Patents

Literature

40results about How to "Eliminate flow marks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Spraying-free polyester composition having special aesthetic effects and preparation method and application thereof

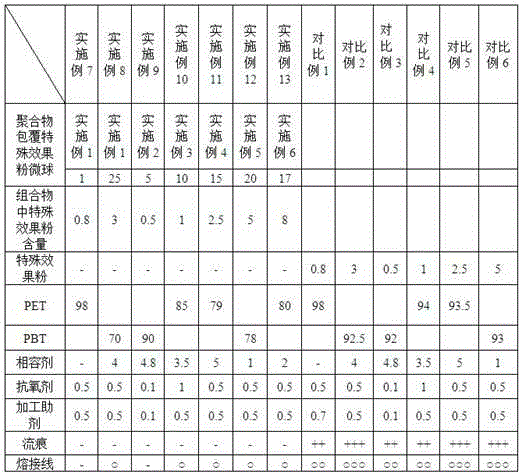

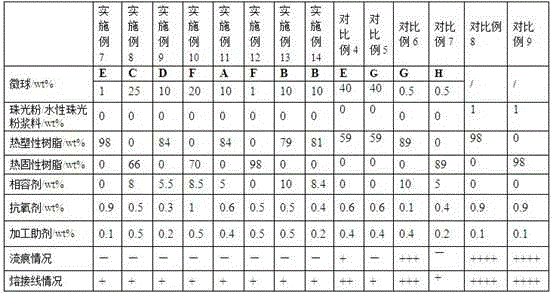

The invention discloses a spraying-free polyester composition having special aesthetic effects and a preparation method and an application thereof. The spraying-free polyester composition comprises the following components: 70-98 wt% of polyester, 1-25 wt% of microspheres formed by coating a special-effect powder with a polymer, 0-10 wt% of a compatibilizer, 0.1-1 wt% of an antioxidant, and 0.1-0.5 wt% of a processing auxiliary agent. The special-effect powder is coated with a water-based polymer dispersion liquid to form the microspheres, and then the microspheres are dispersed to the polyester, so that the compatibility of the special-effect powder and the polyester can be significantly improved, flow marks formed on the surface of products in an extrusion or injection molding process are eliminated, and weld lines are reduced; and the prepared spraying-free polyester composition has relatively obvious metal texture, pearly flashing effects and other special aesthetic effects, and the market application range of spraying-free materials is greatly improved.

Owner:KINGFA SCI & TECH CO LTD

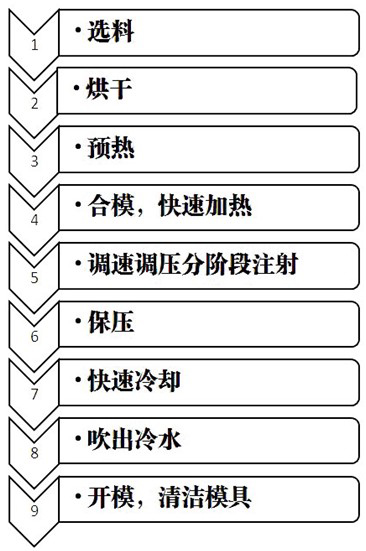

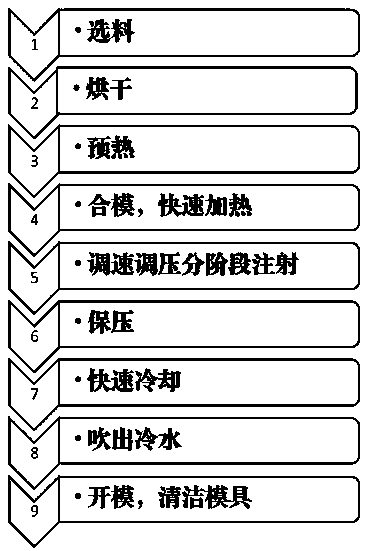

Steam type highlight and traceless injection-molding and forming process for complex precise product

The invention discloses a steam type highlight and traceless injection-molding and forming process for a complex precise product. The process sequentially comprises the following steps of: selecting raw materials, baking, pre-heating, combining a die, then quickly heating, adjusting speed and pressure, injecting in sections, maintaining the pressure, cooling quickly, blowing out cold air, opening the die and cleaning the die. An advanced pressure-regulation and speed-regulation staging injection process and an automatic blowing and impurity-removing technology are adopted in the invention. A special heating and cooling technology is that the shapes, the widths and the arrangement density of water passages are designed according to nonuniform heat and cold of the complex precise product in the injection-molding and forming course and the overall shape variation of the product. The steam type highlight and traceless injection-molding and forming process for the complex precise product has the advantages that the residual stress of the product is effectively decreased, various defects generated in the course of producing the plastic product are greatly reduced, the surface quality and the precision of the product are remarkably improved, and the life of the product is remarkably prolonged at the same time because the special process ensures heating and cooling rates of each part of the complex product in the injection-molding and forming course tend to be consistent.

Owner:海门市创豪工业设计有限公司

High-gloss spraying-free ABS (acrylonitrile butadiene styrene) composite material with special effect and preparation method thereof

InactiveCN105199294AImprove the lubrication effectImprove wettabilityAntioxidantAcrylonitrile butadiene styrene

The invention relates to the technical field of polymer materials, in particular to a high-gloss spraying-free ABS (acrylonitrile butadiene styrene) composite material with special effect and a preparation method thereof. The composite material comprises, by weight: 70-90 parts of ABS resin, 4.0-10 parts of a compatilizer, 5.0-10 parts of a toughener, 1.0-3.0 parts of white oil, 0.4-0.6 part of a composite antioxidant, 0.5-1.0 part of a lubricant, and 1.0-5 parts of pearl powder. The preparation method is simple, and the prepared ABS composite material has good mechanical properties, low aid emigration rate, significant pearl effect, smooth surface free of flow marks and scratch resistant, and long service life.

Owner:SILVER AGE ENG PLASTICS DONGGUAN

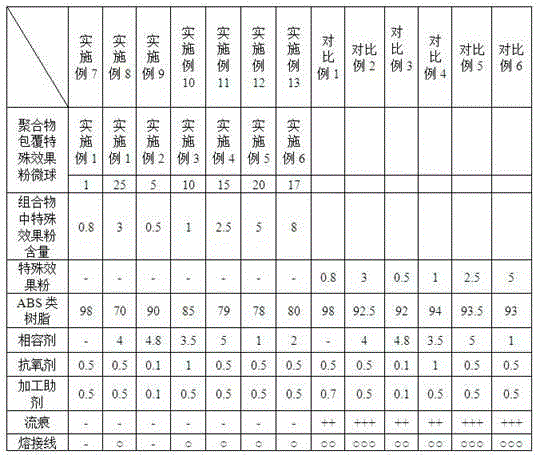

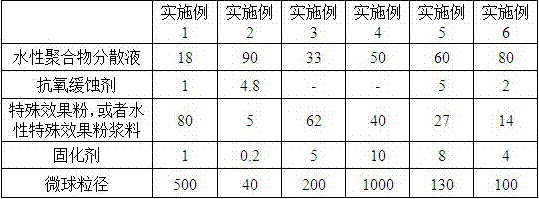

Spraying-free ABS composition with special aesthetic effect, preparation method and applications thereof

The invention discloses a spraying-free ABS composition with a special aesthetic effect, a preparation method and applications thereof. The ABS composition consists of 70 to 98 wt% of ABS resin, 1 to 25 wt% of polymer-coated microspheres with a special effect, 0 to 10 wt% of compatilizer, 0.1 to 1 wt% of antioxidant, and 0.1 to 0.5 wt% of processing aid. The powder with a special effect is coated by aqueous dispersion liquid to form microspheres, then the microspheres are dispersed into the ABS resin so as to improve the compatibility between the powder with a special effect and the ABS resin, thus the flow marks on the surface during the extrusion or injection moulding process can be eliminated, and the weld lines can be reduced. The prepared spraying-free ABS composition has a prominent metal texture and special aesthetic effects such as pearl-liked sparkling, and the application range of spraying-free materials is greatly enlarged.

Owner:TIANJIN KINGFA NEW MATERIAL

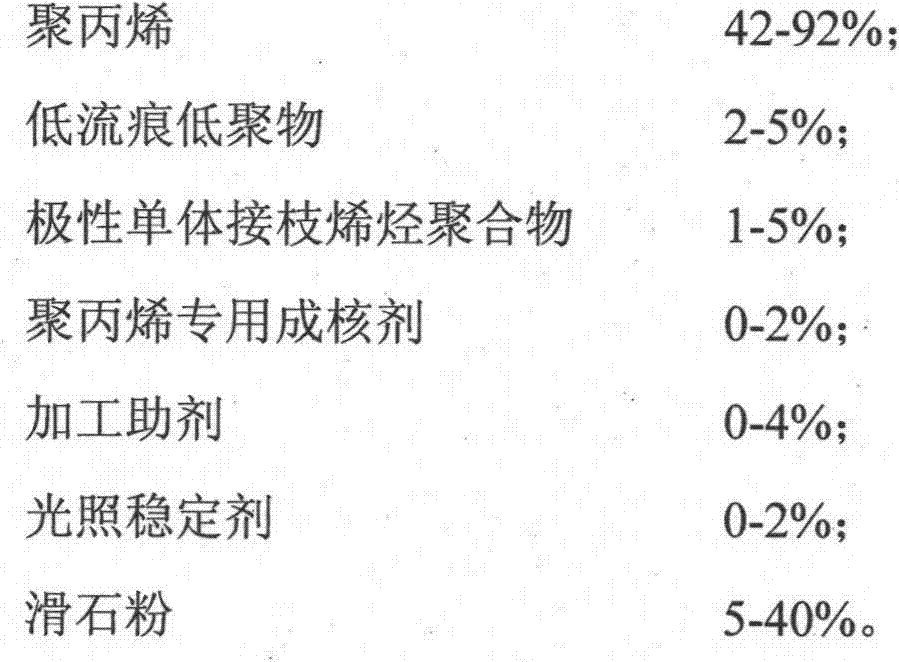

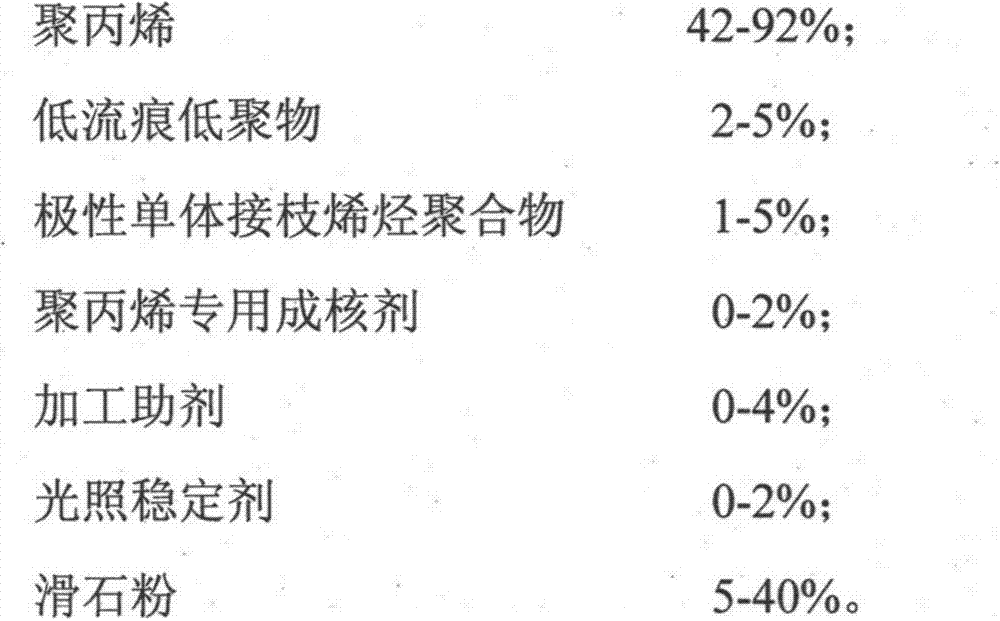

High-rigidity polypropylene composite without flow marks as well as preparation method of polypropylene composite

The invention discloses a polypropylene composite for a fender as well as a preparation method of the polypropylene composite. The polypropylene composite is prepared from 42-92wt% of polypropylene, 2-5wt% of an oligomer with few flow marks, 1-5wt% of a polar monomer graft olefin polymer, 0-2wt% of a special nucleating agent for polypropylene, 0-4wt% of a processing aid, 0-2wt% of a light stabilizer and 5-40wt% of talcum powder. The preparation method comprises the following steps: melting, mixing and dispersing the polypropylene, the oligomer with few flow marks, the polar monomer graft olefin polymer, the special nucleating agent for polypropylene, the processing aid and the light stabilizer in a double-screw extruder; feeding the talcum powder into the double-screw extruder from one side by an agravic metering balance; and extruding and granulating, thereby finally obtaining the product, namely the polypropylene composite. The polypropylene composite has the characteristics of high rigidity, high gloss and no flow marks and meets the requirements of large-sized polypropylene parts on appearance, and polypropylene injection molded parts have no flow marks.

