Patents

Literature

148results about How to "Eliminate quality issues" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

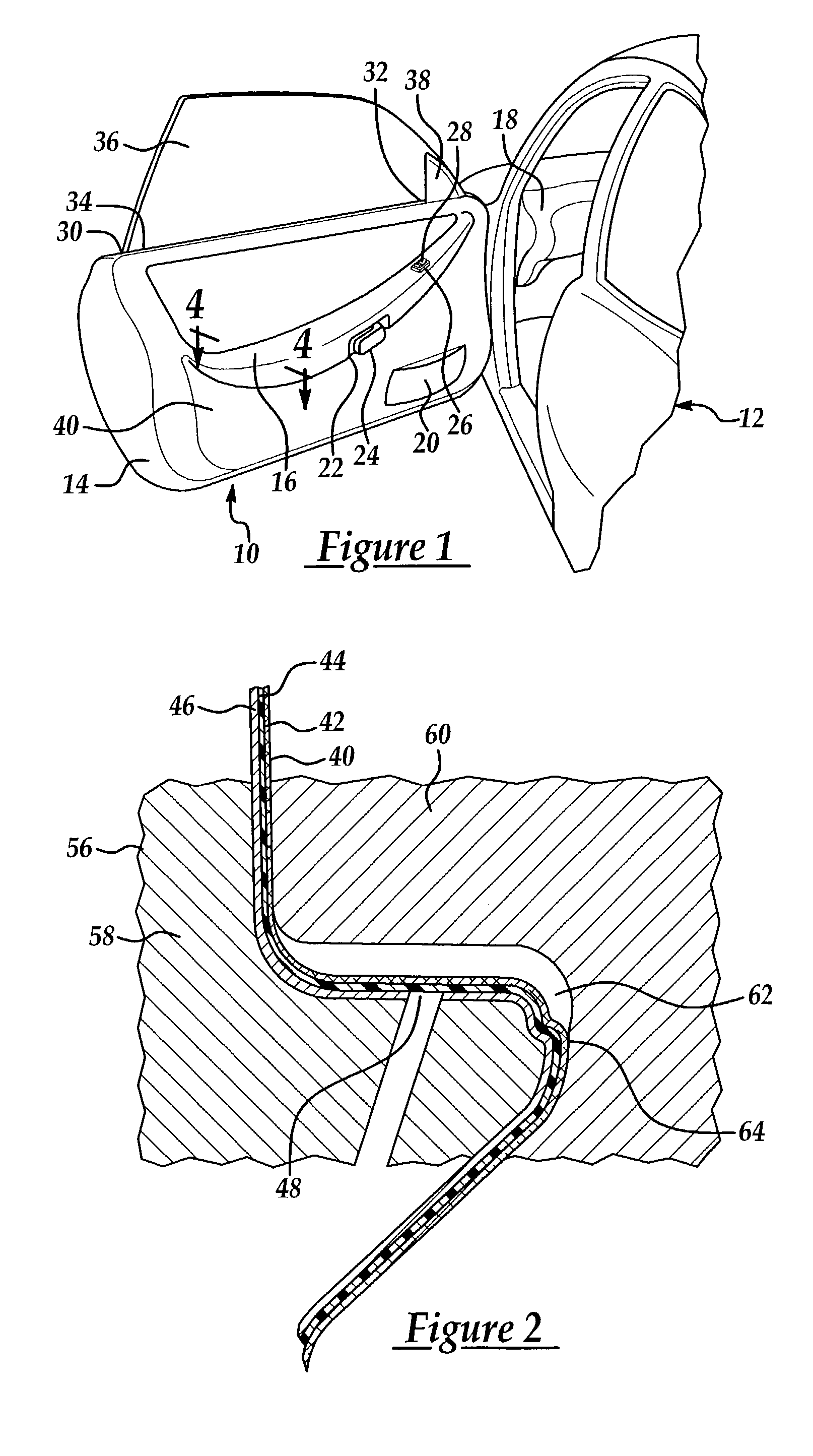

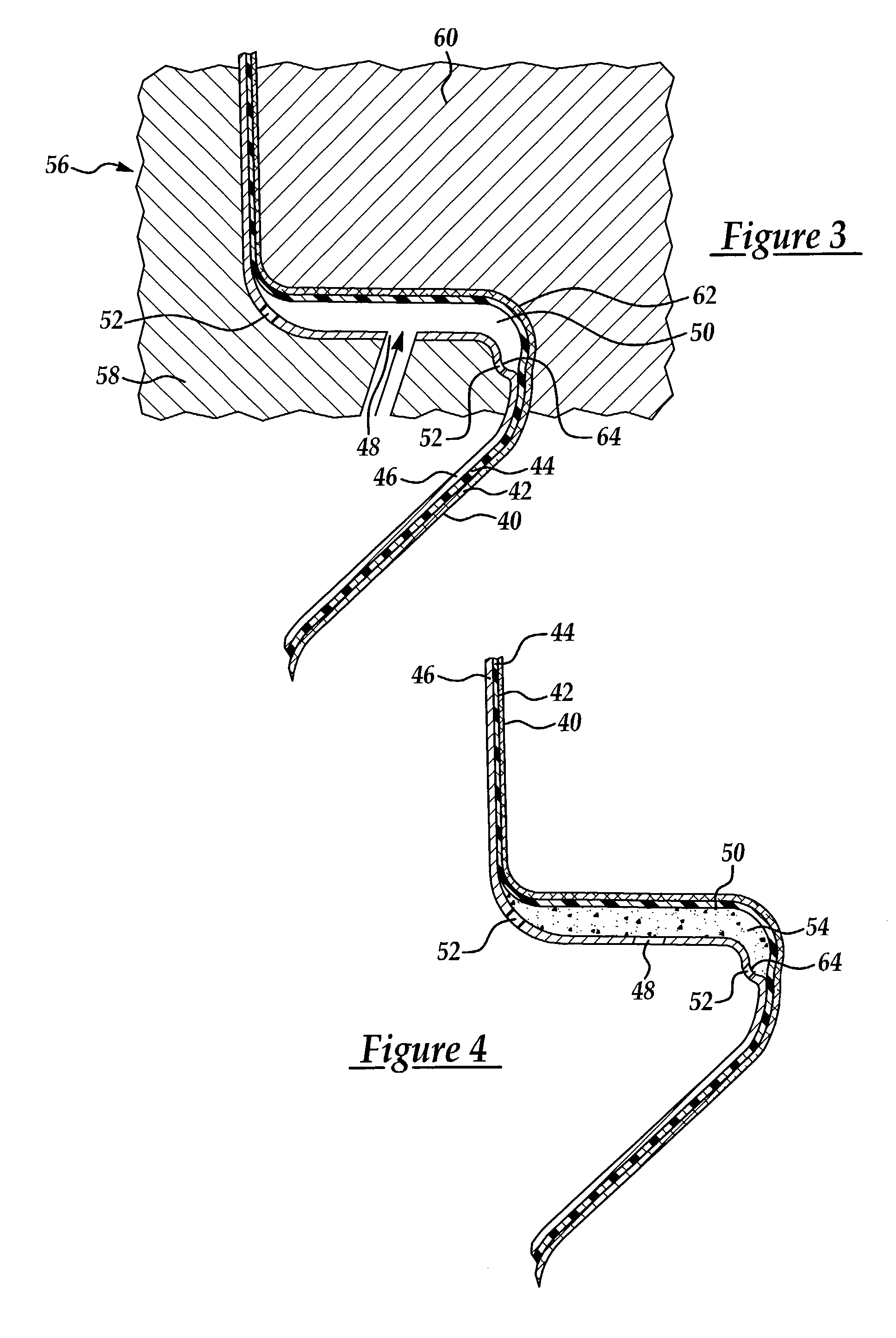

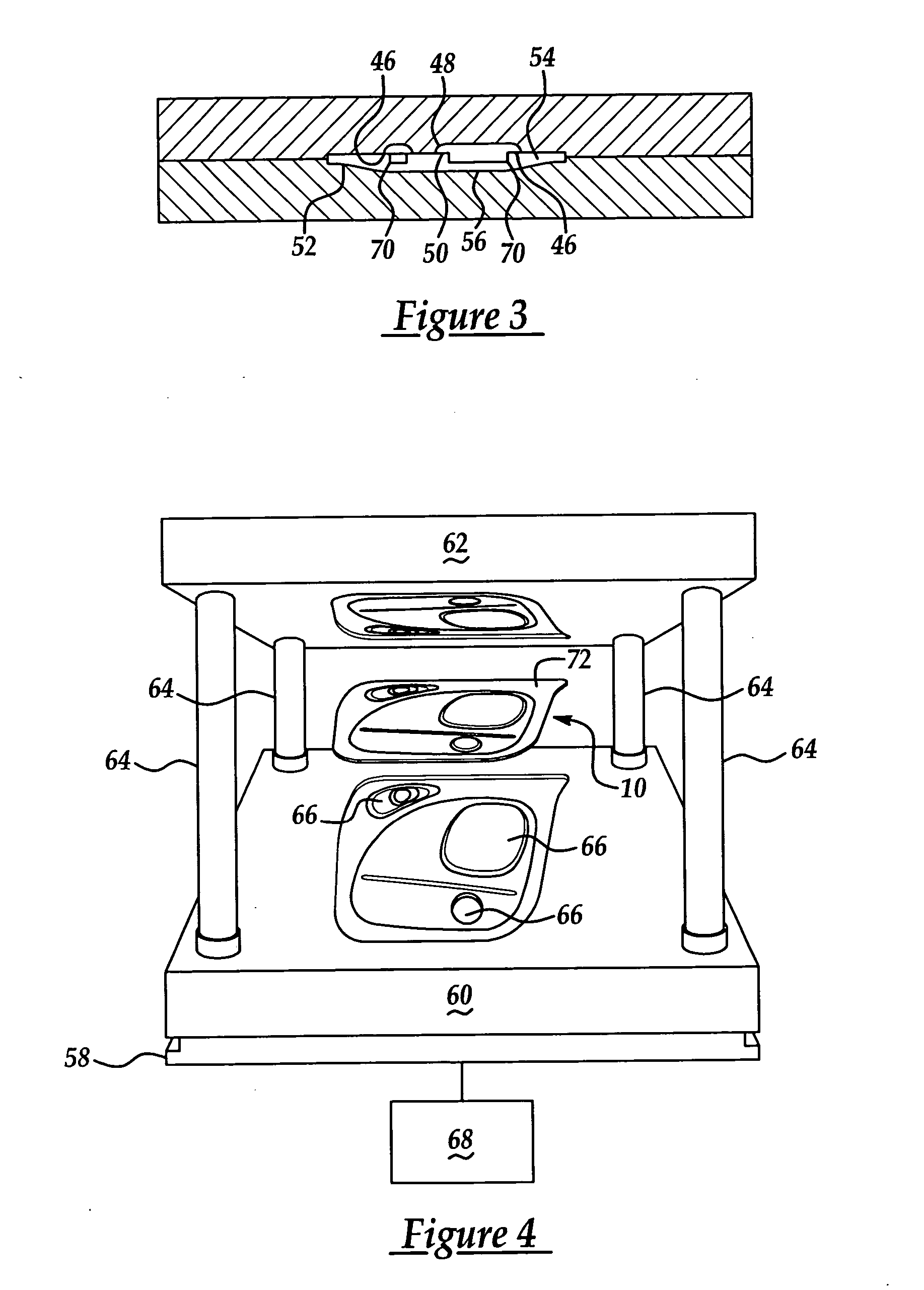

Vehicle interior trim panel assembly having an integrated soft-touch arm rest and method of manufacturing same

InactiveUS7005092B2Reduce stepsEliminate quality issuesLaminationLamination apparatusPolymer substrateEngineering

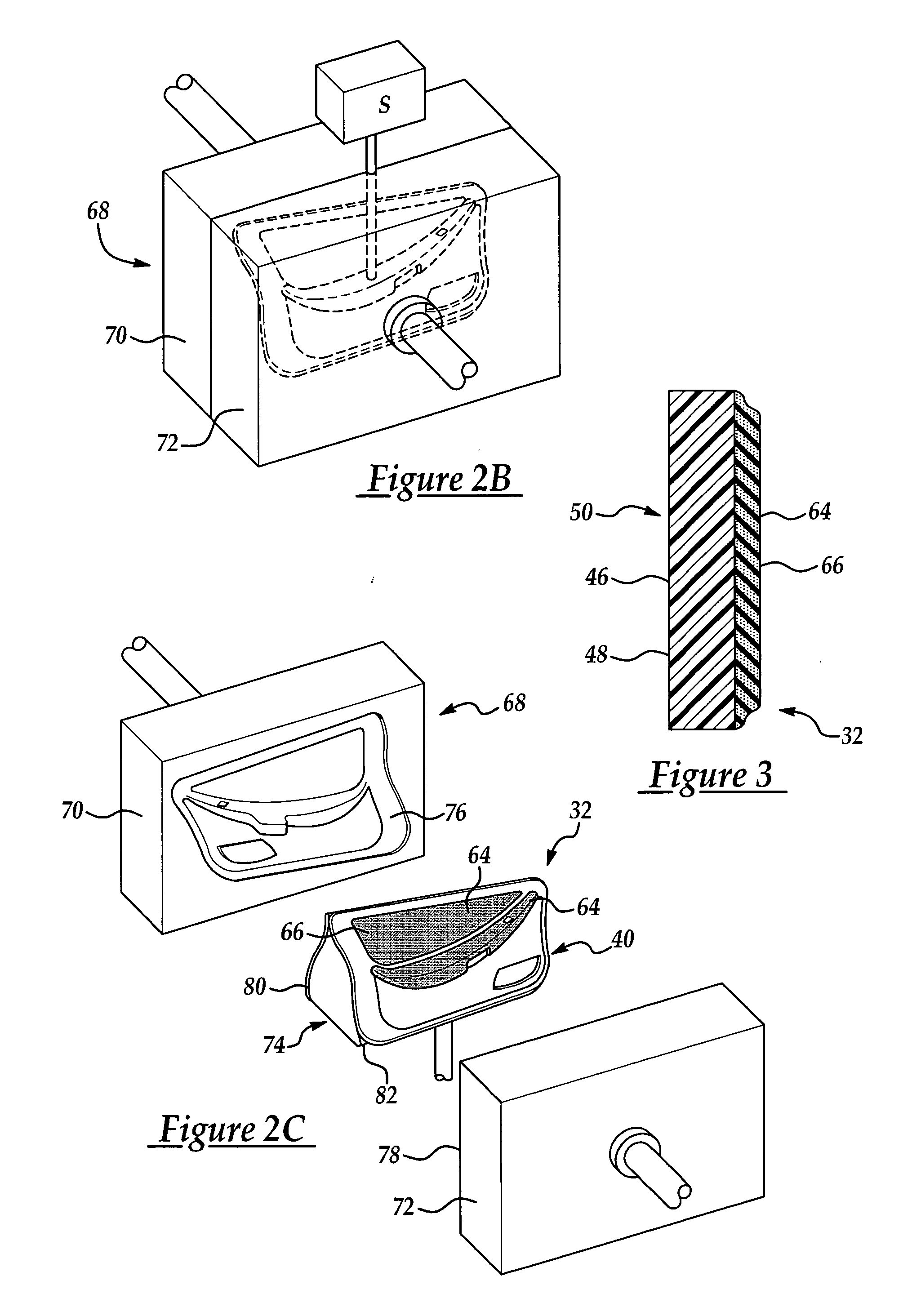

The present invention relates to a method of manufacturing an interior trim panel assembly having an integrated soft-touch area for improved aesthetic trim component quality. The method of manufacturing a trim panel assembly for the interior of a vehicle having an integrated soft-touch area of the present invention includes placing a molded trim panel including a coverstock having an exposed outer surface and a foam backing disposed opposite the outer surface and a rigid substrate having at least one aperture bonded to the coverstock into a mold cavity. The method of manufacture further includes separating the bonded coverstock and rigid polymer substrate in a localized area to define an internal chamber accessible by the aperture. The method of manufacture also includes injecting soft foam into the internal chamber through the aperture so as to be juxtaposed between the coverstock and the rigid polymer substrate in at least one predetermined location to define an integrated soft-touch area.

Owner:INT AUTOMOTIVE COMPONENTS GRP NORTH AMERICA INC

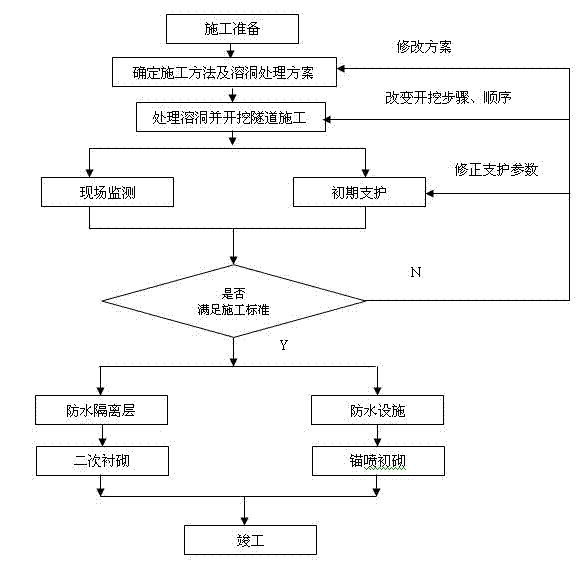

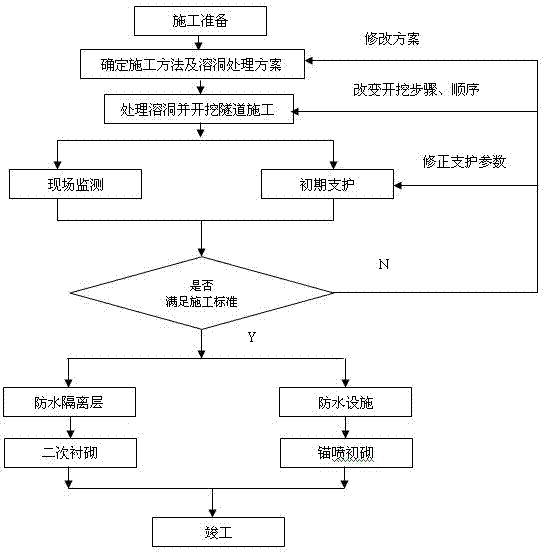

Construction technology for allowing tunnel to pass through ultra-large karst cave

ActiveCN102383806ADo not delay the construction periodQuality assuranceUnderground chambersFoundation engineeringShotcreteMesh reinforcement

The invention relates to a construction technology for allowing a tunnel to pass through a karst cave, and in particular relates to a construction technology for allowing a tunnel to pass through an ultra-large karst cave. The technology at least comprises the following steps of: 1) performing simple bridge treatment on the underground part of the karst cave; 2) performing primary support, namelyarranging a support wall at one side of the karst cave; 3) forming parallel guide holes; 4) performing bottom treatment; 5) treating the tunnel hole body at the inlet section of the karst cave; 6) filling C25 early strength sprayed concrete within 1 meter at the top of the support wall, and arranging phi 50 small grouting conduits with the lengths of 3 meters in the concrete, wherein the distancebetween the small conduits is 1.5 meters; 7) supporting the arch part and the side wall surrounding rock of the karst cave by adopting phi 22 cartridge anchor rods arranged in a plum blossom shape and at a distance of 150cm*150cm, hanging phi6 reinforcing meshes at a distance of 15cm*15cm, and spraying C25 early strength concrete with the thickness of 15 centimeters; 8) treating the accumulation of the karst cave; and 9) monitoring and measuring when the tunnel passes through the ultra-large karst cave. The construction technology for allowing the tunnel to pass through the ultra-large karst cave is simple in process, convenient for construction, low in cost, scientific, effective, energy-saving and environmentally-friendly.

