Epoxy resin coating in marine steel pipe 3PE anticorrosive coating and preparation method thereof

A technology of epoxy resin coating and anti-corrosion coating, which is applied in the field of coatings, can solve the problems of reducing the service life and safety of submarine steel pipes, and cannot prevent the immersion of small molecule corrosive media, so as to increase the impact resistance of seawater and improve physical and mechanical properties , the effect of reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The epoxy resin coating 30g in a kind of submarine steel pipe 3PE anticorrosion coating provided by the present invention, described epoxy resin anticorrosion coating is made up of following components by mass percentage:

[0033] Epoxy 60%

[0034] Pigments and fillers 29%

[0035] Auxiliary 11%.

[0036] The epoxy resin is composed of 40% (12g) of E-12 epoxy resin and 20% (6g) of novolac epoxy resin by mass percentage. The E-12 epoxy resin used in the present invention is a bisphenol A type epoxy resin, and its molecular structure determines that its cured product has high strength and bonding strength, and has good adhesion and corrosion resistance. Novolac epoxy resin has high phenyl content, short carbon chain, good heat resistance and rigidity, and the cured product has high crosslink density, good mechanical strength, good heat resistance, and effectively compensates for the poor weather resistance of E-12 epoxy resin lack of.

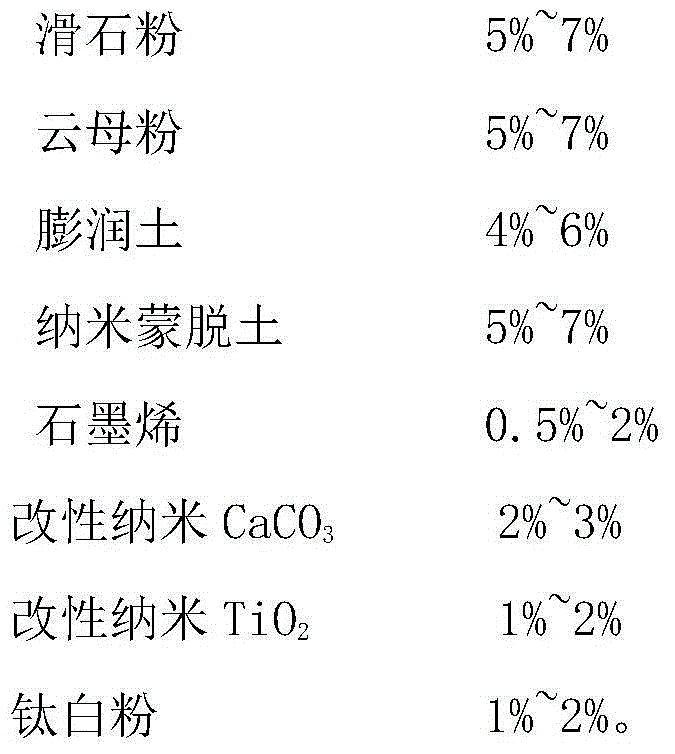

[0037] The pigments and filler...

Embodiment 2

[0051] The difference between embodiment 2 and embodiment 1 is: a kind of marine anticorrosion coating 50g of the present invention, described epoxy resin anticorrosion coating is made up of following components by mass percentage:

[0052] Epoxy 55%

[0053] Pigments and fillers 34.6%

[0054] Auxiliary 10.4%

[0055] Wherein the epoxy resin is composed of 39% (19.5g) of E-12 epoxy resin and 16% (8g) of novolak epoxy resin by mass percentage.

