Wall column timber formwork joint seam anti-grout-leakage sealing device and method

A technology of sealing device and splicing seam, which is applied to the joints of formwork/formwork/work frame, the preparation of building components on site, construction, etc., can solve the problems of time-consuming and labor-intensive, and achieve the reduction of loss rate, fast construction, The effect of ensuring the visual quality of concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

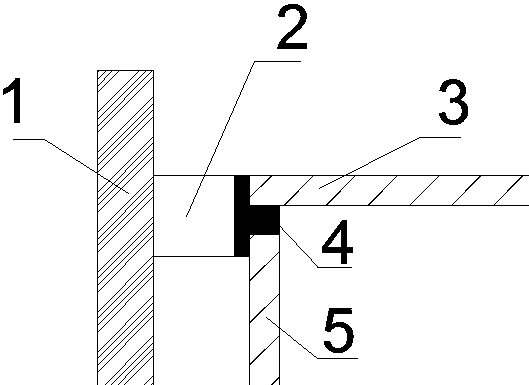

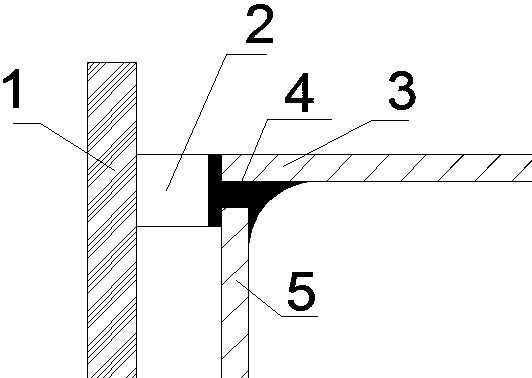

[0020] In order to better understand the present invention, below in conjunction with embodiment and accompanying drawing, technical scheme of the present invention is described further (as figure 1 , 2 shown).

[0021] An anti-leakage grout sealing device for the splicing joints of wooden formwork for wall columns, which includes channel steel 1, wooden squares 2 and rubber strips 4; figure 1 As shown, the rubber strip 4 is a T-shaped cross-sectional structure (that is, the rubber strip 4 is a T-shaped steel structure, including webs and flanges), the length of the web of the rubber strip 4 is the same as the thickness of the template, and the web of the rubber strip 4 is located at Inside the formwork seams (such as figure 1 , 2 The seam between formwork one 3 and formwork two 5), the flange of the rubber strip 4 is located outside the formwork; the wooden square 2 is attached to the flange of the rubber strip 4, and the channel steel 1 is located on the outside of the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com