Supportless construction method for cast-in-place floor of high-rise steel structure house

A technology of cast-in-place floor slabs and construction methods, which is applied to floors, building components, building structures, etc. It can solve the problems of affecting the installation speed of steel structures, the high probability of scaffold collapse, and the difficulty of rescue, so as to eliminate potential safety hazards and reduce construction The effect of shortening the process and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

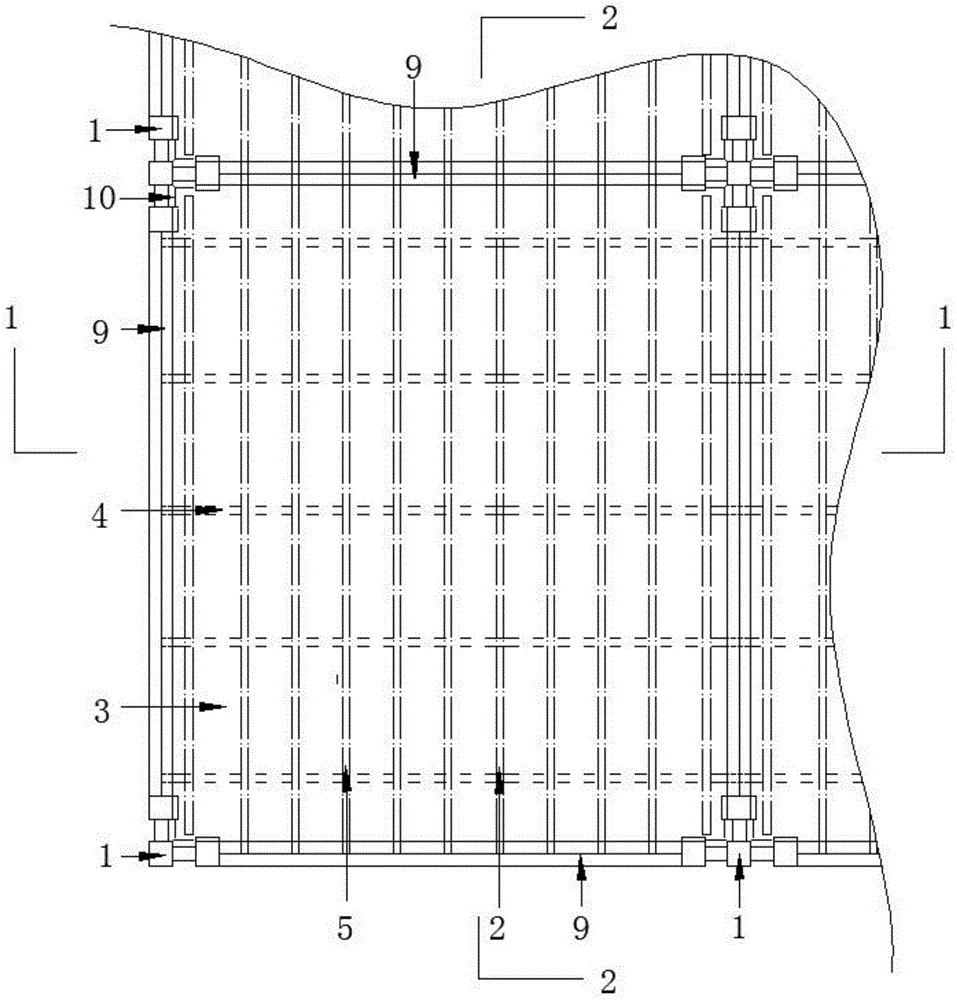

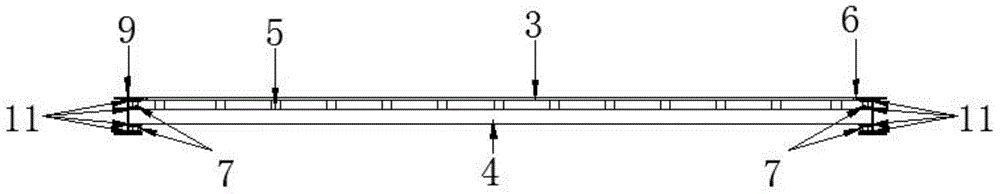

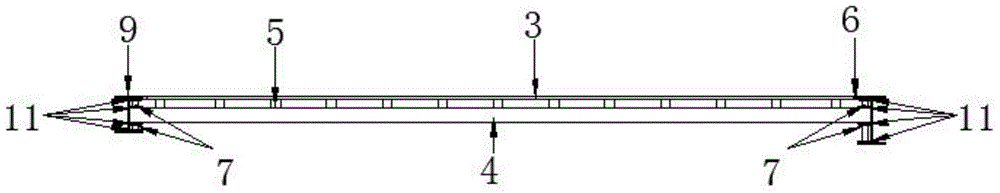

[0034] Such as figure 1 , Figure 4 and Figure 5 Shown, the present invention provides a kind of high-rise steel structure residential cast-in-place floor slab unsupported construction method, comprises the following steps:

[0035] Step 1. Calculate the load on the unsupported cast-in-place floor of the residence according to the situation of the actual high-rise steel structure residence, that is, the bay of the residential building on the construction site, and select the steel pipe 4 and the support rod 5 Cross-sectional size and arrangement spacing, the steel pipe of the present invention is a square steel pipe, the support rod is a square wooden flute, and a plurality of steel pipes and support rods are arranged at equal intervals.

[0036]Step 2: Fix the selected s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com