Owner:SHANGHAI KINGFA SCI & TECH

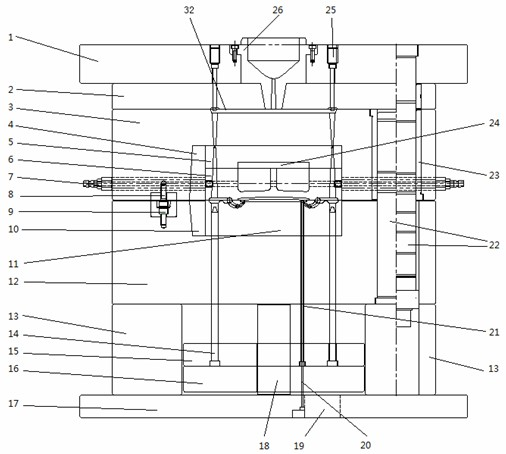

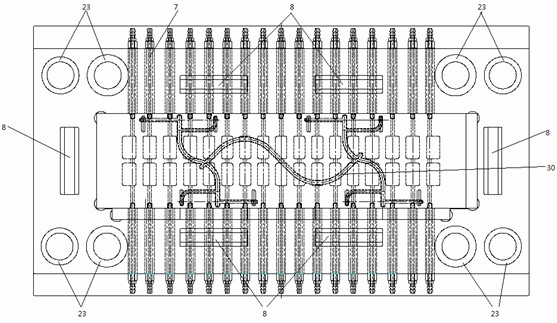

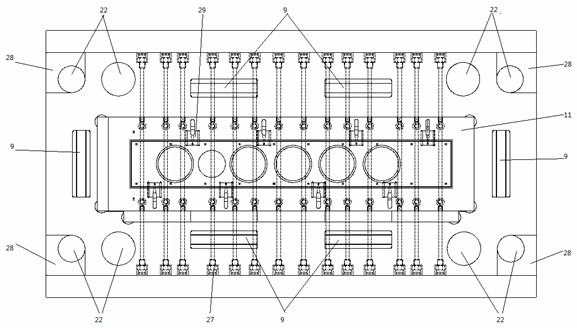

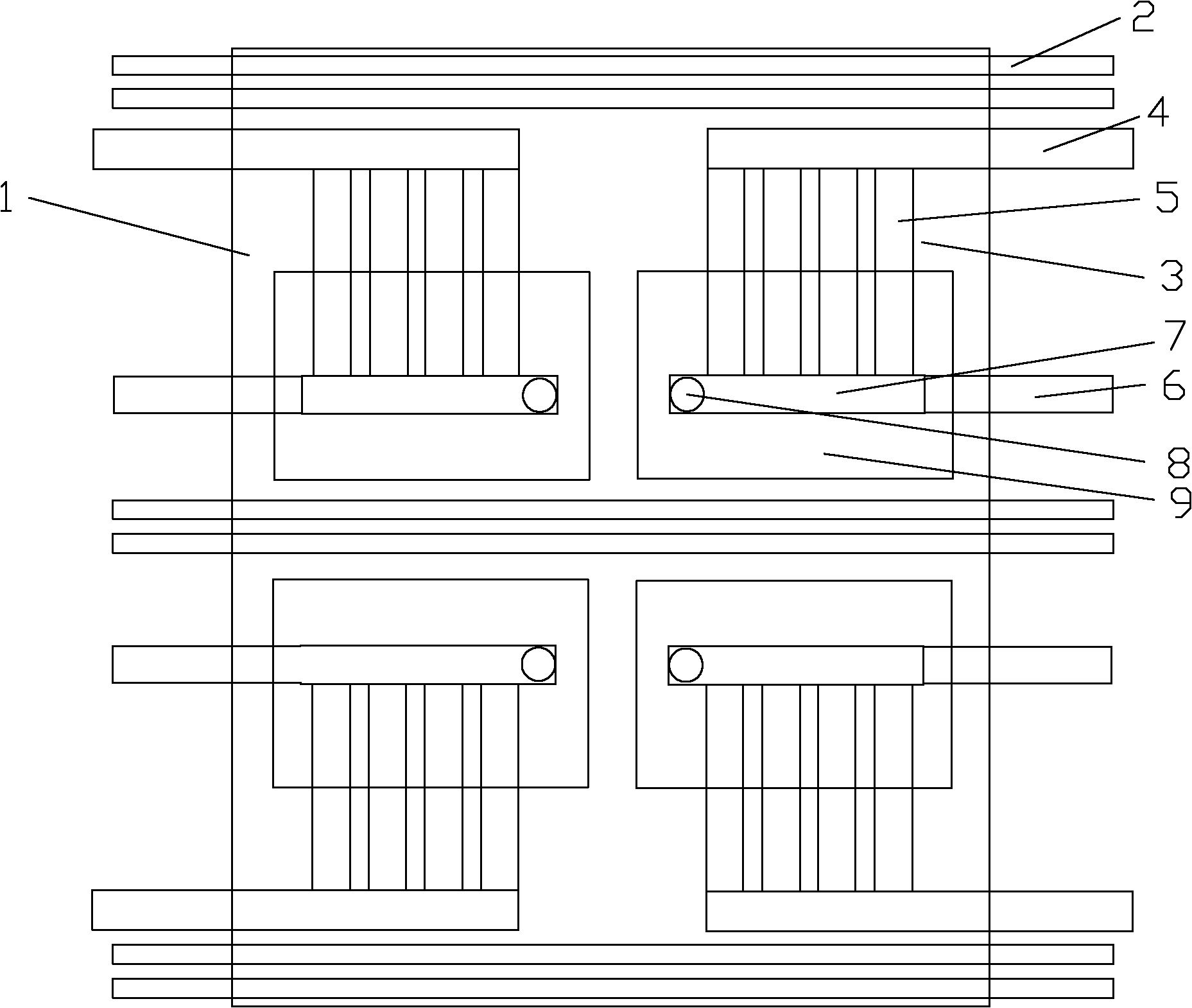

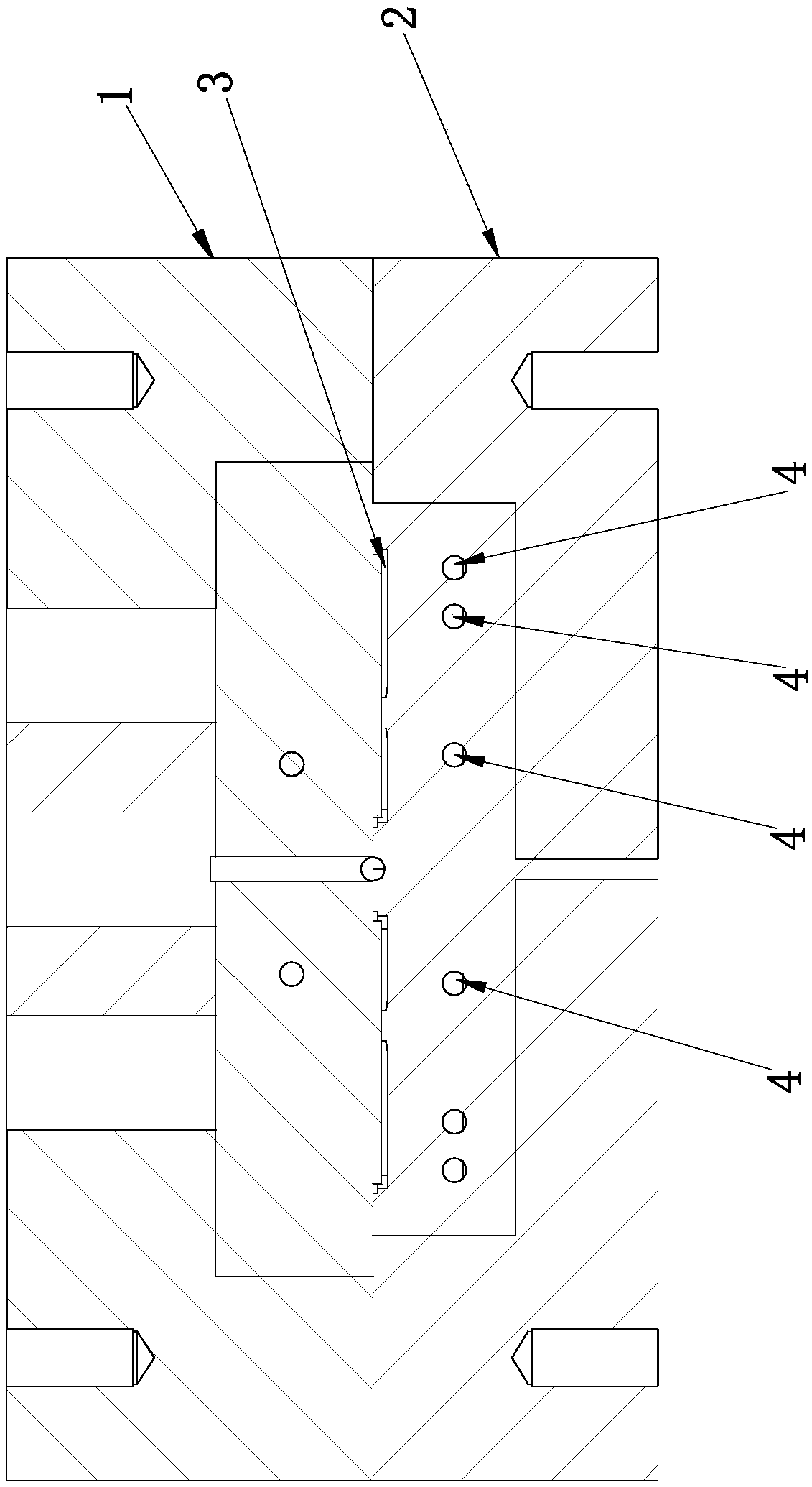

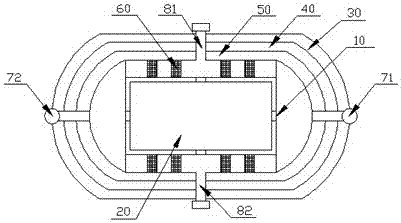

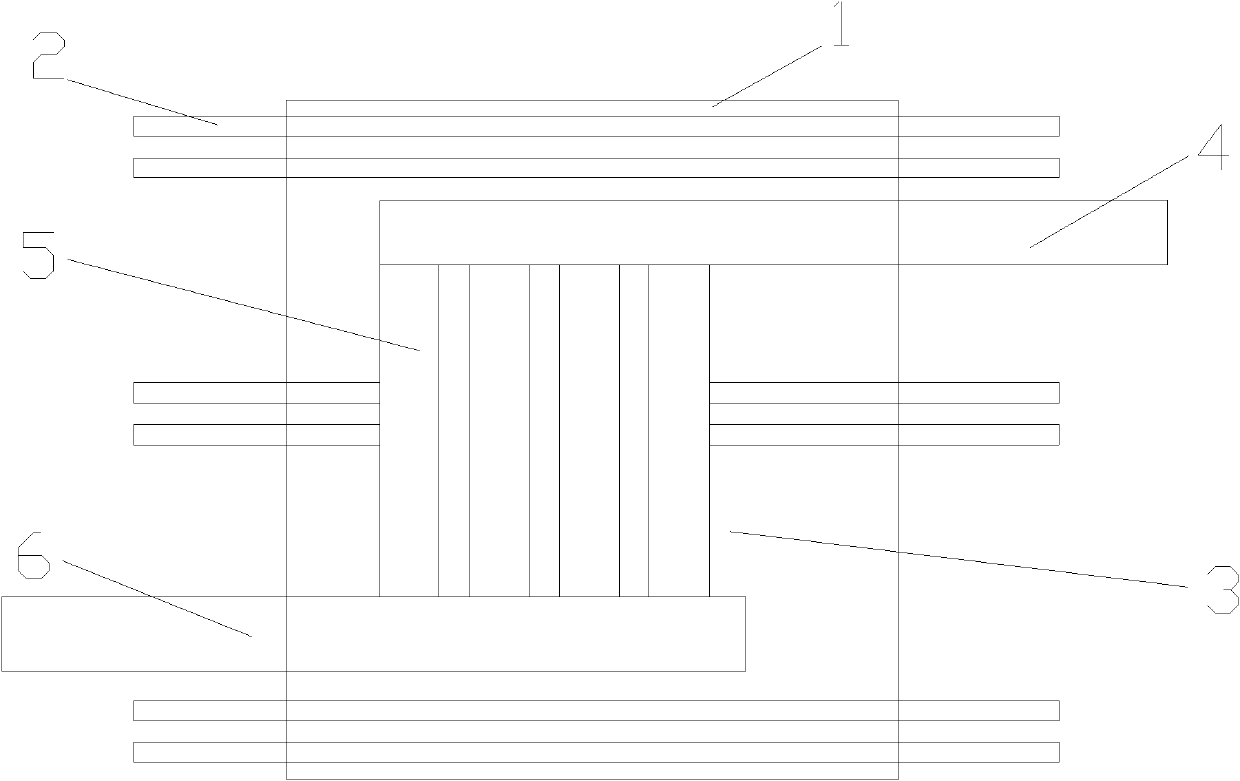

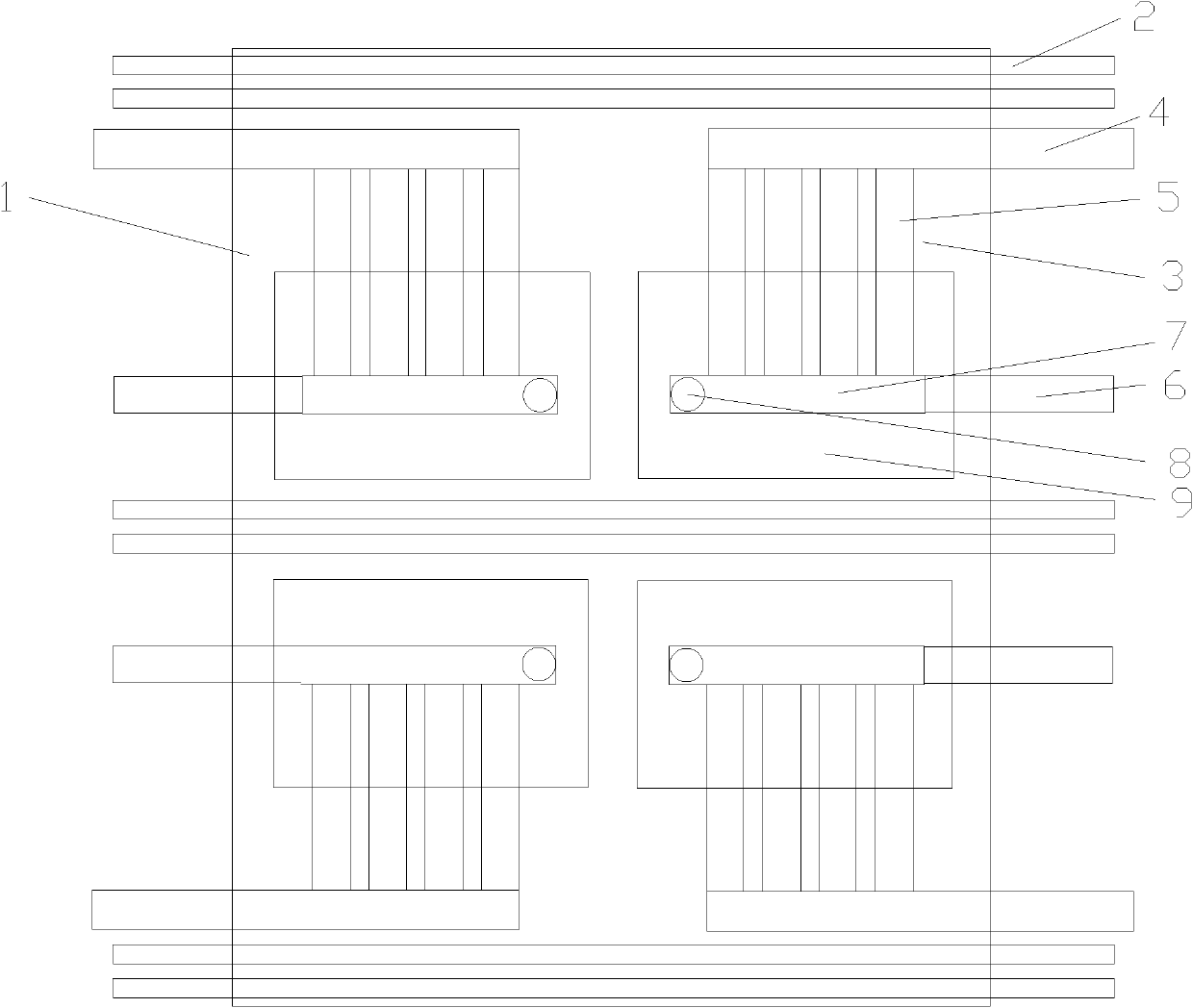

High-brightness non-melted mark steam injection mold and using method thereof

The invention discloses a high-brightness non-melted mark steam injection mold and a using method thereof. The high-brightness non-melted mark steam injection mold consists of an upper mold, a lower mold, a pouring system, a cooling water channel and an ejecting mechanism; the upper mold has an inlaying structure and consists of an upper mold inlaying plate, an upper-layer insert and a lower-layer insert, the upper-layer insert and the lower-layer insert are fixed in the upper mold inlaying plate, and the lower-layer insert is provided with a steam channel; the lower mold has an inlaying structure and comprises a lower mold inlaying plate and a lower mold insert, the lower-layer insert of the upper mold and the lower mold insert form a cavity, and the lower mold is internally provided with the cooling water channel; the pouring system is connected with the cavity by the upper mold inlaying plate, the upper-layer insert, the lower-layer insert and the lower mold insert; and the ejecting mechanism consists of an ejector rod, an ejector sleeve and a top plate. In the invention, a heat-insulating plate is arranged for heat insulation so as to deform the upper mold, improve the productquality and prolong the service life of the mold; the inlaying structure is adopted to effectively utilize the materials; and feeding is carried out from the inside of the product so as to have markson the surface after a sprue is removed, and ensure the outer surface quality of the product.

Owner:CIXI SHENGYI MOLD

Sharp cooling and sharp heating highlight forming die

The invention discloses a sharp cooling and sharp heating highlight forming die, belonging to the technical field of injection moulding. The invention comprises a cavity insert and is characterized in that the inside of the cavity insert is provided with a plurality of cooling water channels transversely and a steam line; the steam line contains a main gas inlet pipe, shunts and a main gas outletpipe; the main gas inlet pipe extends in the upper right of the cavity insert and extends