Longitudinal bridge direction joint connecting structure of profile steel UHPC composite board

A technology of longitudinal bridge and combined slabs, which is applied in bridges, bridge parts, bridge construction, etc., can solve the problems of insufficient tensile capacity of the bottom surface of the joint, difficulty in applying to long-span bridges, insufficient tensile capacity, etc., and reduce the on-site The effect of UHPC pouring volume, optimized layout position and layout method, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

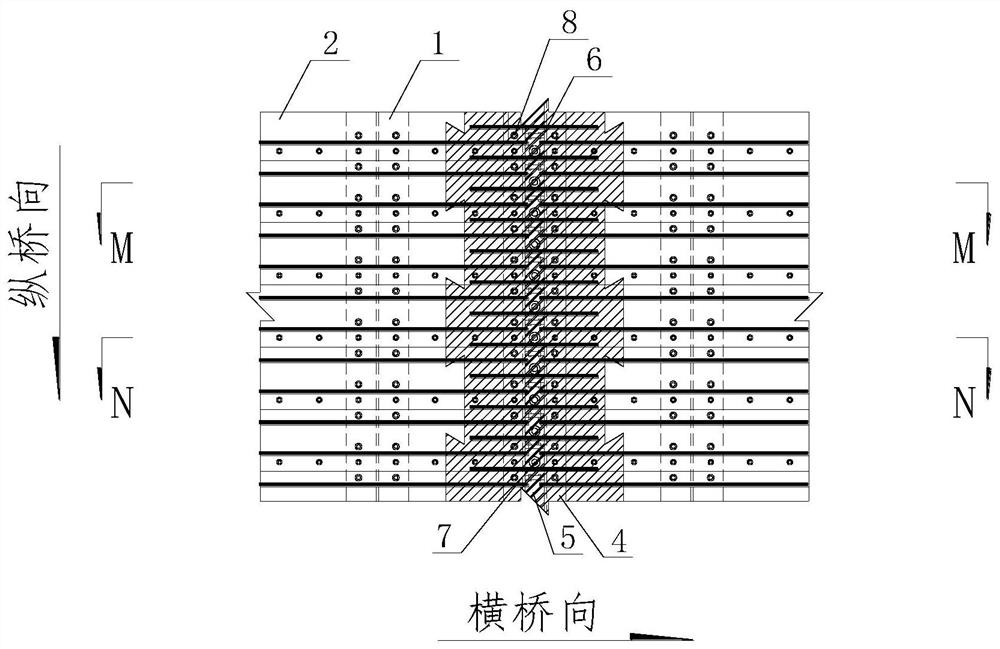

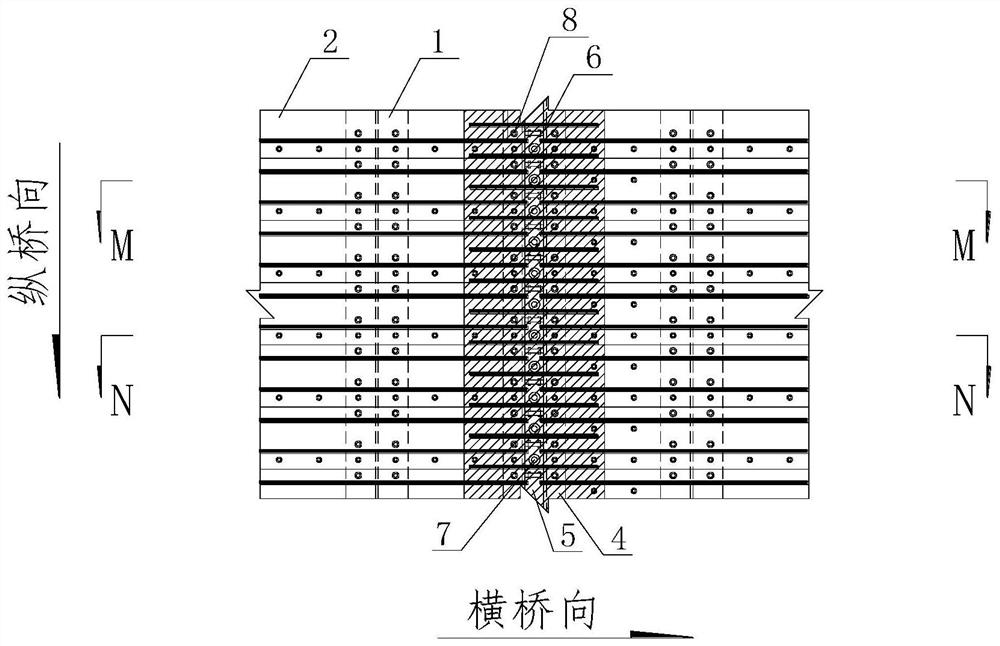

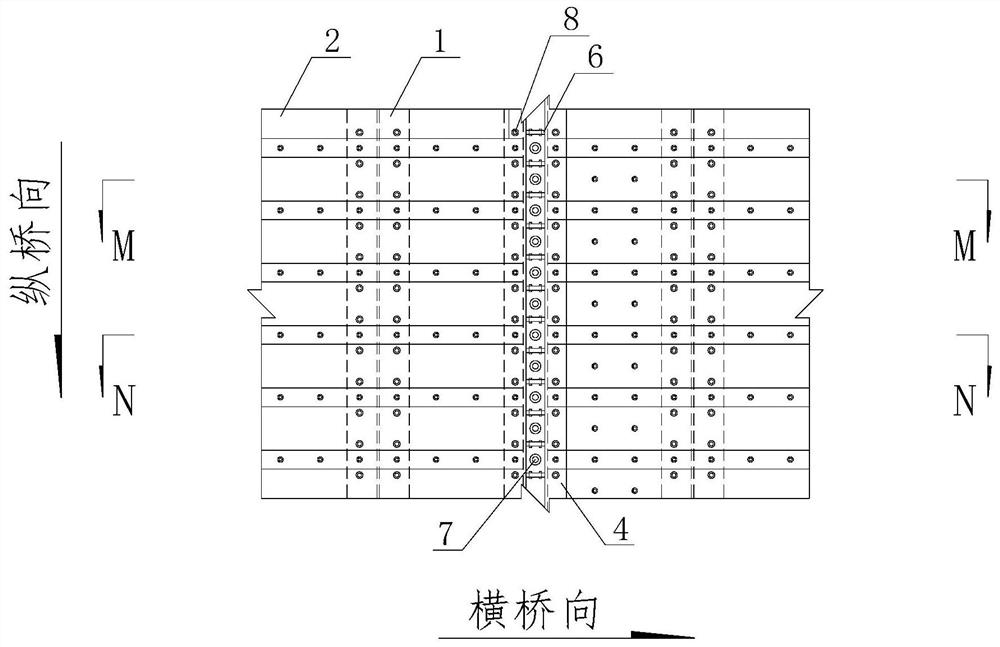

[0052] like Figure 1-Figure 6As shown, the longitudinal bridge seam connection structure of the profile steel-UHPC composite board in this embodiment, the profile steel-UHPC composite board includes a UHPC board 2 and a profile steel 1 arranged below the UHPC board 2, and the profile steel-UHPC composite board is provided with steel 1 below the composite board. Beam 3, longitudinal stiffening plates 4 are provided at the transverse ends of the section steel-UHPC composite plate, and the longitudinal bridge joint connection structure includes the section steel-UHPC composite plate, which is arranged adjacent to the transverse bridge, and the middle web / small plate of the steel beam 3. The cast-in-place connecting portion 5 between the longitudinal beams 31 and the reinforcing connecting piece extending into the cast-in-situ connecting portion 5; the reinforcing connecting piece includes at least one row of transverse shear connecting pieces 6 ( Vertically arranged on the longi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com