Patents

Literature

146results about How to "Reduce the cost of quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

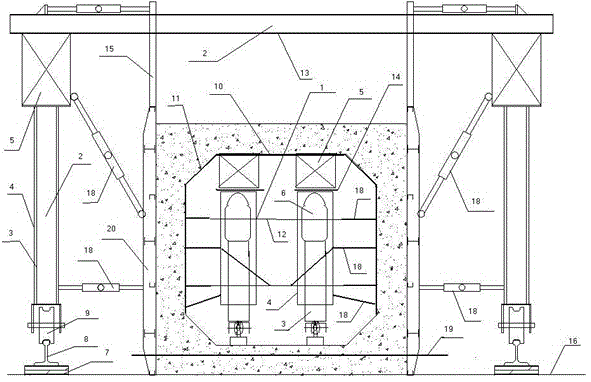

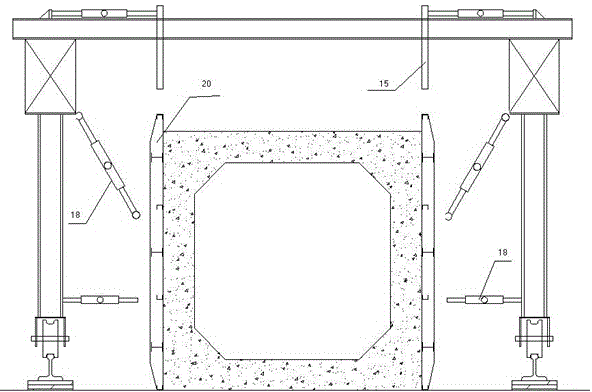

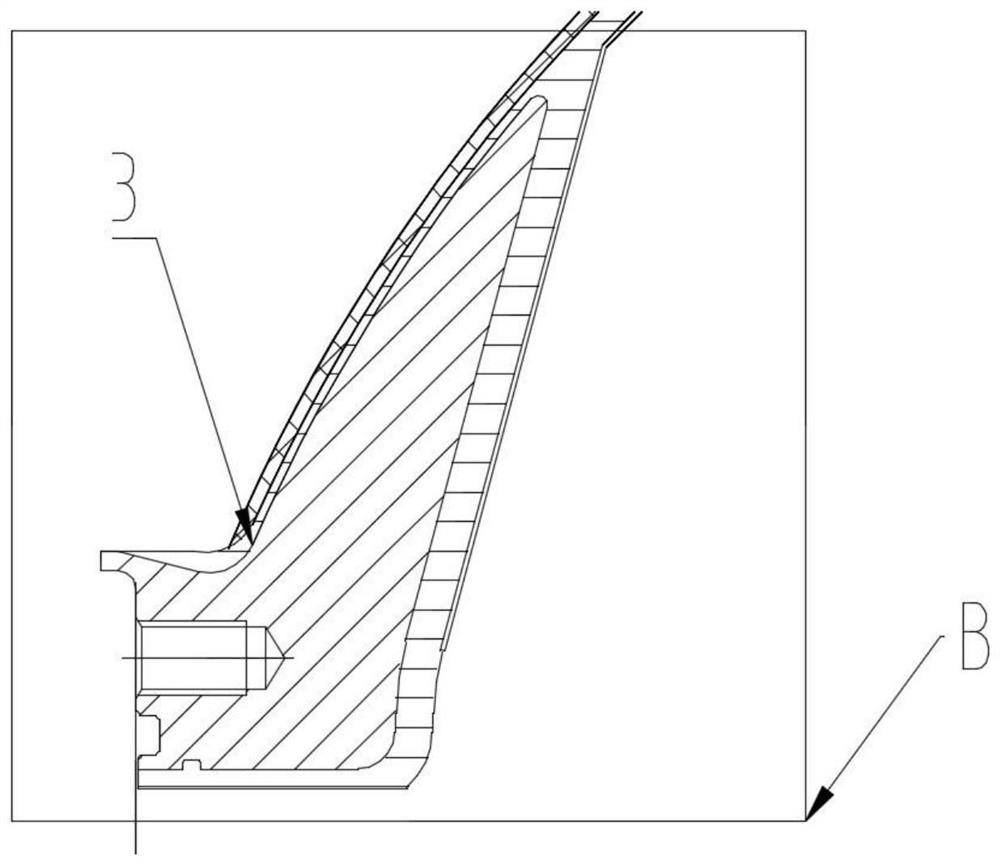

Modularization steel die trolley and construction process thereof

ActiveCN104895584AExcellent anti-rustEasy to remove formworkUnderground chambersTunnel liningSupporting systemEngineering

The invention provides a modularization steel die trolley and a construction process thereof. The trolley comprises an inner die trolley and an outer die trolley. The inner die trolley is of a semi-closed steel structure and comprises a support elevating system and a walking system. The outer die trolley also comprises the same support elevating system and the same walking system. The inner die trolley also comprises a support template. The outer die trolley also comprises a support system, an outer support template and a lead screw. According to the invention, one set of special outer die trolley door frame can be used with multiple sets of common template assemblies.

Owner:金中天建设集团有限公司

Intelligent factory MES system

InactiveCN107831748AImprove work efficiencySolve quality bottlenecksTotal factory controlProgramme total factory controlService flowComputerized maintenance management system

The invention discloses an intelligent factory MES system. The intelligent factory MES system comprises a service flow, quality inspection management, product quality tracing management, equipment monitoring management, equipment maintenance management, software and hardware or other external system interface requirements. According to the invention, a complete management system is provided for afactory, and the unnecessary waste of the factory is reduced. The all-dimensional tracing management of products from the material incoming step to the factory leaving step is realized. The quality ofproducts is greatly improved, and the safe and long-term operation of equipment is guaranteed. The data support is provided for the management layer during the macroscopic evaluation process of the product quality and the working efficiency of the quality inspection personnel is improved. As a result, products can become clear and transparent in the whole production process. The cause of qualityproblems can be found rapidly. Meanwhile, the measures for solving the quality bottleneck problem are formulated, and the quality cost is reduced. The warning equipment can be quickly handled with andthe system is complete. The intelligent management of the factory is greatly improved, and the management vulnerability of the factory is greatly reduced.

Owner:GUANGDONG HUILIPU ROAD & BRIDGE INFORMATION ENG

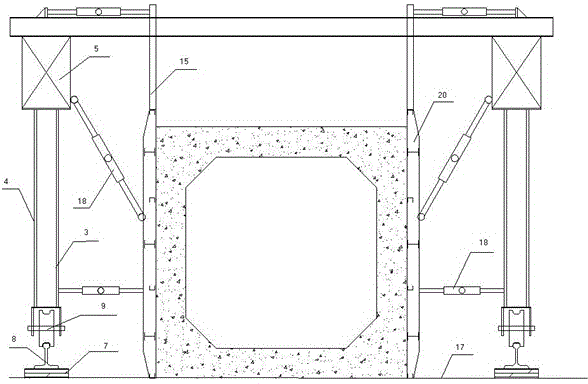

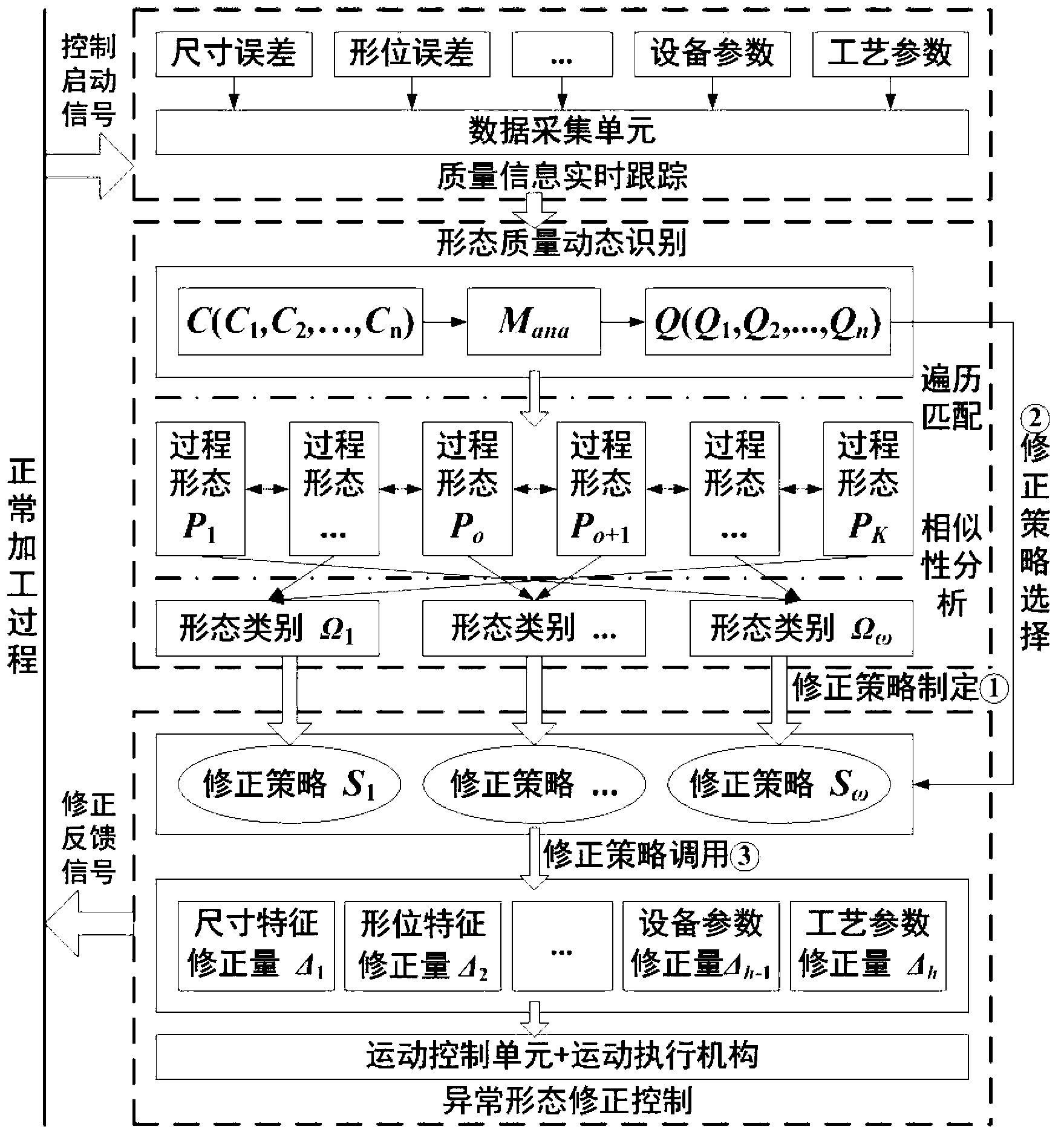

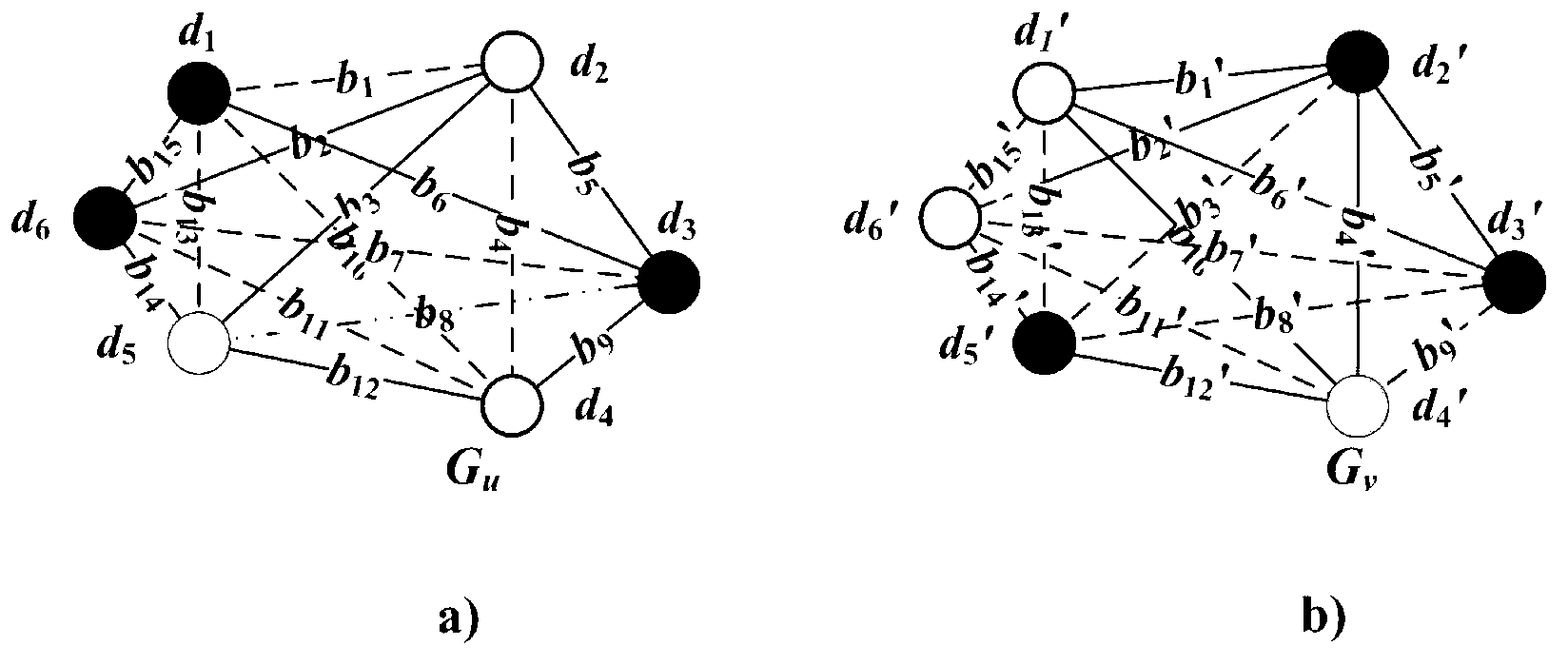

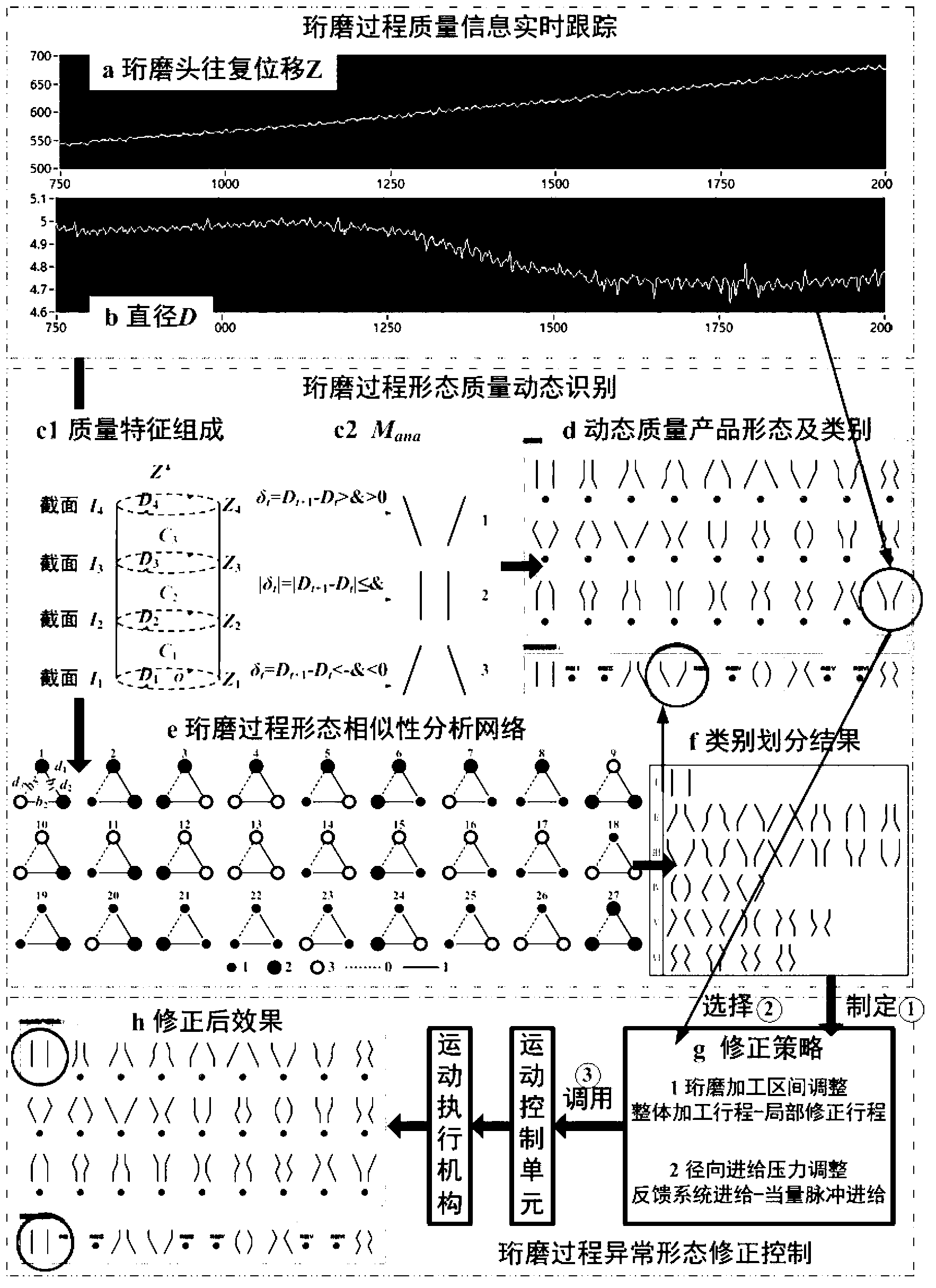

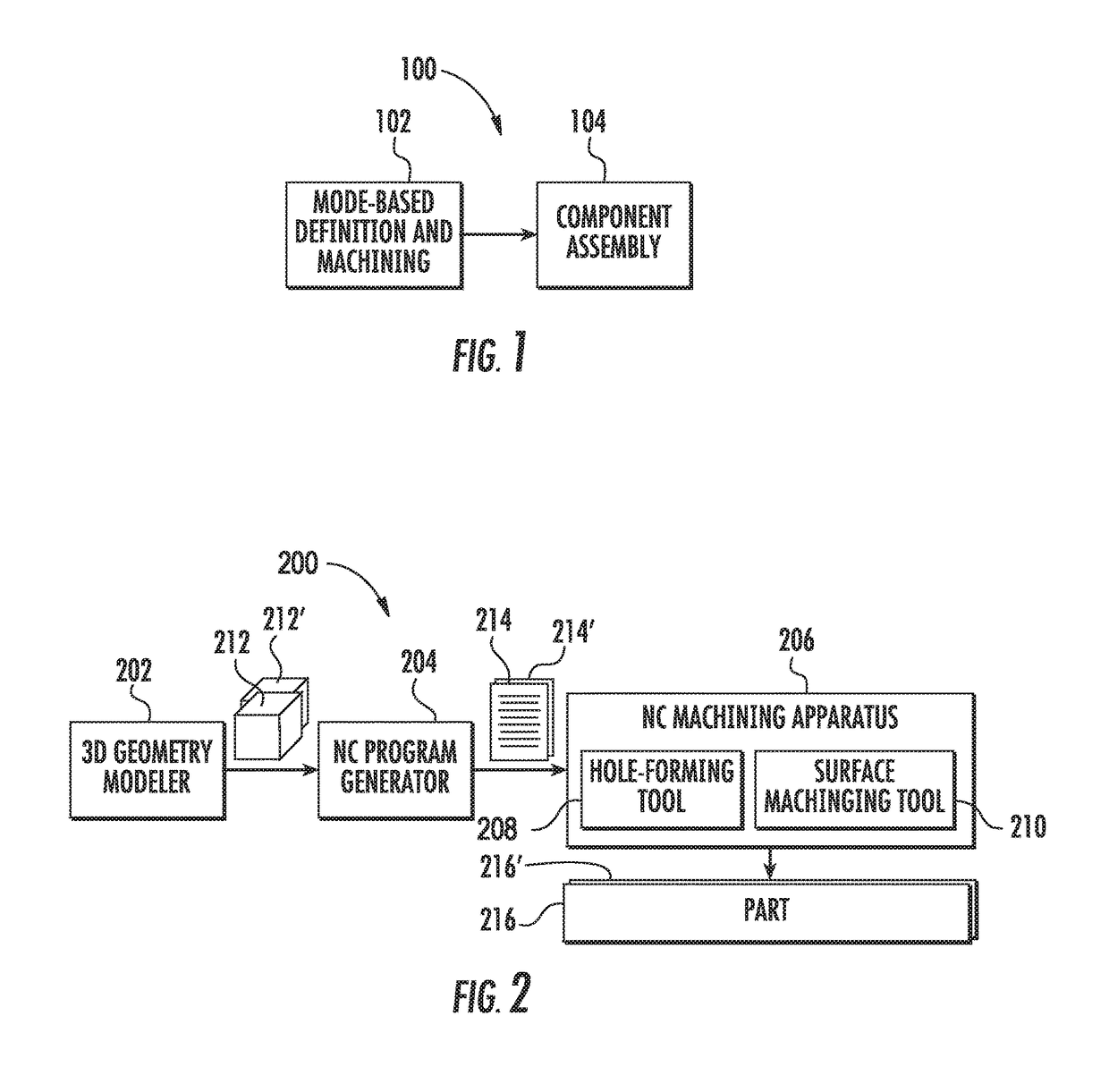

Form quality dynamic identification and modification control method in machining process

ActiveCN103257615AClear control processAvoid reprocessingProgramme controlComputer controlSimilarity analysisEconomic benefits

The invention discloses a form quality dynamical identification and modification control method in machining process. The form quality dynamical identification and modification control method in the machining process comprises the steps of (1) quality information real-time tracking, (2) form quality dynamic identification and (3) unusual form modification control, wherein the quality information real-time tracking is used for meeting the requirement that a large amount of bottom-layer data can reflect a present quality state of a workpiece form in the process of dynamic identification and modification, the form quality dynamic identification is used for carrying out data processing on acquired form quality information to acquire a dynamical quality product form, searching a form which is matched with the dynamical quality product form through an ergodic process form set and determining a belonging form type of the dynamical quality product form through similarity analysis, and the unusual form modification control is used for adopting a modification strategy ' deciding+choosing+calling' mechanism, dynamically carrying out modification control on a process exception form through a motion control unit and a motion executing mechanism. By the adoption of the form quality dynamical identification and modification control method in the machining process, the improvement of machining quality is benefited, the defects of quality is overcome in advance, quality cost is reduced, the improvement of production efficiency is benefited, off-line detection is avoided, sub-quality products can be machined again, and the economic benefit of an enterprise is improved.