to the middle part of the cavity insert; four shunts are connected on the main gas inlet pipe side by side and extend downwards; the tail parts of the four shunts are connected with the main gas outlet pipe; and the main gas outlet pipe is arranged transversely and extends out of the lower left of the cavityinsert. The invention solves the problem of the prior art that the injection moulding equipment can not realize the fast heating and fast cooling of the mould, thus the product has the appearance quality defects such as weld marks and flow marks, and provides the sharp cooling and sharp heating highlight forming die which has simple structure and can realize fast heating and fast cooling and achieve better injection moulding effect.

Owner:KUNSHAN ESON PRECISION ENGINEERING CO LTD

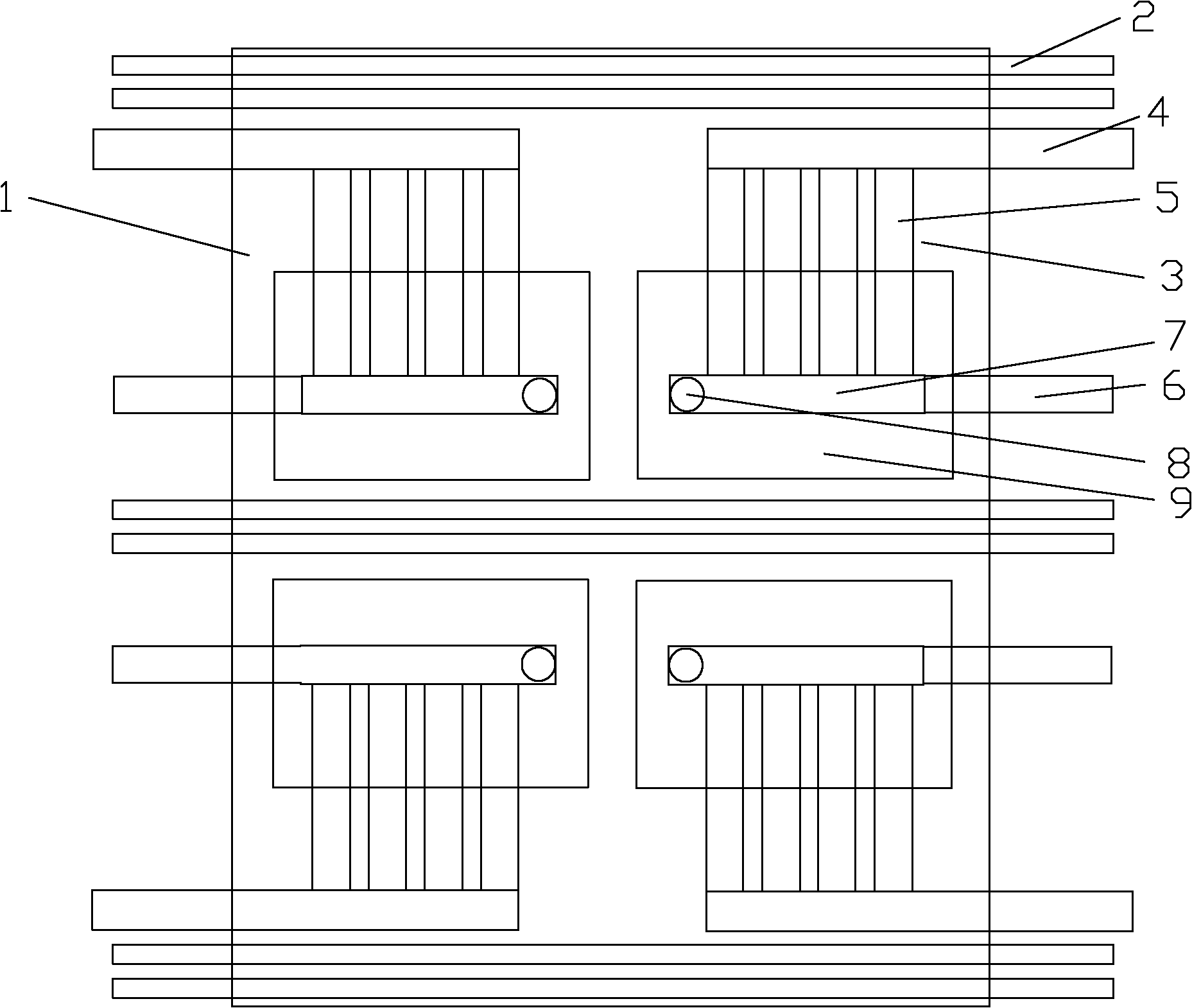

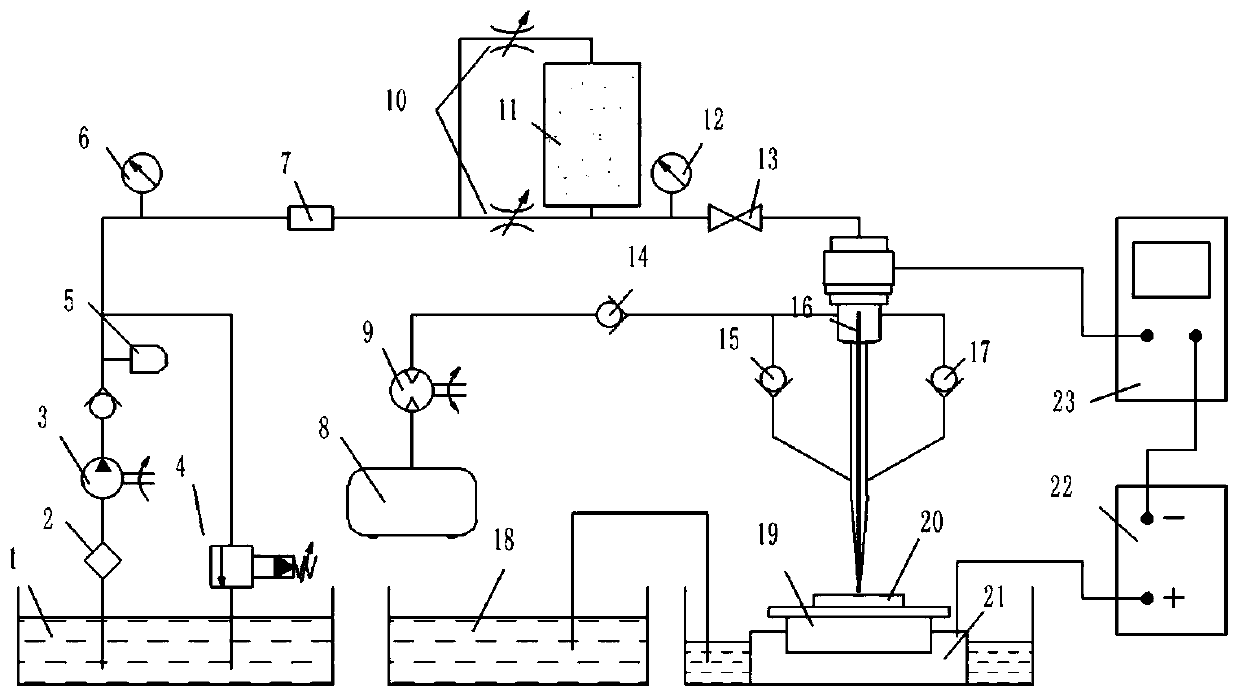

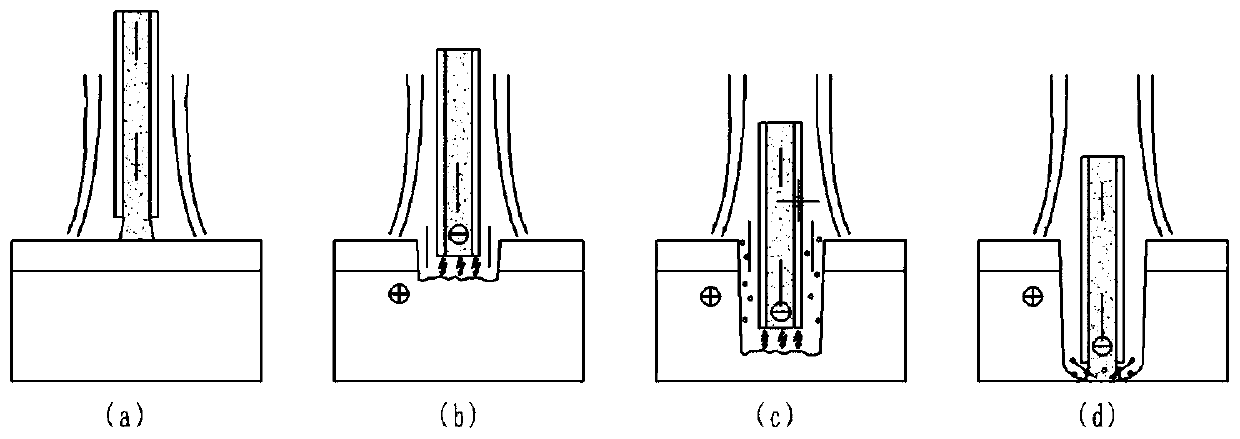

Electric spark-electrolysis combined machining device and machining method with micro abrasive inward spraying function

The invention discloses an electric spark-electrolysis combined machining device and machining method with a micro abrasive inward spraying function, and belongs to the field of micro-hole combined machining. The electric spark-electrolysis combined machining method with the micro abrasive inward spraying function is combined with abrasive grinding, electric spark corrosion and electrolytic corrosion, work liquid is sprayed out of a tube electrode with a certain pressure, the abrasive continuously impacts a workpiece, through the grinding effect, the surface insulation coating material is removed, after a metal matrix is exposed, the tube electrode is continuously fed, when the gap between the end face and the workpiece is smaller than the electric spark discharge gap, electric spark discharging appears in the end face and the workpiece under the high-pressure pulse effect, and high-speed punching is carried out; when the gap between the electrode side wall and the hole wall is largerthan the electric spark discharge gap, electrolysis corrosion removing is executed in the electrode side wall and the hole wall under the low-pressure pulse effect, the hole wall re-cast layer is removed, in the machining process, the abrasive is continuously supplied, machining efficiency is improved, small hole one-time rapid forming machining is achieved, operation is easy, and machining efficiency is high.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

