Patents

Literature

114results about How to "Improve metallic texture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

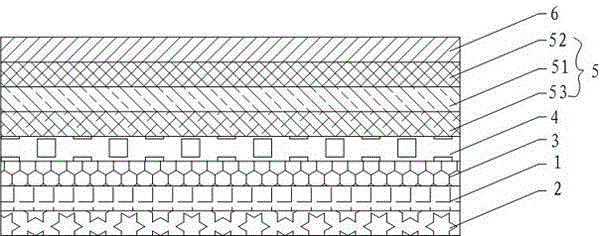

Shell, preparation method thereof and electronic device

InactiveCN108966552AHigh glossImprove metallic textureOrnamental structuresCasings/cabinets/drawers detailsEngineeringMetal

The present invention provides a shell, a preparation method thereof and an electronic device. The shell includes a base material, a pattern layer, an optical coating layer, a gradual change transparent layer, and a bottom color layer; the pattern layer is disposed on the lower surface of the base material; the optical coating layer is disposed on the lower surface of the base material, and coversthe pattern layer; the gradual change transparent layer is disposed on the lower surface of the optical coating layer; and the bottom color layer is disposed on the lower surface of the gradual change transparent layer. Thus, the shell can have high gloss; a plurality of colors of the shell can be uniformly changed; the shell has the high metallic texture of a grating effect; and the shell can satisfy consumers' need for the changeable appearance of the shell.