Owner:XI AN JIAOTONG UNIV

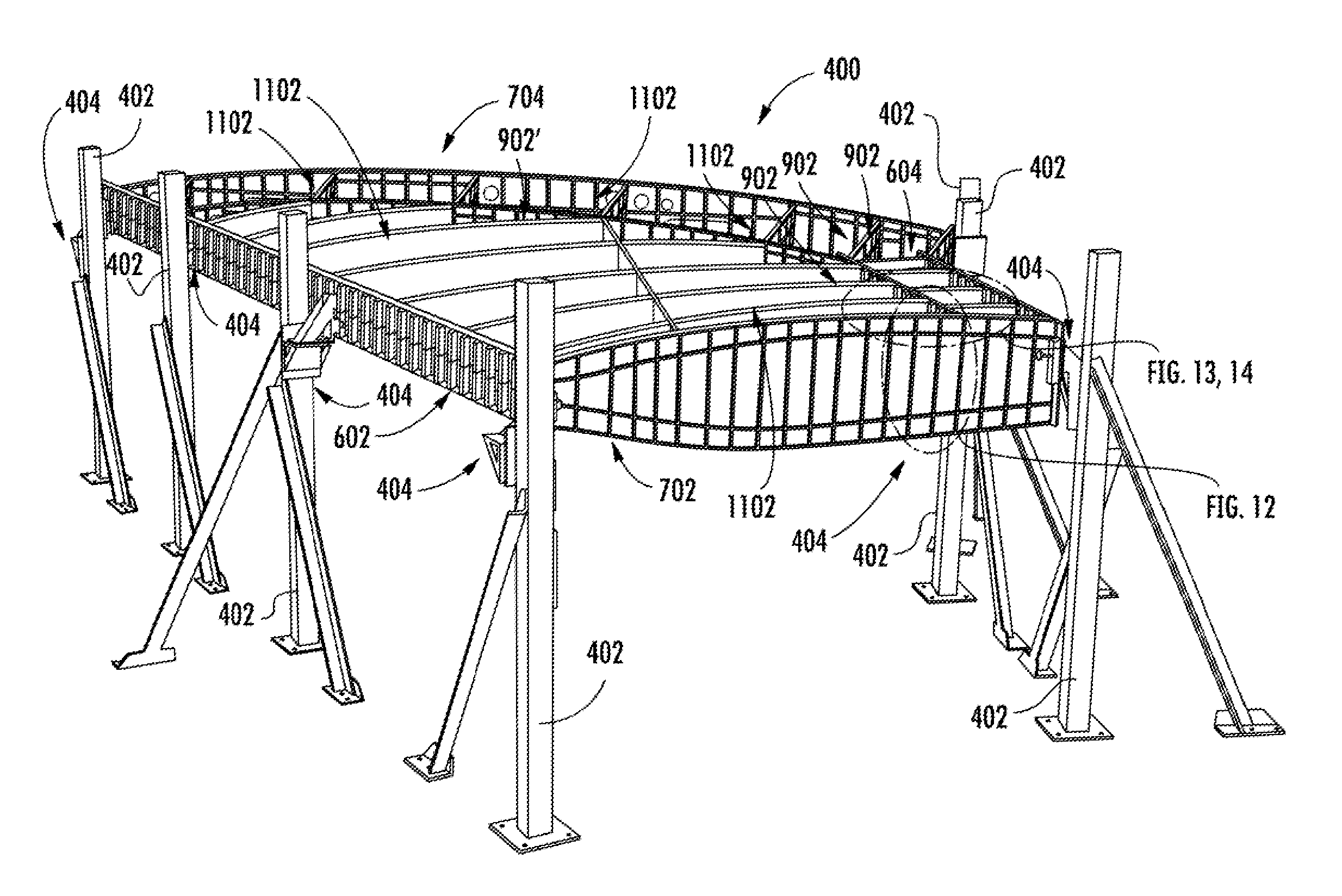

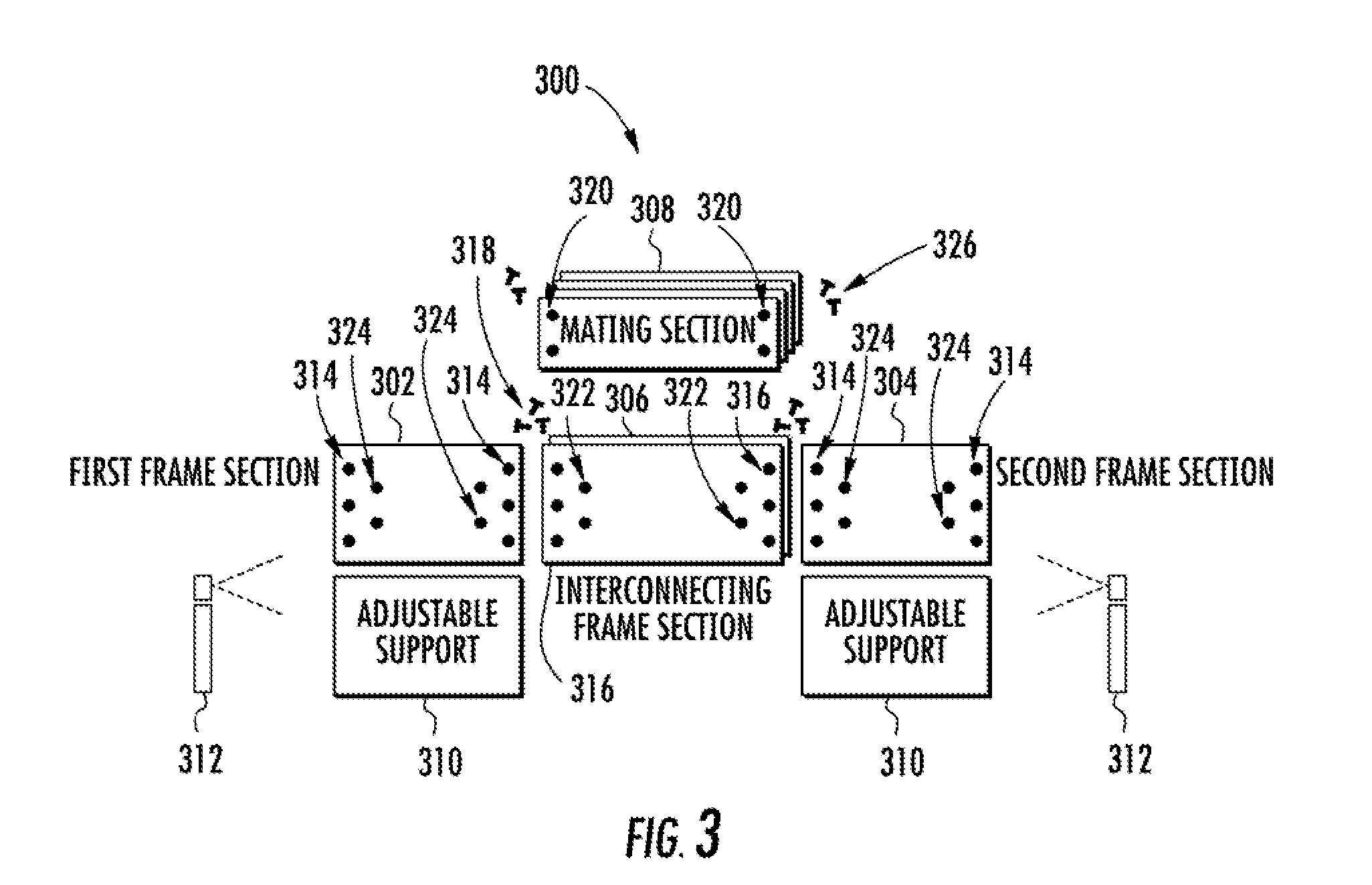

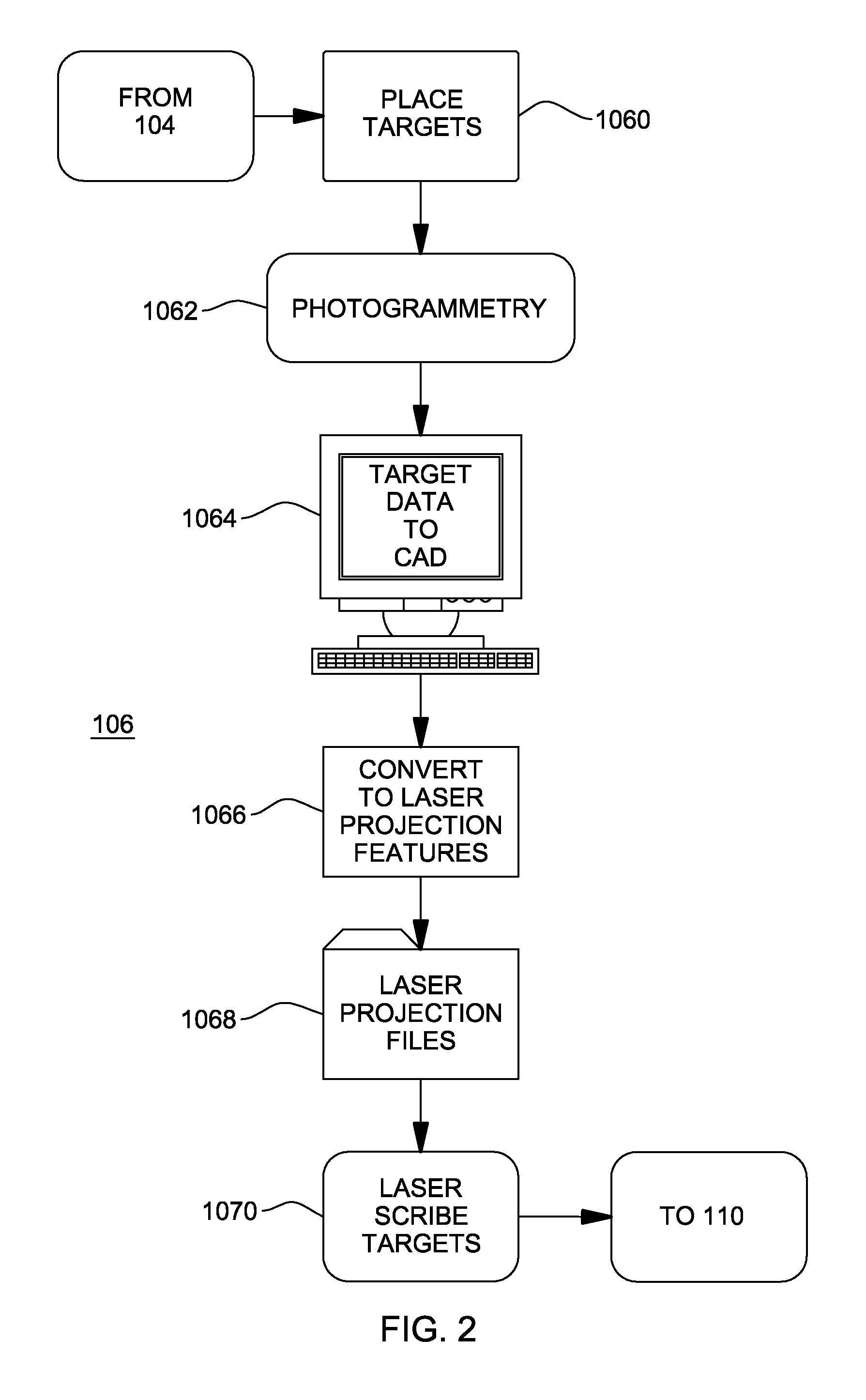

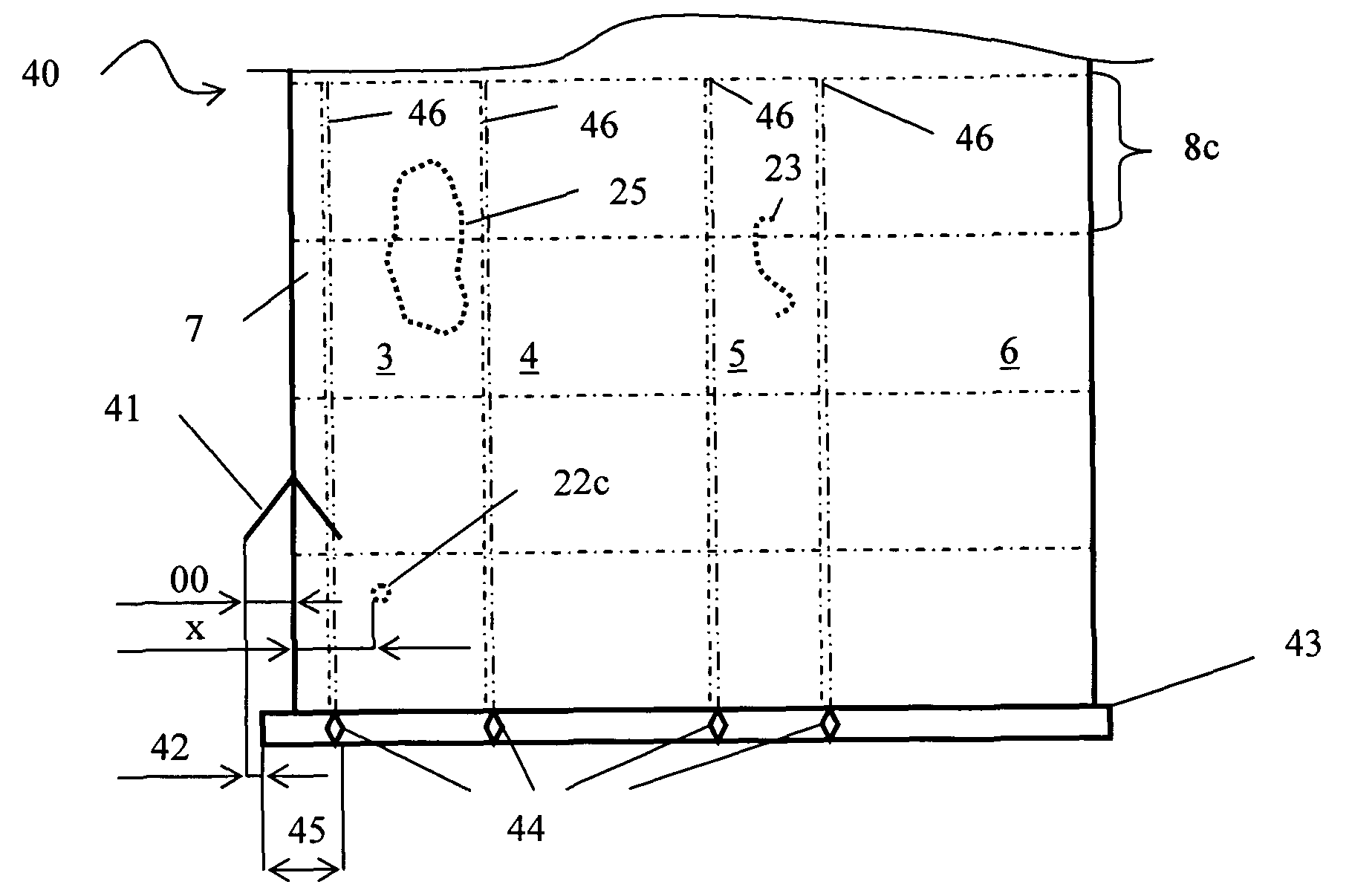

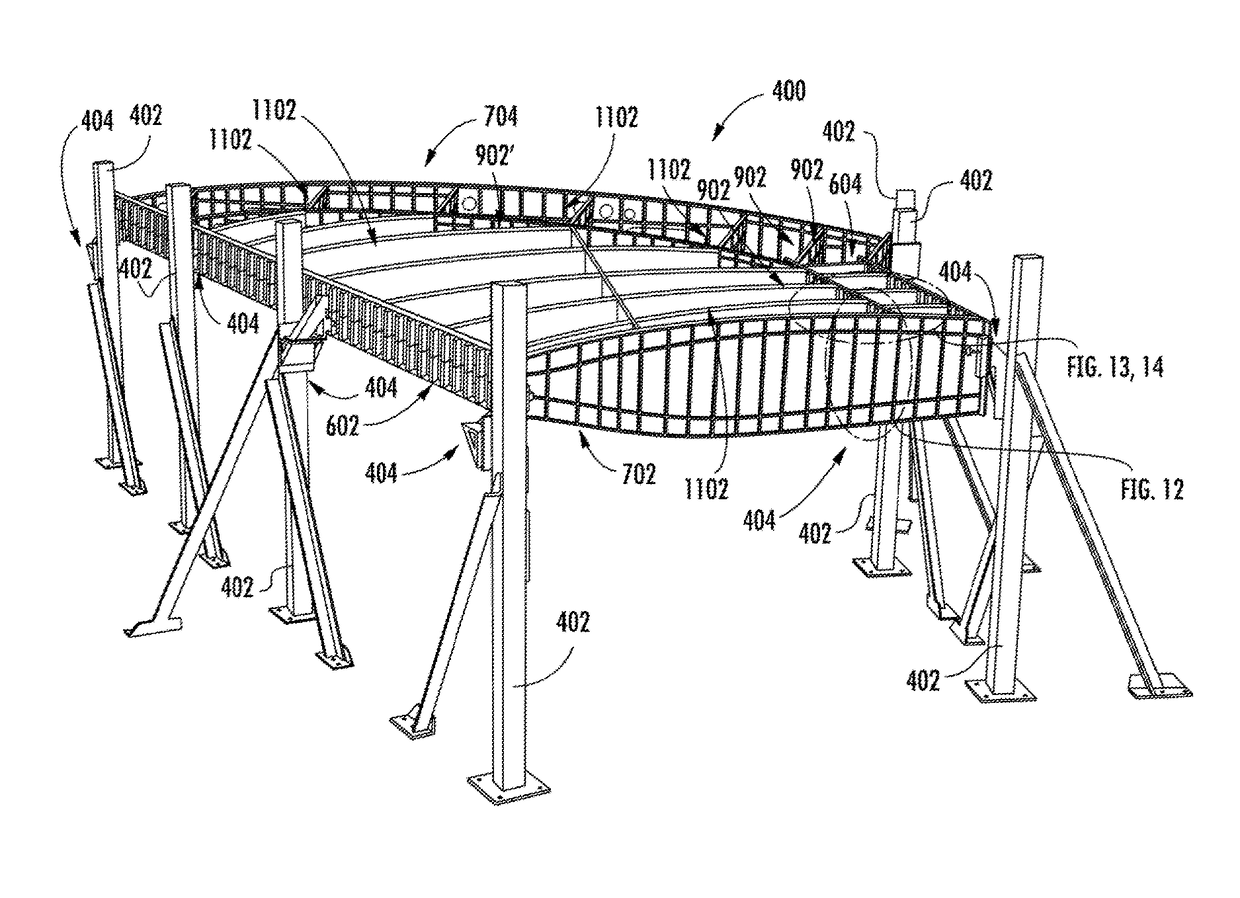

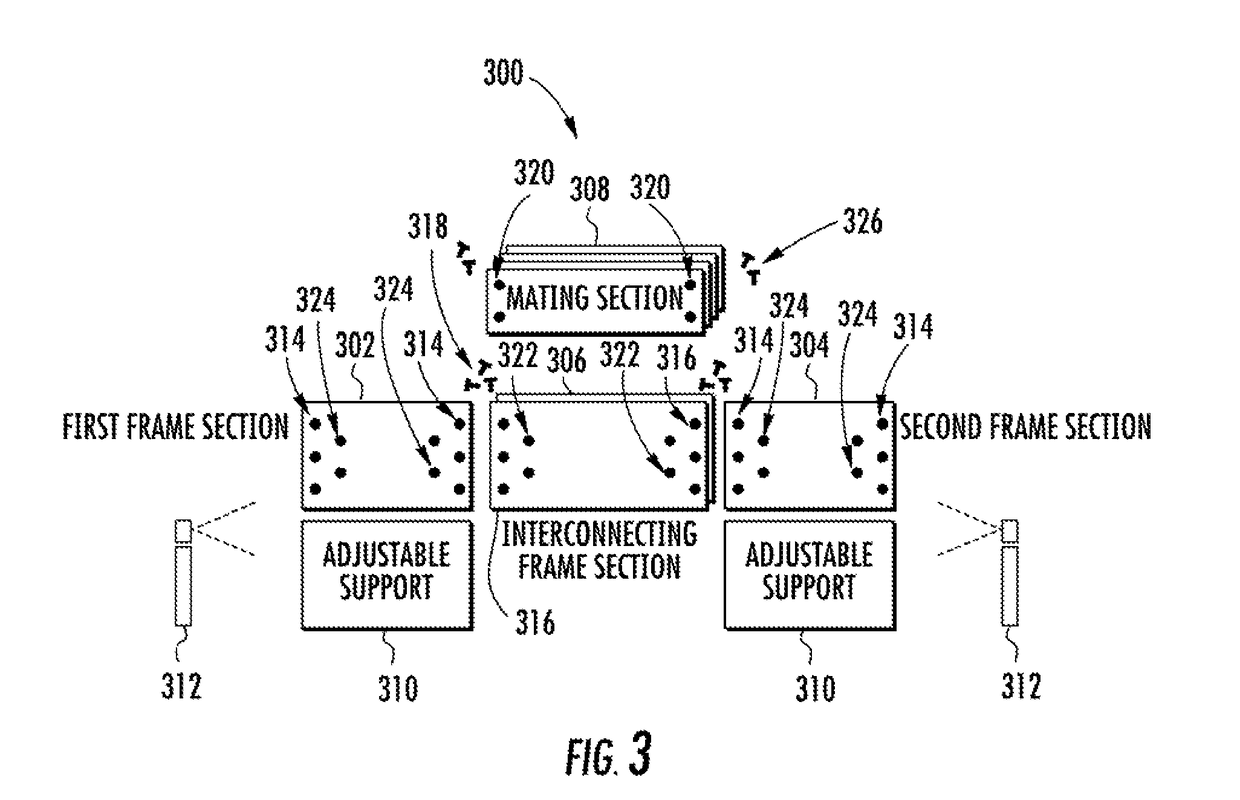

Assembly of an aircraft structure assembly without shimming, locating fixtures or final-hole-size drill jigs

A method is provided for assembling an aircraft structure assembly composed of a plurality of sections, and doing so without use of any shimming, locating fixtures or final-hole-size drill jigs. The method includes supporting the first and second frame sections on respective adjustable supports, and positioning the interconnecting frame section therebetween. The method includes aligning first pre-drilled mating holes in the interconnecting frame section with first pre-drilled mating holes in the first and second frame sections, and installing fasteners though the aligned, first pre-drilled mating holes. The method includes positioning a structural mating section relative to the first and second frame sections and interconnecting frame section. And aligning second pre-drilled mating holes in the structural mating section with second pre-drilled mating holes in at least one of the frame sections, and installing fasteners through the aligned, second pre-drilled mating holes to secure the structural mating section.

Owner:THE BOEING CO

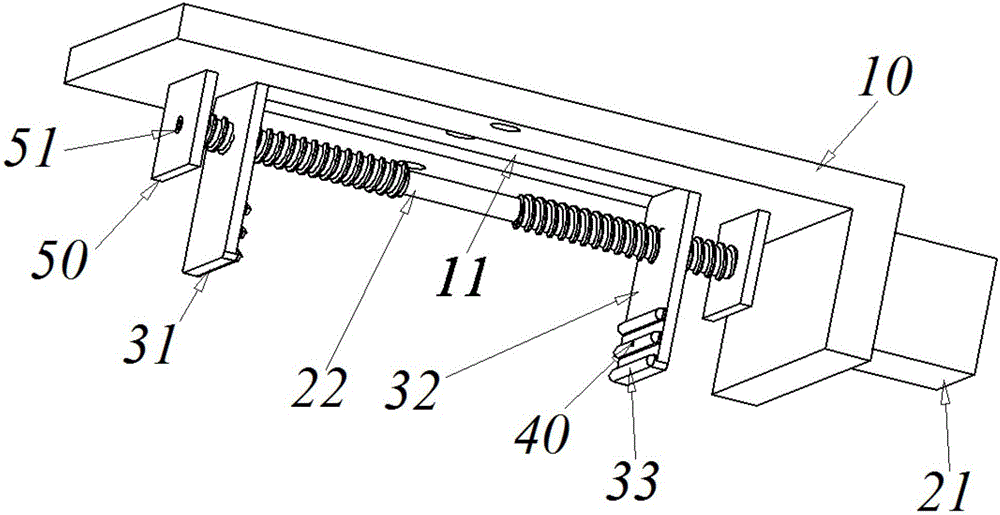

Lateral grabbing assembling device for new energy battery

InactiveCN105774764AHigh precisionOvercoming problems such as short circuit scrappingGripping headsElectric propulsion mountingNew energyUltimate tensile strength

The invention provides a lateral grabbing assembling device for a new energy battery. The lateral grabbing assembling device comprises a supporting plate, a power mechanism, a grabbing mechanism and a control mechanism, wherein the power mechanism comprises a servo motor and a spiral screw rod; the servo motor is mounted on the supporting plate and is in driving connection with the grabbing mechanism through the spiral screw rod; the grabbing mechanism comprises a first clamping jaw and a second clamping jaw; the first clamping jaw and the second clamping jaw are mounted on the spiral screw rod in a sliding form; a battery clamping space is formed between the first clamping jaw and the second clamping jaw; the control mechanism is mounted on the first clamping jaw or the second clamping jaw and faces to the clamping space between the first clamping jaw and the second clamping jaw; the control mechanism is in signal transmission with the servo motor. The lateral grabbing assembling device for the new energy battery can be used for reducing the labor intensity for manually mounting an integrated battery pack, increasing the accuracy of battery mounting and integration, increasing the production efficiency and overcoming the problems of battery short circuit and scrapping caused by the fault of persons during a battery mounting process, so that the labor cost, manufacturing cost and quality cost of a battery assembling enterprise are greatly reduced.

