Patents

Literature

55 results about "Quality costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In process improvement efforts, quality costs or cost of quality is a means to quantify the total cost of quality-related efforts and deficiencies. It was first described by Philip B Crosby in a 1956 Harvard Business Review article.

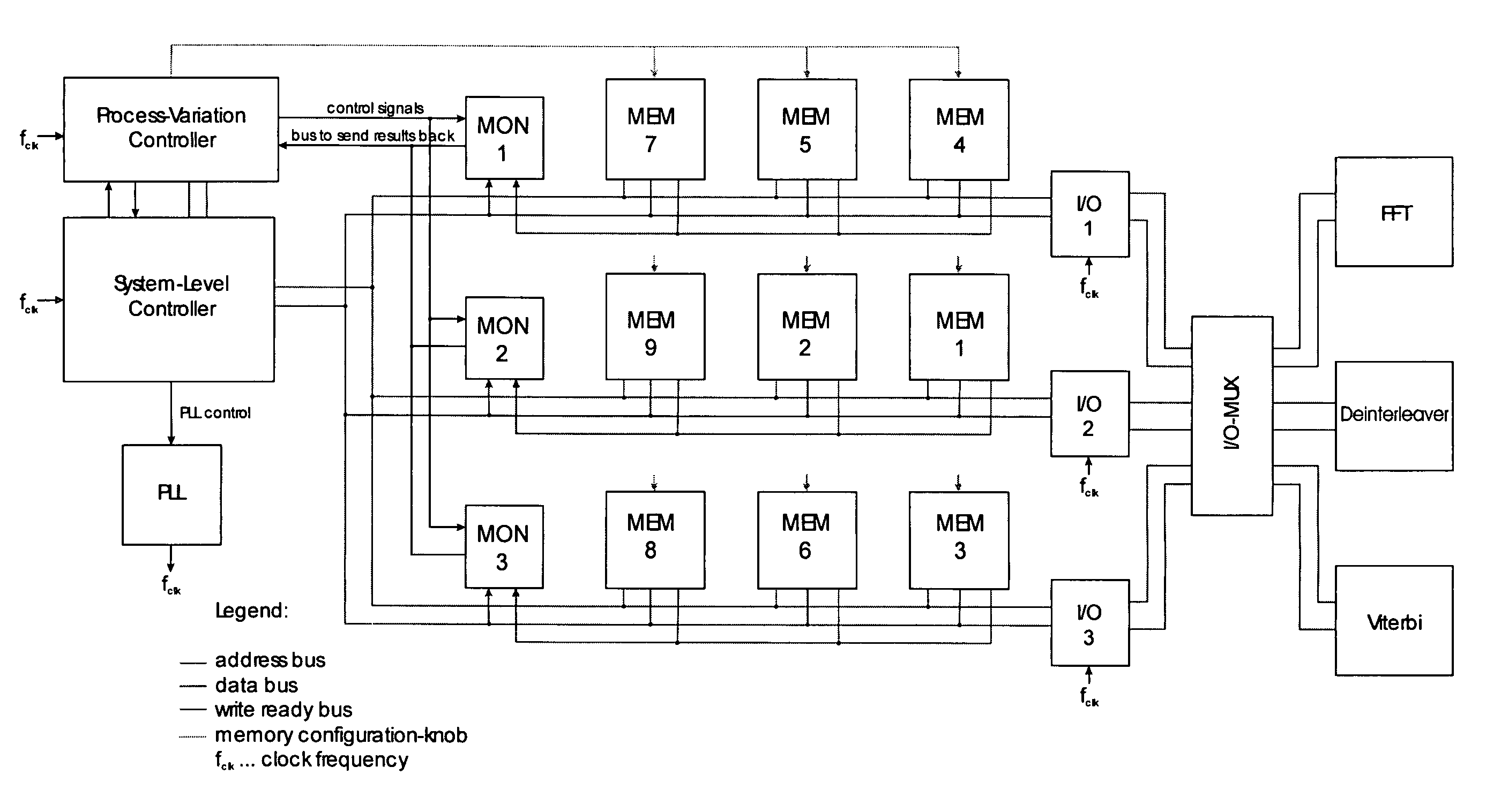

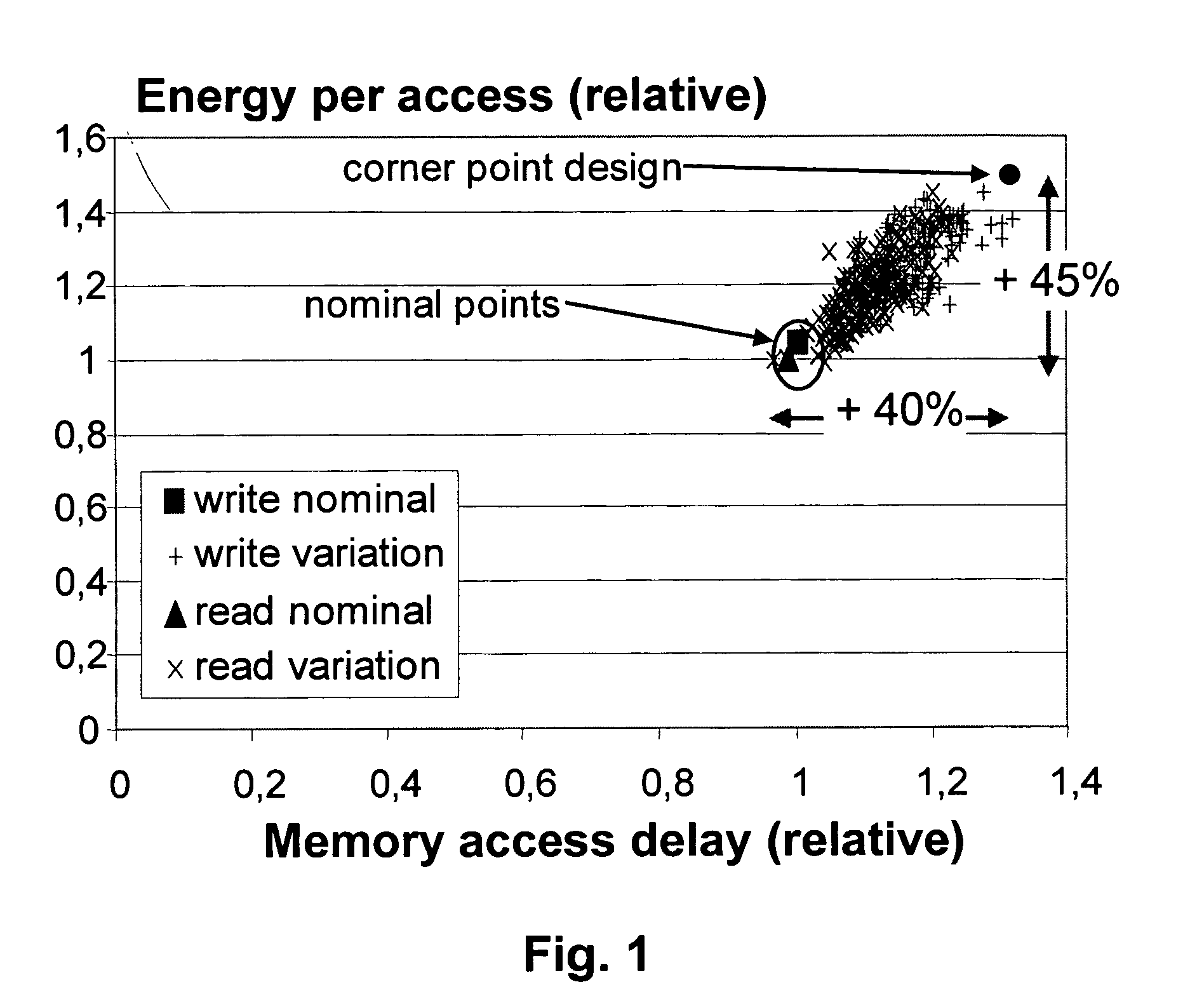

Method and apparatus for designing and manufacturing electronic circuits subject to process variations

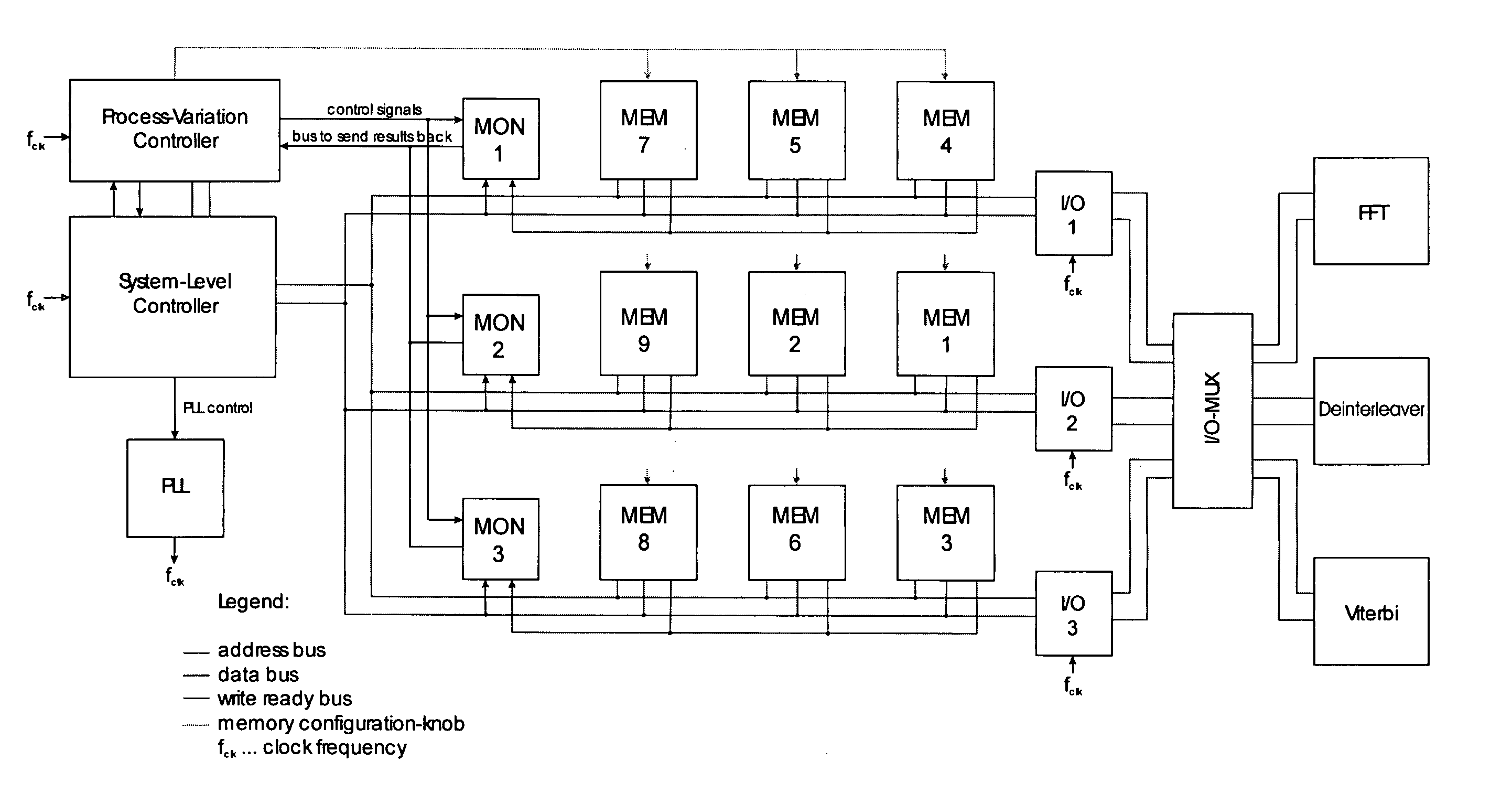

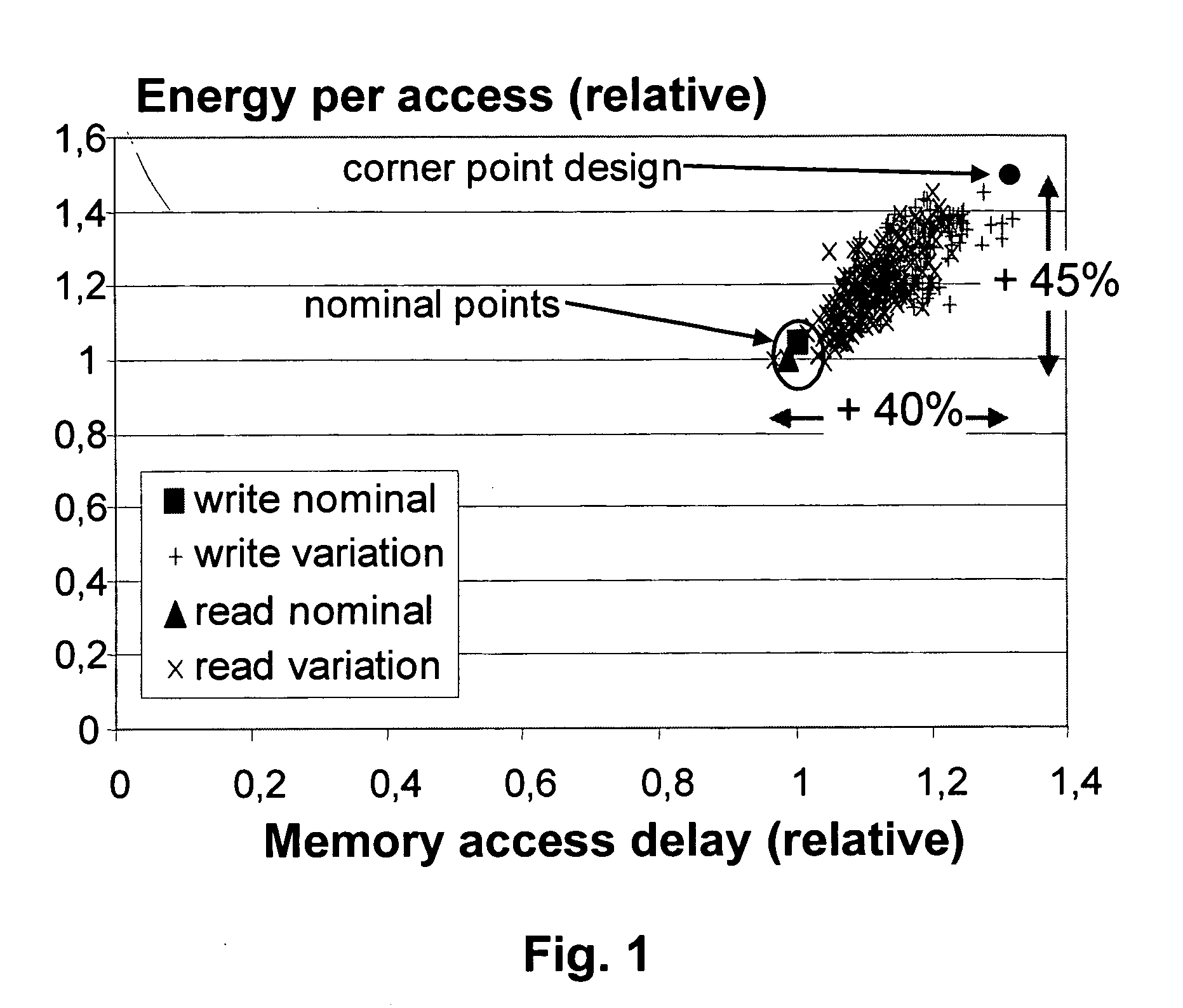

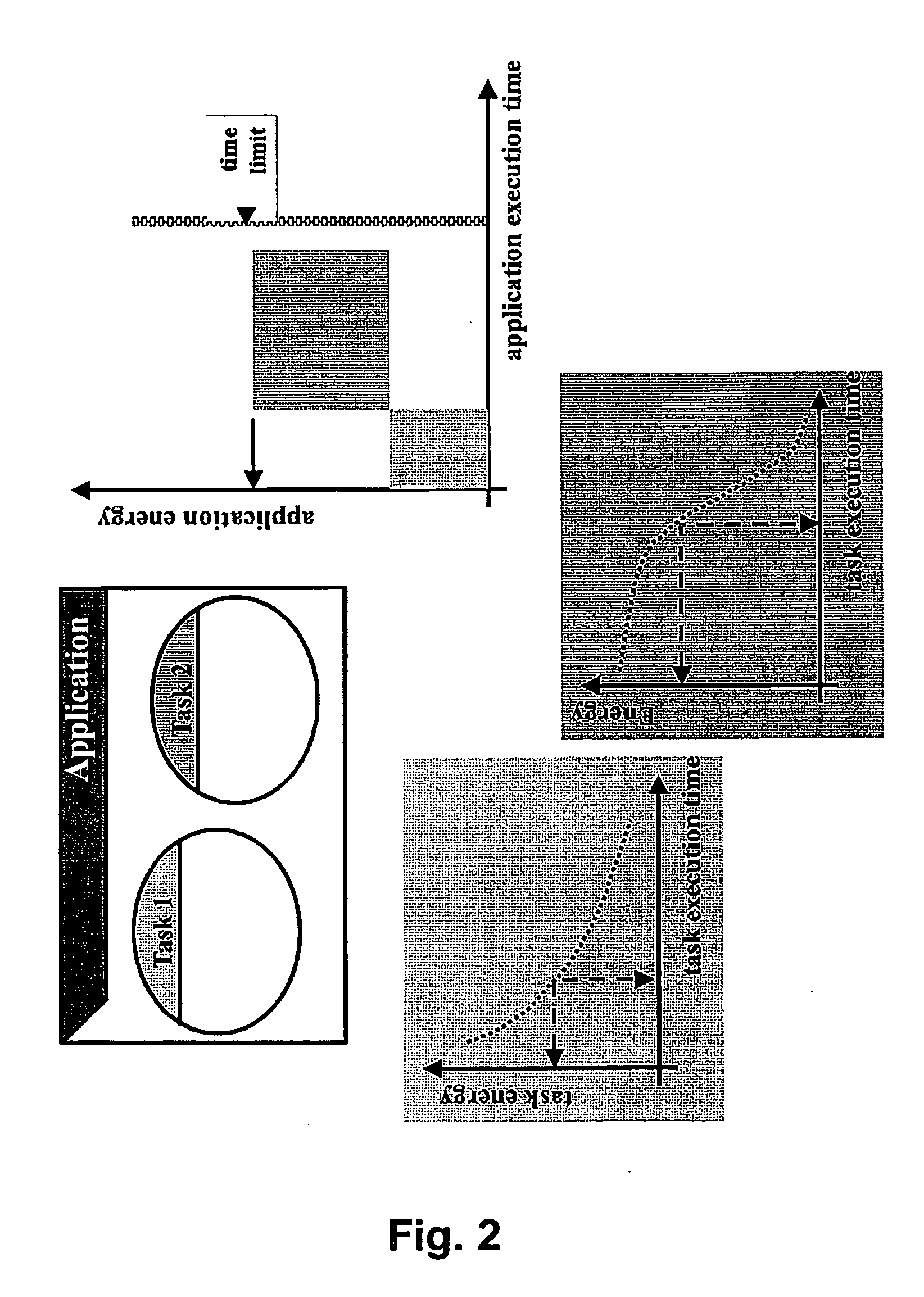

ActiveUS20050235232A1Additional circuitryImprove the environmentDetecting faulty computer hardwareCAD circuit designDisplay deviceTrade offs

