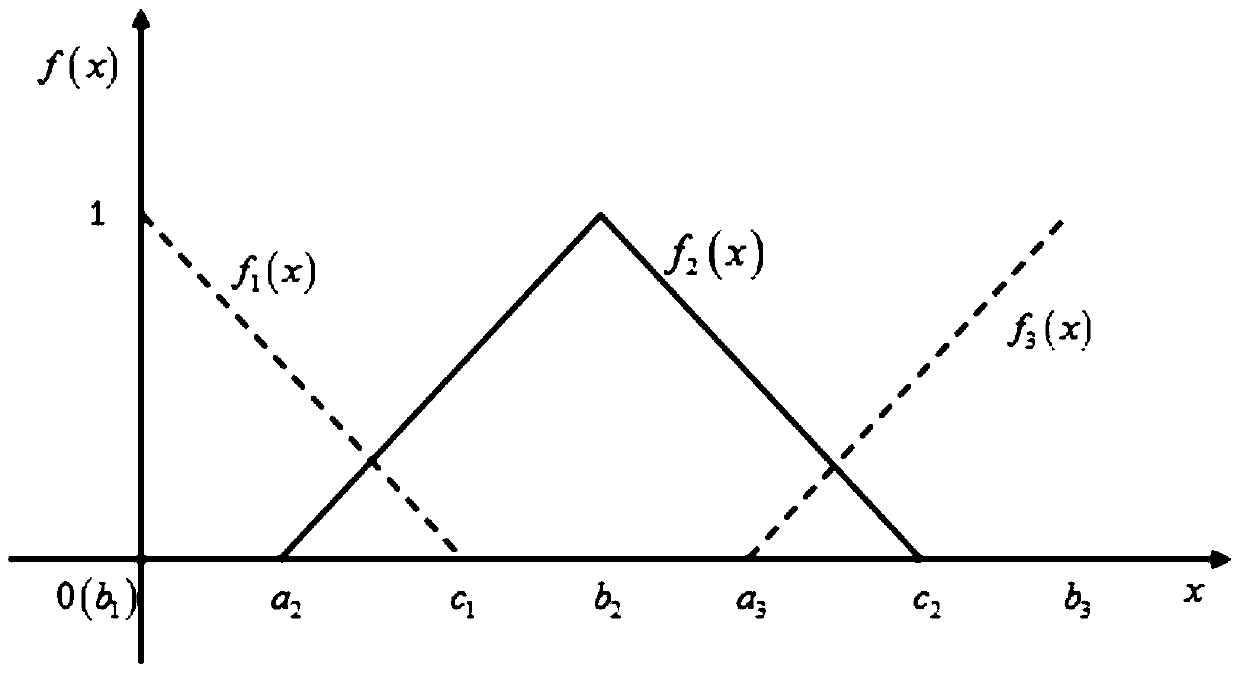

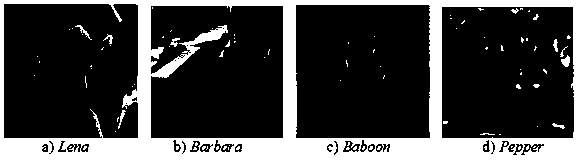

EMD (n, m, [Delta]) adaptive image secret writing method based on complexity

ActiveCN109194846AIncrease embedding capacityGood embedding capacityPictoral communicationPattern recognitionUltimate tensile strength

The present invention provides an EMD (n, m, [Delta]) adaptive image secret writing method based on complexity. The method comprises the steps of: determining the maximum of the [Delta] according to carriers PSNR and SSIM and a control threshold value, and calculating block complexity according to the carrier blocking block intensity, the block contrast, block positions, blocks edge and block textures and determining regulation amount of the blocks; and finally, organizing a carrier secret-embedded information table and adaptively embedding 2-bit secret bits from high to low according to the EMD (n, m, [Delta]) and the complexity. In order to improve the safety, a carrier block Hash value and a user secret key are introduced to dynamically generate block secret-embedded parameters n and mand scramble a secret-embedded regulation table. Compared to the current method, the method provided by the invention performs embedding maximization of the secret information while maintaining the high visual quality and the structure similarity, the embedding process is tightly bound with the user secret key and the carrier block Hash value, and a secret-containing carrier has a high visual quality through embedding of the complexity from high to low and enhances the safety.

