Poly acrylate composite emulsion for pressure' sensitive adhesive and its preparing and using method

A polyacrylate and pressure-sensitive adhesive technology, which is applied in the direction of adhesives, adhesive types, ester copolymer adhesives, etc., can solve the problem of uncontrollable thickness of the core layer and shell layer of latex particles, uneven dispersion, and pressure-sensitive adhesives. Problems such as initial adhesive performance and cohesive performance cannot be taken into account at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] (1) Preparation of nano-silica alcohol sol

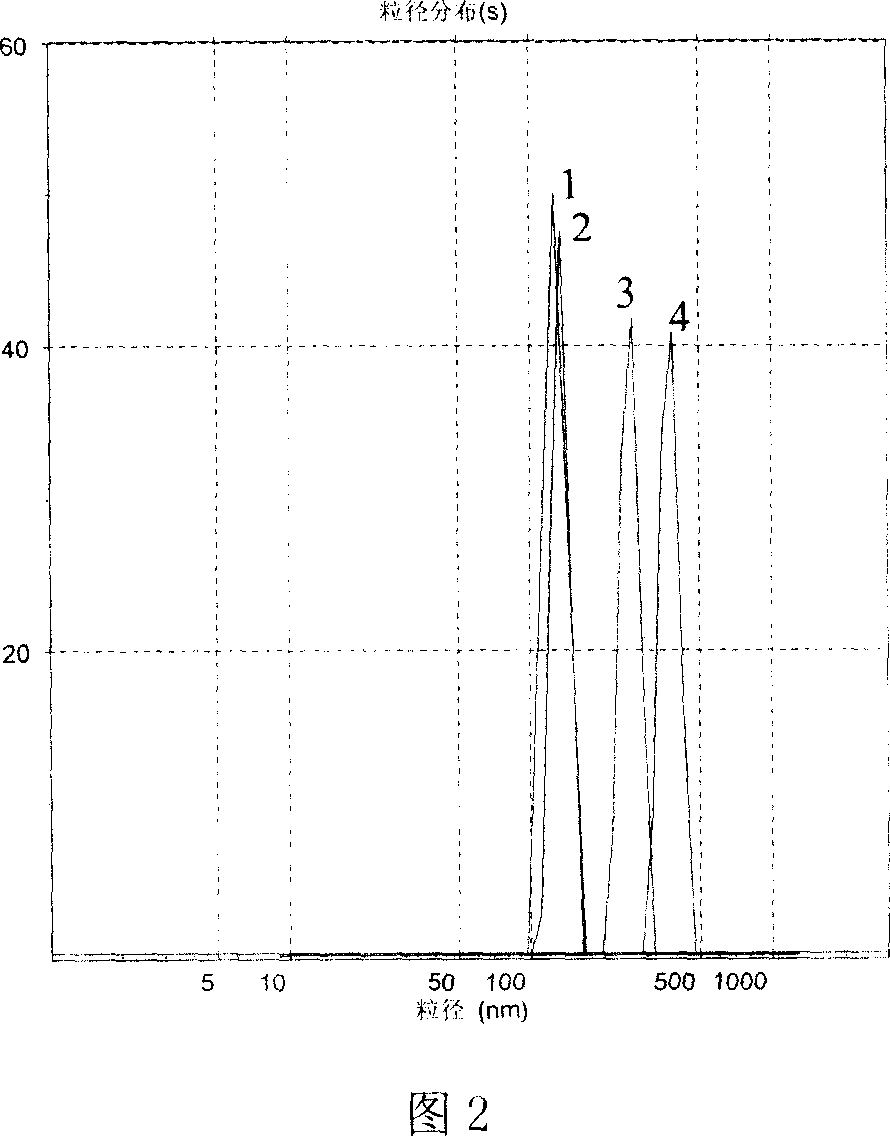

[0084] Install a stirrer, a reflux condenser and a thermometer on a 1000mL three-necked flask, first add 750mL of absolute ethanol and 45mL of ammonia water with a concentration of 25wt%, stir for 5 minutes to make the solution evenly mixed, and then add dropwise at a rate of 22.5mL per hour 45mL tetraethyl orthosilicate, after the tetraethyl orthosilicate was added dropwise, reacted in a water bath at 40°C for 4 hours to obtain a monodisperse nano-silica alcohol sol with a particle size of 125 nm and a particle size distribution index of 0.0492 SiO is used in the following table 2 Express), the mass percent composition of nano-silica in this silanol sol measured by drying weighing method is 1.94%;