Owner:OPPO CHONGQING INTELLIGENT TECH CO LTD

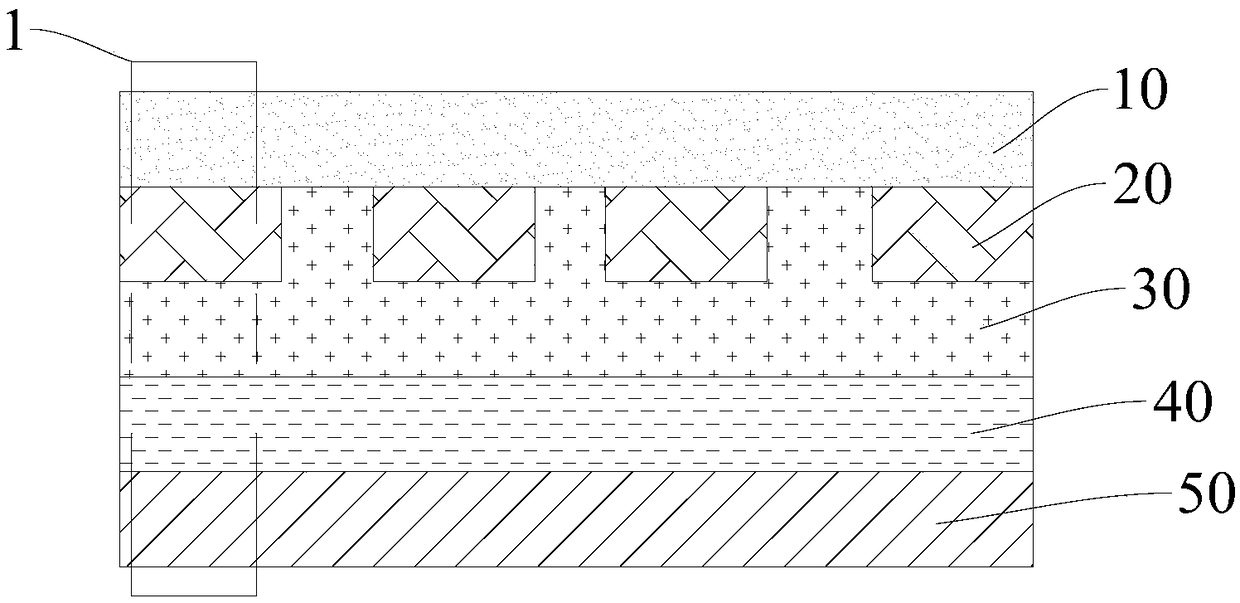

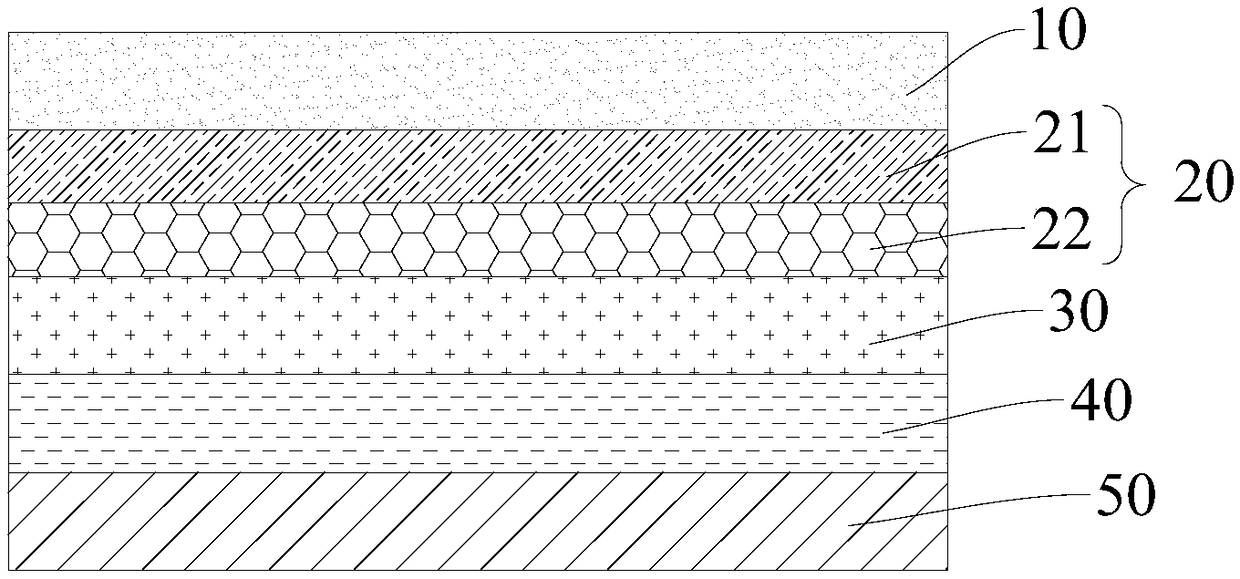

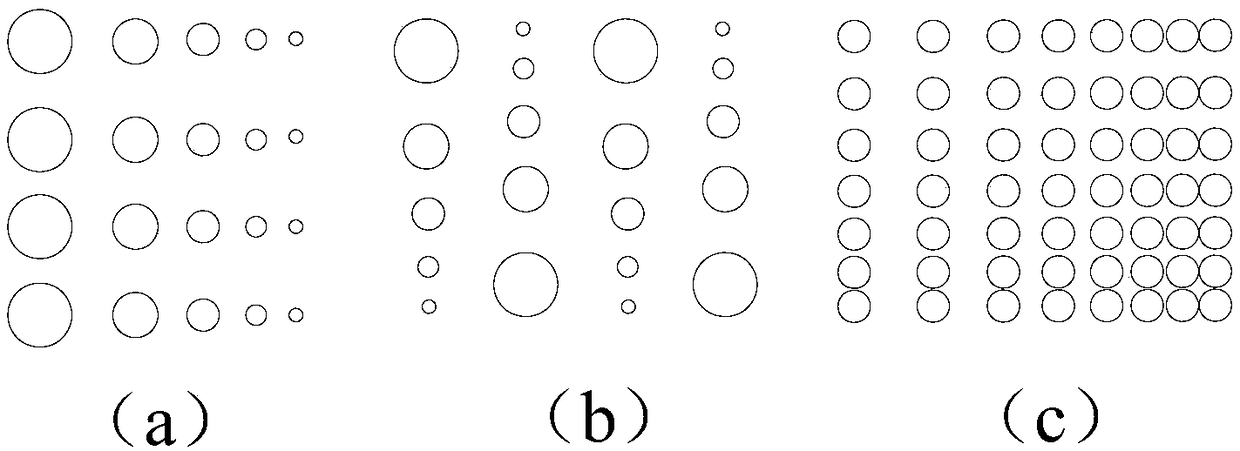

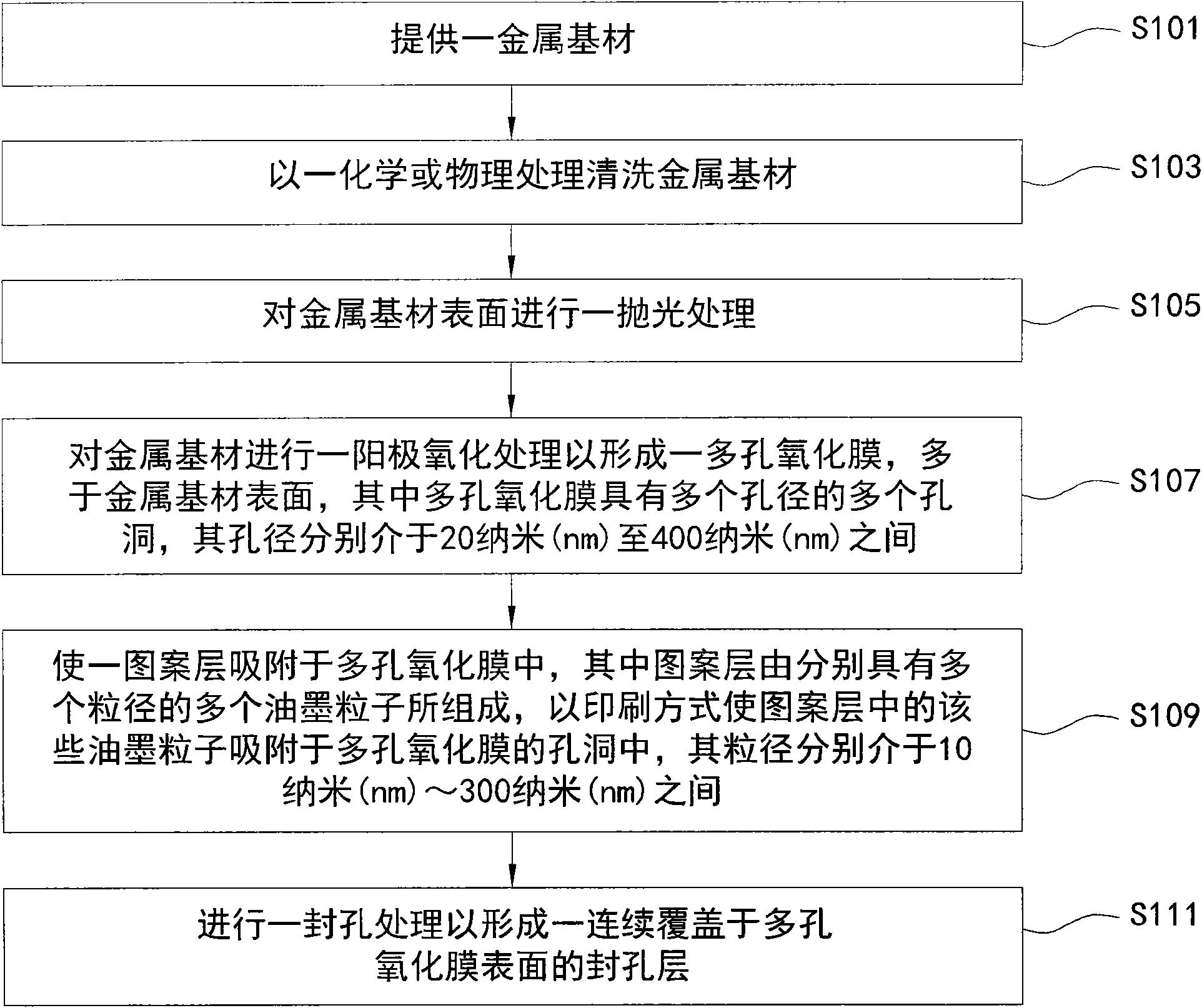

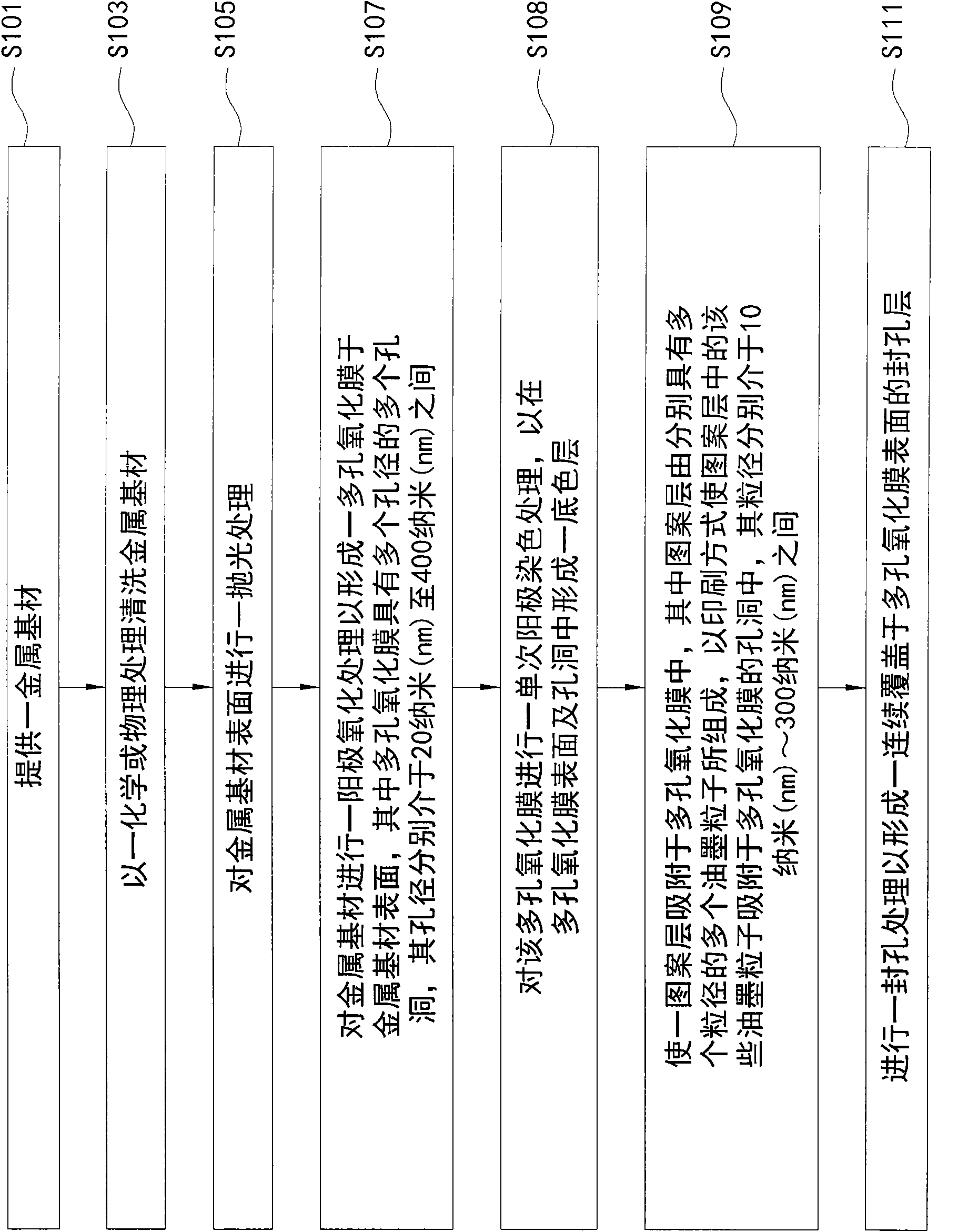

Method and structure for patterning metal surface

InactiveCN102071447AImprove metallic textureWear-resistantSurface reaction electrolytic coatingPore diameterParticle adsorption

The invention provides a method for patterning a metal surface. The method comprises the following steps of: firstly, cleaning a metal substrate by chemical or physical treatment and polishing the metal substrate; secondly, performing anodic oxidation treatment on the metal substrate so as to form a porous oxide film on the surface of the metal substrate, wherein the porous oxide film is provided with a plurality of pores with the pore diameters of between 20 and 400 nanometers; thirdly, providing a pattern layer and absorbing ink particles into the pores of the porous oxide film in a printing mode, wherein the particle sizes of the ink particles are between 10 and 300 nanometers; and lastly, sealing the pores so as to form a pore sealing layer which is continuously covered on the surface of the porous oxide film.

Owner:BIN CHUAN ENTERPRISE

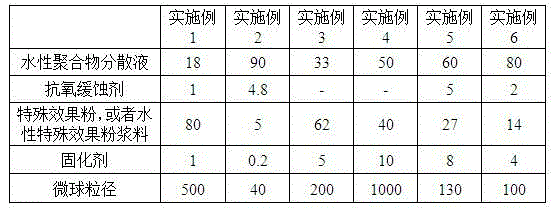

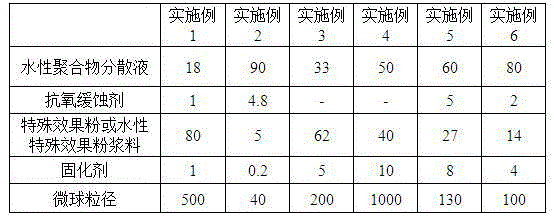

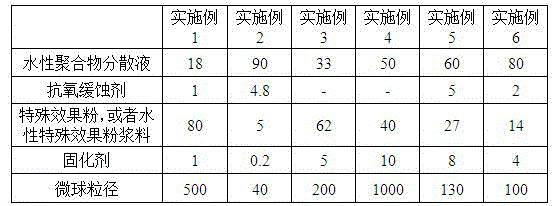

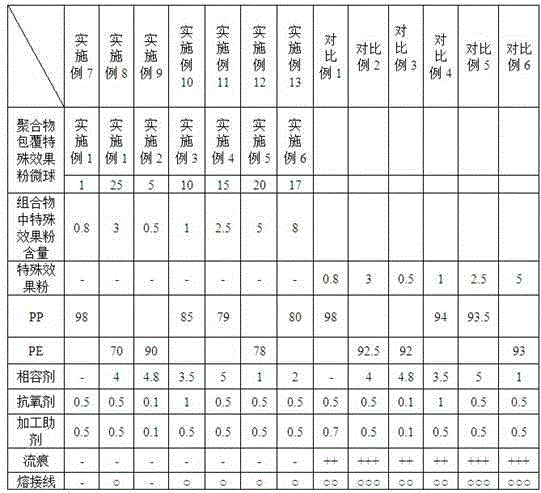

Spraying-free polyester composition having special aesthetic effects and preparation method and application thereof

The invention discloses a spraying-free polyester composition having special aesthetic effects and a preparation method and an application thereof. The spraying-free polyester composition comprises the following components: 70-98 wt% of polyester, 1-25 wt% of microspheres formed by coating a special-effect powder with a polymer, 0-10 wt% of a compatibilizer, 0.1-1 wt% of an antioxidant, and 0.1-0.5 wt% of a processing auxiliary agent. The special-effect powder is coated with a water-based polymer dispersion liquid to form the microspheres, and then the microspheres are dispersed to the polyester, so that the compatibility of the special-effect powder and the polyester can be significantly improved, flow marks formed on the surface of products in an extrusion or injection molding process are eliminated, and weld lines are reduced; and the prepared spraying-free polyester composition has relatively obvious metal texture, pearly flashing effects and other special aesthetic effects, and the market application range of spraying-free materials is greatly improved.

Owner:KINGFA SCI & TECH CO LTD

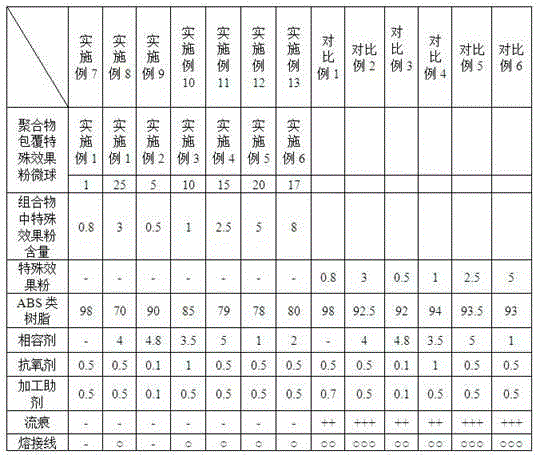

Spraying-free ABS composition with special aesthetic effect, preparation method and applications thereof

The invention discloses a spraying-free ABS composition with a special aesthetic effect, a preparation method and applications thereof. The ABS composition consists of 70 to 98 wt% of ABS resin, 1 to 25 wt% of polymer-coated microspheres with a special effect, 0 to 10 wt% of compatilizer, 0.1 to 1 wt% of antioxidant, and 0.1 to 0.5 wt% of processing aid. The powder with a special effect is coated by aqueous dispersion liquid to form microspheres, then the microspheres are dispersed into the ABS resin so as to improve the compatibility between the powder with a special effect and the ABS resin, thus the flow marks on the surface during the extrusion or injection moulding process can be eliminated, and the weld lines can be reduced. The prepared spraying-free ABS composition has a prominent metal texture and special aesthetic effects such as pearl-liked sparkling, and the application range of spraying-free materials is greatly enlarged.

Owner:TIANJIN KINGFA NEW MATERIAL

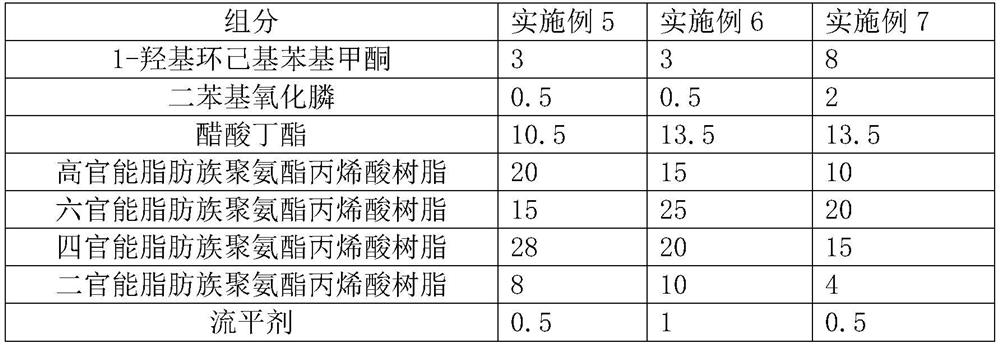

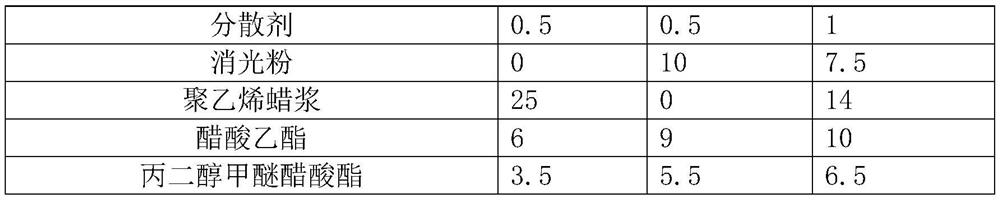

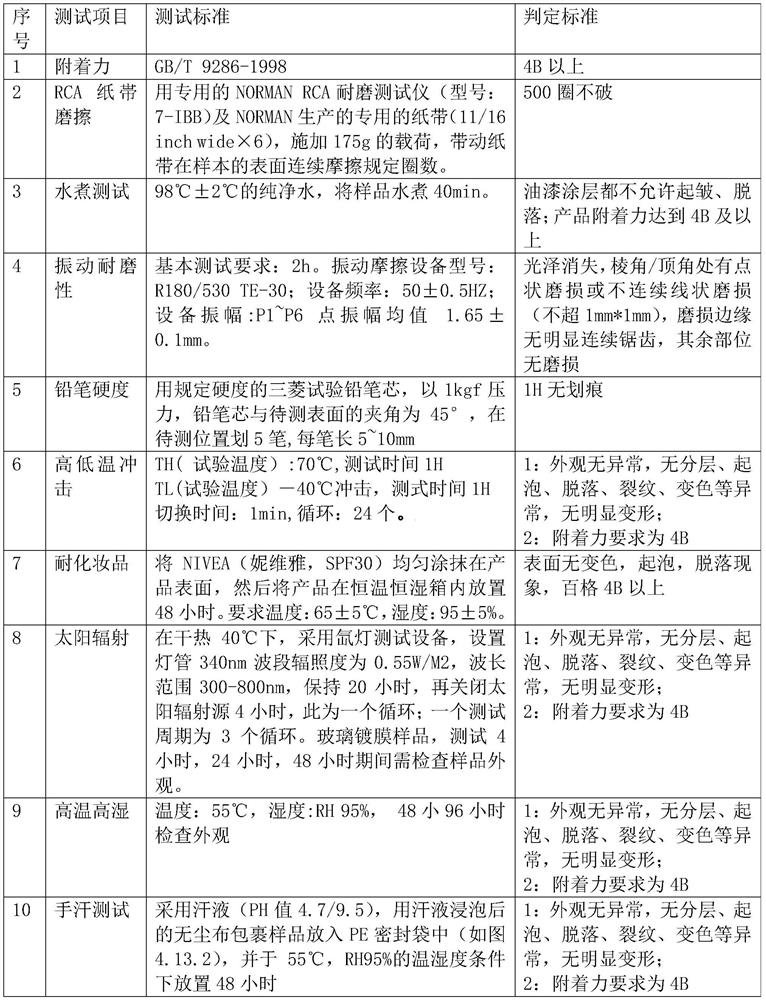

Vibration wear-resistant coating and preparation method and spraying process thereof

ActiveCN112538293AInhibit sheddingSolve the phenomenon of uncertain performance such as sheddingPretreated surfacesPolyurea/polyurethane coatingsCellulosePolymer science

The invention provides a vibration wear-resistant coating and a preparation method and a spraying process thereof. The vibration wear-resistant coating comprises PU type primer and UV photocurable finish coating. The PU type primer is prepared from 40-50 parts of thermoplastic acrylic resin, 10-20 parts of hydroxy acrylic resin, 1-3 parts of cellulose acetate butyrate, 1-2 parts of adhesion promoter, 2-4 parts of auxiliaries, 15-25 parts of pigment filler and 20-30 parts of mixed solvent; and the UV photocurable finish coating comprises the following components in parts by weight: 10-20 partsof high-functionality polyurethane acrylate, 15-25 parts of six-functionality polyurethane acrylate, 15-28 parts of four-functionality polyurethane acrylate, 4-10 parts of two-functionality polyurethane acrylate, 0.5-1 part of a dispersing agent, 0.5-1 part of a leveling agent, 0-10 parts of extinction powder, 0-25 parts of wax liquor, 0-10 parts of a photoinitiator and 20-30 parts of a mixed solvent. When the vibration wear-resistant coating is applied to a mobile phone (plastic material) frame or a mobile phone side key, the vibration wear resistance and durability of the product can be improved, and a coating film can be prevented from falling off after long-time use.