Owner:SHAANXI NORMAL UNIV

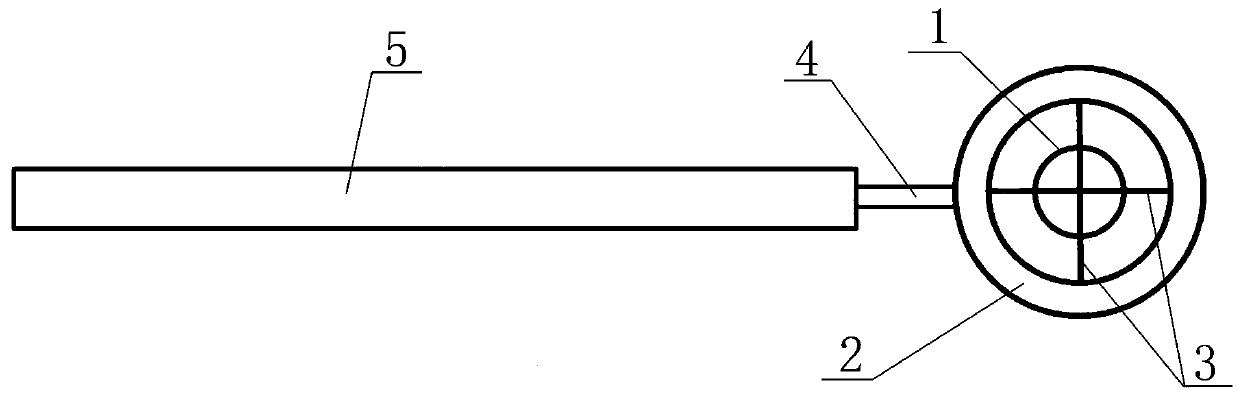

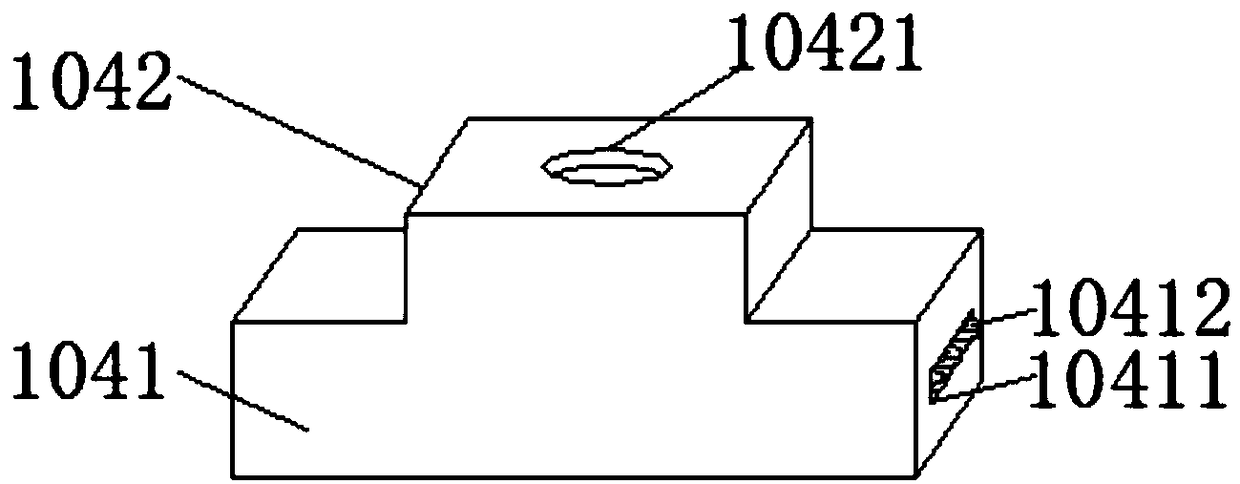

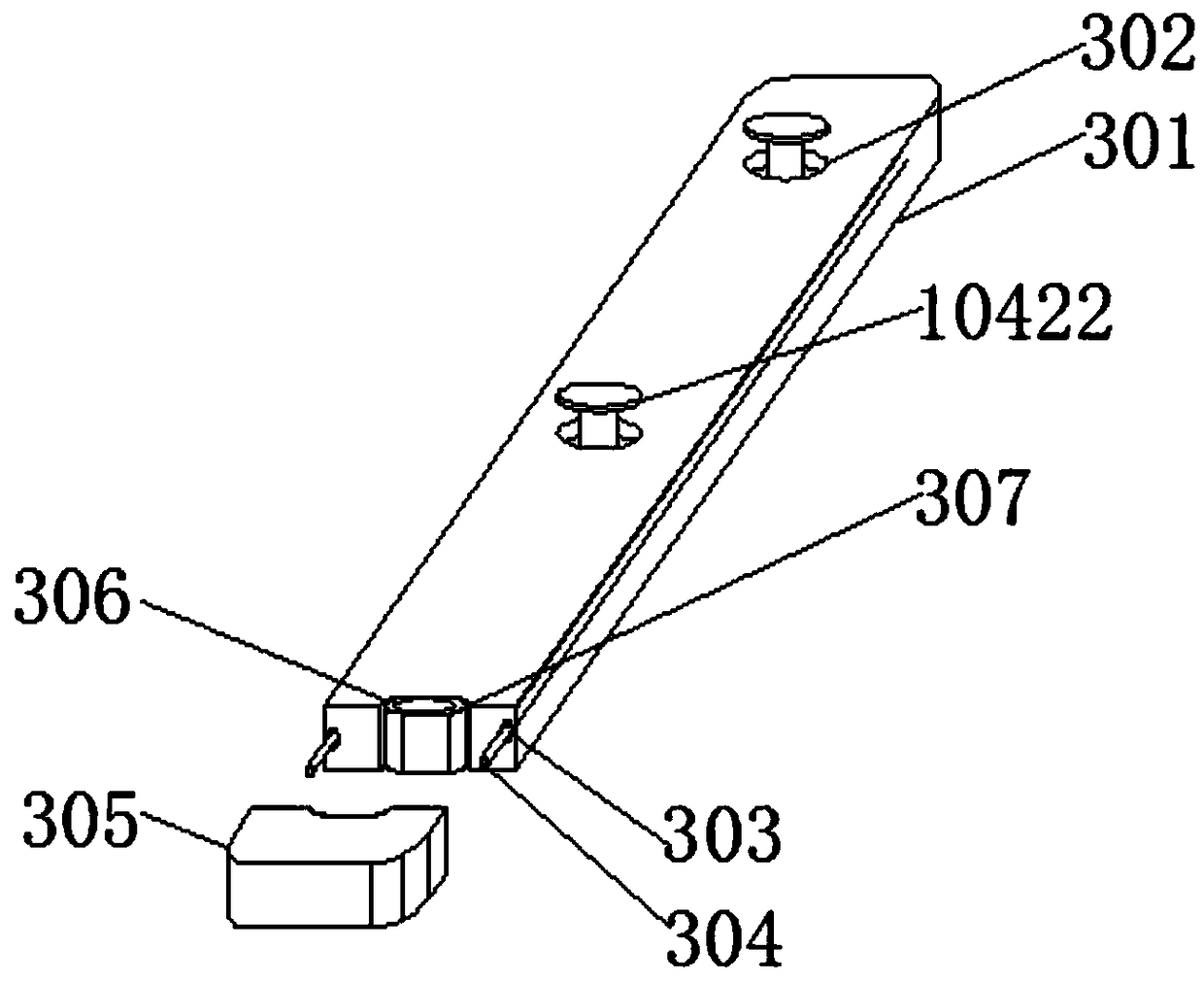

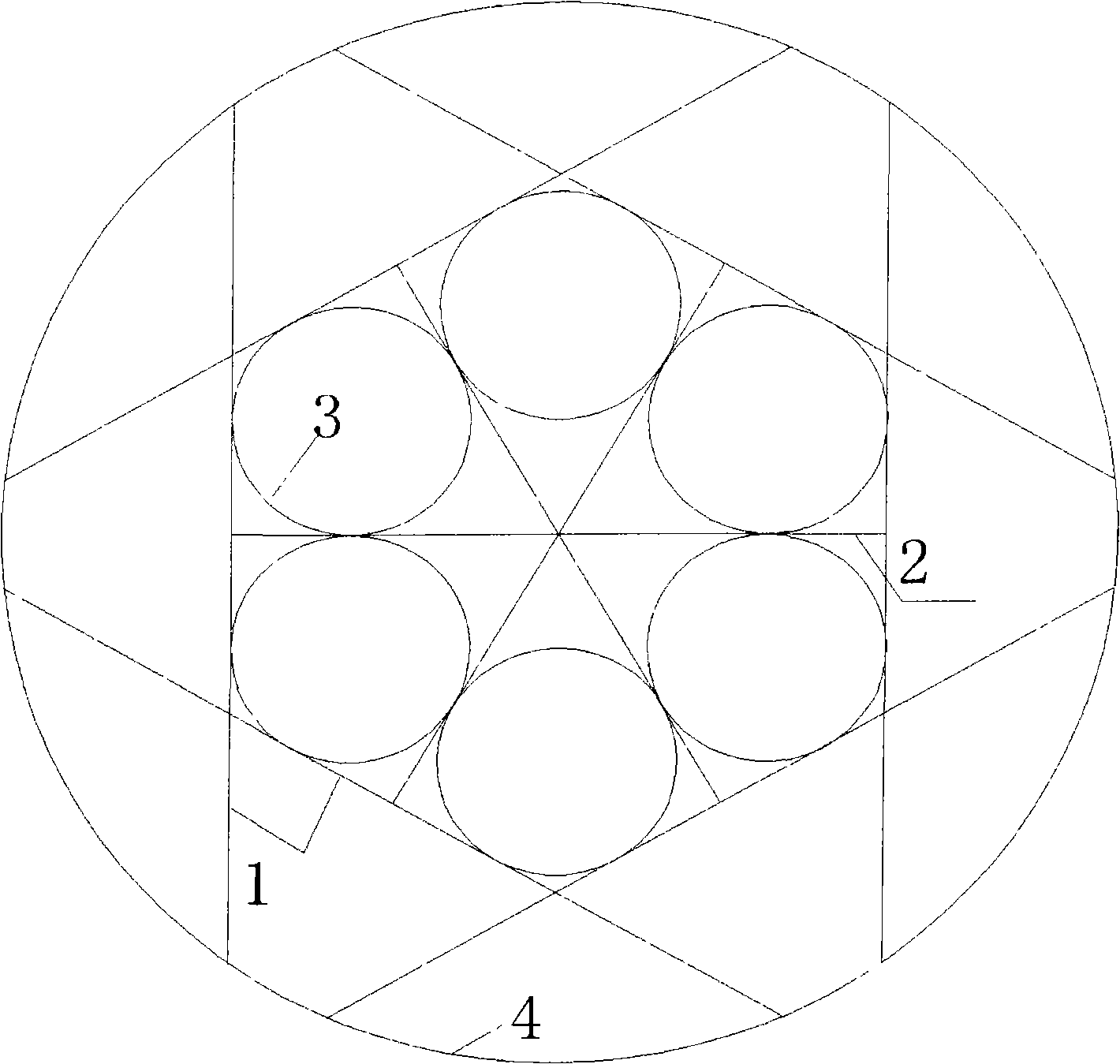

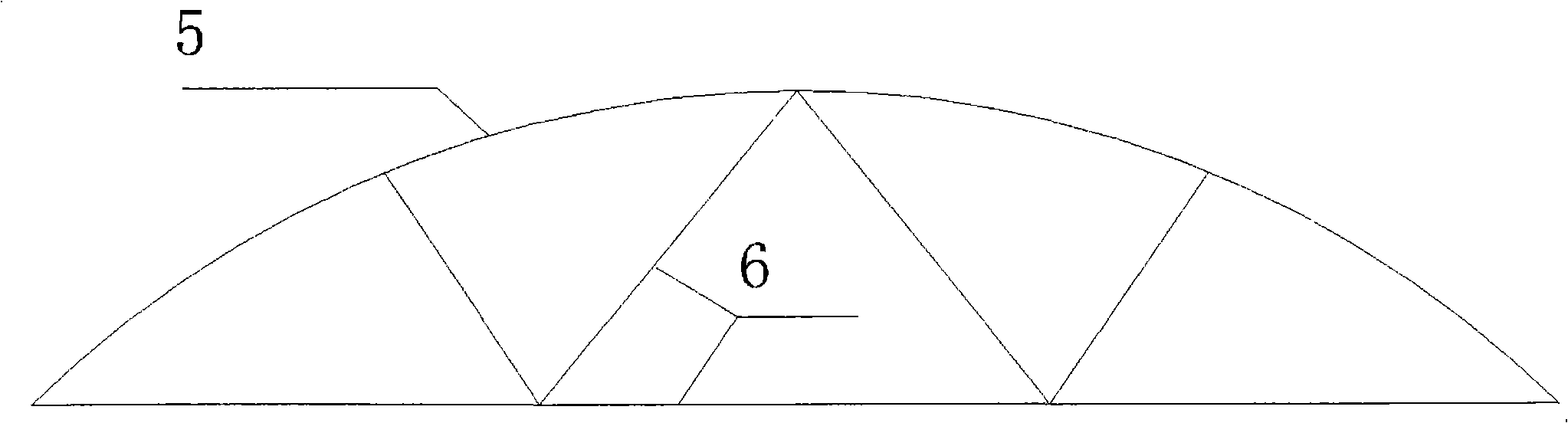

Capsule tearing assisting device for centrally positioning capsule bag

PendingCN109528390AImprove visual qualityPrevention of dementiaEye surgeryAnatomical structuresBiomedical engineering

The invention discloses a capsule tearing assisting device for centrally positioning a capsule bag. The device comprises a cornea imprint ring (1) which is connected to a dial disc (2) through connecting rods (3), the cornea imprint ring (1) is concentric to the dial disc (2), and 360 degree scales are marked on the dial disc (2). Length based on mm is marked on the connecting rods (3). The dial disc (2) is connected to a bent transitional handle (4) (the angle is about 145 degrees). The transitional handle (4) is connected to a handle (5). The two connecting rods (3) are crossed, and the crosspoint of the connecting rods is the center of circle of the cornea imprint ring (1). By adopting a design concept that the dial disc and the cornea imprint ring are combined, the central position ofthe capsule bag of a patient can be positioned precisely according to the actual eye anatomical structure of the patient. CCC guide is carried out by using the cornea imprint ring, and the central property of the capsule bag of CCC is achieved finally, so that the operative accuracy and the postoperative effect are improved.