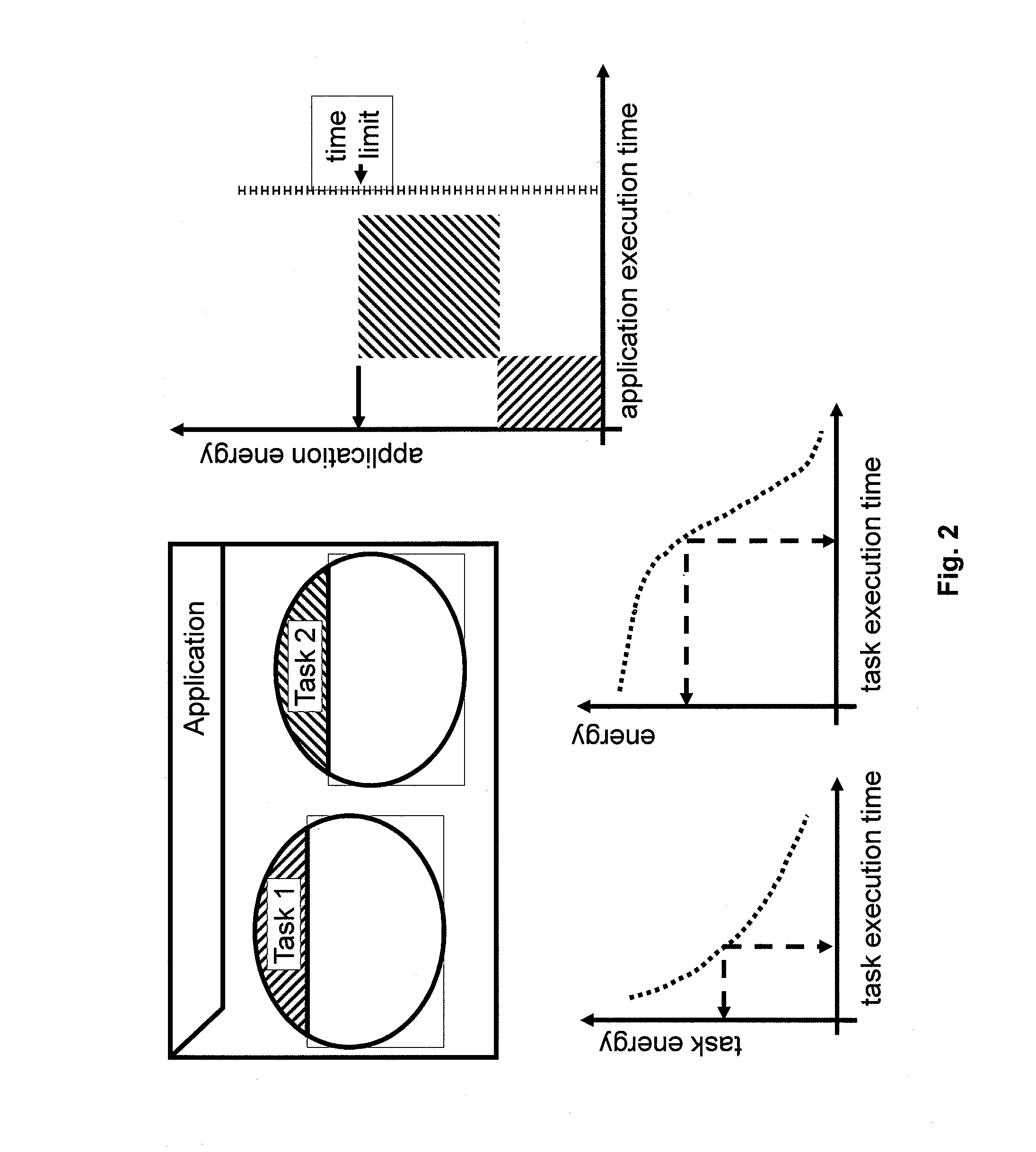

Methods and apparatus are described in which, at design-time a thorough analysis and exploration is performed to represent a multi-objective “optimal” trade-off point or points, e.g. on Pareto curves, for the relevant cost (C) and constraint criteria. More formally, the trade-off points may e.g. be positions on a hyper-surface in an N-dimensional Pareto search space. The axes represent the relevant cost (C), quality cost (Q) and restriction (R) criteria. Each of these working points is determined by positions for the system operation (determined during the design-time mapping) for a selected set of decision knobs (e.g. the way data are organized in a memory hierarchy). The C-Q-R values are determined based on design-time models that then have to be “average-case” values in order to avoid a too worst-case characterisation. At processing time, first a run-time BIST manager performs a functional correctness test, i.e. checks all the modules based on stored self-test sequences and “equivalence checker” hardware. All units that fail are deactivated (so that they cannot consume any power any more) and with a flag the run-time trade-off controllers, e.g. Pareto controllers, are informed that these units are not available any more for the calibration or the mapping. At processing time, also a set of representative working points are “triggered” by an on-chip trade-off calibration manager, e.g. a Pareto calibration manager, that controls a set of monitors which measure the actual C-Q-R values and that calibrates the working points to their actual values. Especially timing monitors require a careful design because correctly calibrated absolute time scales have to be monitored.

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW)

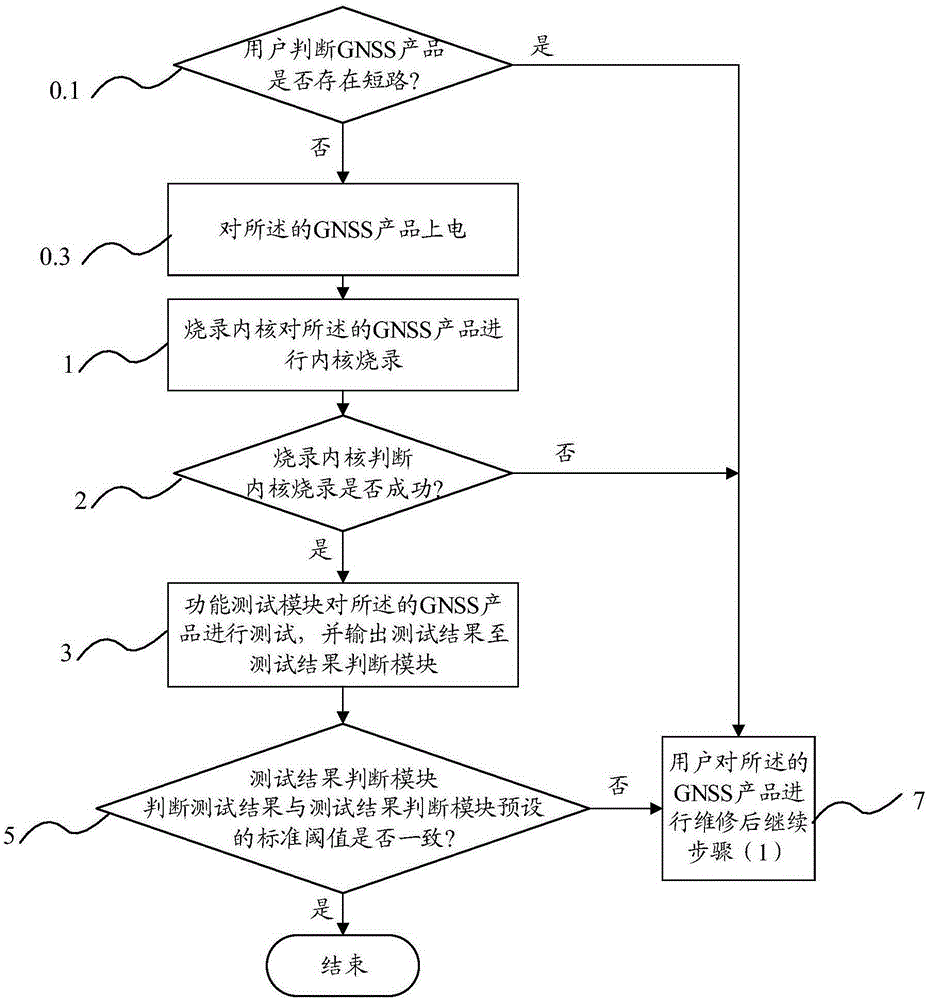

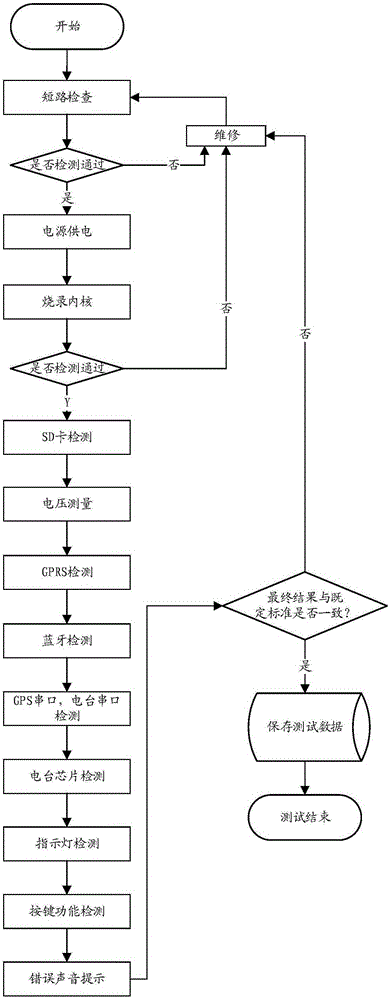

GNSS product automatic test method based on function test

InactiveCN105182371AReduce quality inspection costsSimplify the commissioning processSatellite radio beaconingTest efficiencyFunctional testing

The invention relates to a GNSS (Global Navigation Satellite System) product automatic test method based on function test. A function test module is in connection with a detected GNSS product through a test point, controls the on-off of power-on, burning and detection switches, and successively completes function model test of the GNSS product so as to detect whether each function module of the GNSS product is normal. According to the invention, after the surface mount of the GNSS product, a common operator of a supplier can directly complete mainboard debugging and aging work, requiring no professional debugging personnel to perform test, thereby simplifying a whole debugging process, minimizing manual operation, improving test efficiency and accuracy, meanwhile reducing surface mount quality costs, promoting the surface mount process improvement of the supplier, and realizing win-win.

Owner:SHANGHAI HUACE NAVIGATION TECH

Intelligent factory MES system

InactiveCN107831748AImprove work efficiencySolve quality bottlenecksTotal factory controlProgramme total factory controlService flowComputerized maintenance management system

The invention discloses an intelligent factory MES system. The intelligent factory MES system comprises a service flow, quality inspection management, product quality tracing management, equipment monitoring management, equipment maintenance management, software and hardware or other external system interface requirements. According to the invention, a complete management system is provided for afactory, and the unnecessary waste of the factory is reduced. The all-dimensional tracing management of products from the material incoming step to the factory leaving step is realized. The quality ofproducts is greatly improved, and the safe and long-term operation of equipment is guaranteed. The data support is provided for the management layer during the macroscopic evaluation process of the product quality and the working efficiency of the quality inspection personnel is improved. As a result, products can become clear and transparent in the whole production process. The cause of qualityproblems can be found rapidly. Meanwhile, the measures for solving the quality bottleneck problem are formulated, and the quality cost is reduced. The warning equipment can be quickly handled with andthe system is complete. The intelligent management of the factory is greatly improved, and the management vulnerability of the factory is greatly reduced.

Owner:GUANGDONG HUILIPU ROAD & BRIDGE INFORMATION ENG

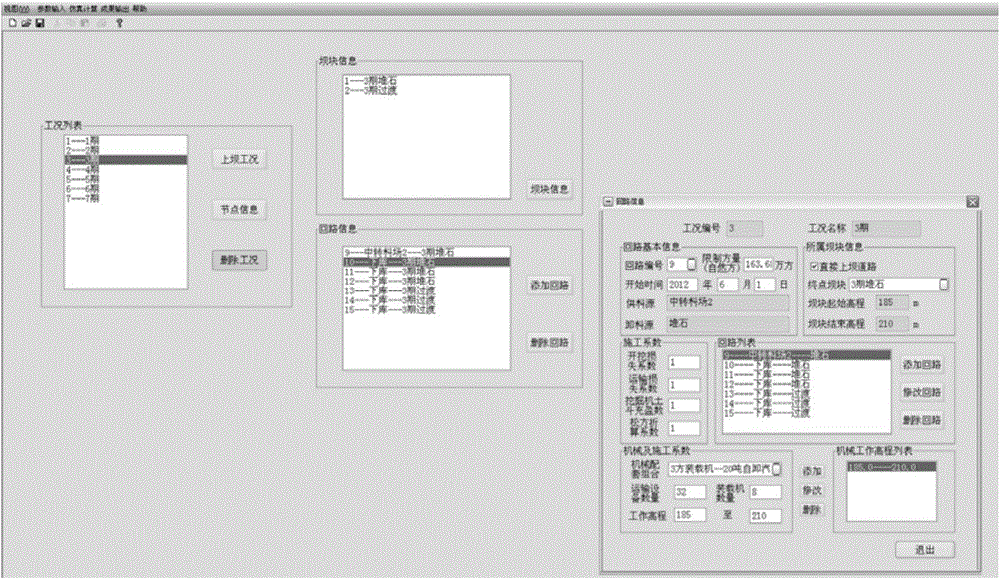

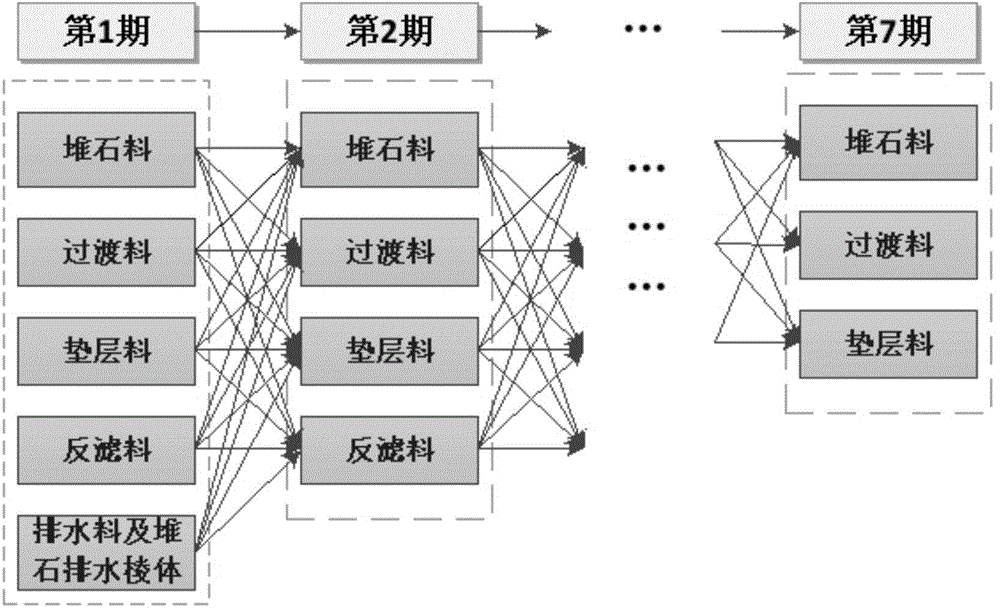

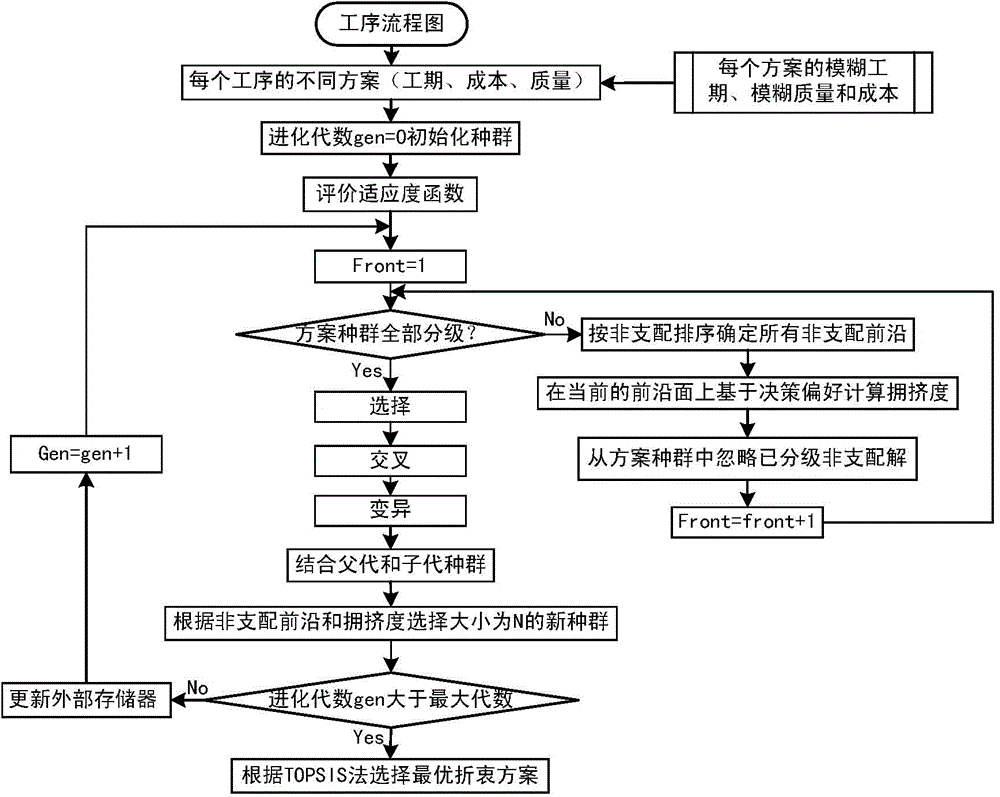

Balancing-optimalizing method, for project time limit, quality and cost, used in concrete faced rockfill dam construction

InactiveCN104156782AReal-time managementReal-time controlGenetic modelsForecastingDecision makerTime limit

The invention belongs to the technical field of civil engineering, and provides a theoretical basis and a feasible, effective and practical method for an engineering decision, meanwhile, assists managerial staff of an engineering project in managing and controlling dam body filling construction; besides, the balancing-optimalizing method performs consideration from the whole life cycle of the engineering to comprehensively consider the important influence from the project time limit and the quality on the cost, and provides a construction scheme which more meets practical construction requirements and is more economical for decision makers. Therefore, the technical scheme adopted by the invention is that a balancing-optimalizing method, for the project time limit, the quality and the cost, used in the concrete faced rockfill dam construction builds a balancing-optimalizing model which is based on quality cost and decision preference, and gives a non-dominated sorting genetic algorithm which is used for optimizing model solution and based on fuzzy project time limit and fuzzy quality; a built mathematical model is a built objective function; a fuzzy measure Me method is adopted to calculate the project time limit, the quality, the construction cost and the total cost of each general scheme. Thus, the balancing-optimalizing method provided by the invention is mainly applied to the civil engineering.