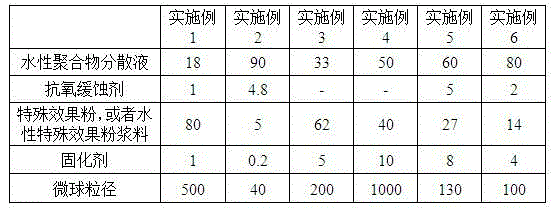

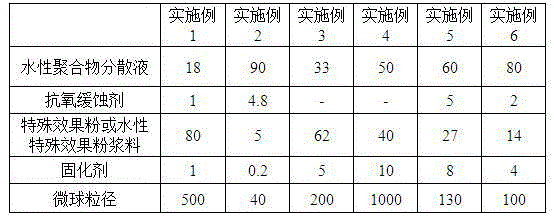

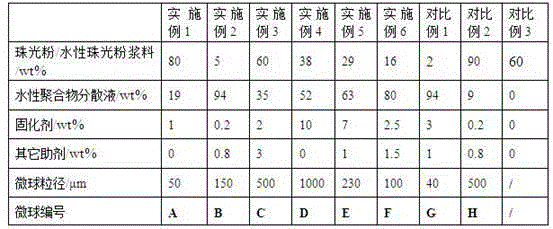

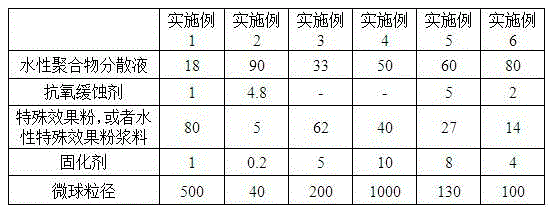

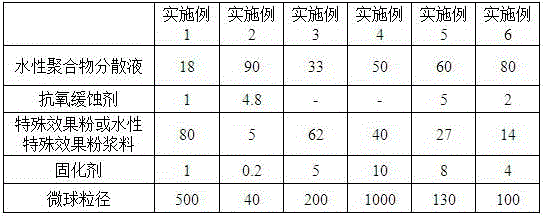

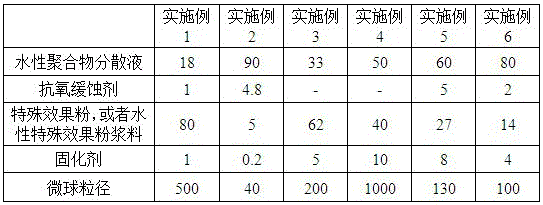

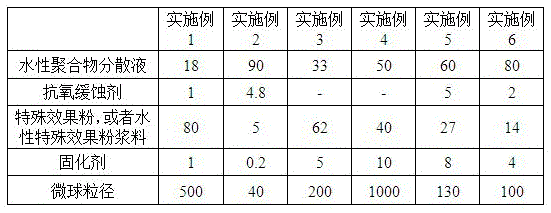

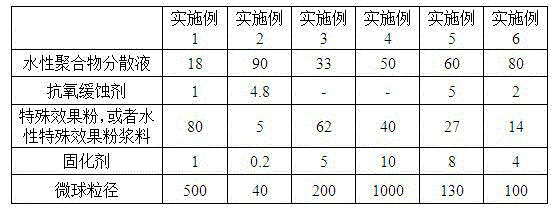

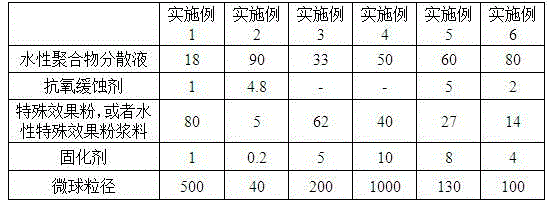

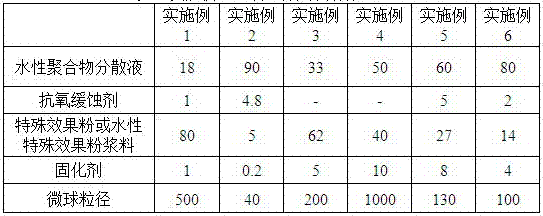

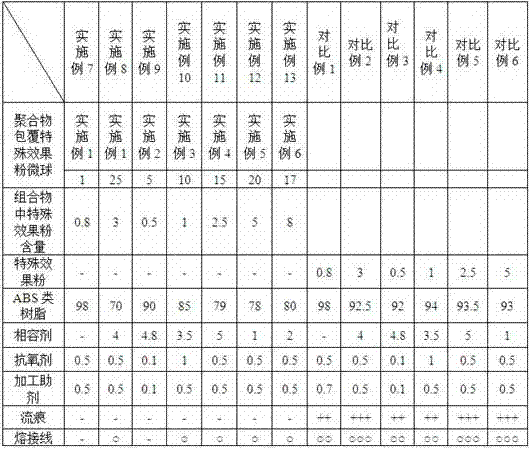

Pearl essence coated polymer microspheres and preparation method and application thereof

InactiveCN104629088AImprove shear resistanceGood compatibilityPigment treatment with macromolecular organic compoundsPolymer scienceMicrosphere

The invention discloses pearl essence coated polymer microspheres. The microspheres comprise the following components: 5-80wt% of pearl essence / aqueous pearl essence paste, 18-90 wt% of an aqueous polymer dispersion liquid and 0.2-10 wt% of a curing agent. A preparation method includes the steps of: a) slowly adding the pearl essence / aqueous pearl essence paste subjected to surface treatment into the aqueous polymer dispersion liquid at room temperature, stirring while adding the curing agent, and continuing stirring for 30-120 min to obtain a pearl essence coated polymer composite dispersion liquid; and b) conducting spray drying on the composite dispersion liquid, subjecting the pearl essence coated polymer droplets formed by spray to curing crosslinking reaction through the curing agent, so as to obtain the pearl essence coated polymer microspheres. The prepared pearl essence coated polymer microspheres can improve the compatibility between pearl essence and the matrix resin, improve the flow uniformity of pearl essence with a melt in an extrusion or injection molding process and, thereby eliminating flow mark on the surface of the product, and reduce the weld bond. Therefore, the invention can be used in the preparation of free-spraying materials.

Owner:KINGFA SCI & TECH CO LTD

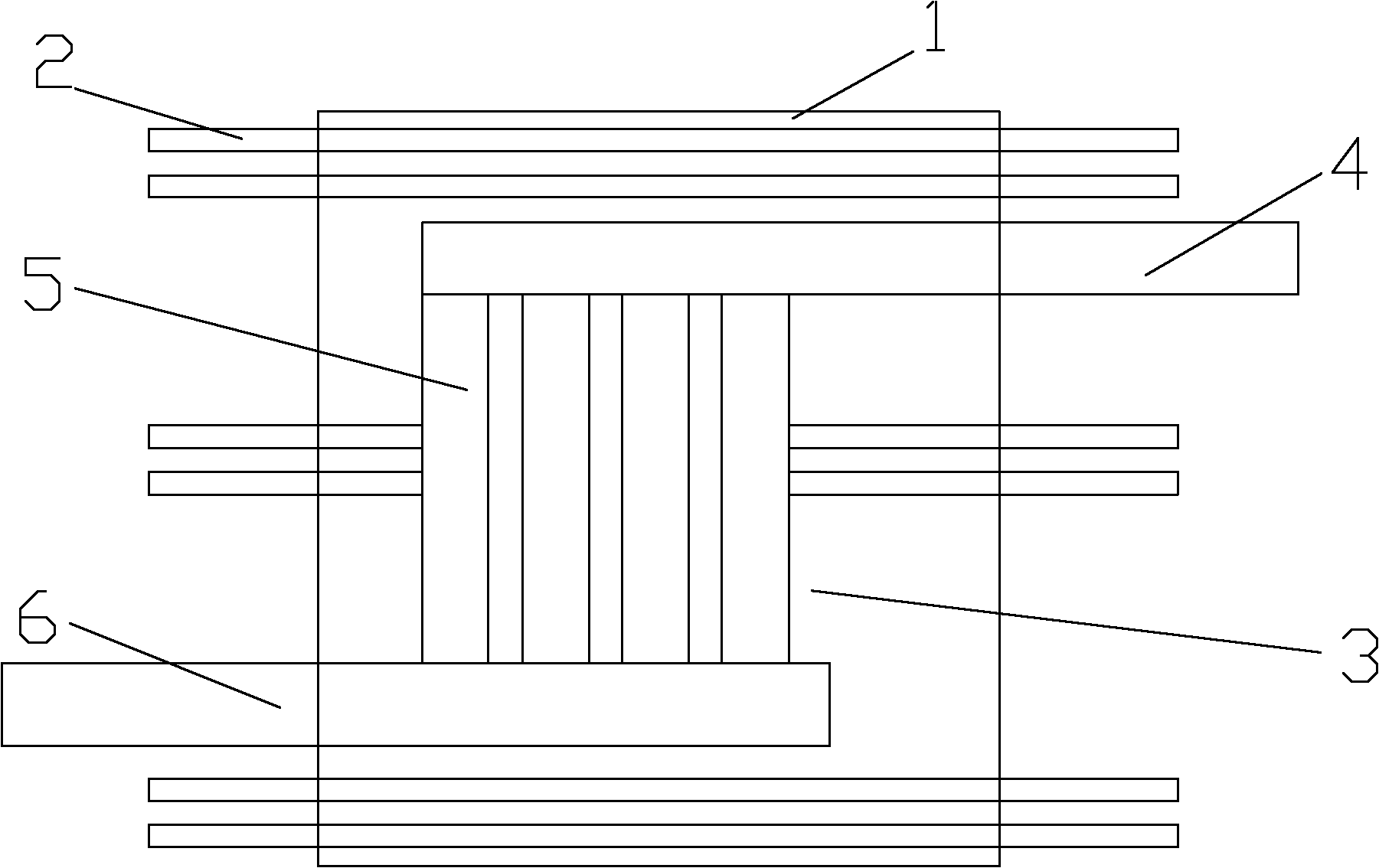

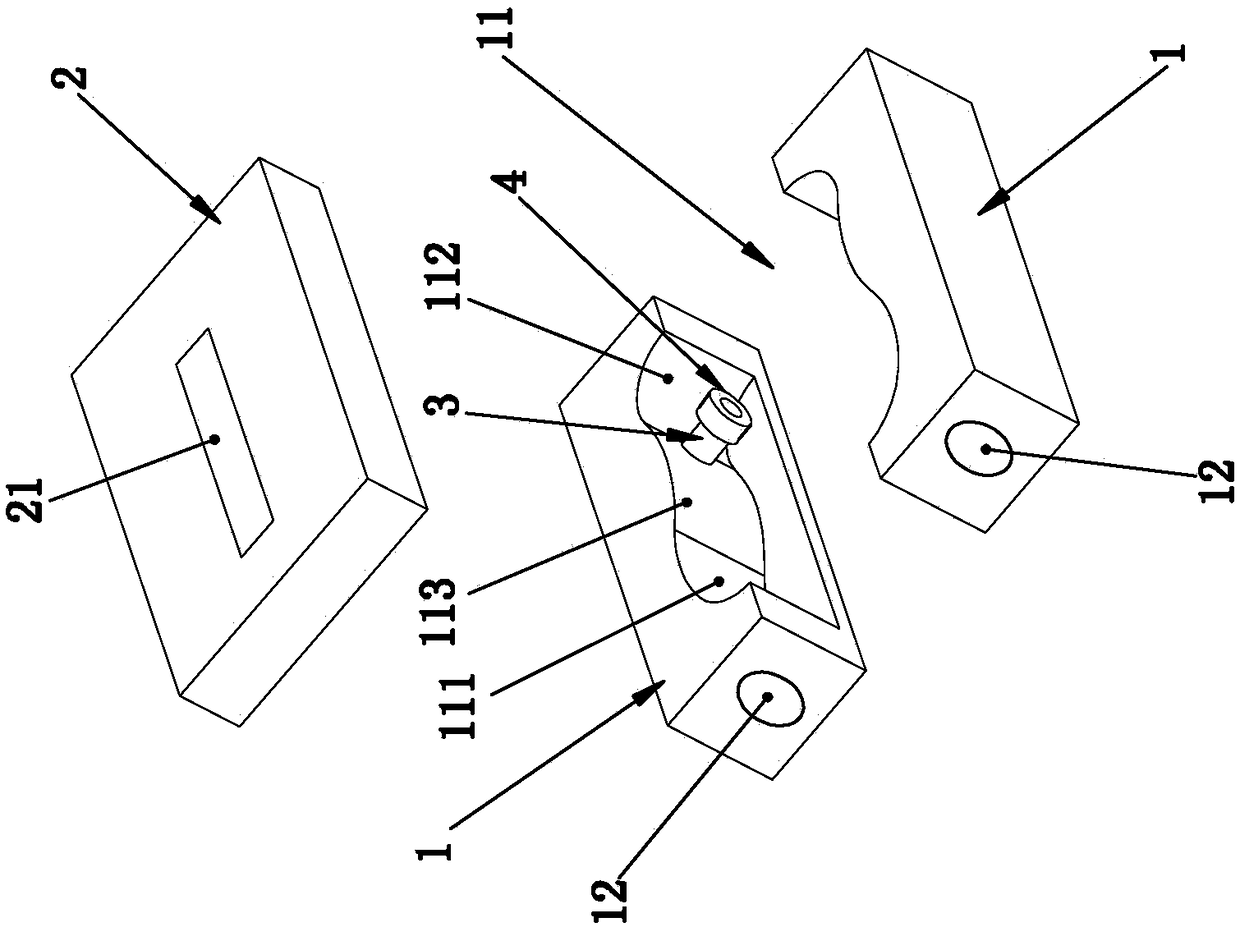

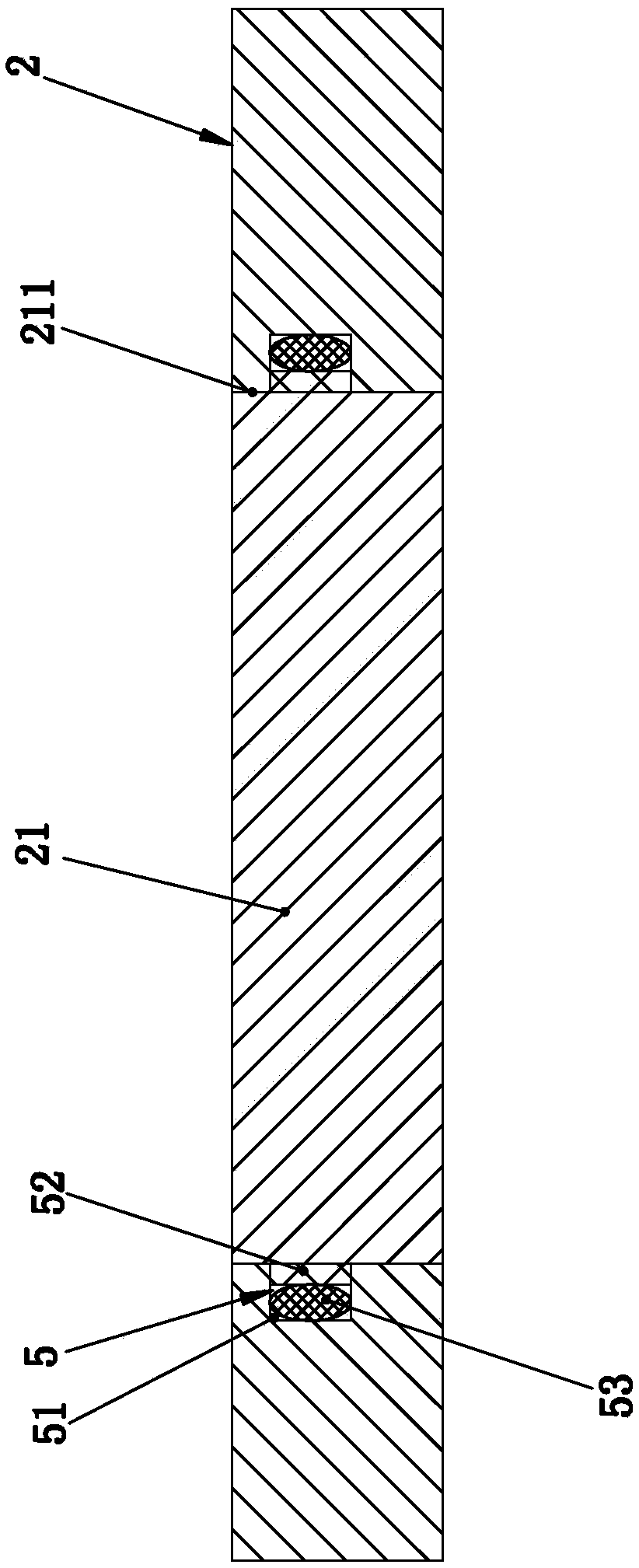

Flow mark-free processing mold and method for panel with polished surface

The invention relates to a panel with a polished surface, in particular to a flow mark-free processing mold and method for a panel with a polished surface. According to the technical scheme, the flowmark-free processing mold for the panel with the polished surface comprises an upper mold body and a lower mold body which can be combined with the upper mold body. A cavity for forming the panel is formed between the upper mold body and the lower mold body. A feeding port communicating with the cavity is formed in the upper mold body or the lower mold body. A heating channel which is provided with one end serving as an inlet end and the other end serving as an outlet end, isolated from the cavity and used for inputting heating media is formed in the upper mold body. The heating channel is located at the tail end of an insertion hole or a spiral hole formed in the panel after liquid materials enter the cavity via the feeding port. By adoption of the flow mark-free processing mold and method for the panel with the polished surface, surface flow marks are eliminated, the structure is simple, operation is convenient, and the surface aesthetic degree is guaranteed.