Owner:邓明辉 +2

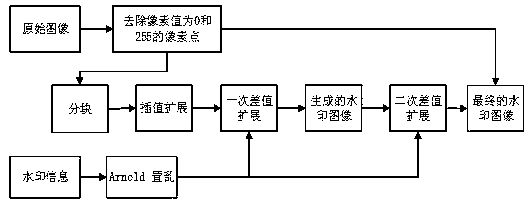

Reversible image watermarking algorithm combining quadratic difference expansion and interpolation expansion

ActiveCN111199506ANo need to worry about occupying effective spaceIncrease embedding capacityImage data processing detailsImaging processingAlgorithm

The invention relates to the technical field of image processing, and discloses a reversible image watermarking algorithm combining quadratic difference expansion and interpolation expansion, which comprises two parts of watermarking embedding and watermarking extraction; watermarking embedding: removing a pixel point with a pixel value of 0 or 255, and combining interpolation expansion and quadratic generalized difference expansion to carry out watermarking embedding on an image; and watermark extraction: removing pixel points with pixel values of 0 or 255, and performing watermark extractionon the image by combining interpolation expansion and secondary inverse generalized difference expansion. Compared with the prior art, watermark embedding is completed by utilizing secondary generalized difference expansion and interpolation expansion algorithms, the trouble that an overflow positioning graph occupies effective space does not need to be considered, the embedding capacity is improved, the overall performance is high, the invisibility is good, the visual quality is relatively high, and complete recovery of an original image can be realized.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

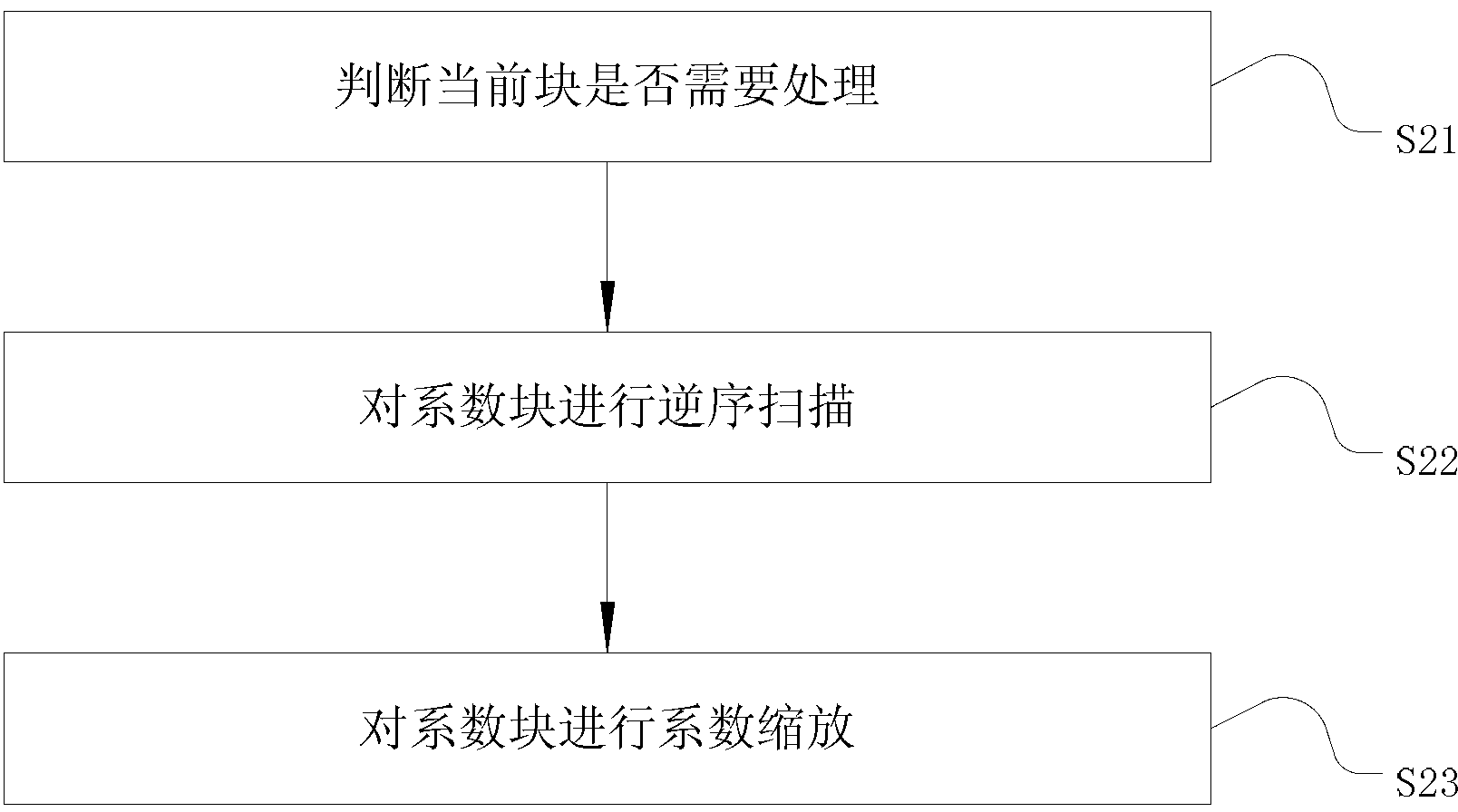

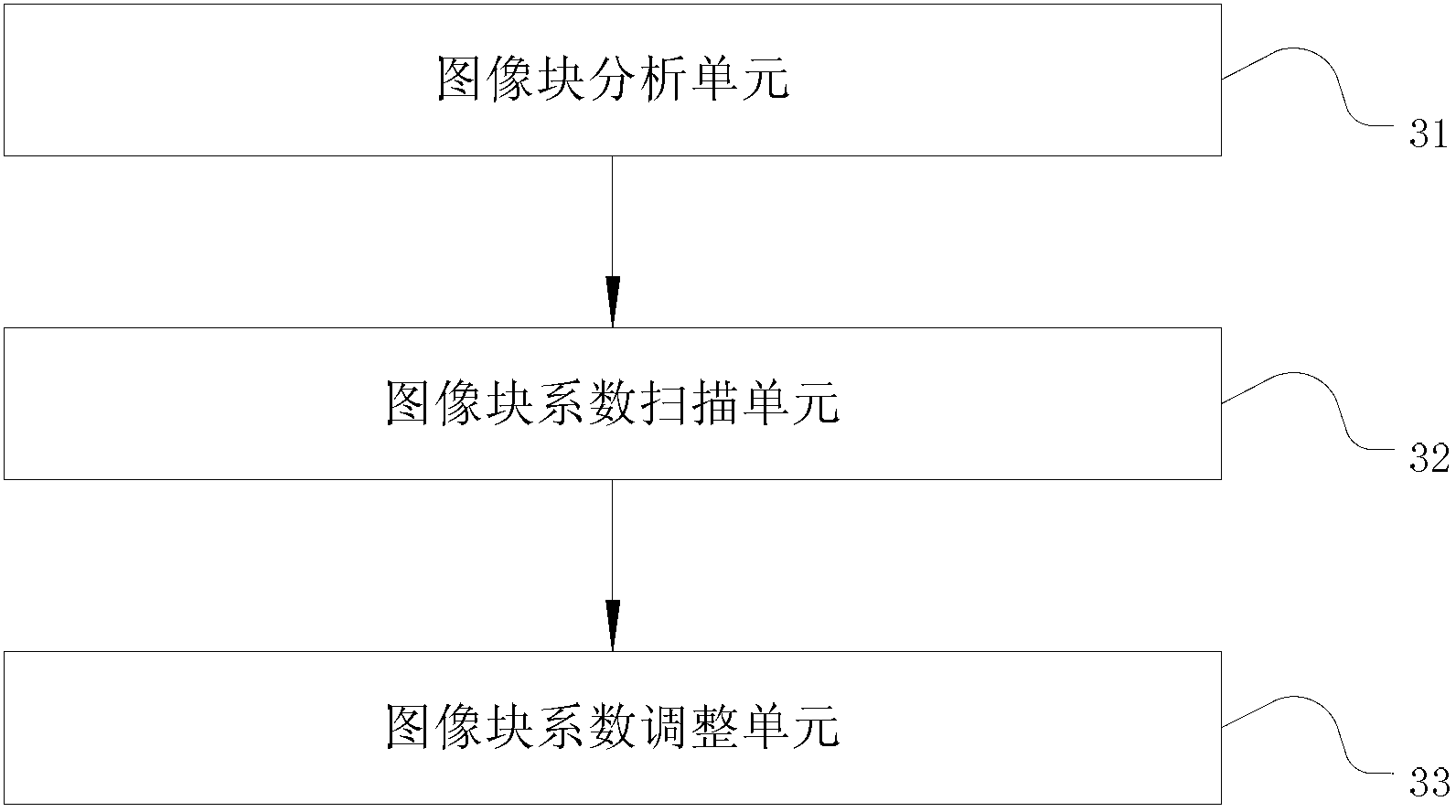

Method and device for adaptively adjusting coefficients of image blocks

InactiveCN103297779AReduce bit rateGuaranteed visual qualityTelevision systemsCoding blockComputer architecture

The invention discloses a method and a device for coding images. The method includes dividing an image into code blocks and processing the code blocks; selecting processing techniques for the code blocks according to characteristics of coding coefficients of the image; scanning coding coefficients in reversed order; adaptively contracting brightness and chromaticity coefficients according to the selected processing techniques. The method and the device have the advantages that a reasonable process for contracting the coefficients is designed, so that values of high-frequency coefficients can be reduced without affecting the subjective visual quality, the coding rate is reduced, and the coding efficiency is improved.