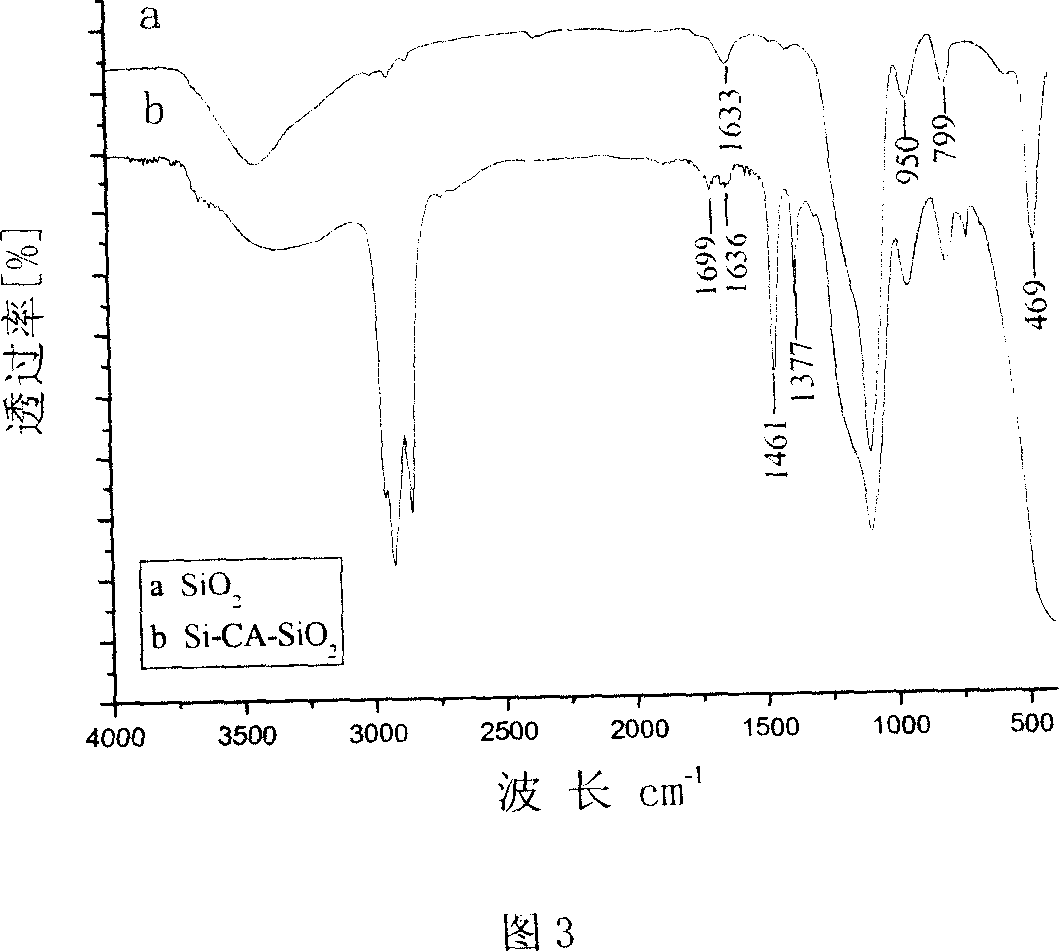

[0085] (2) Surface modification of nano-silica

[0086] Weighing the above-mentioned silica sol quality is 610g, and the mass percentage is 1.94%, then the quality of silicon dioxide is 11.834g; Add 10 μ mol silane coupling age...

Embodiment 2~5

[0098] Just change the consumption of the silane coupling agent in (2) step silicon dioxide surface modification step of embodiment 1, formula sees table 1, the silicon dioxide after the modification of different consumption silane coupling agents is used for embodiment 1 (3) 1. the preparation of step seed emulsion, formula sees Table 2, and all the other operations are the same as embodiment 1, and the parameters in the prepared seed emulsion and the final composite emulsion are shown in Table 14; The prepared pressure-sensitive adhesive tape properties are shown in Table 15.

[0099] Example serial number

[0100] MPS in Table 1 represents the silane coupling agent γ-methacryloxypropyltrimethoxysilane

[0101] Example

[0102] In Table 2, BA is butyl acrylate, AA is acrylic acid, and TDM is dodecyl mercaptan

Embodiment 6~8

[0104] Just change the consumption of the modified nano silicon dioxide powder in the preparation step of (3) step seed emulsion in embodiment 1, formula is shown in Table 3, and all the other operations are with embodiment 1, prepared seed emulsion and final The parameters in the composite emulsion are shown in Table 14; the properties of the prepared pressure-sensitive adhesive tape are shown in Table 15.

[0105] Example

[0106] In Table 3, BA is butyl acrylate, AA is acrylic acid, and TDM is dodecyl mercaptan.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com