Orthotropic steel plate-fiber grating reinforced concrete combined deck structure

A technology of reinforced concrete and fiber grid, which is applied to the coagulation pavement, bridges, bridge parts and other directions laid on site, can solve the problems of fatigue cracking of steel bridge deck structure, damage of asphalt mixture pavement layer, hidden safety hazards, etc. Achieve the effect of enhancing shear resistance, preventing cracking of pavement layers, and preventing cracking between layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

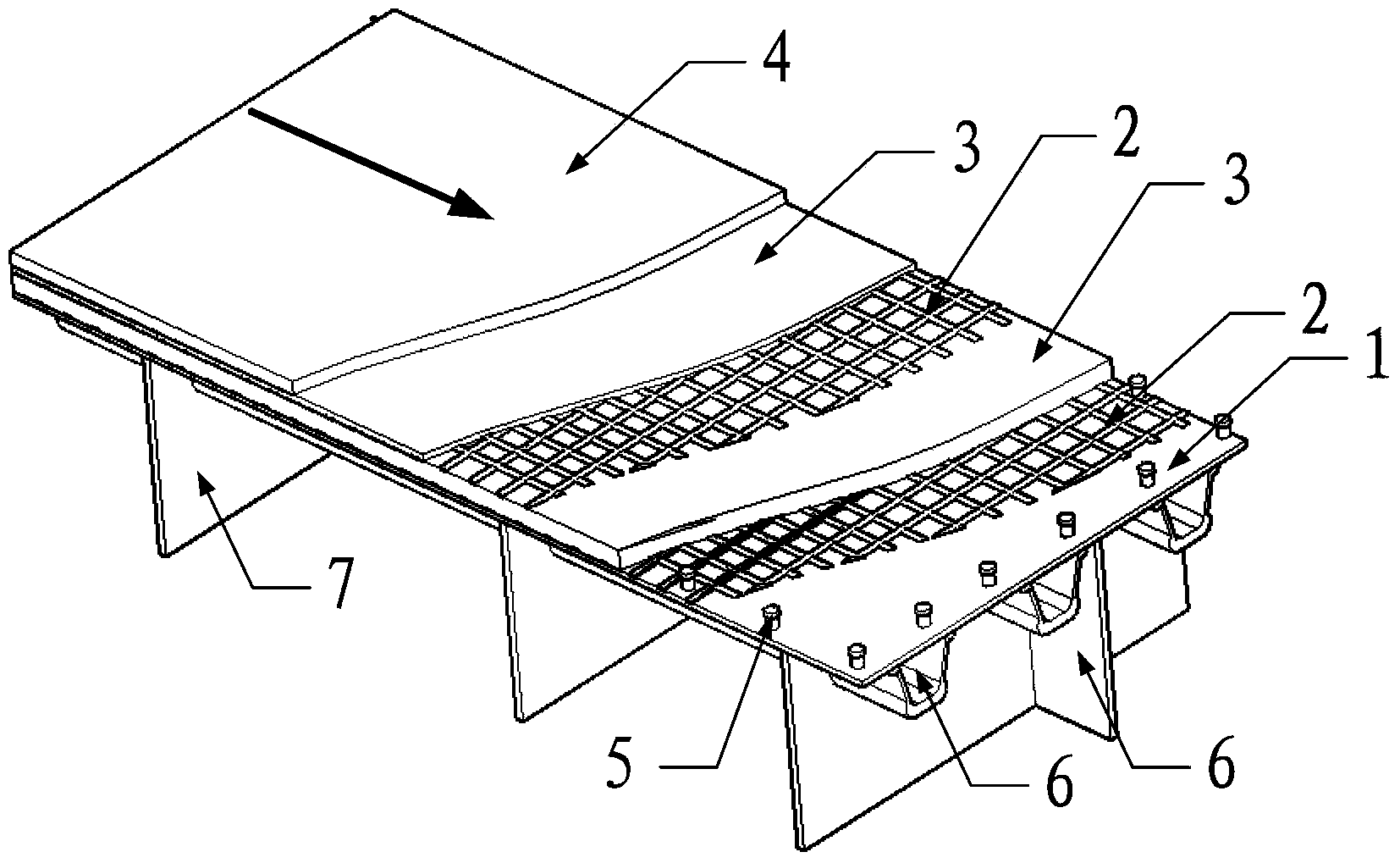

[0022] Such as figure 1 and 2 As shown, the orthotropic steel plate-fiber grid reinforced concrete composite bridge deck structure of the present invention comprises an orthotropic steel plate 1, and the orthotropic steel plate 1 is provided with shear keys 5 in the form of screws around the orthotropic steel plate 1. A layer of fiber grid 2 with a thickness of 2mm and a grid spacing of 50mm×50mm is laid on the upper layer. The fiber grid 2 is glued to the surface of the orthotropic steel plate 1 through high-performance epoxy resin, and 30mm thick concrete is laid on the fiber grid 2 in turn. 3. A fiber grid 2 with a thickness of 1mm and a grid spacing of 50mm×50mm, a 10mm thick concrete 3 and a 20mm thick modified asphalt SMA wear layer 4. The fiber grid 2 is made of woven fiber grid cloth, and the latitudinal fiber bundles and radial fiber bundles are made of carbon fiber orthogonally woven and cured with epoxy resin to form a whole. The concrete 3 is made of epoxy resin c...

