Method for manufacturing secondary post-cast ring beam

A production method and flexible technology, applied in the field of secondary post-cast ring beam production, can solve problems such as adverse user effects, increased maintenance and rework quality costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0019] The making of embodiment secondary post-casting ring beam

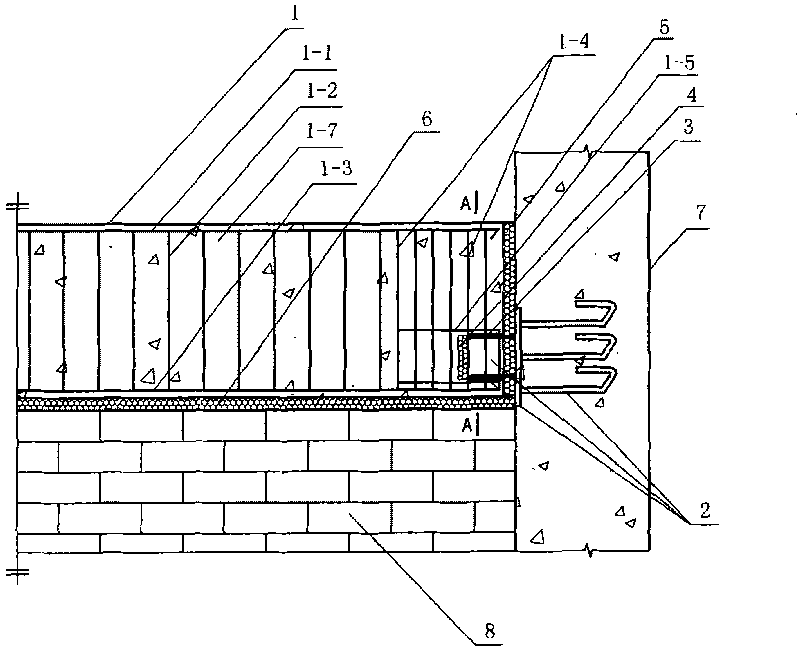

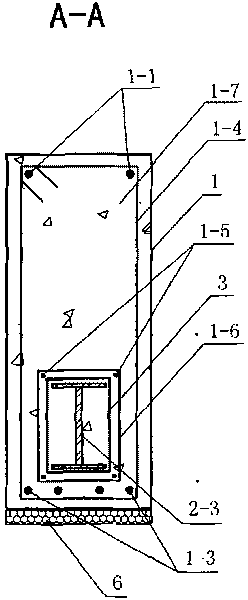

[0020] The manufacturing process of the secondary post-cast ring beam will be described below in conjunction with the accompanying drawings.

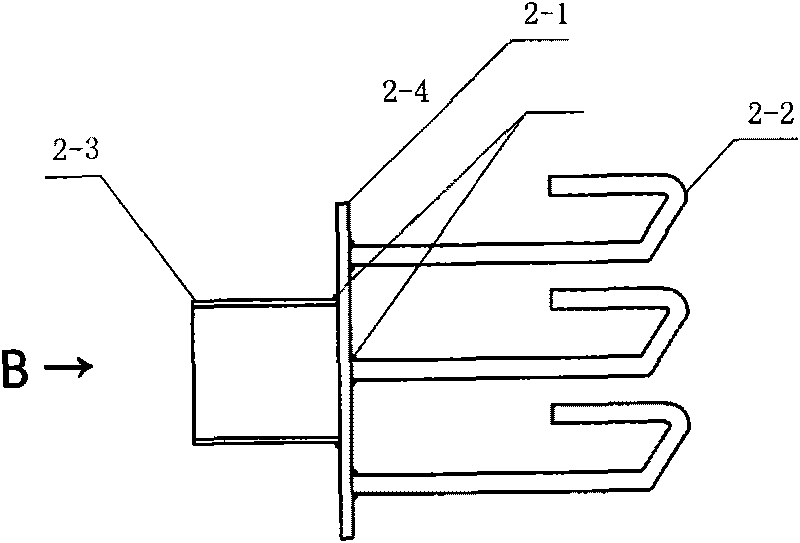

[0021] Prefabricated or on-site connection components, structures such as image 3 , Figure 4 Among them, the anchor plate 2-1 is 10mm thick, and the six U-shaped anchor bars 2-2 are made of HRB335 grade rebar (thickness, size of the anchor plate, diameter and quantity of the anchor bars are determined by mechanical checking according to the actual situation of the project). The center line of the I-beam 2-3 and the anchor plate 2-1 should be consistent, and the quality of the weld seam should not be lower than the third grade, and the appearance should not be lower than the second grade. Embed the horizontal U-shaped anchor bar 2-2 together with the anchor plate in the concrete wall / column 7 of the main structure, and make the plane of the anchor plate consistent wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com