Owner:王朝翔

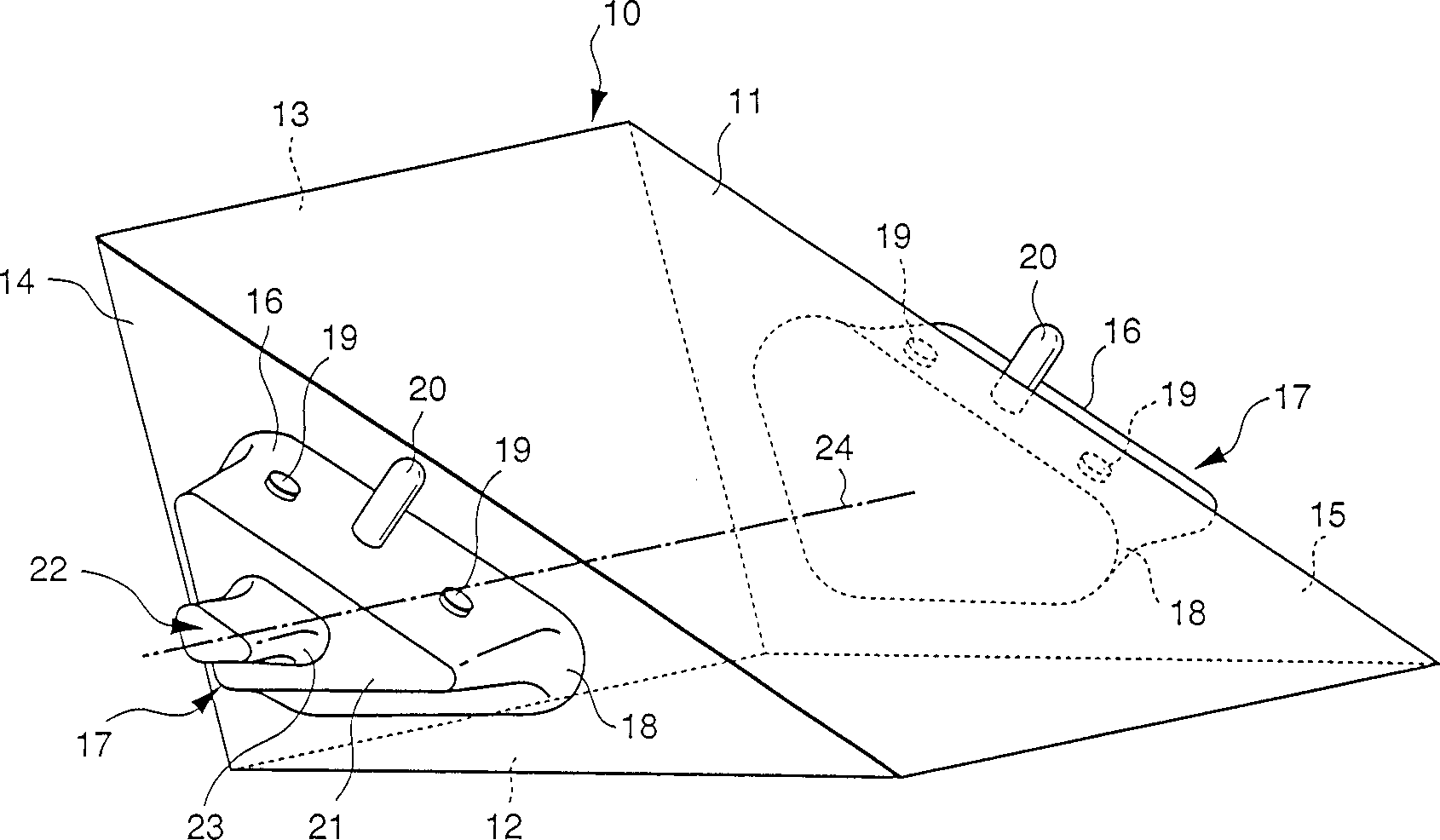

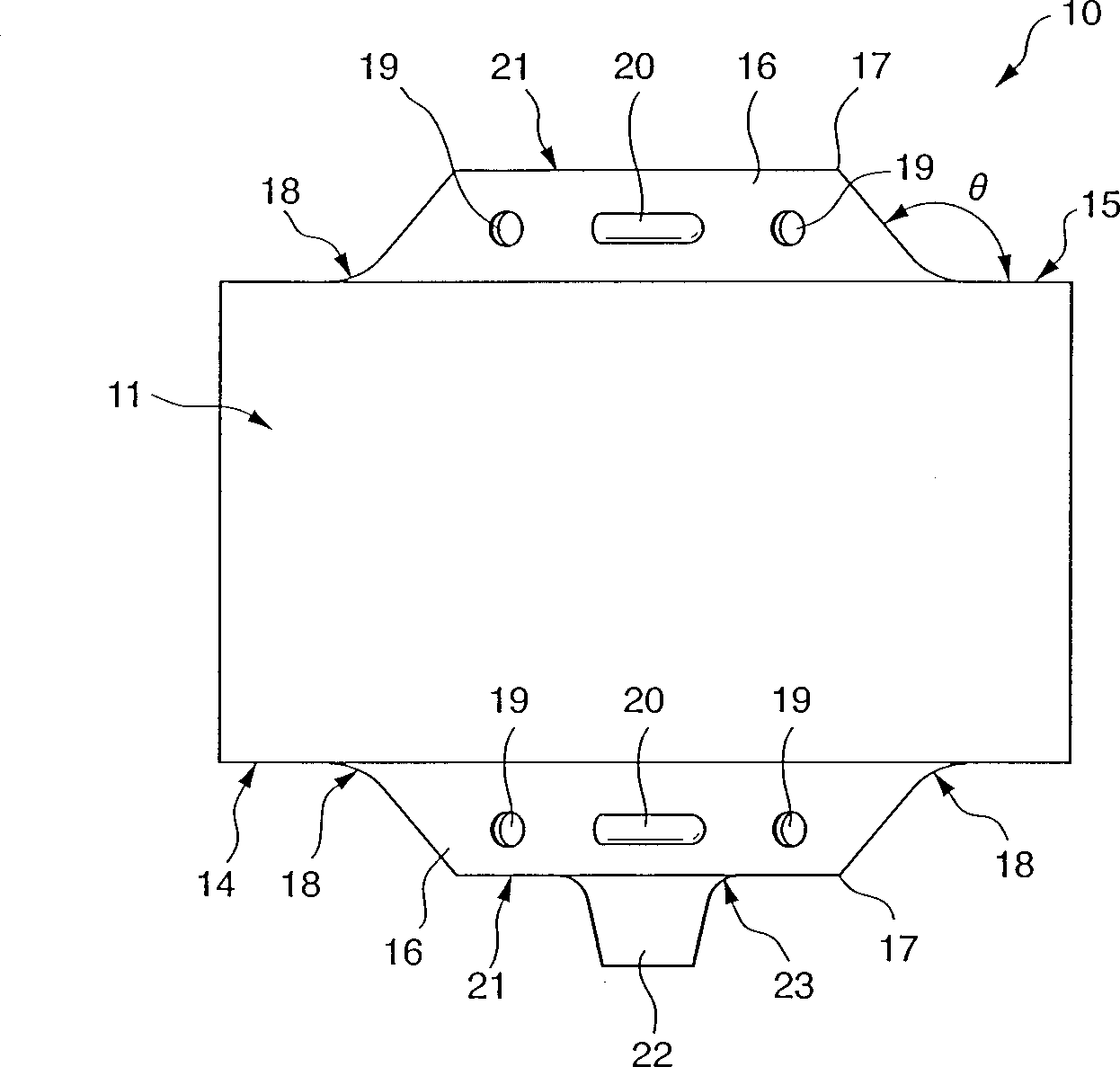

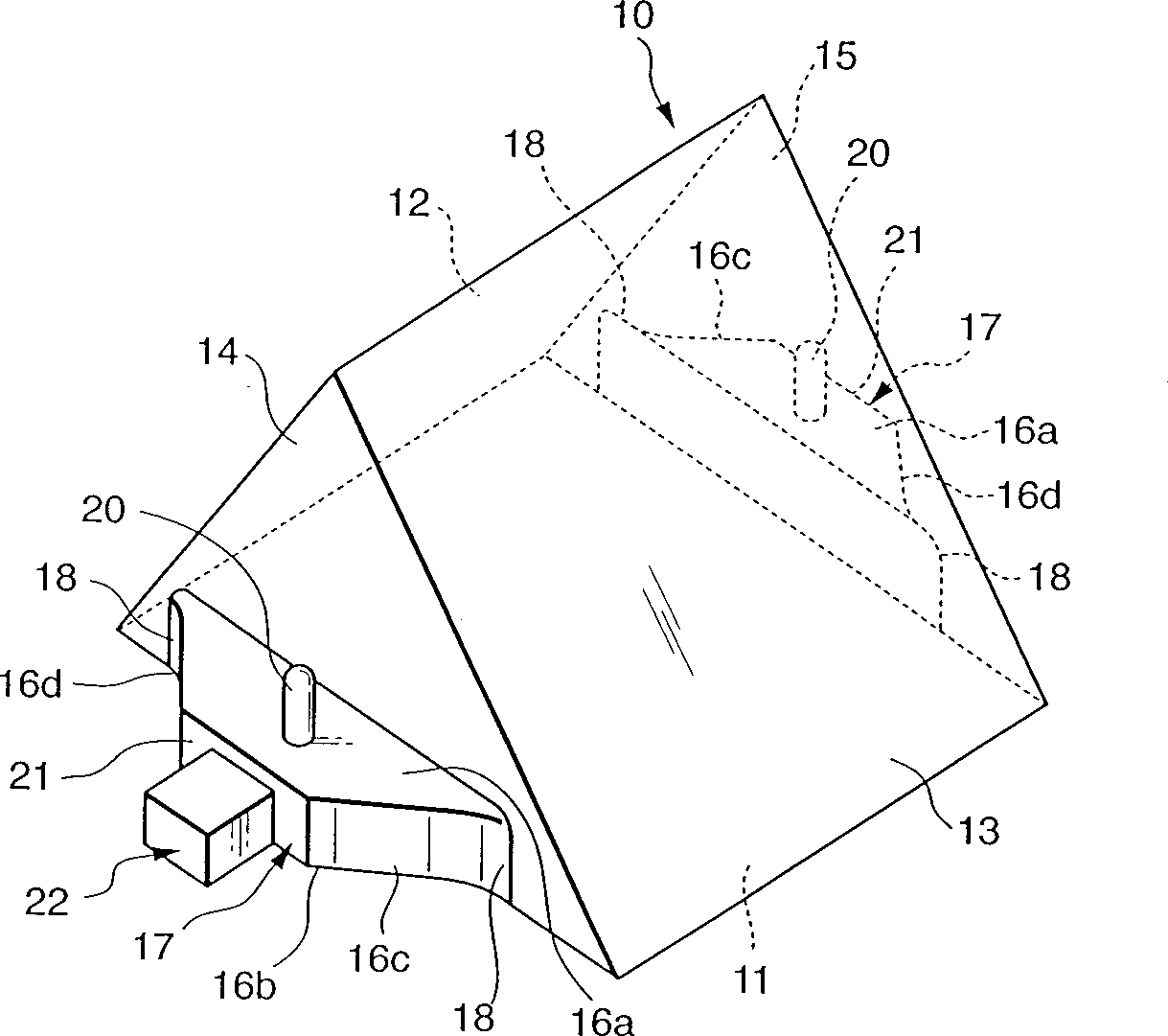

Resin molded prism and its mold

A flow mark or residual stress occurring in the vicinity of a gate adversely affects the optical characteristics of a resin prism which is to be formed by injection molding. Thus, the molding conditions for the resin prism are strict, and accordingly the resin prism has poor moldability. In view of this, according to this invention, the resin prism includes two or more optical surfaces (11-13) that are not parallel to each other, a pair of side end faces (14, 15) substantially perpendicular to the optical surfaces (11-13), at least one reference block (17) projecting from either one of the pair of side end faces (14, 15) and having a circumferential end face (16) extending in a projecting direction of the reference block, a positioning portion (19, 20) formed on the circumferential end face (16) of the reference block (17), and a curved surface (18) for smoothly connecting the circumferential end face (16) of the reference block (17) and corresponding one of the pair of side end faces (14, 15), wherein the circumferential end face (16) and the corresponding one of the side end faces (14, 15) form an angle of 90 DEG or more.