Owner:TIANJIN UNIV

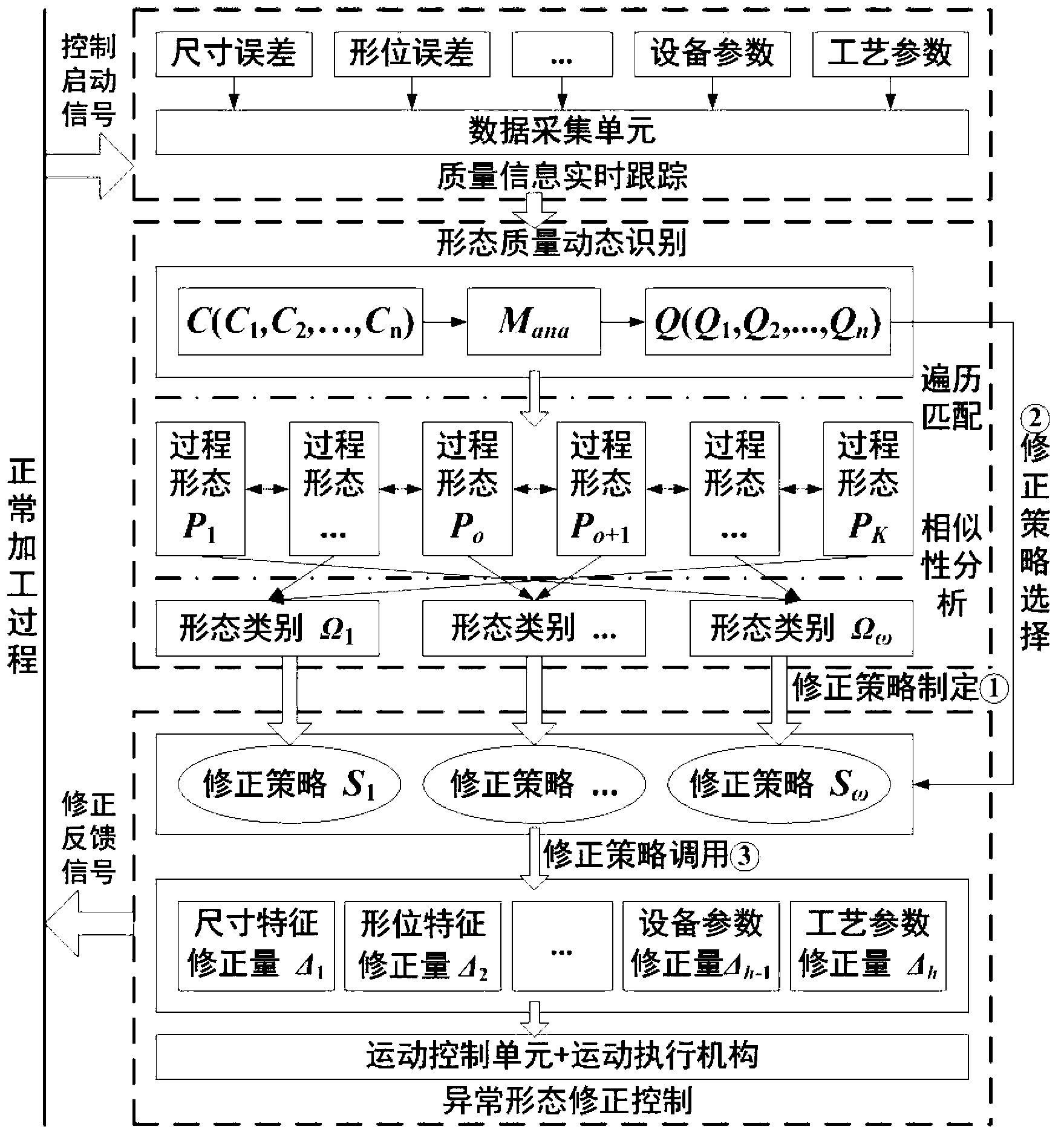

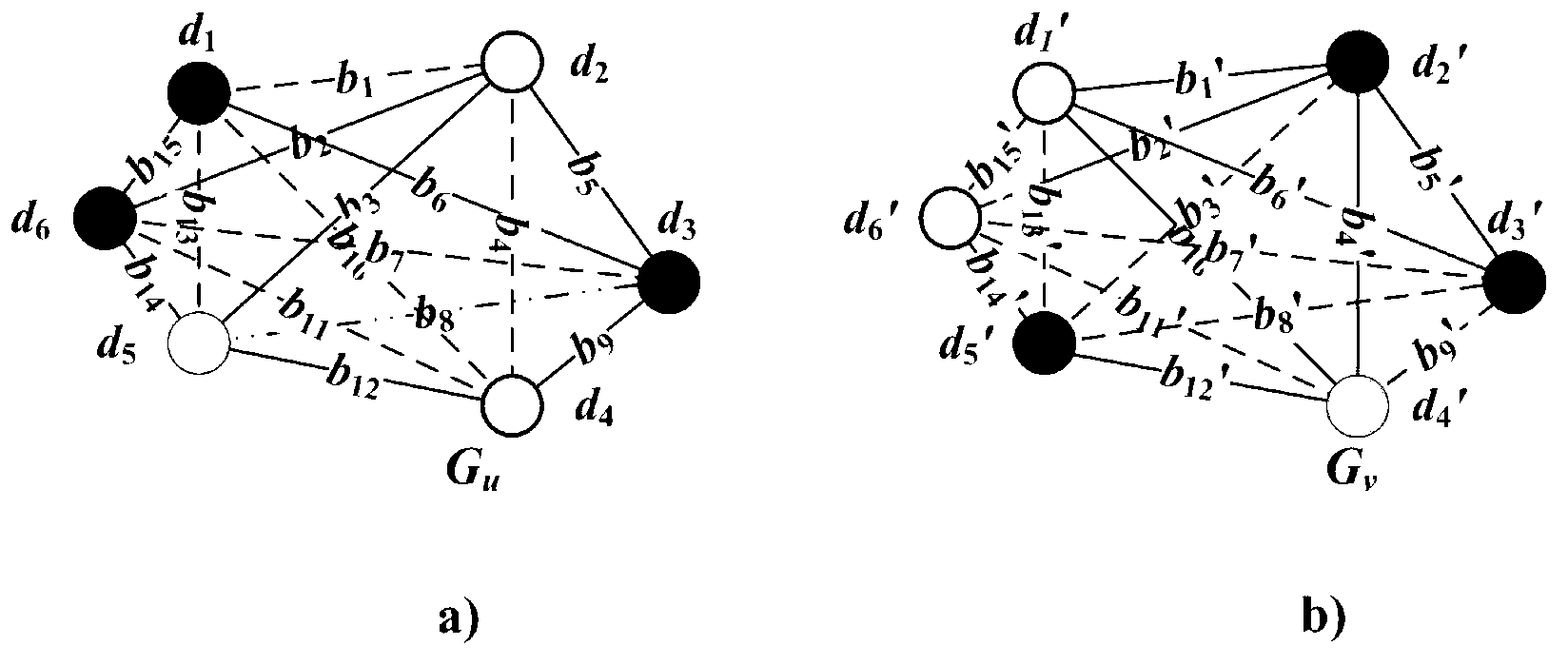

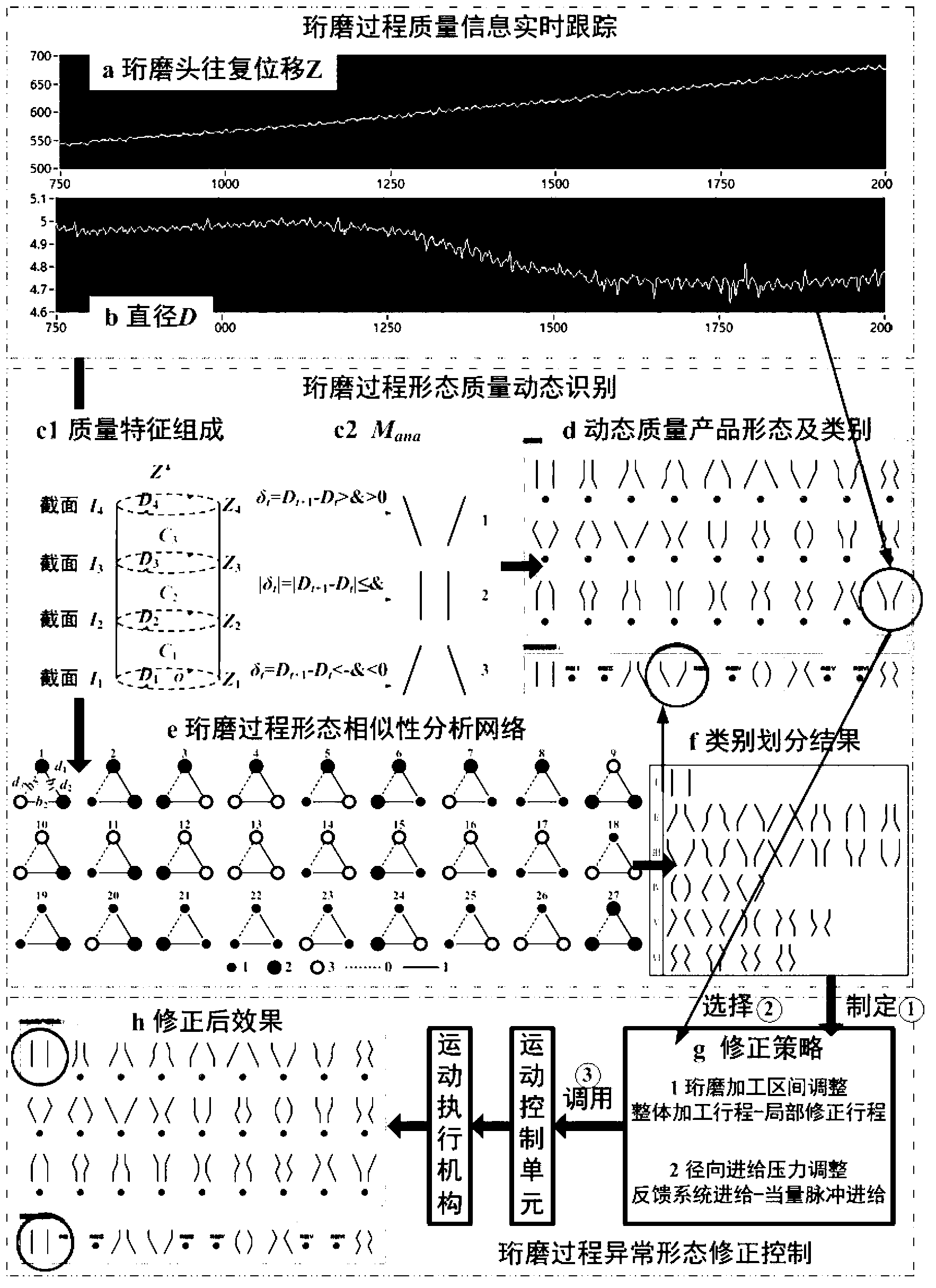

Form quality dynamic identification and modification control method in machining process

ActiveCN103257615AClear control processAvoid reprocessingProgramme controlComputer controlSimilarity analysisEconomic benefits

The invention discloses a form quality dynamical identification and modification control method in machining process. The form quality dynamical identification and modification control method in the machining process comprises the steps of (1) quality information real-time tracking, (2) form quality dynamic identification and (3) unusual form modification control, wherein the quality information real-time tracking is used for meeting the requirement that a large amount of bottom-layer data can reflect a present quality state of a workpiece form in the process of dynamic identification and modification, the form quality dynamic identification is used for carrying out data processing on acquired form quality information to acquire a dynamical quality product form, searching a form which is matched with the dynamical quality product form through an ergodic process form set and determining a belonging form type of the dynamical quality product form through similarity analysis, and the unusual form modification control is used for adopting a modification strategy ' deciding+choosing+calling' mechanism, dynamically carrying out modification control on a process exception form through a motion control unit and a motion executing mechanism. By the adoption of the form quality dynamical identification and modification control method in the machining process, the improvement of machining quality is benefited, the defects of quality is overcome in advance, quality cost is reduced, the improvement of production efficiency is benefited, off-line detection is avoided, sub-quality products can be machined again, and the economic benefit of an enterprise is improved.

Owner:XI AN JIAOTONG UNIV

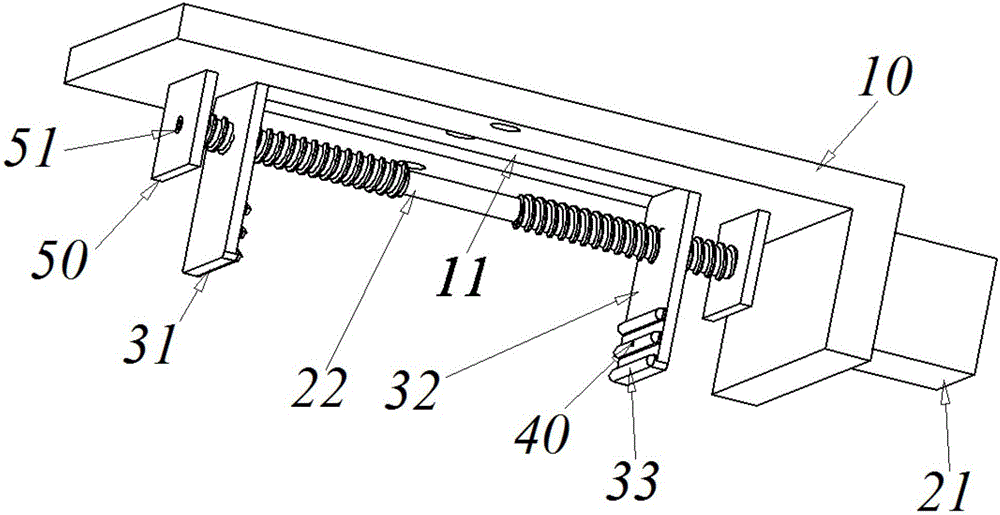

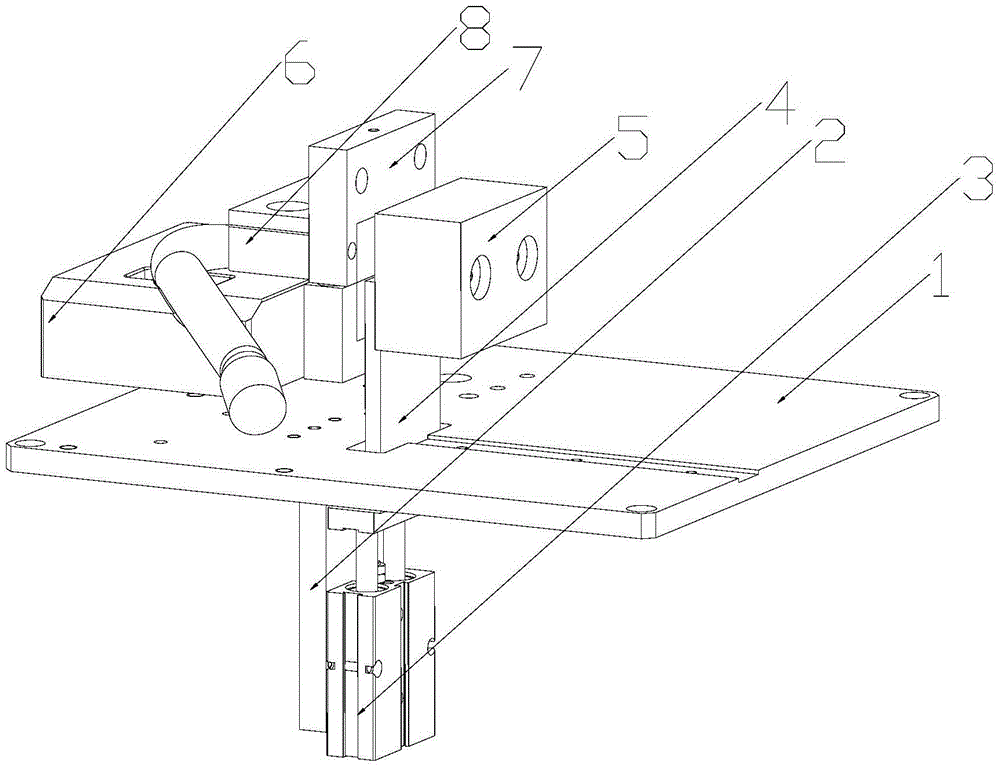

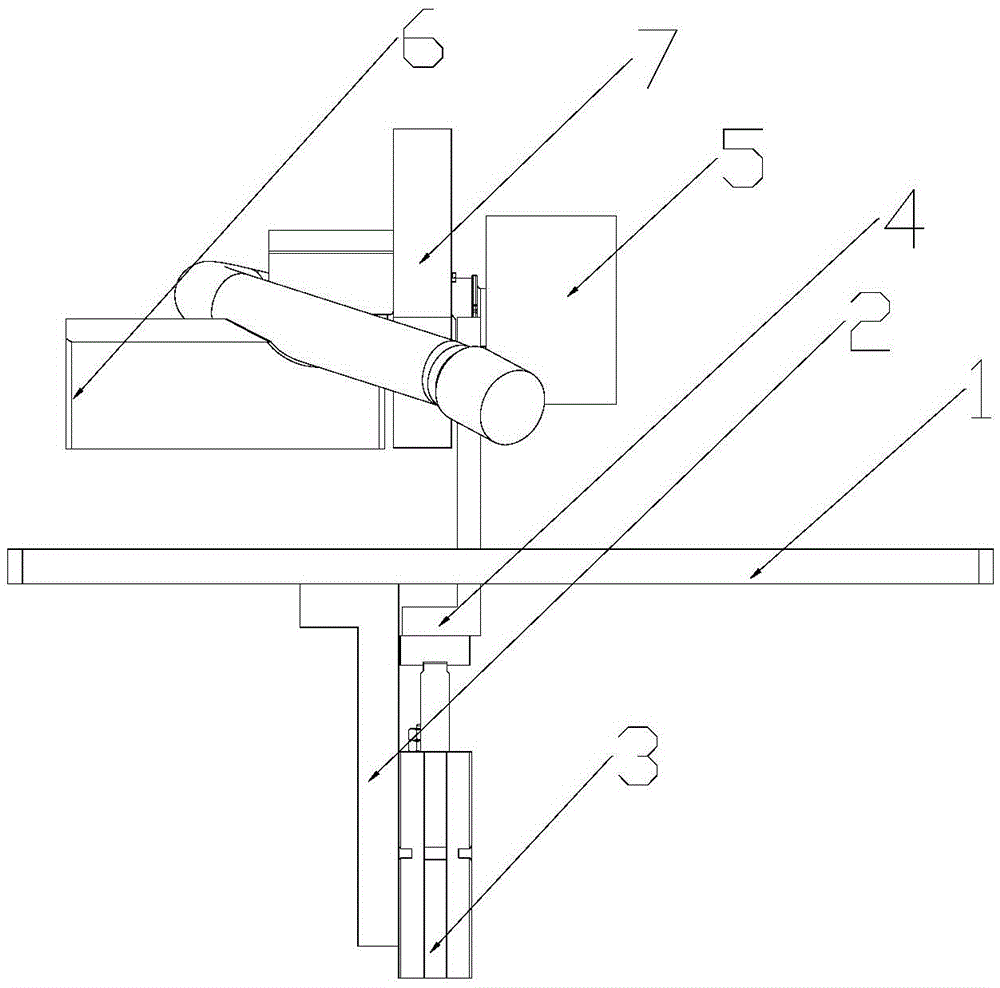

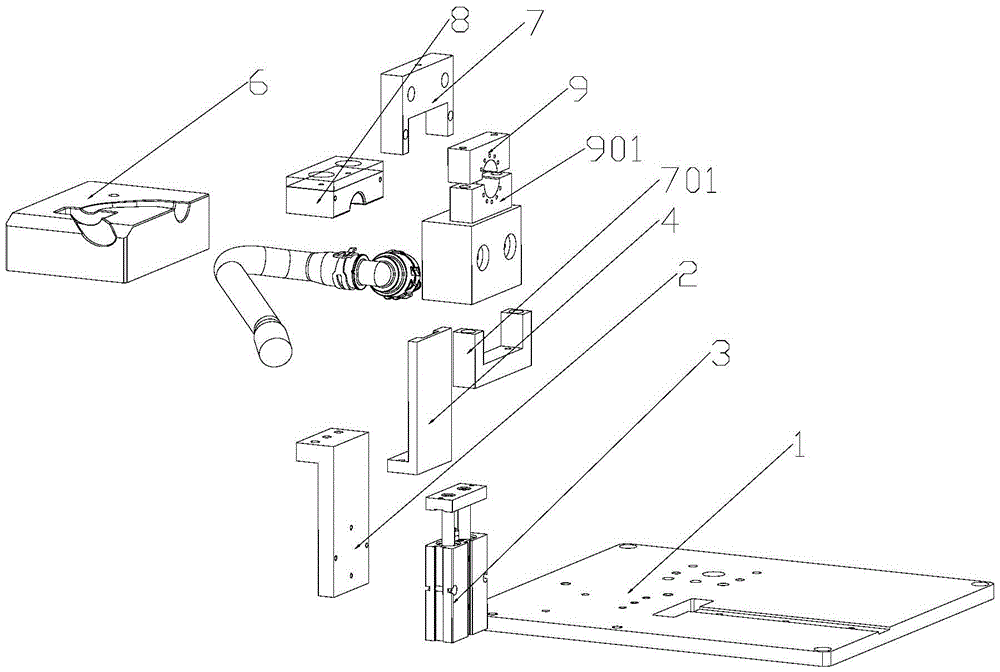

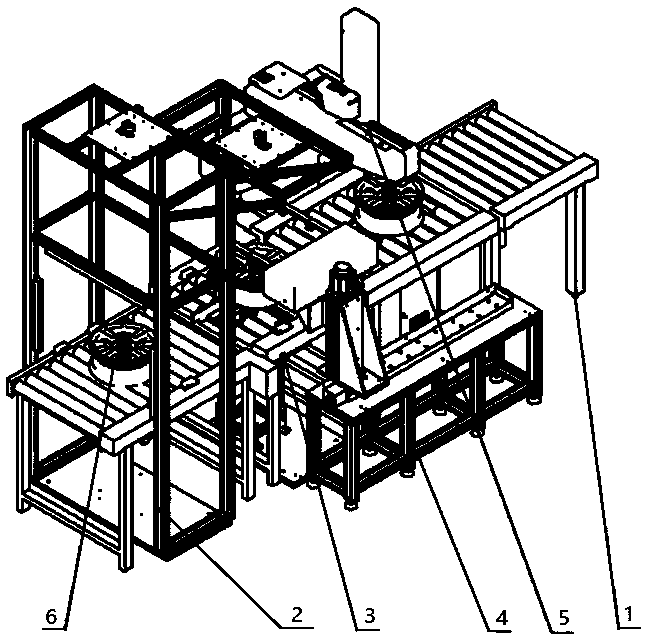

Lateral grabbing assembling device for new energy battery

InactiveCN105774764AHigh precisionOvercoming problems such as short circuit scrappingGripping headsElectric propulsion mountingNew energyUltimate tensile strength

The invention provides a lateral grabbing assembling device for a new energy battery. The lateral grabbing assembling device comprises a supporting plate, a power mechanism, a grabbing mechanism and a control mechanism, wherein the power mechanism comprises a servo motor and a spiral screw rod; the servo motor is mounted on the supporting plate and is in driving connection with the grabbing mechanism through the spiral screw rod; the grabbing mechanism comprises a first clamping jaw and a second clamping jaw; the first clamping jaw and the second clamping jaw are mounted on the spiral screw rod in a sliding form; a battery clamping space is formed between the first clamping jaw and the second clamping jaw; the control mechanism is mounted on the first clamping jaw or the second clamping jaw and faces to the clamping space between the first clamping jaw and the second clamping jaw; the control mechanism is in signal transmission with the servo motor. The lateral grabbing assembling device for the new energy battery can be used for reducing the labor intensity for manually mounting an integrated battery pack, increasing the accuracy of battery mounting and integration, increasing the production efficiency and overcoming the problems of battery short circuit and scrapping caused by the fault of persons during a battery mounting process, so that the labor cost, manufacturing cost and quality cost of a battery assembling enterprise are greatly reduced.