Embodiment 2

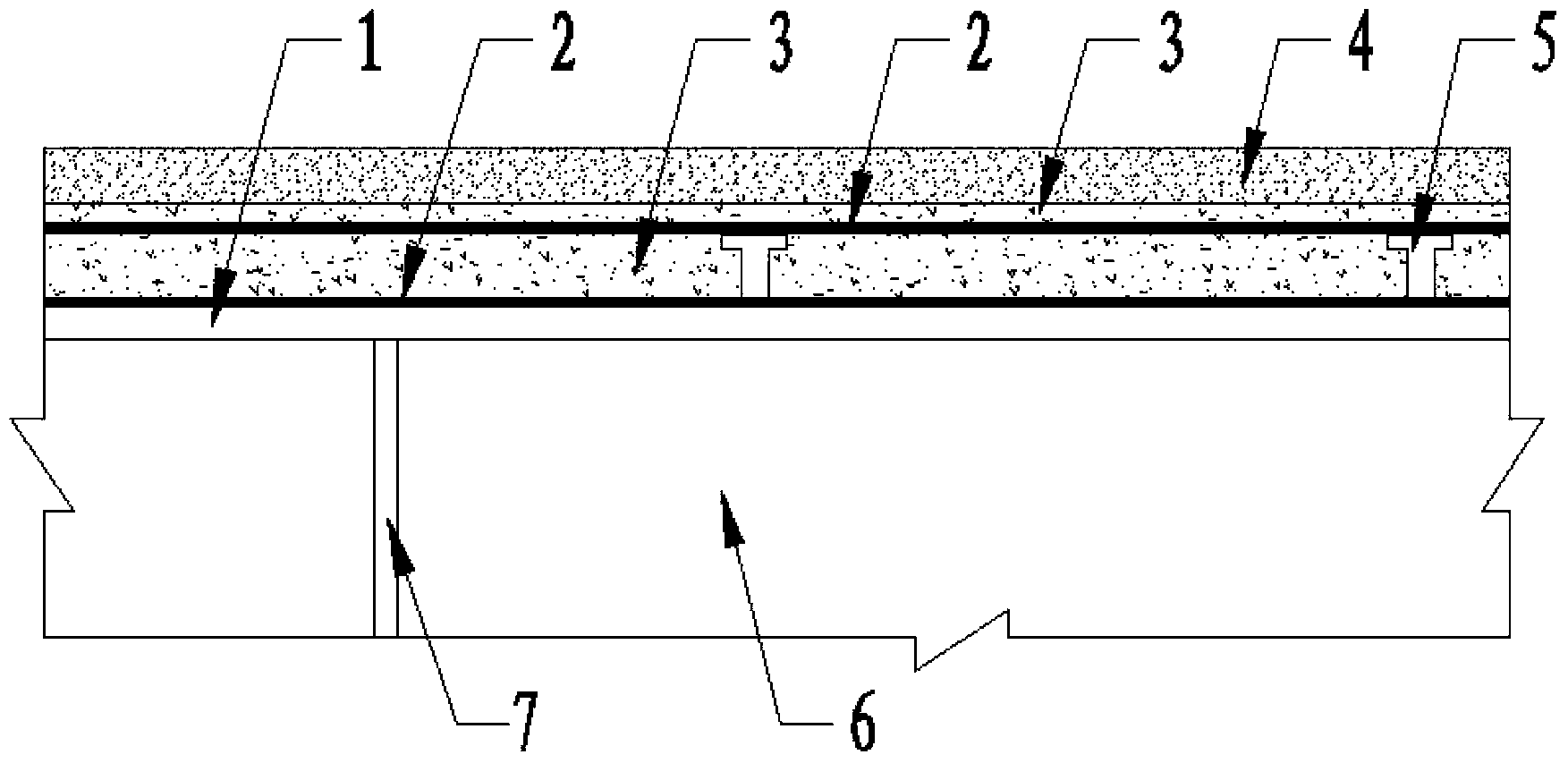

[0024] Such as image 3 and 4 As shown, the orthotropic steel plate-fiber grid reinforced concrete composite bridge deck structure of the present invention comprises an orthotropic steel plate 1, and the two sides of the orthotropic steel plate 1 are provided with a shear bond 5 in the form of a screw, and on the orthotropic steel plate 1 A layer of fiber grid 2 with a thickness of 2mm and a grid spacing of 25mm×25mm is laid on the upper layer. The fiber grid 2 is glued to the surface of the orthotropic steel plate 1 through high-performance epoxy resin, and 20mm thick concrete is laid on the fiber grid 2 in turn. 3. A fiber grid 2 with a thickness of 2mm and a grid spacing of 25mm×25mm and a 30mm thick epoxy asphalt mixture wear layer 4. The fiber grid 2 is made of woven fiber grid cloth, the weft fiber bundles are made of glass fibers, and the radial fiber bundles are made of carbon fibers, which are woven orthogonally and cured with epoxy resin to form a whole. The concret...