Owner:CANON KK

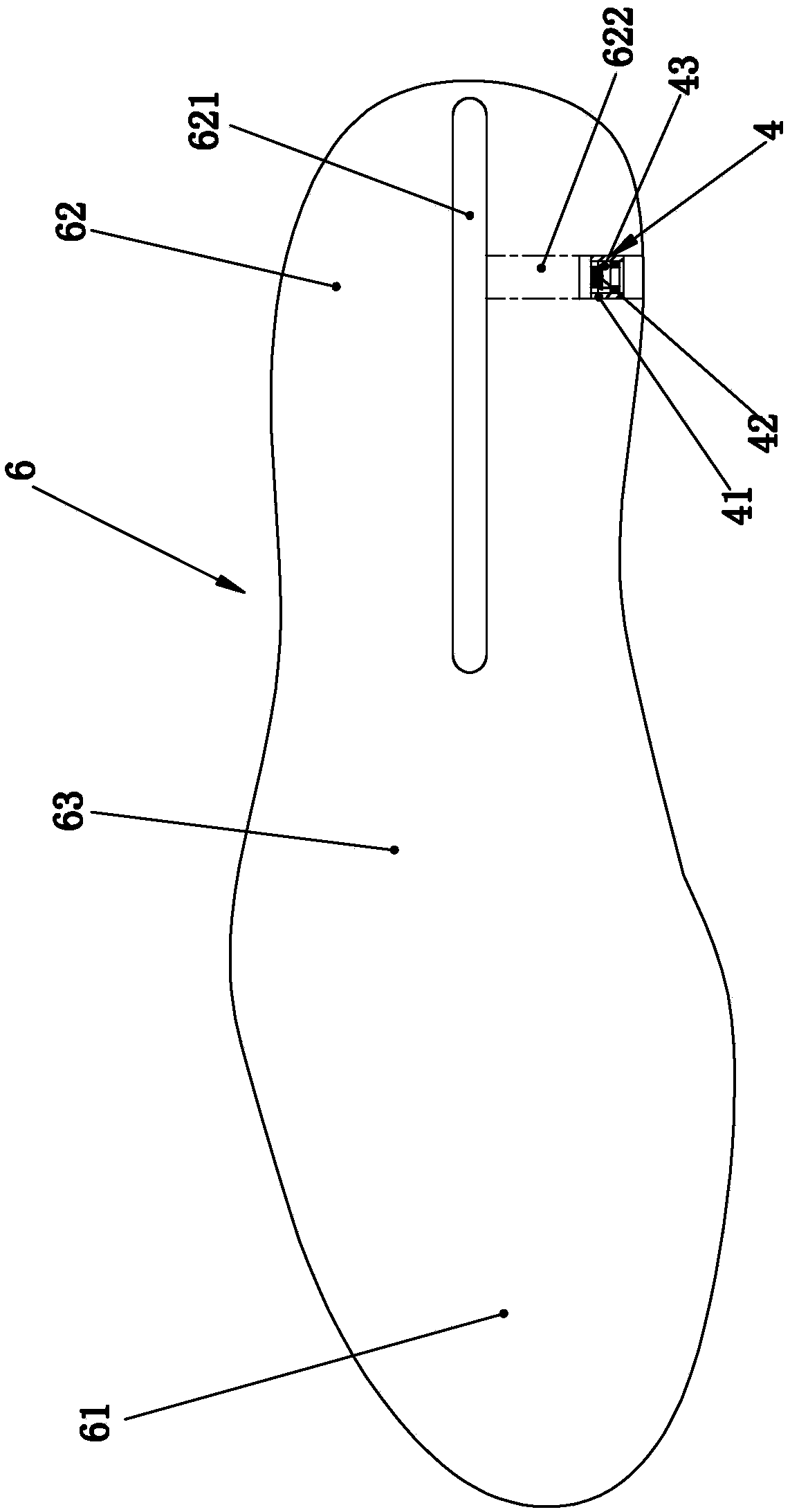

Shoe sole injection mold and shoe sole processed by adopting same

The invention relates to a shoe sole, in particular to a shoe sole injection mold and a shoe sole processed by adopting the same. According to the technical scheme, the shoe sole injection mold comprises two half-spliced combined or separated modules, a cavity for allowing the shoe sole to be formed is formed between the two modules, the top of the cavity is provided with a mold cover which can beseparated from or attached to the modules, and heating channels which are arranged in the longitudinal directions of the two modules are correspondingly formed in the two modules; and an exhaust channel injection molding block capable of reciprocating towards the cavity is arranged on the end face, facing the cavity, of the mold cover, the cavity comprises a shoe sole fore foot part, a shoe soleheel part and a shoe sole middle part, wherein a mounting hole positioning column which extends towards the transverse middle part of the cavity is arranged on any side, located at the shoe sole heelpart, of the cavity, and the other end of one end, which is linked relative to the cavity, of the mounting hole positioning column extends to the position corresponding to the exhaust channel injection molding block. By the adoption of the technical scheme, the shoe sole injection mold and the shoe sole processed by adopting the same have the advantages that the processing efficiency is improved,and the processing process is reduced.

Owner:瑞安市霹雳虎鞋业有限公司

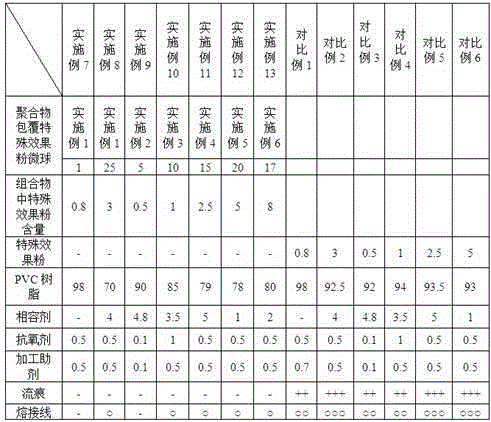

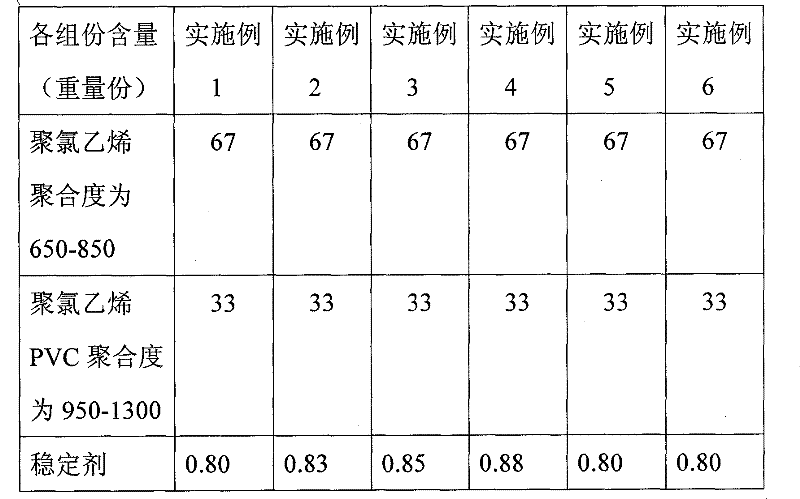

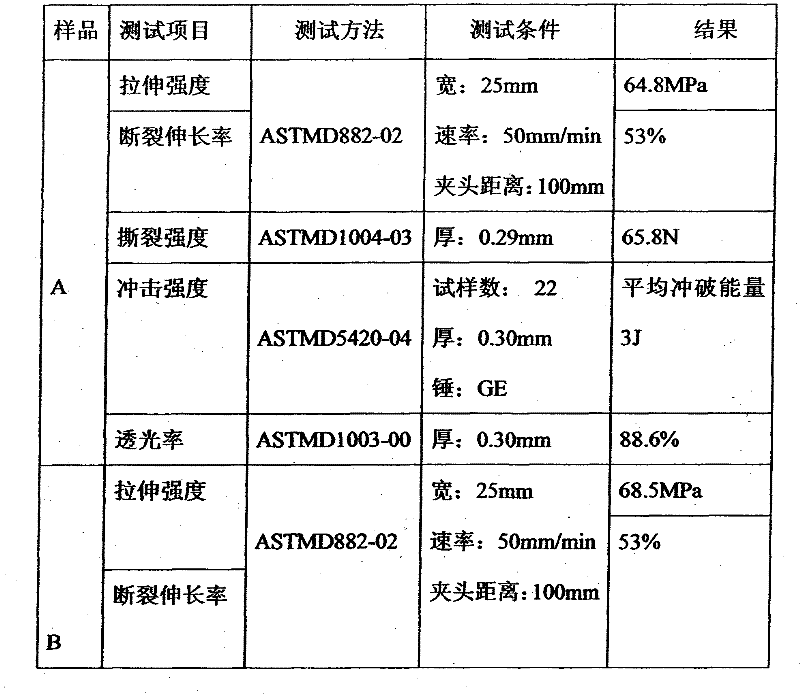

Spraying-free PVC composition having special aesthetic effects and preparation method and application thereof

The invention discloses a spraying-free PVC composition having special aesthetic effects and a preparation method and an application thereof. The spraying-free PVC composition comprises the following components: 70-98 wt% of PVC resin, 1-25 wt% of microspheres formed by coating a special-effect powder with a polymer, 0-10 wt% of a compatibilizer, 0.1-1 wt% of an antioxidant, and 0.1-0.5 wt% of a processing auxiliary agent. The special-effect powder is coated with a water-based polymer dispersion liquid to form the microspheres, and then the microspheres are dispersed to the PVC resin, so that the compatibility of the special-effect powder and the PVC resin can be significantly improved, flow marks formed on the surface of products in an extrusion or injection molding process are eliminated, and weld lines are reduced; and the prepared spraying-free PVC composition has relatively obvious metal texture, pearly flashing effects and other special aesthetic effects, and the market application range of spraying-free materials is greatly improved.

Owner:KINGFA SCI & TECH CO LTD

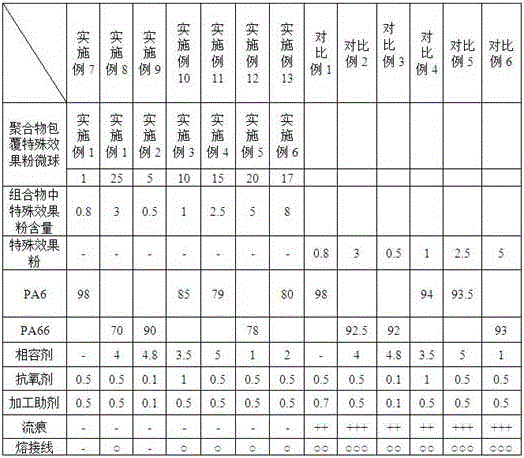

Spray-free nylon resin composition with special aesthetic effect and its preparation method and application

The invention discloses a spraying-free nylon resin composition with special aesthetic effect and a preparation method and application thereof. The composition comprises the following components: 70-98 wt% of nylon resin, 1-25 wt% of polymer coated powder microspheres with special effect, 0-10 wt% of a compatibilizer, 0.1-1 wt% of an antioxidant and 0.1-0.5 wt% of a processing aid. The powder with special effect coats with an aqueous polymer dispersion liquid to form microspheres which are then dispersed into nylon resin, so as to significantly improve the compatibility of the powder with special effect and nylon resin, and eliminate the flow mark formed on the surface of products in the extrusion or injection molding process and reduce the weld line. The prepared spraying-free nylon resin composition has aesthetic effects of obvious metal texture and pearly flashing, and greatly improves the scope of market application of spraying-free materials.

Owner:KINGFA SCI & TECH CO LTD

Injection molding process for multi-air-channel auxiliary plastic mold

The invention discloses a multi-air channel auxiliary plastic mold injection molding process, comprising the following steps: step (1) plastic mold design; step (2) mold precooling stage; step (3) melt injection stage; step (4) multiple Airway gas injection control stage; step (5) partial nitrogen filling stage; step (6) gas injection end stage; step (7) gas withdrawal stage. The invention eliminates the internal stress existing in the injection molded parts, so that the quality of the injection molded parts is high, and the production efficiency and yield of the mold are greatly improved.

Owner:滁州市博康模具塑料有限公司

Silica gel sponge material and preparation method thereof

The invention discloses a silica gel sponge material which comprises polyurethane sponge and a silica gel solution, and a functional auxiliary agent is added into the silica gel solution. The preparation method comprises the following steps: S1, designing the size and thickness of polyurethane sponge, the flowability of a silica gel solution and the proportion of a functional auxiliary agent according to product requirements; s2, according to design requirements, cutting the polyurethane sponge into sheets with corresponding thicknesses by using cutting equipment; s3, preparing a silica gel solution with corresponding flowability according to design requirements, and adding a functional auxiliary agent in a corresponding proportion into the silica gel solution; and S4, adding a silica gel solution on the polyurethane sponge sheet. According to the silica gel sponge material and the preparation method thereof, the silica gel solution is added on the polyurethane sponge, so that the polyurethane sponge has the effect of multiply increasing the tearing strength, meanwhile, the oxidation resistance and the high temperature resistance are improved, and the silica gel can also inhibit the generation of bacteria.

Owner:东莞市汇朋高分子科技有限公司

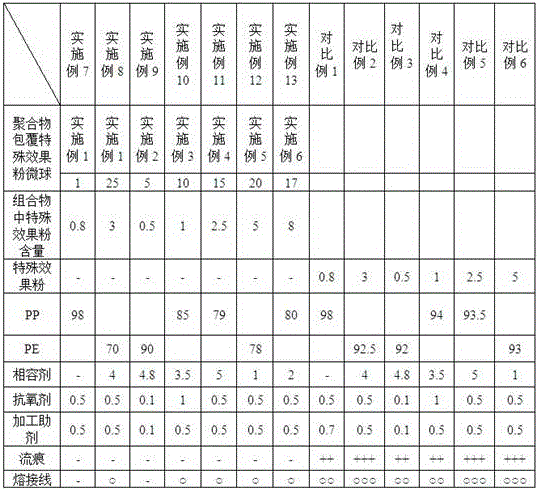

Spray-free polyolefin composition with special aesthetic effect and its preparation method and application

Owner:KINGFA SCI & TECH CO LTD

Spray-free PC composition with special aesthetic effect and its preparation method and application

The invention discloses a spray-free PC composition with special aesthetic effects and its preparation method and application, comprising the following components: PC 70-98wt%; polymer-coated special effect powder microspheres 1-25wt%; compatible Antioxidant 0-10wt%; Antioxidant 0.1-1wt%; Processing aid 0.1-0.5wt%; The present invention can be obviously Improve the compatibility of special effect powder and PC, eliminate the flow mark formed on the surface of the product during extrusion or injection molding, and reduce the weld line. The aesthetic effect greatly improves the market application range of spray-free materials.