Owner:东莞市贝特利新材料有限公司

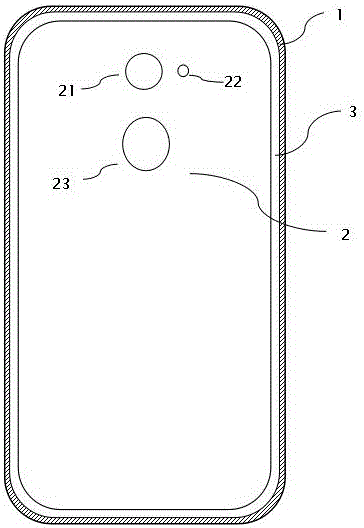

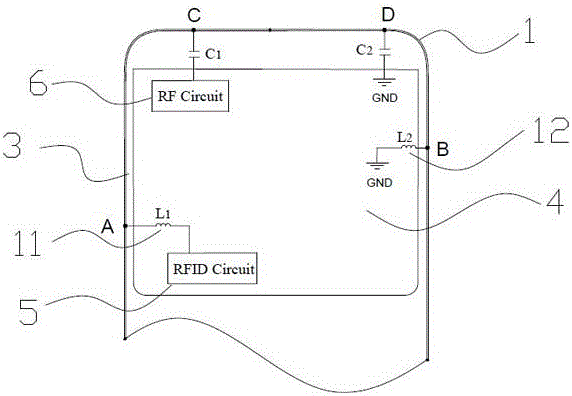

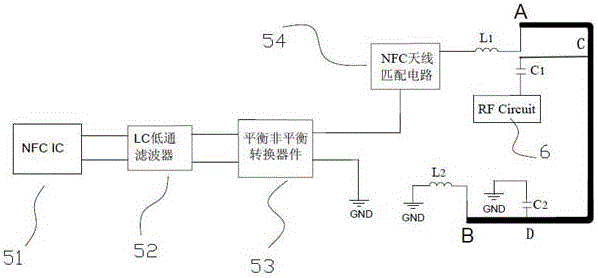

Application of near field communication (NFC) antenna in completely closed metal frame

ActiveCN106099357ALow costThe appearance is simple, fashionable and texturedAntenna supports/mountingsAntenna equipments with additional functionsAntenna designCapacitance

The invention provides application of a near field communication (NFC) antenna in a completely closed metal frame. A mobile terminal with the completely closed metal frame also comprises a rear cover, two arbitrary points on the metal frame are taken as a feeding point and a grounding point of the NFC antenna, meanwhile, two arbitrary points on the metal frame are taken as a feeding point and a grounding point of a mobile communication antenna, the feeding point of the NFC antenna is connected with a radio frequency identification circuit module through a first inductor, and the feeding point of the mobile communication antenna is connected with a mobile communication radio frequency circuit module through a first capacitor. Aiming at the NFC antenna design of the mobile terminal with the completely closed metal frame, the NFC antenna is applied to the mobile terminal with the completely closed metal frame; the problem of mutual influence with various mobile communication antennas is solved by connecting impedance components to the feeding points; and meanwhile, greater flexibility and design freedom are brought to the arrangement of the feeding points and the grounding points by debugging a matching circuit.

Owner:HUIZHOU SPEED WIRELESS TECH CO LTD

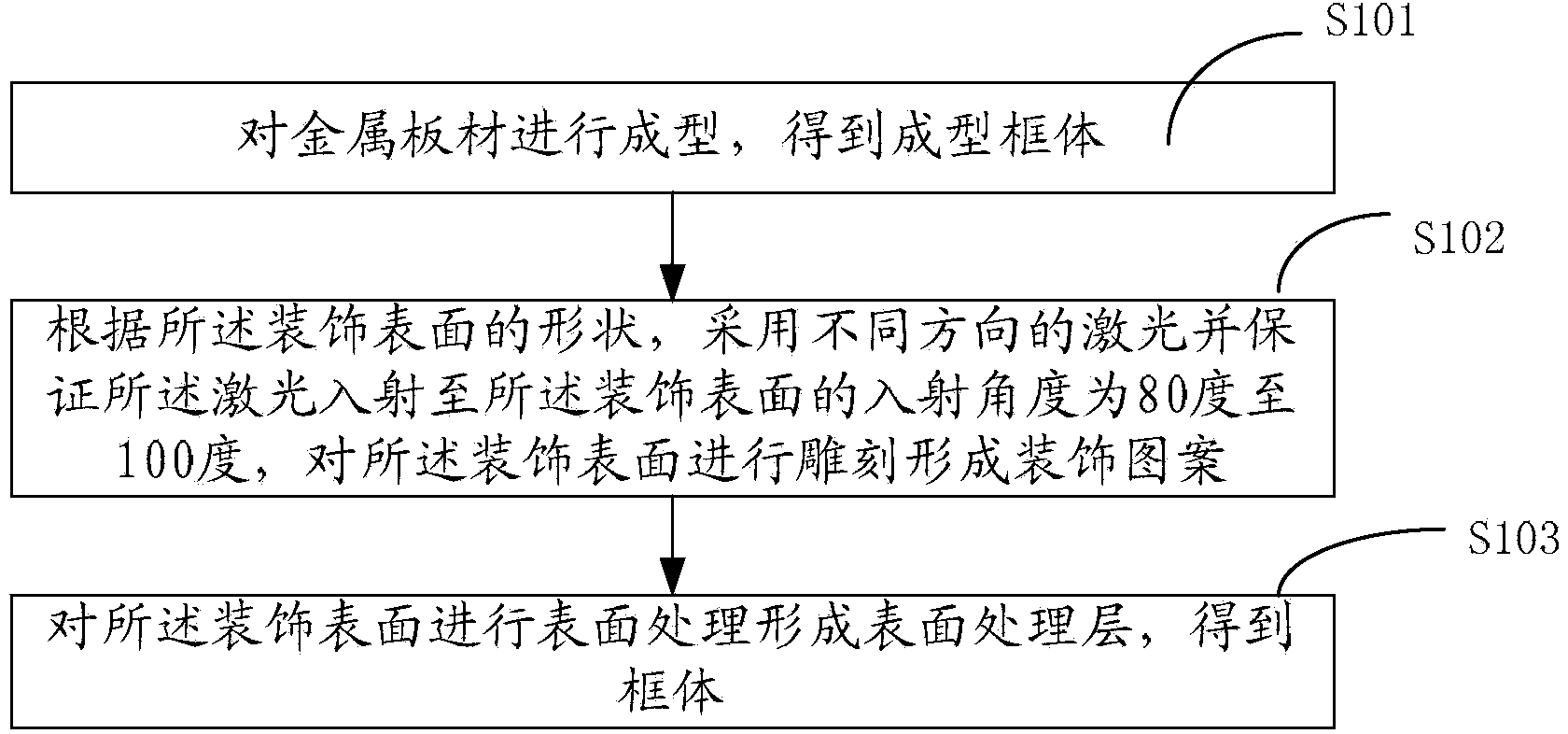

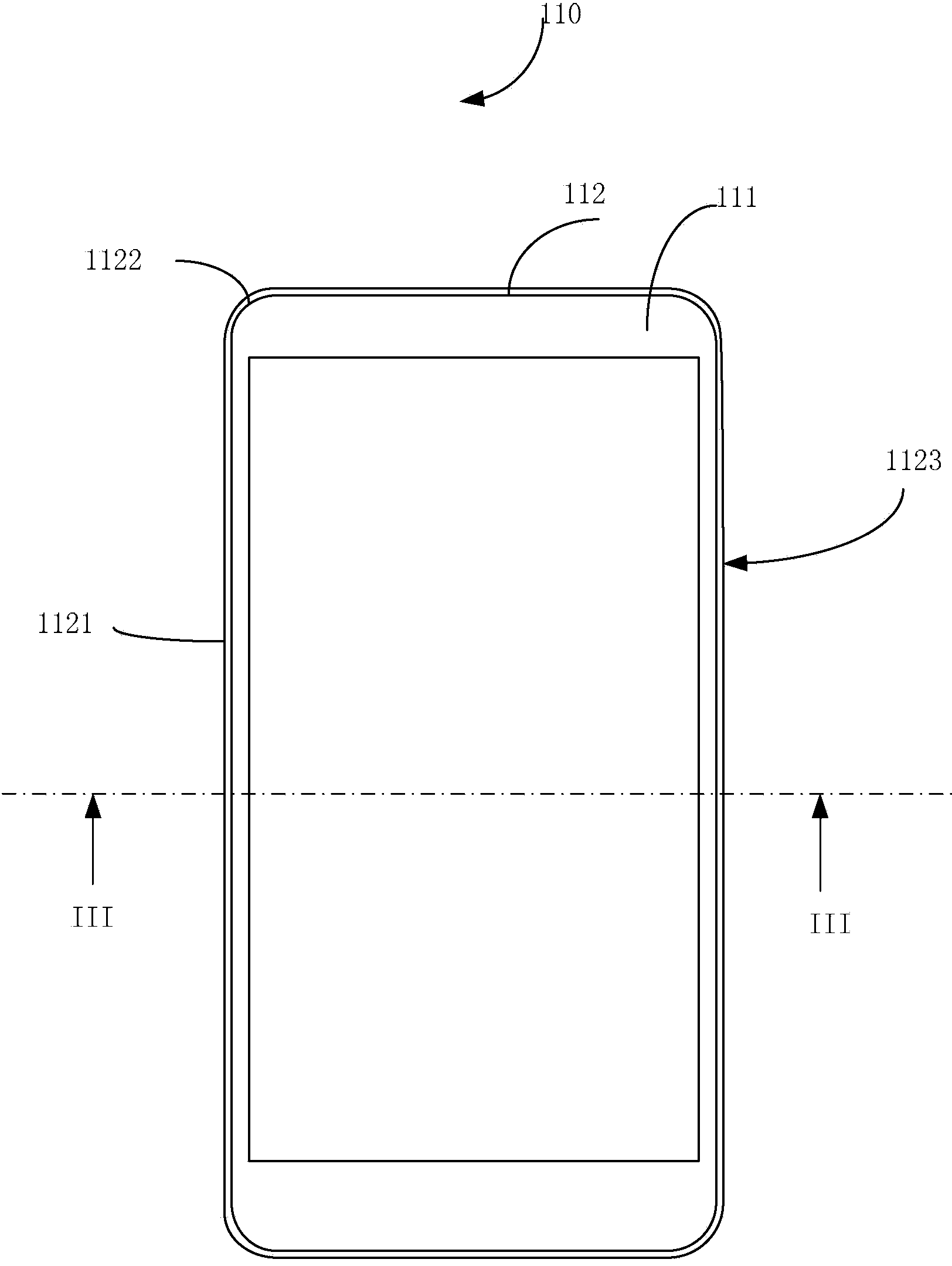

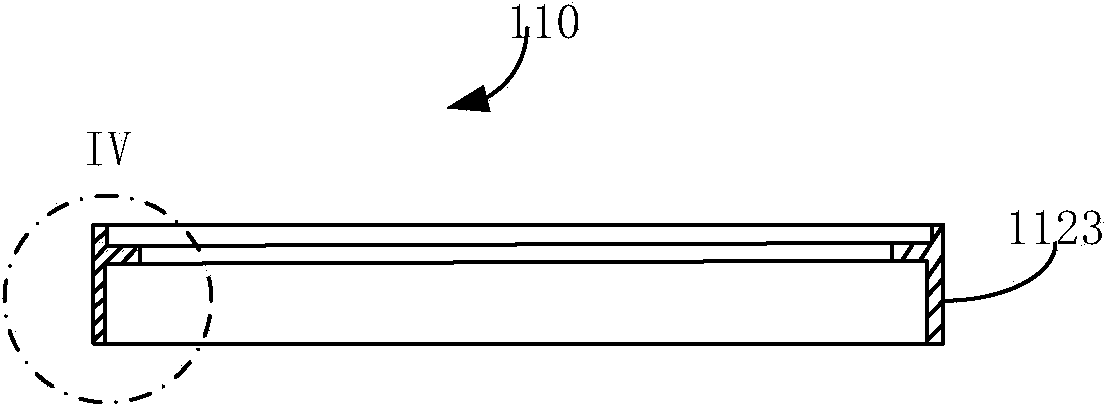

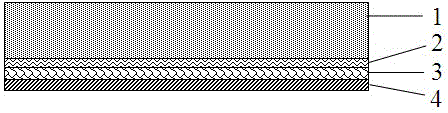

Frame, processing method for frame and terminal

InactiveCN104139246AUniform textureImprove textureLaser beam welding apparatusComputer terminalComputer vision

The invention provides a processing method for a frame. The processing method comprises the following steps: forming a metal plate, thereby acquiring a formed frame which is provided with a decorative surface, and adopting laser in different directions for carving the decorative surface and forming a decorative pattern according to the shape of the decorative surface, wherein the incident angles of the laser emitting to the decorative surface are at 80-100 degree. The invention also provides the frame processed according to the method and a terminal comprising the frame. According to the technical scheme, the appearance texture of a metal frame, such as a mobile phone frame, is increased.