Owner:BERGSTROM INTELLIGENT EQUIP KUNSHAN CO LTD

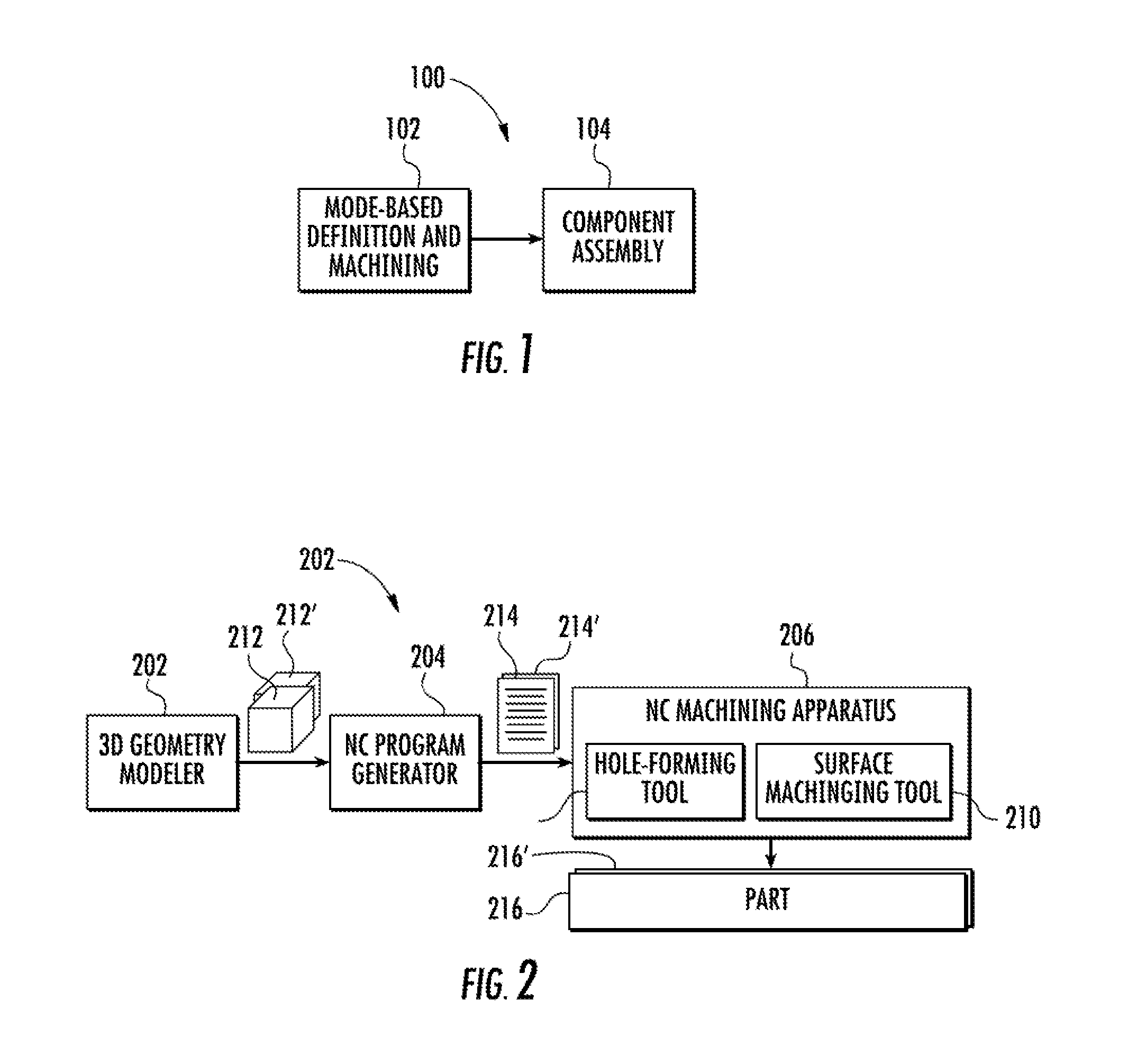

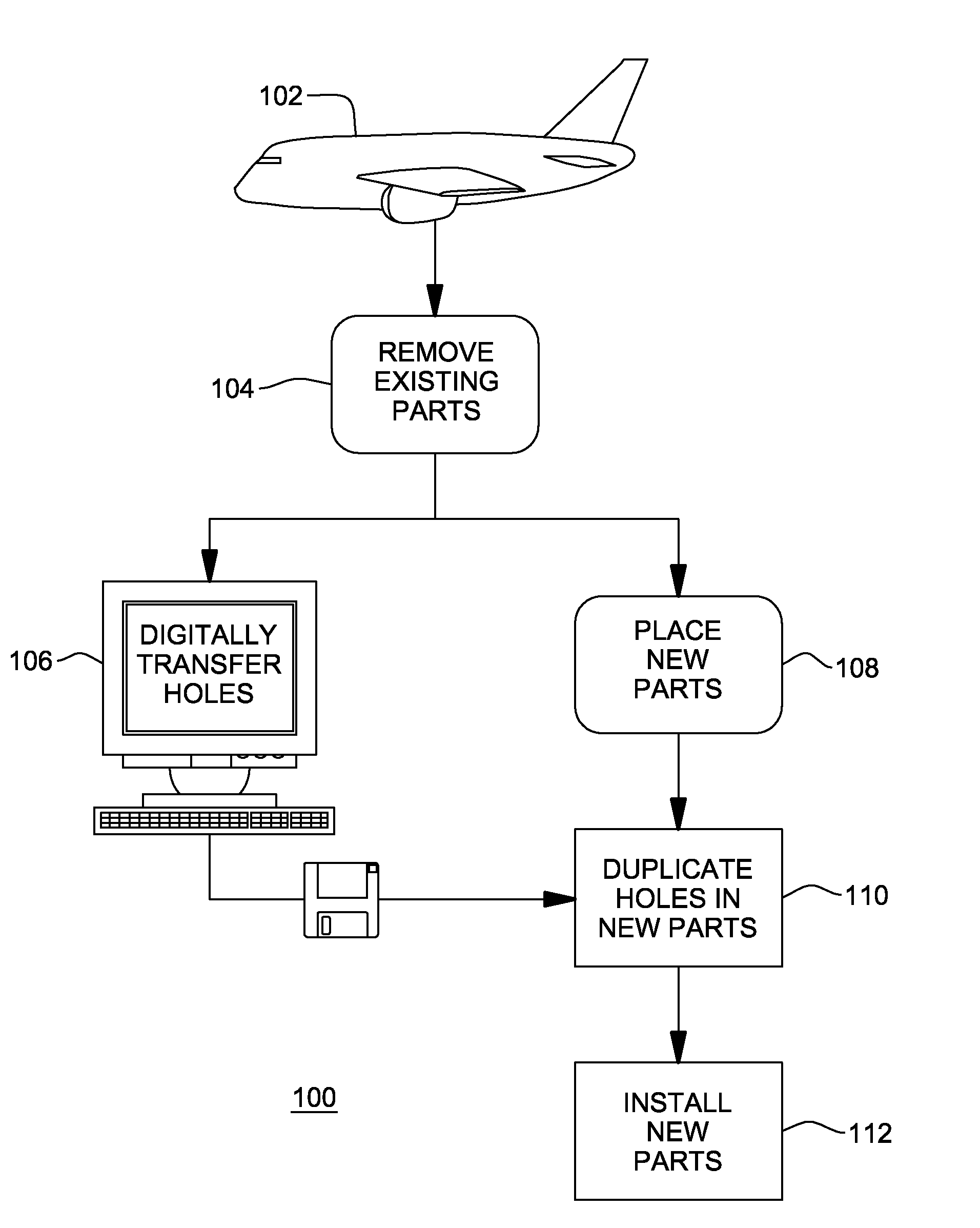

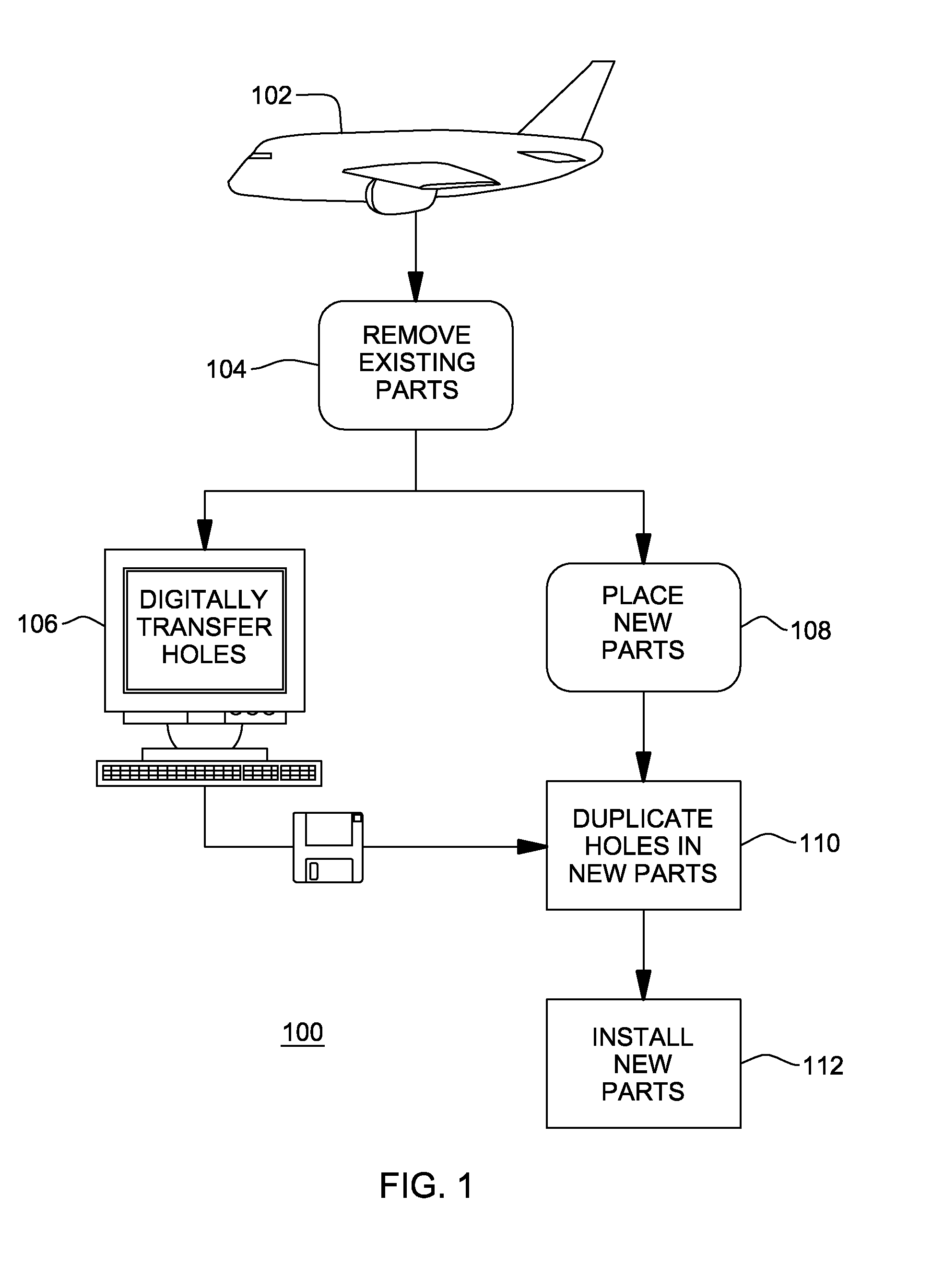

Method of rapid hole transfer to replacement parts

ActiveUS20080289163A1Effective matingReduce labor costsProgramme controlAircraft maintainanceEngineeringAirplane

A method of replacing an existing part or parts on a structure such as an aircraft. The structure is inducted for modification. An existing part is removed and a new part is temporarily installed. Hole locations are digitally transferred to the new part, e.g., photographically captured in a three-dimensional coordinate measurement system, converted to targets printable in a laser projection system. Targets are laser projected or printed on the replacement part. Holes are drilled at each printed target. The holes drilled at printed targets match hole locations on the existing part. Then, the new / replacement part is permanently attached to the structure.

Owner:THE BOEING CO

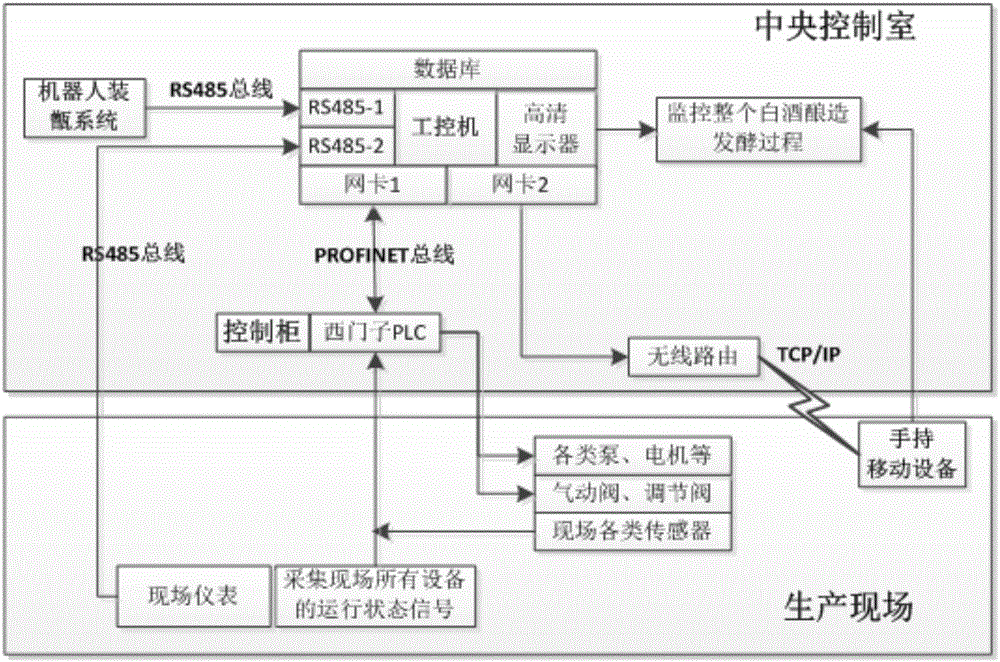

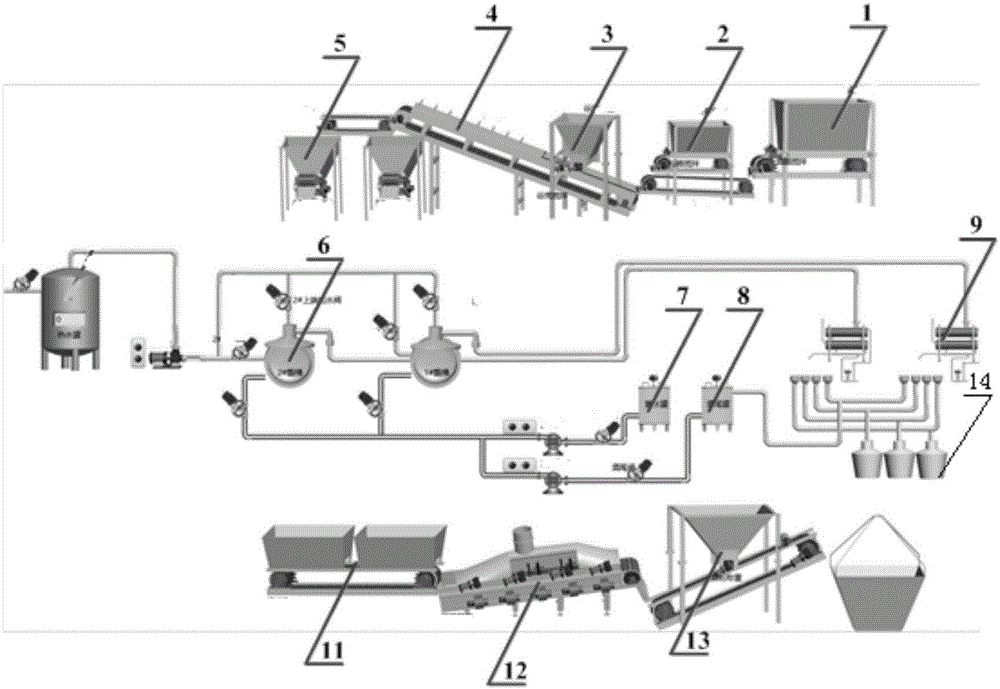

Intelligent control system and control method of liquor production

PendingCN106434233APromote technology upgradeAchieve standardizationAlcoholic beverage preparationTotal factory controlAdditive ingredientAgricultural engineering

The invention discloses an intelligent control system of liquor production. The intelligent control system comprises a control device, a robot steamer-filling system, a PLC, various pumps, valves, motors, various sensor and various instruments. The invention also discloses an intelligent control method of liquor production by adopting the intelligent control system of liquor production. The method comprises the steps of ingredient weighing, automatic steamer-filling, distilling and wine taking, spreading for cooling, and distiller's yeast adding. The system and the method solve the problem of need of automatic real-time onsite monitoring in the liquor brewing process, are in favor of realizing the technology upgrading of the manufacturing industry of liquor devices, realize standardization, automation and intelligentialization of the liquor solid brewing industry, and are of great significance to establish a novel liquor brewing fermentation device system, enhance the science and technology content and the competition advantage of liquor enterprises, improve the technology level and the management level of manufacturing enterprises and reduce the production, mass and management cost.

Owner:无锡美湖信息科技有限公司

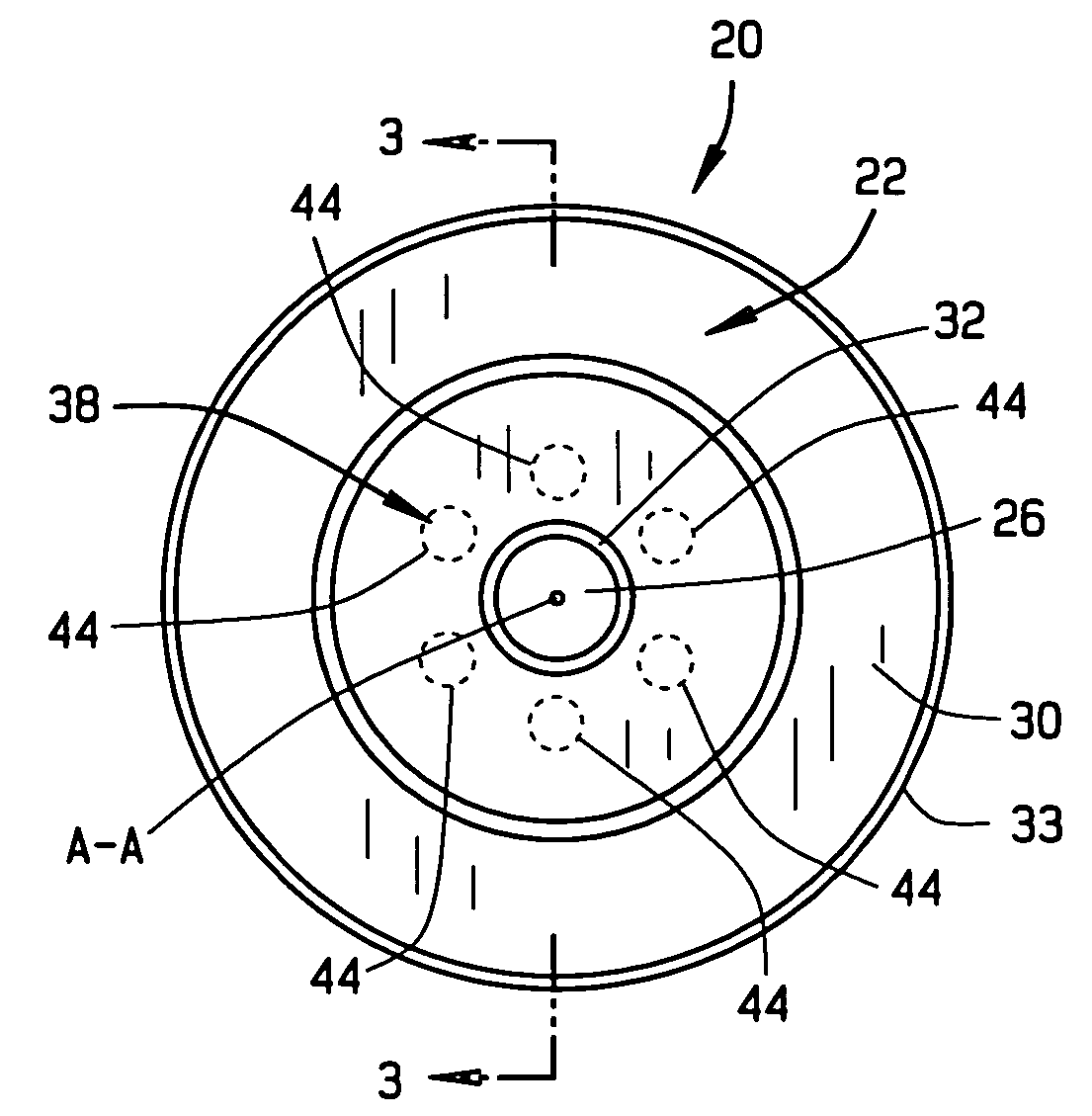

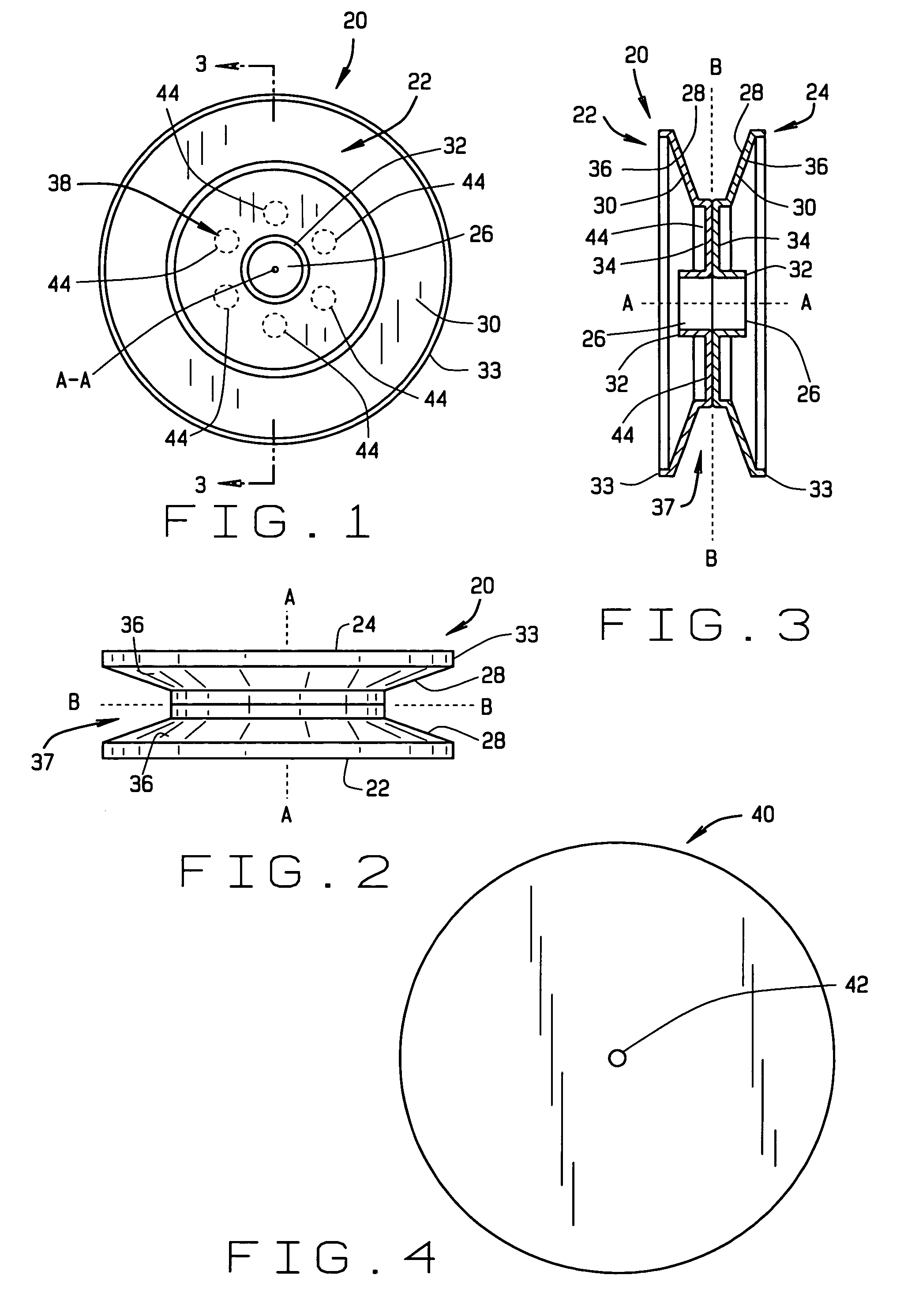

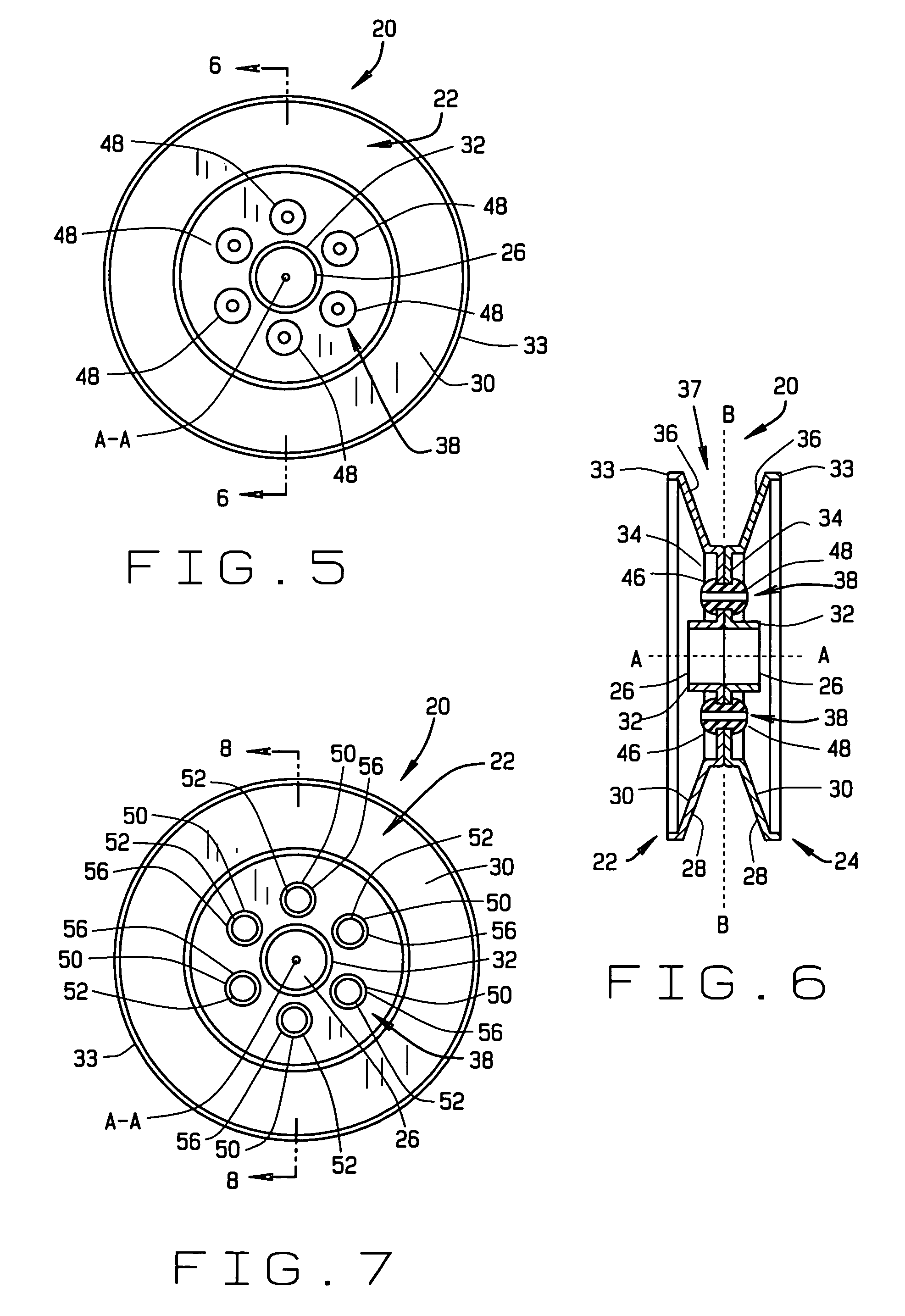

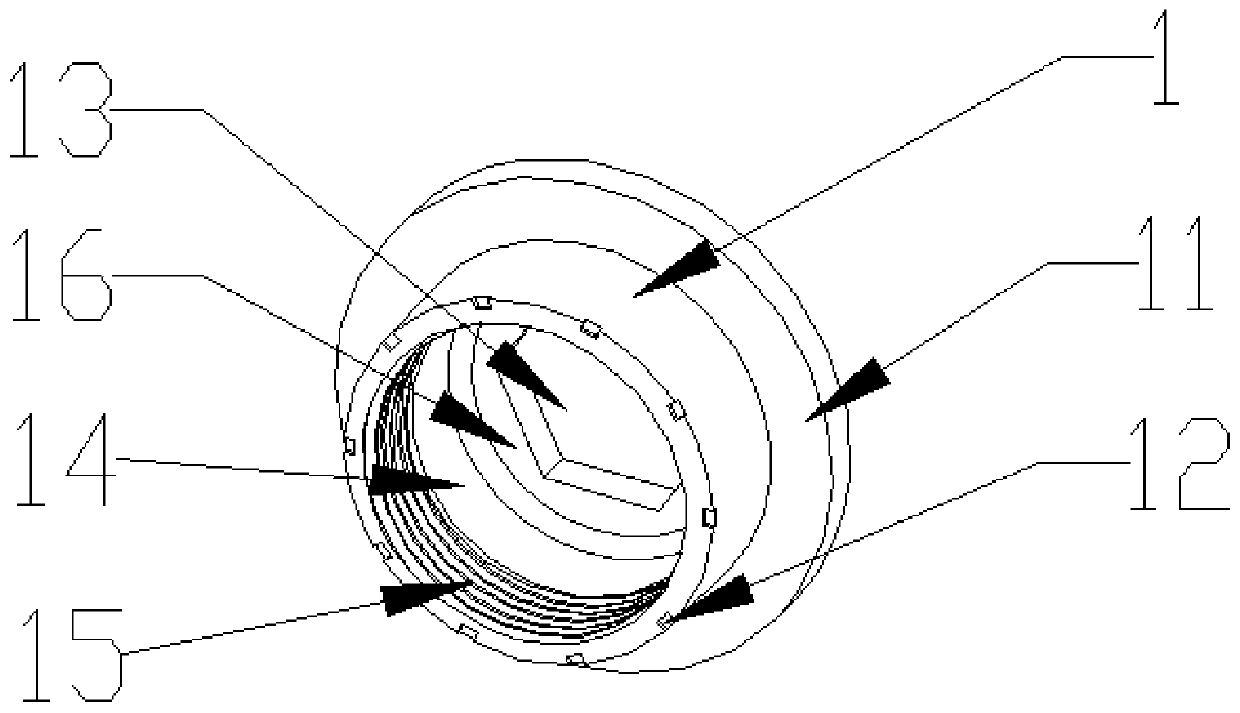

Two piece stamped steel pulley

A pulley is provided with first and second disks each having an outer surface and an inner surface, and a center hole with a center axis. Each disk has a hub formed at its center hole that extends outwardly from the disk outer surface. The inner side of each disk has a drive surface and a connection surface extending around its respective center hole. The connection surface is perpendicular to the center axis and the drive surface is angled relative to the connection surface to form the outer surface of each disk with a generally concave shape. The connection surfaces of the first and second disks are abutted and secured together using a fastening mechanism. The disks are arranged where the drive surfaces form an annular groove around the hubs and the hubs of each disk are aligned concentrically with the groove.