Owner:KINGFA SCI & TECH CO LTD

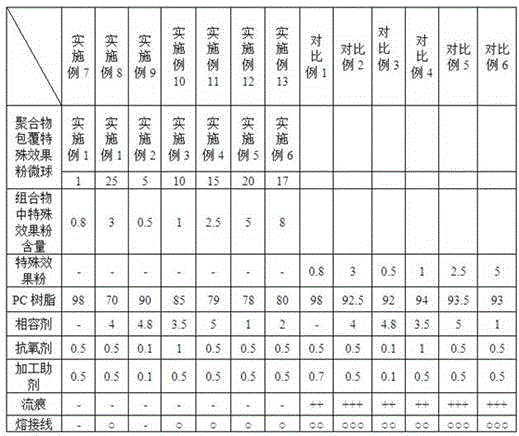

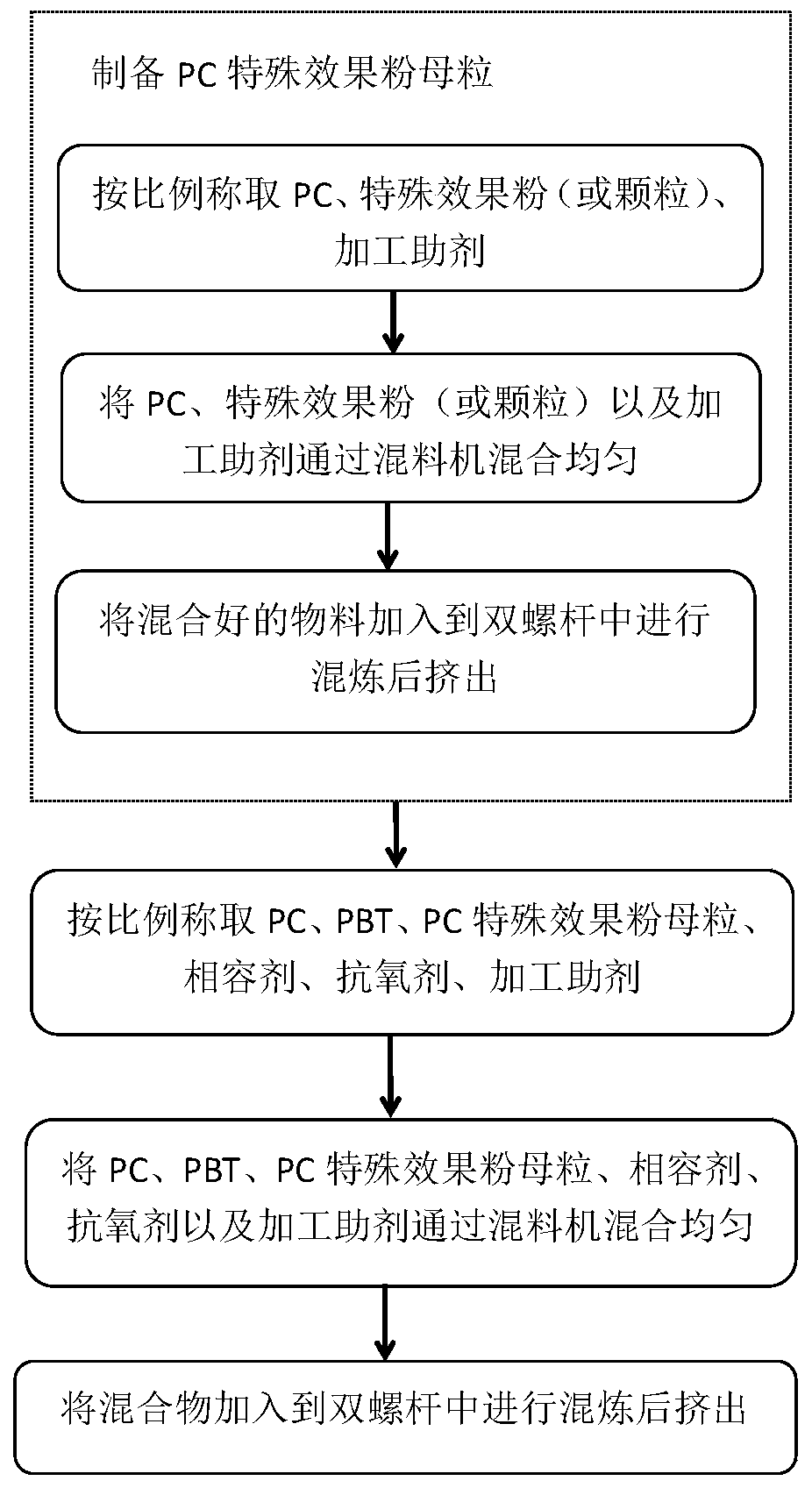

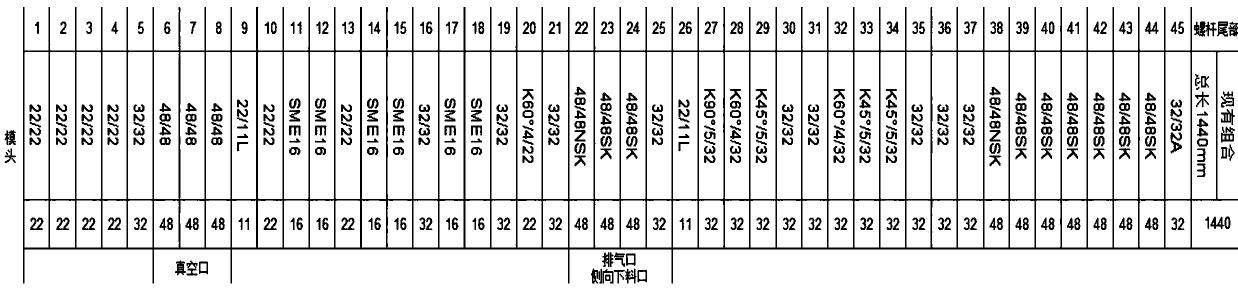

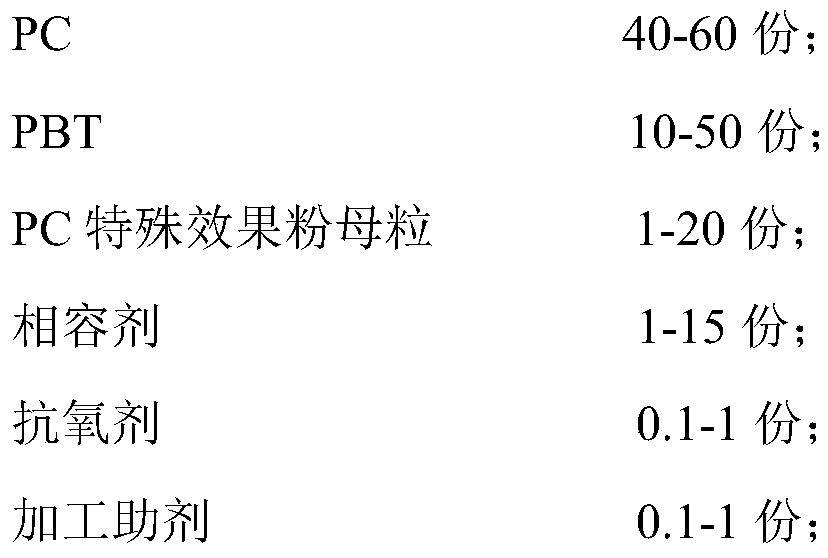

Spraying-free PC/PBT alloy material and preparation method thereof

The invention discloses a spraying-free PC / PBT alloy material and a preparation method thereof, and relates to the field of high polymer materials. The spraying-free PC / PBT alloy material comprises, by weight, 40 to 60 parts of PC; 10 to 50 parts of PBT; 1-20 parts of PC special effect powder masterbatch; 1-15 parts of a compatilizer; 0.1 to 1 part of an antioxidant; and 0.1 to 1 part of a processing aid; wherein the PC special effect powder masterbatch comprises, by weight, 18 to 90 parts of PC, 5-80 parts of special effect powder or particles and 0.1-1 part of a processing aid. According tothe PC / PBT alloy material, the masterbatch is prepared from the special effect powder or particles through PC and then dispersed into the PC / PBT alloy material, the compatibility of the special effectpowder and matrix resin can be obviously improved, the dispersity of the special effect powder or particles is improved, and therefore flow marks and fisheyes on the surface of a product are eliminated, and weld lines are reduced; in addition, PC and PBT are used as alloy materials, so that the thermal deformation temperature of the material is effectively increased, and the market application range of the spraying-free material is greatly widened.

Owner:JIANGSU BOILN PLASTICS CO LTD

Sharp quenching and sharp heating highlight molding technology of die

The invention discloses a sharp quenching and sharp heating highlight molding technology of a die, belonging to the field of injection molding technology. The technology comprises the following steps: 1. sharp heating control stage of die temperature; 2. plastic injection step; 3. sharp quenching step of die temperature; and 4. die sinking step. The invention solves the appearance quality problems that the produced products have conjugation lines, flow liners, indenture and the like because the injection molding technology in the prior art can not realize the purposes of sharp quenching and sharp heating of the die. The invention provides a sharp quenching and sharp heating highlight molding technology of dies, the quick switch of die temperature reaches the temperature requirement suitable for different stages in the injection molding process, the conjugation lines on the surface of the plastic product can be effectively reduced, the surface of a product containing glass fibre does not generate floated fiber, the product texture with a texture surface is clear, and the gloss of the product surface of the highlight-surface product can be improved.

Owner:KUNSHAN ESON PRECISION ENGINEERING CO LTD

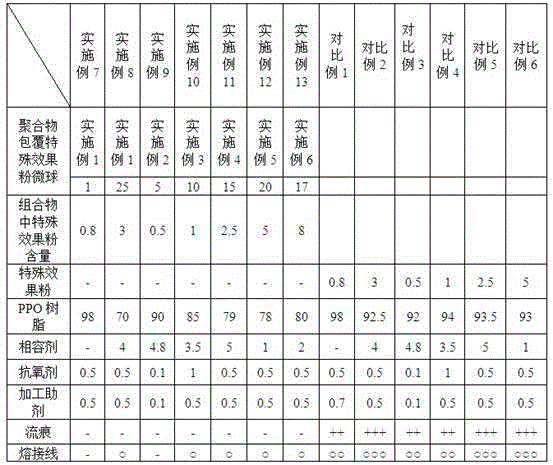

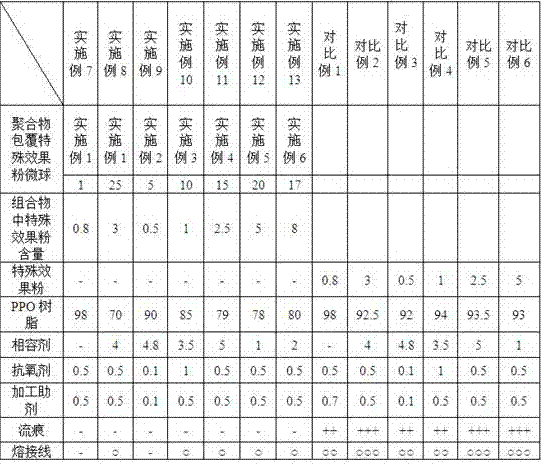

Spraying-free PPO resin composition having special aesthetic effects and preparation method and application thereof

The invention discloses a spraying-free PPO resin composition having special aesthetic effects and a preparation method and an application thereof. The spraying-free PPO resin composition comprises the following components: 70-98 wt% of PPO resin, 1-25 wt% of microspheres formed by coating a special-effect powder with a polymer, 0-10 wt% of a compatibilizer, 0.1-1 wt% of an antioxidant, and 0.1-0.5 wt% of a processing auxiliary agent. The special-effect powder is coated with a water-based polymer dispersion liquid to form the microspheres, and then the microspheres are dispersed to the PPO resin, so that the compatibility of the special-effect powder and the PPO resin can be significantly improved, flow marks formed on the surface of products in an extrusion or injection molding process are eliminated, and weld lines are reduced; and the prepared spraying-free PPO resin composition has relatively obvious metal texture, pearly flashing effects and other special aesthetic effects, and the market application range of spraying-free materials is greatly improved.

Owner:KINGFA SCI & TECH CO LTD

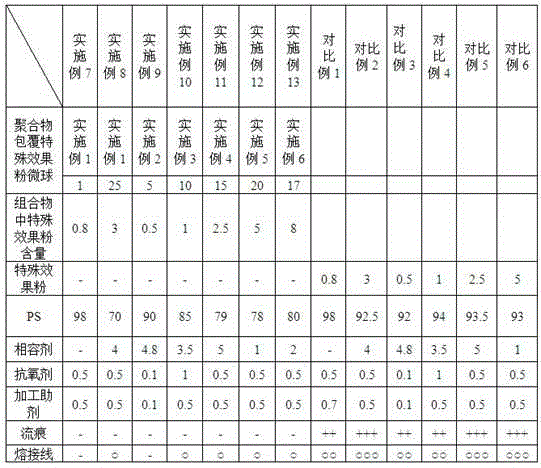

Spraying-free PS composition having special aesthetic effects and preparation method and application thereof

The invention discloses a spraying-free PS composition having special aesthetic effects and a preparation method and an application thereof. The spraying-free PS composition comprises the following components: 70-98 wt% of PS resin, 1-25 wt% of microspheres formed by coating a special-effect powder with a polymer, 0-10 wt% of a compatibilizer, 0.1-1 wt% of an antioxidant, and 0.1-0.5 wt% of a processing auxiliary agent. The special-effect powder is coated with a water-based polymer dispersion liquid to form the microspheres, and then the microspheres are dispersed to the PS resin, so that the compatibility of the special-effect powder and the PS resin can be significantly improved, flow marks formed on the surface of products in an extrusion or injection molding process are eliminated, and weld lines are reduced; and the prepared spraying-free PS composition has relatively obvious metal texture, pearly flashing effects and other special aesthetic effects, and the market application range of spraying-free materials is greatly improved.