Owner:PEKING UNIV

Method for manufacturing secondary post-cast ring beam

InactiveCN101736858AEliminate rigid constraintsPrevent cracking and quality problemsLoad-supporting elementsSurface layerEngineering

The invention relates to a method for manufacturing a secondary post-cast ring beam for a house filled wall of an elevated duplex building, a hidden duplex building or a building with high floor height. The method comprises the following steps: embedding a U-shaped anchorage rib at one end of a connection component into a main body wall / column, wrapping a joist steel at the other end with a flexible asphalt felt, arranging a flexible polyphenyl board at the end part of the joist steel, binding reinforcement frame upright ribs and reinforcement stirrups at the periphery of the connection component, then inserting the connection component into a ring beam reinforcement framework, filling the flexible polyphenyl board between the two ends of the molded ring beam and the main body wall / column after a support die is cast with concrete, and filling the flexible polyphenyl board or a horizontal sliding layer of the flexible asphalt felt between the lower port of the ring beam and the filled wall. The two ends of the secondary post-cast ring beam manufactured by the method are flexibly connected, and the lower port and the filled wall can freely deform and slide so as to prevent common cracking faults of the filled wall and the painted decorative surface layer and the like, ensure the impression quality of the wall and reduce the rectification cost of the engineering.

Owner:JIANGSU SHUANGLOU CONSTR GRP

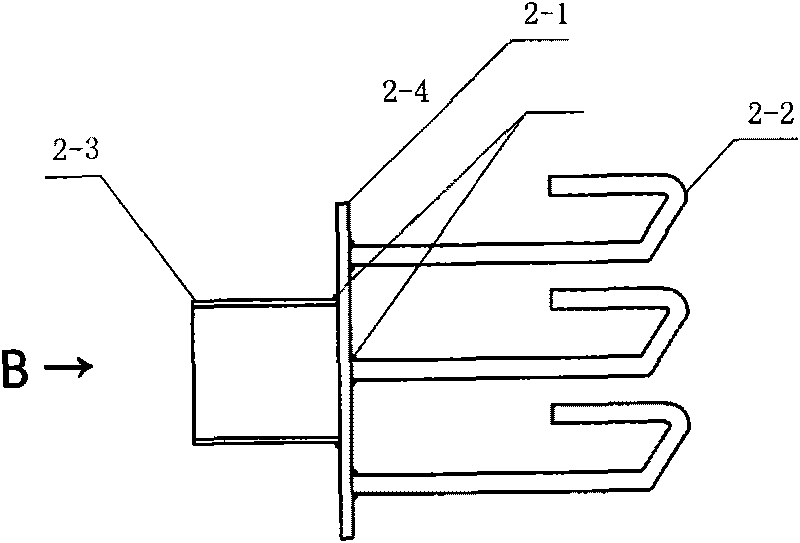

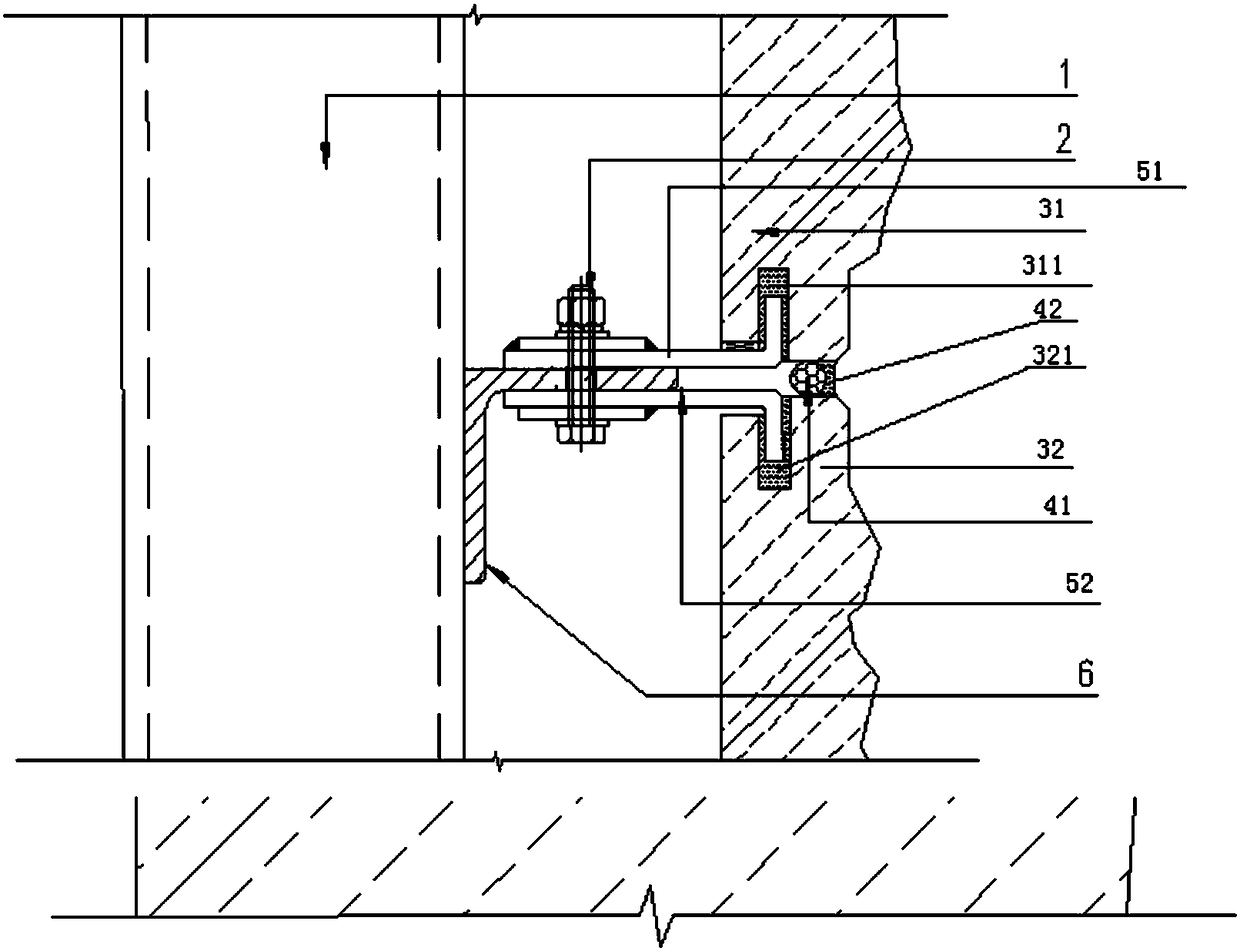

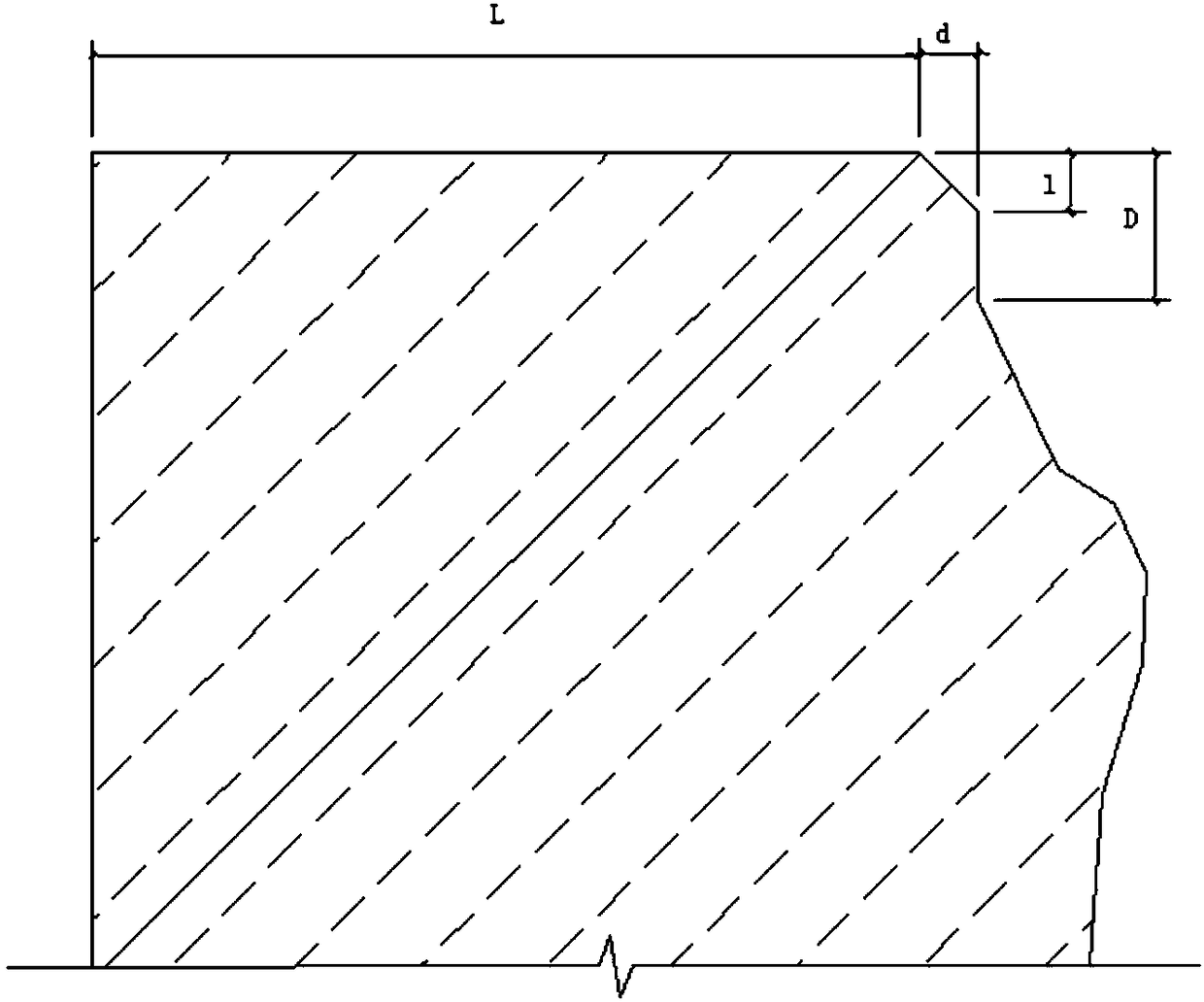

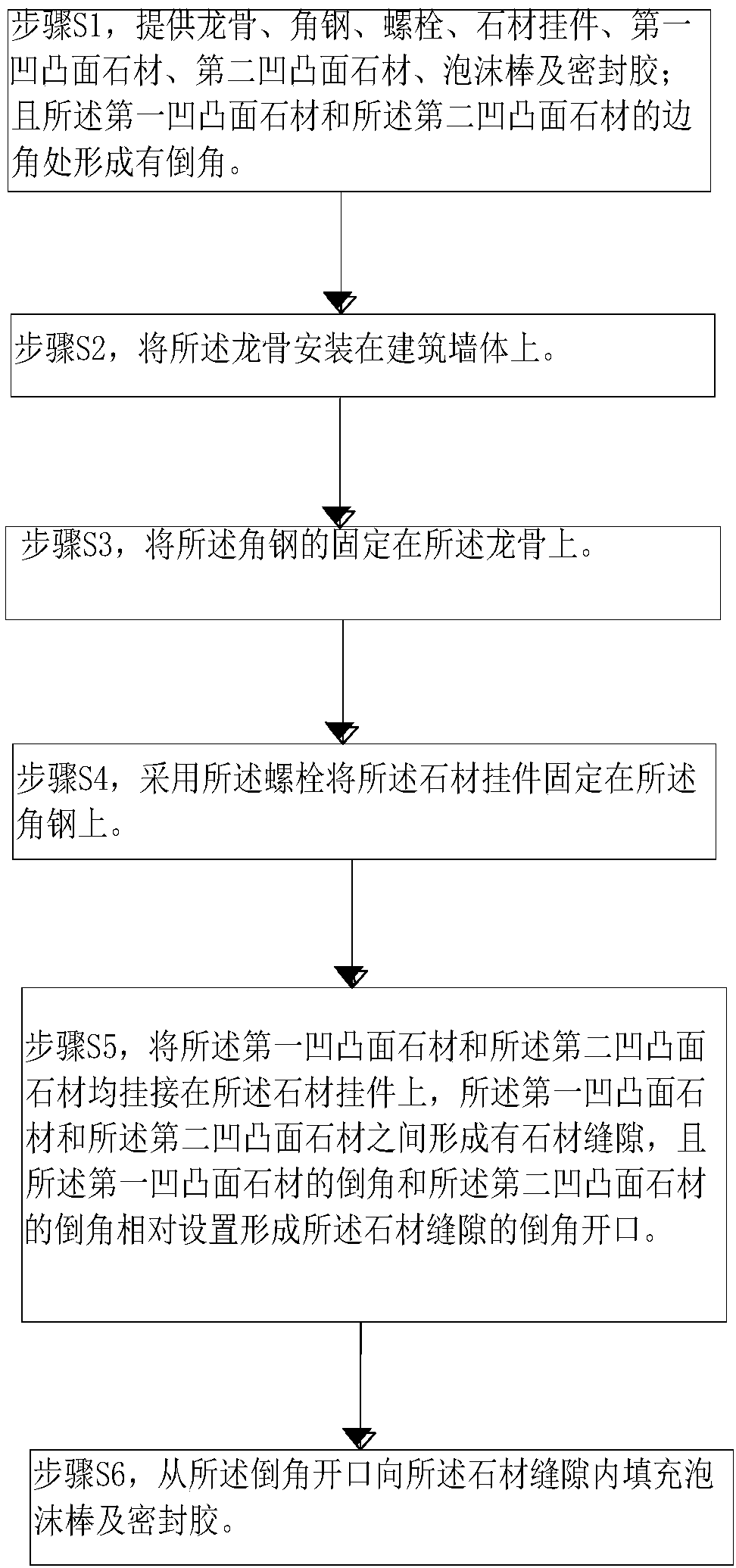

Male and female face dry hanging stone curtain wall and construction method thereof

The invention relates to the technical field of building construction, in particular to a male and female face dry hanging stone curtain wall and a construction method thereof. Male and female face stones, angle iron, bolts, stone hanging pieces, foaming rods, silicone weather-proof sealing glue are utilized to conduct combination arrangement, the attractive and practical efficacies of the male and female face dry hanging stone curtain wall are achieved, chamfers are formed at the corners of the first male and female face stone material and the second male and female face stone correspondinglyby arranging the first male and female face stone material and the second male and female face stone material so that a stone seam can be more easily filled with the foaming rods and the sealing glue, accordingly the appearance quality of the stone joint seam is ensured, and the compactness of filling of the stone seam is ensured.

Owner:MCC5 GROUP CORP SHANGHAI

Roof parapet waterproof seal embedding method

InactiveCN111350315AGuaranteed look and feelImprove the protective effectRoof covering insulationsStructural waterArchitectural engineering