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

Metal wire drawing-imitating decoration film

InactiveCN104416993AImprove adhesion fastnessEasy to useSynthetic resin layered productsSpecial ornamental structuresPrinting inkSteel plates

The invention provides a metal wire drawing-imitating decoration film which comprises a PET base film, a primer layer, a metal wire drawing-imitating pattern layer, and a printing ink layer; the primer layer is printed on the surface of the PET base film; the metal wire drawing-imitating pattern layer is printed on the surface of the primer layer; and the printing ink layer is printed on the surface of the metal wire drawing-imitating pattern layer. The decoration film of the invention is few in production procedures, low in manufacturing cost, and distinct in the metal wire drawing-imitating pattern, has different glossiness effects such as matt, common, highlight, and the like, has high combining strength with various sheet materials, has good aging resistance and long service life, is widely used in surface decoration of color steel plates, integrated furred ceilings, bureau doors, cabinets, and industrial products, and has very good anti-rust, protective, decorative, and beatifying effect on decorated color plates.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

Electronic product key and manufacturing process thereof

InactiveCN101937787AHigh economic valueLow costElectric switchesInput/output processes for data processingHot stampingPrinting ink

The invention provides an electronic product key, which comprises a key body and a partially-hollowed printing ink layer positioned on the back of the key, wherein the hollowed part is provided with a character pattern. The electronic product key further comprises an aluminum layer at least covered on the hollowed part of the printing ink layer, and a gloss oil layer covered on the aluminum layer, wherein the gloss oil layer is used for protecting the aluminum layer. The invention also provides a key manufacturing method. In the method, hot-stamping technology is applied to a key decoration process, so the plastic key can achieve the appearance effects of good metal texture and high luster and is endowed with relatively higher economic value, the cost of PVD or mirror printing ink for achieving the effects is greatly reduced, and the production efficiency is improved.

Owner:BYD CO LTD

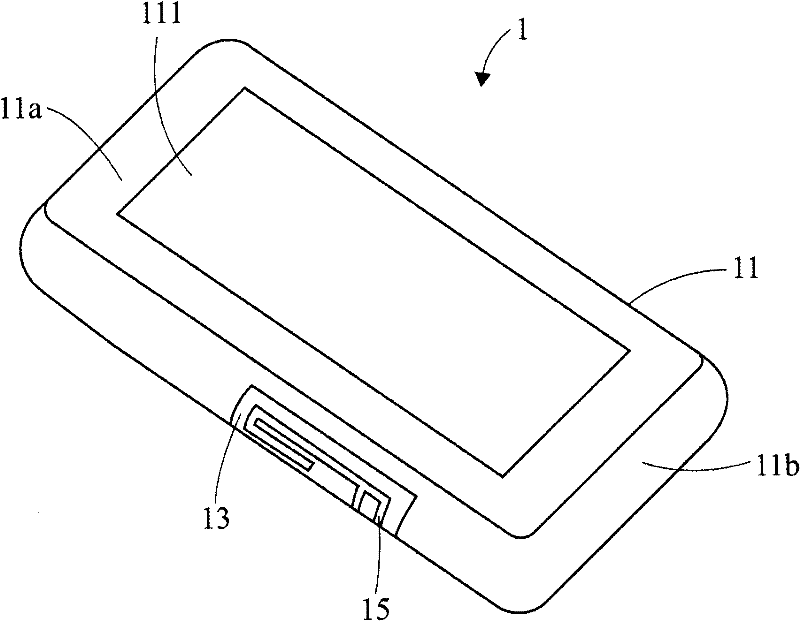

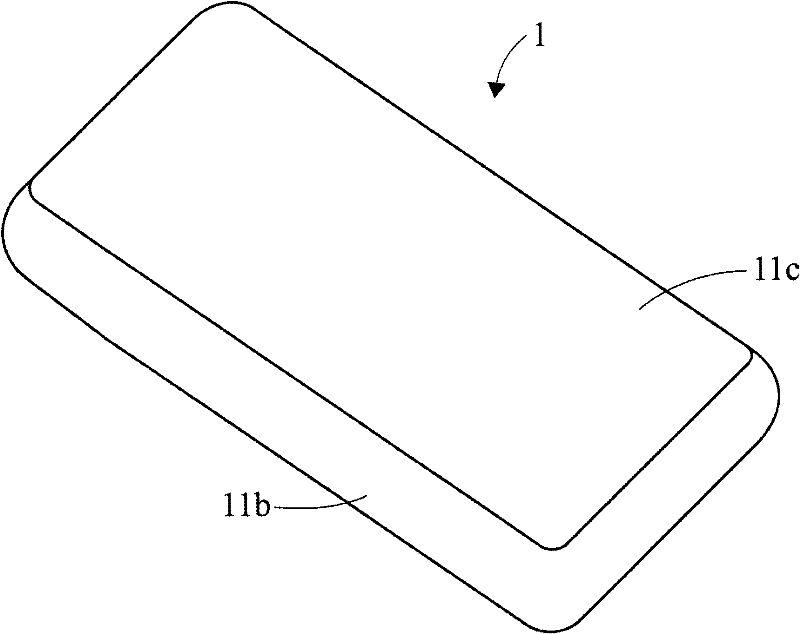

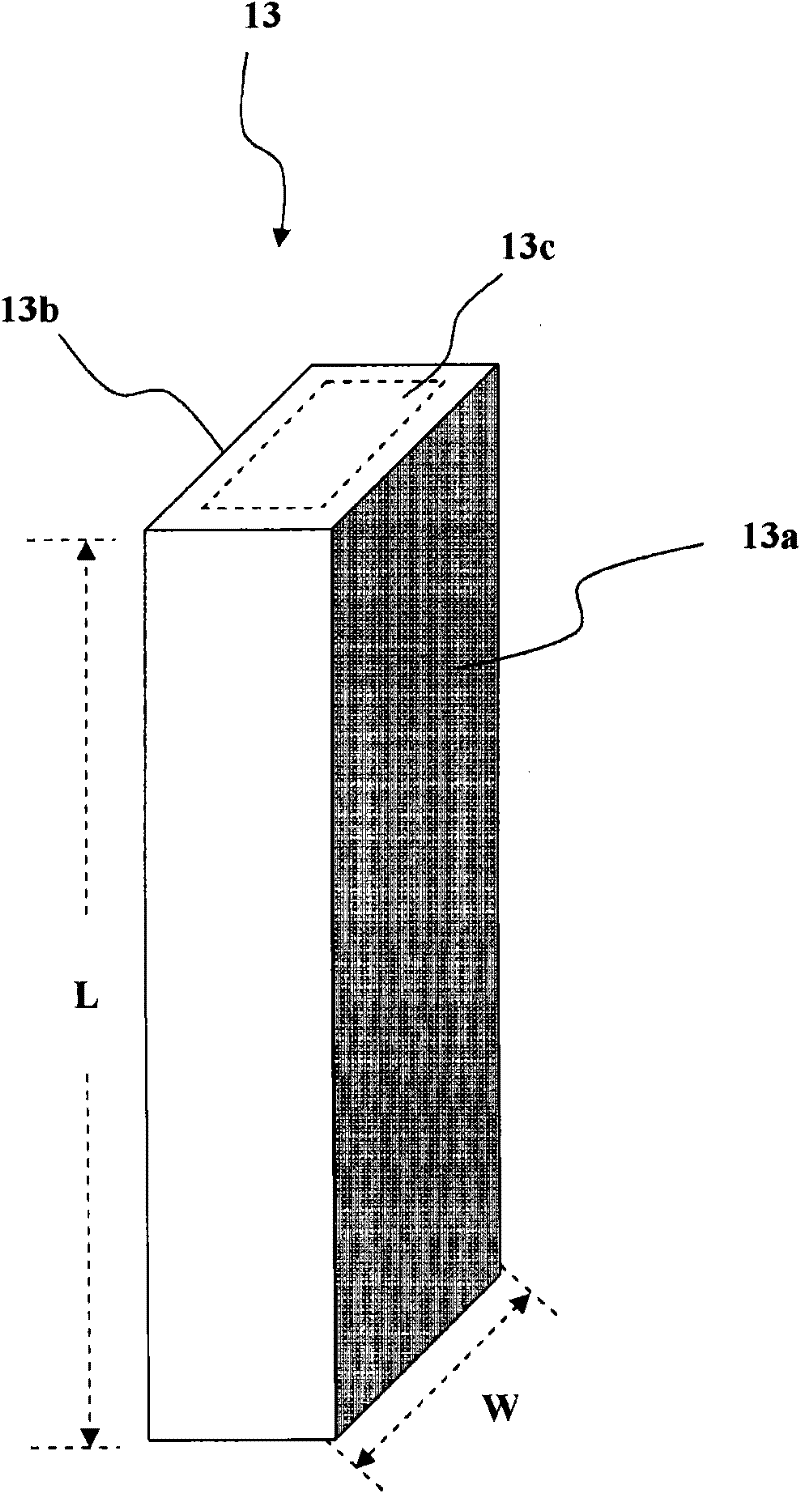

Handheld device

ActiveCN102468528AMaintain Consistency in AppearanceImprove metallic textureAntenna supports/mountingsAntenna equipments with additional functionsEmbedded system

