Pearl essence coated polymer microspheres and preparation method and application thereof

A pearlescent powder and polymer technology, which is applied in the treatment of dyed polymer organic compounds, can solve the problems of easy occurrence of flow marks, formation of flow marks and weld lines, and unstable flow rate, so as to improve shear resistance and reduce welding Line, the effect of improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

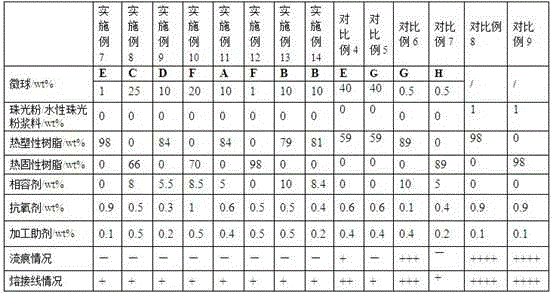

Examples

Embodiment 1-6 and comparative example 1-3

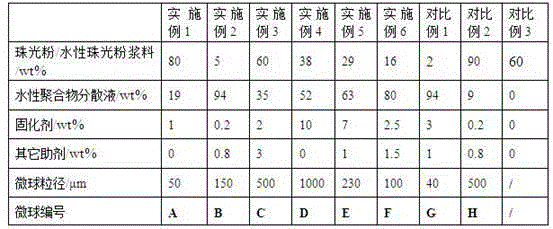

[0028] According to the formulas of Examples 1-6 and Comparative Examples 1-2 in Table 1, slowly add surface-treated pearlescent powder / water-based pearlescent powder slurry to the aqueous polymer dispersion at room temperature, and add curing agent and / or For other additives, continue to stir for 30-120 minutes, so that the pearl powder is fully dispersed and covered by the aqueous polymer dispersion, and the composite dispersion of the polymer-coated pearl powder is obtained; the obtained composite dispersion is spray-dried. During the drying process, the small droplets of polymer-coated pearl powder formed by spraying are cured and cross-linked by the curing agent to obtain microspheres of polymer-coated pearl powder; the temperature of the air inlet during the spray drying process is 150-300°C , The outlet temperature is 50-130°C.

[0029] Table 1

[0030]

Embodiment 1

[0031] Embodiment 1: the pearlescent powder is a mica-coated pearlescent powder, and the metal oxide coated on its surface is titanium oxide; the particle size is 5 μm; the aqueous polymer dispersion is a polyacrylate emulsion, and its solid content is 10wt%; the curing agent For amino resins.

Embodiment 2

[0032] Example 2: the pearlescent powder is bismuth oxychloride crystalline pearlescent powder, and the metal oxides coated on its surface are titanium dioxide and chromium oxide; the particle size is 100 μm; the aqueous polymer dispersion is polyurethane emulsion, and its solid content is 50wt% ; Curing agent is polyisocyanate, other additives are 0.4wt% silicone defoamer and 0.4wt% polycarboxylic acid dispersant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com