The invention discloses a roof parapet waterproof seal embedding method and relates to the technical field of roof waterproof construction. The roof parapet waterproof seal embedding method involves aconcrete structure, cement mortar, a finished product embedded piece, a waterproof roll, waterproof factice, fixing screws and parapet reinforcing steel bars. The finished product embedded piece is made of 3 mm flat iron. Screw holes are arranged in the middle of the finished product embedded piece at the equal interval of 30 cm. By the adoption of the roof parapet waterproof seal embedding method, installation is easy and convenient, operation is easy; after installation, the thickness of a parapet reinforcing steel bar protective layer can be guaranteed, and the reinforcing steel bars cannot be damaged like a traditional grooving manner; a cement mortar surface layer can be formed in a one-off manner, the construction quality and the appearance quality of the roof parapet waterproof seal are effectively guaranteed, and work time can be saved; and a series of expense spent on treatment conducted when the parapet waterproof seal is damaged is avoided.

Owner:CHINA MCC17 GRP

Auxiliary drawing tool used for elliptical teaching

InactiveCN109203793AImprove teaching speedGuaranteed visual qualityNon-circular curve drawing instrumentsEngineering

Owner:吴继帅

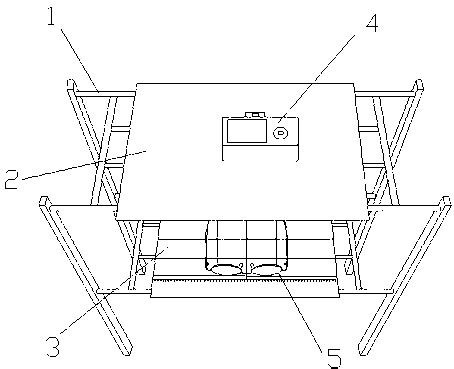

Spectacle frame wearing deformation displacement measuring device and measuring method thereof

ActiveCN103322935AEnsure objectivityEnsure normal refractive developmentUsing optical meansCamera lensFrame size

The invention relates to a spectacle frame wearing deformation displacement measuring device which is formed by a fixing support, a camera fixing plate, a spectacle frame size measuring plate and a high resolution digital camera. The fixing support comprises at least two layers of horizontal fixing support bodies, the camera fixing plate is fixed on the upper layer fixing support body, the spectacle frame size measuring plate is fixed on the lower layer fixing support body, a camera lens clamping hole for placing a camera lens is arranged in the center of the camera fixing plate, and scales are marked on the spectacle frame size measuring plate. The spectacle frame wearing deformation displacement measuring device has the advantages that an optical method is used for measuring, the whole shooting process is finished by a machine, the final results are measured and analyzed through engineering drawing software, the objectivity of the whole measurement is greatly guaranteed, shortcomings of the traditional manual measuring method are overcome, obtaining of dynamic comparison parameters relative to spectacle frame stability are facilitated, spectacle frame deformation displacement situations caused by various reasons after a user wears a pair of spectacles can be corrected in time, the spectacle wearing visual quality and normal refraction development of eyes can be guaranteed, and the spectacle frame wearing deformation displacement measuring device is worth popularizing and applying.