Owner:HTC CORP

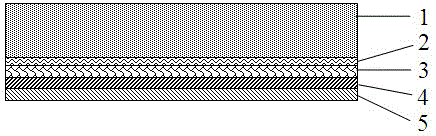

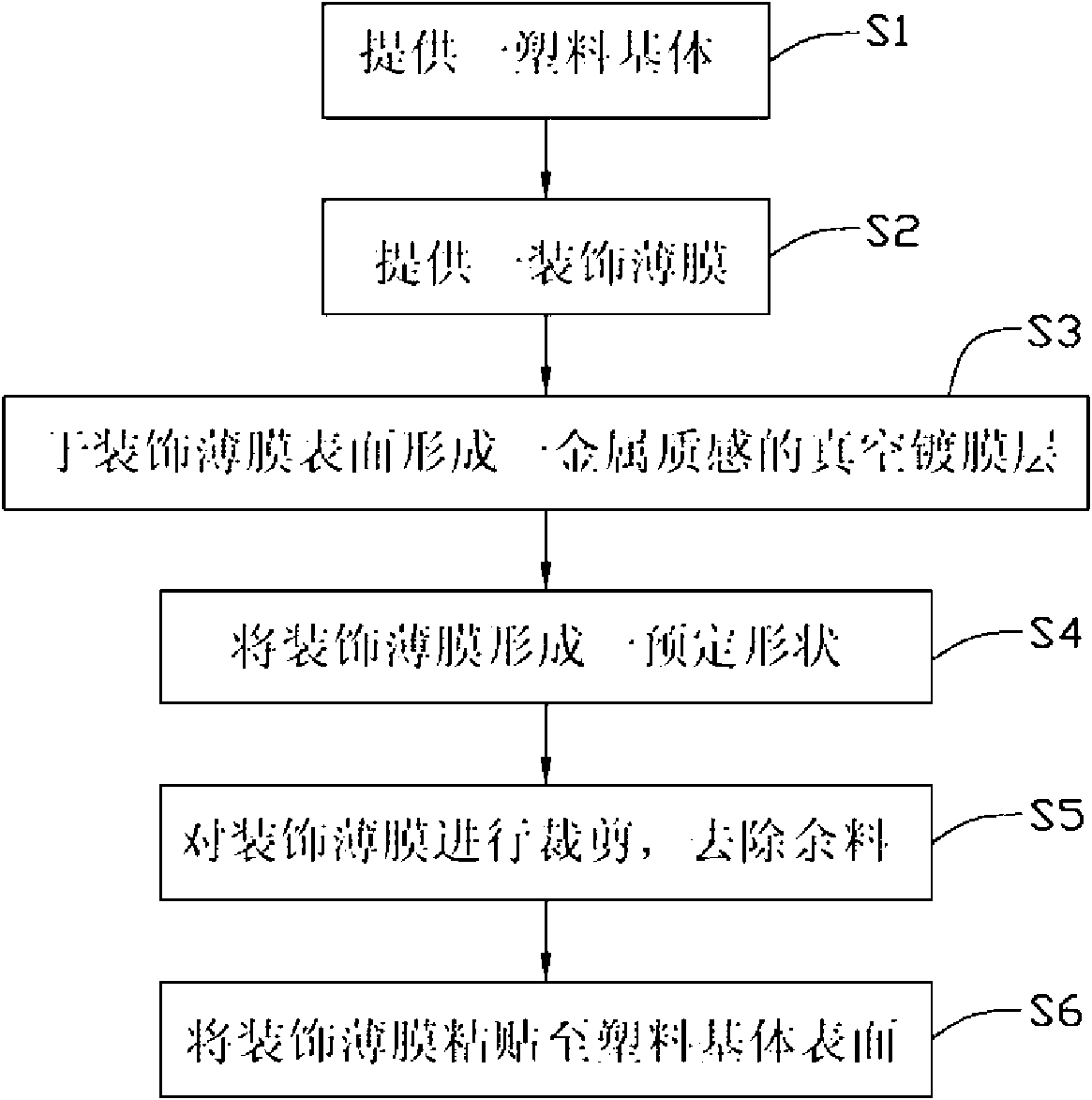

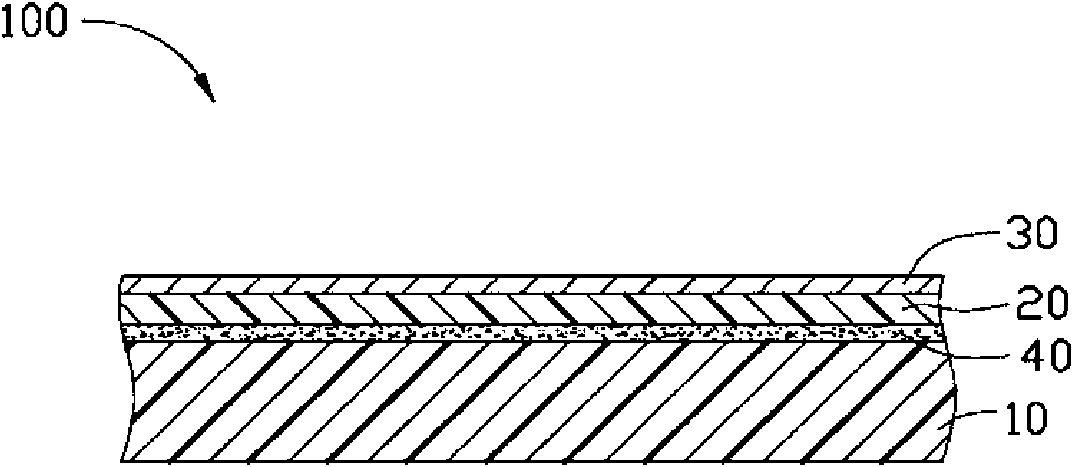

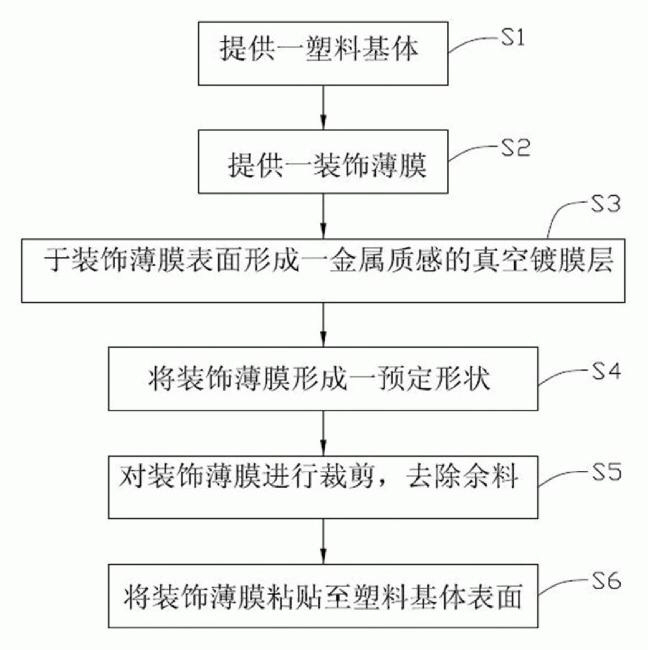

Manufacturing method of metalline shell and shell manufactured by same

InactiveCN101941314AImprove metallic textureHigh glossLamination ancillary operationsDecorative surface effectsEngineeringShape fitting

The invention provides a manufacturing method of a metalline shell, comprising the following steps: providing a plastic matrix with the pre-manufactured shell structure; providing a decorative film; forming a metalline non-conducting coated layer on the surface of the decorative film; ensuring the decorative film covered by the non-conducting coated layer to form a predetermined shape; cutting the decorative film with the predetermined shape to ensure the contour of the decorative film to form the periphery shape fitting the plastic matrix; and sticking the cut decorative film to the surface of the plastic matrix. The invention also provides the shell manufactured by the method.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

Method for preparing high metallic texture high transmission lens

InactiveCN101561519AStrong metal textureHigh light transmittanceVacuum evaporation coatingSputtering coatingSurface finishingMetal

The invention belongs to the technical field of surface processing, in particular to a method for preparing high metallic texture high transmission lens. The method comprises the following: step one, optical filming: a product to be filmed is subjected to five-layer optical filming in an optical filming device; wherein the first layer is TiO2 filming; the second layer is SiO2 filming; the third layer is TiO2 filming; the fourth layer is SiO2 filming; the fifth layer is TiO2 filming; step two, priming coat spraying: priming coat is sprayed on the surface of the product filming to be roasted in an oven; step three, UV finishing coat spraying: the UV finishing coat is sprayed on the surface of the product filming to be roasted by the oven and solidified by a UV furnace. The plastic lens processed by the method has strong metal texture, friction and scratch resistance and high transmission rate reaching 98 percent.

Owner:GUANGDONG JANUS SMART GRP CO LTD

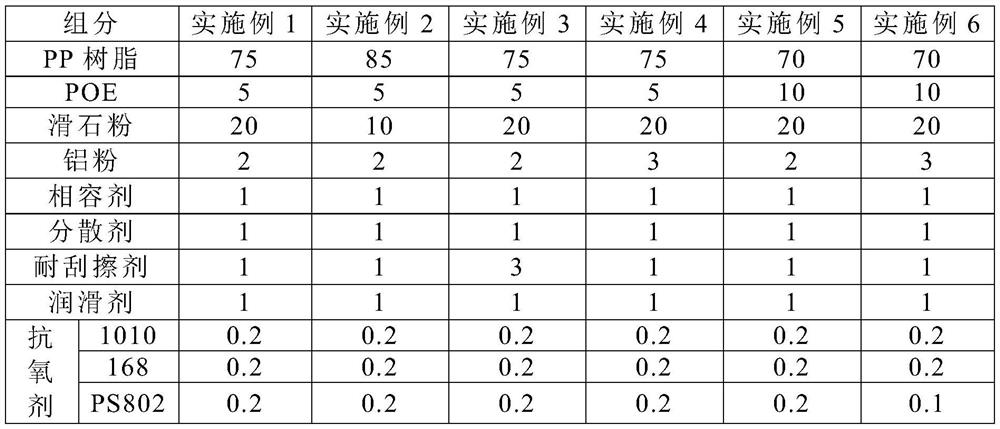

High-fluidity scratch-resistant spraying-free metallic-silvery-color modified polypropylene material for vehicles

The invention belongs to the technical field of polymer materials, and particularly relates to a high-fluidity scratch-resistant spraying-free metallic-silvery-color modified polypropylene material for vehicles. Raw materials comprise the following components in parts by weight: 50 to 80 parts of PP resin, 5 to 20 parts of polyolefin elastomer, 10 to 40 parts of talcum powder, 0.5 to 5 parts of metal powder, 0.5 to 2 parts of a compatilizer, 0.5 to 2 parts of a dispersing agent, 1 to 3 parts of a scratch-resistant agent, 0.5 to 2 parts of a lubricant, 0.5 to 1 part of an antioxidant and 0.5 to1 part of an ultraviolet absorbent. On the basis of a common polypropylene formula, high-fluidity PP resin is used as a matrix; POE, small-particle-size talcum powder and medium-particle-size aluminum powder are added for modification and cooperate with a compatilizer, the dispersing agent, the scratch-resistant agent and the lubricant to prepare the spraying-free material with high fluidity andscratch resistance, so that the product meets the appearance requirements of high gloss and metallic silvery color and has the advantages of high quality, low cost, safety, environmental friendlinessand the like.

Owner:NINGBO TAIYONG AUTOMOTIVE PARTS

Coating preparation method of automobile part

InactiveCN107812685ALower requirementHigh fullnessPretreated surfacesCoatingsColor effectCoating system

The invention discloses a coating preparation method of an automobile part. The coating preparation method comprises the following steps: selecting a plastic electroplating part manufactured by adopting the highlighting nickel process, and enabling the plastic electroplating part to be subjected to seven process steps: pretreatment, primer spraying, primary levelling, colored paint spraying, secondary leveling, baking, and discharging. The coating preparation method of the automobile part has the benefits as follows: through reasonable selection of materials, pretreatment process and the coating system, a diversified color effect is achieved, the prepared coating has a high plumpness, high grade of transparency and highly metallic appearance, the coating effect and color diversity are enriched, the scratch resistant and ageing resistant performances are realized without additionally arranging a protecting coating, the high-performance requirements of the surface coating of the automobile part are met, the long-term usage of the high-cost process of performing paint spraying after vacuum coating is avoided, and the production cost is further reduced.

Owner:SHANGHAI REAL INDAL

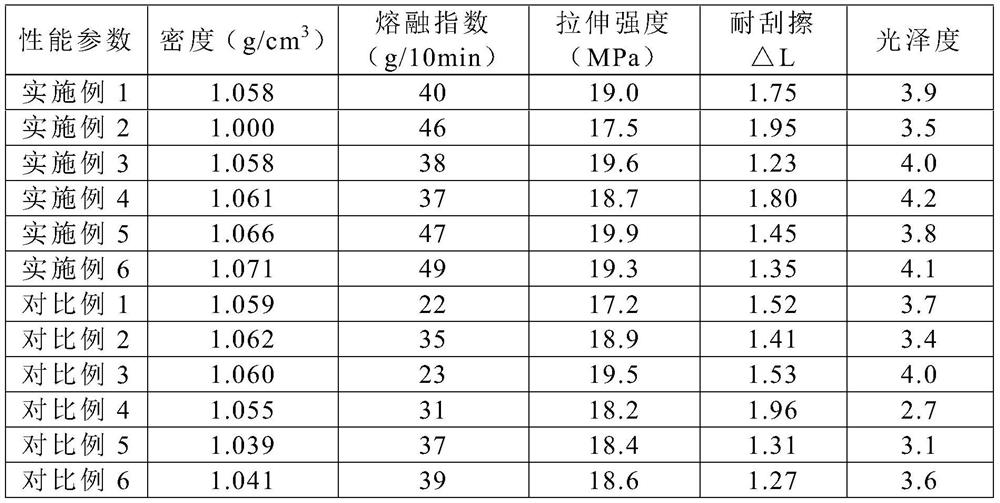

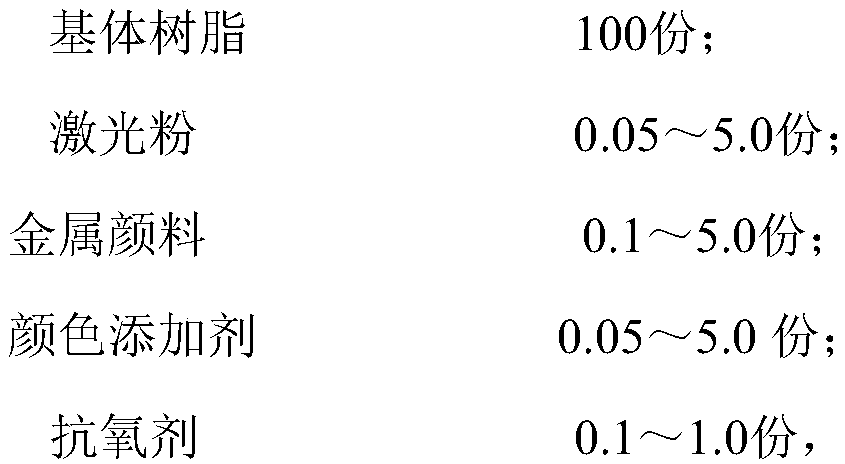

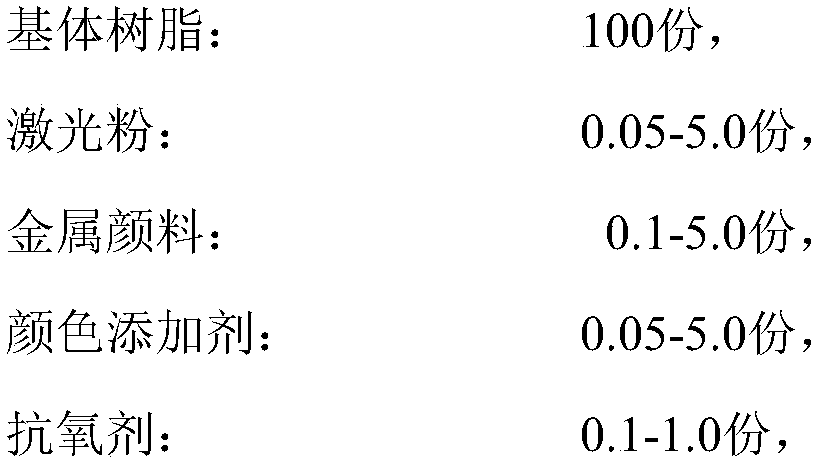

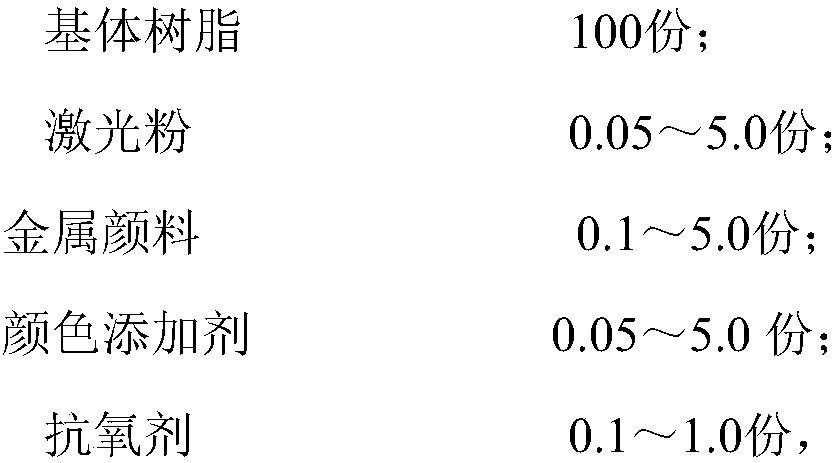

Resin composition applicable to laser welding and with high metal texture and preparation method thereof