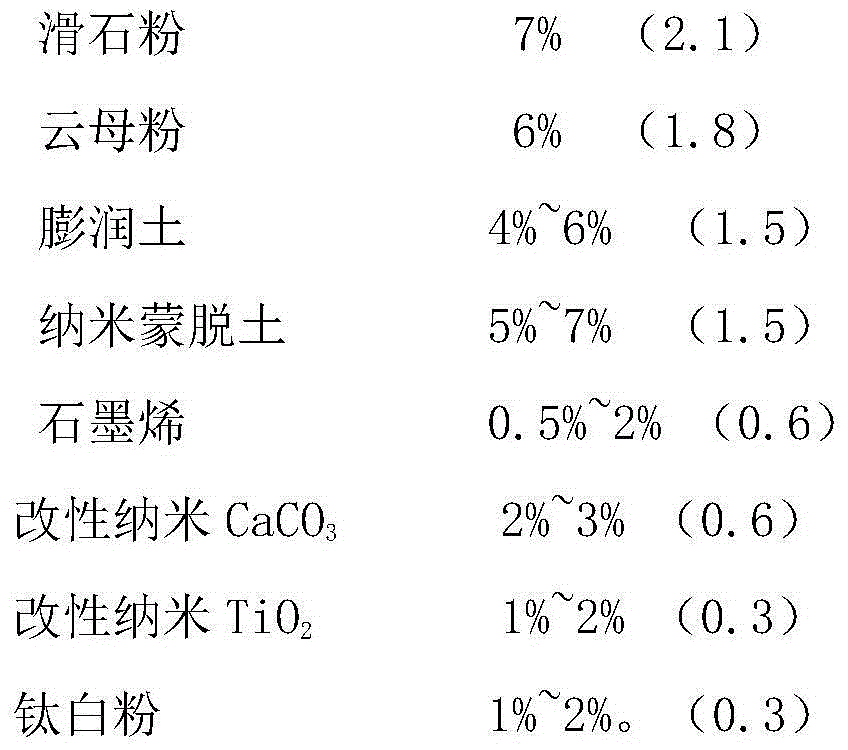

[0056] The pigments and fillers are composed of the following components by mass percentage:

[0057]

[0058]

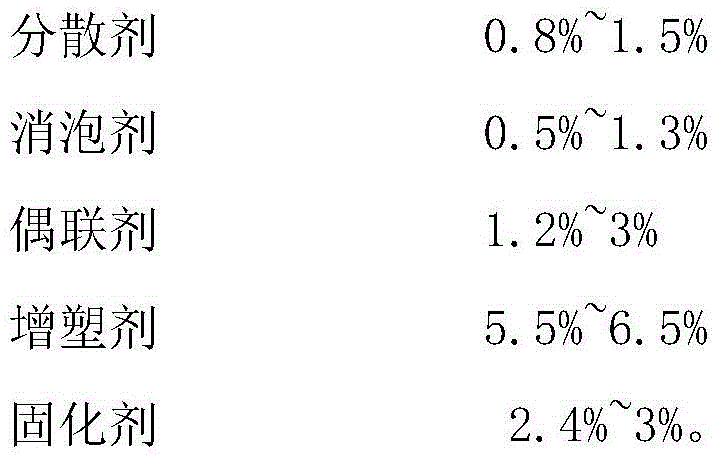

[0059] The auxiliary agent consists of the following components by mass percentage

[0060]

[0061] The method for preparing the epoxy resin coating in the described submarine steel pipe 3PE anticorrosion coating of the present invention may further comprise the steps:

[0062] In step (1), the fineness of the grinding powder during grinding and dispersion in the sand mill is 20 μm.

[0063] In step (2), the m...

Embodiment 3

[0066] The difference between embodiment 3 and embodiment 1 is: a kind of marine anticorrosion coating 100g of the present invention, described epoxy resin anticorrosion coating is made up of following components by mass percentage:

[0067] Epoxy 57%

[0068] Pigment and filler 30%

[0069] Auxiliary 13%.

[0070] Wherein the epoxy resin is composed of E-12 epoxy resin 41% (41g) and novolac epoxy resin 16% (16g) by mass percentage.

[0071] The pigments and fillers are composed of the following components by mass percentage:

[0072]

[0073]

[0074] The auxiliary agent consists of the following components by mass percentage

[0075]

[0076] The method for preparing the epoxy resin coating in the described submarine steel pipe 3PE anticorrosion coating of the present invention may further comprise the steps:

[0077] In step (2), the modified nano-CaCO 3 , modified nano-TiO 2 , graphene, and nano-montmorillonite were mixed and ultrasonically treated to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com