Owner:CCCC SHEC DONGMENG ENG CO LTD

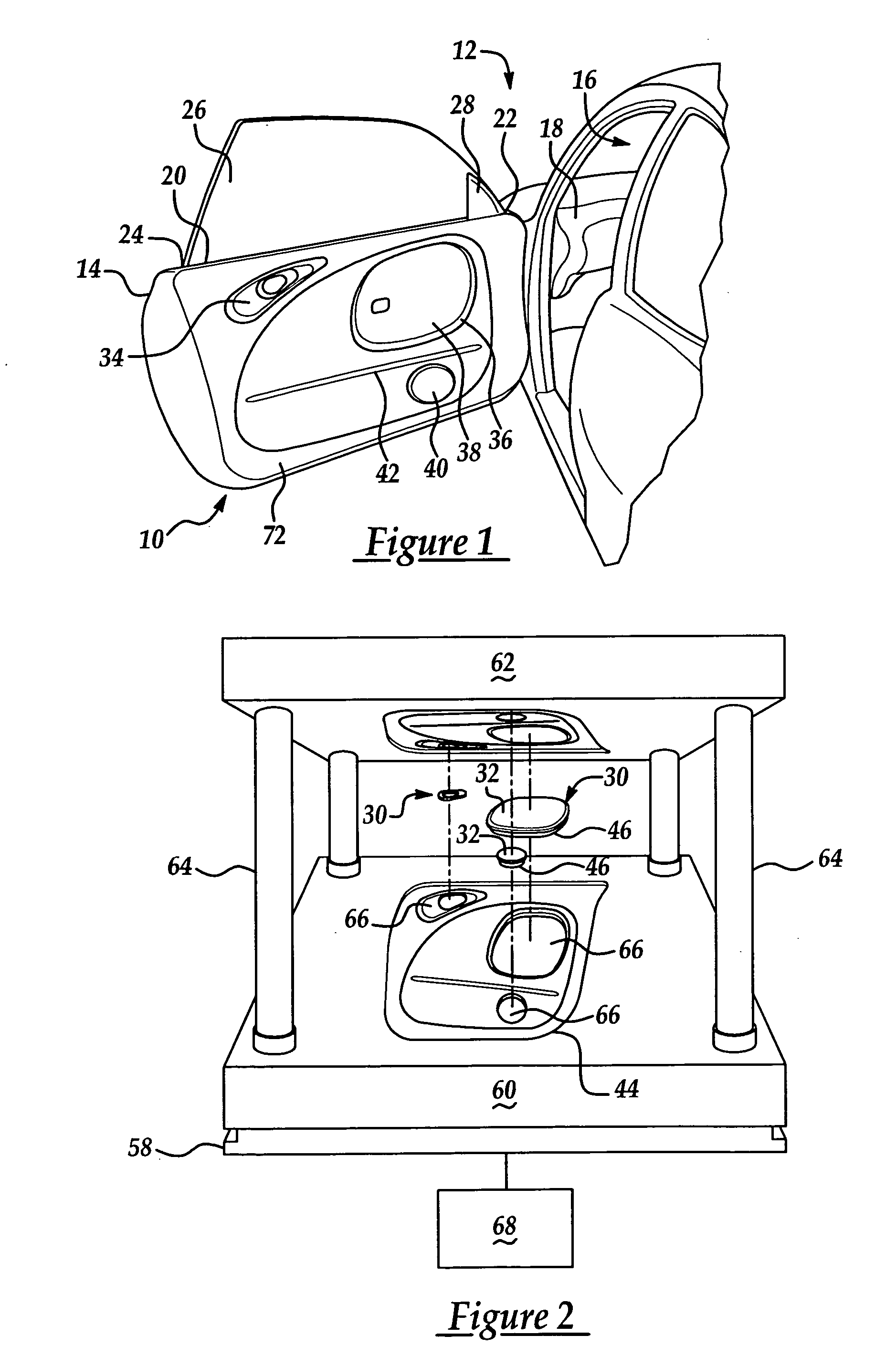

Vehicle interior trim panel component assembly and in-mold method of manufacturing same

InactiveUS20050140167A1Reduce stepsEliminate quality issuesSuperstructure subunitsMonocoque constructionsEngineeringThermoplastic materials

The present invention relates to a method of manufacturing an interior trim panel assembly having integrated trim panel components. The method of manufacture includes providing a die including a pair of die halves cooperating to define a mold cavity to form a interior trim panel where at least one of said die halves includes a surface defining an A-surface and the mold cavity includes a plurality of recesses. The method further includes placing a trim panel component into a recess and closing the die halves to form a rigid substrate within the mold cavity by injecting a molten thermoplastic material into the mold cavity mold cavity. The method further includes bonding the molten thermoplastic material to a trim panel component within the mold cavity while the rigid substrate is formed.

Owner:INT AUTOMOTIVE COMPONENTS GRP NA INC

Veneering production process for artificial board

InactiveCN102896868AAvoid deformationGuaranteed quality and performanceLamination ancillary operationsLaminationChemistryEnvironmental geology

The invention relates to a veneering production process for an artificial board. The process comprises the following steps of: (1) treating an artificial board base material and a figured veneer at constant temperature and humidity to adjust water content, so that the water content of the artificial board base material is 6 to 10 percent, the water content of the figured veneer is 8 to 12 percent, and water is uniformly distributed; (2) completely removing a compact hardened layer from the surface of the artificial board base material to avoid warpage deformation or cracking caused by stress unbalance or environmental change in the veneering process of the figured veneer; (3) attaching the figured veneer to the surface, from which the compact hardened layer is removed, of the artificial board base material to form a semi-finished veneered decoration plate; and (4) and curing the semi-finished veneered decoration plate. By the process, the defects of dry shrinkage, bending, deformation, panel cracking and the like after the figured veneer is attached to the artificial board base material are overcome, and the quality of the veneered decoration plate is obviously improved; and compared with the traditional veneering process, the process has the advantage that quality loss is reduced by over 60 percent.

Owner:SHANTOU YIHUA FURNITURE +1

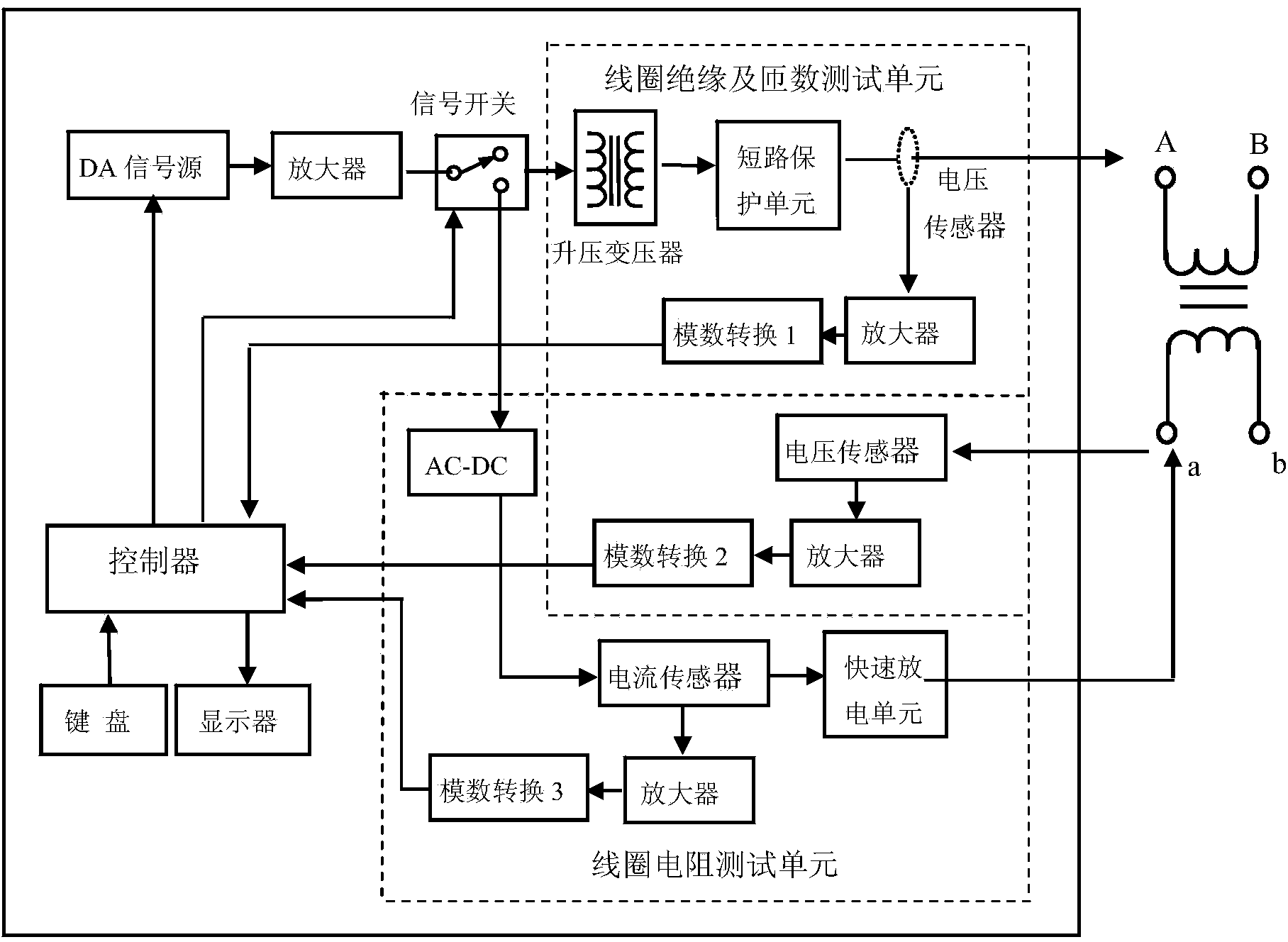

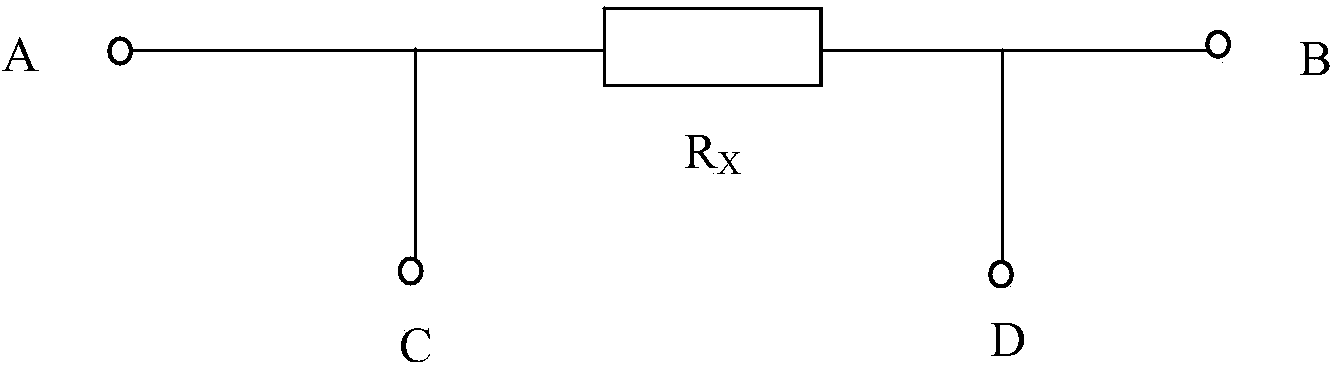

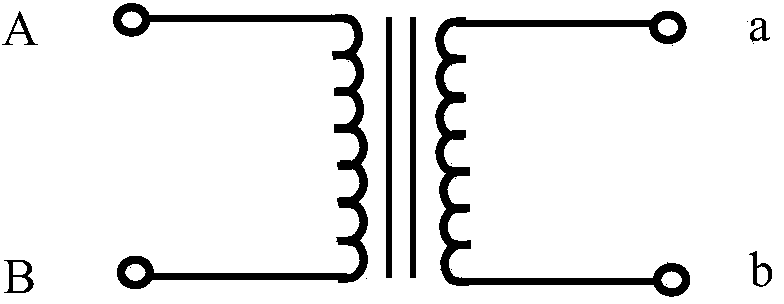

Device for testing characteristics of breaker opening and closing coils

ActiveCN103454580AImprove accuracy and anti-interference abilityEliminate test errorsTesting dielectric strengthCircuit interrupters testingEngineeringPull off test

The invention discloses a device for testing the characteristics of breaker opening and closing coils. The device comprises a controller, a coil resistance testing unit and a coil insulation and number-of-turns testing unit. The controller is respectively connected with a signal source, the coil resistance testing unit and the coil insulation and number-of-turns testing unit, the coil resistance testing unit and the coil insulation and number-of-turns testing unit perform testing through a coil to be tested, tested data are sent to the controller, the controller performs fault diagnosis on the breaker opening and closing coils in real time, and therefore real-time monitoring of the breaker opening and closing coils is realized. According to the device, the performance and the quality of the coils are estimated through testing of the characteristics of the coils, quality defects and fault hidden dangers are eliminated, the reliability and the stability of products in use are guaranteed, and the operation safety of a power system is improved.

Owner:STATE GRID CORP OF CHINA +1

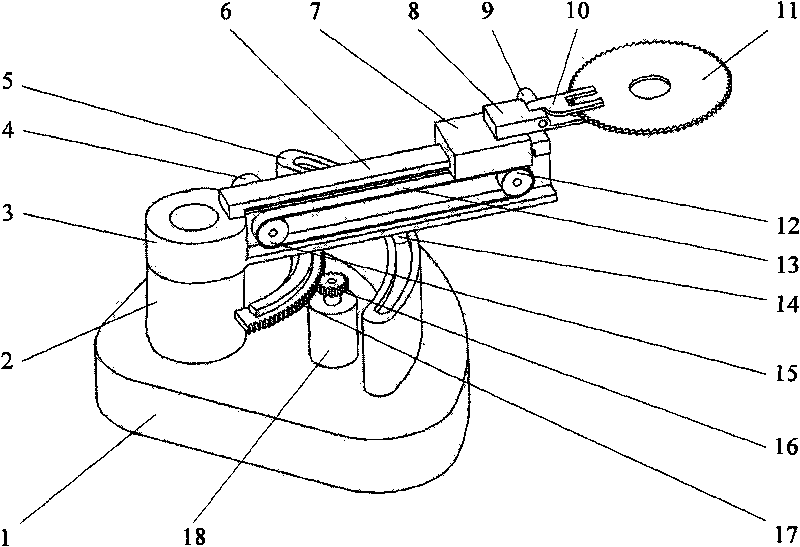

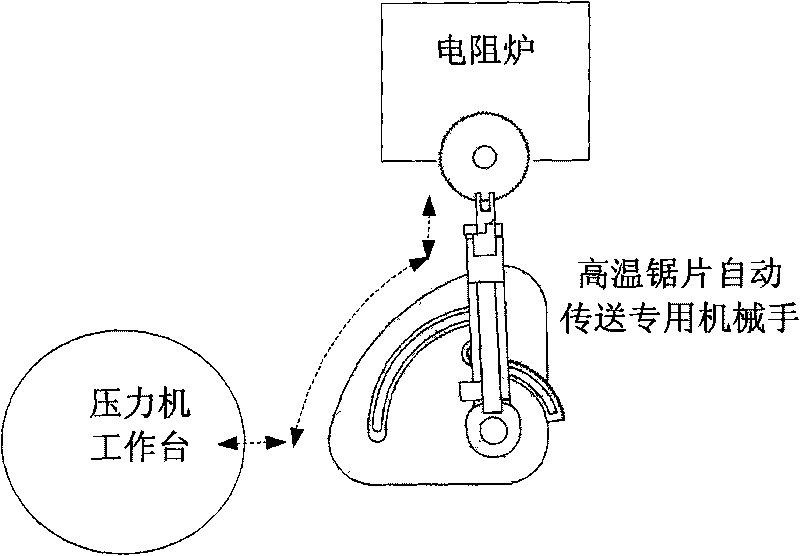

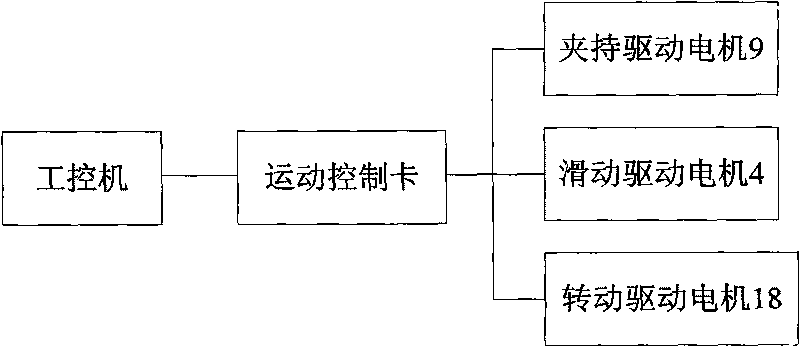

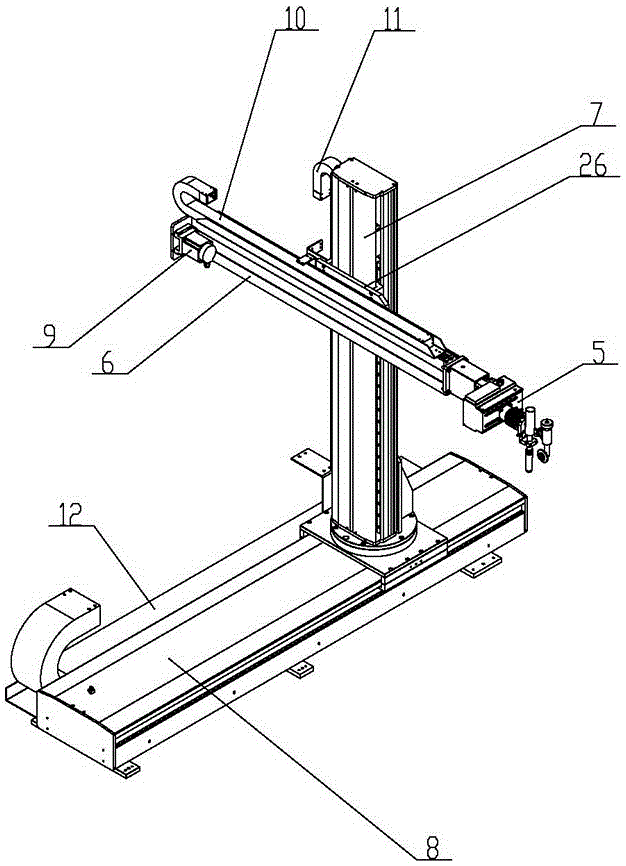

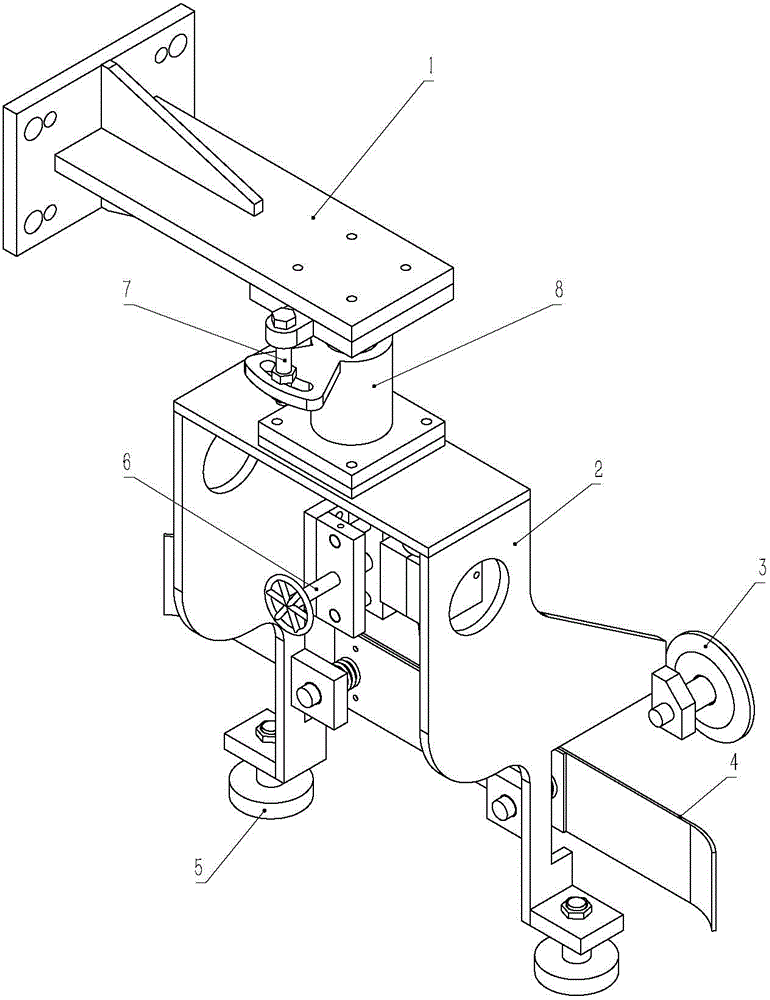

Special mechanism for automatically conveying high-temperature saw bit

ActiveCN101698253AEfficient transmissionEliminate bad effectsProgramme-controlled manipulatorMetal sawing tool makingEngineeringPulley