Owner:NIDEC MOTOR CORP

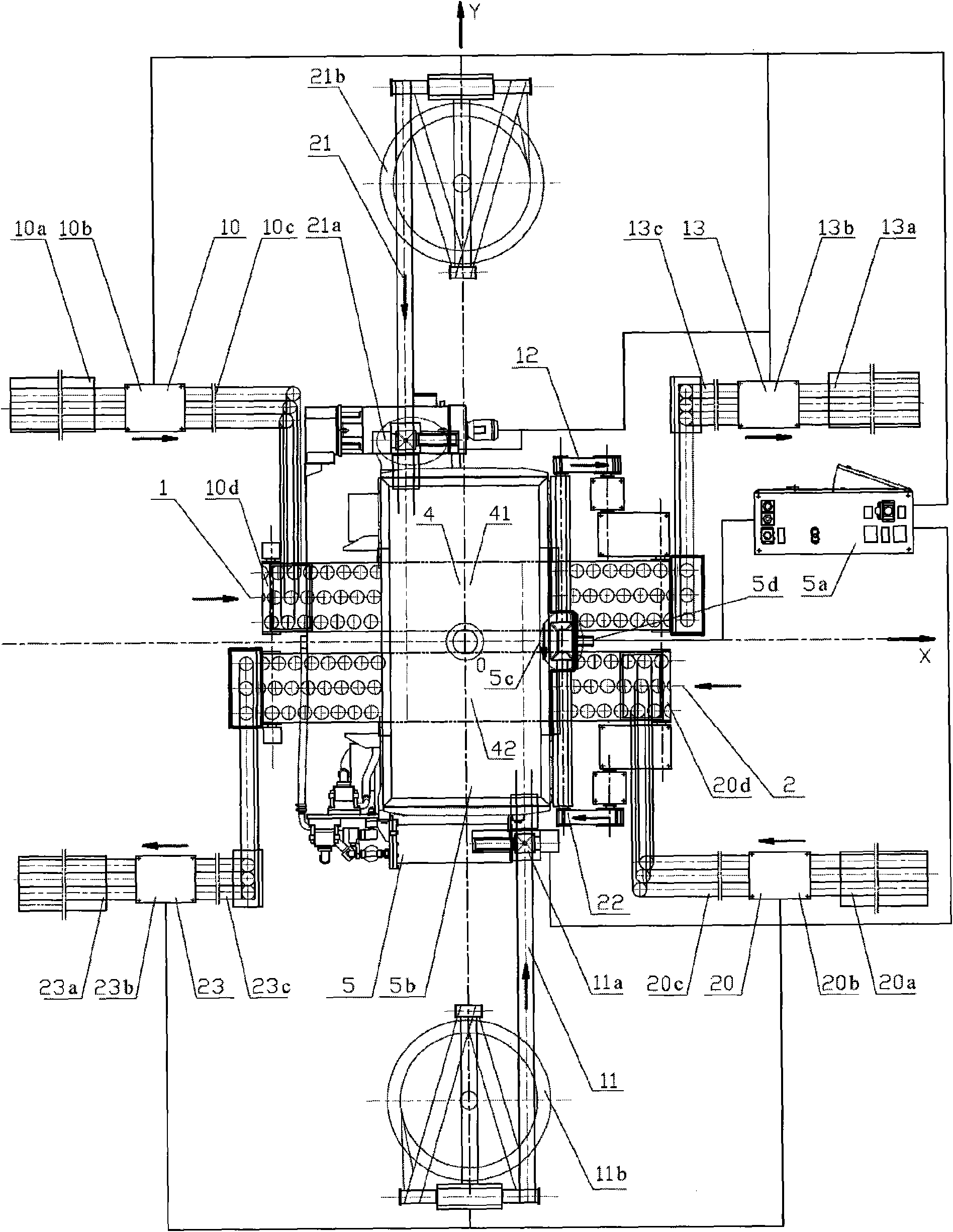

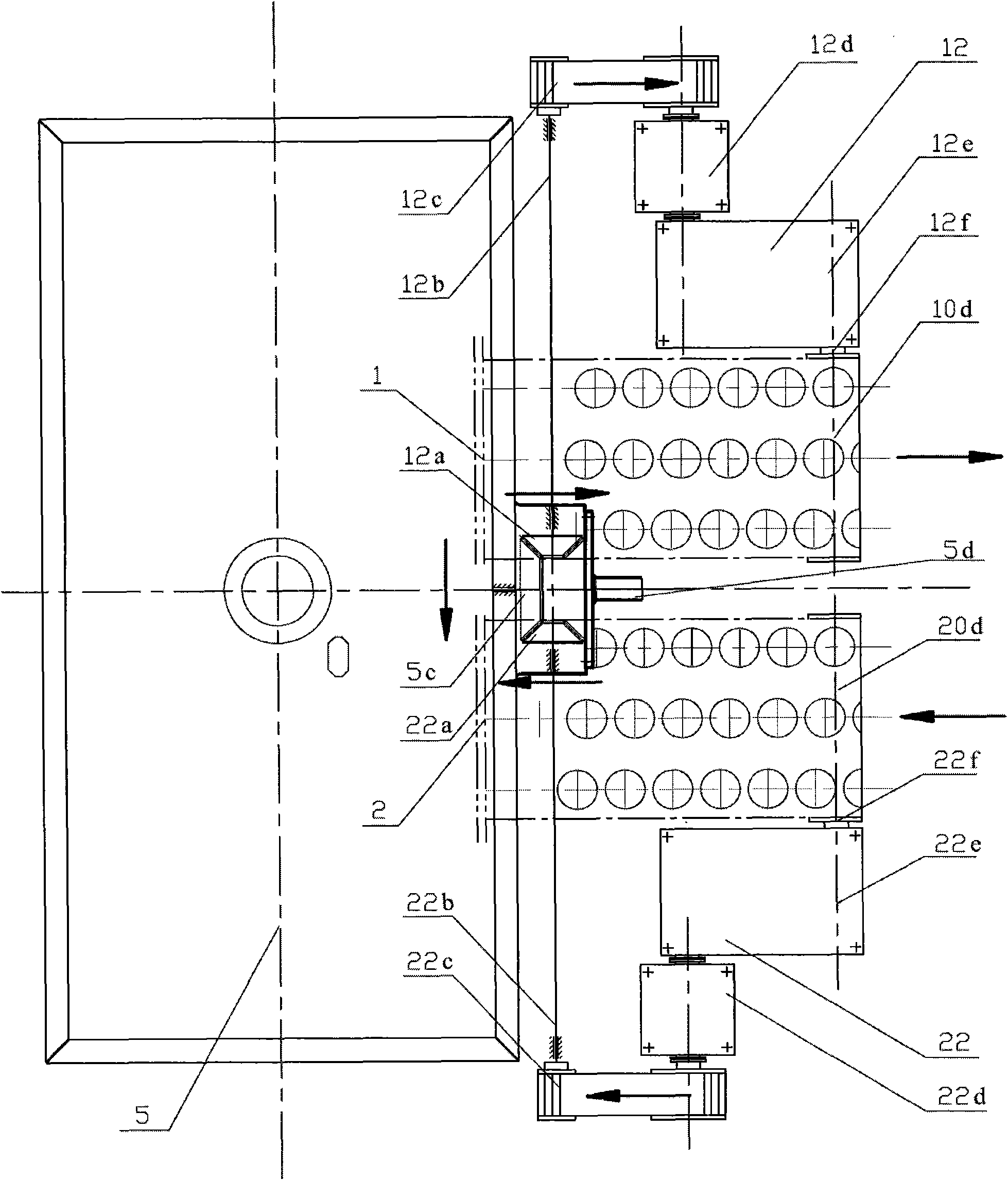

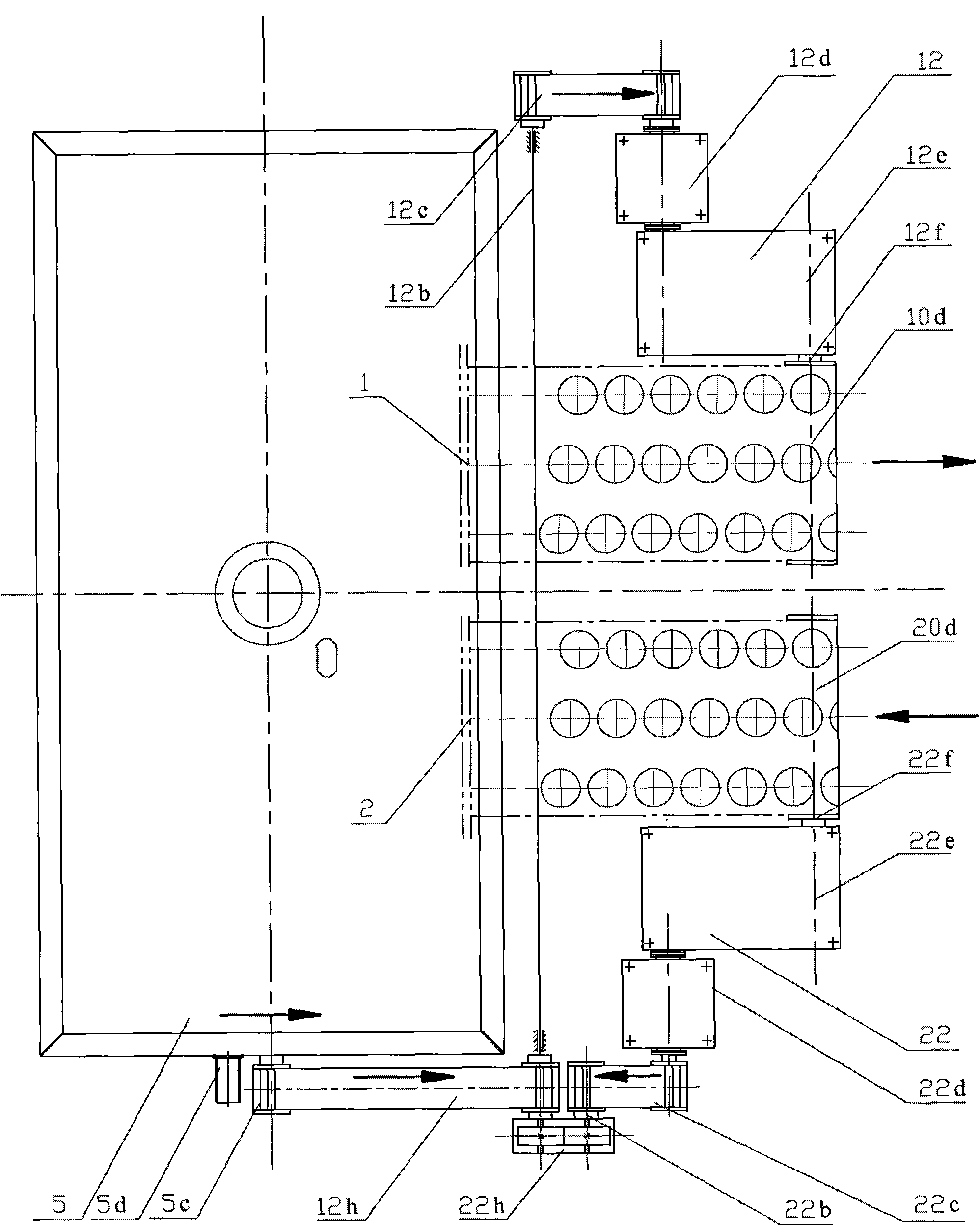

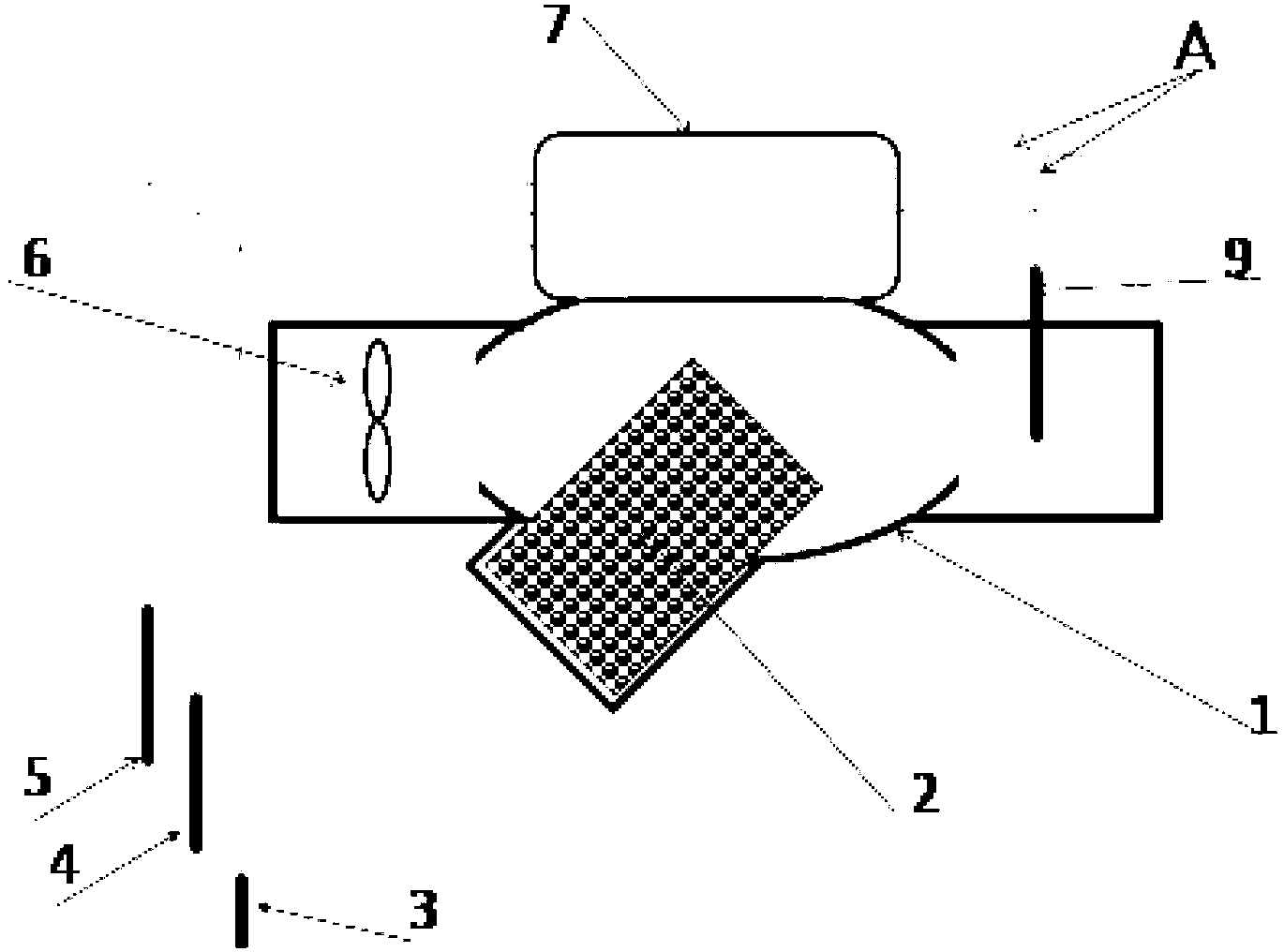

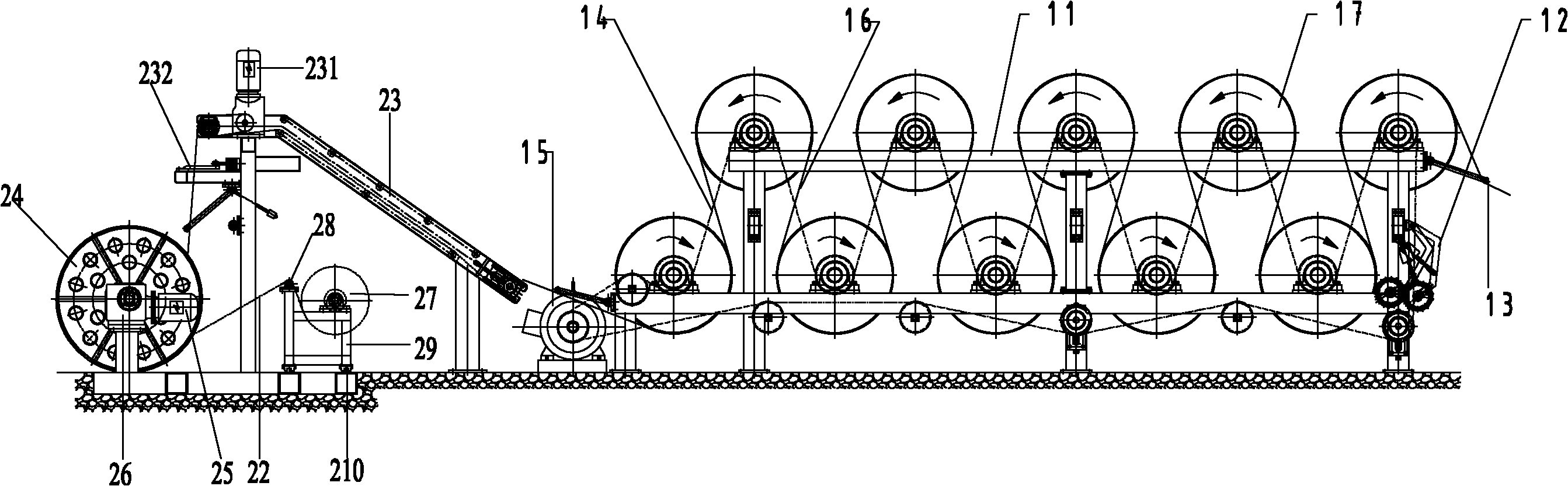

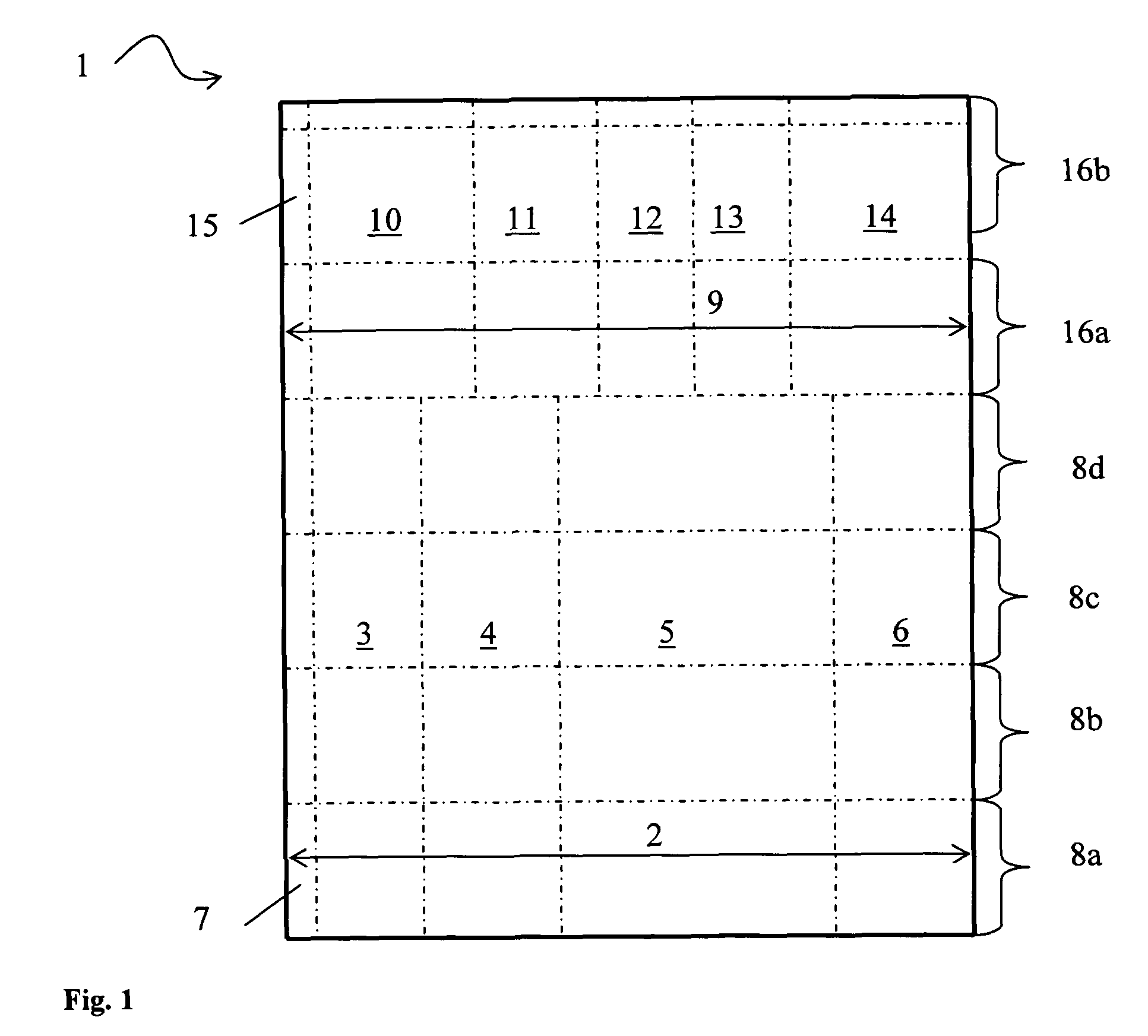

Multi-channel easy-open lid automatic stamping engineering design scheme and production line

InactiveCN101623728ASolve the problem of stamping eccentric loadBreak through the bottleneck limitHollow articlesProduction linePunch press

The invention relates to a multi-channel easy-open lid automatic stamping engineering design scheme and a production line, particularly suitable for constructing a metal easy-open lid automatic stamping production line with 4 channels, 6 channels, 8 channels, 10 channels or more even channels. An easy-open lid stamping channel group A (1) and a channel group B (2) in opposite progressive directions are arranged in parallel on a high-speed punch; the same numbers of forming channels are respectively arranged on the channel group A (1) and the channel group B (2), and the progressive directions of all the forming channels on either channel group are the same. The invention solves the eccentric load problem of easy-open lid stamping, constructs the automatic stamping production line with 6 channels, 8 channels, 10 channels or more even channels on the high-speed punch, decreases the investment cost and manifolds the yield and the quality stability of the single stamping line, wherein the yield of the production line with 6 channels is larger than 3600 pieces / min, the yield of the production line with 8 channels is larger than 4800 pieces / min, and the yield of the production line with 10 channels is larger than 6000 pieces / min.

Owner:温庆普

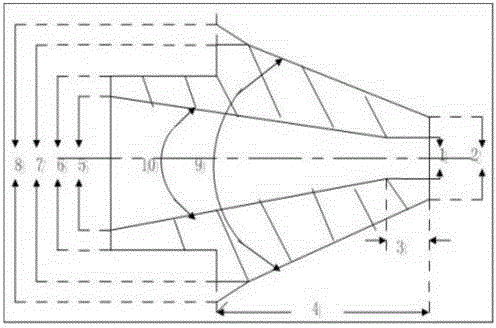

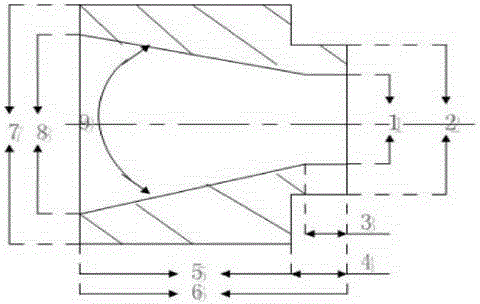

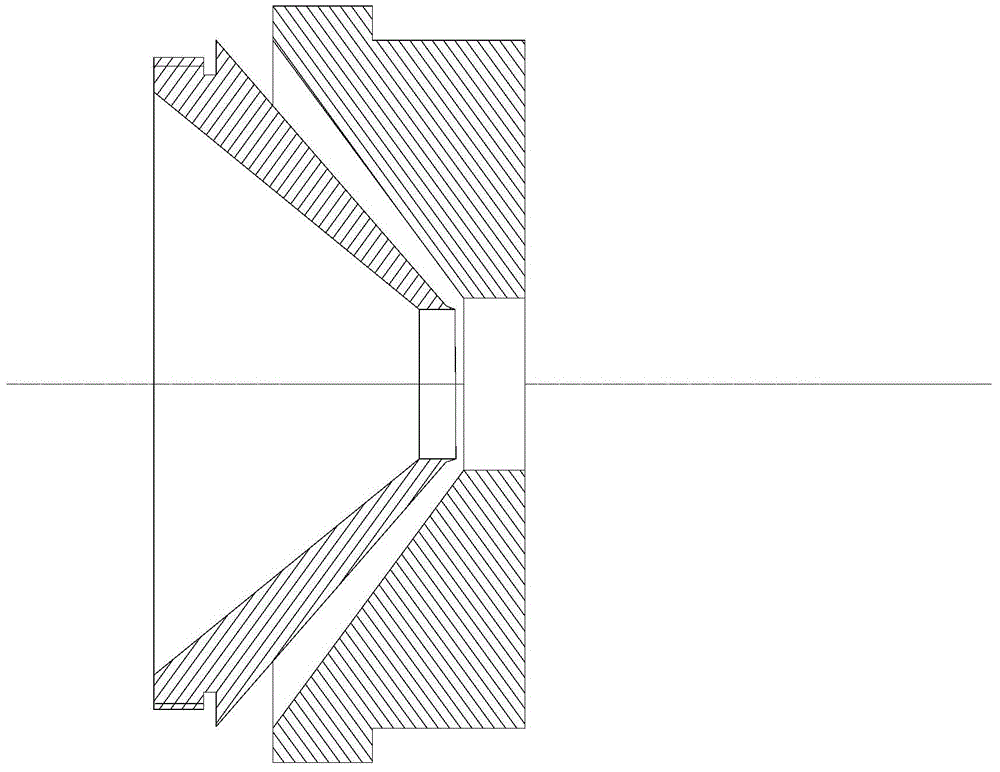

Extrusion-type mold and method for preparing special-shaped conductor cable by extrusion-type mold

InactiveCN103600481ALow costReduce the cost of qualityInsulated cablesDetails of conductive coresElectrical conductorEngineering

The invention discloses an extrusion-type mold for rubber insulated cable extrusion and a method for preparing a special-shaped conductor cable by the extrusion-type mold, and belongs to the technical field of wire cable manufacture. Through the extrusion-type mold, five types of special-shaped conductor insulated cable cores are processed to form the round special-shaped conductor cable so that unwrapping of the cable cores in compound stranding extrusion is avoided and the problem that the molded conductor cable fed to a take-up reel is easily unwrapped, so that a cable quality cost is reduced.