The invention relates to the field of automotive materials, in particular to a resin composition applicable to laser welding and with high metal texture and a preparation method thereof. The resin composition comprises, by weight, 100 parts of matrix resin, 0.05-5.0 parts of laser powder, 0.1-5.0 parts of metal pigment, 0.05-5.0 parts of pigment additive and 0.1-1.0 part of antioxidant. The preparation method includes: sufficiently mixing the matrix resin, the laser powder, the metal pigment, the pigment additive and the antioxidant in a low-speed mixer, feeding into a double-screw extruder through a metering device, performing screw conveying, shearing and mixing to allowing the materials to sufficiently melt and mix, and performing extrusion, drawing, cooling and grain-sized dicing to obtain the resin composition applicable to laser welding. The prepared resin composition with high metal texture can have excellent laser welding performance.

Owner:HASCO VISION TECHNOLOGY CO LTD

Metal housing and surface treating method thereof

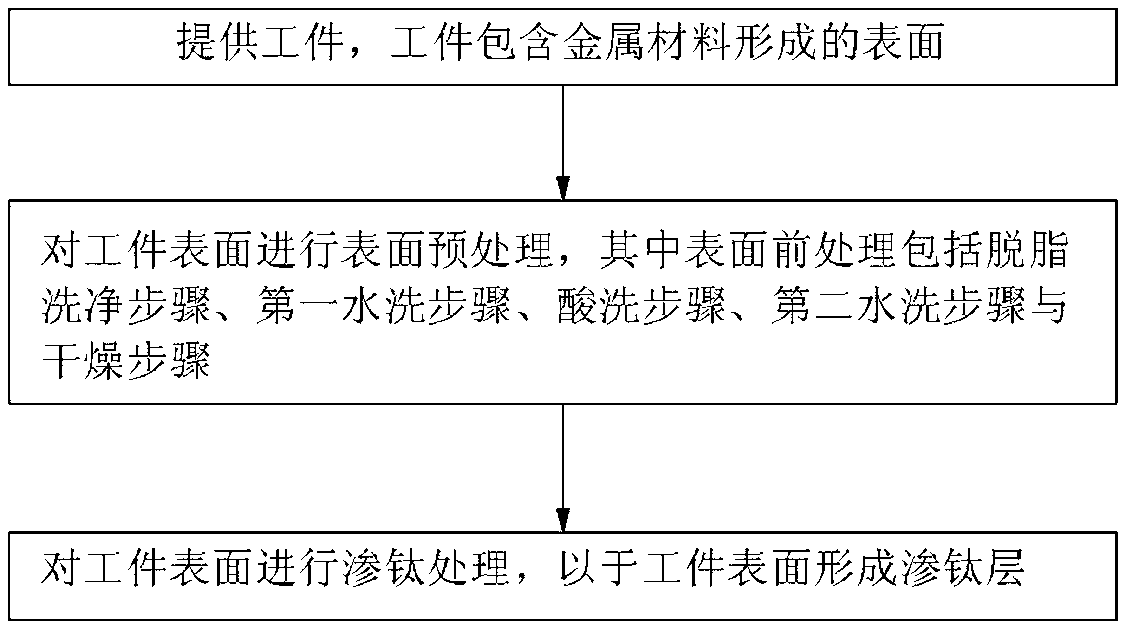

InactiveCN102719786AImprove wear resistanceImprove heat resistanceVacuum evaporation coatingSputtering coatingMetallic materialsTitanium

The invention provides a surface treating method of a metal housing, including: providing a workpiece having metal materials on a surface of the workpiece; carrying out a surface pretreatment on the surface of the workpiece to clean the surface, the surface pretreatment including a degreasing and washing step; and proceeding a titanizing treatment on the surface of the workpiece to form a titanizing layer on the surface of the workpiece, the titanizing layer being formed by titanizing into structural voids of the workpiece.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Spraying-free polyolefin composition with special aesthetic effect and a preparation method and application thereof

The invention discloses a spraying-free polyolefin composition with special aesthetic effect and a preparation method and application thereof. The composition comprises the following components: 70-98 wt% of polyolefin, 1-25wt% of polymer coated powder microspheres with special effect, 0-10 wt% of a compatibilizer, 0.1-1 wt% of an antioxidant and 0.1-0.5wt% of a processing aid. The powder with special effect coats with an aqueous polymer dispersion liquid to form microspheres which are then dispersed into polyolefin, so as to significantly improve the compatibility of the powder with special effect and polyolefin, and eliminate the flow mark formed on the surface of products in the extrusion or injection molding process and reduce the weld line. The prepared spraying-free polyolefin composition has aesthetic effects of obvious metal texture and pearly flashing, and greatly improves the scope of market application of spraying-free materials.

Owner:KINGFA SCI & TECH CO LTD

Mobile phone shell and preparation process thereof

InactiveCN107299260AMaintain fine grain structureHigh strengthCoatingsTelephone set constructionsPunchingUltimate tensile strength

The invention provides a mobile phone casing and a preparation process thereof. The mobile phone casing contains the following raw materials in parts by weight: 1-1.8 parts of Mg, 0.5-1.1 parts of Si, 0.3-1 part of Co, and the balance is Al and Unavoidable impurities. The aluminum alloy shell provided by the present invention has very excellent stamping performance and high strength, and is especially suitable for the preparation of mobile phone shells that need to be stamped and formed through multiple passes, and at the same time require high strength, and meet high appearance and performance requirements. Requirements for thin-walled shell members. The coated decorative film layer makes the mobile phone shell have the advantages of high brightness and metal texture, and has high brightness and good adhesion.

Owner:合肥展游软件开发有限公司

Embossed PET (Polyethylene Terephthalate) laminated colorful steel plate and production method thereof

InactiveCN104070728AImprove metallic textureHigh cost of solutionSynthetic resin layered productsMetal layered productsSteel platesSheet steel

The invention provides an embossed PET (Polyethylene Terephthalate) laminated colorful steel plate which comprises a base plate, wherein the upper surface of the base plate is a chemical processing layer, the back surface of the base plate is a back paint layer, the chemical processing layer is coated with a glue water layer, and an embossed PET compound colorful film is arranged on the glue water layer. The invention further provides a production method of the embossed PET laminated color steel plate. The production method comprises the following basic processes: uncoiling the base plate; pretreating the base plate; coating the steel plate with back paint; coating glue water in front of the steel plate; laminating in front of the steel plate; and laminating a protection film in front; and coiling. According to the embossed PET laminated colorful steel plate, a metal effect of a stainless steel plate is shown, the metal texture on the surface of the plate is improved, the problems of high cost and pollution of products are effectively solved, and the profitability of the products is improved.

Owner:HAIER GRP CORP +2

Aluminum alloy material housing using aluminum alloy material

The invention provides an aluminum alloy material which comprises the following components, by mass percent, 4.5-12.0% of zinc, 0.7-3.0% of magnesium, less than or equal to 0.6% of copper, 0.001-0.5% of titanium, 0.00011-0.2% of boron, less than or equal to 0.01% of manganese, less than or equal to 0.2% of chromium, less than or equal to 0.2% of zirconium, less than or equal to 0.3% of silicon, less than or equal to 0.3% of iron, and the balance aluminum and other unavoidable impurities.

Owner:HUAWEI TECH CO LTD

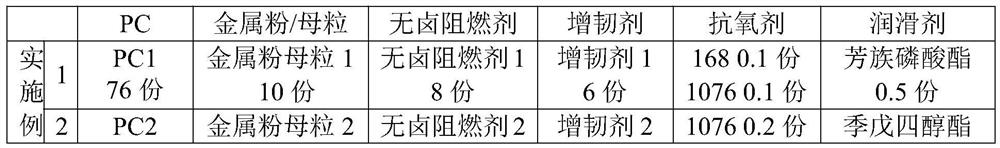

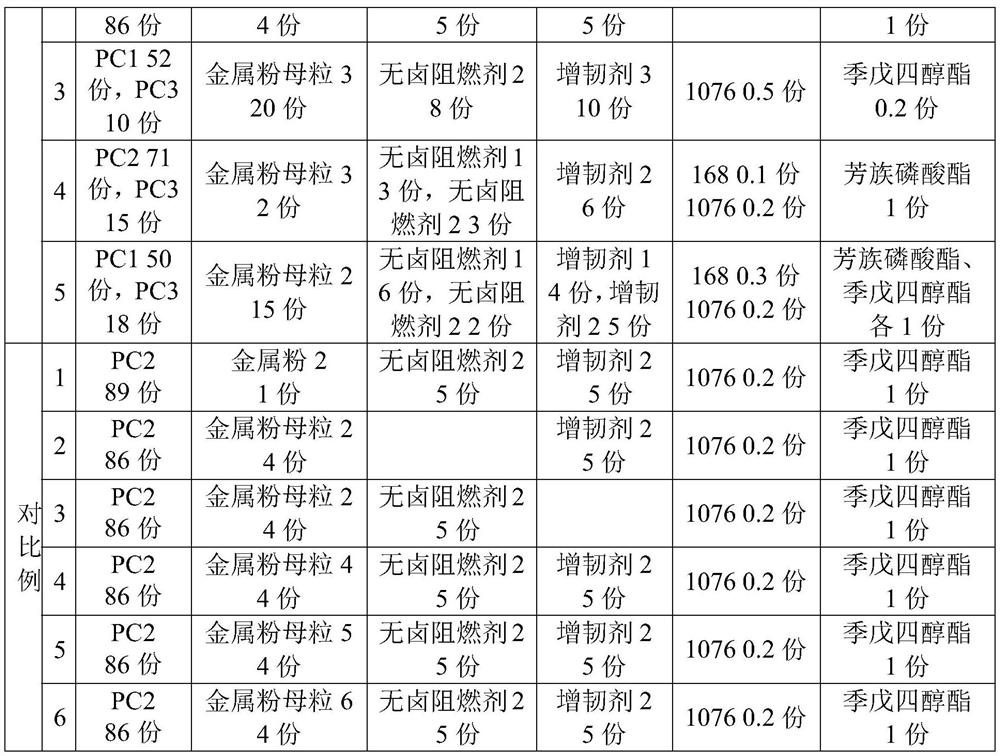

Spraying-free high-flowability high-impact flame-retardant PC material with metal texture and preparation method and application of material

The invention discloses a spraying-free high-flowability high-impact flame-retardant PC material with metal texture as well as a preparation method and application of the material. The material is prepared from 55 to 89 parts of PC resin, 1 to 25 parts of metal powder master batch, 5 to 10 parts of halogen-free flame retardant, 5 to 10 parts of flexibilizer, 0.1 to 0.5 part of antioxidant and 0.2 to 2 parts of lubricant; wherein the metal powder master batch is metal powder subjected to coating treatment by an MAH-St-MMA copolymer. The compatibility between the metal powder and PC is improved through MAH-St-MMA, the material performance and the metal texture are improved, and the technical problem that in the prior art, the flowability, the impact property and the flame retardant property of a metal texture PC material cannot be considered at the same time is solved through cooperative use of high-flowability PC, the metal powder master batch, the flexibilizer and the halogen-free flame retardant; meanwhile, the material has a good appearance effect, high flowability, impact resistance and flame retardance, is easy to form and meets the requirements of wall switches.