The invention discloses a special mechanism for automatically conveying a high-temperature saw bit. The mechanism comprises a base, an upright post and the like, wherein the upright post is fixed on the base, a rotating crossarm is connected with the upright post and can rotate around the upright post, and a slider fixed on a conveyer belt is driven to move on a sliding guide rail by a sliding driving motor which is fixed on the rotating corssarm through pulley transmission; actions of a movable paw of clamping and loosening a high-temperature sheet are realized through the rotation of a clamping driving motor fixed on the slider; and the rotating driving motor is fixed on the base, an output shaft is provided with a pinion which is meshed with a circular arc rack fixed on the rotating crossarm to drive the rotating crossarm to rotate around the upright post, and a positioning pin on the rotating corssarm slides on the rotating guide rail during rotating so as to realize the function of rotatably conveying the high-temperature saw bit. The mechanism can realize the high-speed high-efficiency conveying of the high-temperature saw bit, eliminates adverse influence such as the pressing precision reduction and quality reduction of the saw bit caused by overlarge temperature drop in the conveying process, and has the advantages of high efficiency, high speed, accuracy and reliability.

Owner:NANJING UNIV OF SCI & TECH

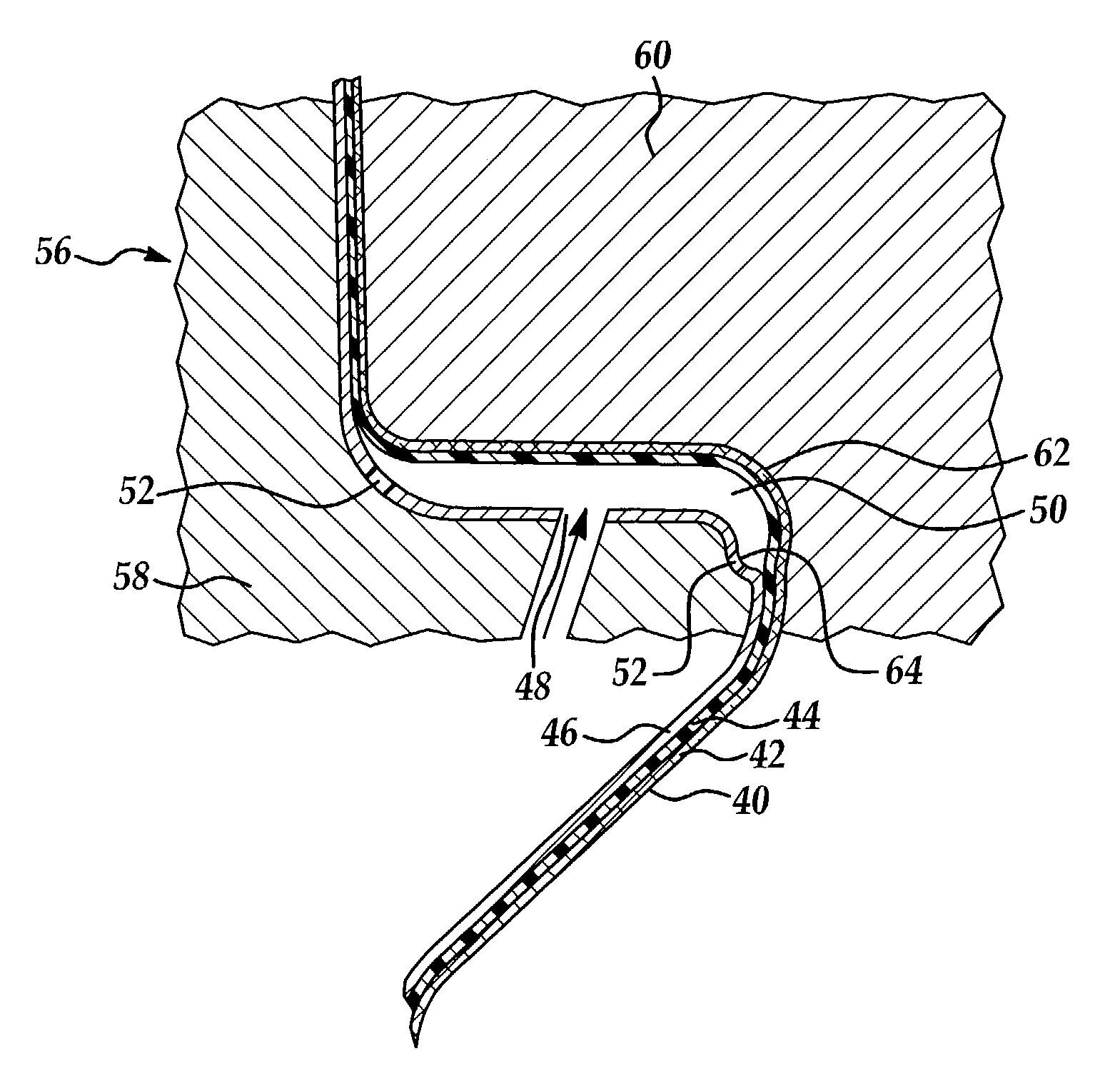

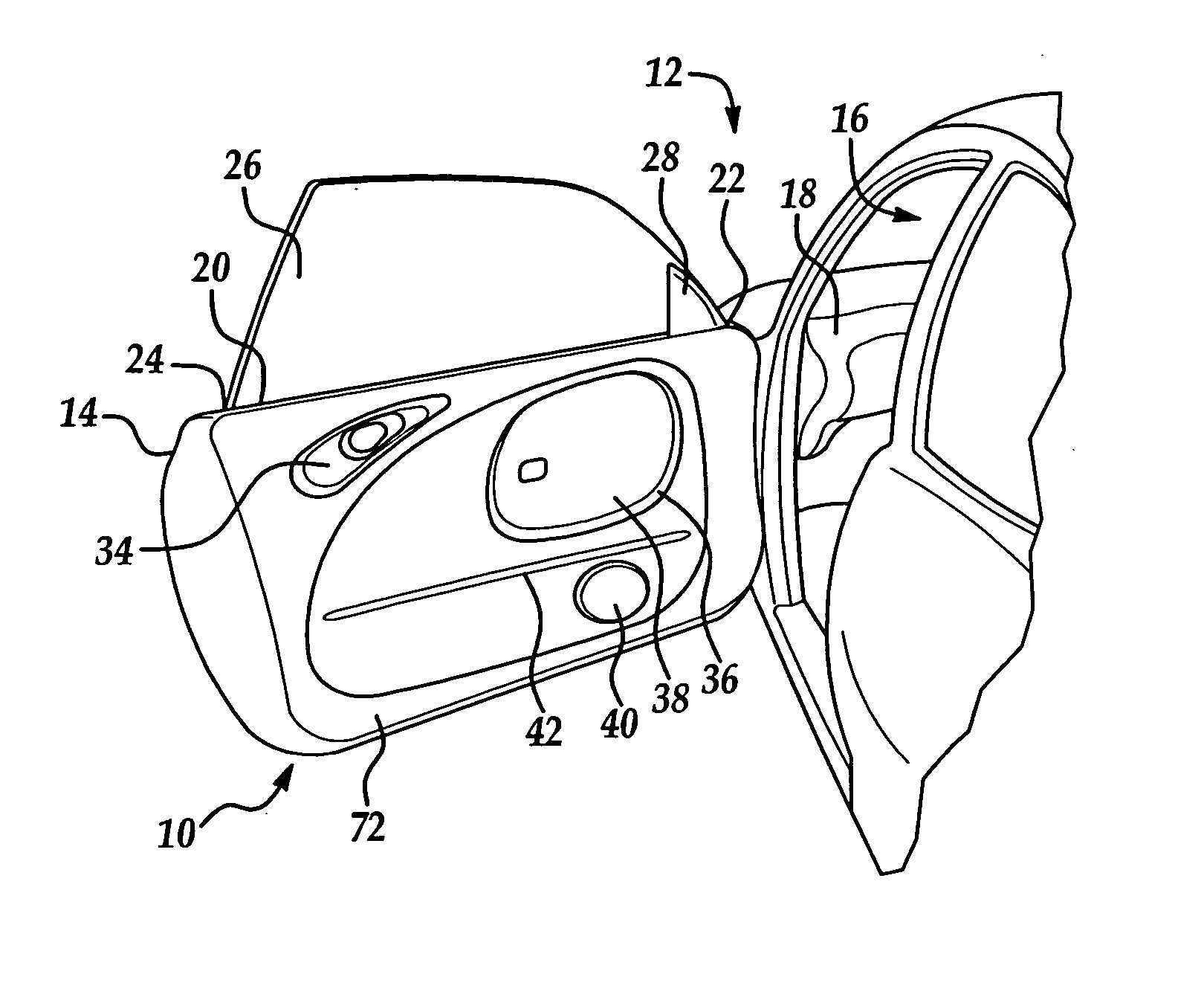

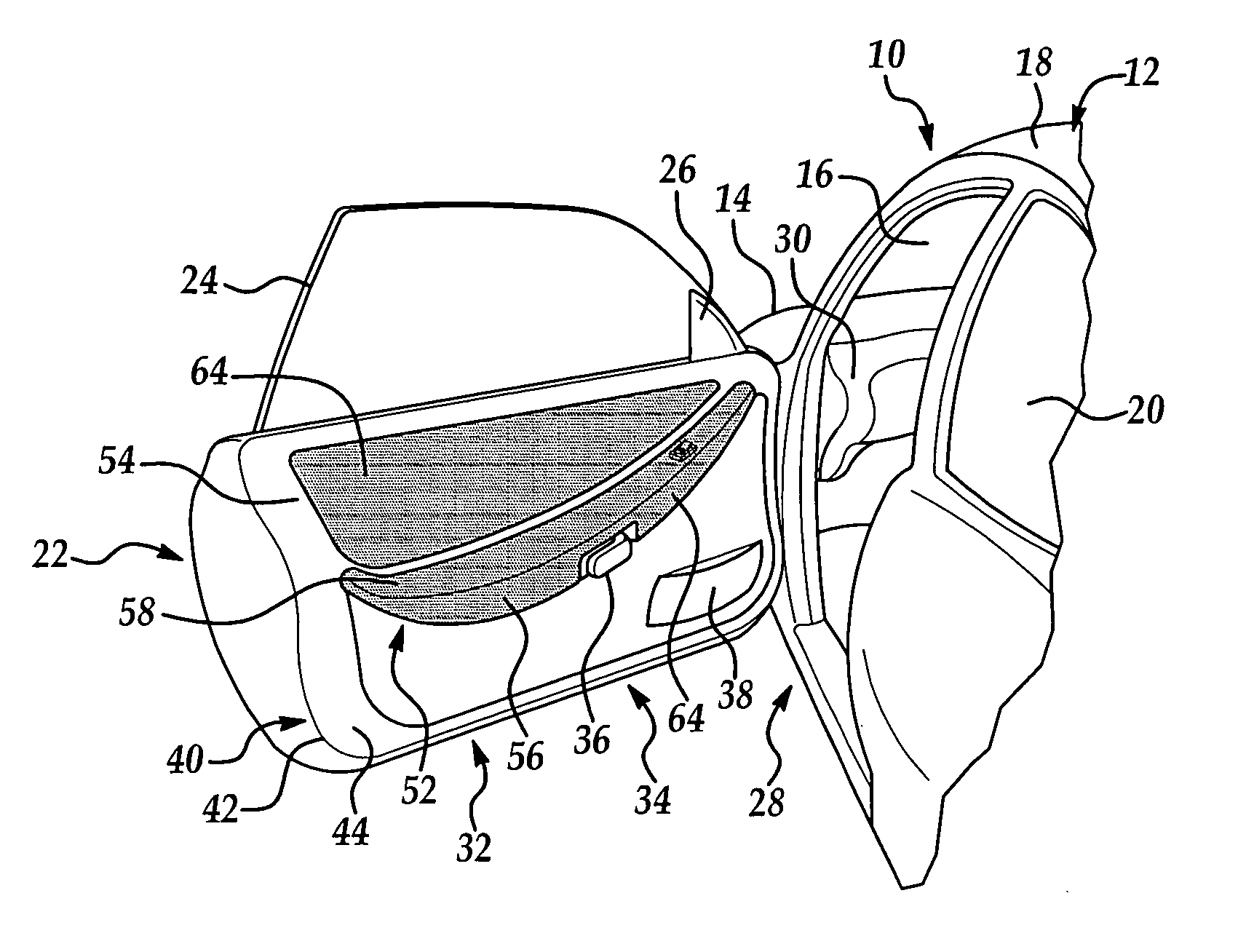

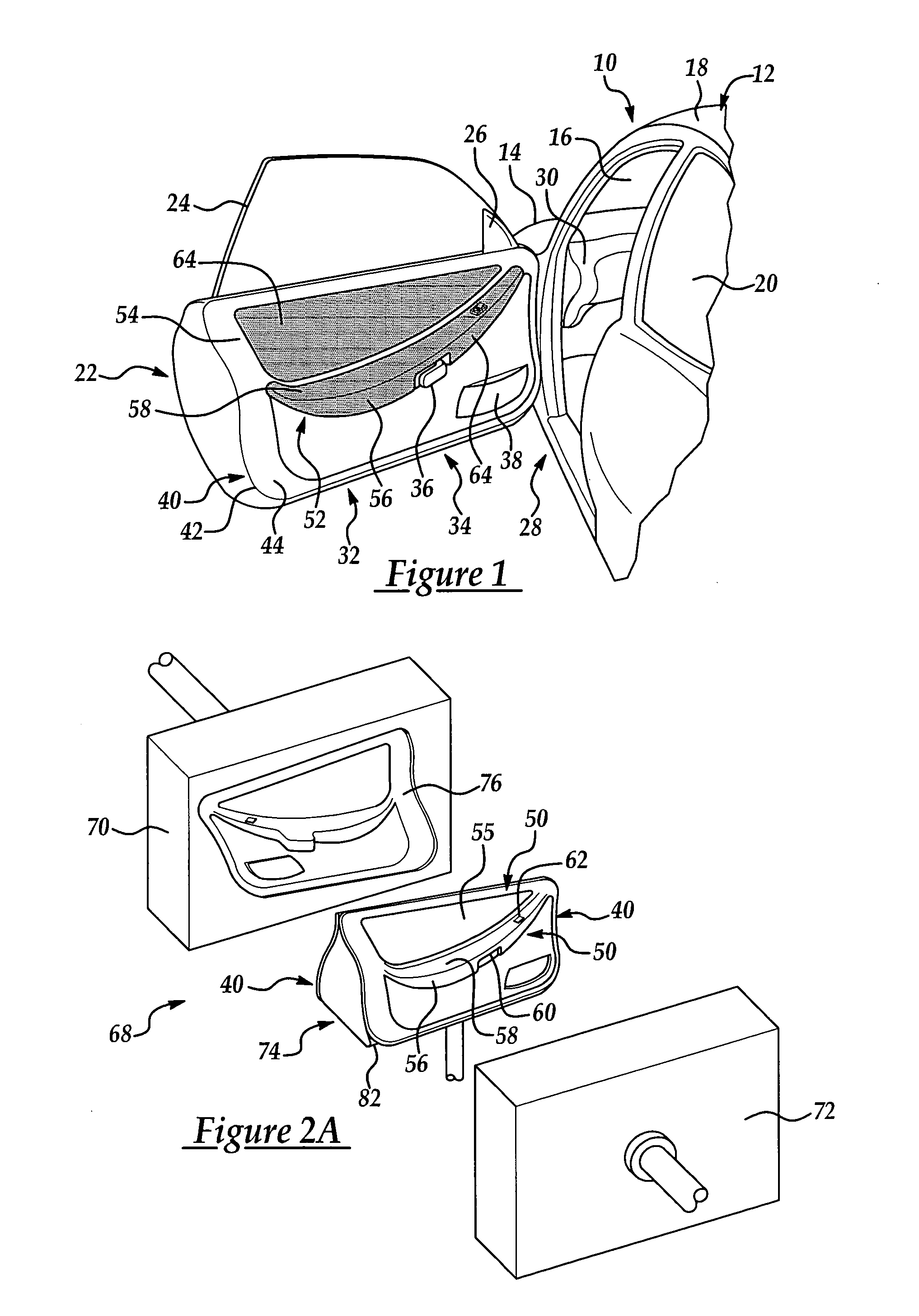

Door trim panel assembly having integrated soft-touch aesthetic feature and method of manufacturing same

InactiveUS20050140168A1Step be reduceEliminates quality issueSuperstructure subunitsDomestic articlesStructural elementVolumetric Mass Density

The present invention relates to a method of manufacturing a door trim panel assembly having an integrated soft-touch area including actuating a core within a mold cavity so as to partition at least one area of the mold cavity, to prevent a first molten thermoplastic material from completely filling the mold cavity. A first molten thermoplastic material having a predetermined density is then injected into a mold cavity so as to fill the mold cavity thereby forming a structural element. The core is then retracted within the mold cavity to provide at least one secondary void within the mold cavity. A second molten thermoplastic material having a density less than the predetermined density of the first molten thermoplastic material is then injected into said secondary void of the mold cavity to form at least one soft-touch area bonded to and adjacent at least a portion of the structural element.