Owner:BAIYIN NONFERROUS GROUP

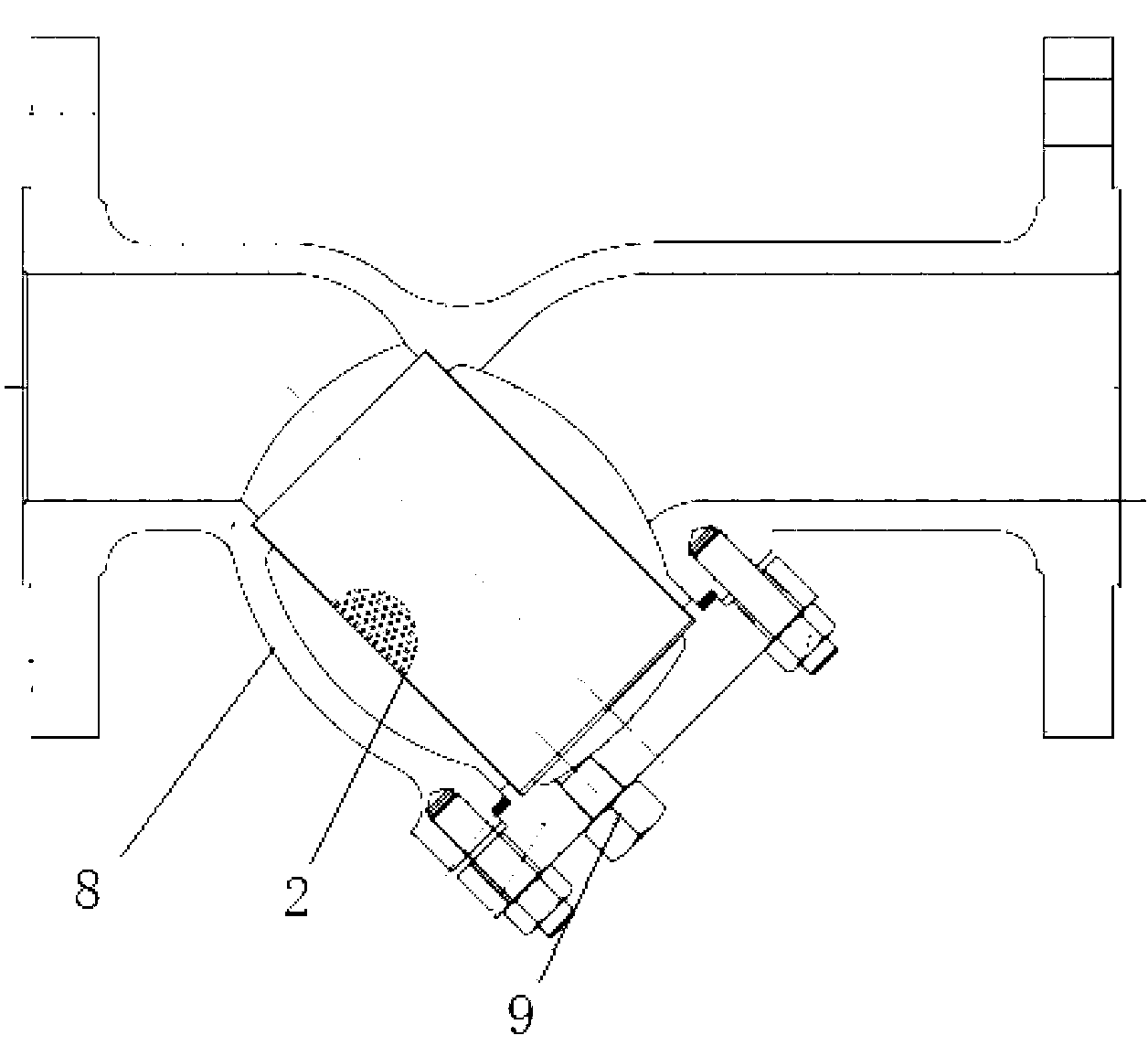

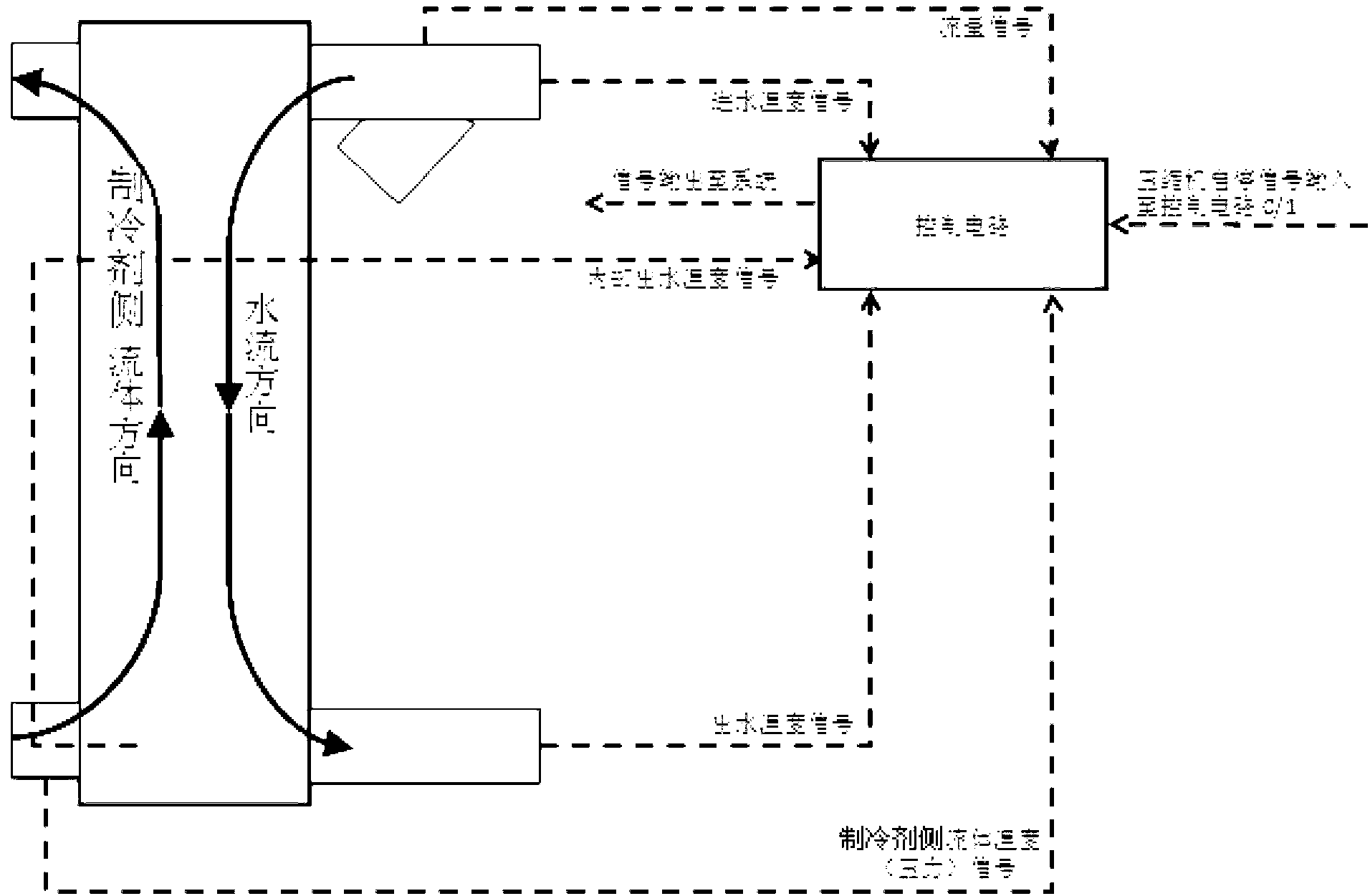

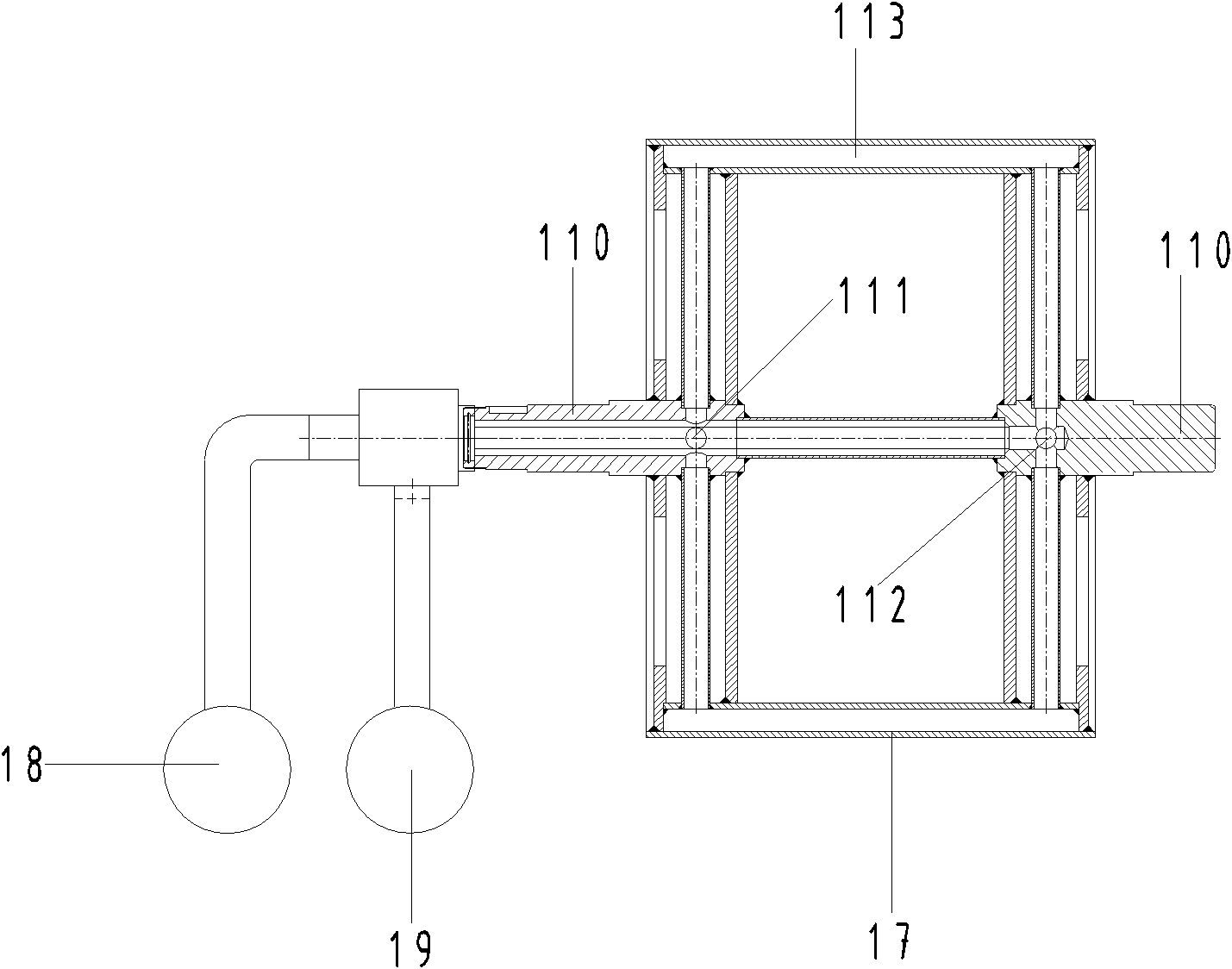

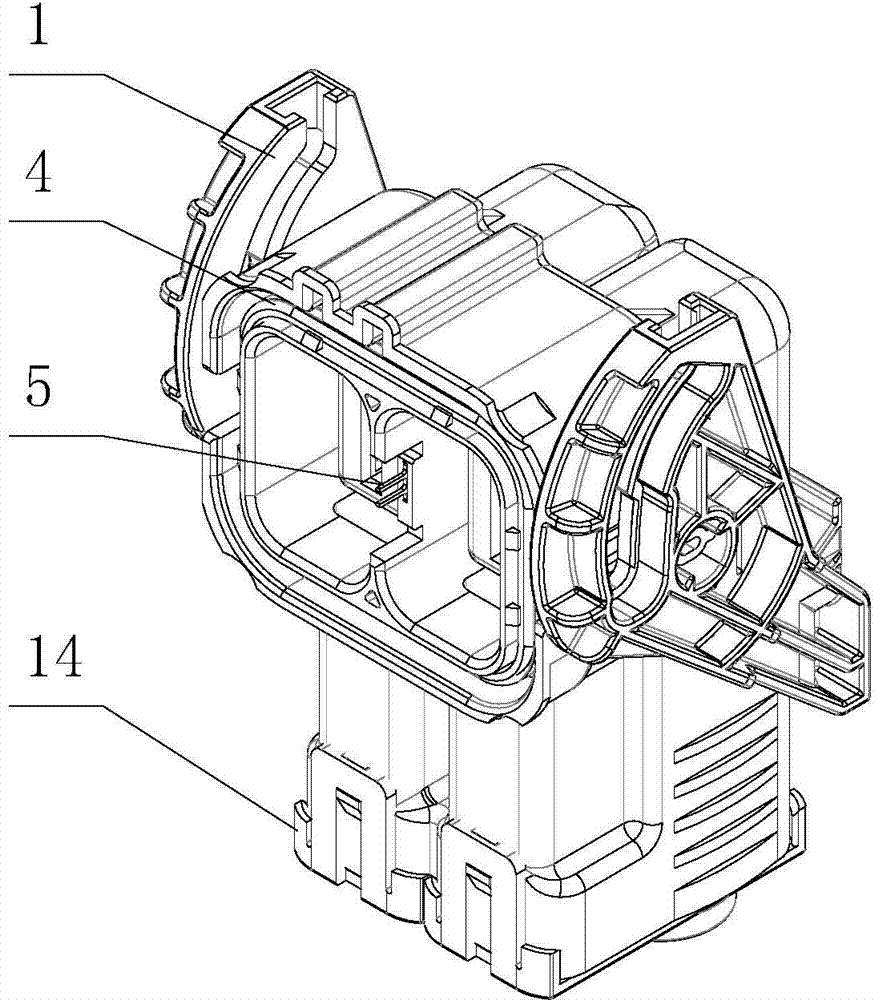

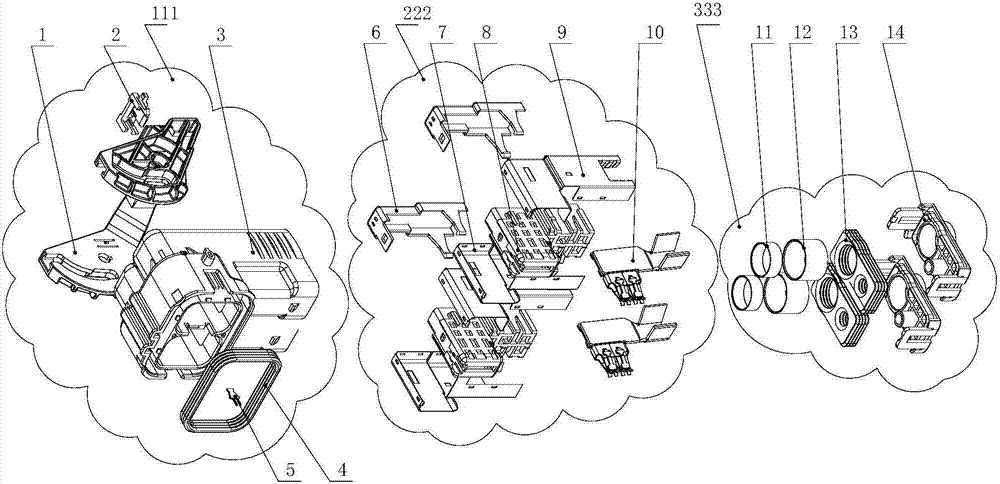

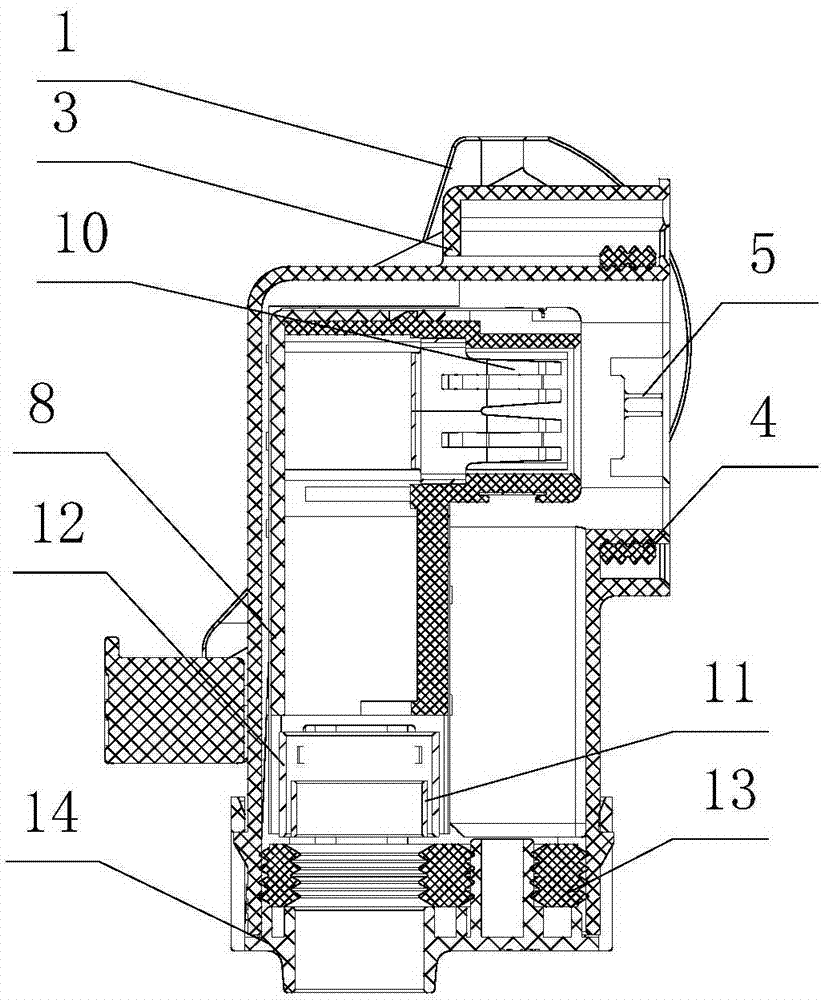

Integrated water route protective device

ActiveCN103256689APerfect protectionGood economic benefitsSpace heating and ventilation safety systemsSpace heating and ventilation control systemsHeating systemThermoregulatory system

The invention discloses an integrated water route protective device, and belongs to the technical field of safety control of temperature control systems. The integrated water route protective device is used on water routes relative to air conditioners or freezing systems or heating systems, and can ensure the reliable operation of a heat exchanger. The integrated water route protective device comprises a protective device body, a fluid temperature detection part, an outlet water temperature detection part, a flow detection part, a detection part controller and an inlet water temperature detection part, wherein the fluid temperature detection part is arranged on the side of a cooling agent of the heat exchanger, the outlet water temperature detection part is arranged at the water outlet end of a water route, the detection part controller is arranged on the protective device body, and the inlet water temperature detection part is arranged at the water inlet end of the water route. Two ends of the protective device body are correspondingly arranged at the water outlet end and the water inlet end of the water route respectively, the flow detection part is arranged in the protective device body, and the detection part controller receives a working order of an external system, then collects output signals of the fluid temperature detection part arranged on the side of the cooling agent of the heat exchanger, the outlet water temperature detection part, the flow detection part and the inlet water temperature detection part, judges abnormal conditions of specific working conditions, and outputs early warning signals. The integrated water route protective device can improve reliability of system operation, and effectively avoid the situation that the heat exchanger looses effectiveness due to filth blockage or misoperation.