Owner:BERGSTROM INTELLIGENT EQUIP KUNSHAN CO LTD

Manufacturing method for circuit board having POFV resin plug via and unfilled laser via

ActiveCN105848419AReduce the number of grinding platesReduced copper thickness extremesPrinted circuit aspectsPrinted element electric connection formationElectricityCopper plating

The invention provides a manufacturing method for a circuit board having a POFV resin plug via and an unfilled laser via. The manufacturing method comprises the following steps: (a) the former process in which an internal layer circuit board is preprocessed; (b) lamination; (c) brownification; (d) laser drilling; (e) the first time of slice analysis; (f) de-brownification; (g) drilling of the resin plug via; (h) adhesive removing and copper plating; (i) via filling and electroplating of the whole board; (j) the second time of slice analysis; (k) external layer via pattern plating; and (l) via plating. Furthermore, the steps of the third time of slice analysis-film removing-the resin plug via-abrasive belt plate grinding-external layer via drilling-adhesive removing and copper plating-external layer electroplating-external layer patterning-pattern electroplating-external layer etching-external layer AOI-the later process are included after the step (l). The manufacturing method has the advantages that the production process can be reduced, production and quality cost can be reduced and production efficiency can be enhanced.

Owner:鹤山市中富兴业电路有限公司

Picture processing method, picture processing device and picture processing platform

ActiveCN105430393AEnhance expressive abilityImprove performanceDigital video signal modificationComputer graphics (images)Lossless compression

The invention provides a picture processing method, a picture processing device and a picture processing platform. The method comprises the following steps: obtaining attribute information of an original picture; aiming at a PNG picture, firstly performing lossless compression on the original picture, and then judging a transparent characteristic of the original picture; if a transparent pixel point does not exist, judging the area of the original picture or a picture color value; when the area of the picture is less than an area threshold or the picture color value is less than a color threshold, compressing the picture after the lossless compression, converting a format of the picture after the lossless compression into a JPG format, and then performing compression; and obtaining the picture, which has the smaller volume in the two pictures, through a comparison, and selecting the picture as a processed picture. In the scheme, judgments are performed through combinations with the picture transparent characteristic, the color value and the area of the PNG picture, original picture information is represented well in the smaller picture volume, the picture expression effect is improved, and the picture volume and quality cost performance are improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

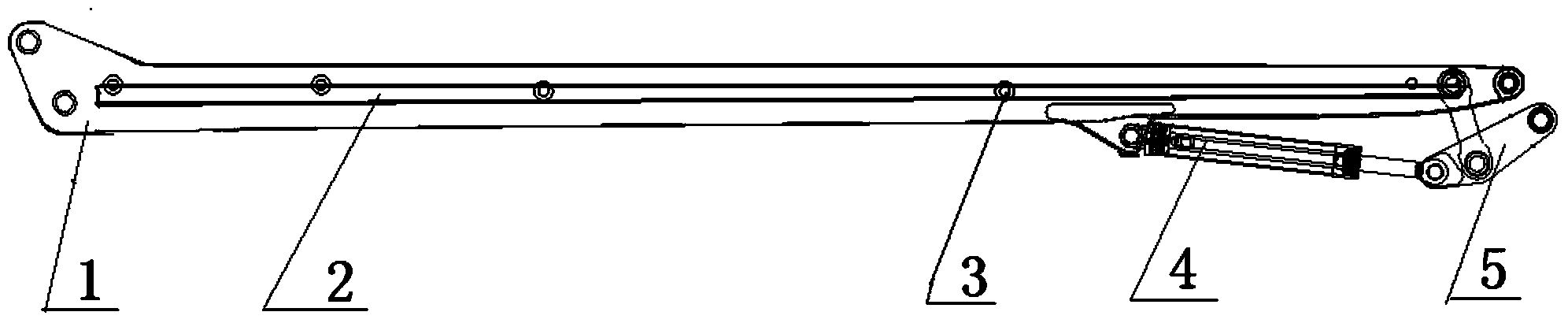

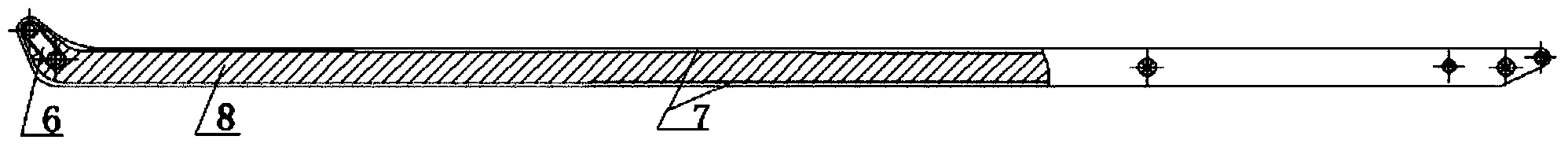

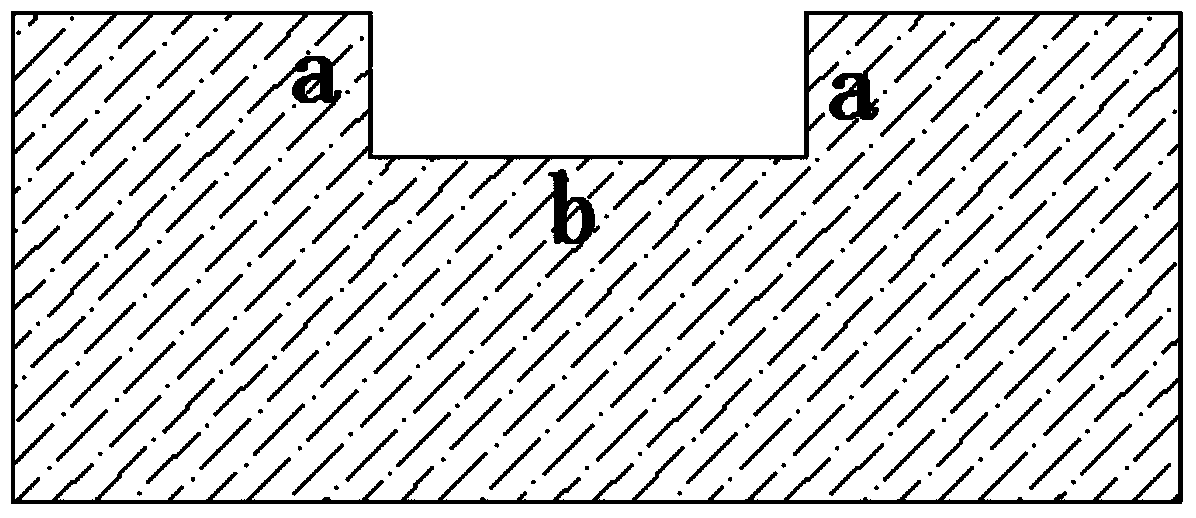

Composite material cantilever section for cantilever crane of concrete pump truck and manufacturing method thereof

ActiveCN103953195AStrong design adaptabilityReduce the cost of qualityBuilding material handlingEngineeringCantilever

The invention relates to a composite material cantilever section for a cantilever crane of a concrete pump truck and a manufacturing method of the composite material cantilever section for the cantilever crane of the concrete pump truck, and belongs to the technical field of concrete pump trucks. The composite material cantilever section comprises a framework, a concrete conveying pipeline, a connecting bolt, a hydraulic mechanism and a connecting pin shaft, wherein the framework comprises a large end connector located at one end, a main body located in the middle part, and a small end connector located at the other end. The composite material cantilever section for the cantilever crane of the concrete pump truck is stronger in design adaptability, and a higher structure effect is acquired with lower quality cost to the greatest extent through the changes of the designable composite material, structure size and process.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

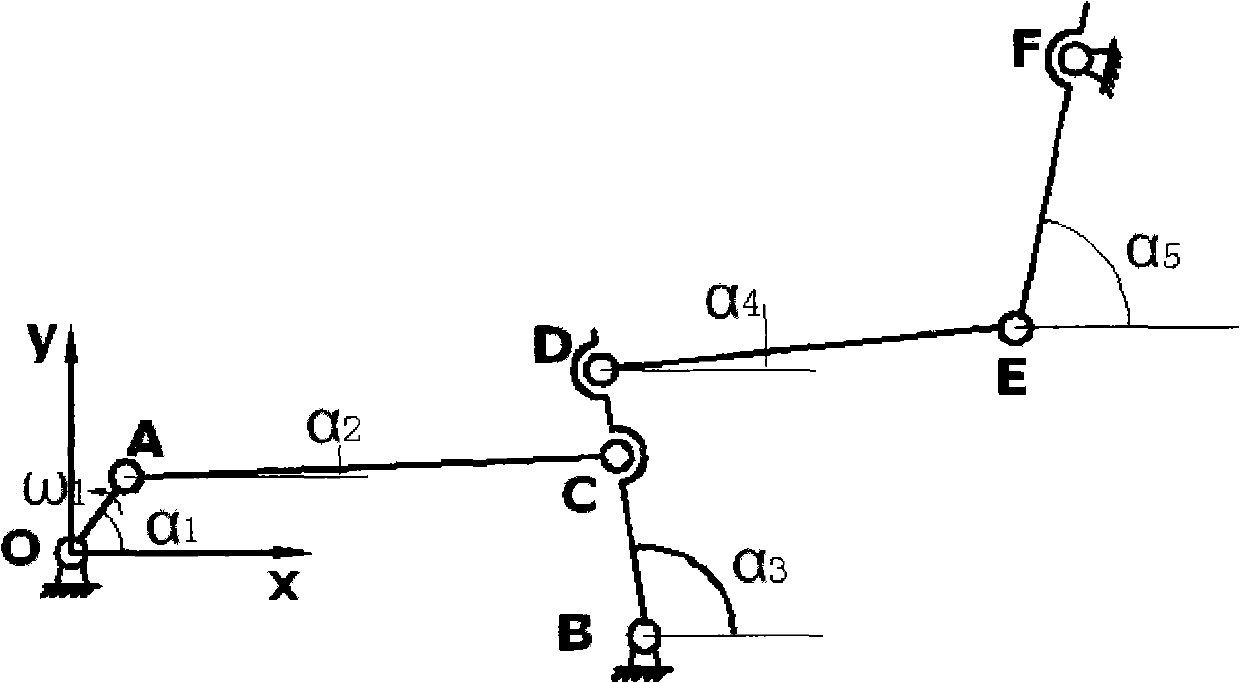

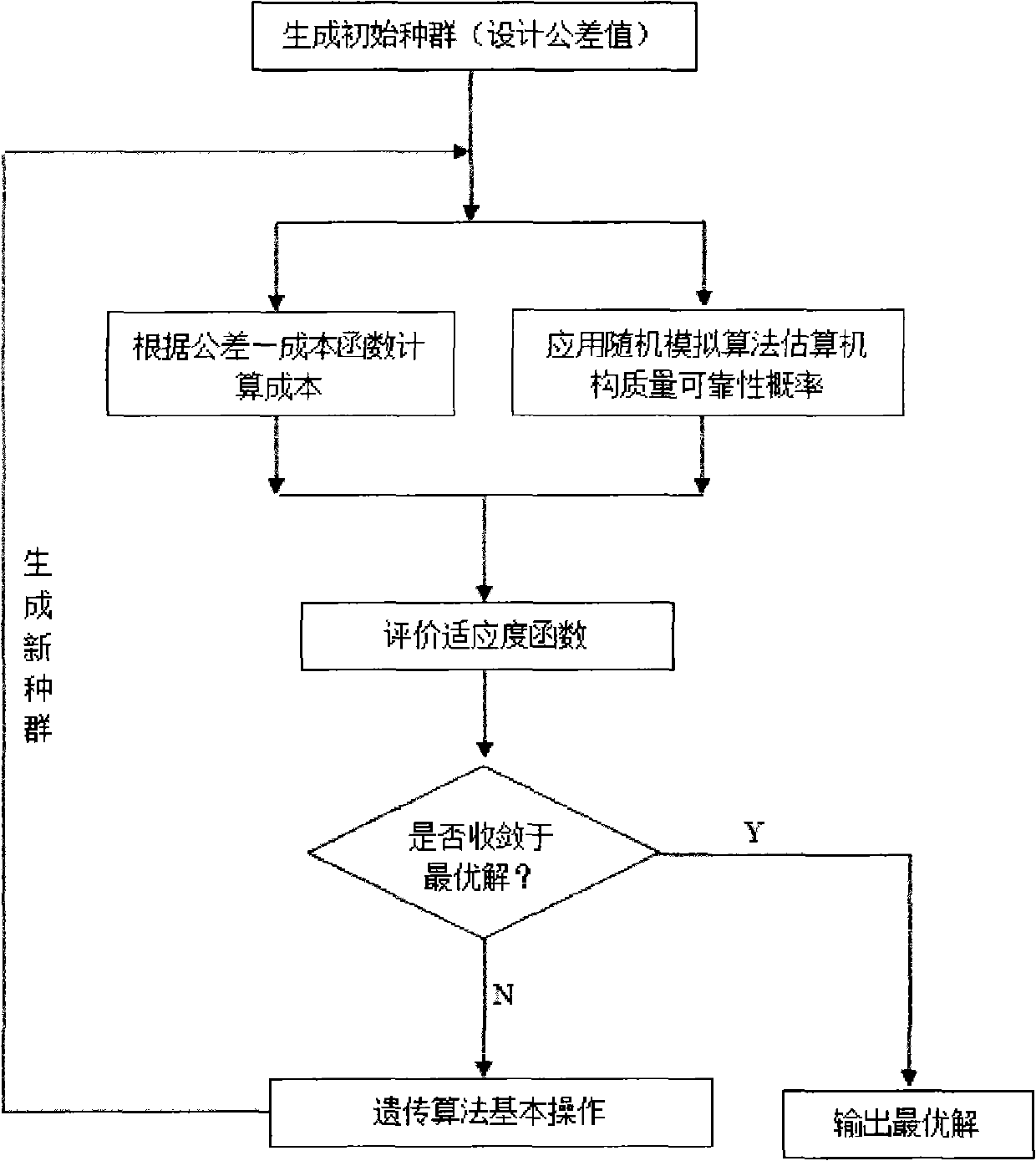

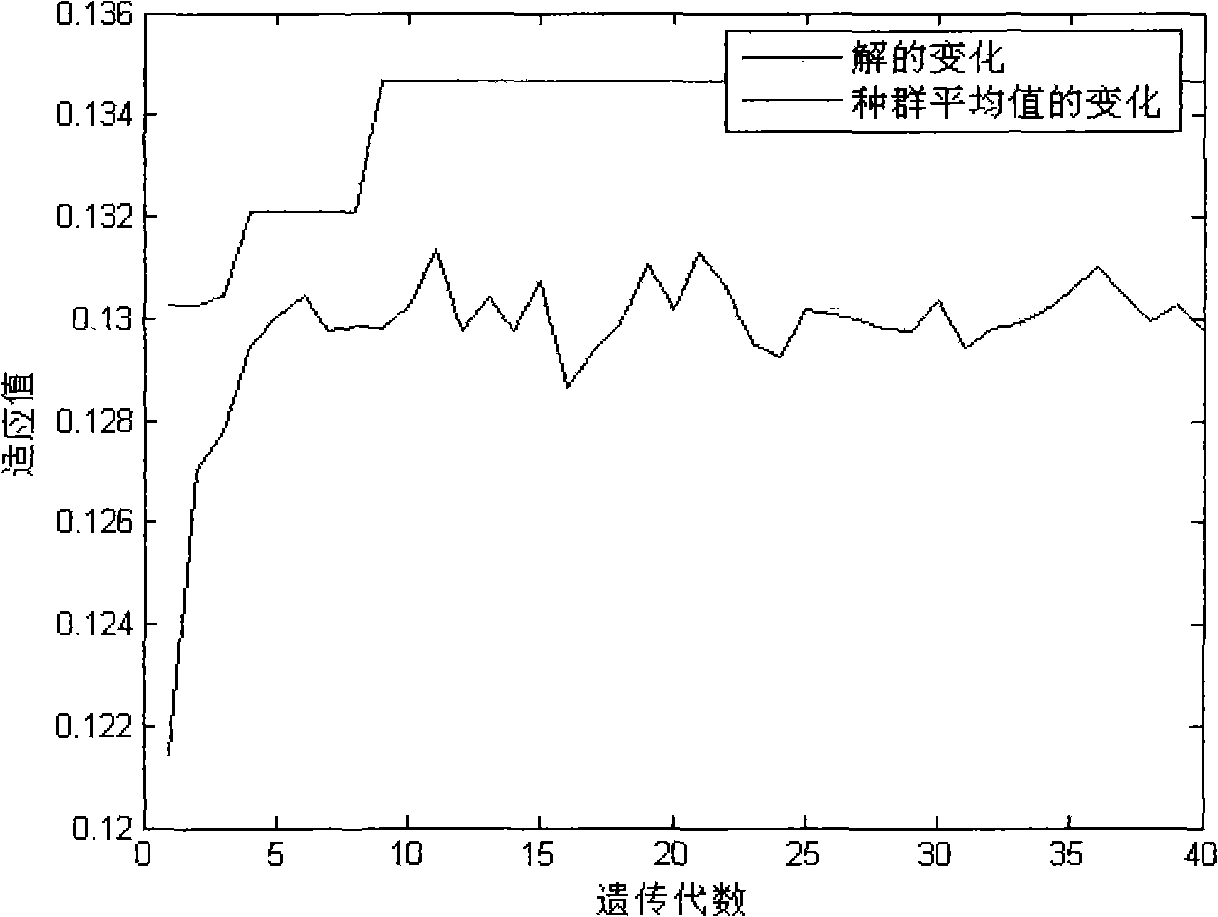

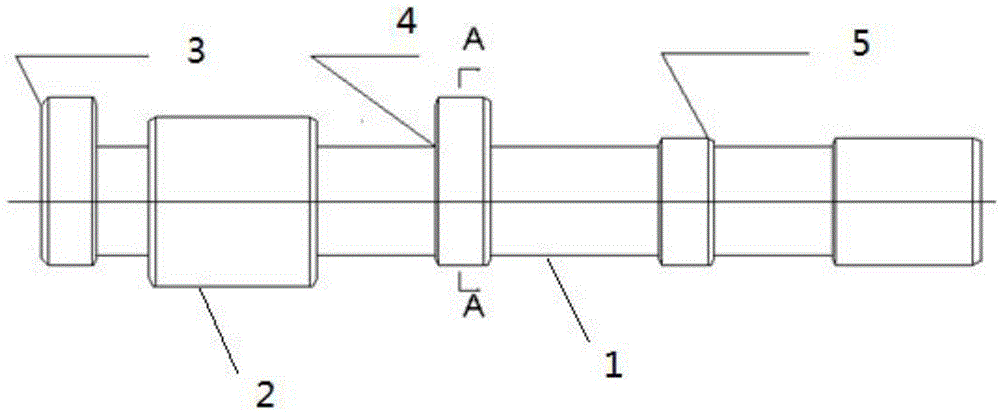

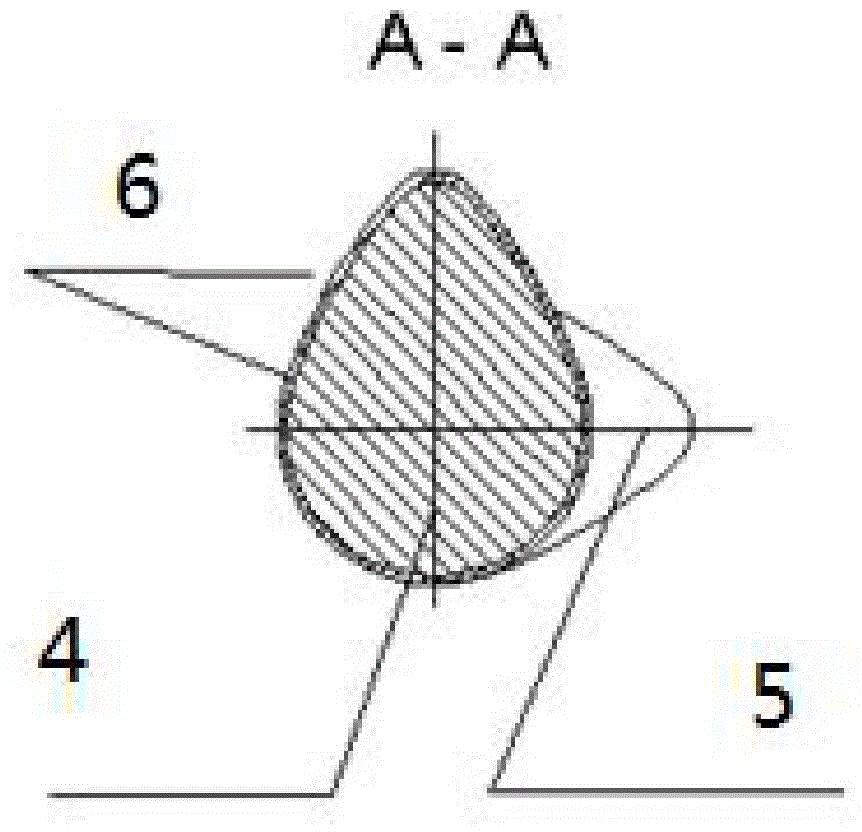

Tolerance optimization method of feed mechanism

InactiveCN102662356AImprove robustnessReduce processing costsTotal factory controlProgramme total factory controlCost evaluationWeight coefficient

The invention discloses a tolerance optimization method of a feed mechanism. The method comprises the following steps: A, establishing a feed mechanism tolerance-processing cost function model: C(t)=a0e<-a1t>, wherein the C(t) expresses processing cost of a corresponding tolerance t and a0 and a1 are weighting coefficients of different processing cost evaluation functions; B, employing a random simulation algorithm to calculate a correlated statistic characteristic of a feed mechanism quality characteristic according to design parameters of all components of the feed mechanism and initial tolerance data; and C, employing a genetic algorithm to output an optimized tolerance of the design parameters according to the correlated statistic characteristic of the feed mechanism quality characteristic. According to the invention, correlated knowledge of tolerance robustness is employed and a quality-cost balance relation is utilized as a quality maxim for a tolerance robustness optimization design; therefore, it can be ensured that the quality of the feed mechanism has good robustness and processing cost of the mechanism can be effectively reduced, thereby reaching an optimum balance between the product quality and the cost and thus further improving product market competitiveness.

