Processing method of local-reinforcement type full fiber cylinder barrel of hydraulic cylinder

A technology of local strengthening and processing method, applied in the field of hydraulic cylinder, can solve the problem that designers are difficult to choose, and achieve the effect of improving quality reliability, optimizing load distribution, and increasing the size of dangerous sections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

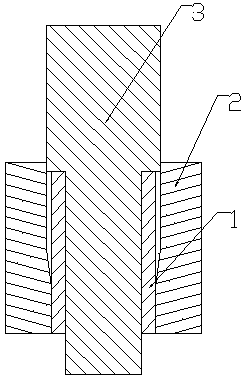

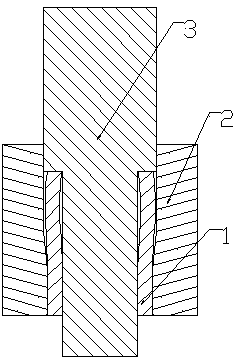

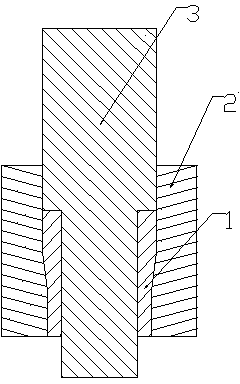

[0032] The following is a specific embodiment of the present invention, and the present invention will be further described in conjunction with the accompanying drawings.

[0033] Such as Figure 1 to Figure 3 As shown, a processing method of locally reinforced all-fiber hydraulic cylinder barrel, one end of the cylinder barrel has a section of local strengthening area with thicker wall thickness, and the local strengthening area of the cylinder barrel is formed by local upsetting;

[0034] The concrete processing steps of described cylinder barrel are:

[0035] 1. Material selection: choose straight cold-drawn tube as cylinder body 1, control cylinder wall thickness difference ≤ 10%, cylinder grain size ≥ 6 grades, no bad structures such as widmansite and banded crystals;

[0036] 2. Flaw detection: ultrasonic flaw detection;

[0037] 3. Cutting: reserve the total length of the blank according to the total deformation;

[0038] 4. Straightening: the straightness of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com