Owner:李智华

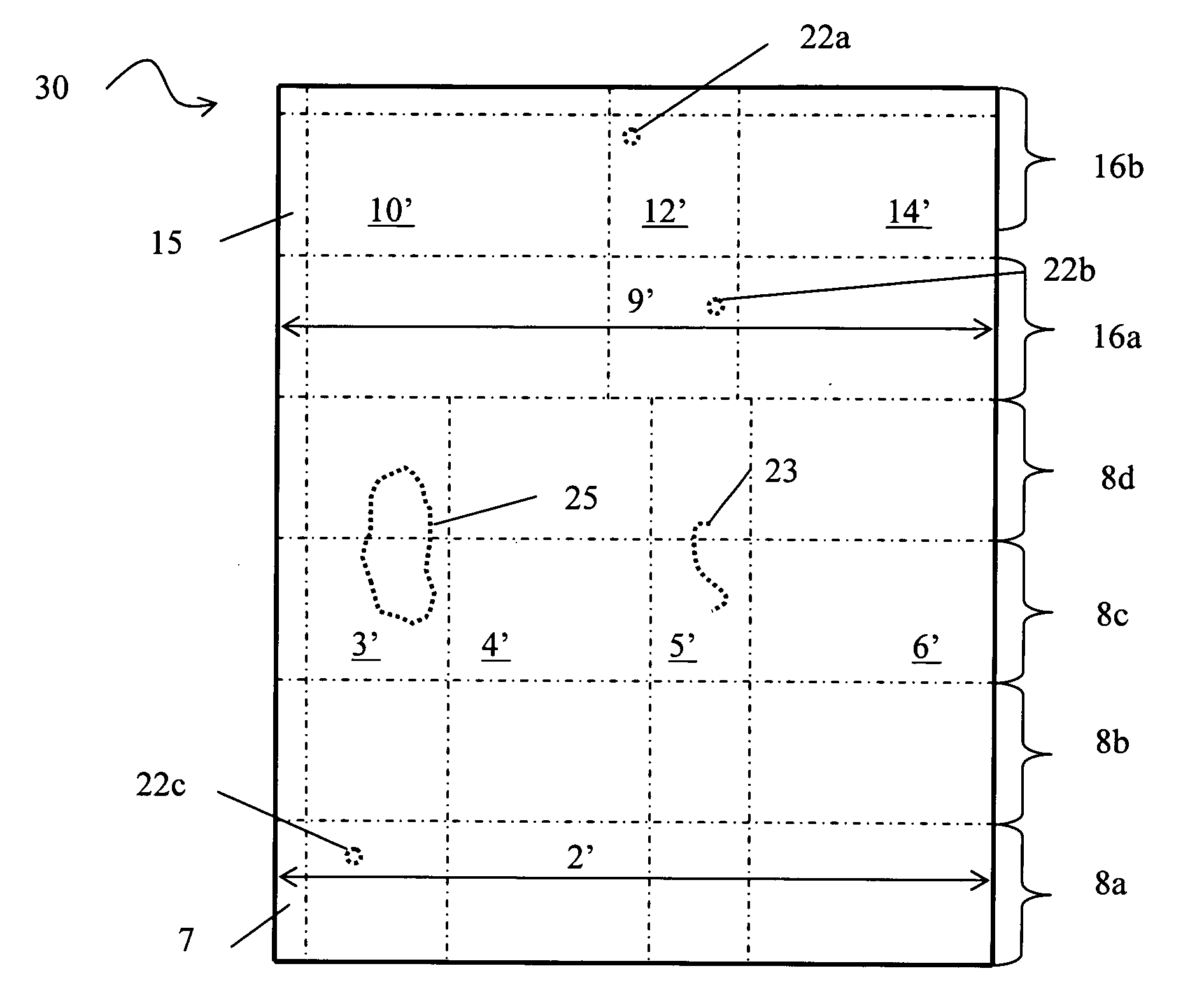

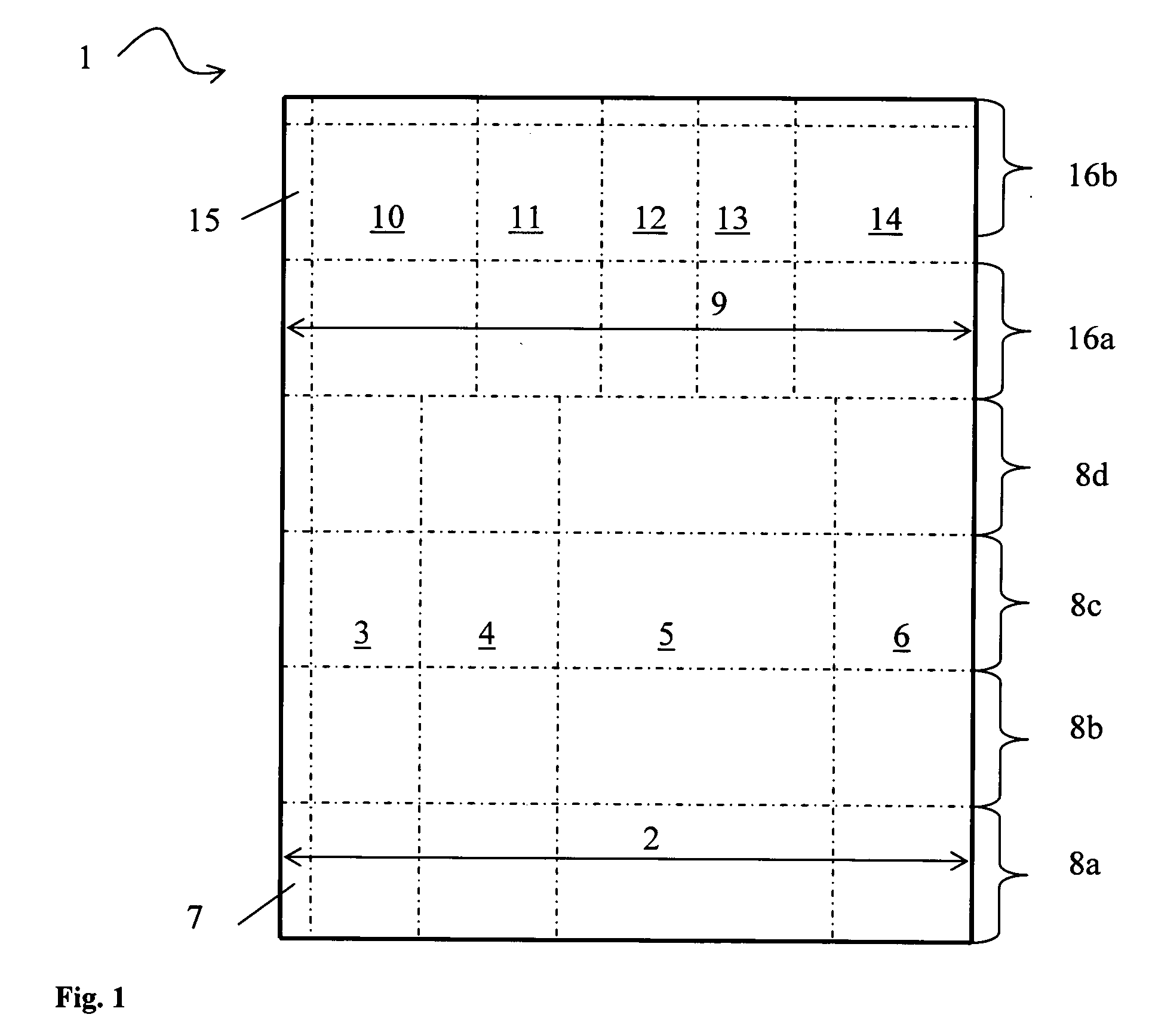

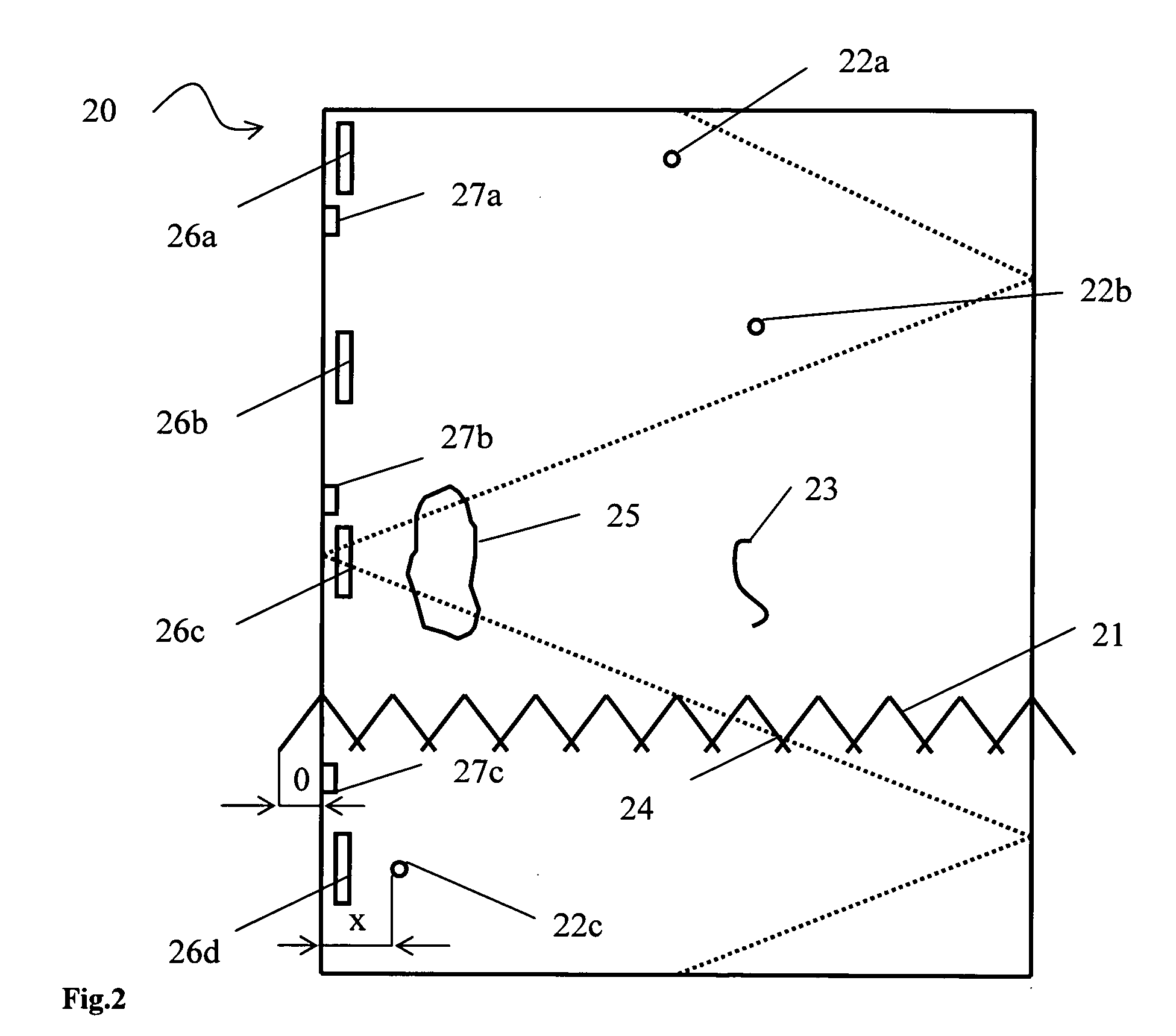

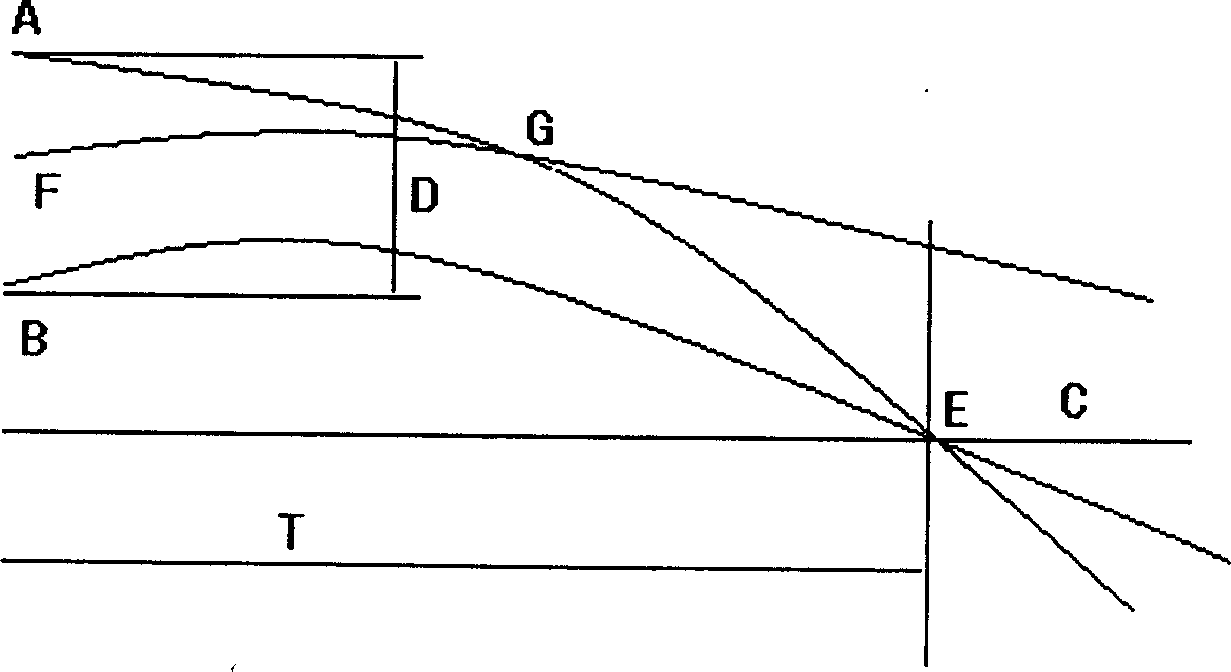

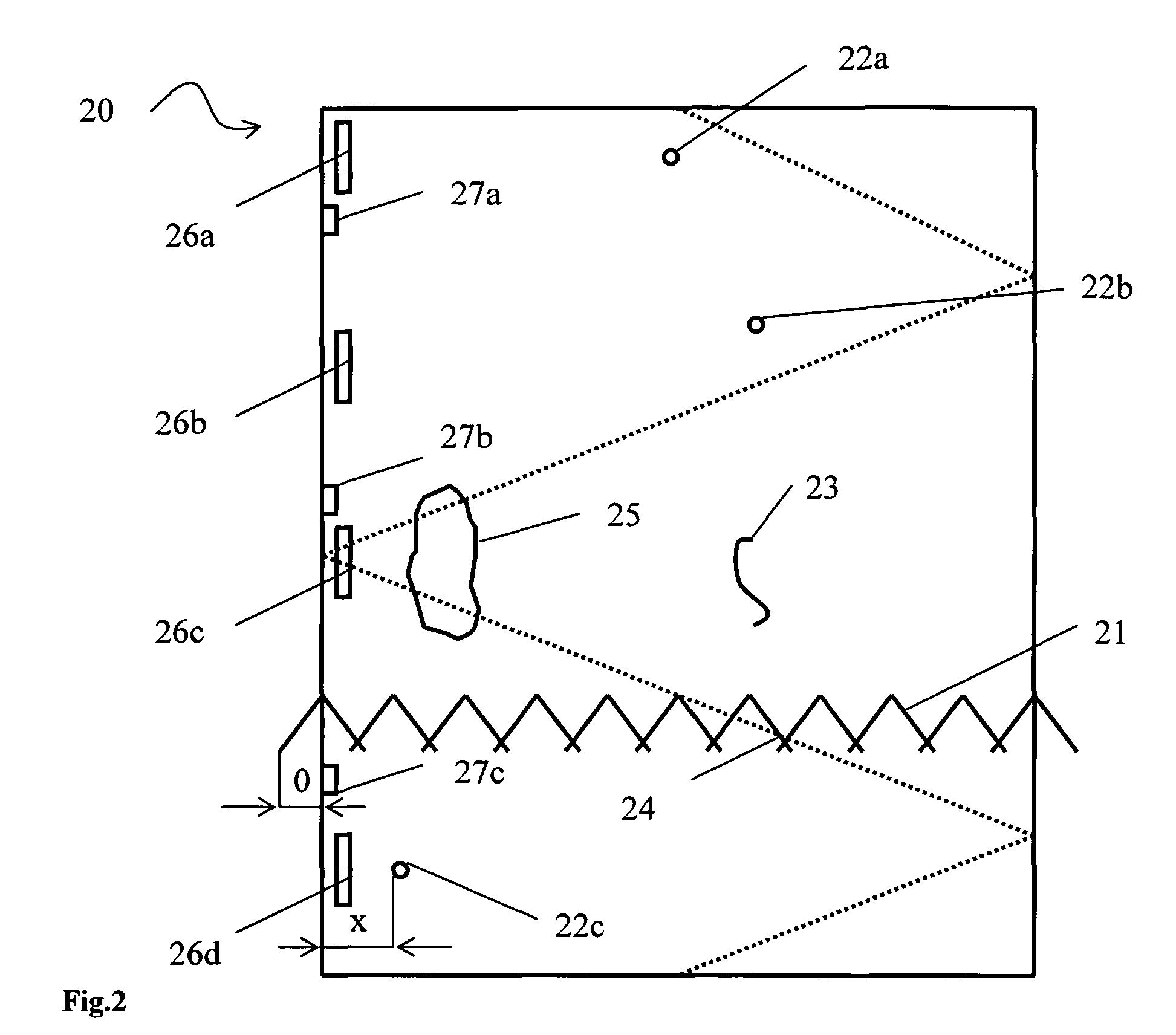

Method for creating a cutting plan for a strip-like material

ActiveUS20080288100A1Maximize qualityIncrease correspondenceFibreboardProgramme controlProduct dataManufacturing engineering

A method for creating a cutting plan for a strip-like material for maximizing a quality yield of the process is invented. In the method a cutting plan for a strip-like material is made based on end-product data, and the strip-like material is driven at a production speed in a manufacturing machine or in a finishing machine, and strip length data is recorded. A chart of the strip-like material characteristics is generated and stored in a memory. The recorded strip length data and the chart of the strip-like material characteristics is calibrated with calibration data in a winding process, and during a set change in the winding process the cutting plan for the strip-like material is optimized for maximizing a quality yield of the process based on the end-product data and the calibrated chart of the strip-like material characteristics, and a revised cutting plan is created from the optimization result.

Owner:ABB OY

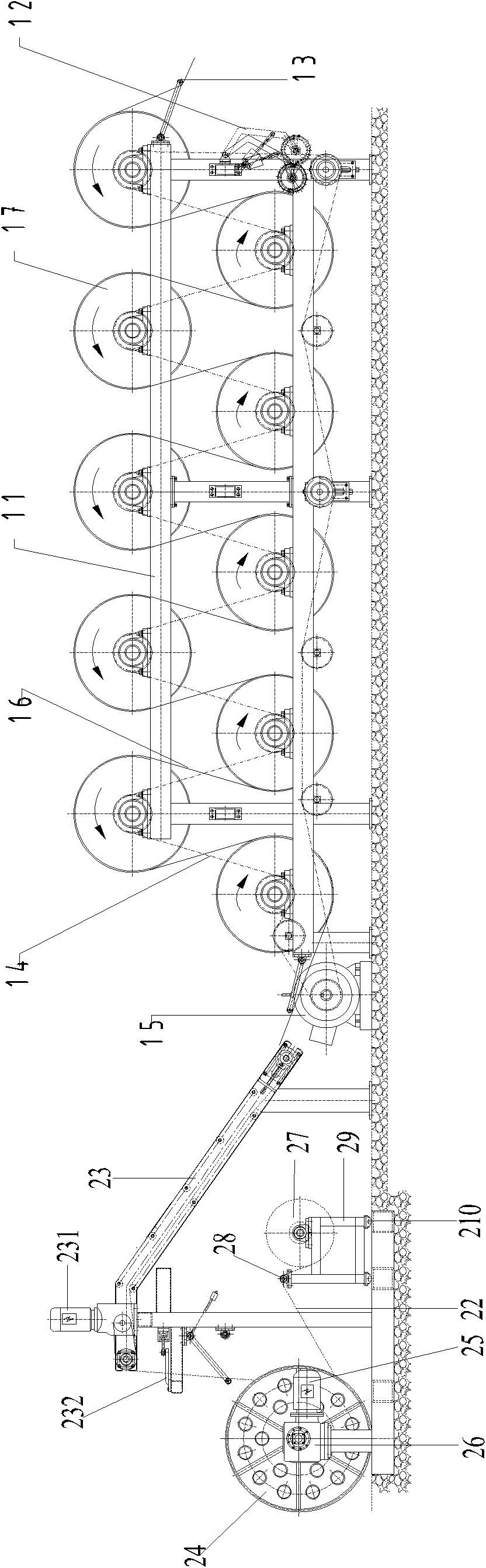

Continuous production line for sizing material

The invention discloses a continuous production line for a sizing material, which comprises a sizing cutting machine, a belt weigher, a kneader, an open mill, a tablet press, a sizing tablet cooling device and a coiling device. The sizing cutting machine cuts off the sizing material which is weighed through the belt weigher, then is conveyed to a kneader through a material feeding conveying belt, the sizing material is kneaded through the kneader, and then is conveyed to the open mill through a hopper type conveyor. After being milled by the open mill, the sizing material is conveyed to the tablet press through a bridge conveying belt, after being pressed into tablets through the tablet press, the sizing material is cooled through the sizing tablet cooling device, and finally the sizing tablets are coiled through the coiling device. Compared with the prior art, the continuous production line for the sizing material can solve the problem of white sizing production and achieve the aims of reducing quality cost, improving qualification rate and reducing working strength of operators.

Owner:GUANGZHOU FENGLI RUBBER TIRE

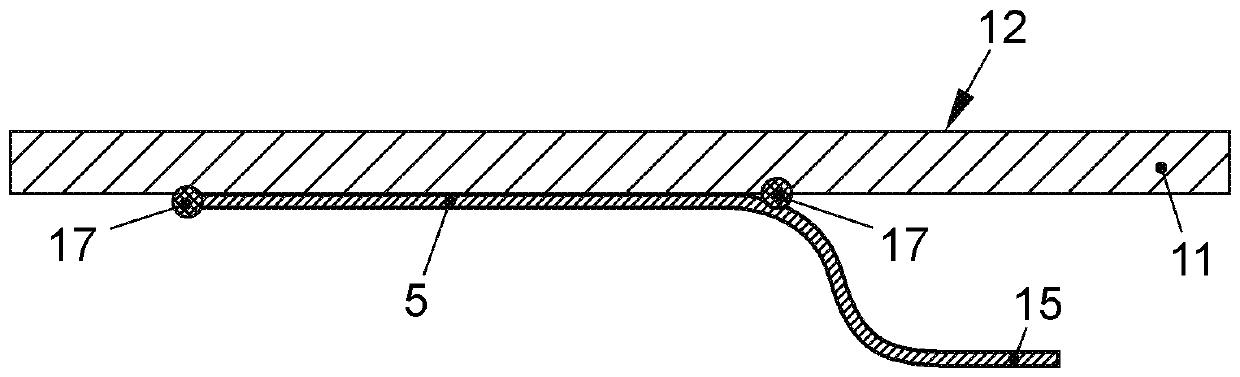

Sequentially etched and plated lead frame structure without island prepacked plastic sealed material and producing method thereof

ActiveCN102324415ASimple designReduce material costsSemiconductor/solid-state device detailsSolid-state devicesEngineeringLead frame

The invention relates to a sequentially etched and plated lead frame structure without an island prepacked plastic sealed material and a producing method thereof. The structure comprises pins (2), wherein front faces of the pins (2) are plated with first metal layers (5); back faces of the pins (2) are plated with second metal layers (6); etching regions between the pins (2) and the pins (2) are filled with plastic sealed materials (4); and the plastic sealed materials (4) are aligned with the front face and the back face of a metal substrate (9). The sequentially etched and plated lead framestructure provided by the invention has the following advantages: a layer of expensive high temperature resistant soft organic adhesive film needs not to be attached on the bottom of the lead frame; various problems possibly generated in loading, routing and encapsulating are avoided in the background; the yield of the finished products is largely increased; convenience can be brought to the circuit board design while loading is made without a metal island; and the front face and the back face of the lead frame are etched at the same time so that the complicatedness of at least 50% can be reduced in the procedure, the cost is reduced and the malposition risk caused by secondary alignment can be reduced.

Owner:JCET GROUP CO LTD

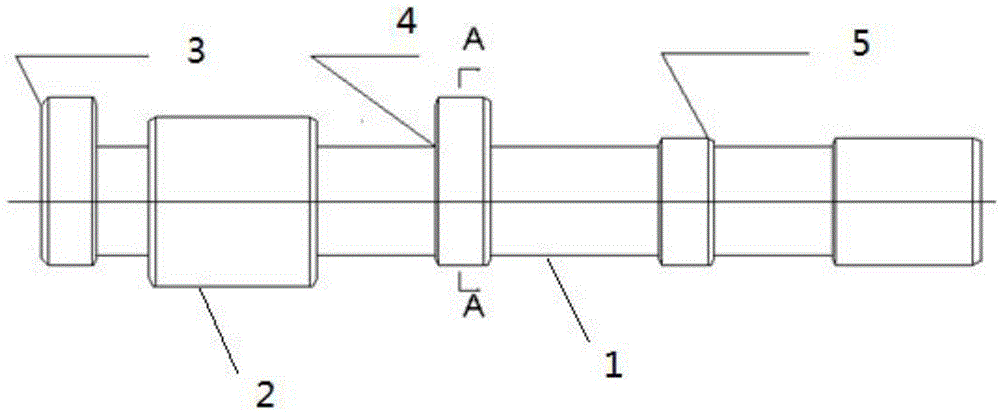

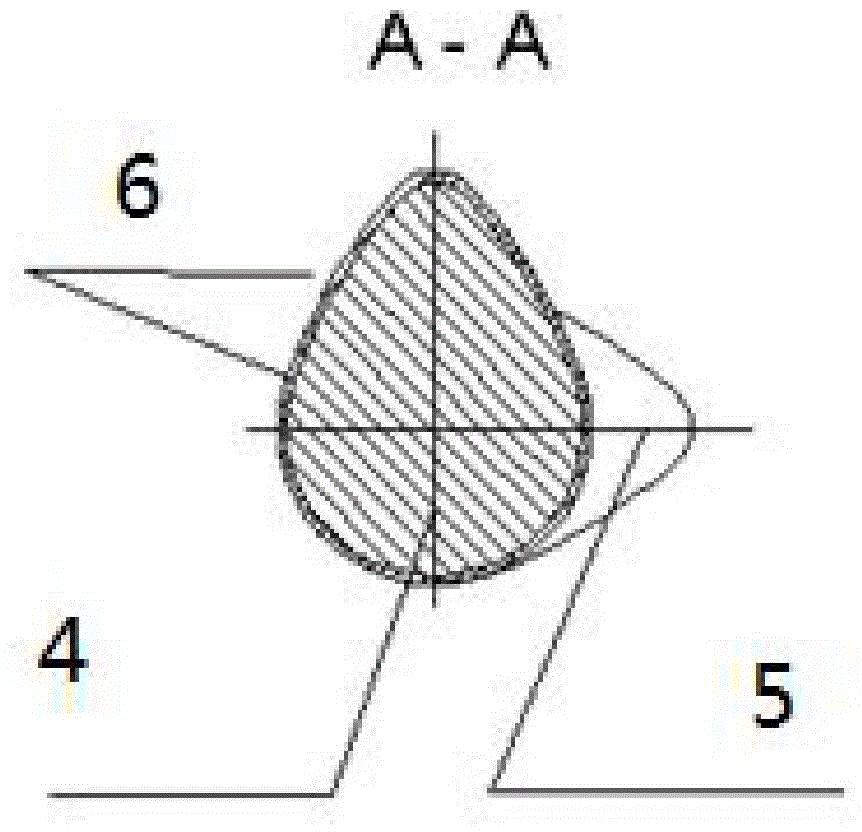

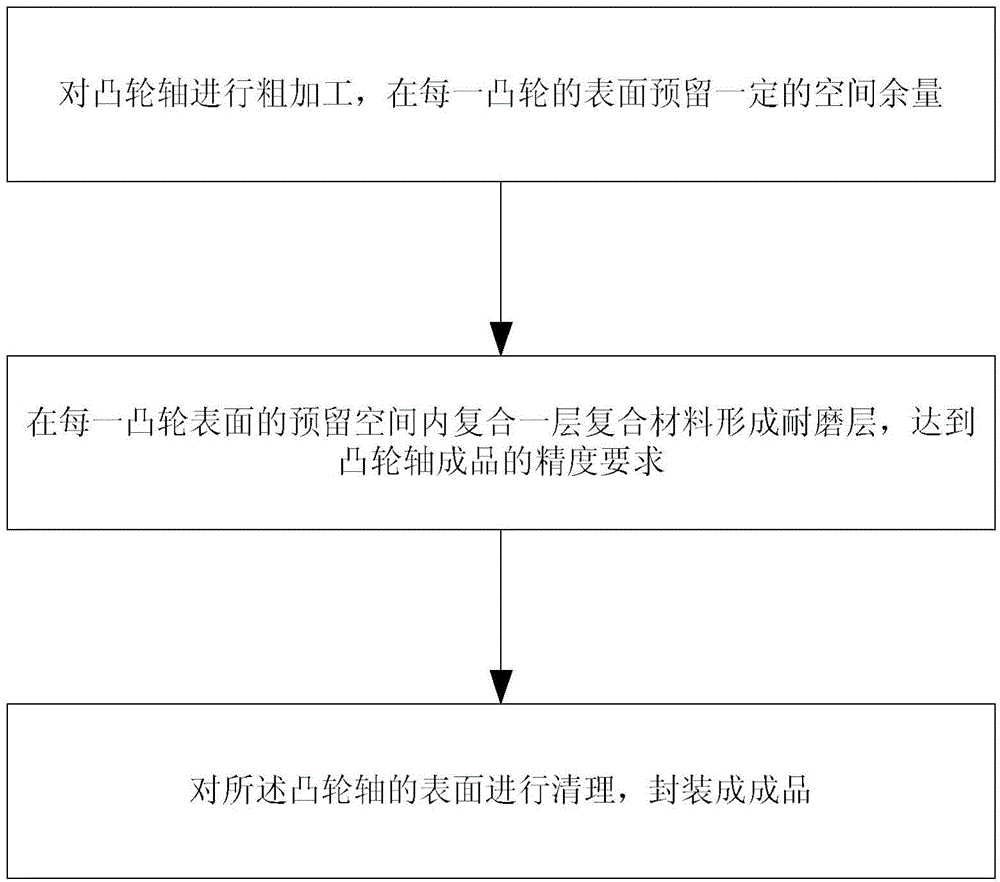

Engine camshaft and preparation method thereof

InactiveCN103953407AGuaranteed service lifeGuaranteed toughnessValve arrangementsMolten spray coatingWaste productEngineering

The invention relates to an engine camshaft. The engine camshaft comprises a main shaft, a plurality of cams and bearings, wherein the main shaft of the camshaft is made of one material for maintaining tenacity and strength; part of the surface of each cam adopts another abrasive resistant material to form an abrasive resistant layer so as to have resistance to abrasion and effectively ensure the service life of the engine camshaft. According to the preparation method, a heat treatment quenching process, a flaw detection process and a hardness test process are eliminates, loss of waste products of which the surfaces have slight cracks due to quenching is avoided, and the comprehensive economic cost and the quality cost are low.

