Metal wire drawing-imitating decoration film

A technology of imitating metal and decorative film, applied in special decorative structures, decorative arts, layered products, etc., can solve the problems of losing the metal texture of metal materials, covering, etc., and achieve the goal of improving adhesion fastness, reducing costs, and beautiful and novel appearance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1 (imitation metal brushed PET decorative film)

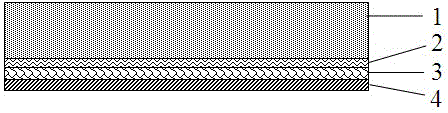

[0027] The surface of the PET base film 1 is coated with a primer layer 2, and the surface of the primer layer 2 is printed with an imitation metal wire drawing pattern layer 3, and the surface of the imitation metal wire drawing pattern layer 3 is printed with an ink layer 4 (such as figure 1 shown). The thickness of the PET base film 1 is within the range of 25±1μm, the primer layer is made of polyurethane resin, and the thickness is controlled within the range of 0.2±0.05μm, and the imitation metal drawing pattern layer is realized by the gravure printing process, and the thickness is 0.6±0.1μm Within the range, the ink layer is realized by gravure printing process, and the thickness is within the range of 1.4±0.2μm. The aluminum-silver paste in the ink layer is a non-leafing ordinary aluminum-silver paste with a particle size of 1.3±0.2μm.

[0028] The advantages of the metal-like brushed PET decorative fi...

Embodiment 2

[0029] Example 2 (imitation metal brushed PET decorative film)

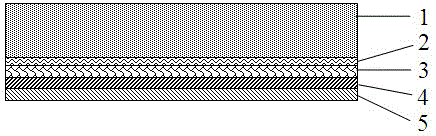

[0030] The surface of the PET base film is coated with a primer layer, the surface of the primer layer is printed with an imitation metal drawing pattern layer, and the surface of the imitation metal drawing pattern layer is printed with an ink layer. The thickness of the PET base film is within the range of 23±1μm, the primer layer is made of polyacrylate resin, the thickness is 0.3±0.1μm, the thickness of the imitation metal drawing pattern layer is 0.5±0.1μm, and the thickness of the ink layer is 1.4±0.2μm , The aluminum-silver paste in the ink layer is a non-leafing ordinary aluminum-silver paste with a particle size of 1.3±0.2μm.

Embodiment 3

[0031] Example 3 (imitation metal brushed PET decorative film)

[0032] The surface of the PET base film is coated with a primer layer, the surface of the primer layer is printed with an imitation metal drawing pattern layer, and the surface of the imitation metal drawing pattern layer is printed with an ink layer. The thickness of the PET base film is 20±1μm, the primer layer is made of polyurethane polyacrylate hybrid resin, the thickness is 0.3±0.1μm, the thickness of the imitation metal drawing pattern layer is 0.5±0.1μm, and the thickness of the ink layer is 1.4±0.2μm , The aluminum-silver paste in the ink layer is a non-leafing ordinary aluminum-silver paste with a particle size of 1.3±0.2μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com