Owner:TIANJIN KINGFA NEW MATERIAL

Formula for ABS injection product

The invention provides a formula for an ABS injection product. The formula comprises 50 to 70 parts of EVA, 10 to 20 parts of a pigment, 1 to 2 parts of PPA, 0 to 1 part of a hyperdispersant, 0 to 1.5 parts of an antioxidant, 8 to 10 parts of polyethylene wax, 1 to 2 parts of a titanate coupling agent and 0.5 to 1 part of white oil. According to the invention, the proportion of PPA in masterbatch is adjusted, so die buildup can be effectively reduced, quality problems like silk wires, streaks and flow marks are overcome, surface defects of products are removed, defects on shark skin and other products are eliminated, and the impact strength of products is improved.

Owner:无锡优谛幻彩色母有限公司

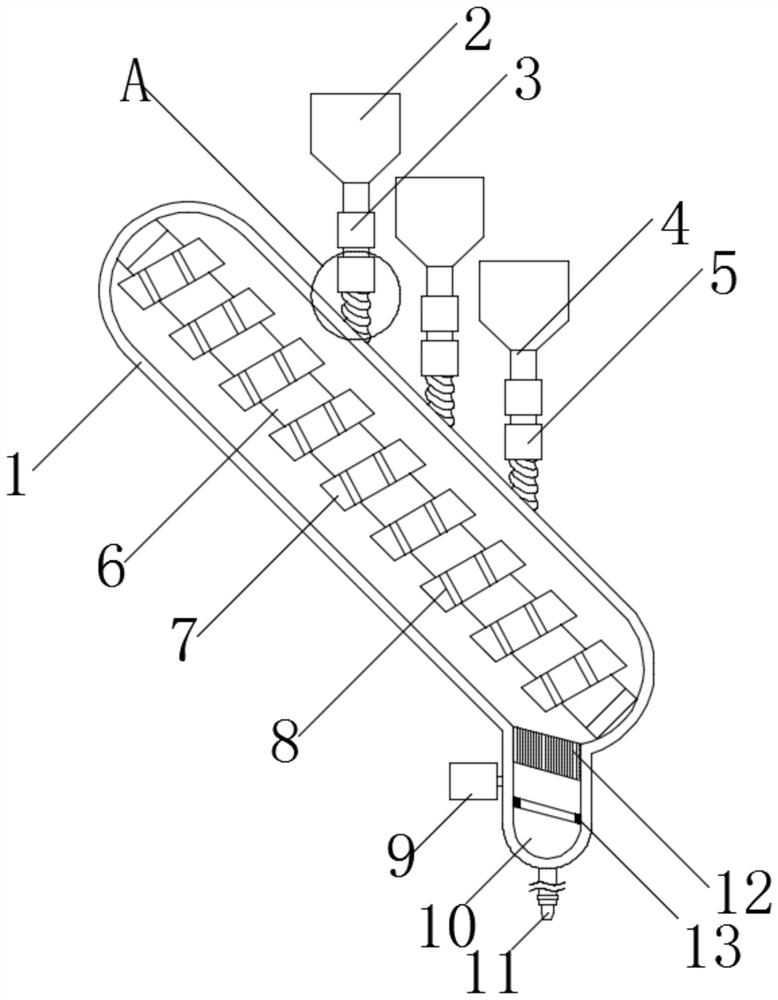

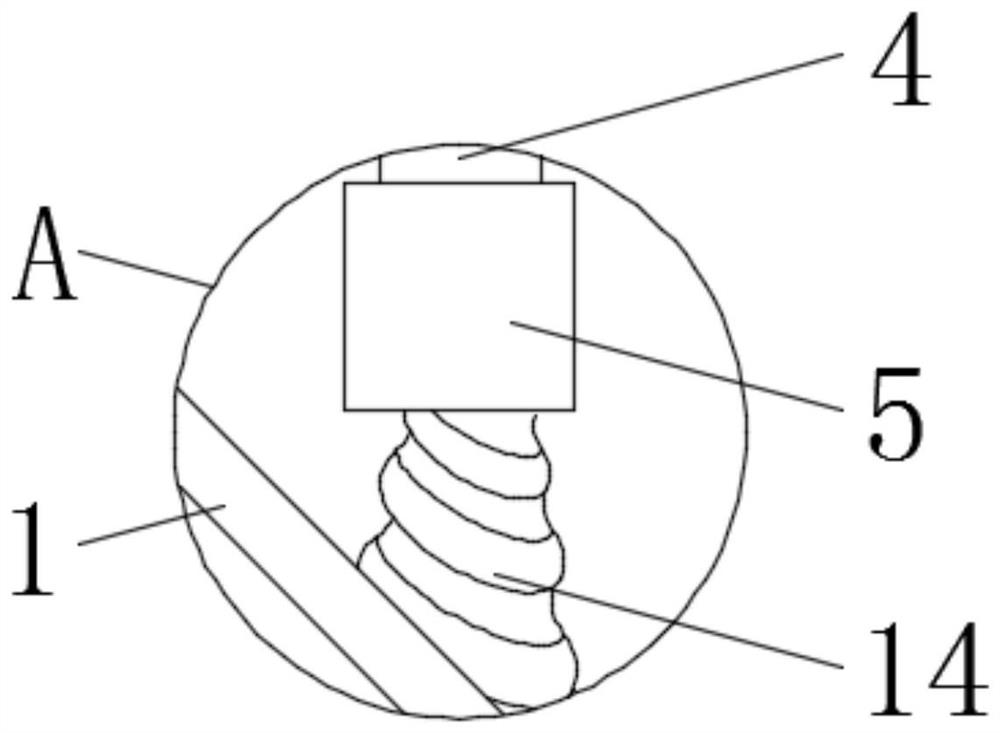

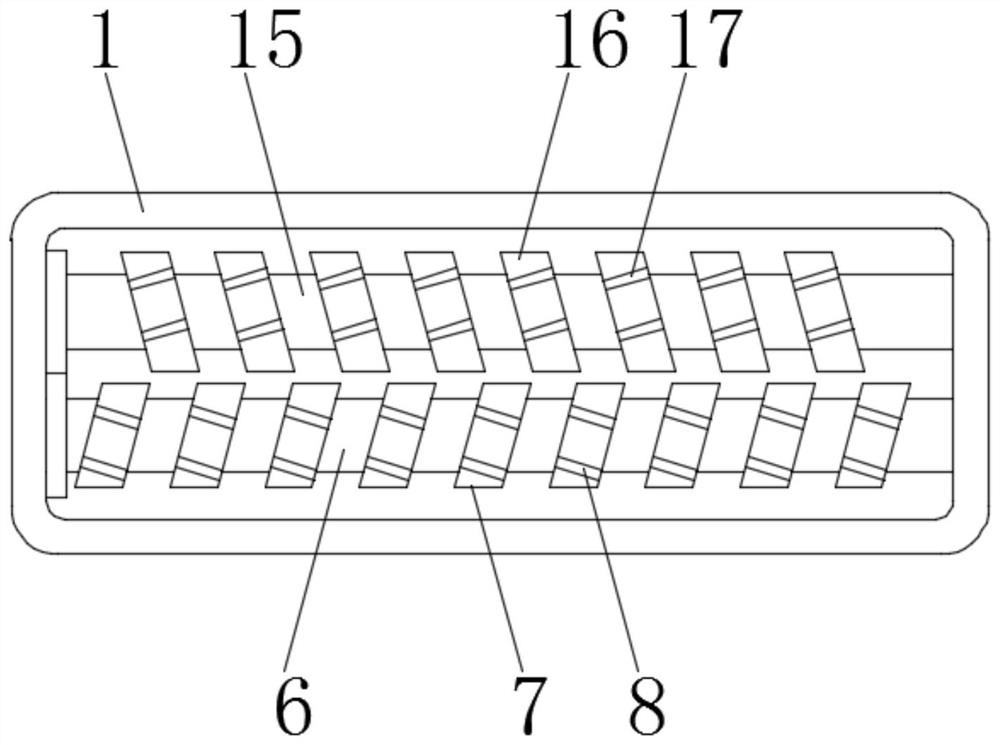

A polyurethane foam machine

The invention discloses a polyurethane foaming machine, which comprises a casing, a silo and a driving shaft. A silo is arranged above the casing, and the number of silos is multiple groups. The bottom of the silo is connected with a feed pipe. , the bottom of the feed pipe is communicated with a first pressure pump. According to the density of different raw materials, the present invention can place high-density raw materials in high-position bins through the connection of multiple sets of silos and shells. When raw materials are mixed in an inclined shell, gravity factors can be avoided to cause higher densities. Large raw materials are concentrated under the inner cavity of the shell to prevent uneven mixing of raw materials. At the same time, the inclined shell makes it neither the same nor tangent to the incoming direction of raw materials, which increases the degree of confusion when raw materials enter the shell. The gap between the driving shaft and the driven shaft is large, and the blades have grooves, which increases the throughput of raw materials, improves the distribution and mixing effect of raw materials in the shell, and is beneficial to the mixing of raw materials in the foaming machine. It is suitable for a wide range of promotion and use.

Owner:WENZHOU FEILONG POLYURETHANE ENG

Steam type highlight and traceless injection-molding and forming process for complex precise product

The invention discloses a steam type highlight and traceless injection-molding and forming process for a complex precise product. The process sequentially comprises the following steps of: selecting raw materials, baking, pre-heating, combining a die, then quickly heating, adjusting speed and pressure, injecting in sections, maintaining the pressure, cooling quickly, blowing out cold air, opening the die and cleaning the die. An advanced pressure-regulation and speed-regulation staging injection process and an automatic blowing and impurity-removing technology are adopted in the invention. A special heating and cooling technology is that the shapes, the widths and the arrangement density of water passages are designed according to nonuniform heat and cold of the complex precise product in the injection-molding and forming course and the overall shape variation of the product. The steam type highlight and traceless injection-molding and forming process for the complex precise product has the advantages that the residual stress of the product is effectively decreased, various defects generated in the course of producing the plastic product are greatly reduced, the surface quality and the precision of the product are remarkably improved, and the life of the product is remarkably prolonged at the same time because the special process ensures heating and cooling rates of each part of the complex product in the injection-molding and forming course tend to be consistent.

Owner:海门市创豪工业设计有限公司

Sharp cooling and sharp heating highlight forming die

Owner:KUNSHAN ESON PRECISION ENGINEERING CO LTD

Spray-free ABS composition with special aesthetic effect, preparation method and application thereof

The invention discloses a spray-free ABS composition with special aesthetic effects and its preparation method and application, comprising the following components: ABS resin 70-98wt%; polymer-coated special effect powder microspheres 1-25wt%; Compatibilizer 0-10wt%; Antioxidant 0.1-1wt%; Processing aid 0.1-0.5wt%; The present invention disperses the special effect powder into microspheres with water-based polymer dispersion and then disperses them into ABS resin Among them, it can significantly improve the compatibility of special effect powder and ABS resin, eliminate the flow mark formed on the surface of the product during extrusion or injection molding, and reduce the weld line. The prepared spray-free ABS composition has a more obvious metallic texture Special aesthetic effects such as , pearlescent flashing, etc., have greatly improved the market application range of spray-free materials.

Owner:TIANJIN KINGFA NEW MATERIAL

Spray-free PPO resin composition with special aesthetic effect and its preparation method and application

The invention discloses a spraying-free PPO resin composition having special aesthetic effects and a preparation method and an application thereof. The spraying-free PPO resin composition comprises the following components: 70-98 wt% of PPO resin, 1-25 wt% of microspheres formed by coating a special-effect powder with a polymer, 0-10 wt% of a compatibilizer, 0.1-1 wt% of an antioxidant, and 0.1-0.5 wt% of a processing auxiliary agent. The special-effect powder is coated with a water-based polymer dispersion liquid to form the microspheres, and then the microspheres are dispersed to the PPO resin, so that the compatibility of the special-effect powder and the PPO resin can be significantly improved, flow marks formed on the surface of products in an extrusion or injection molding process are eliminated, and weld lines are reduced; and the prepared spraying-free PPO resin composition has relatively obvious metal texture, pearly flashing effects and other special aesthetic effects, and the market application range of spraying-free materials is greatly improved.

Owner:KINGFA SCI & TECH CO LTD

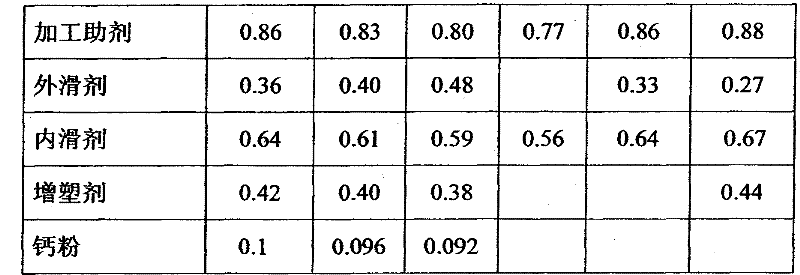

Polyvinyl chloride composition for producing sheet material by rolling process

The invention discloses a PVC compound which produces 0.03mm to 1.5mm hard piece and semi-hard piece sheets through a rolling method. The compound is characterized in that good toughness effect is achieved through the combination of PVC with different polymerization degree without impact modifier, and largely saves cost; the elasticity and physical property of the obtained PVCD compound are equalto that got by using the impact modifier, the granulation and flow mark are basically removed, and the light transmittance is better; therefore, the compound is applicable to relevant industries, such as shrinked plastics, blow molding, printing, gluing, etc.

Owner:陈小朋

Surface active agent for workpiece, preparation method and spraying pretreatment method for workpiece surface

ActiveCN108424713BIncrease hydrophilic compatibilityExcellent hydrophilic compatibilityAntifouling/underwater paintsPretreated surfacesPretreatment methodActive agent

The invention relates to a surfactant used for workpieces, a preparation method thereof, and a workpiece surface spraying type pre-treatment method. The surfactant comprises deionized water, an interface complexing agent, a composite low-foam surfactant, an antistatic agent, a water film spreading agent, and an adhesion promoter at a mass ratio of 60-80:0-10:5-15:1-15:1-10:0.5-5. The antistatic agent is one or a composition of a plurality of ingredients selected from ethoxylated amines, ionic quaternary ammonium salts, tertiary amines, and carboxylates; the water film spreading agent is one ora composition of a plurality of ingredients selected from condensation products of alcohol ethers with ethylene oxide, fluorine containing surfactants, and carbon hydrogen surfactants. The surfactantcan be used for spraying at normal temperature, is capable of eliminating water stains and flow stains on the surfaces of workpieces, increasing the adhesion force of workpieces with paint. The preparation method and the workpiece surface spraying type pre-treatment method are simple in operation, and are suitable for large batch production.

Owner:佛山科富科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com