Owner:SUZHOU INDAL PARK INSTITUE OF VOCATIONAL TECH

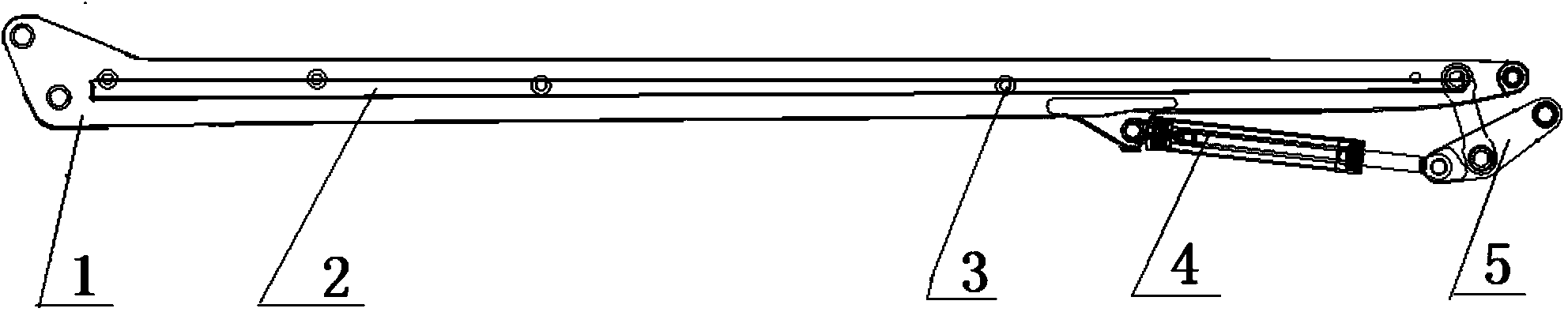

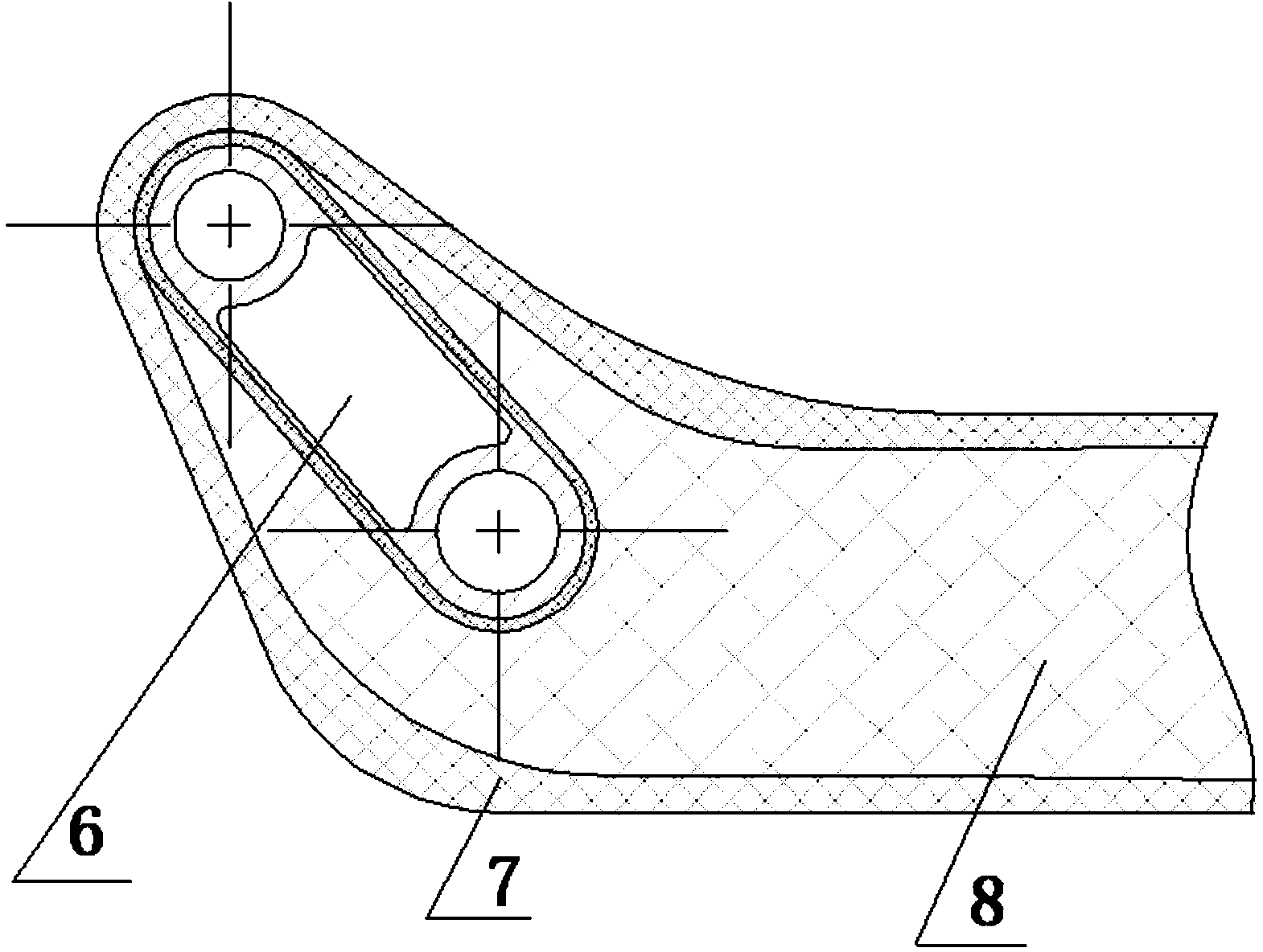

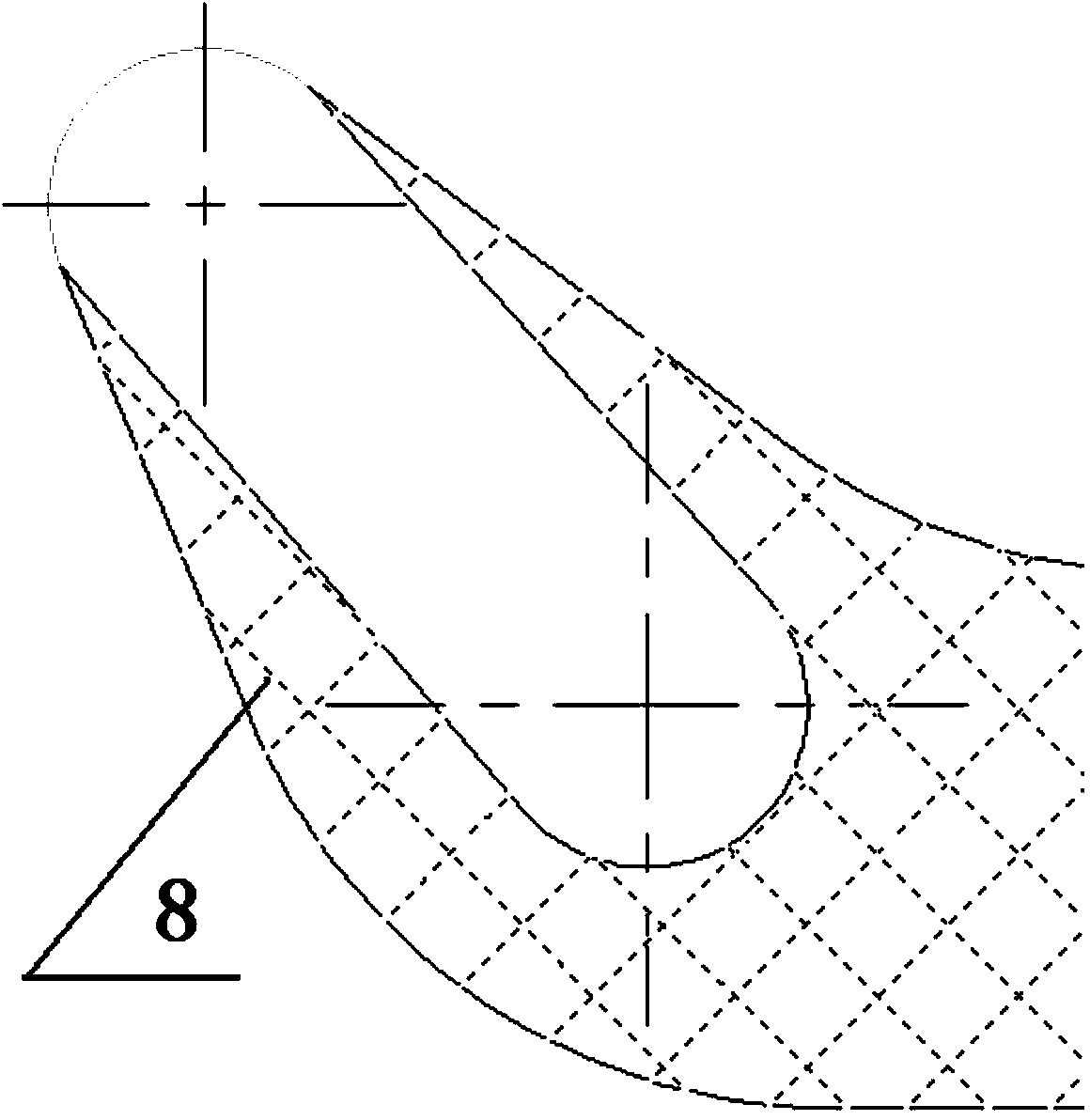

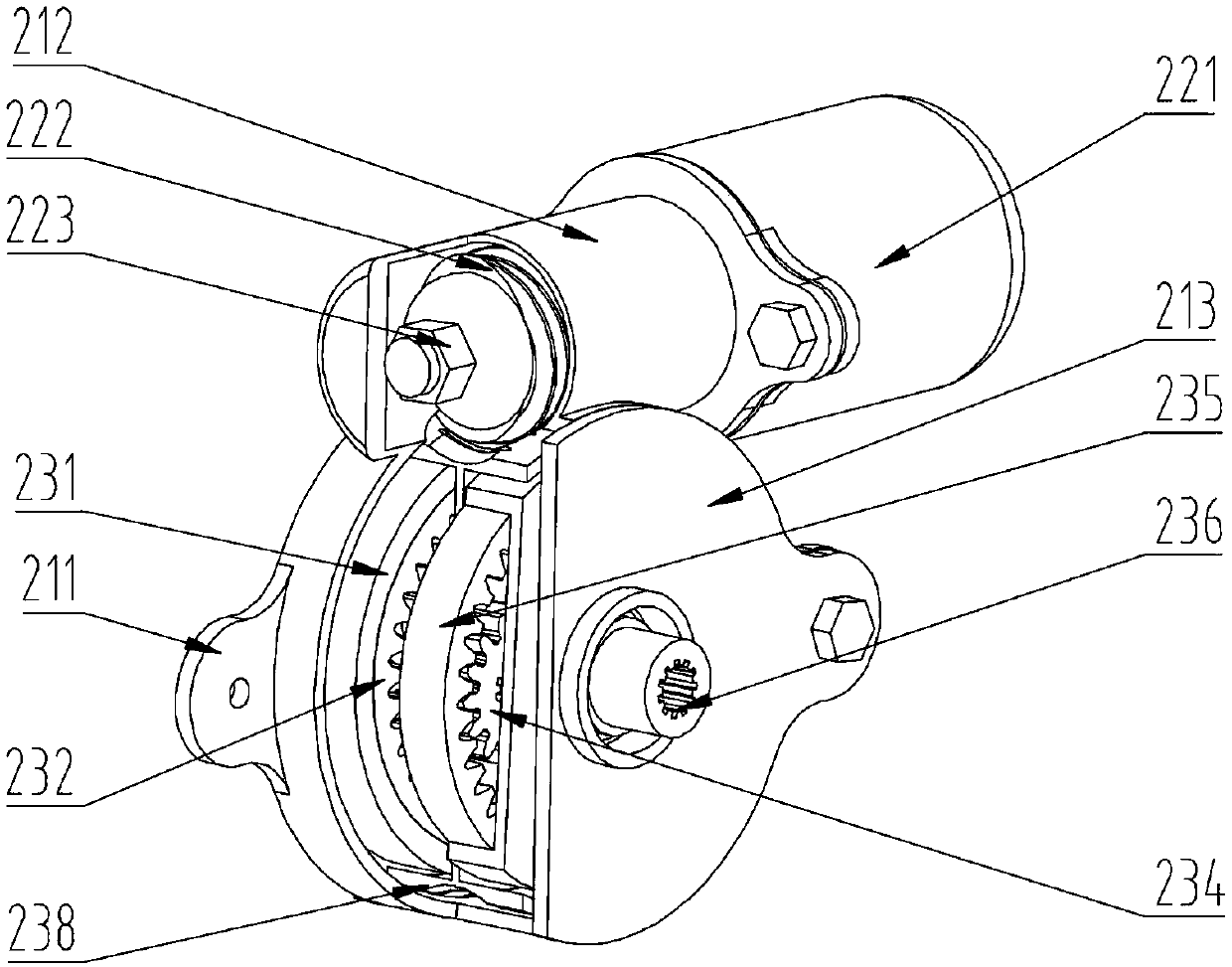

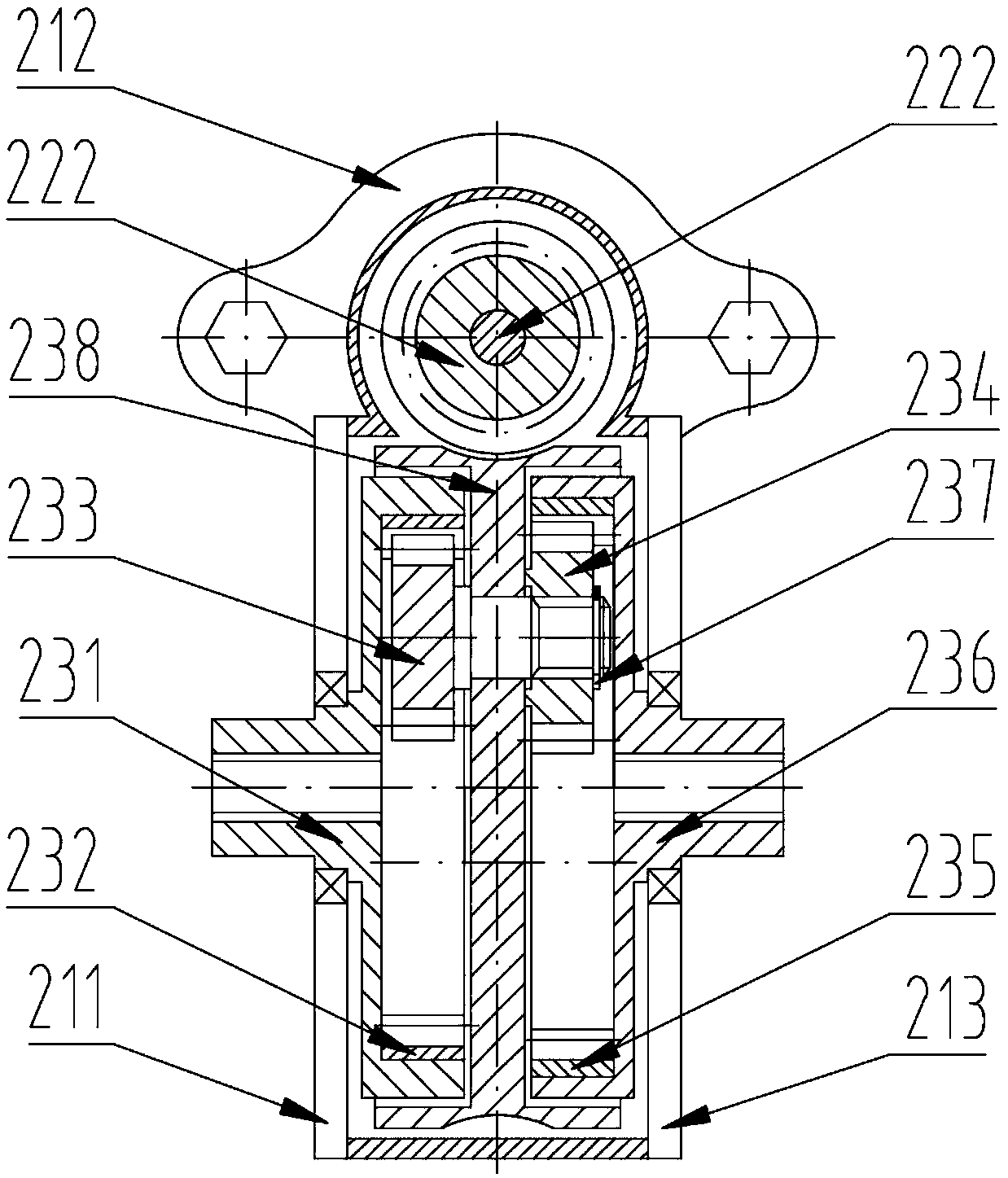

Composite joint for concrete pump truck boom

ActiveCN103953196AReduce the cost of qualityImprove structural efficiencyBuilding material handlingComposite jointMain bearing

The invention relates to a composite joint for a concrete pump truck boom and belongs to the technical field of concrete pump truck boom connection. The joint is of a composite sandwich structure and comprises a composite skin, a core material and a metal tenon, wherein the metal tenon is embedded in the core material, one end surface of the metal tenon is flush with the end surface of the core material, and the composite skin is positioned outside the core material and the metal tenon; the core material performs a shaping function, and the metal tenon and the composite skin are used as main bearing parts. According to the joint, higher structural efficiency can be obtained at lower mass cost to an utmost degree through the structure and size variation of a resin matrix composite, the core material and the tenon.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

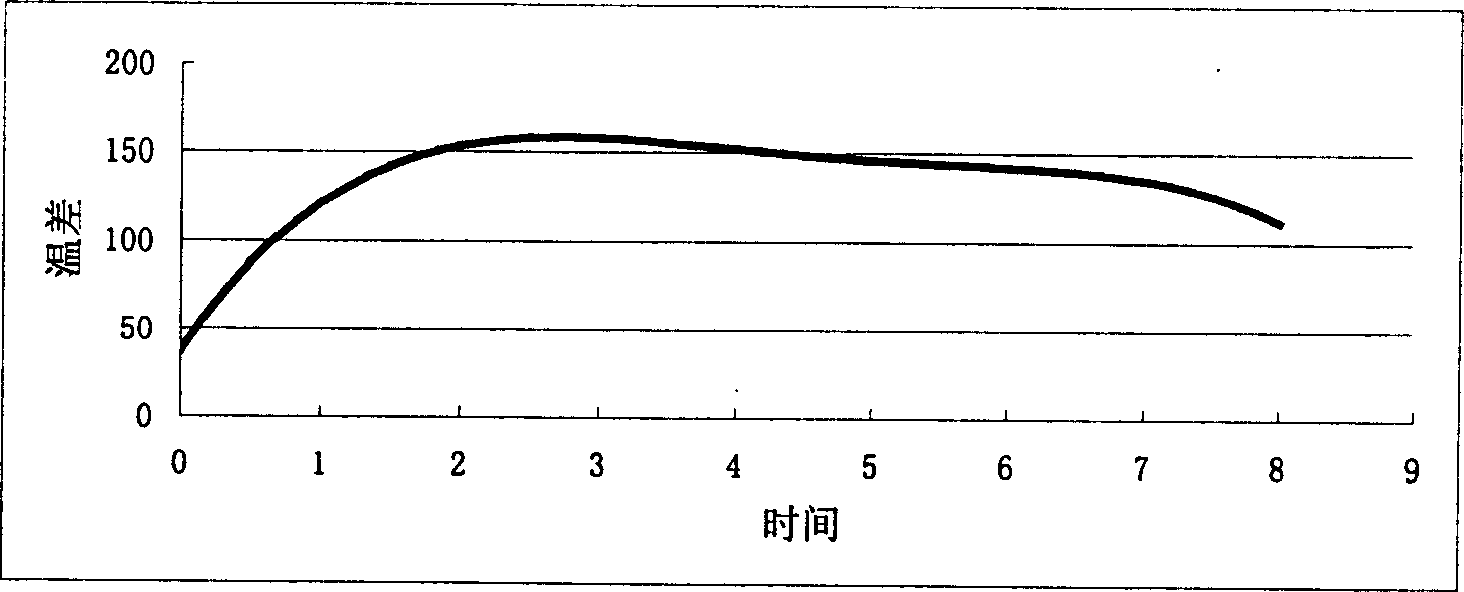

Annealing treating process for cold rolled steel coil

InactiveCN1858269AReduce the incidence of bond defectsReduce the cost of qualityFurnace typesHeat treatment process controlIncrease temperaturePressure stress

The present invention relates to heat treatment of metallurgical product, and is especially one annealing treatment process for cold rolled steel coil in the cover furnace. Technologically, the present invention features the high maintaining temperature difference and temperature lowering and maintaining control. That is, the annealing treatment process has raised annealing temperature below the phase change line, increased temperature difference between inside and outside the steel roll, prolonged time with steel roll outer temperature lower than the steel roll core temperature, lowering the steel roll core temperature in the later temperature maintaining stage to lower the pressure stress inside the steel roll to avoid sticking fault. The present invention has raised annealing quality and output.

Owner:ANGANG STEEL CO LTD

Powder metallurgy copperized agent and method for producing the same

InactiveCN101113511AReduce the cost of qualityMixing methodsSolid state diffusion coatingMetallurgyPrepared Material

The invention relates to a powder metallurgy copperizing agent, which is characterized in that the copperizing agent essentially consists of the mass percentages of materials of: 1.7 percent to 2.1 percent of Fe powder, 3.9 percent to 4.3 percent of Mn powder, 93.6 percent to 94.4 percent of Cu powder. The producing method of the copperizing agent is that: the prepared material is mixed in a double tapered mixer at a rotating speed of 19 to 21r / min for 30 to 35min. the powder metallurgy copperizing agent of the invention does not erode products and affect the strength of products.

Owner:包敢锋

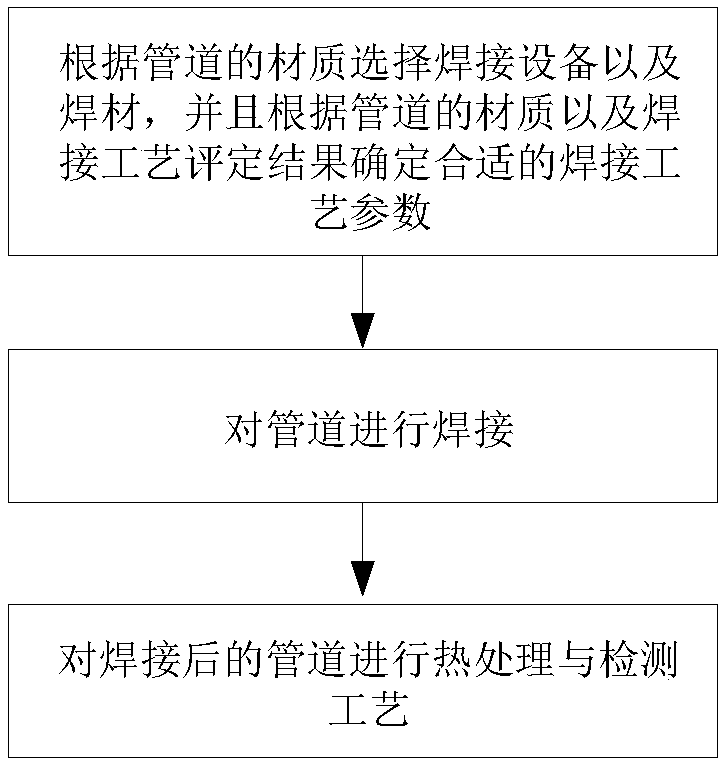

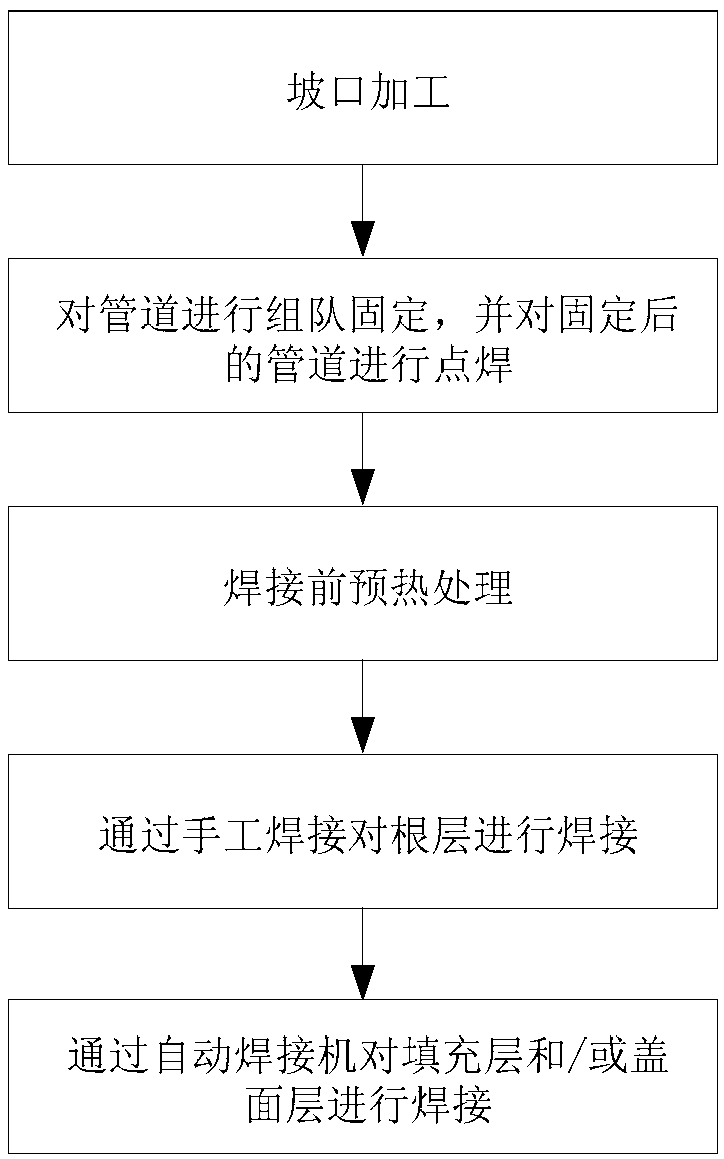

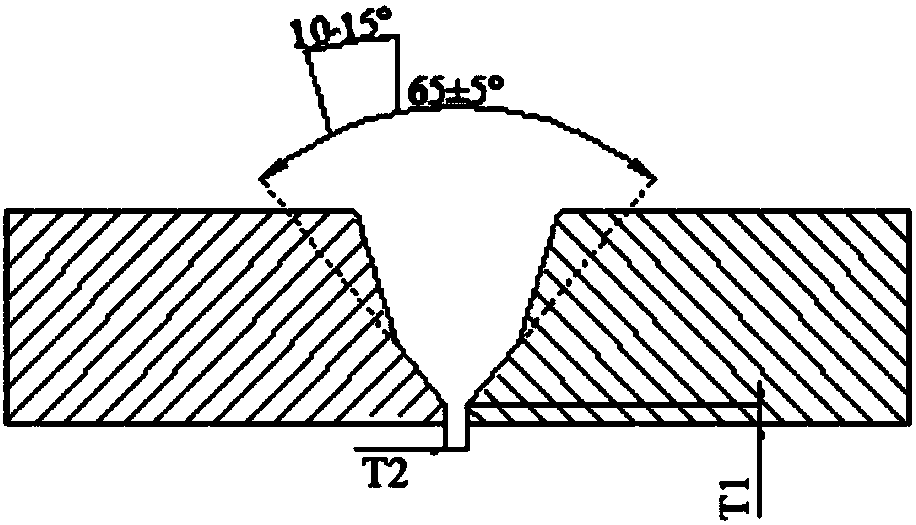

Pipeline welding process

InactiveCN107552987AEasy to operateHigh first pass rateWelding apparatusTubular articlesSurface layerFirst pass yield

The invention provides a pipeline welding process. The pipeline welding process comprises the steps of welding a root layer through manual welding and welding a filling layer and / or a cover surface layer through an automatic welding machine. The welding process provided by the invention has the advantages that under the circumstance of not increasing welders on a large area, the construction progress is promoted and the labor cost is greatly reduced; the welding construction of large-diameter thick-walled pipelines can be carried out on a large area and the production efficiency is high; moreover, the first pass yield of welding lines is high by adopting the welding process provided by the invention, unnecessary reworking is avoided, the construction quality is high and the quality cost isreduced; and the operability of the construction process is high, the operation is easy, the quality accident rate and the safety accident rate in the practical application are both zero and the process is safe and reliable.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Method for creating a cutting plan for a strip-like material

A method for creating a cutting plan for a strip-like material for maximizing a quality yield of the process is invented. In the method a cutting plan for a strip-like material is made based on end-product data, and the strip-like material is driven at a production speed in a manufacturing machine or in a finishing machine, and strip length data is recorded. A chart of the strip-like material characteristics is generated and stored in a memory. The recorded strip length data and the chart of the strip-like material characteristics is calibrated with calibration data in a winding process, and during a set change in the winding process the cutting plan for the strip-like material is optimized for maximizing a quality yield of the process based on the end-product data and the calibrated chart of the strip-like material characteristics, and a revised cutting plan is created from the optimization result.

Owner:ABB OY

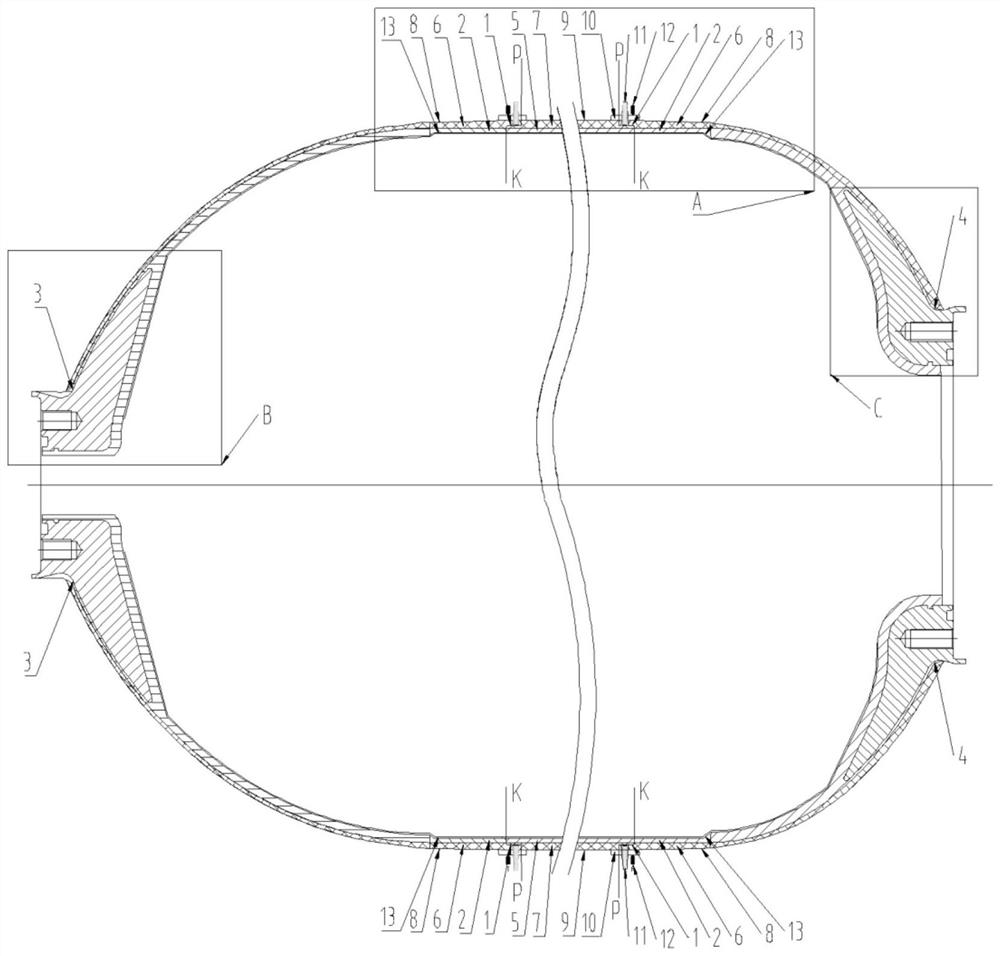

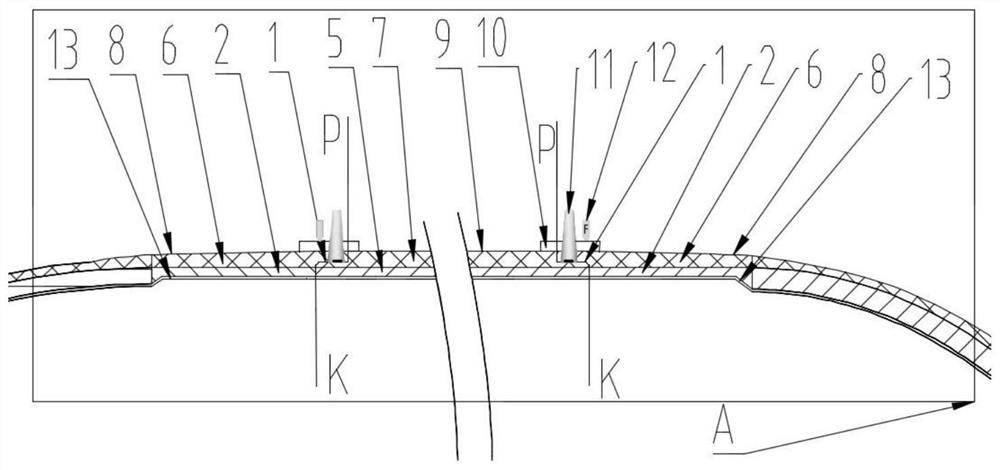

Laser welding forming method for sectional type composite material shell of solid rocket engine

ActiveCN112277337AReduce the cost of qualityReduce manufacturing costInsulation layerLaser soldering

The invention discloses a laser welding forming method for a sectional type composite material shell of a solid rocket engine. The laser welding forming method comprises the following steps that (1),a core mold is prepared; (2), a heat insulation layer is manufactured; (3), sectional prefabricated parts are manufactured; (4), surface treatment is carried out on the prefabricated parts; (5), laserwelding assembly is carried out on the sectional prefabricated parts; and (6), the outer layer of the shell is reinforced. According to the laser welding forming method for the sectional type composite material shell of the solid rocket engine, a laser welding forming process is designed according to various loads of an engine shell and sectional connecting parts, so that inner composite layer connection and integral forming of the engine shell are achieved for shell front and rear head plate prefabricated parts and shell barrel segment prefabricated parts correspondingly through laser welding and outer layer winding reinforcement, efficient and reliable connection of the sectional type composite shell is achieved, the production cost is further reduced, and the inertia mass of an engineis reduced; and meanwhile, the production efficiency and the charging space are improved.