Owner:NINGBO TENGGONG PRECISION MFG

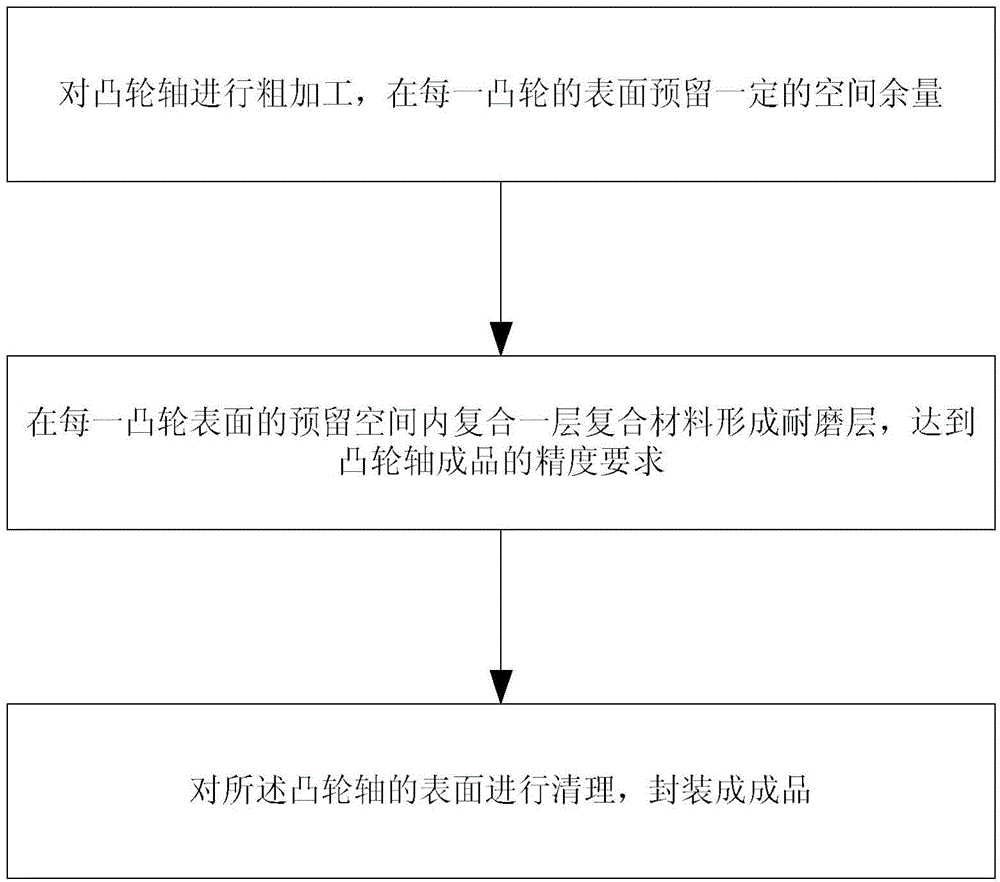

Engine camshaft and preparation method thereof

InactiveCN103953407AGuaranteed service lifeGuaranteed toughnessValve arrangementsMolten spray coatingWaste productEngineering

The invention relates to an engine camshaft. The engine camshaft comprises a main shaft, a plurality of cams and bearings, wherein the main shaft of the camshaft is made of one material for maintaining tenacity and strength; part of the surface of each cam adopts another abrasive resistant material to form an abrasive resistant layer so as to have resistance to abrasion and effectively ensure the service life of the engine camshaft. According to the preparation method, a heat treatment quenching process, a flaw detection process and a hardness test process are eliminates, loss of waste products of which the surfaces have slight cracks due to quenching is avoided, and the comprehensive economic cost and the quality cost are low.

Owner:SUZHOU INDAL PARK INSTITUE OF VOCATIONAL TECH

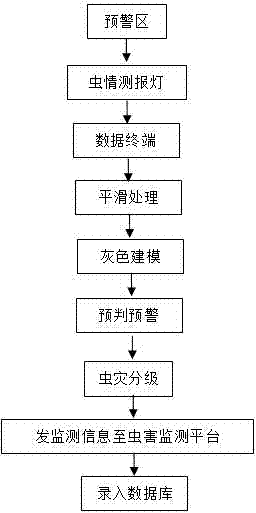

Short-term early warning method for crop pests

ActiveCN107103395ASave preventive treatment costsReduce pesticide residuesForecastingPesticide residueShort terms

The invention discloses a short-term early warning method for crop pests. The short-term early warning method for crop pests comprises the following steps of 1, performing annual monitoring of the number of pests in the early warning area where the pest forecasting lights are located, and sending the monitoring results to the data terminal; 2, smoothly processing data for the monitoring information of the pest forecasting lights; 3, based on the data after the smoothing, using the gray modeling method to establish the normal model of pest situation changes; 4, based on the rising trend of the normal model of pest situation changes, determining the specific time point of crop pest outbreaks; 5, classifying the degree of plague of the early warning area based on the pest data; 6, sending the monitoring information to the plague monitoring network platform; and 7, recording the warning information specific data into the data terminal database. The beneficial effect is that the monitoring is real-time, the implementation is convenient, the manual cost is greatly saved, the early warning is accurate and effective, the prevention cost is saved, the amount of pesticide residues of the crop is reduced, and the crop yield and output are improved.

Owner:宁波鹏博云控科技有限公司

Rubber tube and rubber tube connecting piece assembling structure and assembling workbench

The invention provides a rubber tube and rubber tube connecting piece assembling structure and an assembling workbench. The rubber tube and rubber tube connecting piece assembling structure comprises the workbench, a first rubber tube locating block, a rubber tube limiting sliding block and a rubber tube connecting fixing block. The first rubber tube locating block is arranged above the workbench. An upper rubber tube fixing block is arranged on the upper side of the first rubber tube locating block. A rubber tube fixing device is arranged on the right side of the first rubber tube locating block. The rubber tube connecting fixing block is arranged on the right side of the rubber tube fixing device. Pneumatic assembling of a rubber tube assembly is achieved, the labor intensity of operation workers is lowered, and manual cost is reduced. The consistency of products assembled through a tool is greatly improved relative to manual operation, the quality complaints about the size are reduced, and quality cost can be reduced. Different parts can be fast switched through the tool, and replacement can be achieved within two minutes. Rubber tube locating is accurate through a rubber tube limiting block, operation is easy, and the assembly is taken conveniently. A locating device is relatively independent, and free combination can be achieved. The product tool development cost can be reduced.

Owner:TIANJIN PENGYI GRP CO LTD

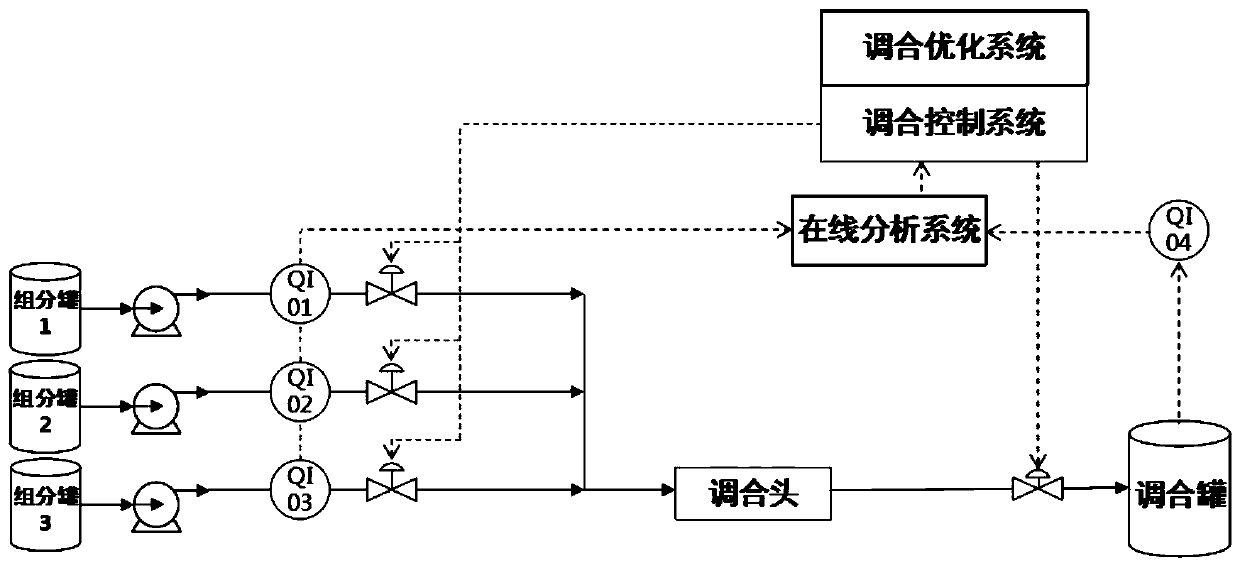

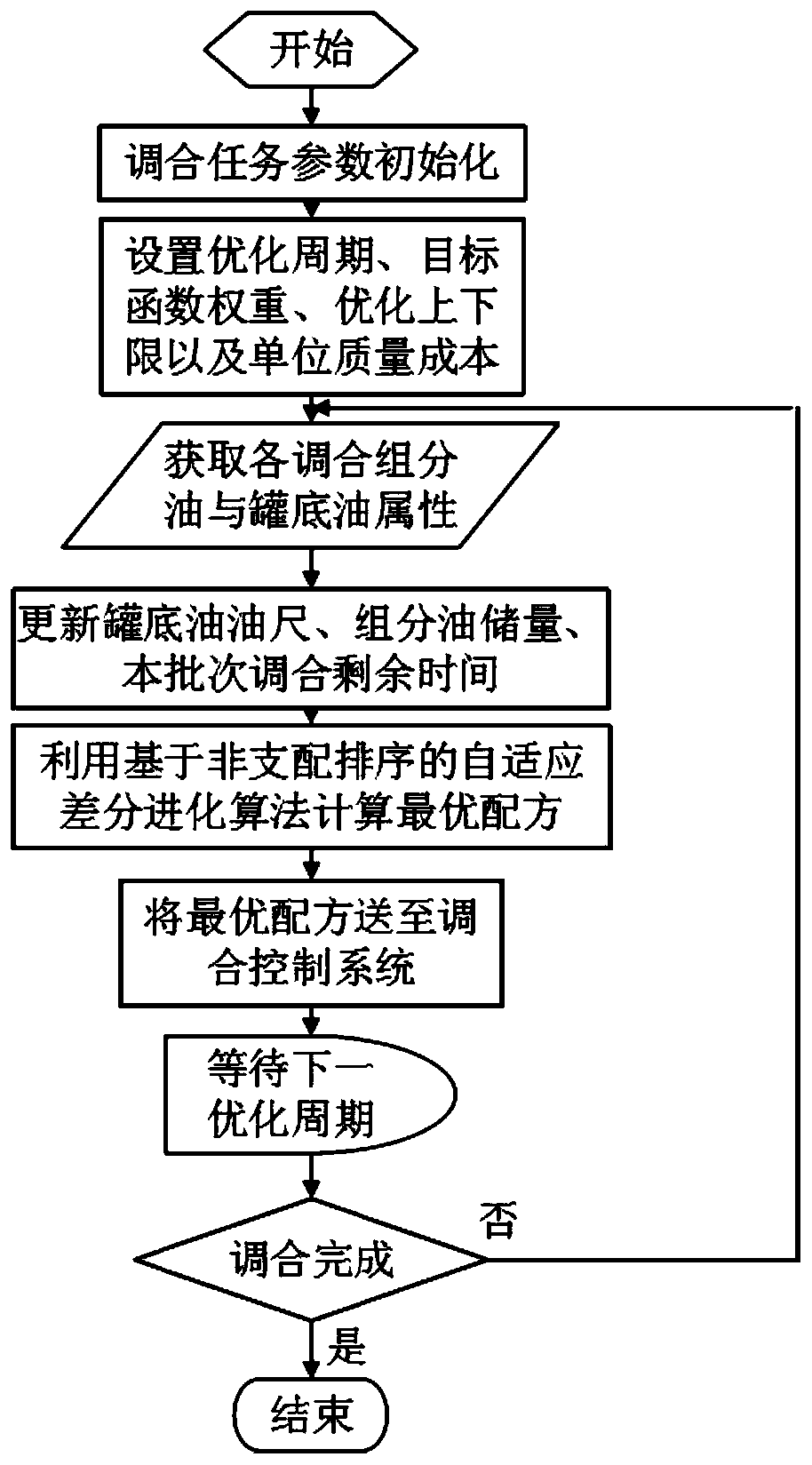

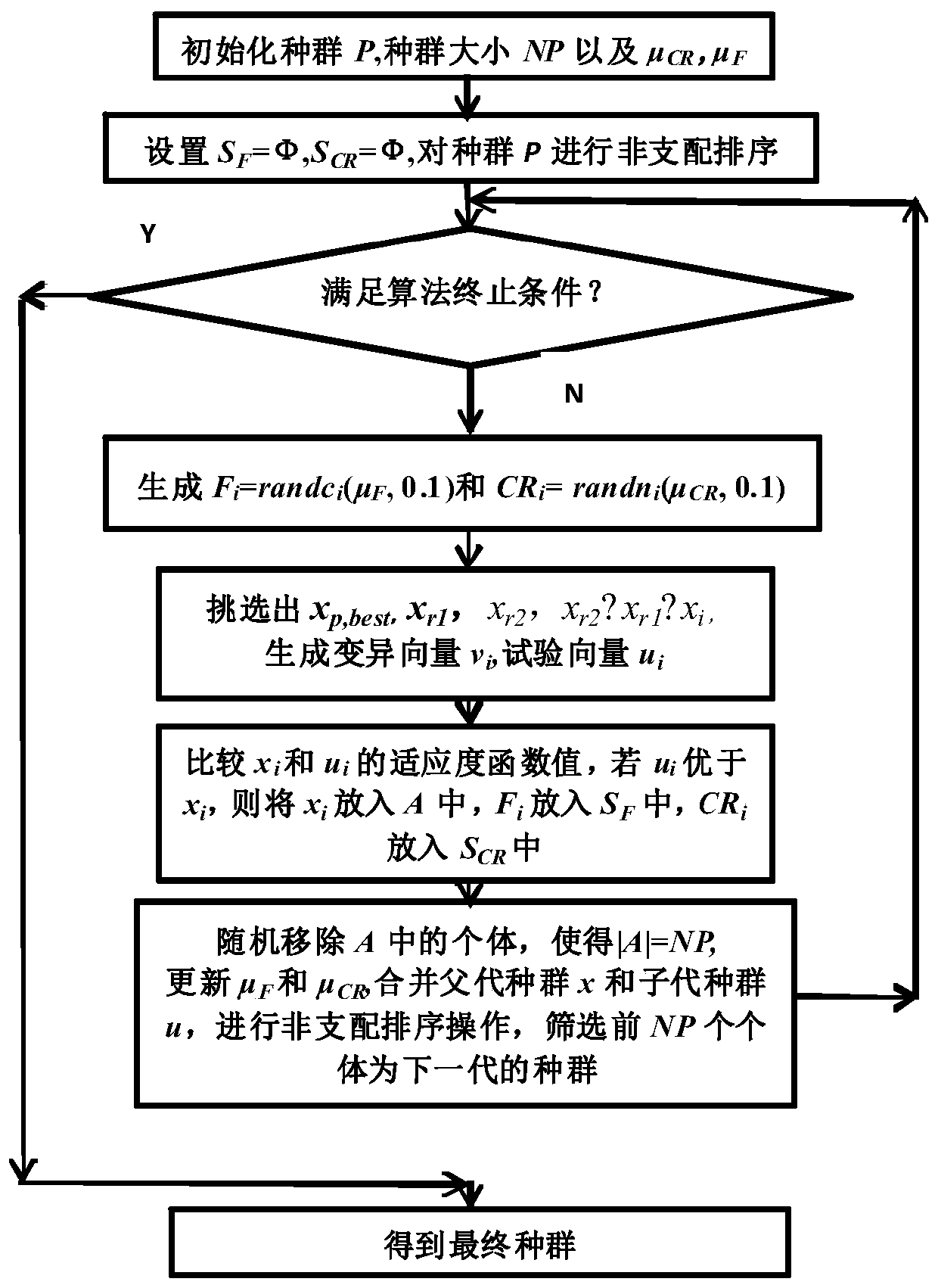

Online multi-object crude oil blending optimization method

The invention discloses an online multi-object crude oil blending optimization method. The method comprises the steps of: firstly, performing blending task parameter initialization; secondly, settingan optimization period and a target function, and setting the upper limit and the lower limit of each attribute index of blended crude oil, the oil reserve of each component, the maximum flow of eachrefining line component coil and the unit quality cost of each component oil; then, according to the predetermined optimization period, obtaining each blending component and tank bottom oil attributedata, and updating a tank bottom oil gauge, the component oil reserve and the blending remaining time of the batch; and finally, solving the optimal formula of each blending component in the current optimization period, and sending to a blending control system to execute.

Owner:EAST CHINA UNIV OF SCI & TECH

A project management system and an implementation method based on an industrial cloud platform

InactiveCN108985703AReduce design costComplete in timeMarket predictionsOffice automationQuality by DesignInformation networks

The invention provides a project management system and an implementation method based on an industrial cloud platform, which is suitable for the platform-based enterprise management mechanism in the field of information network technology to solve the problem that the various phases encountered in the new product development process are difficult to control, fragmentation of project materials, difficult to manage and control the R&D cost of the project. Based on a six Sigma management and amoeba business model, the project management system connects the time node of new product development with quality and cost, and enhances the designer's awareness of design quality cost and time cost, so that the product designed and developed can meet the current market demand of fast product renewal and high cost performance ratio.