Owner:LEAR CORP

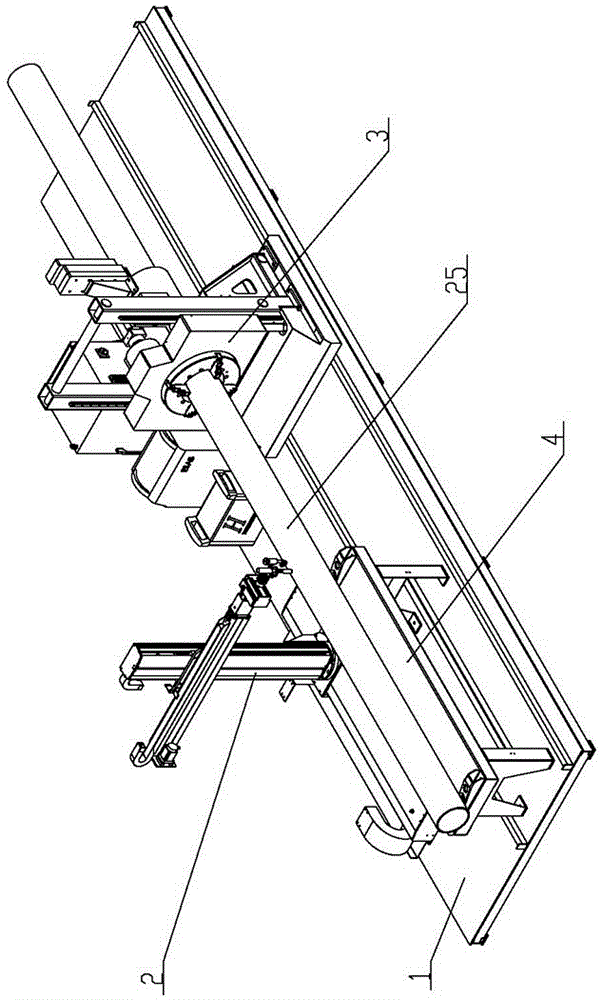

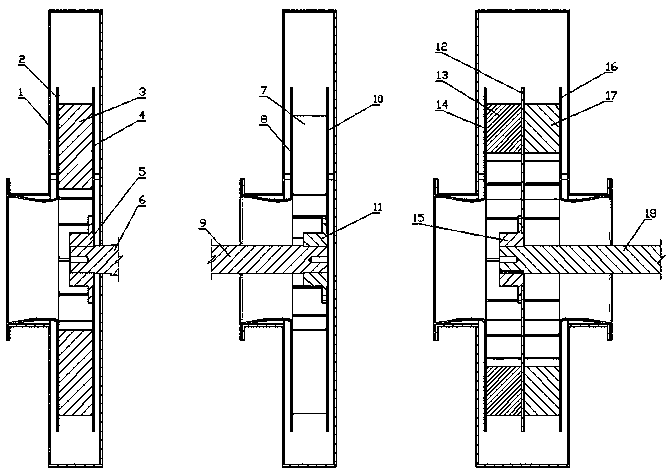

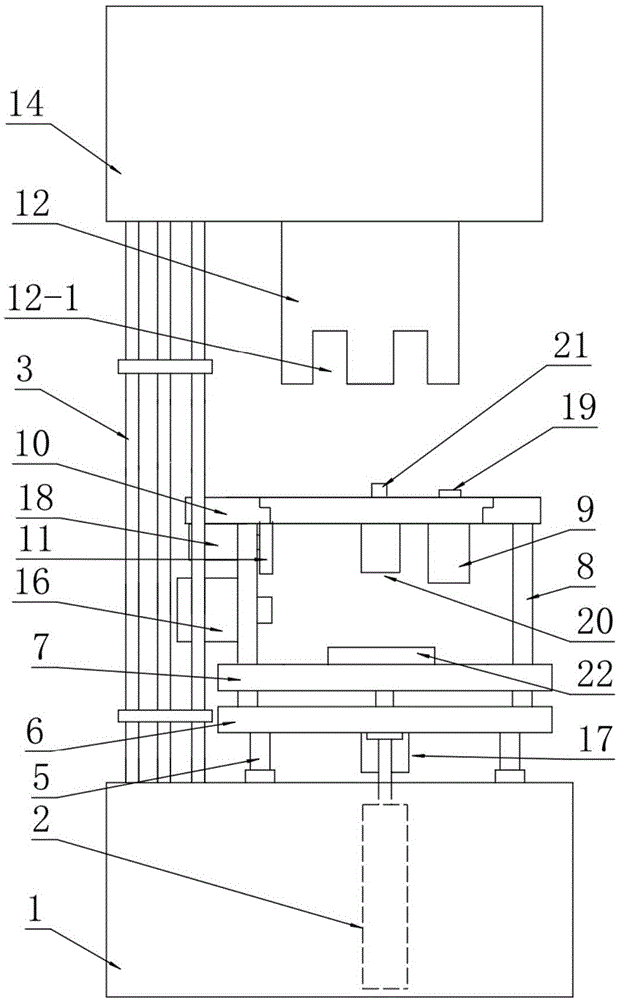

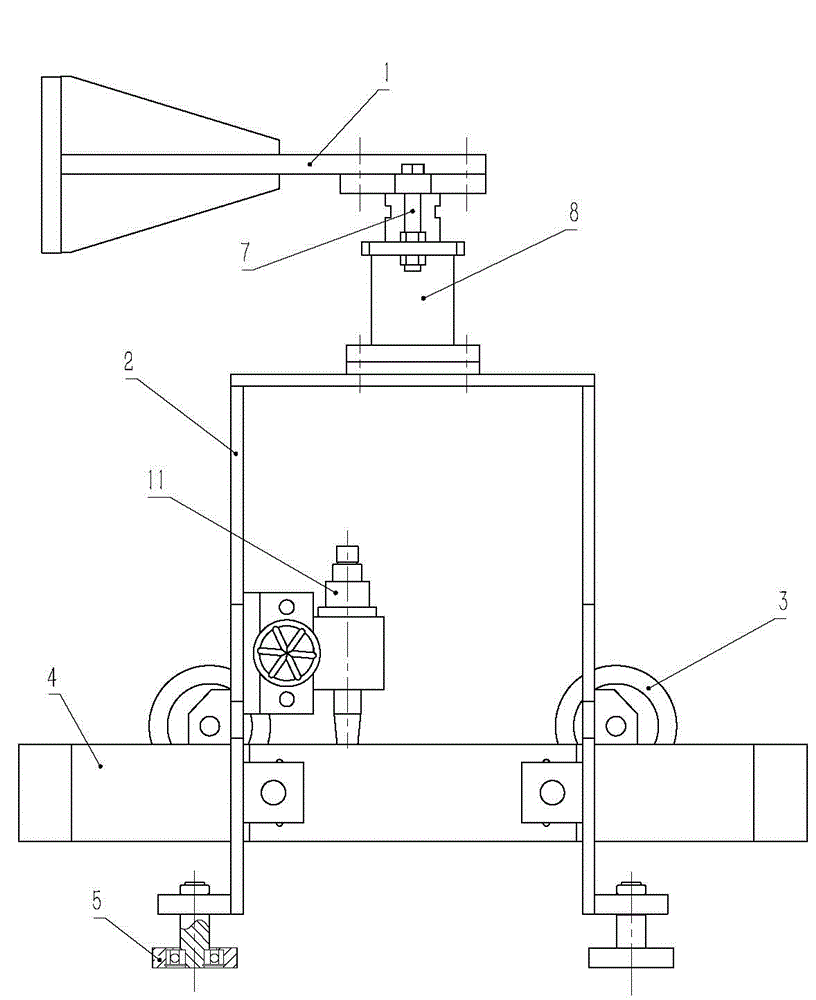

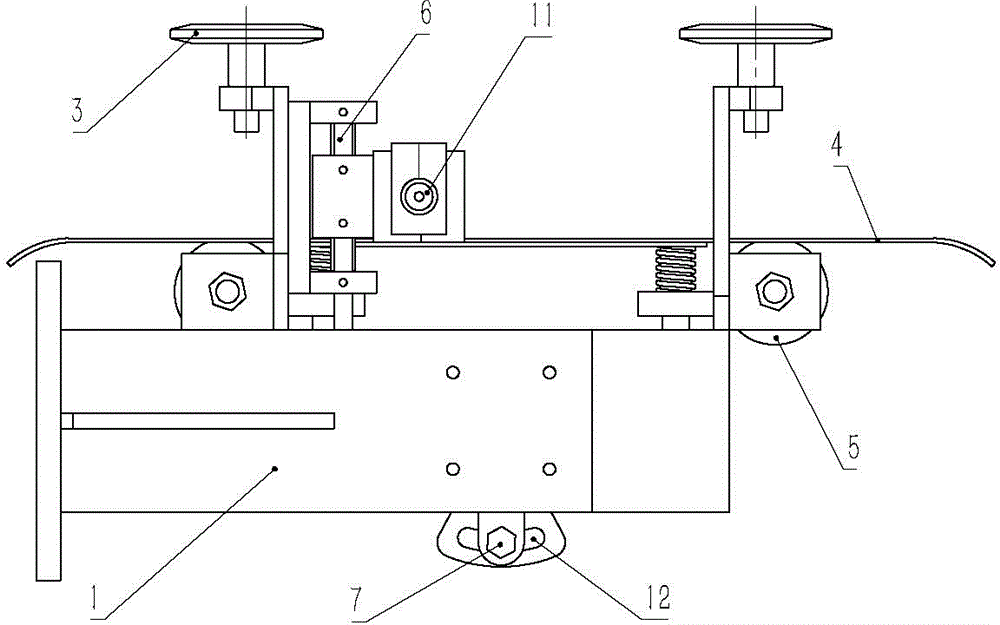

Pipeline tapping cutting and butt weld welding working station

ActiveCN105904132AAdjust levelAdjustabilityWelding/cutting auxillary devicesAuxillary welding devicesButt weldingControl engineering

The invention relates to the technical field of pipeline machining devices, in particular to a pipeline tapping cutting and butt weld welding working station. The pipeline tapping cutting and butt weld welding working station comprises a mobile manipulator, a displacement sensor, a controller and a displayer. The mobile manipulator comprises a manipulator head, a transverse arm, a stand column, a base, a first drive mechanism, a second drive mechanism and a third drive mechanism; the displacement sensor is mounted on the manipulator head, the displacement sensor is connected with the controller, and the controller is connected with the first drive mechanism, the second drive mechanism, the third drive mechanism and the displayer; the manipulator head is carried with the displacement sensor, and therefore the different opposite positions of the manipulator head and a pipeline are transformed; data are introduced into the controller, various parameters of the pipeline are obtained, and the position of the pipeline is manually or automatically adjusted; and in the cutting and welding process, real-time measuring is achieved, the opposite position of the manipulator head and the pipeline is corrected, the influence of disturbing and jumping of the long pipeline in the rotating process on cutting and welding quality and the forming effect is eliminated, and the beneficial effects of being safe, labor-saving, easy, convenient and efficient are achieved.

Owner:新疆威奥科技股份有限公司

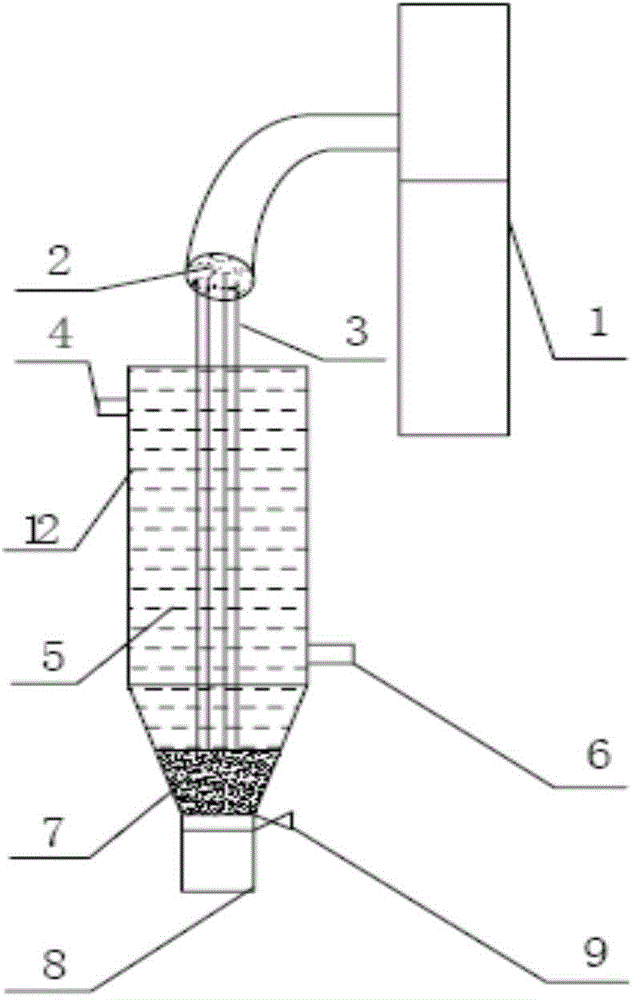

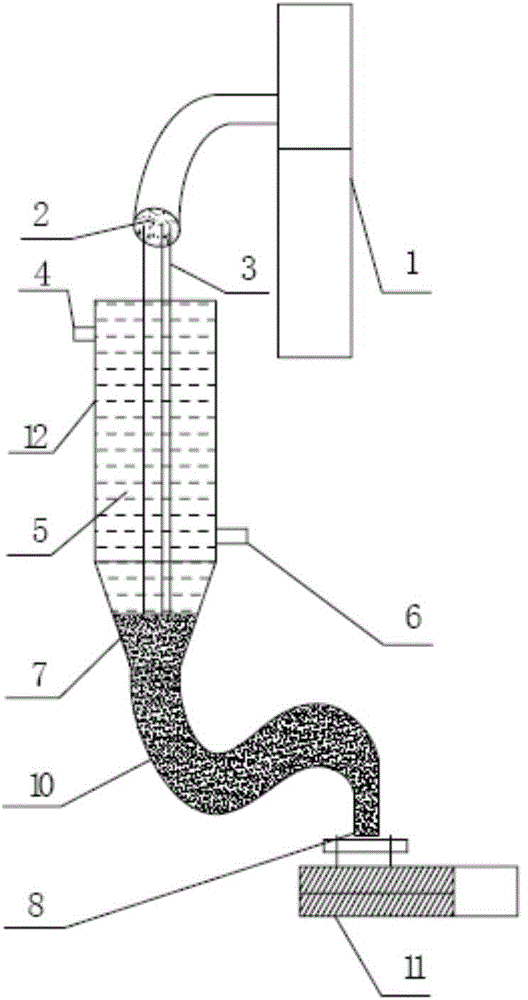

Yunjie mill and applying method thereof and products processed with Yunjie mill

InactiveCN109395824APreserve the flavorImprove economyDrying solid materials with heatFood processingFlavorHigh humidity

The invention discloses a Yunjie mill. The technical scheme that powder milling and drying are finished in a Yunjie mill set in the high-speed circulating flowing process of materials is adopted to realize rapid drying and powder manufacturing in a normal temperature of high-humidity and high-viscosity materials such as fresh agricultural products, and the deficiency existing in equipment of a patent for an invention 2017111181038 is overcome. According to an applying method of the Yunjie mill, the common pain point problems that the quality is poor or the cost is high when a traditional method is used for processing fresh plant materials, meat, liquid materials and the like are solved, an economical solving scheme is provided for processing of feeding agricultural products, and preparation of medicine with volatile components as functional components and the like. According to the products processed by the Yunjie mill, links which generates quality problems in the processing process of the traditional method are eliminated, the finishing time of drying and powder manufacturing is shortened to be within three minutes, and special flavors of the materials under the fresh condition of the products are preserved.

Owner:KUNMING TEKANG TECH CO LTD

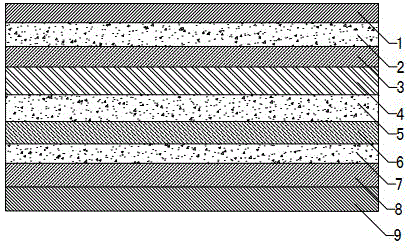

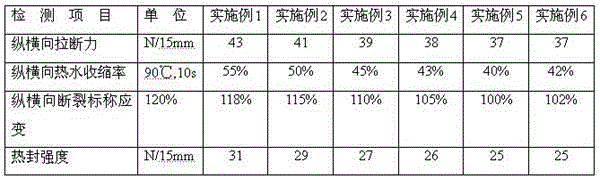

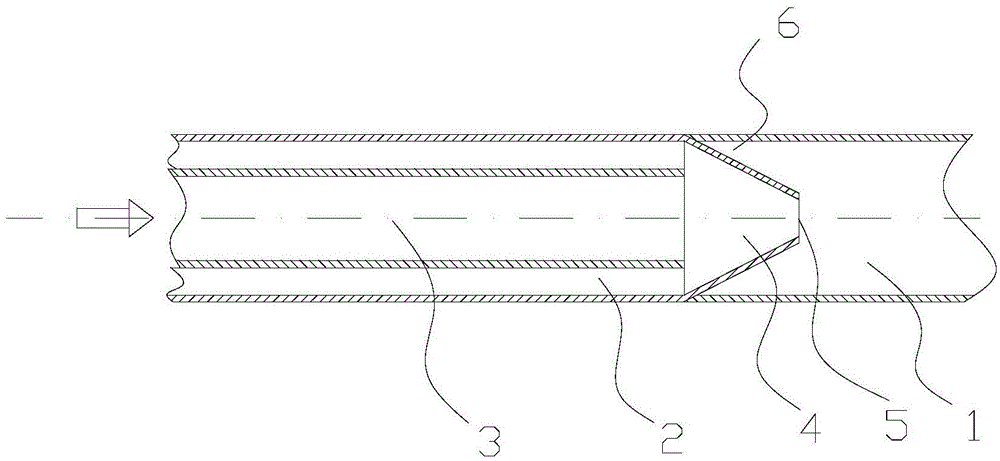

Multilayer improved thermal shrinkage preservative film/bag and base material composition thereof

ActiveCN104608451ALow costReduce wasteSynthetic resin layered productsWater vaporPolyethylene glycol

The invention relates to a multilayer improved thermal shrinkage preservative film / bag and a base material composition thereof, belonging to the technical field of preservative films. The multilayer improved thermal shrinkage preservative film / bag is characterized in that according to the formula, the base material composition comprises the following materials in percentage by weight: 60%-90% of ethanediol modified polyethylene glycol terephthalate copolymers, 5%-20% of ethylene acrylic acid copolymers or maleic anhydride graft polymers and 5%-20% of a soft improver; the preservative film is prepared by adopting the base material composition of the multilayer improved thermal shrinkage preservative film as a resin-based functional layer (4), and at least one functional layer and at least one adhesive layer are co-extruded on the upper surface and the lower surface of the resin-based functional layer (4) so as to form a multilayer layered structure. The multilayer improved thermal shrinkage preservative film / bag disclosed by the invention contains no chloride, is free of crosslinking and has excellent puncture resistance and oxygen and water vapor obstruction property.

