Spraying-free ABS composition with special aesthetic effect, preparation method and applications thereof

A special effect powder, spray-free technology, applied in the field of polymer materials, can solve the problems of uneven distribution of special effect powder, unstable flow rate, poor compatibility, etc. metal texture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

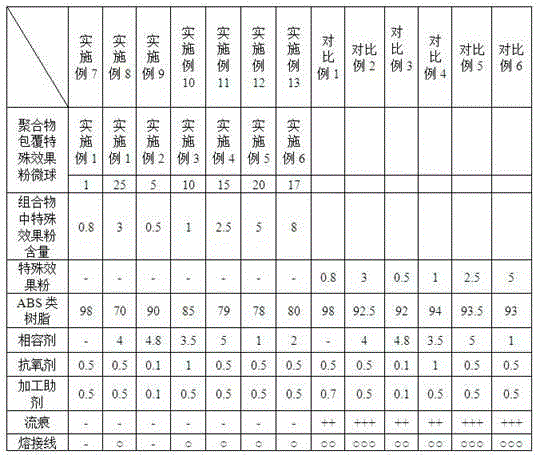

Examples

Embodiment 1-6

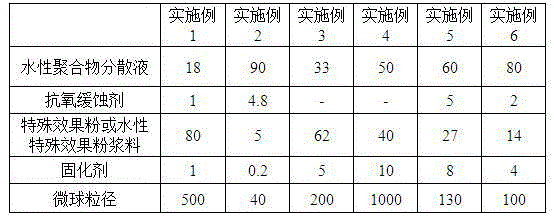

[0044] Example 1-6 Preparation of polymer-coated special effect powder microspheres:

[0045]According to the formula in Table 1, firstly, add anti-oxidation and corrosion inhibitor to the water-based polymer dispersion at room temperature, stir and disperse for 15 minutes to obtain a dispersion; while stirring, slowly add special effect powder, or water-based Special effect powder slurry, then add curing agent while stirring, and continue to stir for 30-120 minutes, so that the special effect powder is fully dispersed and covered by the dispersion liquid, and finally a composite dispersion liquid of polymer-coated special effect powder is obtained; The composite dispersion liquid is spray-dried to obtain polymer-coated special-effect powder microspheres. The temperature of the air inlet during the spray-drying process is 150-300° C., and the temperature of the air outlet is 50-130° C.

Embodiment 1

[0048] In Example 1: the water-based polymer dispersion is a polyurethane emulsion, and its solid content is 10wt%; the metal powder is a surface-treated flake aluminum powder, and the content of the Al element in the aluminum powder is 60wt%, containing Zn and Sn at the same time; The particle size is 100μm; the anti-oxidation and corrosion inhibitor is pyrogallic acid; the curing agent is polyisocyanate.

Embodiment 2

[0049] In Example 2: the water-based polymer dispersion is an acrylate emulsion, and its solid content is 60wt%; the metal powder is a surface-treated flake copper powder, and the content of the Cu element in the copper powder is 70wt%, containing Zn and Sn ; The particle size is 5 μm; the anti-oxidant corrosion inhibitor is benzotriazole; the curing agent is polycarbodiimide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com