Owner:KOCEL INTELLIGENT FOUNDRY IND INNOVATION CENT CO LTD

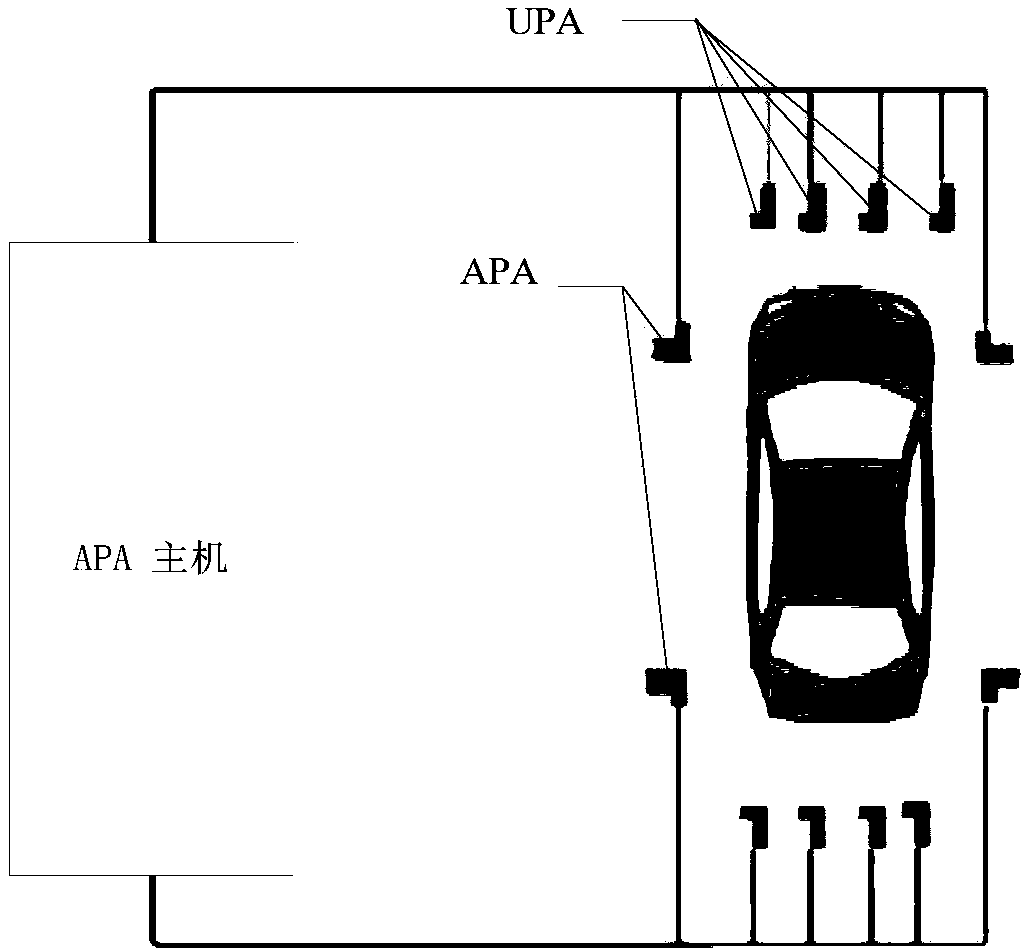

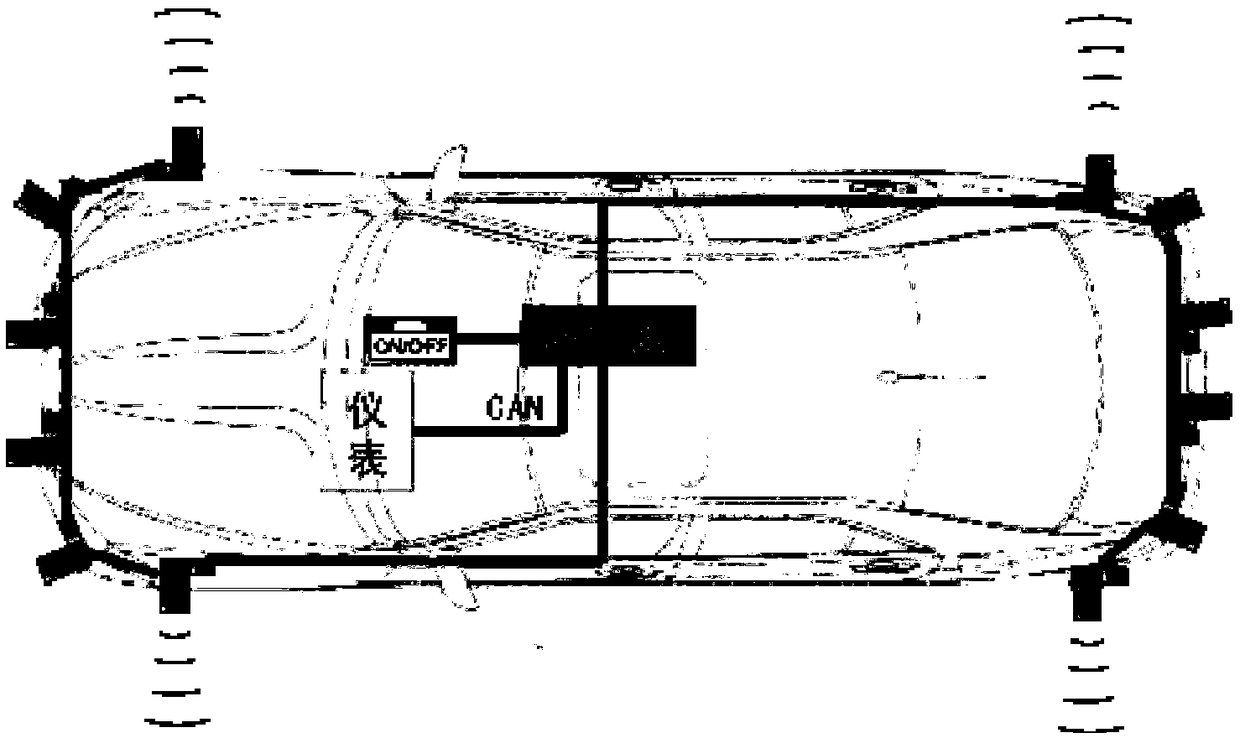

Automatic parking system and method using universal probes

The invention discloses an automatic parking system and method using universal probes, and relates to the technical field of automobile auxiliary systems. The system comprises an automatic parking controller and a plurality of probes of the same type, and the probes are arranged at the front end, rear end, corners and side surfaces of an automobile respectively; the probes arranged at the cornersand the side surfaces detect a parking space, and the probes are changed from two types to one same type; great convenience can be provided for production without distinguishing different parts, and related part design and fool-proof and separated management of production and inventory are omitted; the product detection accuracy (in parking space scanning) is greatly improved, and the automatic parking performance can be significantly improved; through the adoption of the same type of universal probes, the product system cost, management cost, quality cost and maintenance cost are reduced.

Owner:广州优保爱驾科技有限公司

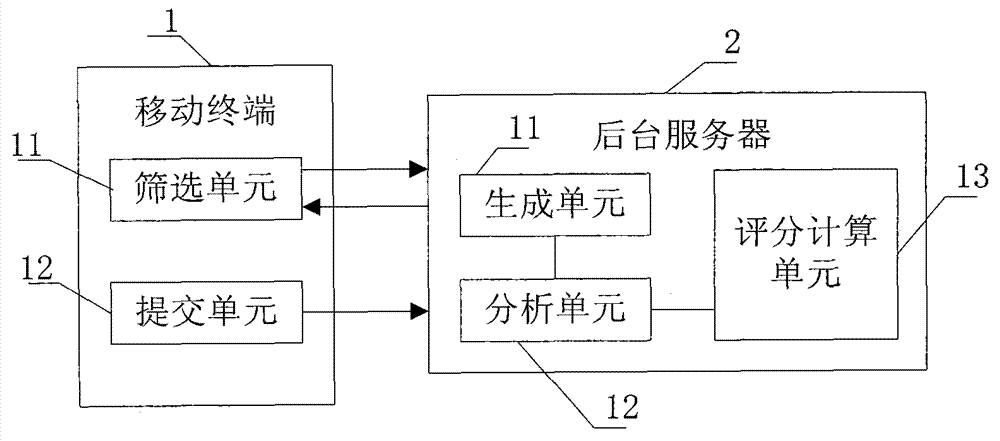

Mobile real estate field service checking system

The invention discloses a mobile real estate field service checking system. The mobile real estate field service checking system comprises a mobile terminal carried by a checker, and a background server. The mobile terminal comprises a screening unit and a submitting unit. The background server comprises a generation unit and an analysis unit. A task is automatically generated through the effective combination of the mobile terminal and the background server; it is ensured that a field efficiently run according to established rules through standard flow solidified in the mobile check system and key points solidified in the mobile check system, and therefore new staff can work according to this, the supervision quality cost is reduced, interaction is timely, the workflow is simplified, data statistics and analysis conform to the characteristics of field check movement, data foundations are provided for performance assessment, copying of multiple projects in the management process is facilitated, the check efficiency and quality are finally improved, and the user experience is improved.

Owner:淳正兴

Method and apparatus for designing and manufacturing electronic circuits subject to process variations

ActiveUS8578319B2Additional circuitryImprove the environmentDetecting faulty computer hardwareCAD circuit designMemory hierarchyEngineering

Methods and apparatus are described in which, at design-time a thorough analysis and exploration is performed to represent a multi-objective “optimal” trade-off point or points, e.g. on Pareto curves, for the relevant cost (C) and constraint criteria. More formally, the trade-off points may e.g. be positions on a hyper-surface in an N-dimensional Pareto search space. The axes represent the relevant cost (C), quality cost (Q) and restriction (R) criteria. Each of these working points is determined by positions for the system operation (determined during the design-time mapping) for a selected set of decision knobs (e.g. the way data are organized in a memory hierarchy). The C-Q-R values are determined based on design-time models that then have to be “average-case” values in order to avoid a too worst-case characterization. At processing time, first a run-time BIST manager performs a functional correctness test, i.e. checks all the modules based on stored self-test sequences and “equivalence checker” hardware. All units that fail are deactivated (so that they cannot consume any power any more) and with a flag the run-time trade-off controllers, e.g. Pareto controllers, are informed that these units are not available any more for the calibration or the mapping. At processing time, also a set of representative working points are “triggered” by an on-chip trade-off calibration manager, e.g. a Pareto calibration manager, that controls a set of monitors which measure the actual C-Q-R values and that calibrates the working points to their actual values. Especially timing monitors require a careful design because correctly calibrated absolute time scales have to be monitored.

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW)

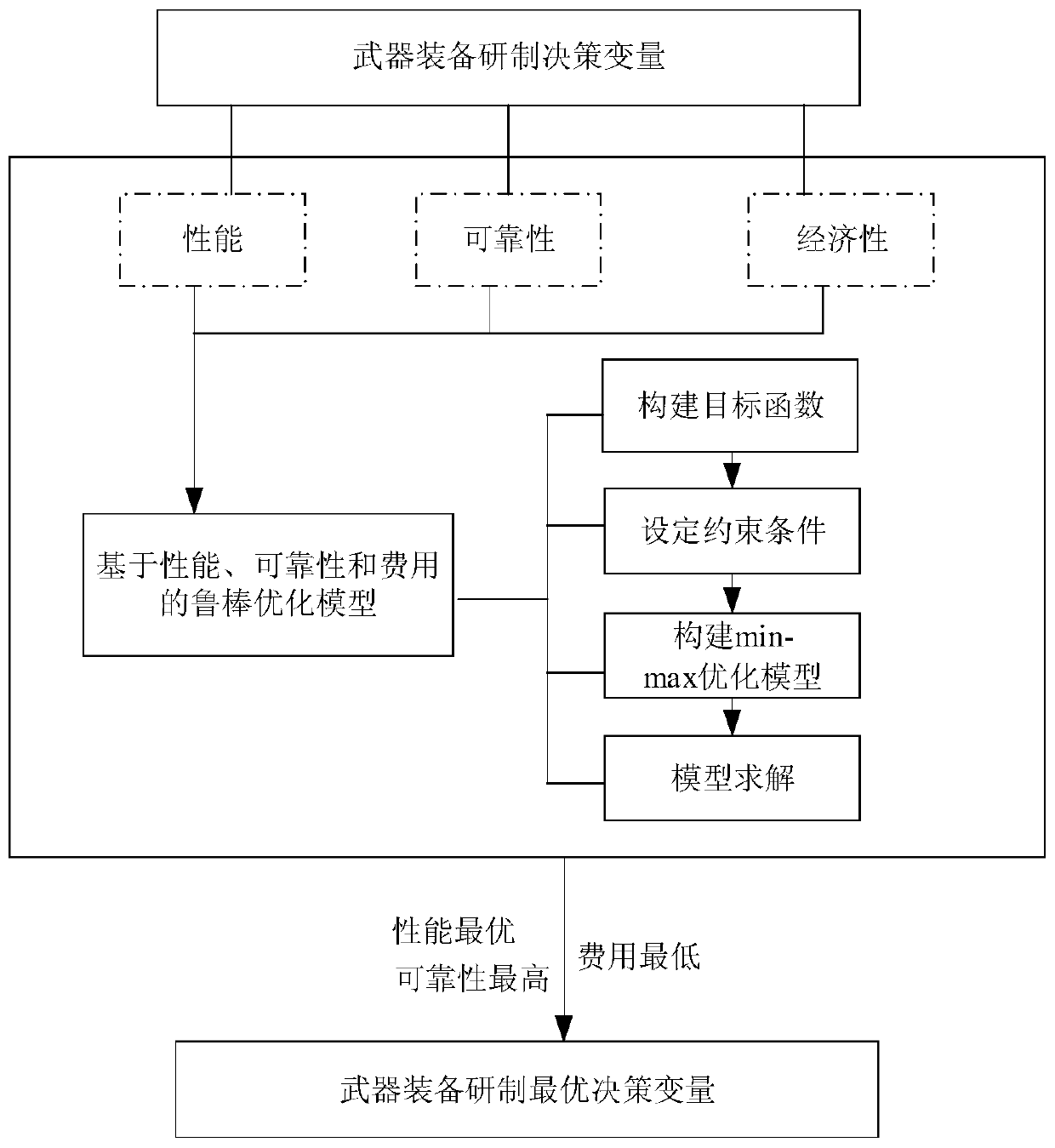

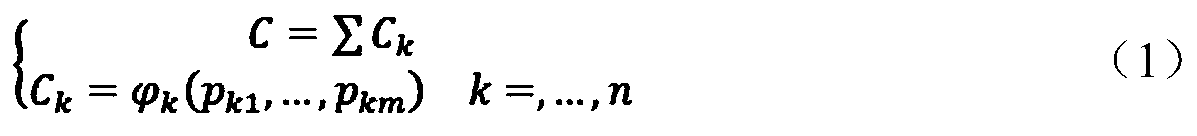

A weapon equipment development decision-making method based on a robust optimization model

The invention relates to a weapon equipment development decision-making method based on a robust optimization model, which belongs to the technical field of product development cost management and technical management, and is suitable for technical research such as development management of weapon equipment products. According to the method, the defects that a conventional cost-efficiency analysismodel only considers the relationship between the performance and the service life cycle cost and a classic quality cost model only considers the relationship between the reliability and the life cycle cost are made up, and the important method support is provided for the integrated management of the equipment performance, the reliability and the economy. The result obtained through the robust optimization method can achieve the purposes of minimum cost, performance optimization and highest reliability at the same time, the organic unification of the performance, the reliability and the economy of the weapon equipment system is achieved, and a reliable and effective means is provided for the weapon equipment research and decision making.