Owner:轩福君

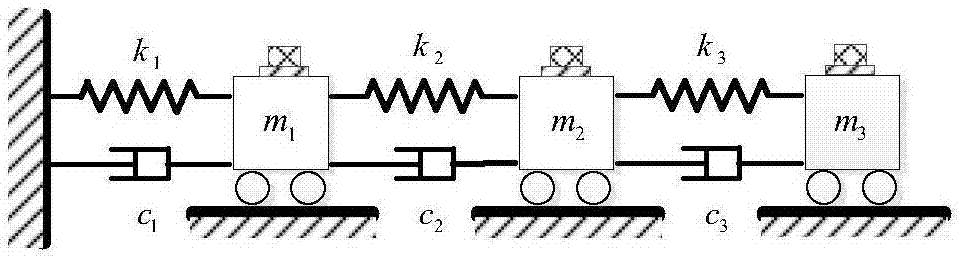

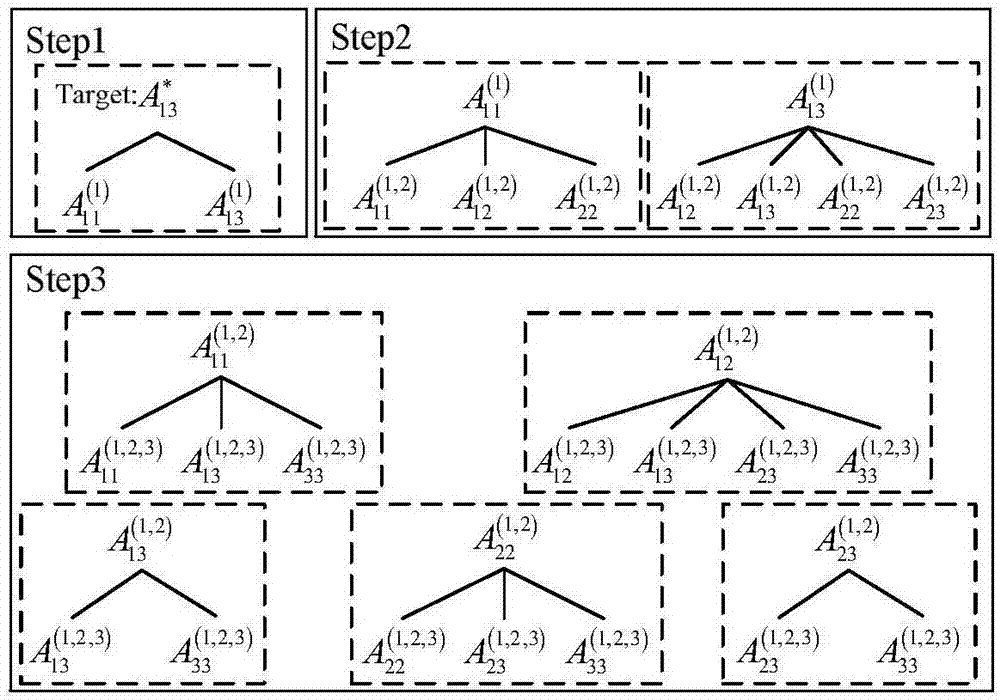

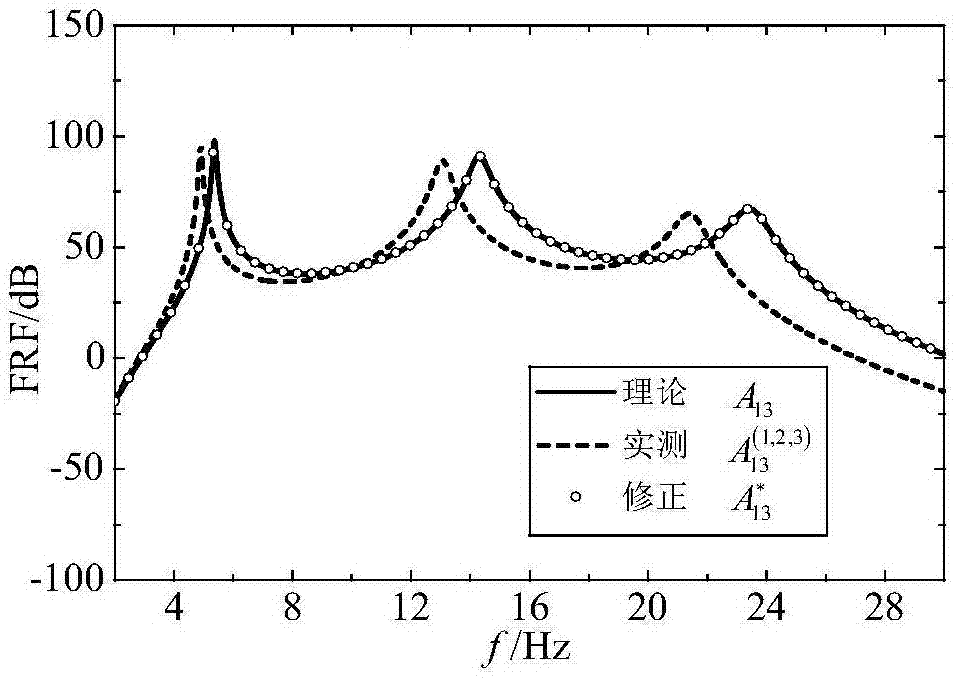

Multi-sensor additional mass elimination method in modal test

ActiveCN107356387AEliminate quality issuesEliminate measurement errorsVibration testingMultiple sensorContact type

The invention provides a multi-sensor additional mass elimination method in a modal test. A multi-sensor mass influence elimination formula in the modal test is deducted, the number of sensors arranged in the modal test and the sequence for eliminating the mass of the sensors are determined, and frequency response functions for eliminating the influence of the mass of the sensors are calculated one by one according to the elimination formula based on actual measurement frequency response functions. According to the method, firstly, the sensor mass influence elimination formula is deducted based on the Sherman-Morrison formula, the required frequency response functions are actually measured according to the formula and substituted into the formula in sequence for elimination one by one, and finally elimination of the mass of multiple sensors is realized. According to the method, measuring errors caused by additional mass of the sensors in the contact type measuring method in the modal test are eliminated, the unfavorable influence of the mass of multiple sensors on the frequency response functions is eliminated through the processing of actual measurement frequency response function signals, and the practical engineering significance is achieved.

Owner:SOUTHEAST UNIV

Freezing-disintegrating process of boswellia carterii and myrrh

ActiveCN1813852ASolve the softening bondFinished product quality is stablePlant ingredientsMyrrhMedicine

The present invention discloses a freeze-pulverizing process of frankincense and myrrh. It is characterized by that on the basis of original low-temperature pulverization technique said invention adopts fractionally-freezing and fractionally-pulverizing method, so that it can make the effective components of medicinal material be fully released, and can make the quality of medicinal material fine powder be greatly raised.

Owner:九寨沟天然药业股份有限公司

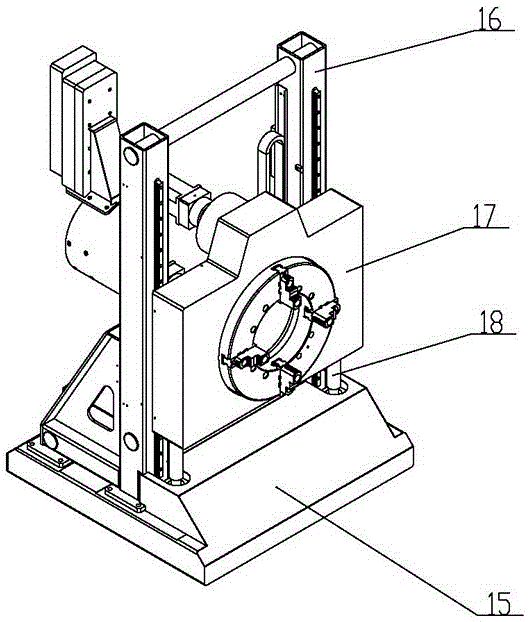

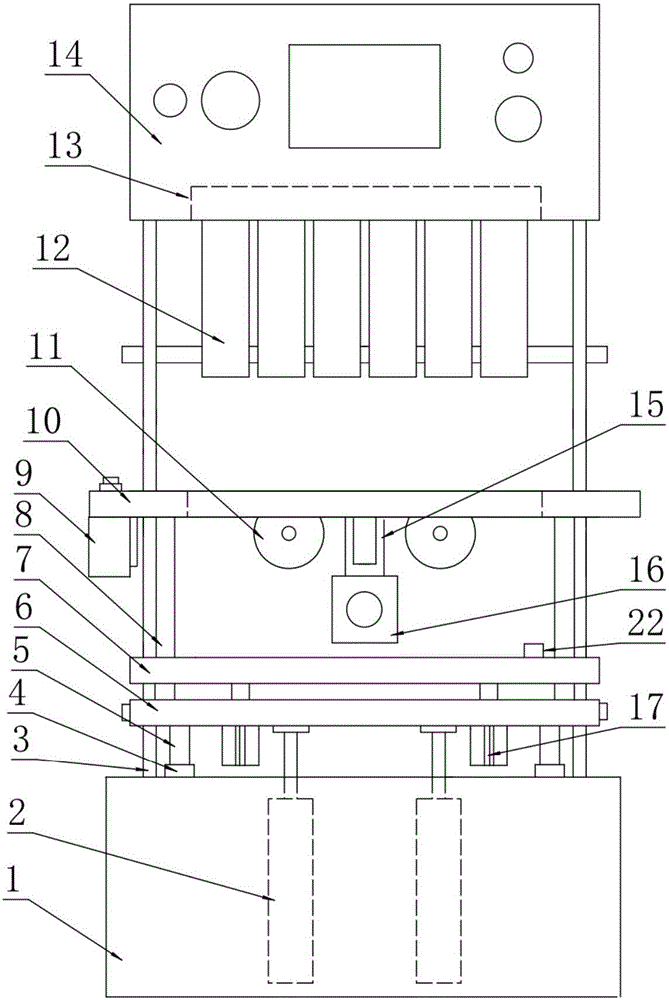

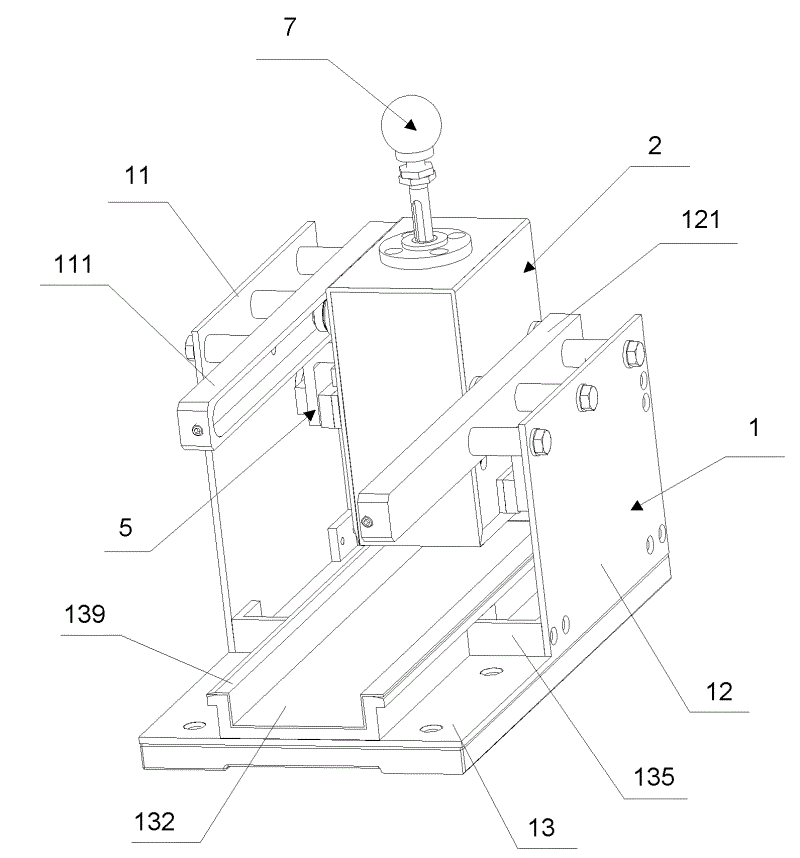

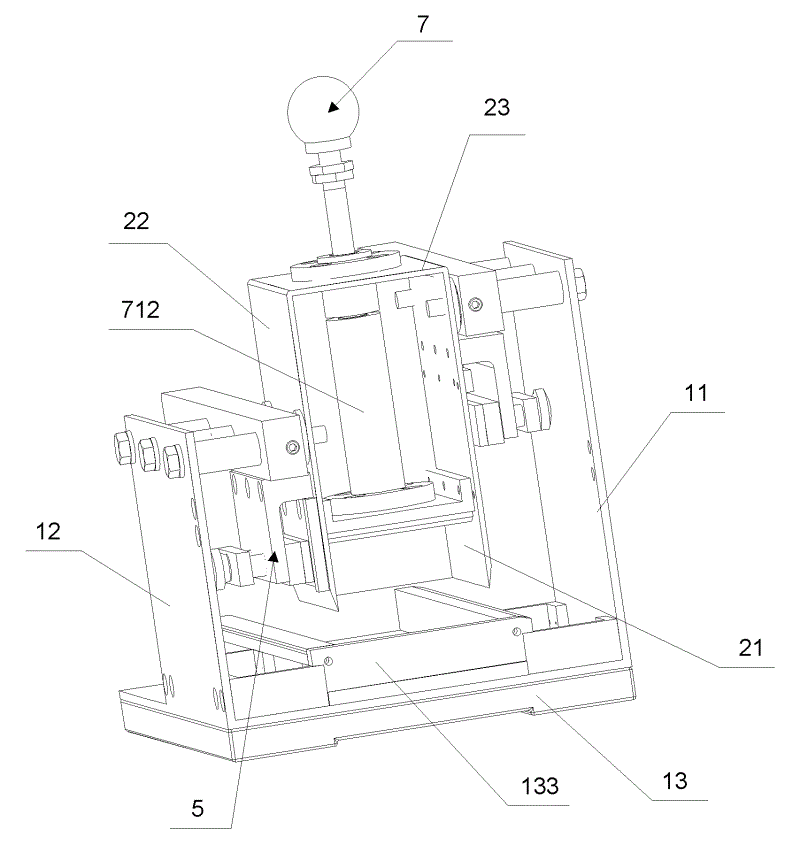

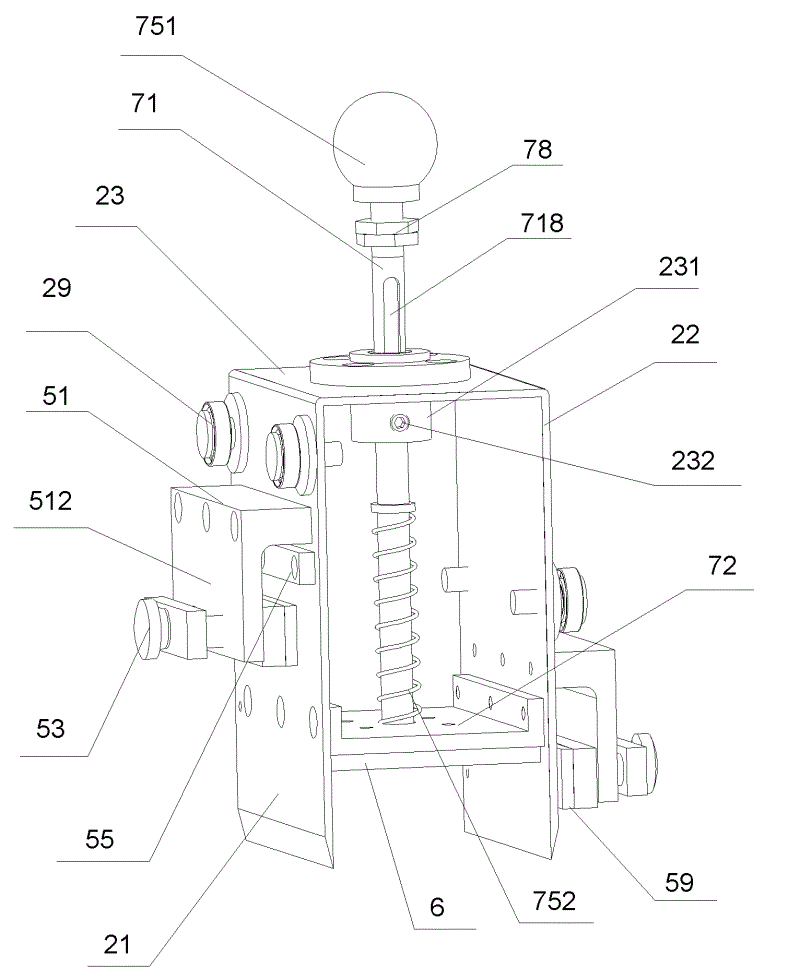

Storage battery automatic slot entering device

ActiveCN106299491ASlot implementationMeet the needs of large-scale productionFinal product manufactureLead-acid accumulators constructionComputer moduleAssembly line

A storage battery automatic slot entering device comprises a base, a slot entering lifting mechanism, a battery shell lifting mechanism, a pole group clamp support frame, a machine head and pole group press-mounting modules, wherein a row of columns are fixed on two sides of the base respectively, the machine head is fixed at the upper parts of the columns, and the pole group press-mounting modules are fixed at the lower part of the machine head; a lifting plate is arranged on the slot entering lifting mechanism and can move up and down relative to the base, a battery shell supporting plate is arranged on the battery shell lifting mechanism and located on the lifting plate and can move up and down relative to the lifting plate, the pole group clamp support frame is located on the battery shell supporting plate, and the pole group press-mounting modules correspond to the pole group clamp support frame in the vertical direction. With the adoption of the storage battery automatic slot entering device, a storage battery can enter a slot automatically, heavy physical labor of an operator is relieved, the production efficiency is improved, and the potential safety hazard and the potential quality hazard are eliminated. Different specifications of storage batteries can enter the slot, the device is matched equipment for storage battery assembly lines, and the requirement of large-scale production of the storage batteries can be met.

Owner:FENGFAN

Intermediate-temperature-sensitized emulsion explosive and preparation method thereof

InactiveCN104803814AGuaranteed processing effectCharge smoothlyExplosivesMINERAL WAXMicrocrystalline wax

The invention discloses an intermediate-temperature-sensitized emulsion explosive and a preparation method thereof. The emulsion explosive is obtained through sensitization of emulsion matrix and a sensitizer, wherein the weight ratio of the emulsion matrix to the sensitizer is 98-99.6:0.4-2; the emulsion matrix comprises 5-10 percentage by weight of oil phase and 90-95 percentage by weight of aqueous phase; the oil phase comprises 28-40 percentage by weight of an emulsifying agent and 60-72 percentage by weight of an oil phase material; the oil phase material is a compound formed by compounding complex wax with any two of liquid paraffin, mineral wax or microcrystalline wax. The preparation method comprises the following steps: the oil phase and the aqueous phase are pressurized through a screw pump and are then mixed in a static mixer to be subjected to pre-emulsification and fine emulsification, so as to obtain emulsion matrix, the emulsion matrix is cooled to 65-75 DEG C and is then pressurized again through the screw pump to be mixed with the sensitizer in the static mixer, and then the mixture is sensitized at a temperature of 65-75 DEG C, so as to obtain the intermediate-temperature-sensitized emulsion explosive. According to the intermediate-temperature-sensitized emulsion explosive and the preparation method thereof, the emulsion matrix has low viscosity at the temperature of 65-75 DEG C, the technical problem that during high-temperature sensitization, opposite phase of the oil phase material of the emulsion explosive is easily caused is solved, and the technical defect that sensitization bubbles are easily damaged when loading low-temperature-sensitized high-viscosity and high-hardness emulsion matrix is overcome.