Owner:JINSHAN HOSPITAL FUDAN UNIV

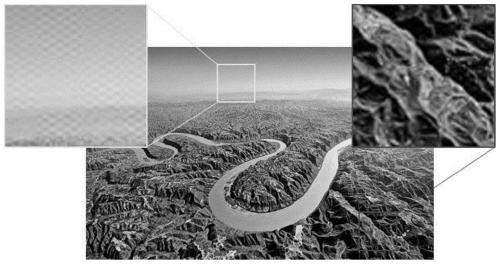

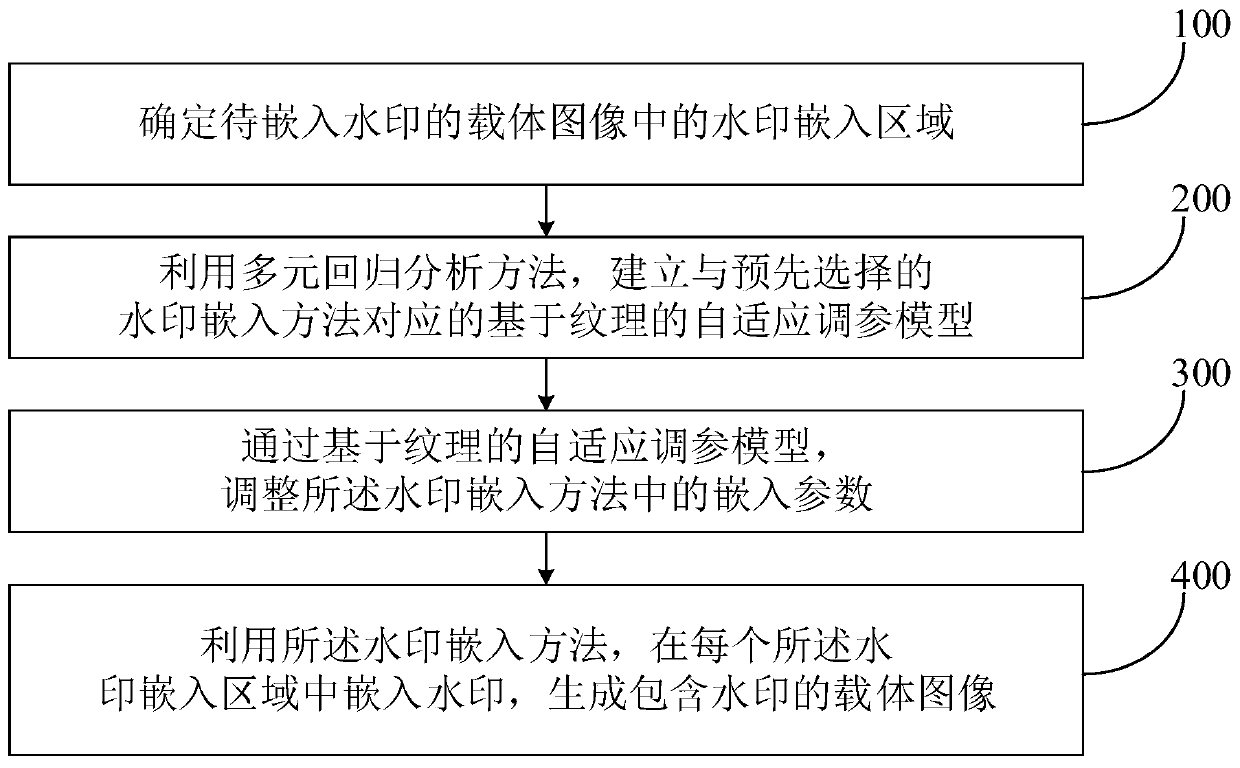

Adaptive image watermark embedding method and system and extraction method and system

InactiveCN111062853AGuaranteed correctnessGuaranteed visual qualityImage watermarkingPattern recognitionComputer vision

The invention relates to a texture-based adaptive image watermark embedding method, a texture-based adaptive image watermark embedding system, a texture-based adaptive image watermark extracting method and a texture-based adaptive image watermark extracting system. The adaptive image watermark embedding method comprises the following steps: determining a watermark embedding area in a carrier imageinto which a watermark is to be embedded, the watermark embedding area being a plurality of non-overlapping texture rough areas; utilizing a multiple regression analysis method to establish a texture-based adaptive parameter adjustment model for adjusting embedding parameters in the watermark embedding method; and embedding a watermark into each watermark embedding region by using the watermark embedding method. According to the invention, the richness of image textures can be truly measured; accurately positioning a texture rough area in the image; through multiple regression analysis, a function relationship between a watermark embedding parameter and a global texture value and a local texture value of a texture rough region is established, and the watermark embedding parameter is adaptively adjusted according to the texture value of the region, so that the invisibility of the watermark is ensured to the greatest extent, and the robustness of the watermark is enhanced.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI +1

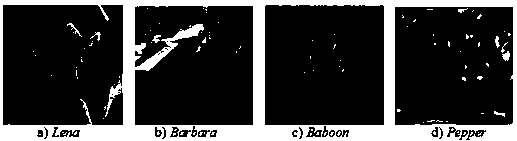

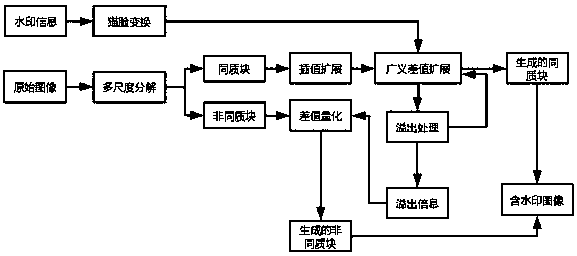

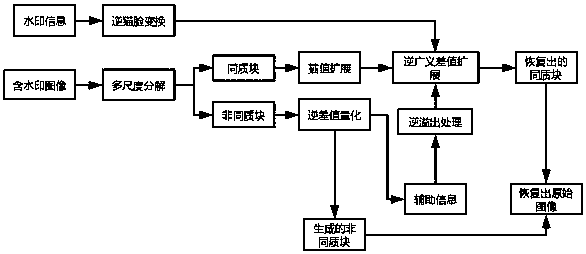

High-capacity reversible image watermarking algorithm based on multi-scale decomposition and interpolation expansion

ActiveCN110738592AImprove homogeneityIncrease embedded valueImage data processing detailsMultiscale decompositionImaging processing

The invention relates to the technical field of image processing, and discloses a high-capacity reversible image watermarking algorithm based on a multi-scale decomposition and interpolation algorithm, which comprises a watermark embedding part and a watermark extracting part, and is characterized in that the watermark embedding capacity is further increased through multi-scale decomposition and interpolation expansion before watermark embedding; watermark information is embedded through a generalized interpolation expansion method, pixel value overflow of overflowing corresponding image pixelpoints is avoided through gray scale overflow processing, then the embedding capacity is further increased, and watermark extraction is an inverse process of watermark embedding. Compared with the prior art, the method has the advantages that when equivalent watermark information is embedded, good watermark-containing image visual quality is kept, and better invisibility and payload capacity areachieved.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Construction method for hoisting double rows of tank top beams synchronously

ActiveCN104775625AEasy installation and constructionOvercoming the defect of difficulty in positioningBuilding material handlingCable stayedPiston

The invention discloses a construction method for hoisting double rows of tank top beams synchronously. The method comprises the following steps of setting up a tank top rack on a gas tank piston plate, welding two baffles at the upper part of a cross beam of the tank top rack, hoisting two bent tank top beams into the gas tank and making them arranged on the tank top rack; welding vertical angle steels and cable-stayed angle steels between two tank top beams; hoisting two tank top beams synchronously and welding the two tank top beams in place. The construction method for hoisting double rows of the tank top beams synchronously provided by the invention solves many problems in the prior art, and the advantages are as follows: double rows of the tank top beams can be supported synchronously, thus the disadvantages in the prior that the measuring is difficult when installing the tank top beam and the installation personnel in place is difficult can be overcome, and the defect in the prior art that the tank top beam is easily skewed in the installation process can be successfully avoided; besides, tedious labor due to the fact that in the existing single-tank top beam installation manner that double rows of the tank top beams need to be repaired again due to the inconsistent intervals between the installed double rows of the tank top beams can also be avoided, thus the construction time is saved, the construction efficiency is improved and the appearance quality of the overall project is also guaranteed.

