Modularization steel die trolley and construction process thereof

A steel mold trolley and modular technology, which is applied in shaft lining, tunnel lining, underground chamber, etc., can solve the problems of low construction efficiency, slow turnover speed, and high cost of use, so as to improve work efficiency, reduce quality cost, simplify The effect of coordination difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

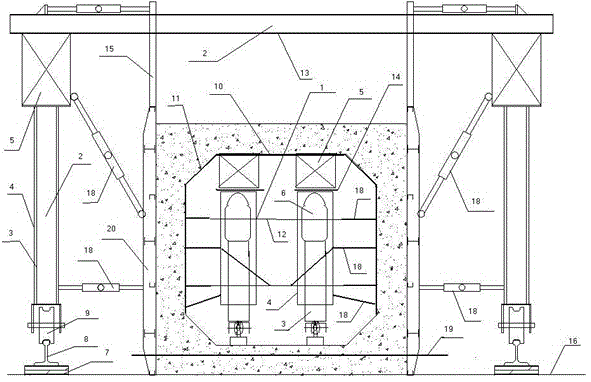

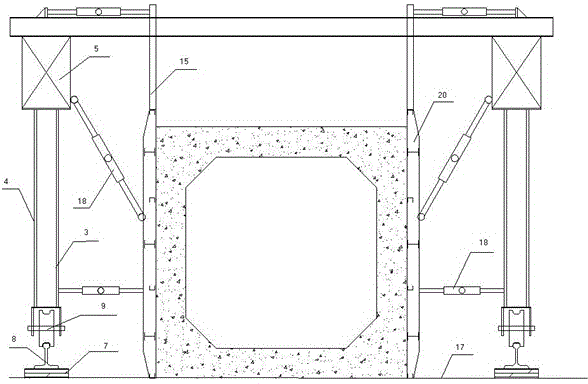

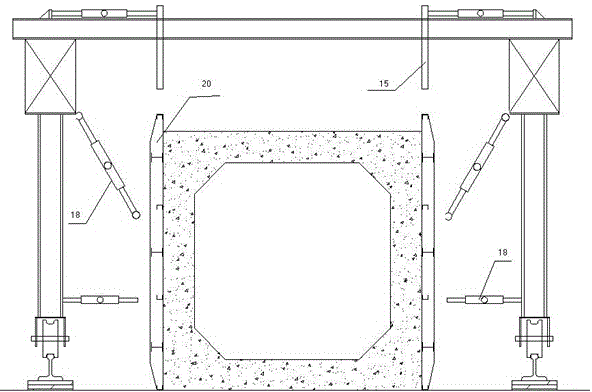

[0048] Such as figure 1 with figure 2 As shown, a modular steel mold trolley according to the present invention is suitable for lining or box culvert construction with regular sections, and the modular steel mold trolley includes two parts: an inner mold trolley 1 and an outer mold trolley 2; The inner mold trolley is a semi-closed steel structure.

[0049] Both the inner mold trolley and the outer mold trolley comprise a supporting lifting system and a walking system of the same structure; the supporting lifting system includes an inner leg 3, an outer leg 4 and a longitudinal truss beam 5, and the inner leg 3 is a steel column with a jack 6 on the top, the outer support leg 4 is a hollow steel column with one end closed, the hollow steel column is buckled upside down on the inner support leg 3, and the longitudinal truss beam 5 is arranged on the outer support leg 4, in order to increase the stress area of the outer leg 4 and keep the truss beam 5 stable, a steel plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com