Owner:CHANGSHA YICHUAN ELECTROMECHANICAL EQUIP TECH

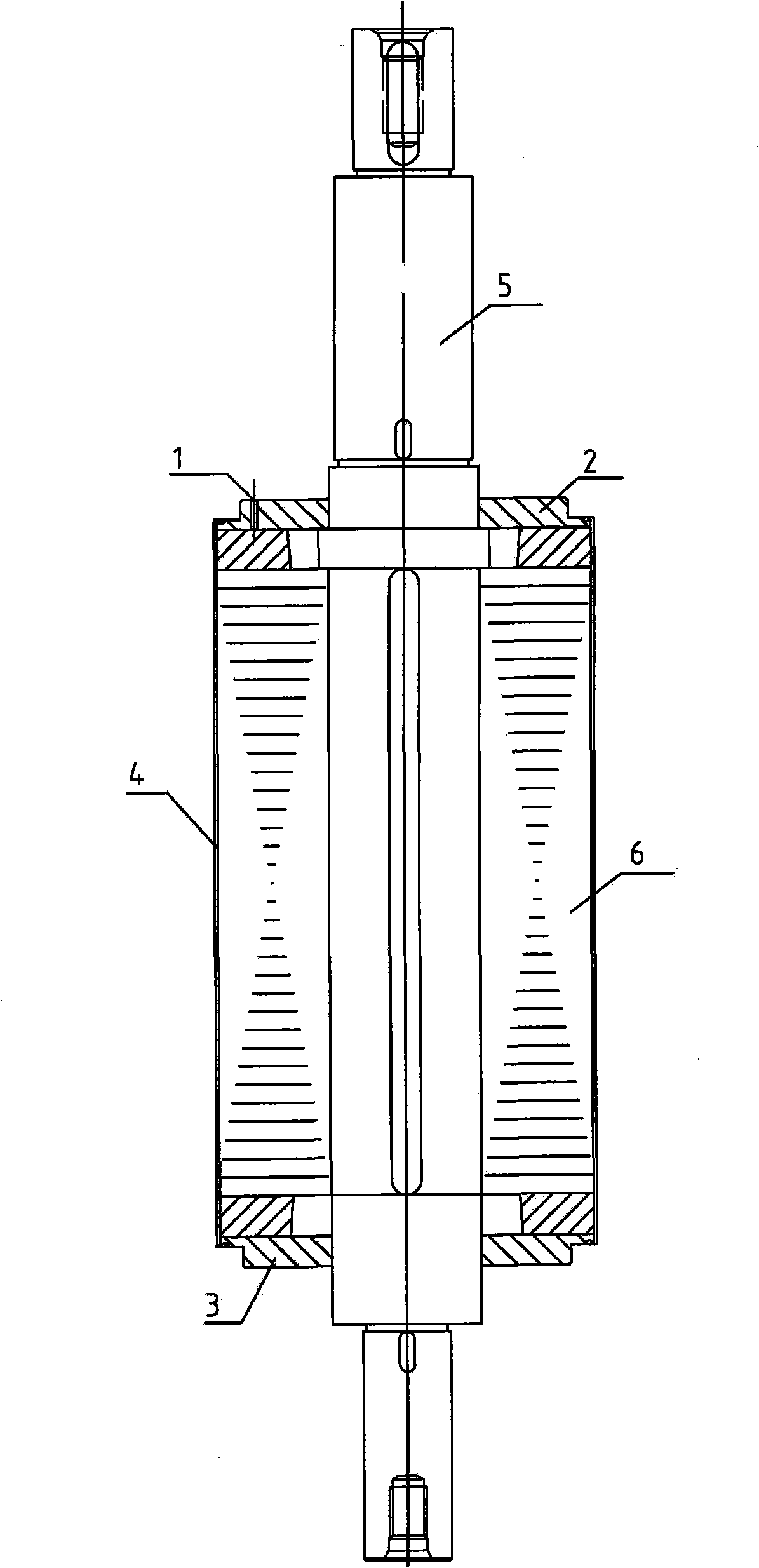

Machining method of shielding motor rotor

ActiveCN101309034AEliminate the bulge of the shielding sleeveNo longer deformedManufacturing stator/rotor bodiesThermal expansionEngineering

Disclosed is a processing method for shielding a motor rotator. Two shielding plates are covered on the shaft when a rotator is processed by rough machining; then the connection part between the shaft and the shielding plate is processed by argon arc welding; then a stainless steel thread is welded by fusion welding on the base to achieve a sealing function; then the rotator is processed by finish machining and a rotator shield cover is installed; and then the rotator is put into an oven and kept at the temperature of 250 DEG C for 4-5 hours to vaporize the moisture out of the rotator inner cavity from the leakage detecting hole by high temperature; after that, the rotator is taken out and the leakage detecting hole is immediately sealed by argon arc welding; and then the rotator can be moved to following processes. Compared with prior art, firstly, the method solves the problem of leaving moisture in the rotator and effectively avoids the bulge phenomena of the rotator shield cover; secondly, the rotator is sealed after being in 250 DEG C for long time, the shield cover can shrink and closely cling to the outer diameter of the rotator iron core after cooling, making the place thereof gapless; moreover, the shield cover will not distort in the future when the pump works because the shield cover performs a certain of thermal expansion and cooling contraction at the situation above the working status.

Owner:HEFEI XINHU CANNED MOTOR PUMP

Automatic welding device of box-type steel member

InactiveCN104785977AImprove work efficiencyImprove processing qualityWelding/cutting auxillary devicesAuxillary welding devicesWeld seamCantilever

The invention discloses an automatic welding device of a box-type steel member. The automatic welding device of the box-type steel member is characterized in that the upper end of a support is connected with the lower end of a cantilever seat in a rotating mode; a movable seat arranged in the middle of the support is longitudinally connected with a welding gun; an outer side support of the welding gun is transversely connected with a walking wheel; an inner side support of the welding gun is transversely connected with a soldering flux stop plate; the support below the soldering flux stop plate is longitudinally connected with a guide wheel; a rotating center of the walking wheel is perpendicular to the center of the welding gun; a rotating center of the guide wheel is parallel to the center of the welding gun. The walking wheel and the guide wheel on the support are driven to correspondingly move on the top face and side faces of the box-type steel member by controlling over the welding device, and meanwhile welding bars in a middle hole of the welding gun are driven to automatically perform even and dense welding along a welding seam in the length direction of the box-type steel member. Soldering flux fluid generated by welding can be blocked stopped by the soldering flux stop plate and be prevented from flowing outwards. The automatic welding device of the box-type steel member obviously improves the working efficiency and machining quality of welding and effectively lowers production and machining costs.

Owner:龙口市正通钢构建设有限公司

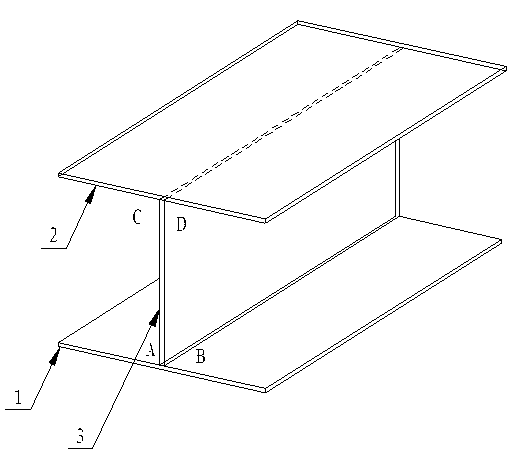

Reversed deformation treatment process before welding of H-shaped steel structures

InactiveCN102990209AEliminate quality issuesImprove work efficiencyArc welding apparatusEconomic benefitsMaterials science

The invention discloses a reversed deformation treatment process before the welding of H-shaped steel structures. An H-shaped steel structure after being assembled by using an upper wing plate, a lower wing plate and a web plate is welded into an H shape. The reversed deformation treatment process comprises the following steps: carrying out feeding and local heat treatment on plates; 2, assembling the plates into an H-shaped steel structure; 3, carrying out submerged-arc welding on the H-shaped steel structure. According to the reversed deformation treatment process before the welding of H-shaped steel structures disclosed by the invention, plates are subjected to preheating treatment in advance, so that the quality problem caused by local deformation in the process of welding is eliminated, and operations of collecting and shaping are not required to be performed after welding, thereby greatly improving the operating efficiency and meeting the practical requirements. Compared with the existing flame heating method, the machining cost of the reversed deformation treatment process is reduced by about 90%, therefore, the reversed deformation treatment process is suitable for wide popularization and application, and has remarkable economic benefits.

Owner:TONGLING FERROUS CONSTR & INSTALLATION STEEL STRUCTURE

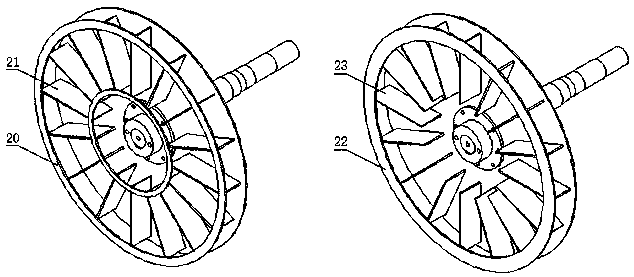

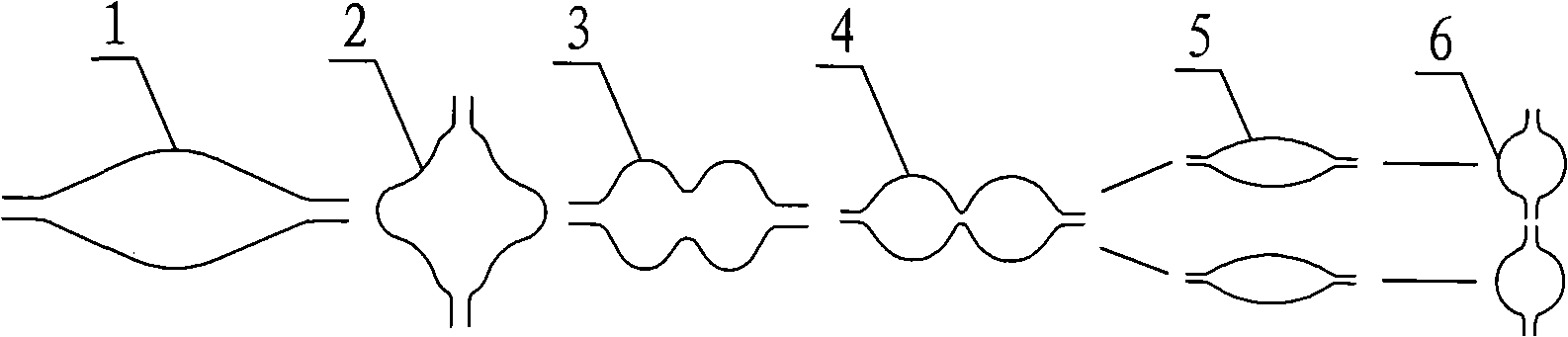

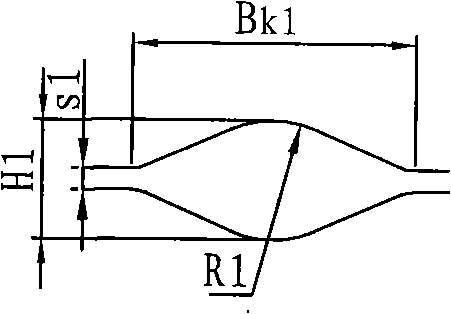

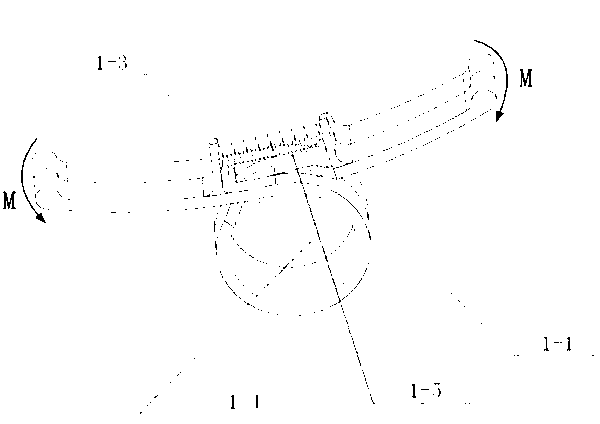

Round steel splitting rolling technique

InactiveCN101306432AHigh speedImprove machine-hour throughputRollsMetal rolling arrangementsProduction rateEllipse

The invention discloses a slit rolling technique of round steel, which comprises the following steps: a blank is rolled into parallel rolled pieces after undergoing the stages of rough rolling, medium rolling and precision rolling; the rolled pieces are slit by a slitting wheel for obtaining the round steel rolled pieces, wherein the roll passes with specific structures and sizes including the rhomboid pass, the cinquefoil square pass, the dumbbell-shaped pre-slit pass, the double-circle slitting pass, the ellipse pass and the round pass are sequentially adopted in the medium rolling and the precision rolling stages, the square rolled pieces rolled by the cinquefoil square pass require further slitting and positioning by a slitting wedge, and the point angle Theta of the slitting wedge is 60 DEG- 65 DEG; finally each thin and narrow connecting band of the rolled pieces is slit by the slitting wheel on a slitting foreplate, wherein the point angle of the slitting wheel is 90 DEG- 95 DEG. The round steel produced by adopting the slit rolling technique of the invention has good surface quality and high production rate, and the slit rolling process can effectively improve the machine-hour yield of the round steel and increase the production efficiency in a factory.

Owner:XINJIANG BAYI IRON & STEEL

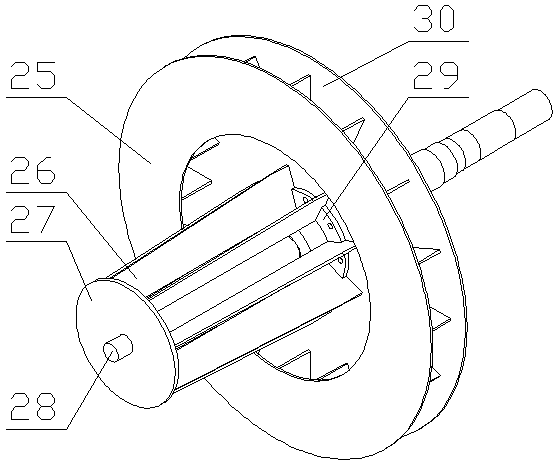

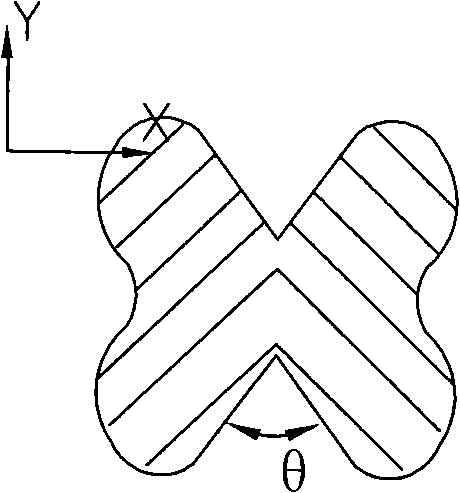

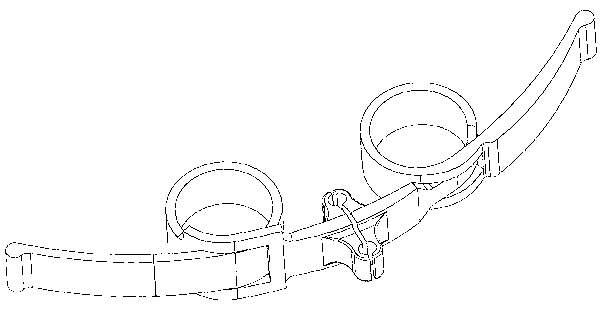

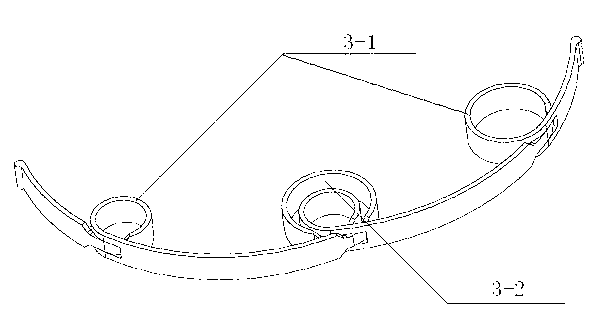

Elastic structural member in through-type rotary geometric shape

ActiveCN103244587AWide selection of mechanical properties of materialsBroaden the range of materials usedConveyorsLeaf springsClassical mechanicsEngineering

The invention discloses an elastic structural member capable of realizing hardness and softness coupled bearing capacity, which is characterized in that the structural member is in a through-type rotatory geometric shape. The through-type rotatory geometric shape provides a path which is easy to balance and realize for allowing the structural member to have the hardness and softness coupled bearing capacity and for performance optimization of the structural member; a material application scope of the elastic structural member can be expanded greatly; either an elastic material, or various rigid materials with larger elastic moduli can be used; the excess mass of the structural member is removed greatly due to the irregular structural form characteristic of the nearly full-coincidence stressed state; and the material is saved, and energy saving and consumption reduction are achieved due to the weight loss of the structural member.