Owner:TIANJIN 20 CONSTR

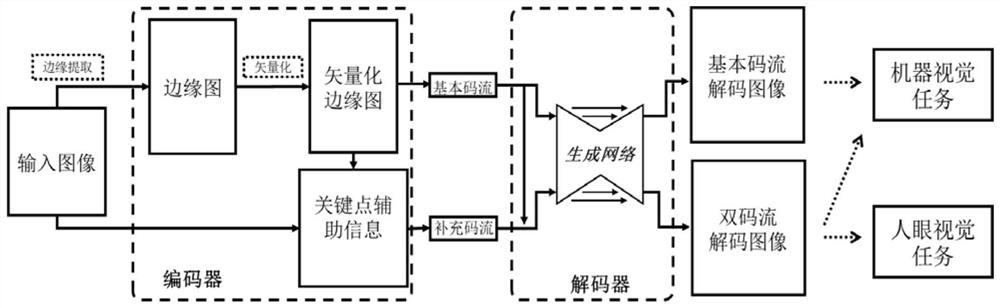

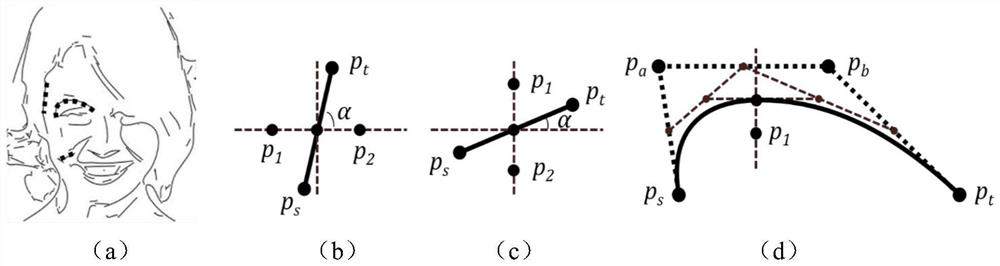

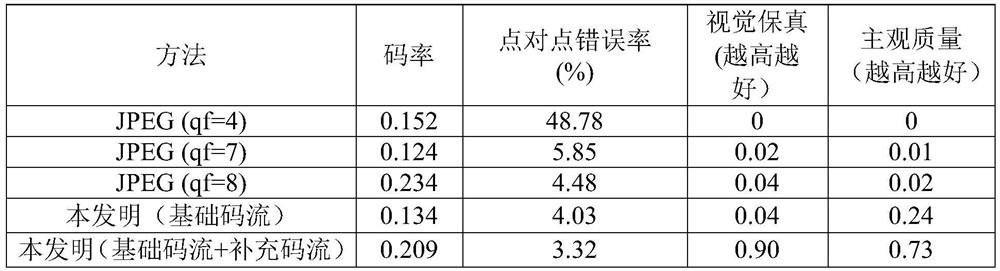

Extensible man-machine cooperation image coding method and coding system

ActiveCN113132755AGuaranteed Visual QualityGuaranteed performanceDigital video signal modificationSelective content distributionSample imageEntropy encoding

The invention discloses an extensible man-machine cooperation image coding method and coding system. The method comprises the following steps: extracting an edge graph of each sample picture and vectorizing the edge graph as a compact representation for driving a machine vision task; performing key point extraction in the vectorized edge image to serve as auxiliary information; respectively carrying out entropy coding lossless compression on the compact representation and the auxiliary information to obtain two paths of code streams; carrying out preliminary decoding on the two paths of code streams to obtain an edge graph and auxiliary information; inputting the edge graph obtained by decoding and auxiliary information into a generative neural network, and performing forward calculation of the network; carrying out loss function calculation according to the obtained calculation result and the corresponding original picture, and carrying out back propagation on the calculated loss to a neural network to carry out network weight updating until the neural network converges, so as to obtain a double-path code stream decoder; obtaining an edge image and auxiliary information of a to-be-processed image, and encoding and compressing the edge image and the auxiliary information to obtain two paths of code streams; and enabling the two-path code stream decoder to decode the received code stream and reconstructs an image.

Owner:PEKING UNIV

Supportless construction method for cast-in-place floor of high-rise steel structure house

The invention relates to the field of template construction, in particular to a supportless construction method for a cast-in-place floor of a high-rise steel structure house. The supportless construction method for the cast-in-place floor of the high-rise steel structure house comprises the steps that a load on a supportless template is calculated according to the condition of an actual high-rise steel structure, and steel tubes and support rods are selected; multiple steel tubes are fixed between a pair of steel beams which are arranged in parallel through locking devices. Each steel tube and a pair of steel beams are vertically arranged. The locking devices are a pair of locking devices. The pair of locking devices clamp one ends of the steel tubes in the middle and limit one ends of the steel tubes in installing spaces of the steel beams. Multiple support rods are fixed above the multiple steel tubes. Two ends of each support rod are fixed in the installing space that a pair of steel beams and the other pair of steel beams are vertically arranged. A bottom die template is arranged above the multiple support rods and is fixed with two pairs of steel beams simultaneously. The supportless construction method for the cast-in-place floor of the high-rise steel structure house has the advantages that the construction period is shortened, safety hazards caused by template collapse due to instability of a scaffold are eradiated completely, at the same time, the construction cost is saved, and the construction quality is guaranteed.

Owner:DAYUAN CONSTR GRP

Large outer wall dry hanging stone flatness and perpendicularity control technology

The invention discloses a large outer wall dry hanging stone flatness and perpendicularly control technology and relates to the technical field of decoration. The large outer wall dry hanging stone flatness and perpendicularly control technology includes the following steps that S1, a horizontal line is popped up on an outer wall beam column according to the stone height; and S2, 10*200*300 galvanized iron sheets are machined in a batched manner, iron sheet horizontal perpendicular center lines are popped up on the 10*200*300 galvanized iron sheets, and four 30*100 rectangular symmetric holesare machined according to each horizontal perpendicular center line. By means of the large outer wall dry hanging stone flatness and perpendicularly control technology, the perpendicularity and the flatness of an outer wall stone dry hanging keel are enhanced, the deformation and distortion phenomenon of the dry hanging stone wall face is reduced, the construction quality of a porous brick fillingwall dry hanging stone wall face is ensured, and therefore the building decoration dry hanging stone system engineering quality and appearance quality are ensured, simpleness and practicability are achieved, construction is convenient, work hours can be saved, one-time accurate adjustment is achieved, the construction cost is reduced, and the effect is obvious.

