Spraying-free PC/PBT alloy material and preparation method thereof

An alloy material and spray-free technology, which is applied in the field of spray-free PC/PBT alloy materials and its preparation, can solve the problems of uneven distribution of special effect powder, unstable flow rate, poor compatibility, etc. Heat distortion temperature, the effect of obvious metallic texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

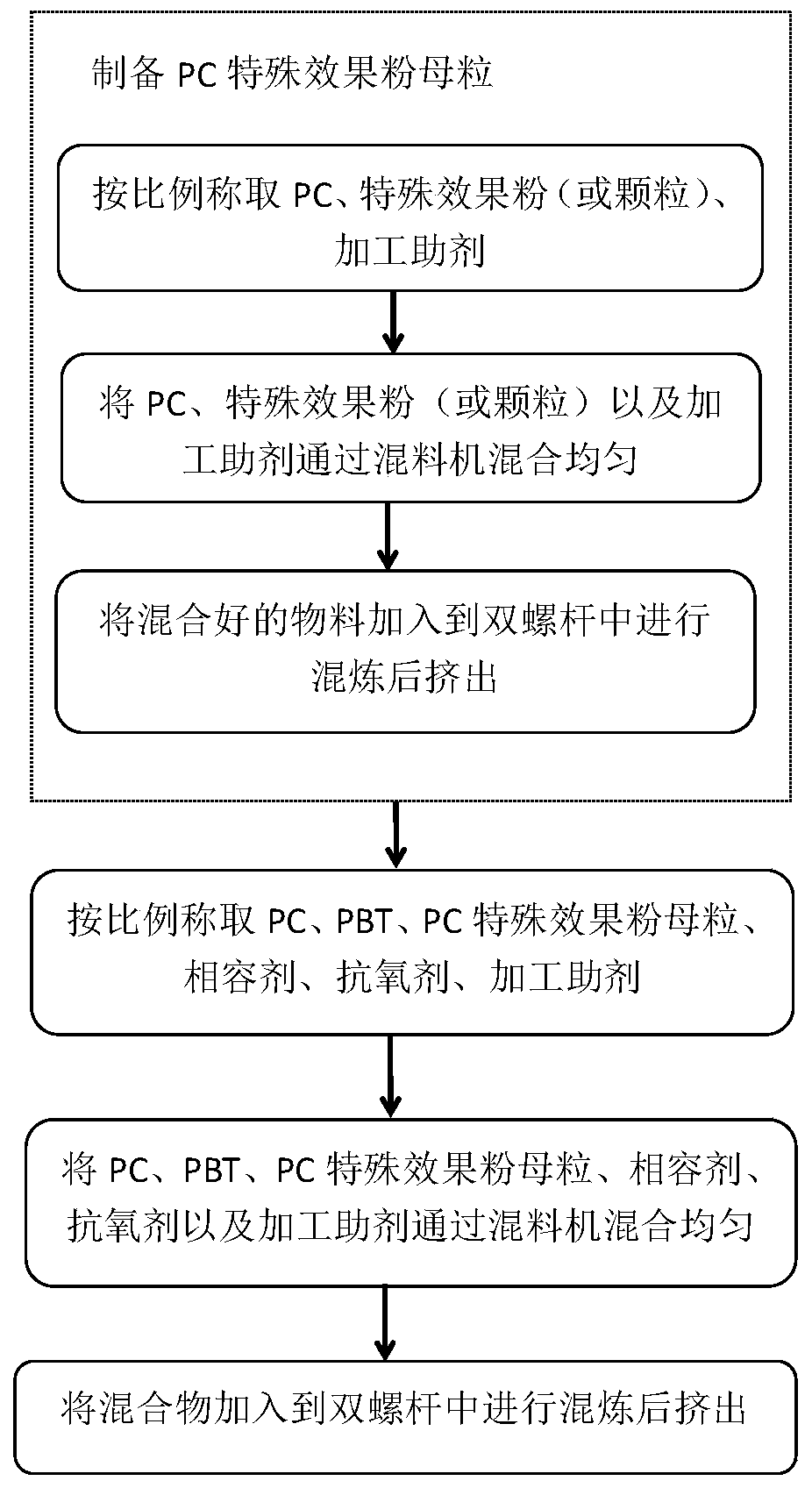

[0049] Based on the same inventive concept, the application also discloses a method for preparing a spray-free PC / PBT alloy material, the operation process of which is as follows: figure 1 shown, including the following steps:

[0050] Preparation of PC special effect powder masterbatch: taking materials, weighing PC, special effect powder or granules and processing aids in proportion; mixing and granulating, mixing PC, special effect powder (or granules) and processing aids through a mixer Evenly, add it to the twin-screw for mixing, the extruded material is cooled by the water tank, the temperature of the cooling water is 15-20 ℃, and the pellets are cut by the pelletizer, the speed of the pelletizer is 200-500rpm, and the dryer is dried. Package;

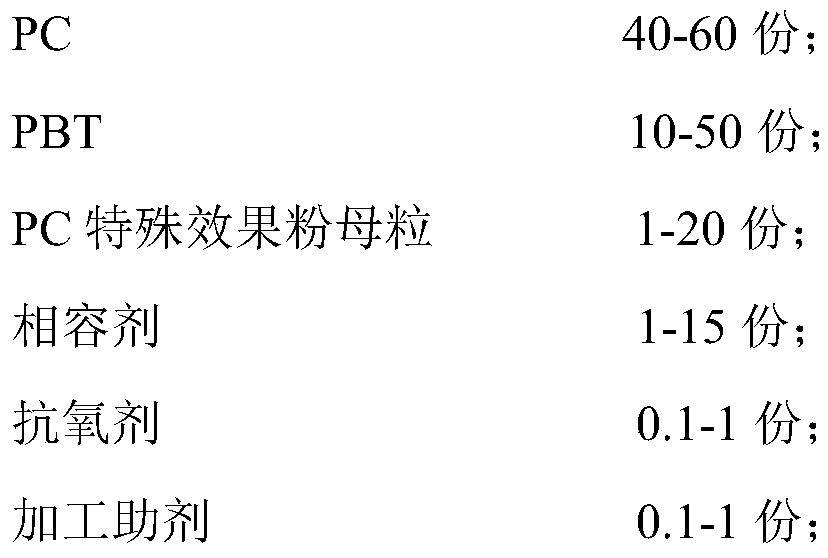

[0051] Preparation of spray-free PC / PBT alloy materials: Take materials, weigh PC, PBT, PC special effect powder masterbatch, compatibilizer, antioxidant and processing aids in proportion; mix and granulate, mix PC, PBT, PC spec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com