Owner:SUS LAB FOR IND SCI & TECH

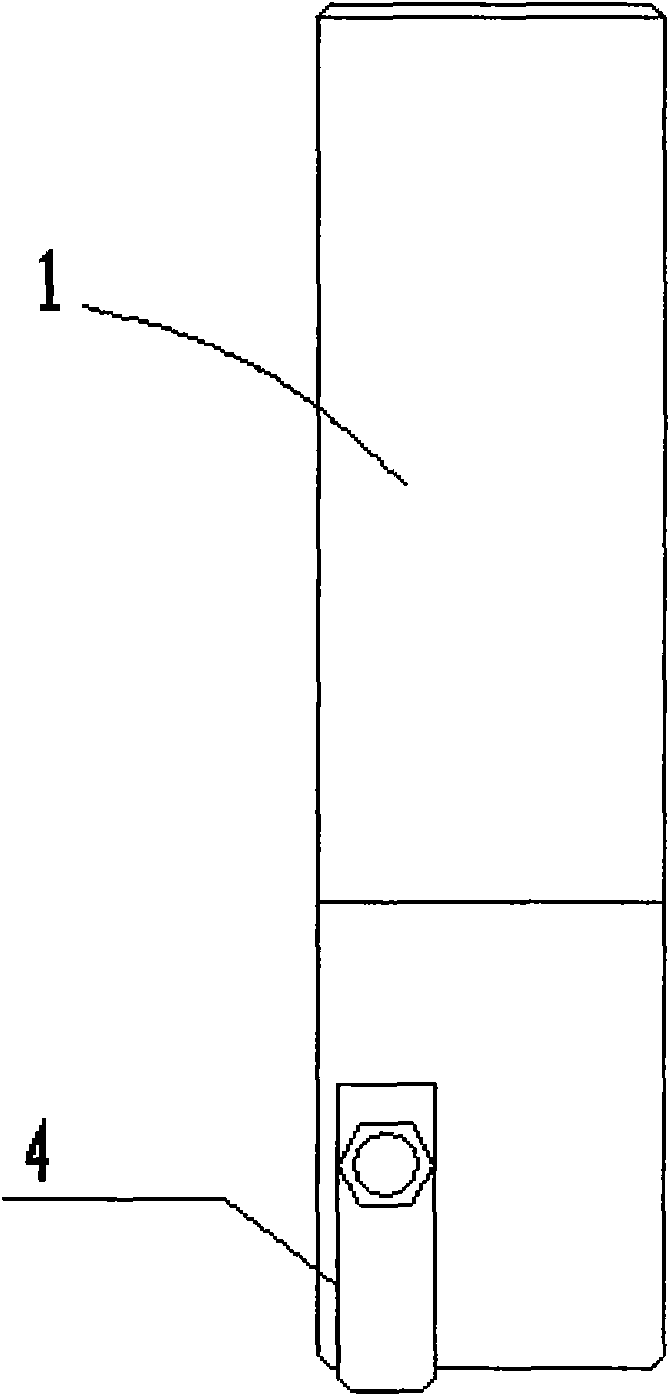

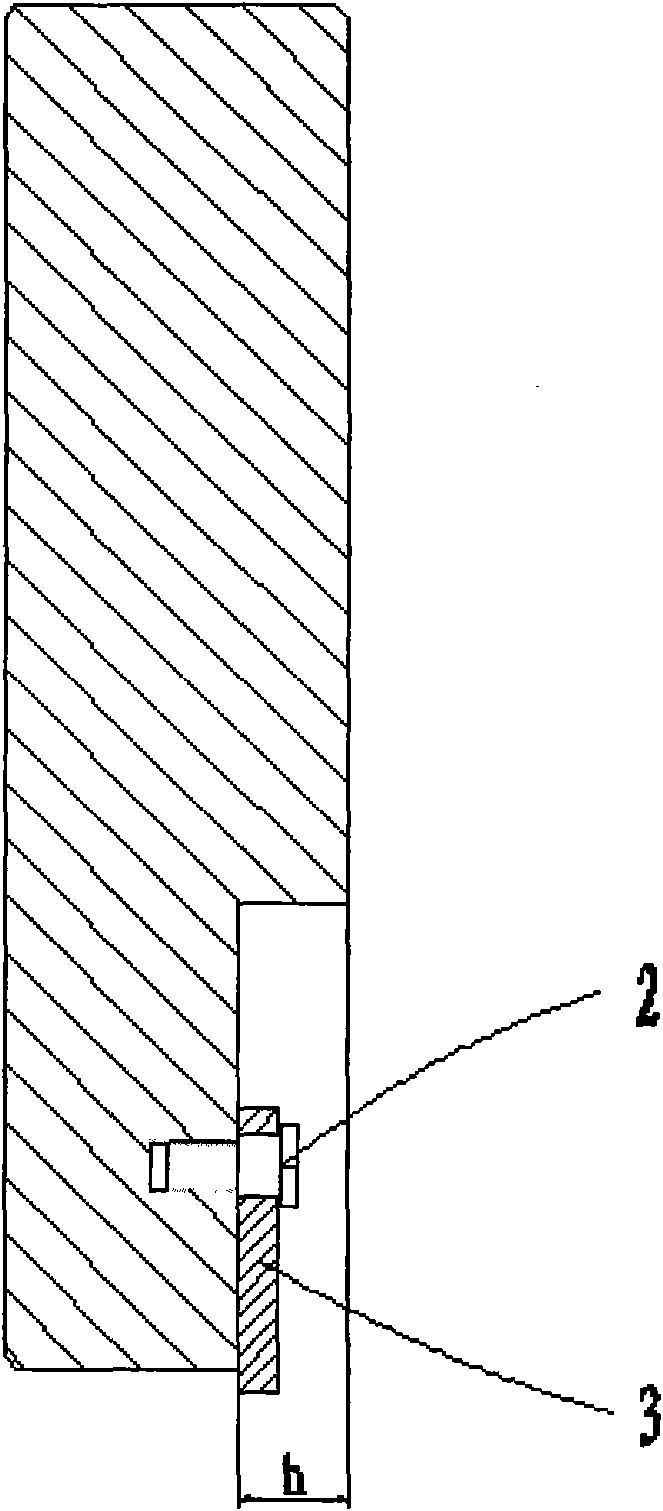

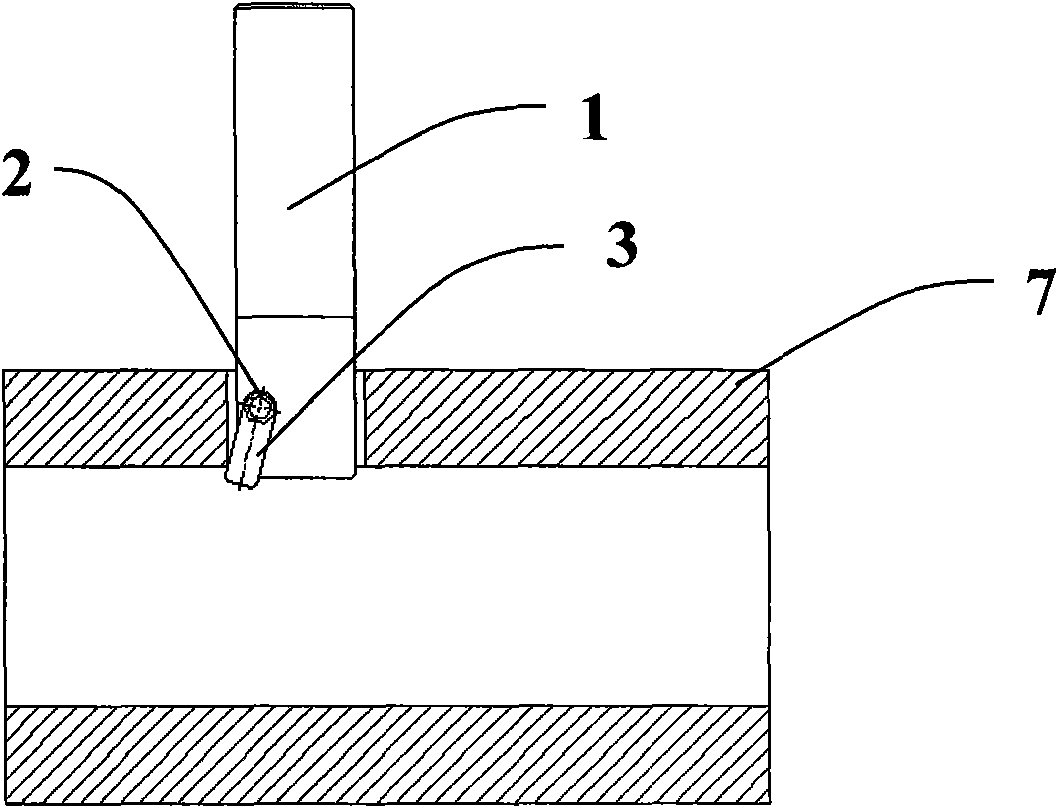

Tool for processing burrs at through position of through hole

InactiveCN102133662ACompact and reasonable structureImprove processing efficiencyEngineeringUltimate tensile strength

The invention discloses a tool for processing burrs at a through position of a through hole, and belongs to the technical field of machining. The tool mainly consists of a tool body, a cutting body and connecting screws. The tool has compact structure, good consistency of removing the burrs and high product burr removal quality, reduces the processing cost, lightens the labor intensity of an operator, and the like. The tool can be widely applied in processing of the removed burrs at the through position of the through hole in machining.

