Welding repair method for surface defects of centrifugal composite roller

A centrifugal composite, roller shaft technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of easy occurrence of pores, slag inclusion, shrinkage, affecting the quality of product appearance, and can not guarantee the shaft strength, etc., to achieve improvement. Welder labor intensity and environment, small product deformation, and the effect of improving the quality of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

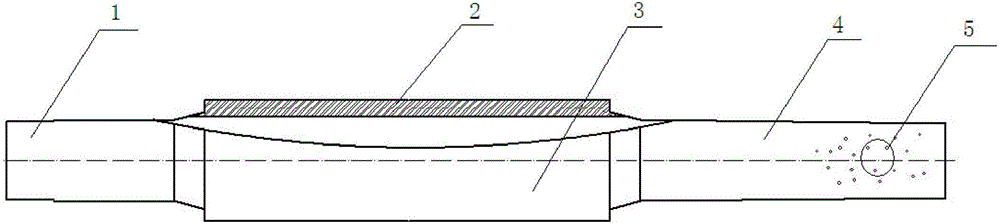

[0019] Embodiments of the present invention are further described below in conjunction with the accompanying drawings:

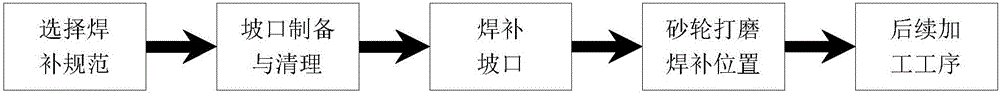

[0020] A welding repair method for surface defects of a centrifugal composite roll shaft, the specific method is as follows:

[0021] 1) Welding repair specification: use small-diameter Z308 nickel-based cast iron electrode, the welding repair current adopts DC reverse connection, that is, the workpiece is connected to the negative electrode, and the welding current is I=(29~34)×d, 2mm<d<5mm.

[0022] In the formula: I—indicates the welding current; d—indicates the diameter of the electrode.

[0023] Small diameter Z308 nickel-based cast iron electrode, the welding core contains high nickel content, and the coating contains graphite. At room temperature, the weld metal with austenite structure can be obtained, with high tensile strength and good crack resistance.

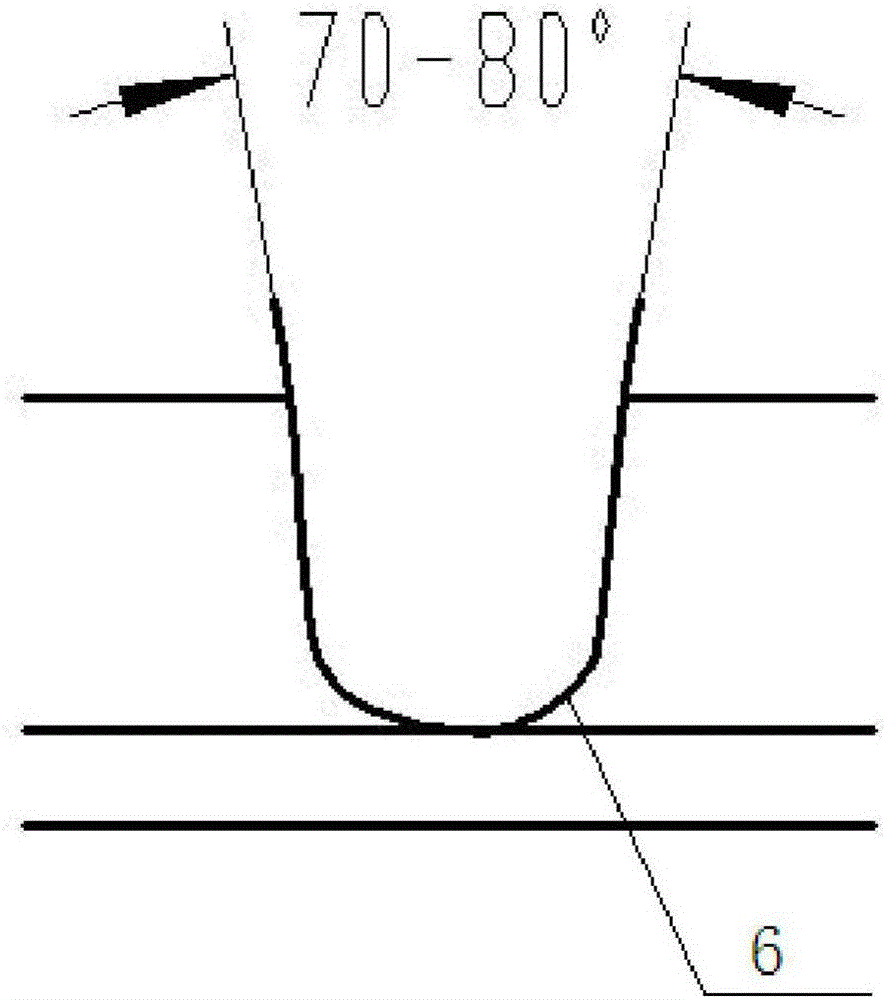

[0024] 2) Grinding the groove: Grind the groove on the defect of the roll shaft. The groove i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com