Stability control method for checker forms of checker color-coated plate

A stable control method, color-coated board technology, applied to the surface coating liquid device, coating, pre-treatment surface, etc., can solve the problem of difficulty in ensuring stable continuous production, unstable texture control, and texture size No other problems, to achieve the effect of improving the quality of texture control, good texture effect, and stable texture control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

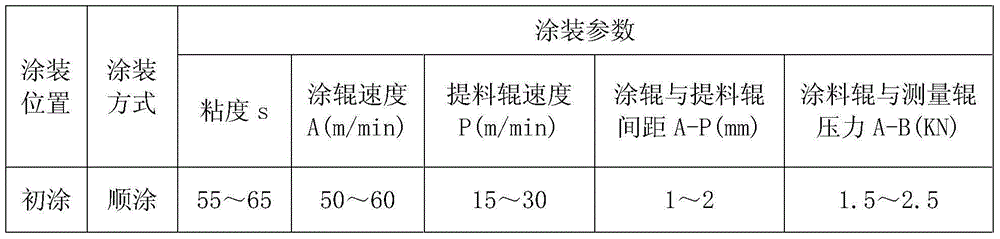

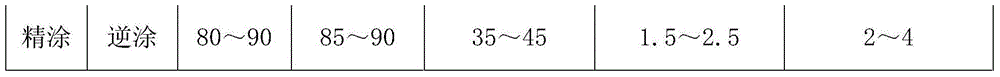

[0040] 1) Select coating control parameters:

[0041]

[0042] Select the production line speed of the unit to be 70m / min.

[0043] 2) Determine the film thickness control principle, scope and monitoring method:

[0044] During the trial coating and production process, use a wet film meter to measure the wet film thickness on the roller surface by staggering the strip steel on the drive side and the operation side of the topcoat pick-up roller. The duration of each contact measurement is 30s, and the readings on both sides of the wet film meter are summed. Taking the average, the wet film thickness of the working side and the transmission side is required to be measured within 180s; for the thickness of the topcoat, the wet film thickness and paint consumption control are mainly monitored, and the thickness of the primer is based on the direct detection of the dry film thickness;

[0045] Through the coating area, coating rate and control of dry film thickness, it is conve...

Embodiment 2

[0054] 1) Select coating control parameters:

[0055]

[0056] Select the production line speed of the unit to be 70m / min.

[0057] 2) Determine the film thickness control principle, scope and monitoring method:

[0058] During the trial coating and production process, use the wet film meter to measure the wet film thickness on the roller surface by staggering the strip steel on the driving side and the operating side of the topcoat pick-up roller. The duration of each contact measurement is 35s, and the readings on both sides of the wet film meter are summed. On average, the wet film thickness of the working side and the transmission side is required to be measured within 180s; for the topcoat thickness, the wet film thickness and paint consumption control are mainly monitored, and the primer thickness is subject to direct detection of the dry film thickness;

[0059] Through the coating area, coating rate and control of dry film thickness, it is converted into paint cons...

Embodiment 3

[0068] 2) Select coating control parameters:

[0069]

[0070] Select the production line speed of the unit to be 70m / min.

[0071] 2) Determine the film thickness control principle, scope and monitoring method:

[0072] During the trial coating and production process, use the wet film meter to measure the wet film thickness on the roller surface by staggering the strip steel on the driving side and the operating side of the topcoat pick-up roller. The duration of each contact measurement is 40s, and the readings on both sides of the wet film meter are summed. On average, the wet film thickness of the working side and the transmission side is required to be measured within 180s; for the topcoat thickness, the wet film thickness and paint consumption control are mainly monitored, and the primer thickness is subject to direct detection of the dry film thickness;

[0073] The coating area, coating rate and controlled dry film thickness are converted into coating consumption p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com