Owner:CHINA AEROSPACE STANDARDIZATION INST

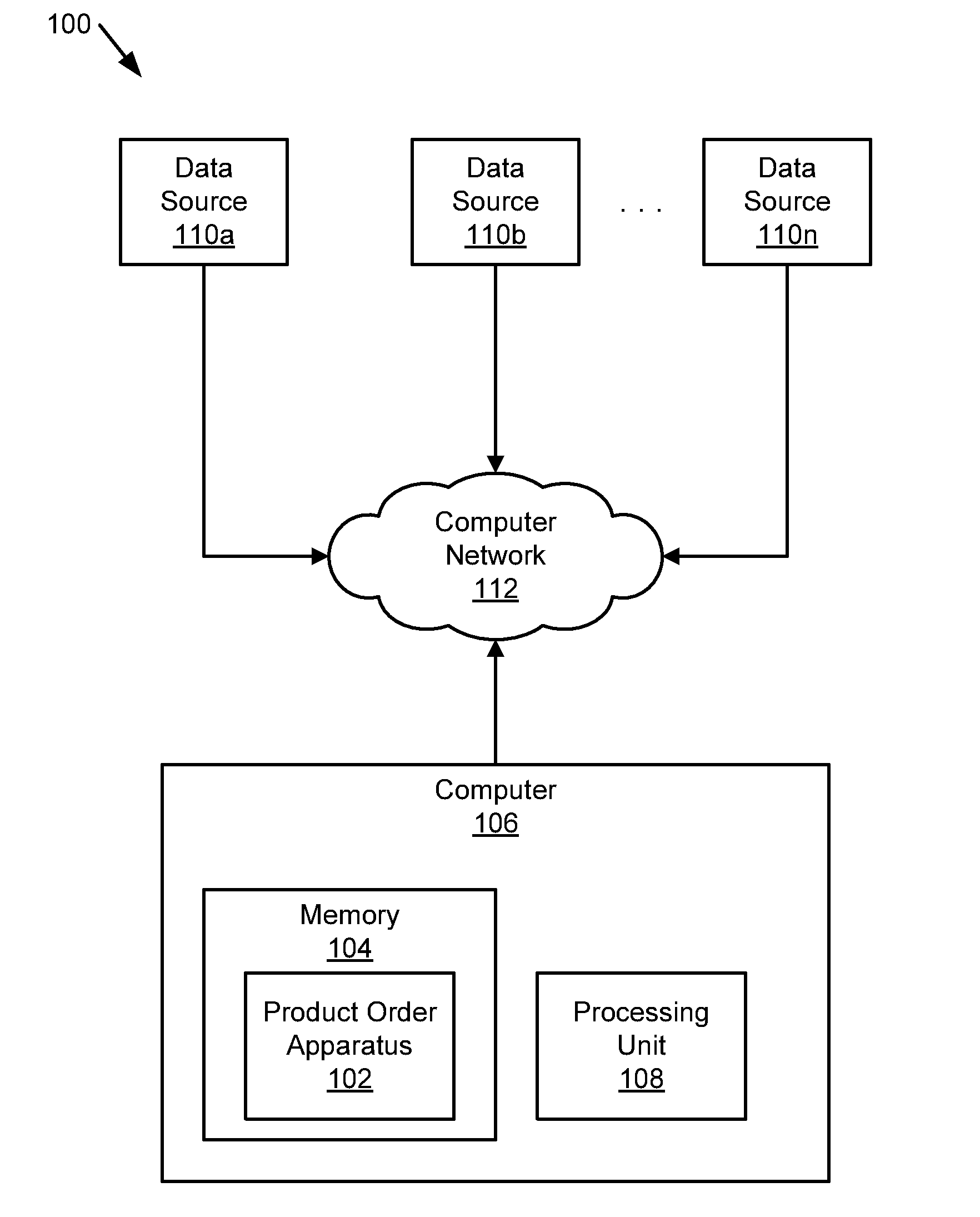

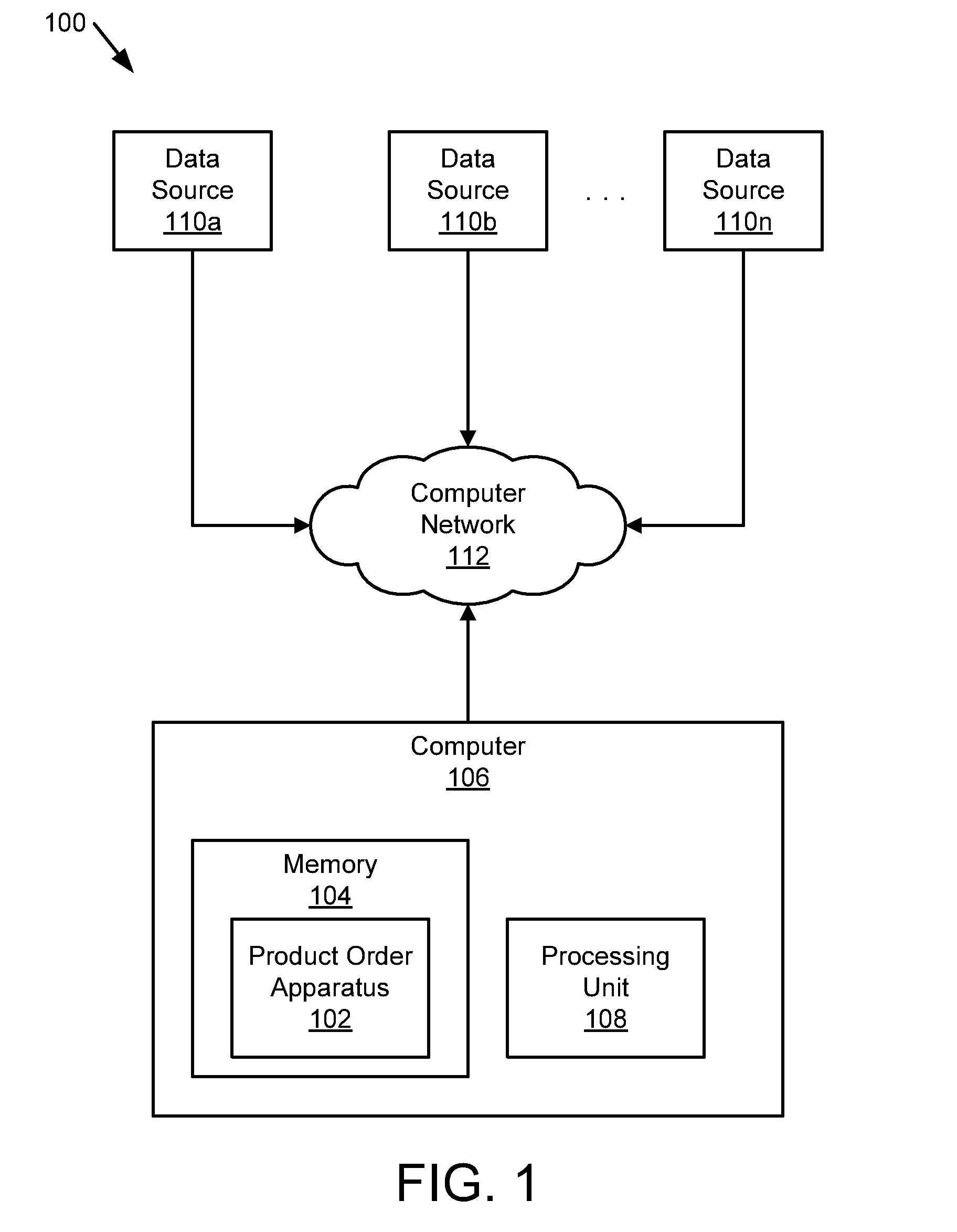

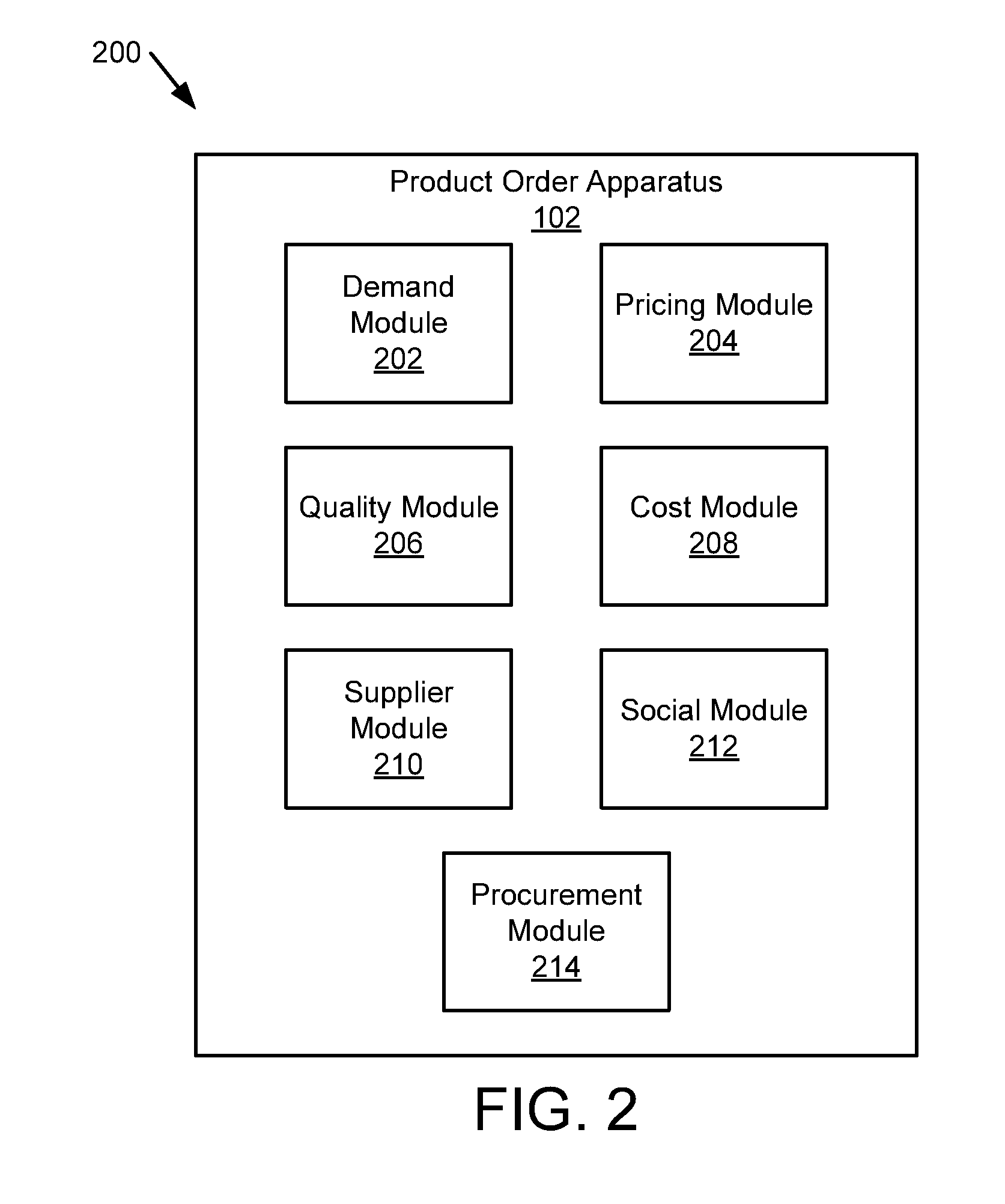

Predictive risk management based product procurement

An apparatus includes a demand module that determines a demand for a product offered from a plurality of suppliers. A pricing module receives cost factors associated with the product to determine a base per unit cost of the product. A quality module receives quality factors associated with the product to determine a per unit quality cost adder. A cost module calculates a procurement cost of the product. A supplier module receives production factors describing a supplier's ability to provide the product. A social module monitors social media for social data describing events related to a supplier's ability to provide the product. A procurement module determines, based on the per unit procurement cost of the product, the production factors, and the social data, a product order allocation for each supplier that fulfills the demand.

Owner:LENOVO ENTERPRISE SOLUTIONS SINGAPORE

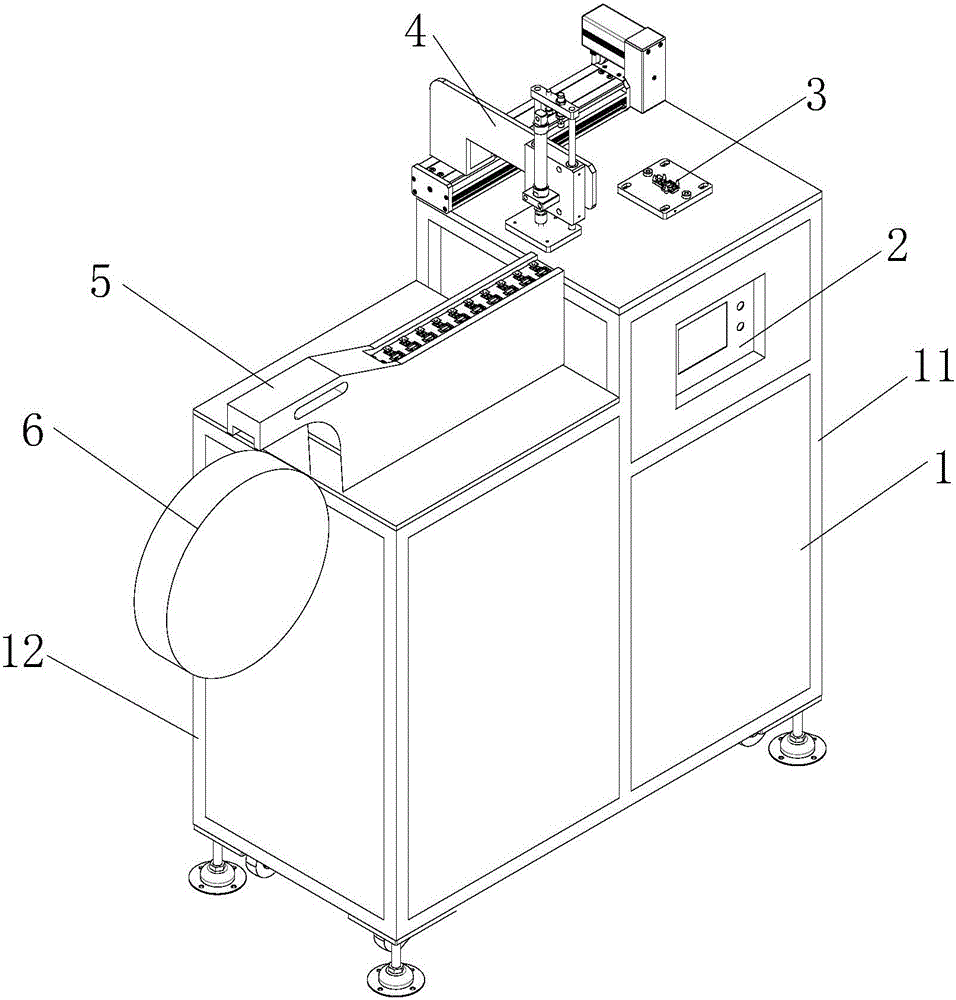

New energy battery assembly device

InactiveCN105730412AHigh precisionReduce labor costsElectric propulsion mountingVehicle servicing/repairingElectrical batteryNew energy

The invention provides a new energy battery assembly device. The new energy battery assembly device comprises a support plate, a pressing plate, a limiting mechanism, a grabbing mechanism and a power mechanism, wherein the support plate is opposite to one surface of the pressing plate, the power mechanism is arranged on the support plate and is in transmission connection with the pressing plate, the limiting mechanism is arranged between the support plate and the pressing plate, the grabbing mechanism is arranged on the other surface of the pressing plate, the grabbing mechanism comprises four grabbing units which are opposite to four positioning holes of a new energy battery, and each grabbing unit comprises a silicone bushing, a sleeve and an inner rod which are positioned in the silicone bushing. The new energy battery assembly device is not limited to the assembly space and size of a battery case and the distance between installation batteries, so that the labor intensity of manual battery installation and integration is reduced, the battery installation and integration precision is increased, the production efficiency is improved, and the problems of scrapping of a short-circuit battery and the like caused by mistakes of people are solved in a battery installation process, thereby reducing the labor cost, manufacturing cost and quality cost of battery assembly enterprises.

Owner:BERGSTROM INTELLIGENT EQUIP KUNSHAN CO LTD

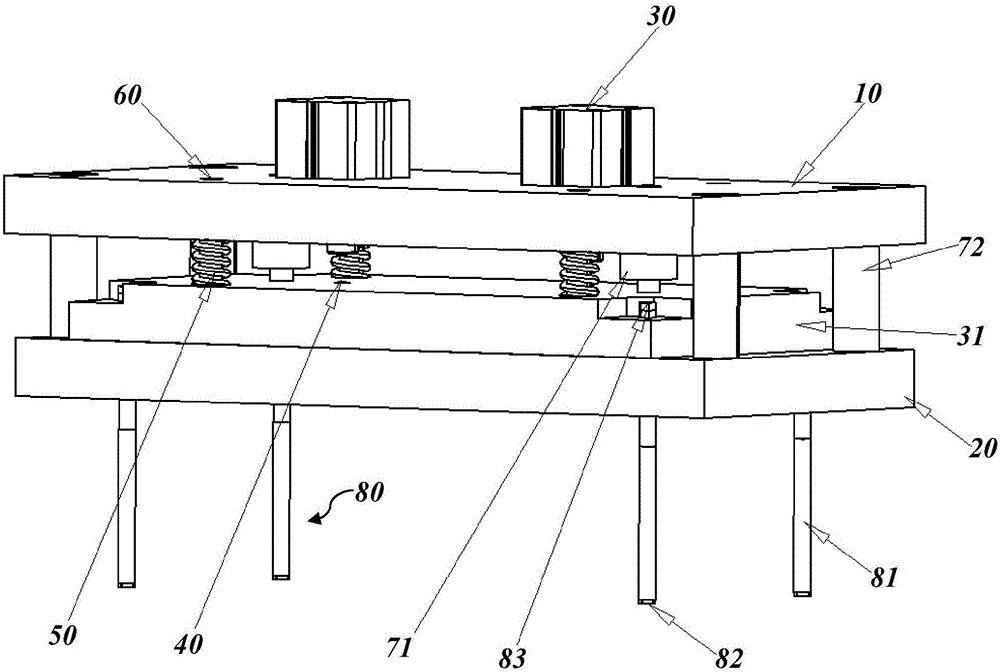

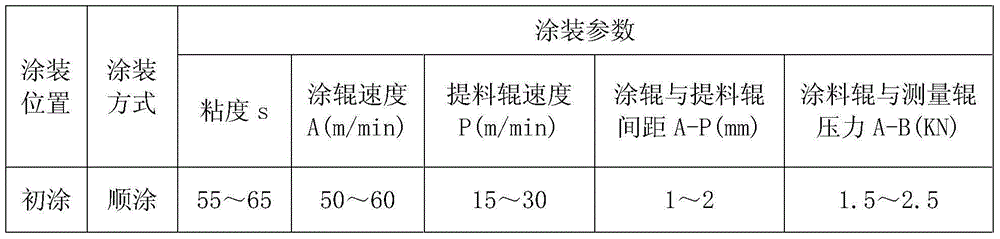

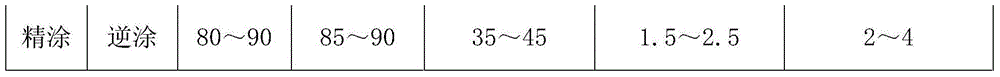

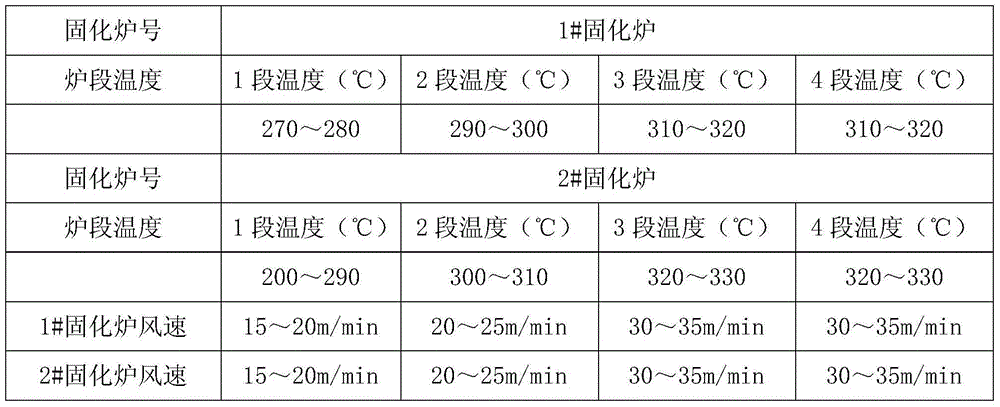

Stability control method for checker forms of checker color-coated plate

Disclosed is a stability control method for checker forms of a checker color-coated plate. The checker forms of the color-coated plate are subjected to surface pretreatment, the coating process, the film-thickness control process, the curing process and the wind-speed control process are optimized, and a strip steel is staggered on the two sides of a finishing coat lifting roller to measure a wet film through a wet film instrument in the trial coating and production processes; meanwhile, coating consumption in unit time is determined through coating area, coating rate and dry film conversion control and monitored; wet film monitoring and coating consumption control prevail in terms of the finishing coat, direct dry film detection serves as the standard of undercoat, and the color-coated plate with the stable checker forms is obtained. Compared with the prior art, the stability control method for the checker forms of the checker color-coated plate has the beneficial effects that the checker effect is good; the control over the checker forms is stable; the quality loss is reduced; continuous stable production is guaranteed; the product yield reaches over 99%; the checker control quality of a checker special-effect color-coated steel plate is improved; the quality cost is reduced.

Owner:ANGANG STEEL CO LTD

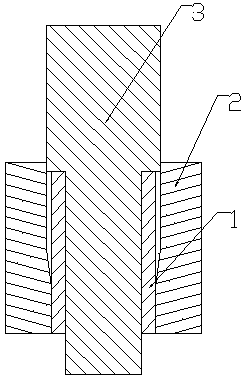

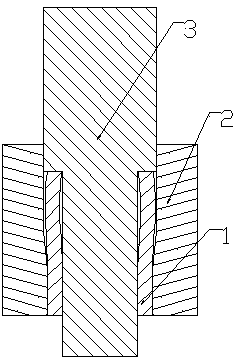

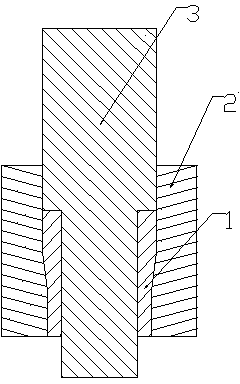

Processing method of local-reinforcement type full fiber cylinder barrel of hydraulic cylinder

ActiveCN104308473AAchieve local reinforcementOptimized load distributionHydraulic cylinderMetal fibers

The invention discloses a processing method of a local-reinforcement type full fiber cylinder barrel of a hydraulic cylinder, and relates to a local-reinforcement type full fiber cylinder barrel of a hydraulic cylinder. The processing method has the advantages that the use quality of the cylinder barrel of the hydraulic cylinder is improved, the design difficulty is decreased, the utilization rate of material is improved, and the processing cost and quality cost are reduced. The main material of the cylinder barrel is directly subject to local upsetting, the continuous distribution of metal fibers on the whole cylinder barrel is maintained, the local reinforcement of the cylinder barrel is realized, the stable transition and distribution of strength between the local reinforcement area and the cylinder barrel is realized, the load distribution of the cylinder barrel can be optimized, and the quality reliability of the cylinder barrel is favorably improved.

Owner:XCMG HYDRAULICS CO LTD

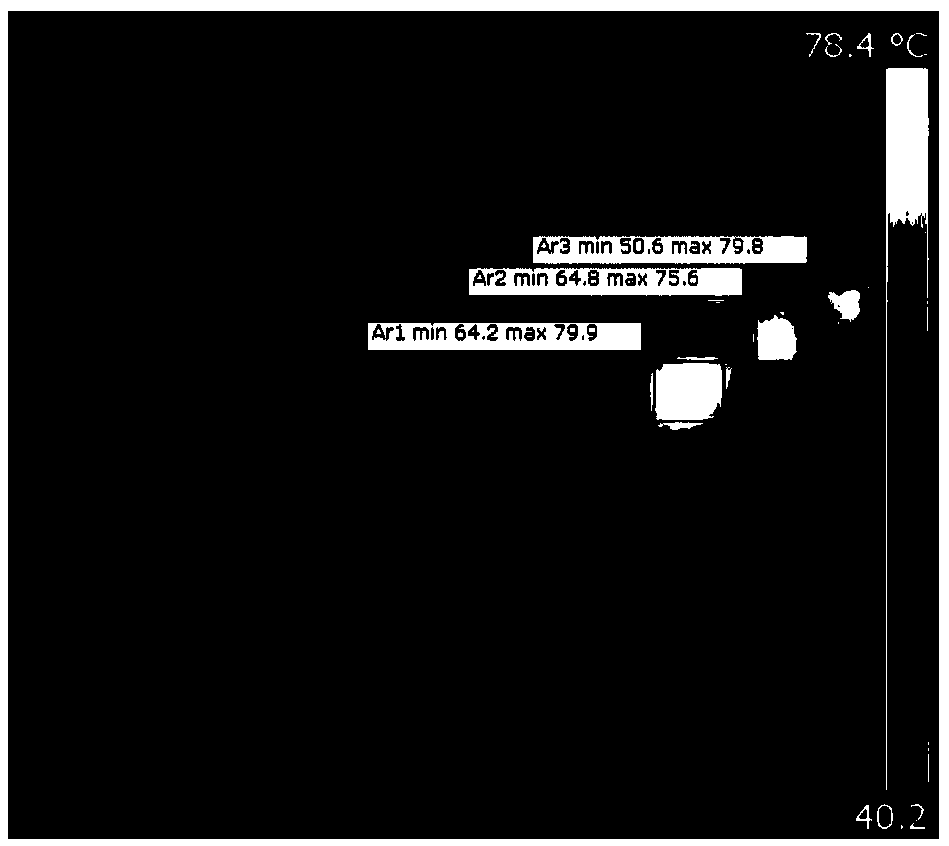

Method for detecting thermal design rationality of electronic product based on infrared thermal imaging technology

InactiveCN108303633AFlexible operationIncrease coverageRadiation pyrometryPrinted circuit testingFailure rateEngineering

The invention discloses a method for detecting the thermal design rationality of an electronic product based on an infrared thermal imaging technology, which comprises the steps that infrared imagingdata of a product to be detected is captured through an infrared thermal imaging instrument, the data is transmitted to a computer, and the computer analyzes and judges the measured data according toset detection standards so as to complete detection for the thermal design rationality of the electronic product. The infrared thermal imaging instrument is taken as a main body for detection, and only the handheld infrared thermal imaging instrument is required to be selected to perform detection on a normally operating or aging product; and the operation is flexible, the coverage is comprehensive, and the universality is high. Compared with the prior art, the operation difficulty can be reduced, the test time can be saved, and the risk of test omission is eliminated. The thermal design rationality serves as a necessary item for the hardware reliability in the research and development and sample design finalizing stages of the electronic product; thermal design defects are effectively measured and discovered before mass production of the electronic product, thereby performing rectification and remedy timely, and being capable of effectively reducing the failure rate and the quality cost of the electronic product after mass production.