Embodiment 3

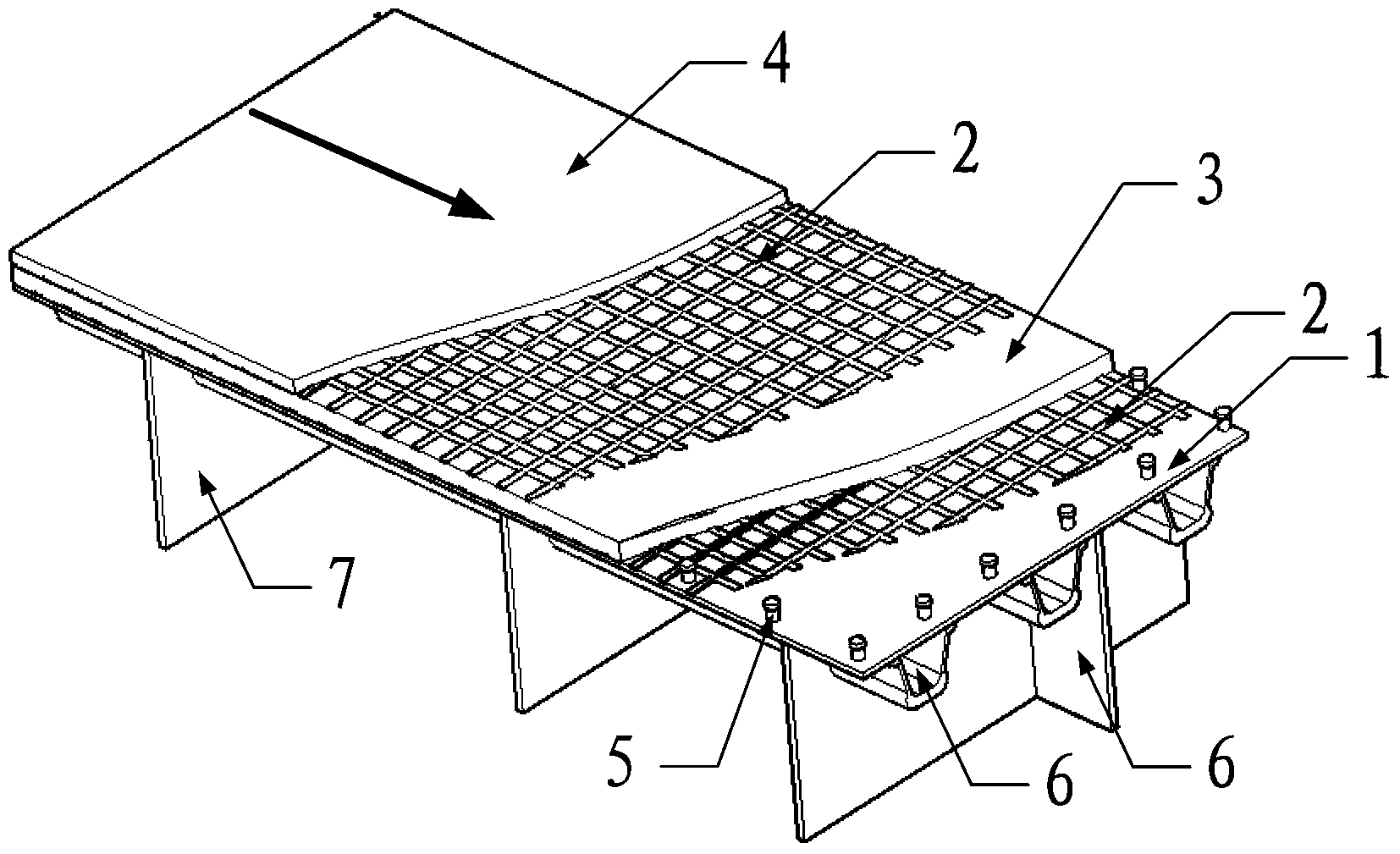

[0026] Such as Figure 5 and 6 As shown, the orthotropic steel plate-fiber grid reinforced concrete composite bridge deck structure of the present invention comprises an orthotropic steel plate 1, and the two sides of the orthotropic steel plate 1 are provided with a shear bond 5 in the form of a screw, and on the orthotropic steel plate 1 A layer of fiber grid 2 with a thickness of 2mm and a grid spacing of 25mm×25mm is laid on the upper layer. The fiber grid 2 is glued to the surface of the orthotropic steel plate 1 through high-performance epoxy resin, and 30mm thick concrete is laid on the fiber grid 2 in turn. 3, and 20mm thick epoxy asphalt mixture wearing course 4. The fiber grid 2 is made of woven fiber grid cloth, the weft fiber bundles are made of glass fibers, and the radial fiber bundles are made of carbon fibers, which are woven orthogonally and cured with epoxy resin to form a whole. Concrete 3 is made of epoxy resin concrete. The orthotropic steel plate 1 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com