Owner:SHANGHAI KUMHO SUNNY PLASTICS +1

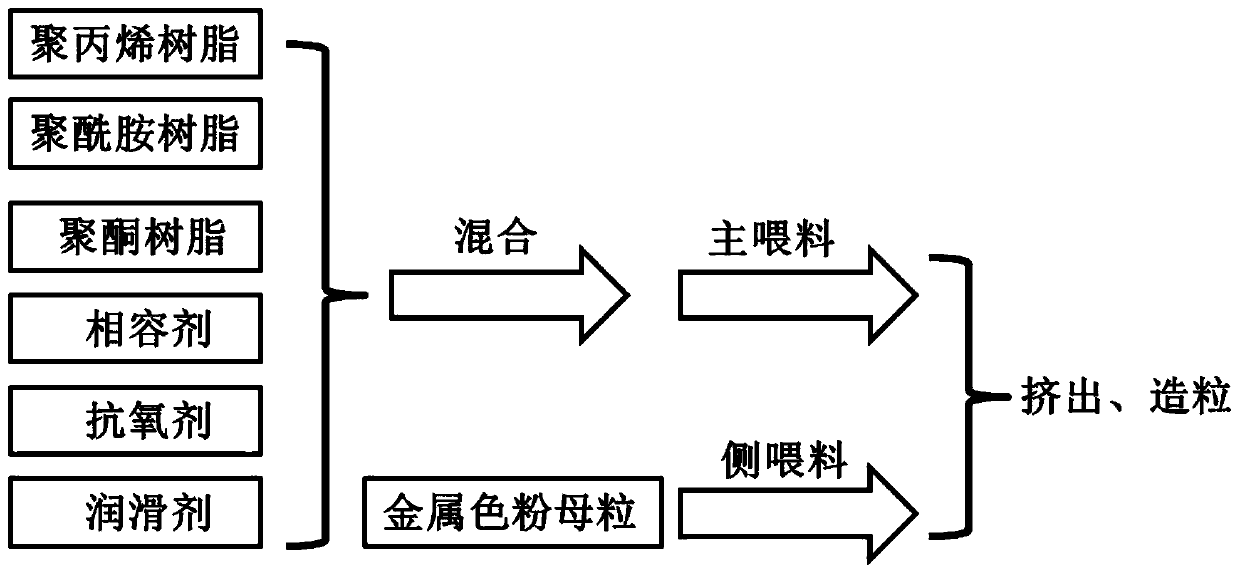

Polypropylene/polyamide/polyketone composite material and preparation method thereof

The invention provides a polypropylene / polyamide / polyketone composite material and a preparation method thereof. The polypropylene / polyamide / polyketone composite material is prepared from polypropylene resin, polyamide resin, polyketone resin, a compatilizer, an antioxidant, a lubricant and metal toner master batches; the compatilizer is at least one of maleic anhydride grafted polypropylene and maleic anhydride grafted polyethylene; and the metal toner master batches are prepared from a metal toner, polyacrylic acid and polypropylene powder. The polypropylene / polyamide / polyketone composite material has the advantages of high metal texture, excellent surface scratch resistance and favorable mechanical properties, and can be applied to the fields of automobiles and household appliances, such as automobile exterior decorations, air conditioner decoration strips, small household appliance exterior decoration structures and the like.

Owner:GUANGDONG ALDEX NEW MATERIAL CO LTD

Ultraviolet curing coating for housing of battery car as well as preparation method and spray-coating method

ActiveCN104231870ASmall footprintLess investmentPretreated surfacesPolyurea/polyurethane coatingsWear resistantSpray coating

The invention discloses an ultraviolet curing coating for a housing of a battery car as well as a preparation method and a spray-coating method. The ultraviolet cutting coating is characterized by consisting of a primer and a finish paint, wherein the primer comprises the following components in percentage by weight: 20 to 40 percent of epoxy acrylate, 10 to 20 percent of urethane acrylate, 2 to 6 percent of 1,6-hexanediol diacrylate, 30 to 40 percent of trimethylolpropane triacrylate, 1 to 5 percent of 1-hydroxycyclohexyl phenyl ketone, 3 to 8 percent of benzyl dimethyl ketone and 0.2 to 1 percent of polyether modified polydimethylsiloxane; the finish coat comprises the following components in percentage by weight: 40 to 60 percent of acrylic ester modified solvent-containing oligomer, 30 to 50 percent of trimethylolpropane triacrylate, 5 to 10 percent of 1-hydroxycyclohexyl phenyl ketone, 1 to 3 percent of 2,4,6-trimethylbenzoyldiphenyl phosphine oxide, 0.5 to 2 percent of polyether modified polydimethylsiloxane, 1 to 3 percent of trifunctional acid ester and 1 to 3 percent of nanoscale color concentrate. The coating is efficient, energy-saving, economic, environment-friendly, scratch-resistant, wear-resistant, bright in color and less in curing investment, and can be easily produced on an assembly line, and a preparation process is simple.

Owner:浙江久而久化学有限公司

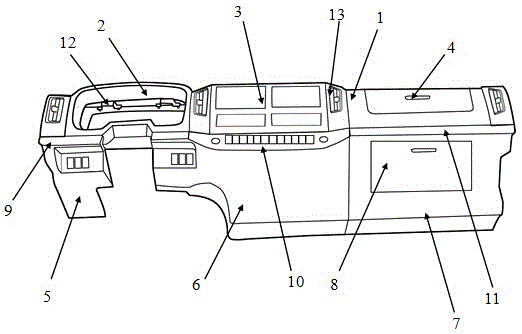

Instrument board assembly for vehicle

InactiveCN105034810AImprove aestheticsSimple structureDashboard fitting arrangementsTherapeutic effectBiomedical engineering

The invention discloses an instrument board assembly for a vehicle. The instrument board assembly comprises an instrument board body (1), wherein the instrument board body (1) is provided with an instrument cover (2), a central control panel (3), a fuse box (4), a left angle board (5), an assistant-driving decorative strip assembly, a driver right lower skirt board (6) and an assistant-driving right lower skirt board (7). The instrument board assembly is characterized in that a plurality of fastener seats are arranged on the back surface of the instrument cover (2) and are internally provided with fasteners; corresponding to the installing surfaces in installing holes, a plurality of installing columns are arranged on the instrument board body (1); a connecting frame (12) is fixedly connected to the installing columns; the connecting frame (12) is provided with fastener matching holes; and the instrument cover (2) is fixedly connected on the instrument board body (1) by the fasteners. The instrument board assembly disclosed by the invention has the advantages that the structure is simple, all parts are fixedly connected on the instrument board body (1) by fastening feet or fasteners, the installation is convenient and fast, the connection is firm and stable, and by various surface treatment effects, the aesthetic feeling of the appearance of the instrument board assembly can be greatly improved.

Owner:JIANGSU QIANCHENG VEHICLE ACCESSORIES

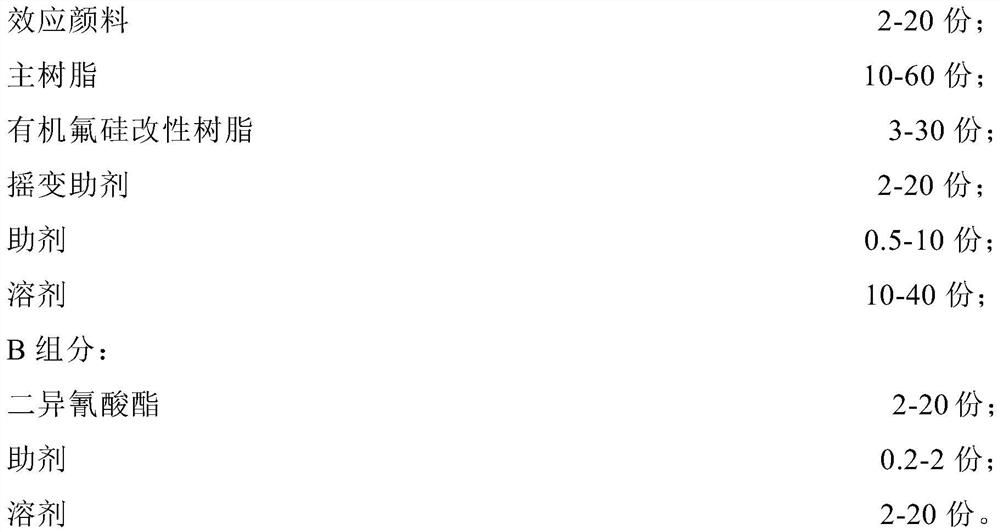

High-wear-resistance coating for automotive upholstery and preparation method of high-wear-resistance coating

The invention relates to a coating for automotive upholstery, in particular to a high-wear-resistance coating for automotive upholstery and a preparation method thereof.The high-wear-resistance coating for automotive upholstery comprises a component A and a component B. The component A comprises, by weight, 2-20 parts of effect pigment; 10 to 60 parts of main resin; 3 to 30 parts of organic fluorine-silicon modified resin; 2-20 parts of a shaking auxiliary agent; 0.5 to 10 parts of an auxiliary agent; 10 to 40 parts of a solvent; a component B: 2 to 20 parts of diisocyanate; 0.2 to 2 parts of an auxiliary agent; and 2-20 parts of a solvent. Compared with the prior art, the modified aldehyde ketone resin is selected as a matrix, the adhesion performance between a paint film and a material can be effectively improved, and the prepared paint is good in water resistance and chemical resistance. The modified aldehyde ketone matrix resin has high molecular weight, can effectively improve the Flip-Flop value of the silver powder, enables the arrangement effect of the silver powder to be excellent, can improve the shielding power of the metallic pigment, and can effectively improve the water resistance, alcohol resistance and high weather resistance of a coating.

Owner:DONGLAI COATING TECH SHANGHAI

Anticorrosion treatment technology of pearl

InactiveCN1686026AImprove long-term wear resistanceIncrease metallic luster and durable wear resistanceJewellerySolventTitanium dioxide

An anticorrosion process for pearl includes dissolving titanate in alcohol solvent, adding stabilizer, regulating pH=6-9, hydrolyzing, polycondensating to obtain TiO2 sol, eluting with alcohol solvent for dewatering it, immersing the pearl in it at 40-80 deg.C for 2-10 days, vacuum distilling for removing alcohol solvent, and drying to obtain anticorrosion pearl.

Owner:浙江千足珠宝有限公司

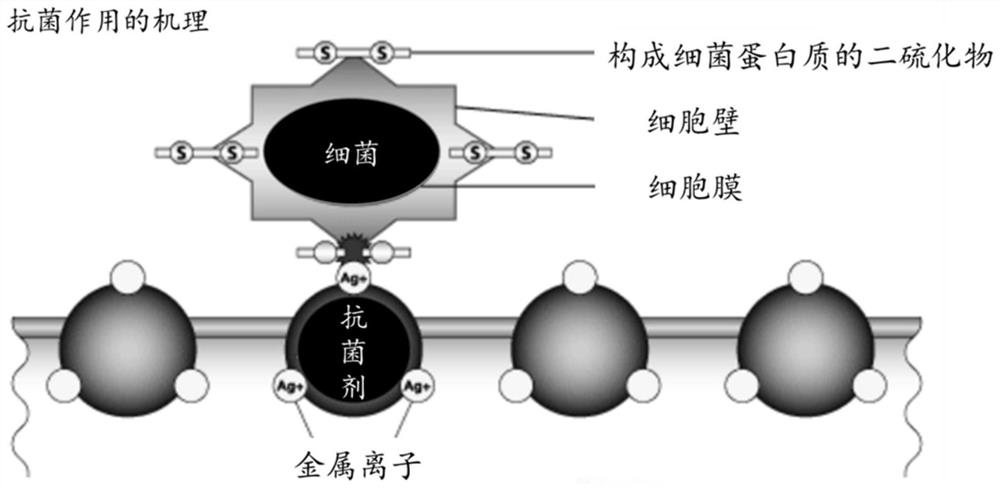

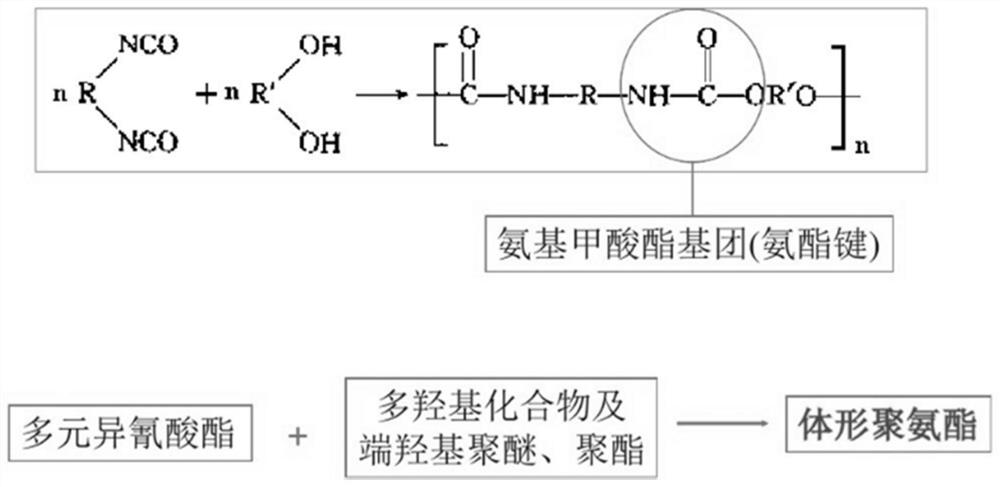

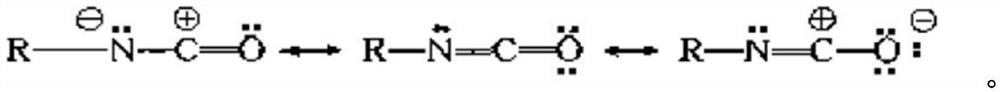

PU antibacterial coating as well as preparation method and application thereof

InactiveCN113372801AHigh solid contentImprove antibacterial propertiesAntifouling/underwater paintsPaints with biocidesPolymer scienceMeth-

The invention discloses a PU antibacterial coating as well as a preparation method and application thereof. The PU antibacterial coating comprises a component A and a component B, the component A is prepared from the following raw materials: hydroxy acrylic resin, thermoplastic acrylic resin, saturated polyester resin, aluminum paste, an antibacterial agent, a diluent, a drier and a flatting agent; and the component B is prepared from the following raw materials: a hexamethylene diisocyanate tripolymer and a solvent I. According to the PU antibacterial coating, the solid content is 35% or above during construction, and VOC emission is reduced (the VOC emission value is smaller than or equal to 700 g / L); the metal texture of the aluminum-silver powder paint is improved; and meanwhile, the PU coating disclosed by the invention is good in antibacterial effect, good in antibacterial coating dispersity, high in antibacterial efficiency and good in antibacterial durability.