Owner:CHINA MCC17 GRP

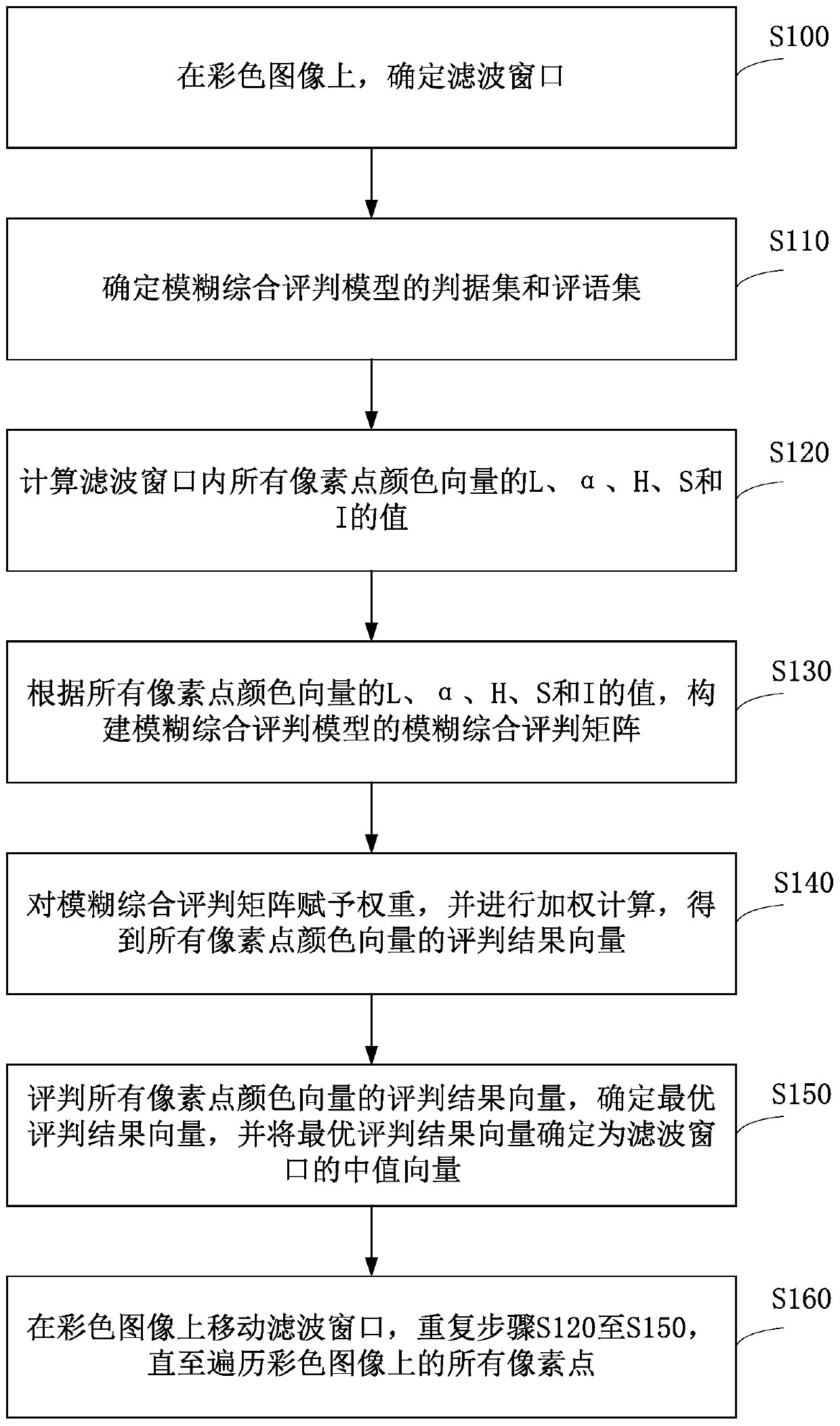

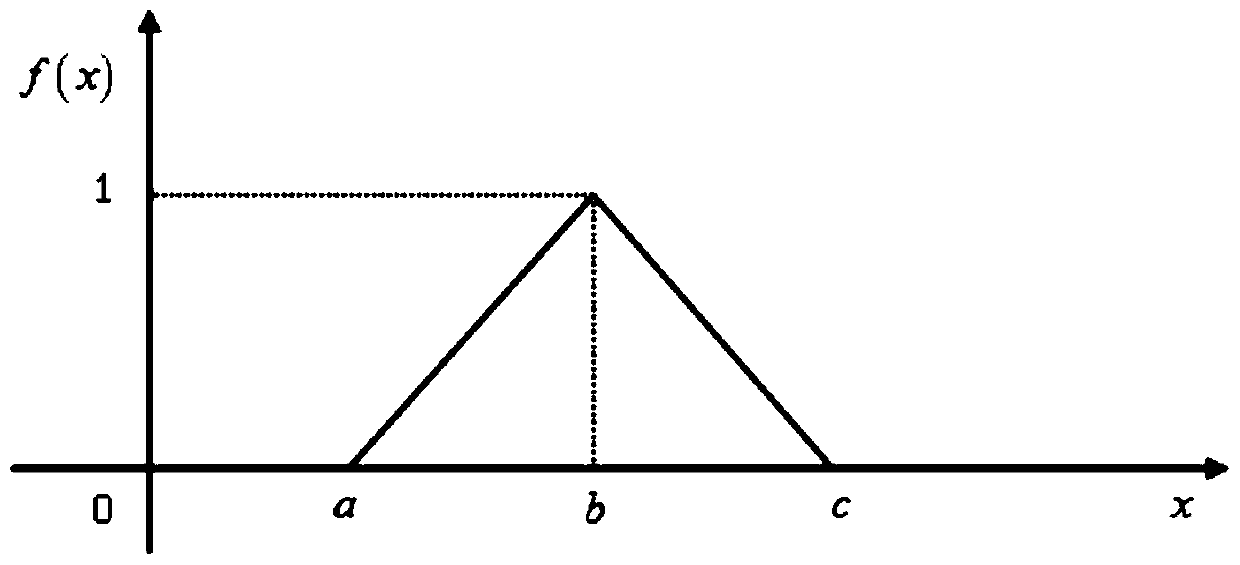

Fuzzy comprehensive evaluation-based color image median filtering method and system

ActiveCN105701779AGuaranteed visual qualityGuaranteed qualityImage enhancementPattern recognitionColor image

The present invention discloses a fuzzy comprehensive evaluation-based color image median filtering method and system, wherein the method comprises the steps of determining a criterion set and a comment set, wherein the criterion set comprises the die lengths L of color vectors, an angle alpha between the color vectors, the chroma H, the saturability S and the intensity I, and the comment set comprises moderation, small deviation and large deviation; calculating the L, alpha, H, S and I values of all pixel point color vectors; constructing a fuzzy comprehensive evaluation matrix of a fuzzy comprehensive evaluation model according to the calculated values; weighting the fuzzy comprehensive evaluation matrix, and carrying out the weighting calculation to obtain the evaluation result vectors of all pixel point color vectors; then determining an optimal evaluation result vector; and finally moving a filtering window on a color image, repeating the above steps until all pixel points in the color image are traversed. By the embodiment of the present invention, the technical problems that how the original image color information and the noise information can be distinguished clearly, and how the salt-and-pepper noise pollution can be filtered strictly, are solved.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

Large-capacity reversible image watermarking algorithm based on multi-scale decomposition and interpolation expansion

ActiveCN110738592BImprove homogeneityIncrease embedded valueImage data processing detailsPattern recognitionMultiscale decomposition

The invention relates to the technical field of image processing, and discloses a large-capacity reversible image watermarking algorithm based on multi-scale decomposition and interpolation algorithm, including two parts: watermark embedding and watermark extraction, and the watermark is further enlarged by multi-scale decomposition and interpolation expansion The capacity of watermark embedding; the watermark information is embedded by the generalized difference extension method, and the overflow corresponding image pixels do not produce pixel value overflow through the grayscale overflow processing, and the embedded capacity is further increased, and the watermark is extracted as the watermark embedded reverse process. Compared with the prior art, the present invention maintains good visual quality of the watermarked image when embedding the same amount of watermark information, and has better invisibility and payload capacity.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

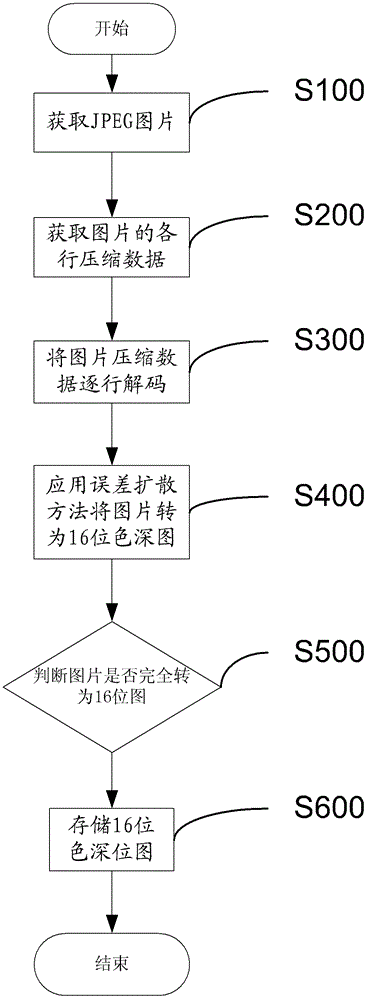

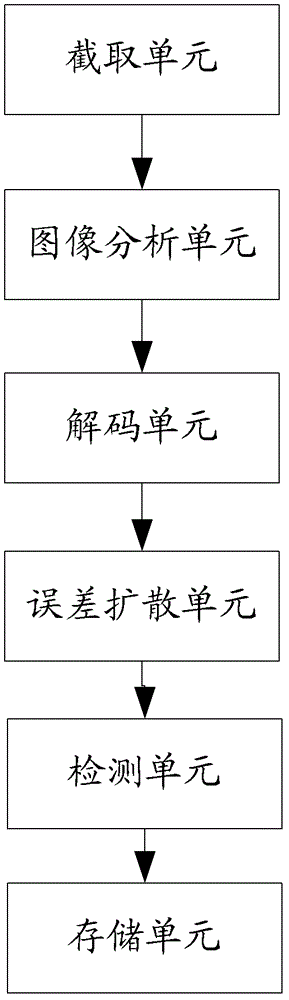

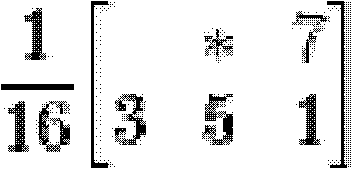

JPEG (Joint Photographic Experts Group) image processing method and system

ActiveCN102547058BReduce occupancyGuaranteed visual qualityPictoral communicationInternal memoryImaging processing

Owner:FUJIAN STAR NET EVIDEO INFORMATION SYST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![EMD (n, m, [Delta]) adaptive image secret writing method based on complexity EMD (n, m, [Delta]) adaptive image secret writing method based on complexity](https://images-eureka.patsnap.com/patent_img/069e348d-8965-4b0b-92b0-da9800942a31/HDA0001821802080000011.png)

![EMD (n, m, [Delta]) adaptive image secret writing method based on complexity EMD (n, m, [Delta]) adaptive image secret writing method based on complexity](https://images-eureka.patsnap.com/patent_img/069e348d-8965-4b0b-92b0-da9800942a31/HDA0001821802080000021.png)

![EMD (n, m, [Delta]) adaptive image secret writing method based on complexity EMD (n, m, [Delta]) adaptive image secret writing method based on complexity](https://images-eureka.patsnap.com/patent_img/069e348d-8965-4b0b-92b0-da9800942a31/HDA0001821802080000031.png)