Owner:湖北三江航天江北机械工程有限公司

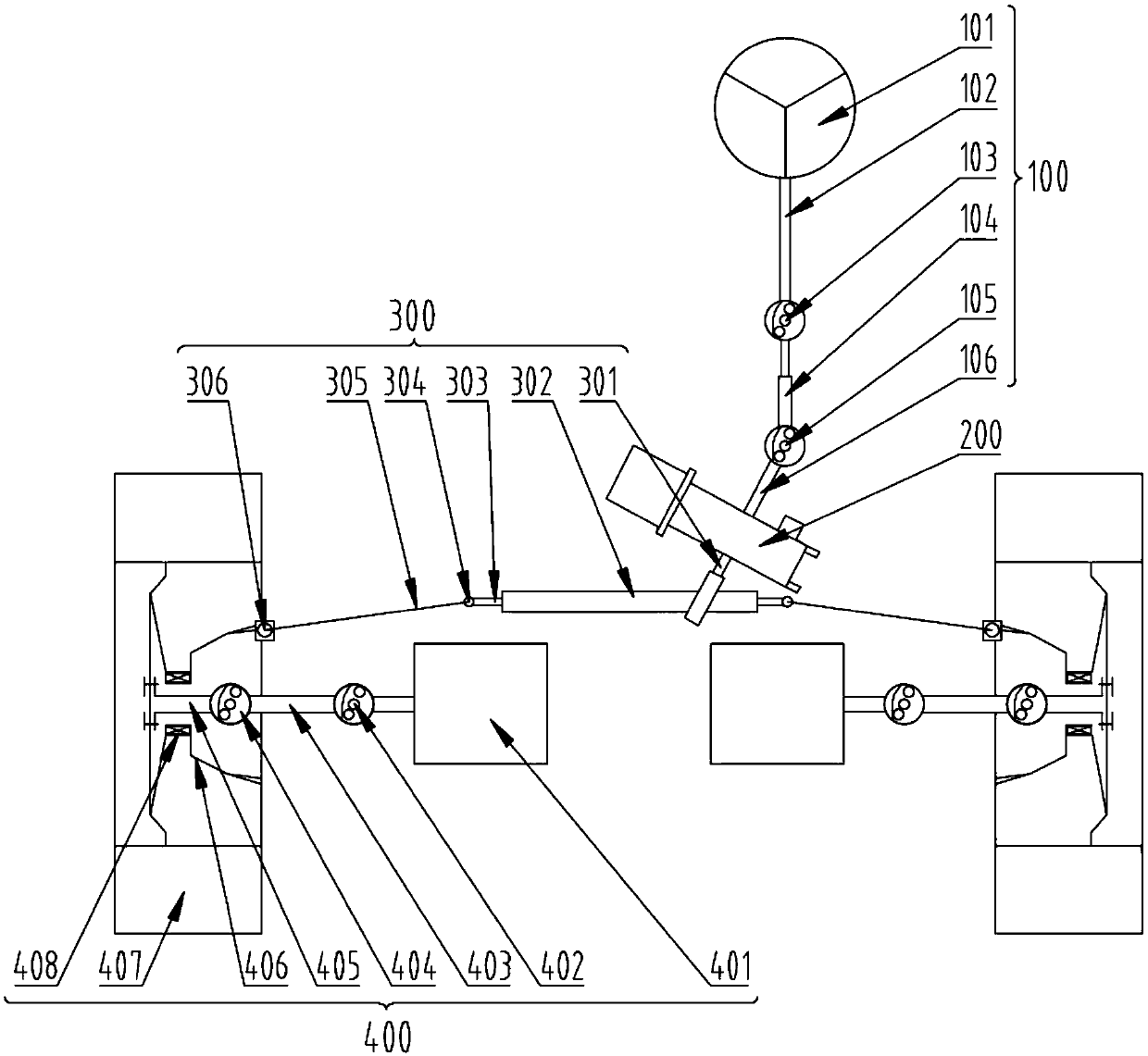

Antenna arrangement and a transport mechanism including same

ActiveCN107819197AImprove reception characteristicsAvoid blockingNear-field transmissionAntenna adaptation in movable bodiesCommunication deviceWireless

The invention relates to an antenna arrangement and a transport mechanism including the same, in particular to a transport mechanism and an antenna arrangement for facilitating the transmission / reception of a portable wireless communication device (2) temporarily arranged in a passenger compartment (8) of a transport. The antenna arrangement includes a supporting body having a shelf area and a flat antenna (4) having an interface, wherein the shelf area holds the wireless communication terminal (2), the flat antenna (4) is arranged parallel to the shelf area on or in the supporting body, and the interface connects via a wiring harness (6) of the transport to an external antenna (3) of the transport.

Owner:VOLKSWAGEN AG

Assembly of an aircraft structure assembly without shimming, locating fixtures or final-hole-size drill jigs

A method is provided for assembling an aircraft structure assembly composed of a plurality of sections, and doing so without use of any shimming, locating fixtures or final-hole-size drill jigs. The method includes supporting the first and second frame sections on respective adjustable supports, and positioning the interconnecting frame section therebetween. The method includes aligning first pre-drilled mating holes in the interconnecting frame section with first pre-drilled mating holes in the first and second frame sections, and installing fasteners though the aligned, first pre-drilled mating holes. The method includes positioning a structural mating section relative to the first and second frame sections and interconnecting frame section. And aligning second pre-drilled mating holes in the structural mating section with second pre-drilled mating holes in at least one of the frame sections, and installing fasteners through the aligned, second pre-drilled mating holes to secure the structural mating section.

Owner:THE BOEING CO

Automobile active steering system adopting differential power-assisted steering and control method thereof

PendingCN108791488AImprove matchLarge transmission ratio variation rangeSteering linkagesMechanical steering gearsCouplingSteering control

The invention discloses an automobile active steering system adopting differential power-assisted steering. The automobile active steering system adopting differential power-assisted steering comprises wheel edge independent driving systems, a steering gear and steering transmission mechanism and a corner coupling mechanism, wherein the wheel edge independent driving systems are arranged on the inner sides of wheels and used for independent driving of the wheels on the left and right sides and can provide steering power assistance by using the driving force difference between the left and right wheels; the steering gear and steering transmission mechanism is fixed to a vehicle body and connected to the inner sides of left and right wheels for pulling the wheels to steer left and right; andthe output end of the corner coupling mechanism is connected to the steering gear and steering transmission mechanism, the corner coupling mechanism is provided with a first input end and a second input end, the first input end is connected to a steering control mechanism, and the second input end is connected to a coupling motor. The corner coupling mechanism has a wider transmission ratio variation range, and the selection of the coupling motor and the matching of the whole vehicle are facilitated. The invention further provides an automobile active steering control method adopting differential power-assisted steering.

Owner:JILIN UNIV

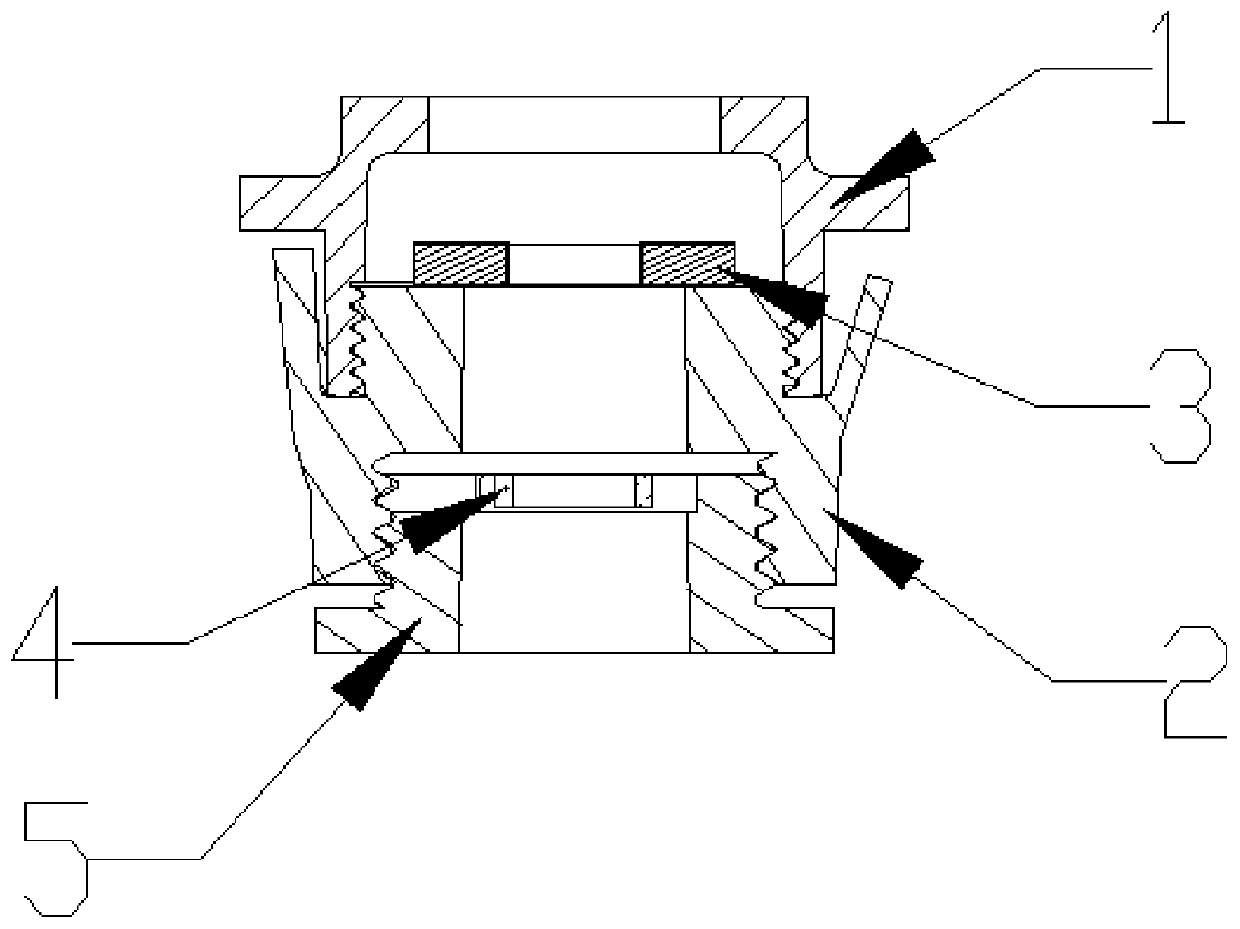

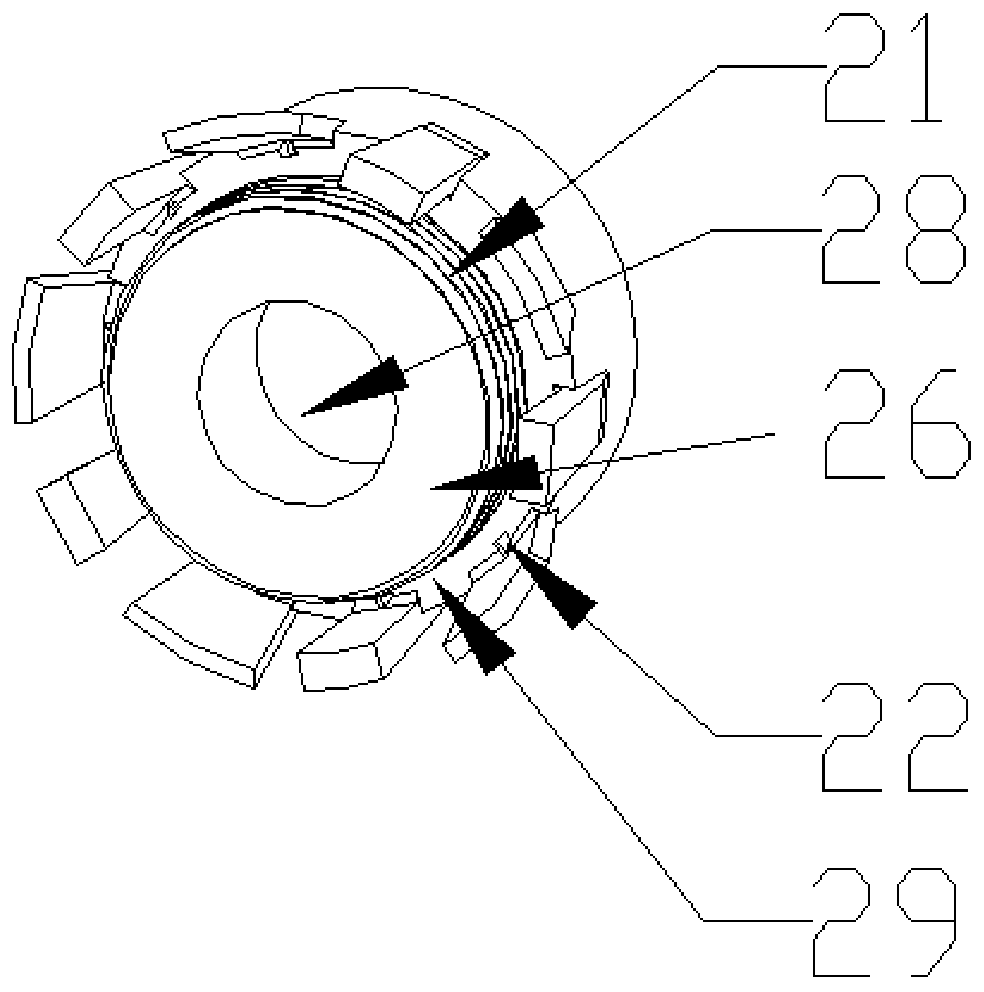

Novel automatic tolerance adjusting device

PendingCN110153948AAchieve lockingRealization of automatic tolerance adjustmentMetal-working hand toolsEngineeringKinetic energy

The invention provides a novel automatic tolerance adjusting device which comprises an upper shell, a positioning stud, a locking gasket, a star-like piece and an adjusting nut. The upper and lower ends of the positioning stud are fixedly connected with the upper shell and the adjusting nut through threads, and the locking gasket is arranged in a first inner cavity of the upper shell and freely moves in an axial hole gap; and the outer wall of the star-like piece is provided with a pusher dog, the star-like piece is arranged in a second inner cavity of the positioning stud and freely moves ina star-like hole gap, and the pusher dog pushes and adjusts a star-like boss of the adjusting nut and drives the adjusting nut to rotate. The novel automatic tolerance adjusting device fully utilizeskinetic energy generated by rotation and advancement of bolts, can achieve automatic rigid supporting to eliminate tolerance accumulation, realizes rapid and effective precise positioning and assembling, and solves the problems that in the prior art, the steps are many, the cost is high, the operation technical difficulty is high, and the work efficiency is low; and meanwhile, the overall structure is fixed in rigidness and suitable for application to special conditions with higher strength.

Owner:SHANGHAI JIAMU AUTO PARTS CO LTD

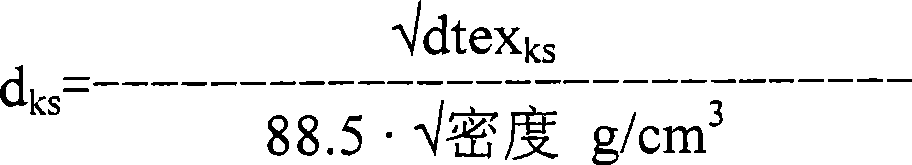

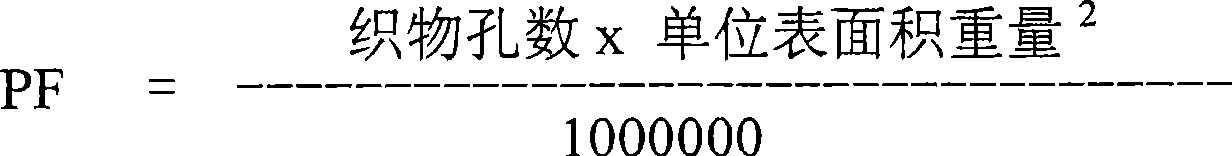

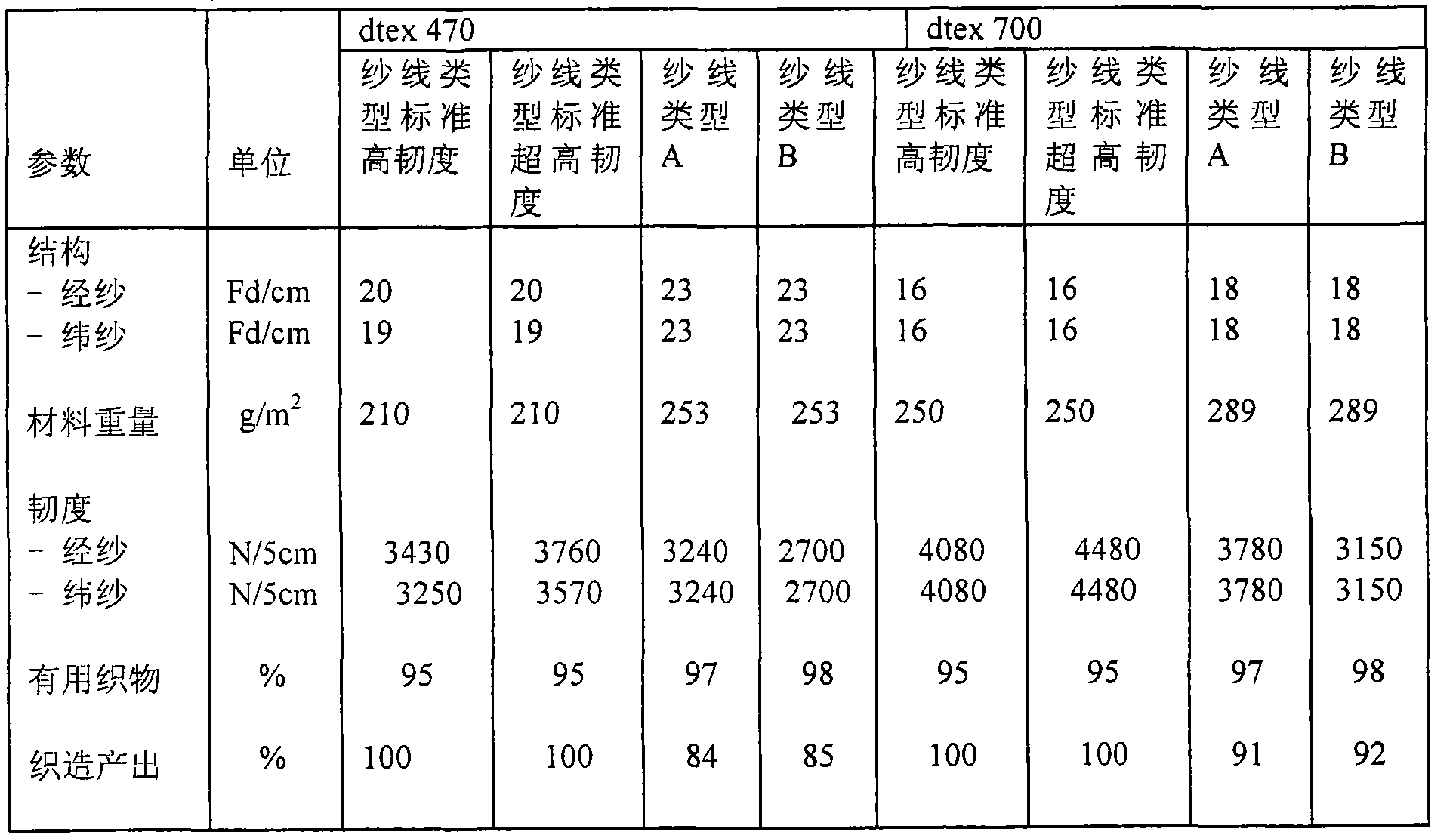

Airbag fabric

InactiveCN101421451AImprove performanceReduce manufacturing costPedestrian/occupant safety arrangementWoven fabricsYarnDifferential pressure

Fabric for an airbag, comprising warp threads and weft threads, in particular using multifilaments, characterized by a weave density greater than the 95% Professor Walz standard. It can also have a permeability (LD) of less than 3 l / dm<2> / min (at 500 Pa differential pressure) pursuant to ISO 9237, and can be characterized by a warp / weft insertion ratio greater than 1.

Owner:ITG AUTOMOTIVE SAFETY TEXTILES GMBH

Bending high-voltage shielding plug

The invention discloses a bending high-voltage shielding plug, and relates to the electric connector field of the electric appliance field of new-energy vehicles, industrial equipment, urban rails and railway vehicles. The bending high-voltage shielding plug comprises a shell assembly, a contact piece, an installation plate assembly and a tail accessory. The shell assembly is composed of a locking handle, a locking block, a plug shell, a seal ring and a signal pin. Locking and unlocking of a connector are achieved by adopting a mechanism which can convert handle rotation motion into rectilinear motion of the plug shell relative to a socket shell, the electric connector can be normally used on the condition that the operation space is narrow, the problem that a locking mode of a traditional electric connector cannot be normally used in the narrow operation space is solved, and meanwhile the handle has the power-assistant effect so that the operability of the connector is improved.

Owner:SICHUAN YONGGUI SCI & TECH CO LTD

Environment-friendly glue for corrugated board high-speed production line and preparation method thereof

InactiveCN104140772AFast bondingImprove adhesionNon-macromolecular adhesive additivesStarch adhesivesProduction lineAdhesive glue

The invention discloses an environment-friendly glue for a corrugated board high-speed production line. The glue is characterized by being prepared from the following raw materials by weight: 70% of water, 26.3% of corn starch, 1.8% of alkali lye, 0.5% of borax and 1.4% of a bridging agent. For the environment-friendly glue used for the corrugated board high-speed production line, the viscosity of a gluing machine is 18 s, the gelatinization temperature of the gluing machine is 56 DEG C, the viscosity of a single-side machine is 16 s, and the gelatinization temperature of the single-side machine is 58 DEG C. The invention also discloses a preparation method for the environment-friendly glue used for the corrugated board high-speed production line. The environment-friendly glue provided by the invention has the characteristics of low preparation and usage temperature, high adhesive strength, quick-drying performance, environment-friendliness and low usage cost; and the preparation method has the advantages of reasonable technology, easiness, low preparation temperature and capacity of improving adhesiveness of the adhesive glue.

Owner:LD PACKING PRINTING SHANGHAI

Rice special for beer and its breeding method

InactiveCN101185489AReduce the cost of qualityReduce manufacturing costFood preparationLow proteinOryza sativa

The invention relates to a beer paddy rice and a cultivating method thereof. The paddy rice contains over 85 percent of starch, below 10 percent of protein and below 0.5 percent of fat, with the other materials of mineral substance and micronutrient and alkali spreading value is more than Grade 6. The cultivating method comprises the procedures: paddy rice seeds are collected; appropriate amount of seeds are kept for use, and the other seeds are processed and made into polished rice; corresponding polished rice of the sample with the alkali spreading value over grade 6 is tested, and processed into polished rice powder; corresponding paddy rice strain with below10 percent of protein and below 0.5 percent of fat is tested; validated strain is reproduced and the stability of hereditary characters of the validated strain is commented; the beer paddy rice is obtained. The beer paddy rice cultivated by the invention is not only meet the paddy rice needed in beer production, but also is conducive to improving yield and quality of the beer and reducing beer production cost since the paddy rice has high total starch, low protein, low fat and low gelatinization temperature.

Owner:ZHEJIANG UNIV

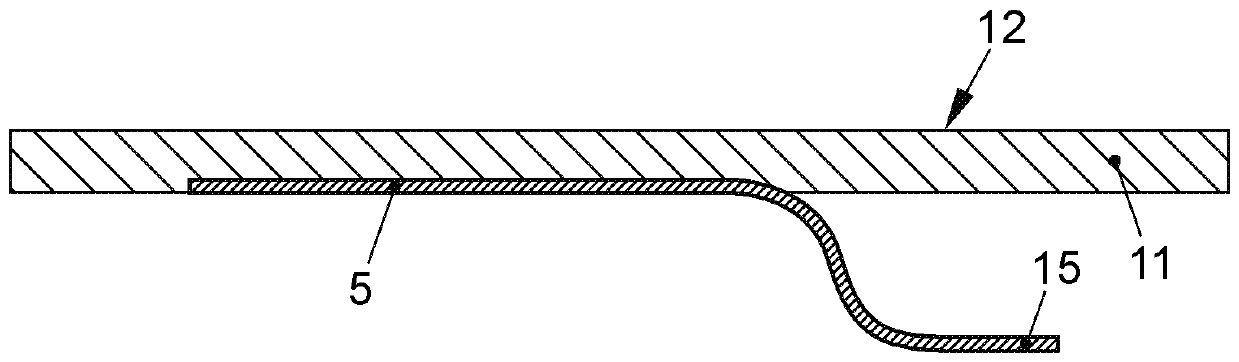

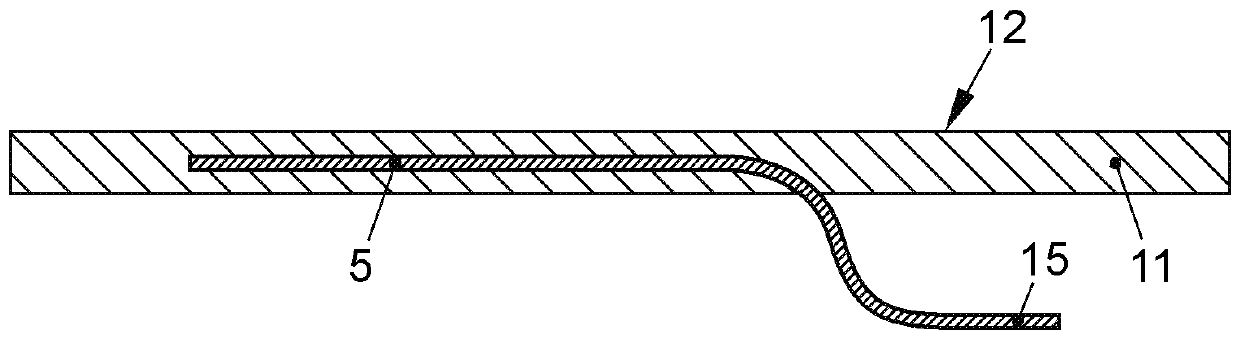

Sequentially etched and plated lead frame structure with island prepacked plastic sealed material and producing method thereof

ActiveCN102324414AReduce material costsReduce processing costsSemiconductor/solid-state device detailsSolid-state devicesEngineeringLead frame

The invention relates to a sequentially etched and plated lead frame structure with an island prepacked plastic sealed material and a producing method thereof. The structure comprises an island (1) and pins (2), wherein front faces of the island (1) and the pins (2) are plated with first metal layers (5); back faces of the island (1) and the pins (2) are plated with second metal layers (6); etching regions between the island (1) and the pins (2) and between the pin (2) and the pin (2) are all filled with plastic sealed materials (4); and the plastic sealed materials (4) are aligned with the first metal layers (5) and the second metal layers (6). The sequentially etched and plated lead frame structure provided by the invention has the following advantages: a layer of expensive high temperature resistant soft organic adhesive film needs not to be attached on the bottom of the lead frame; various problems possibly generated in loading, routing and encapsulating are avoided in the background; the yield of the finished products is largely increased; and the front face and the back face of the lead frame are etched at the same time so that the complicatedness of at least 50% can be reduced in the procedure, the cost is reduced and the malposition risk caused by secondary alignment can be reduced.

Owner:JCET GROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com