Owner:HUNAN SOKAN NEW MATERIAL

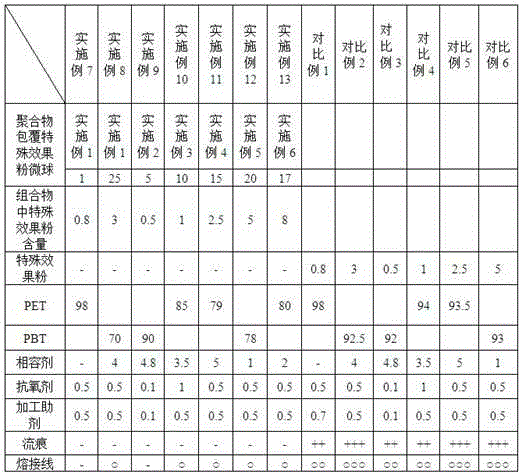

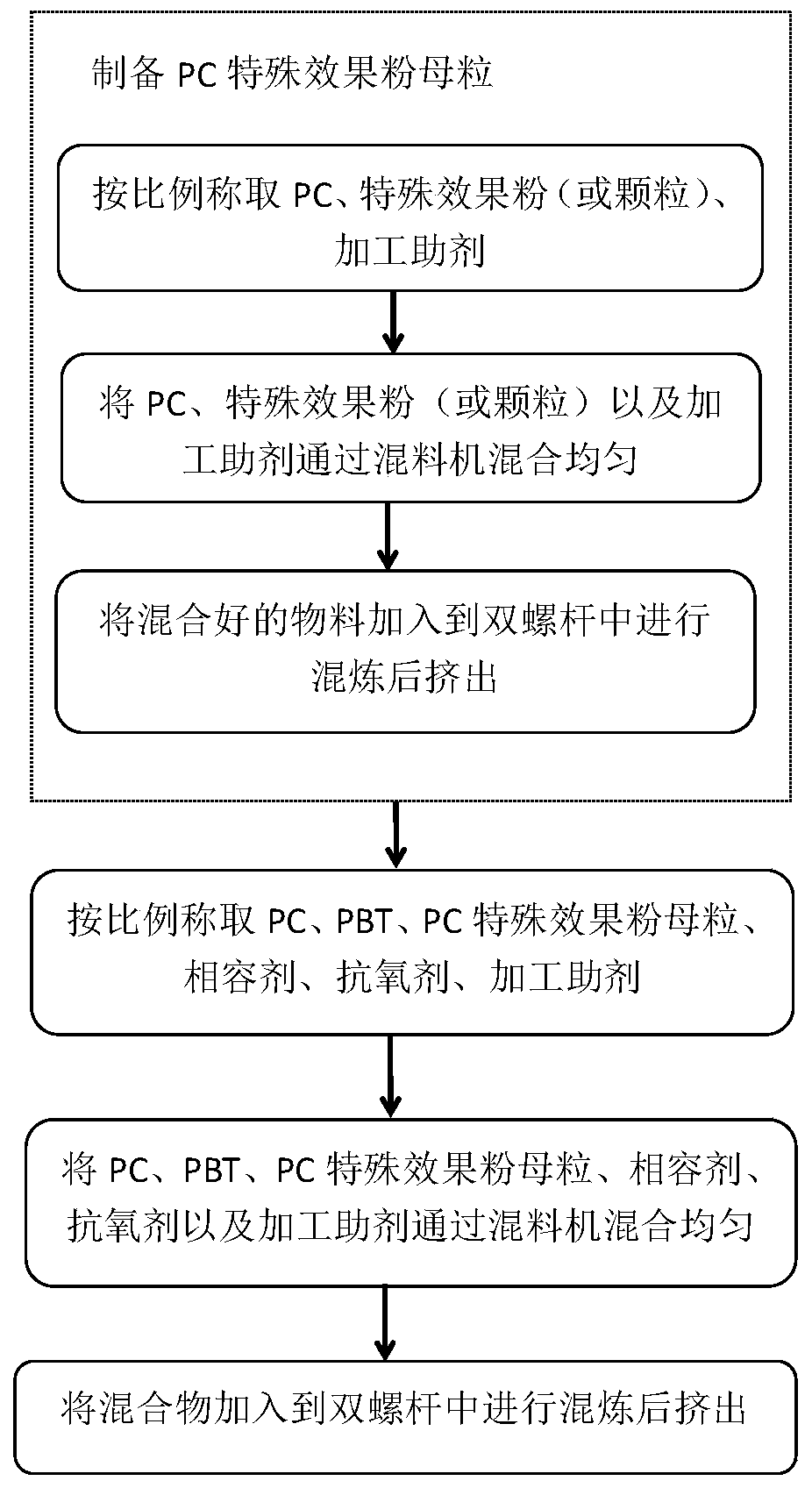

Spraying-free PC/PBT alloy material and preparation method thereof

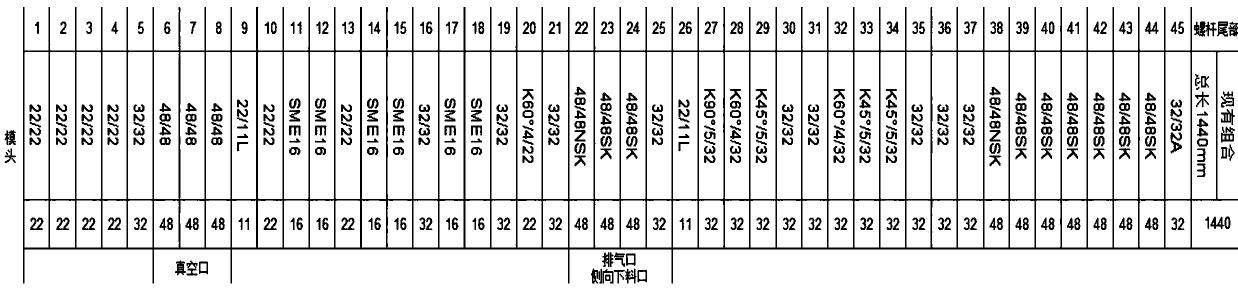

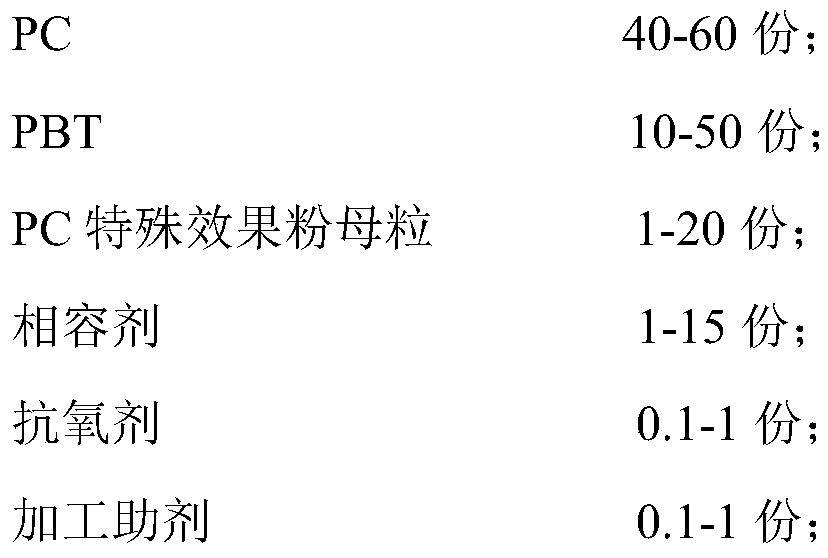

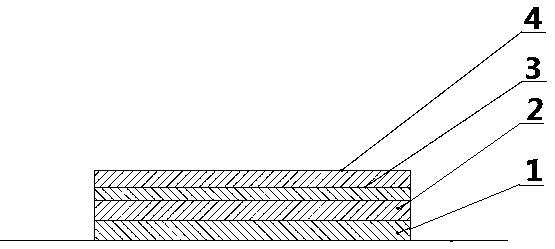

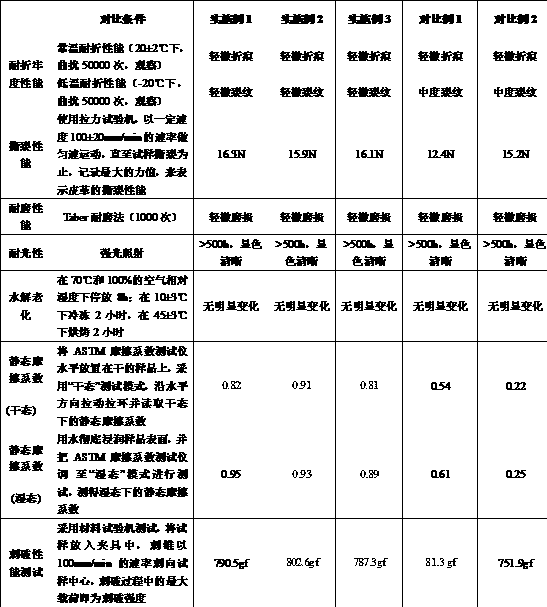

The invention discloses a spraying-free PC / PBT alloy material and a preparation method thereof, and relates to the field of high polymer materials. The spraying-free PC / PBT alloy material comprises, by weight, 40 to 60 parts of PC; 10 to 50 parts of PBT; 1-20 parts of PC special effect powder masterbatch; 1-15 parts of a compatilizer; 0.1 to 1 part of an antioxidant; and 0.1 to 1 part of a processing aid; wherein the PC special effect powder masterbatch comprises, by weight, 18 to 90 parts of PC, 5-80 parts of special effect powder or particles and 0.1-1 part of a processing aid. According tothe PC / PBT alloy material, the masterbatch is prepared from the special effect powder or particles through PC and then dispersed into the PC / PBT alloy material, the compatibility of the special effectpowder and matrix resin can be obviously improved, the dispersity of the special effect powder or particles is improved, and therefore flow marks and fisheyes on the surface of a product are eliminated, and weld lines are reduced; in addition, PC and PBT are used as alloy materials, so that the thermal deformation temperature of the material is effectively increased, and the market application range of the spraying-free material is greatly widened.

Owner:JIANGSU BOILN PLASTICS CO LTD

Anti-sliding and anti-piercing metallic thin film and preparation method thereof

InactiveCN108146042AGood water permeability and oil resistanceExtended use timeSynthetic resin layered productsVacuum evaporation coatingCyclohexanoneEpoxy

The invention discloses an anti-sliding and anti-piercing metallic thin film and a preparation method thereof. The thin film is provided with a coating film layer, a base layer, an anti-sliding layerand an anti-piercing layer from bottom to top, wherein the anti-sliding layer consists of the following components in parts by mass: 35-45% of acrylic resin, 8-10% of tungsten-cobalt alloy sands, 4-8%of nano aluminum oxide and 10-20% of styrene isoprene block copolymer; and the anti-piercing layer consists of the following components in parts by mass: 40-60% of amino resin, 18-25% of epoxy resin,2-3% of a thickening agent, 5-7% of talcum powder, 20-25% of silicon carbide particles, 4-6% of cyclohexanone and 6-9% of titanium dioxide. On the basis of not affecting the physical performance, theanti-sliding performance of the plastic thin film is improved, and the thin film cannot be pierced easily, and meanwhile, the surface of the thin film is metallic on the basis of not affecting the use performance of the thin film.

Owner:瑞年科技(广东)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com