Owner:SICHUAN JINWANGTONG ELECTRONICS SCI & TECH

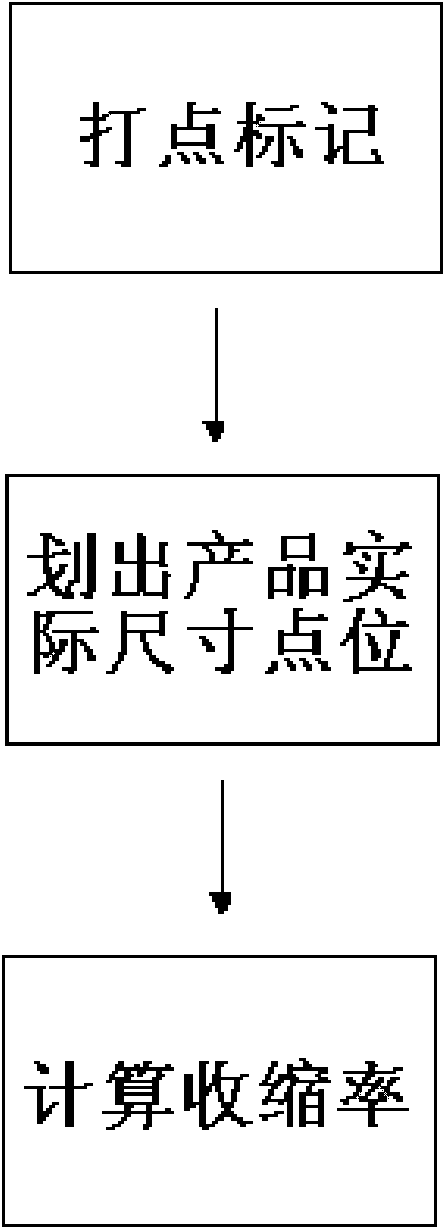

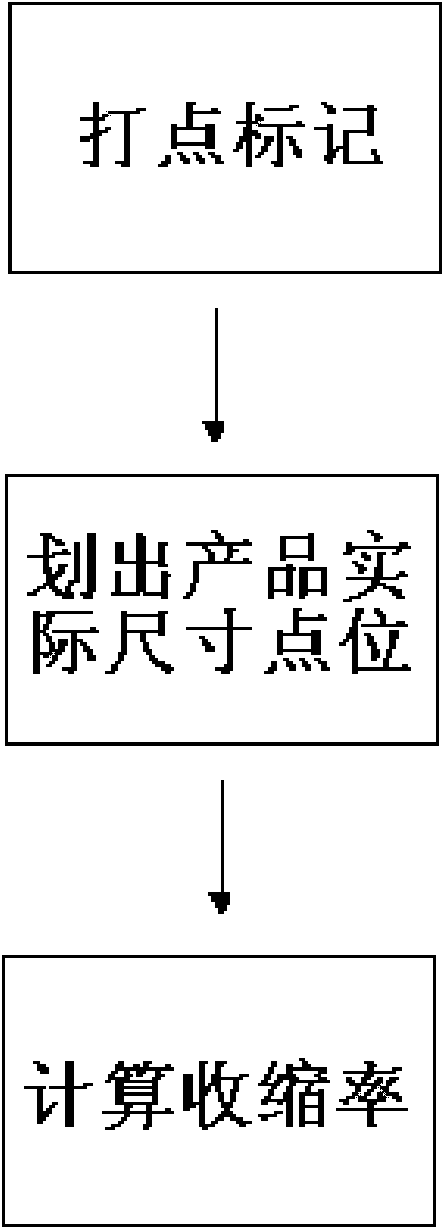

Method for confirming shrinkage of automobile part subjected to injection molding

InactiveCN102179911AImprove project development capabilitiesImprove pass rateSize differenceWaste product

The invention relates to a method for confirming the shrinkage of an automobile part subjected to injection molding, which comprises the following steps of: (1) selecting at least one position on an injection mold of the automobile part, and dotting and marking; (2) performing injection molding on a product on the mold, and marking a point position of the actual size of the product after the product is subjected to injection molding; and (3) comparing the size difference of the mold and the product, and calculating the shrinkage of the part made of a certain material. By the method, product yield is improved, waste products are reduced, and quality cost is reduced; and problems possibly occur after the product is subjected to mass production are demonstrated and foreseen through tests at the product development stage, the project development capability of a factory is improved, and guarantee is provided for upgrading the technology of the production factory and enhancing a cooperative partnership between the production factory and an automobile main engine factory.

Owner:嘉兴敏胜汽车零部件有限公司

Method for eliminating color difference defects of special-effect color-coated sheets

InactiveCN105880134AReduce chromatic aberration defectsHigh yieldCoatingsSpecial surfacesMaterials processingViscosity

A method for eliminating color difference defects of special-effect color-coated sheets comprises coating material processing and color confirmation, coating material viscosity control, coating process selection, and finished product sampling and color confirmation. The method comprises the following steps: scraping a coating material sample, in which no special-effect related additive is added, measuring color difference of the coating material sample, and controlling a color difference value at 0.5-1.0; adding a special-effect related additive into the coating material sample, scrapping and measuring the coating material sample, controlling the color difference value at 0-0.5, and creating a tendency diagram; controlling the coating material stirring time, the stirring revolution and the coating material temperature, and performing coating with primary liquid; ensuring that the liquid supply frequency of a paint supply pump is 60-65 times per minute; ensuring that the ratio of roller speed to linear speed of a lifting roller is 0.7-0.75 and the immersion depth is 17-19 mm; ensuring that the consumption speed is 4.6-5.4 kg / min and the wet film thickness is 65-75 mu m; sampling each sub-roll, and measuring a side-center-side color difference value, and performing color difference comparison; and inspecting each sub-roll twice, and ensuring that the visual colors of a standard sample and the sub-roll sample are basically consistent. Through the method, the color difference defects of color-coated sheets with special effects such as reticulate pattern, wrinkle and fluff can be reduced, the product yield is up to more than 99%, and the quality cost is greatly reduced.

Owner:ANGANG STEEL CO LTD

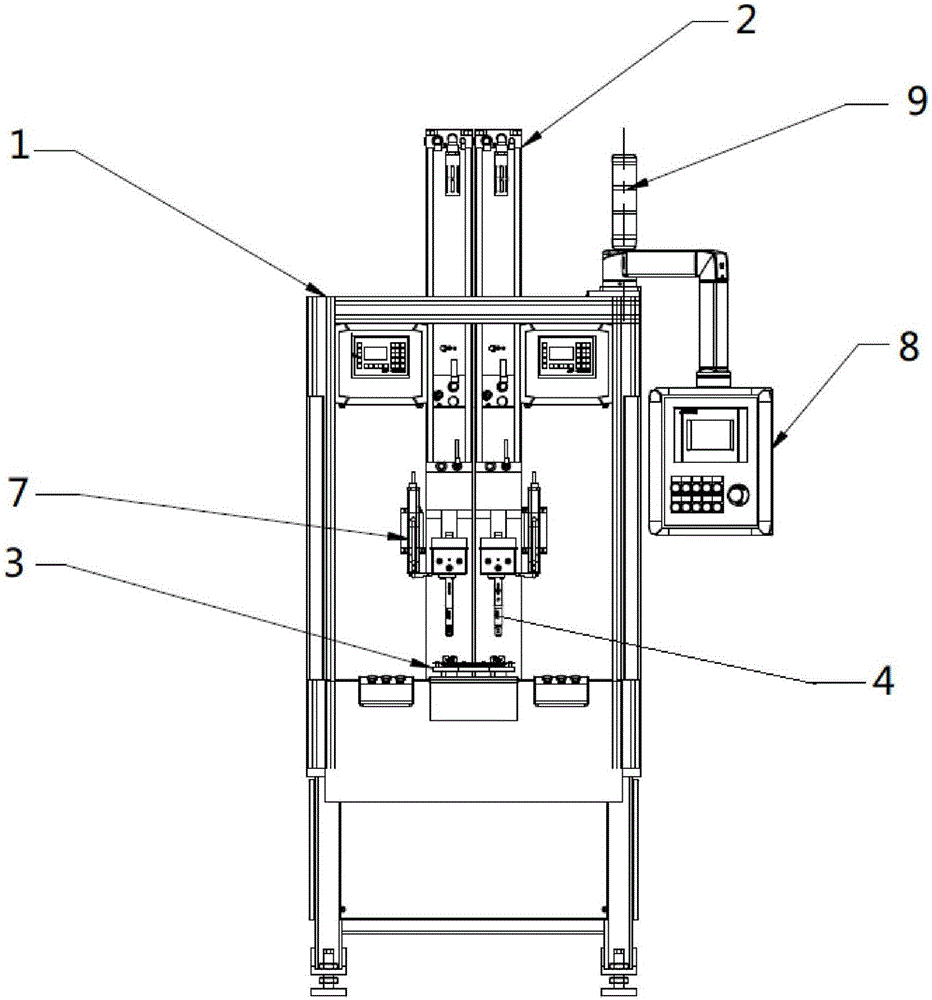

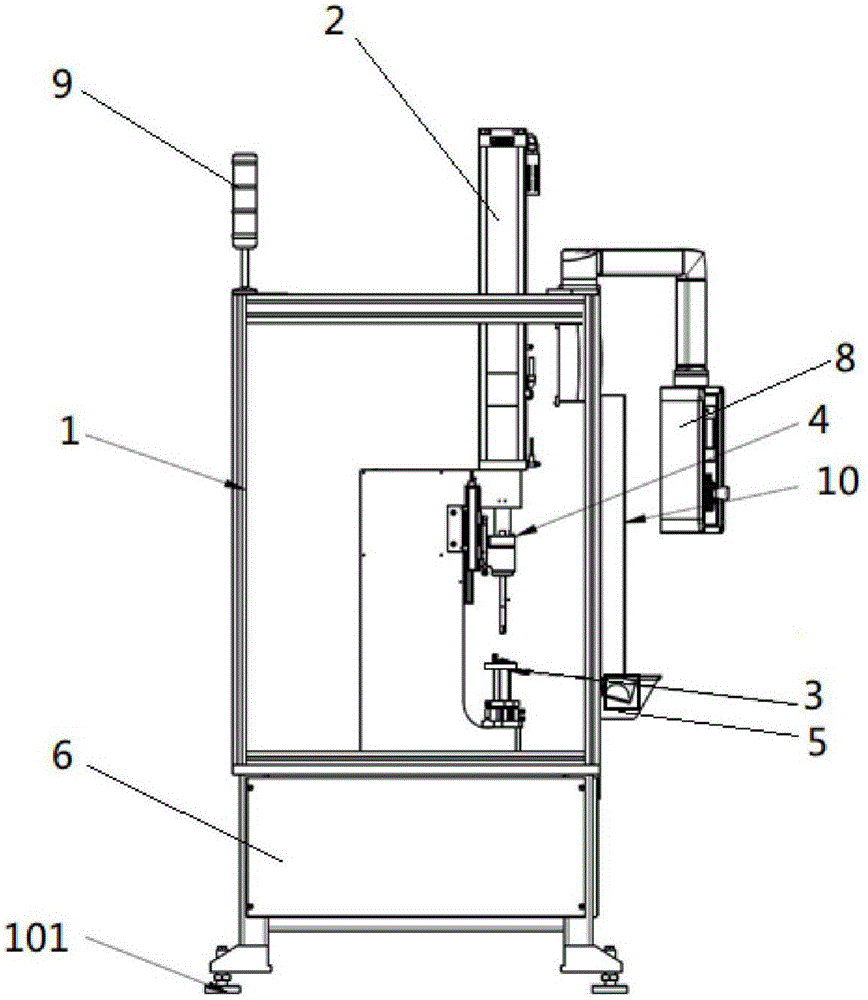

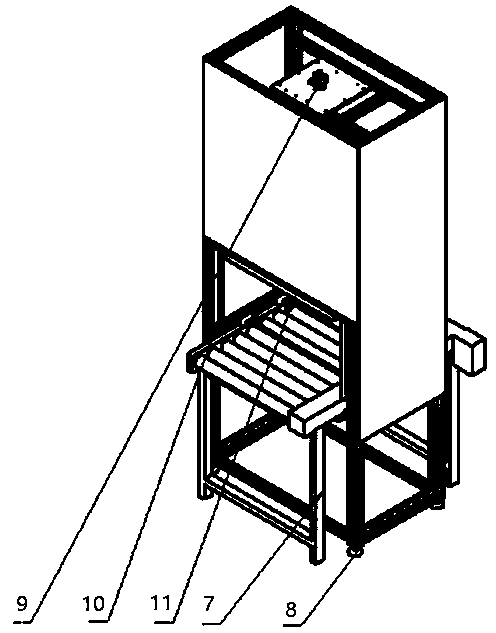

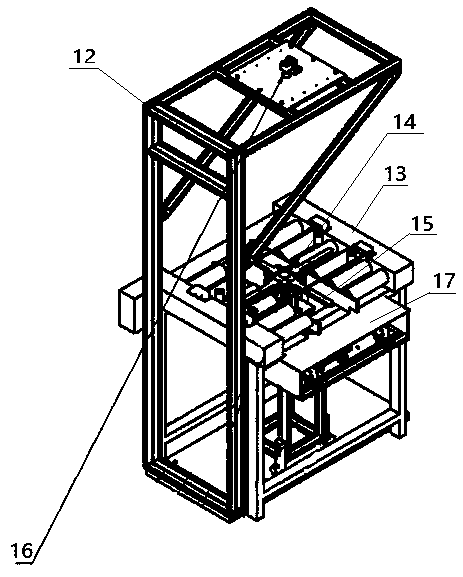

Punch-riveting system applicable to manufacture of automobile parts and components, and operation method for same

InactiveCN106563735AAvoid the risk of breakdownEliminates variations in mechanical propertiesShaping toolsMetal-working feeding devicesPunchingManufacturing technology

The invention relates to the technical field of automobile manufacture and specifically relates to a punch-riveting system applicable to manufacture of automobile parts and components, and an operation method for the same. The punch-riveting system applicable to the manufacture of the automobile parts and components comprises a rack, wherein a press machine which can connect nuts with punching parts in a punching manner is disposed on the rack; the rack adopts a cuboid frame structure; all edges of the cuboid frame are made of steel; protective covers are disposed outside the frame structure; and the protective covers cover the back face, the top face, the bottom face, the left side face and the right side face of the rack. By the technical scheme, the system and the method provided by the invention have the advantages that operations are simple and convenient; positioning is accurate; risks in that the punching parts are punctured by the nuts during punching can be effectively avoided by the operation manner, and the production rejection rate and quality cost can be reduced; and changes of internal mechanical performance of the parts and components caused by thermal effects in traditional welding can be eliminated, and dynamic performance can be enhanced.

Owner:SHANGHAI SUZHEN MACHINERY MFG CO LTD

On-line identification and measurement automation system of vehicle wheel

InactiveCN110530260AAchieving identifiabilityRealize measurementUsing optical meansVehicle wheel testingAutomatic transmissionStatistical analysis

This application relates to the technical field of automation detection systems, and specifically relates to an on-line identification and measurement automation system of a vehicle wheel. The systemcomprises a first automatic transmission material line, a vehicle wheel automatic identification system, a vehicle wheel position and posture automatic adjustment mechanism, a transporting mechanism,an on-line detection device and a second automatic transmission material line, so that automatic identification and measurement of the vehicle wheel can be implemented, automatic operation can be completely implemented, manual work is reduced, and costs are low. Further, a measurement result can be automatically stored to ensure traceability, and statistical analysis software is used, so that a measurement result offset can be fed back to processing equipment, thereby furthest reducing quality costs.

Owner:CITIC DICASTAL +1

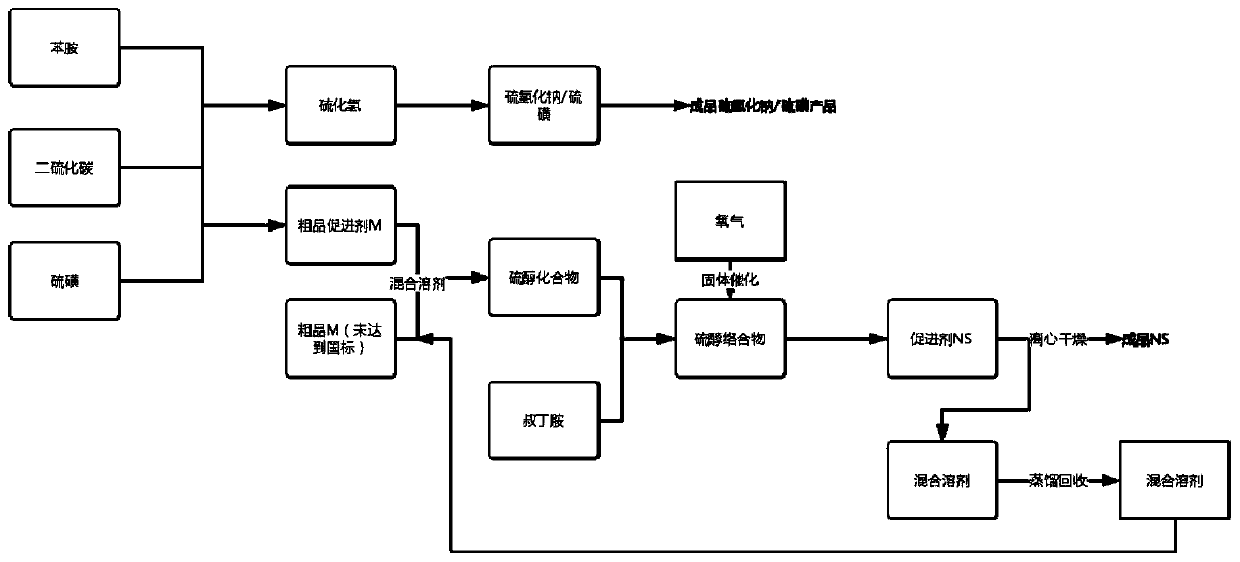

Process for cleaning accelerator NS produced by oxygen oxidation method of crude product M

The invention relates to a rubber accelerator, in particular to a process for cleaning an accelerator NS by an oxygen oxidation method of a crude product M. The process comprises the following steps:(1) dissolving the crude product M in ammonia water with a mass concentration of 10-30 percent, blowing air, performing liquid separation after layering and taking a liquid supernatant; (2) after theliquid supernatant, tert-butylamine and a sold catalyst are uniformly mixed, controlling the temperature to be 55-70 DEG C, introducing oxygen for reaction, maintaining the reaction pressure to be 0.15-0.4 MPa and ending up the reaction after no oxygen consumption; (3) centrifugally separation, washing and drying to obtain a product; the solid catalyst is activated carbon loaded with cobalt sulfate by a dipping method. The process provided by the invention has the benefits that the situation that a large amount of salty wastewater is caused by the use of acids and alkalis when the M is refinedis avoided; compared with a sodium hypochlorite method and a hydrogen peroxide method which are widely used at home, the process has Obvious quality cost advantages, so that the use rate of the disabled crude product M is improved; no overreaction exists, the product color is good, the production cost is low, and the product quality is high.

Owner:淄博拓研化学科技有限公司

Full-automatic small steel sheet machine

The invention discloses a full-automatic small steel sheet machine. The full-automatic small steel sheet machine comprises a machine frame, the machine frame comprises a right machine frame body and a left machine frame body, and the right machine frame body is higher than the left machine frame body; a control interface is arranged on the upper side of the front surface of the right machine frame body, a locating jig and a taking manipulator are arranged on the top of the right machine frame body, the locating jig is located in the center of the top of the right machine frame body, and the taking manipulator is located in the back of the top of the right machine frame body; a feeding mechanism is arranged on the top of the left machine frame body, and the left side surface of the left machine frame body is connected to a small steel sheet loading belt matched with the feeding mechanism. According to the full-automatic small steel sheet machine, steel sheets can be fed in a full-automatic mode, and the effectiveness is high; material feeding by the feeding mechanism specially adopted in the full-automatic small steel sheet machine is accurate and stable, and the feeding mechanism can be suitable for the small steel sheets of any kind; the equipment operation is high in speed, accurate and stable, the labor intensity of staff can be well lowered, the efficiency can be improved, the manpower can be saved, the quality cost can be continuously lowered, and the hands of staff are protected against scalding generated in manual operation.

Owner:西可通信技术设备(河源)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com