Owner:重庆红宇精密工业集团有限公司

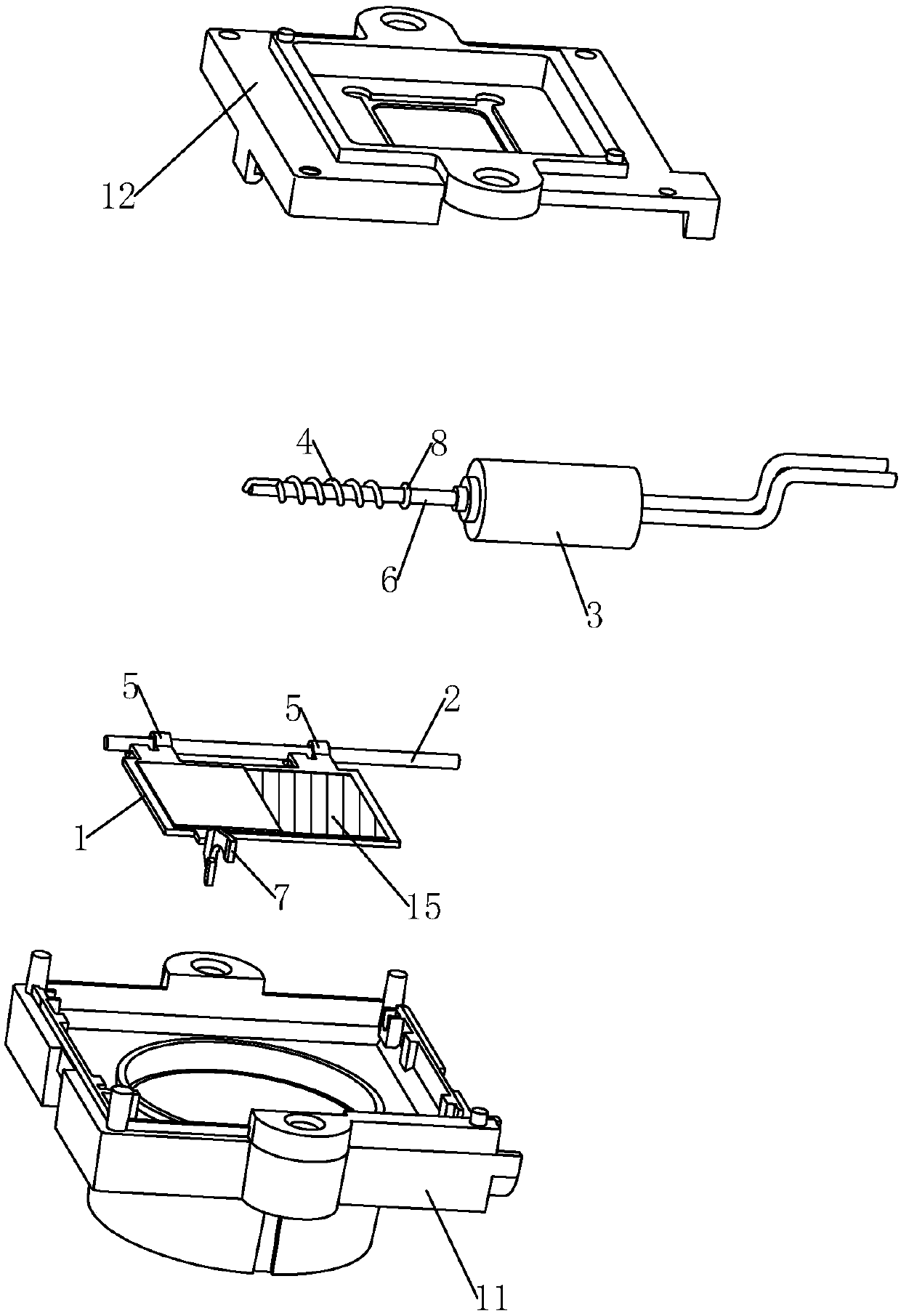

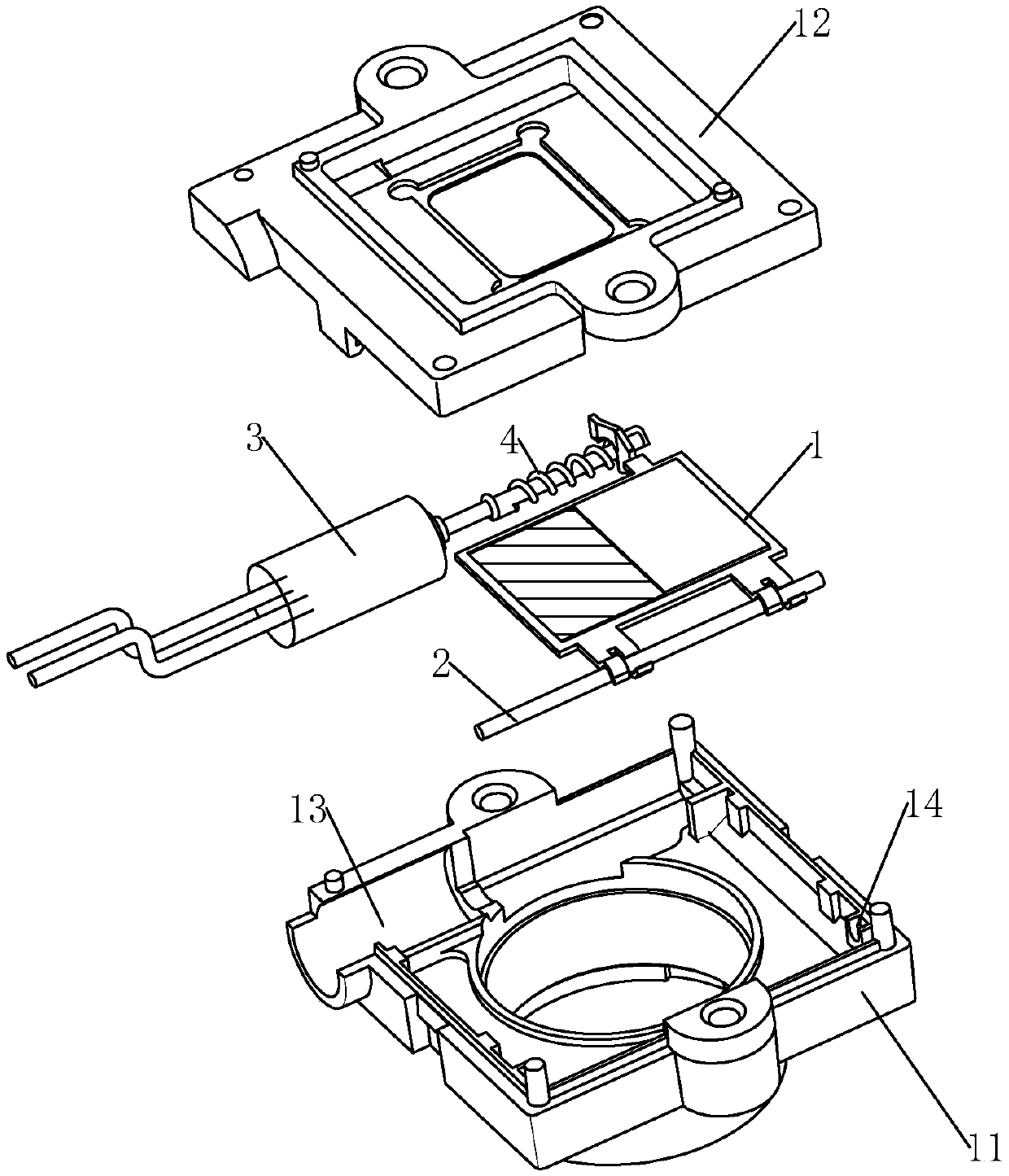

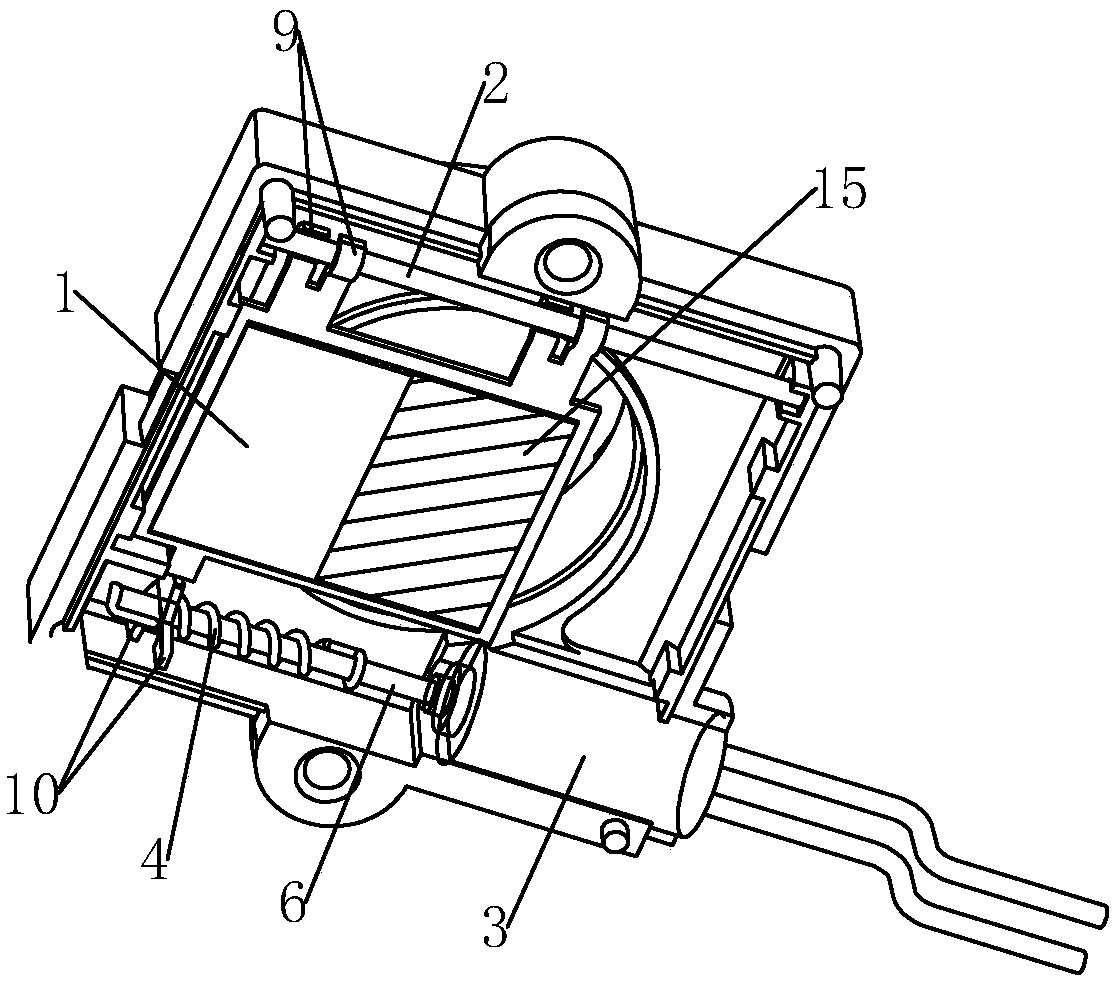

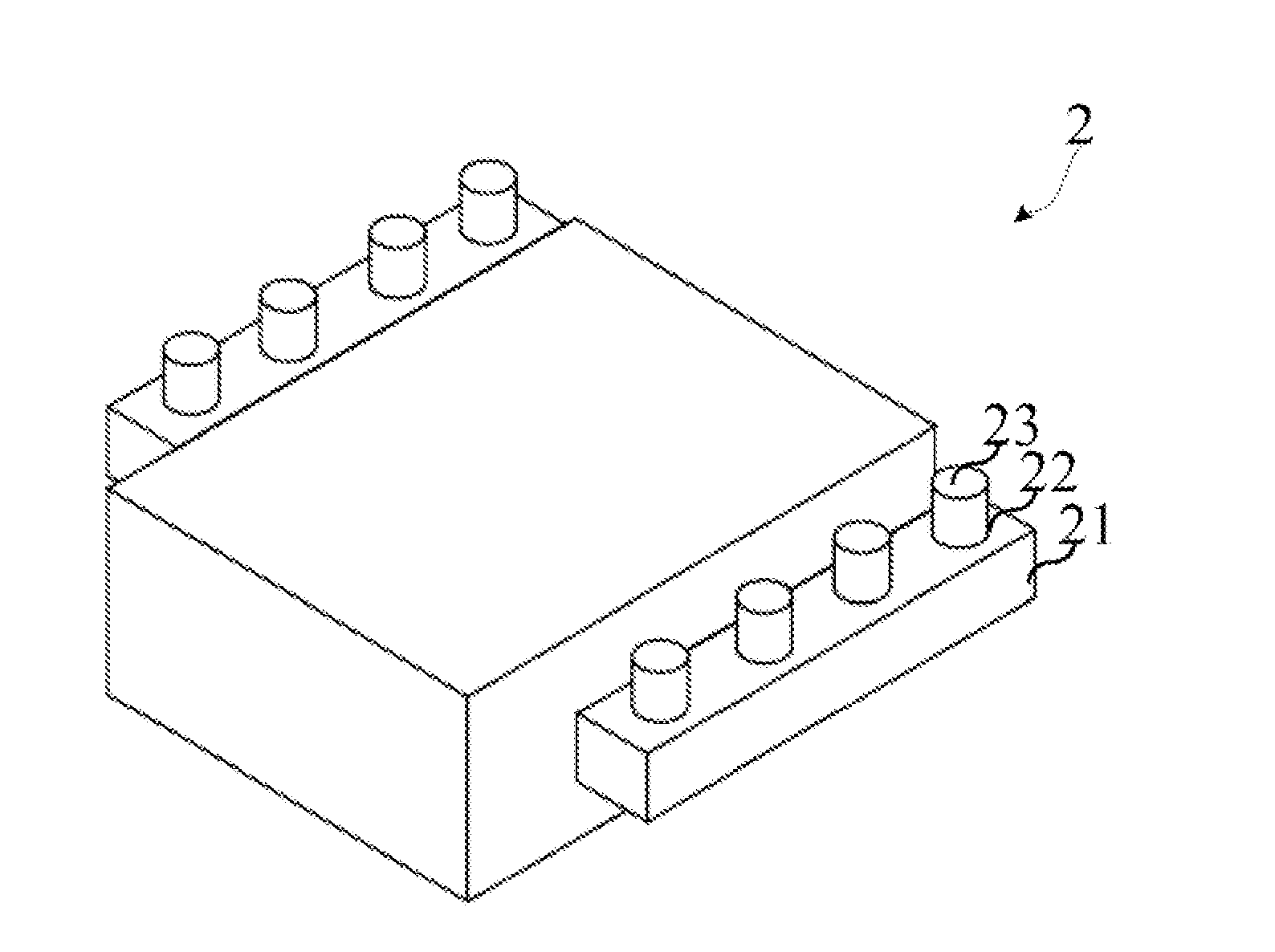

Dual-filter assembly and lens assembly

PendingCN108681064AImprove yieldEliminate quality issuesCamera body detailsOptical elementsProduction line

The invention provides a dual-filter assembly and a lens assembly. The dual-filter assembly comprises a tray, a guide rod, a motor and a spring, wherein the tray is equipped with filters, one side ofthe tray is formed with a first guide member, a second side of the tray is formed with a second guide member, the guide rod is in movable connection with the first guide member, the spring is arrangedon an output rod of the motor in a penetration mode, two ends of the spring are fixedly connected with the output rod, the second guide member is sleeved outside the output rod and is in a spiral gapformed by the spring, and one end of the spring close to the motor is bent to be a limit structure. The dual-filter assembly is advantaged in that switching limit of the tray is achieved through thelimit structure formed by a tail end of the spring, a problem of no switching or defective product flowing-out phenomena caused by dead clamping of a lens arriving at an initial end of the motor as alens tray surpasses the stroke of the motor when a tray is switched on the motor to the tail end in the prior art is solved, and production line yield is improved, and a product to terminal client quality problem is eliminated.

Owner:安徽奇盟光电科技有限公司

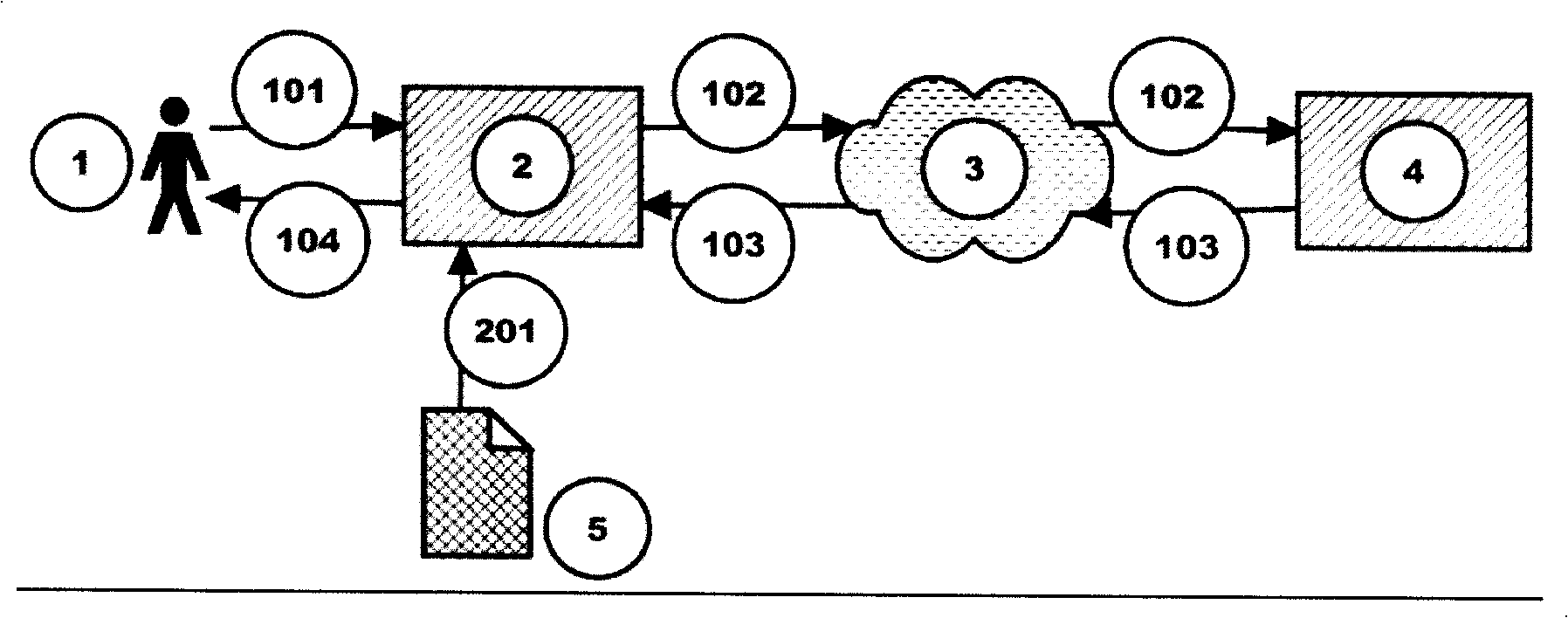

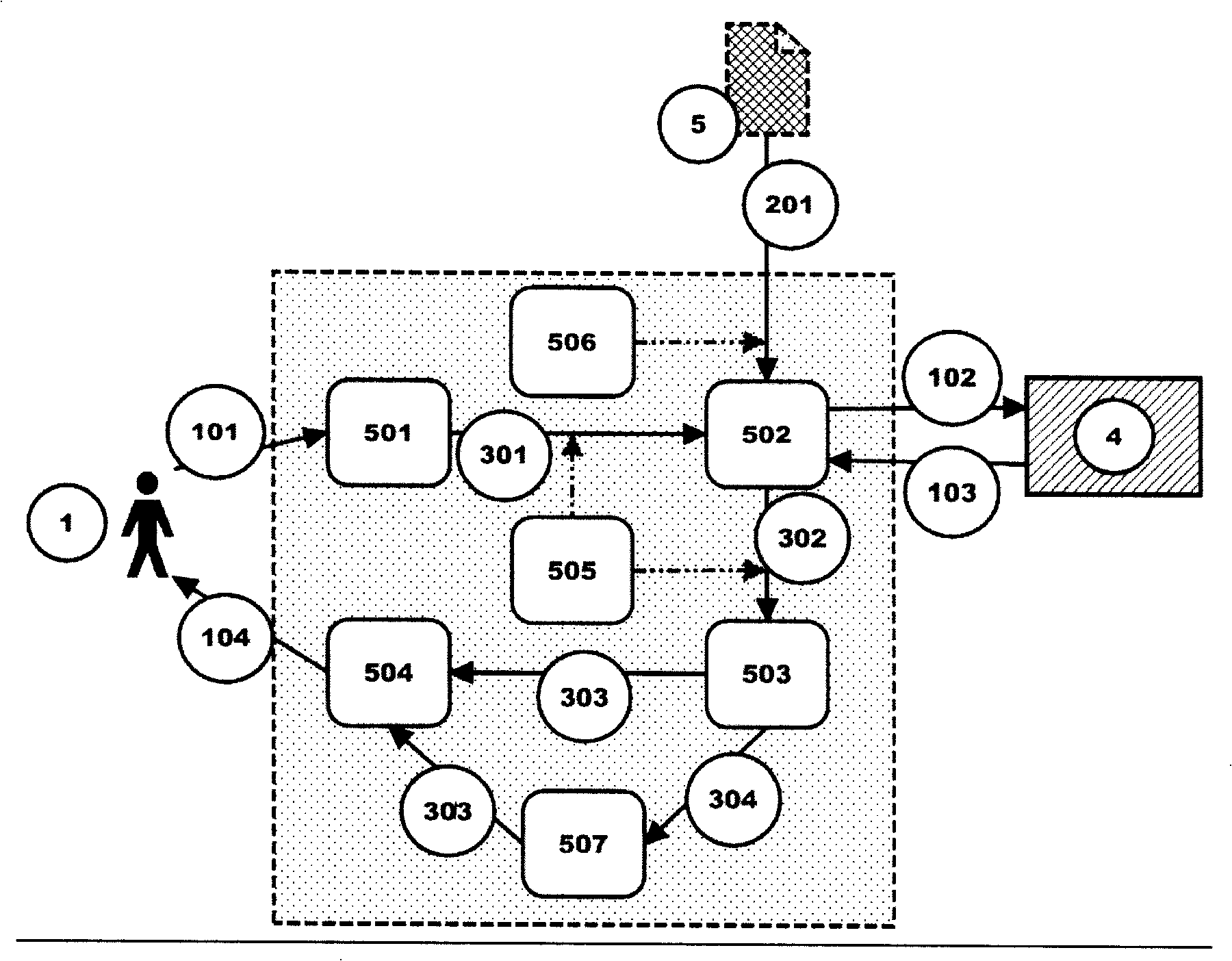

Technical proposal for readable customization conversion of web pages

InactiveCN101539914AImprove efficiencyShorten the timeSpecial data processing applicationsHabitUniform resource locator

A readable customization conversion technique comprises the following steps of: performing corresponding processing of web page data described in web page languages in the prior text version; showing a reader contents selected according to specific rules; and displaying the contents in a mode more complying with the reading habits of the reader. The rules for processing the contents are determined by a source URL or associated URL of the web page data. The processing modes of the rules comprise active selection of specific content and redefinition of the formats of display modes.

Owner:韩露

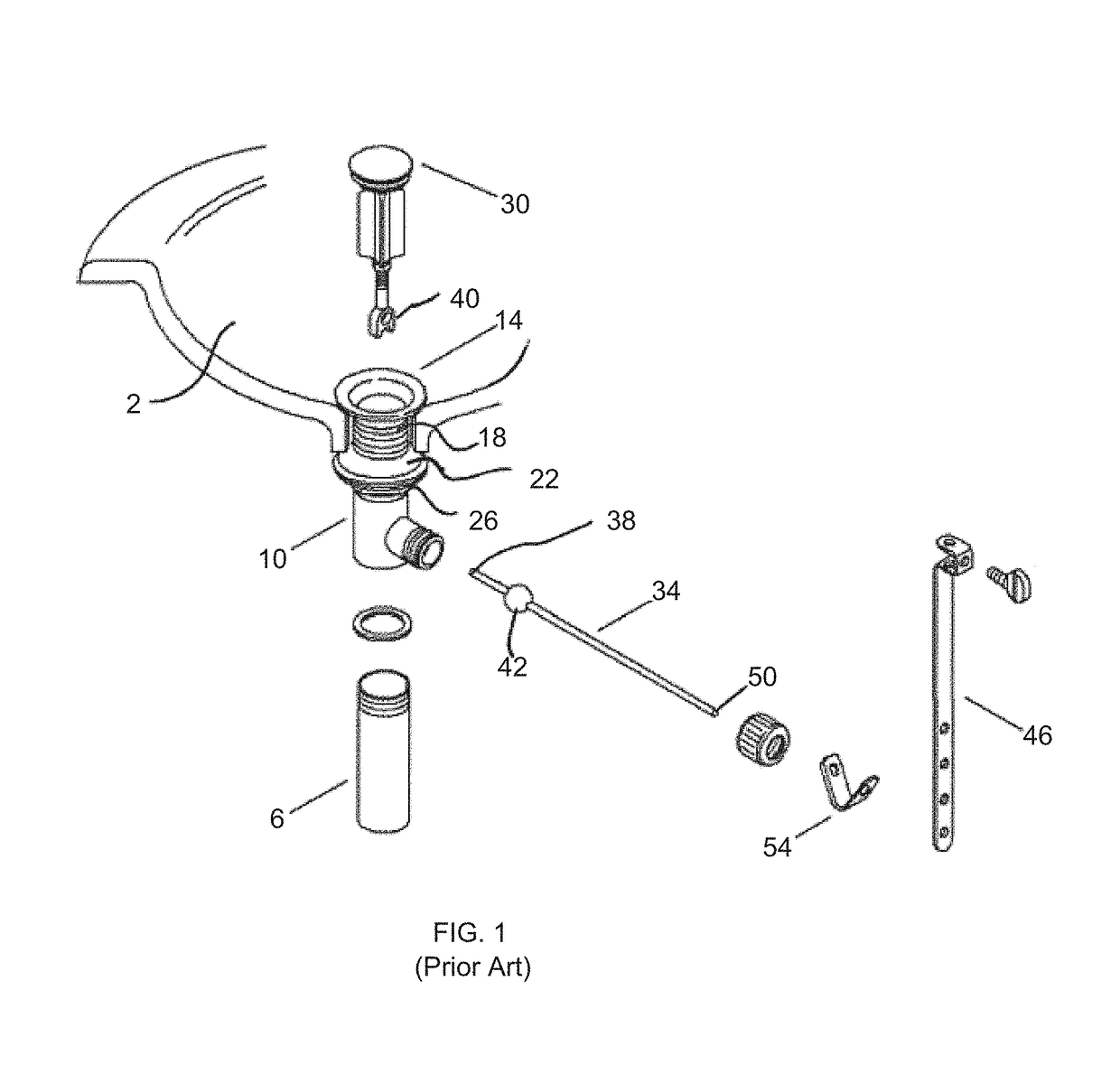

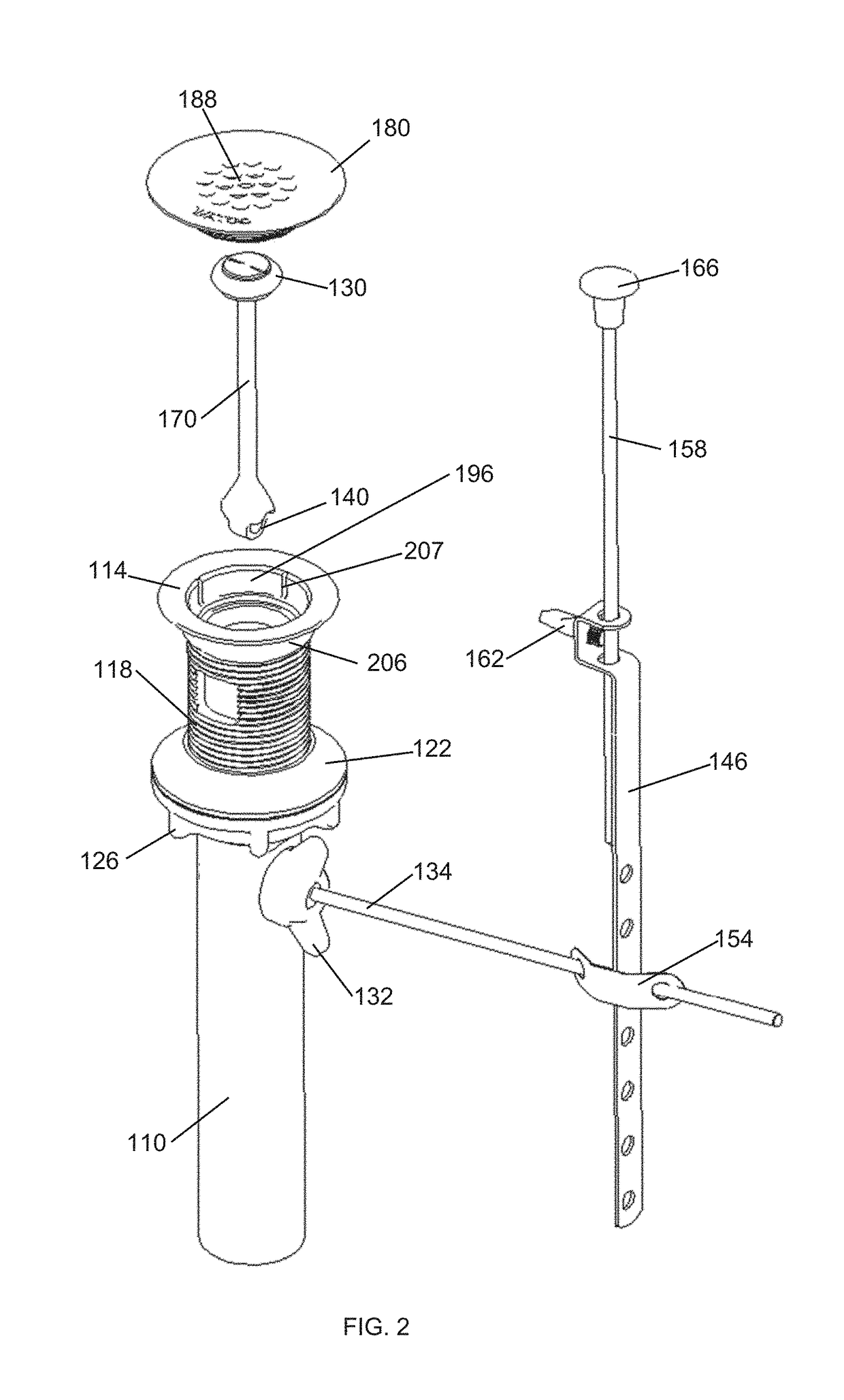

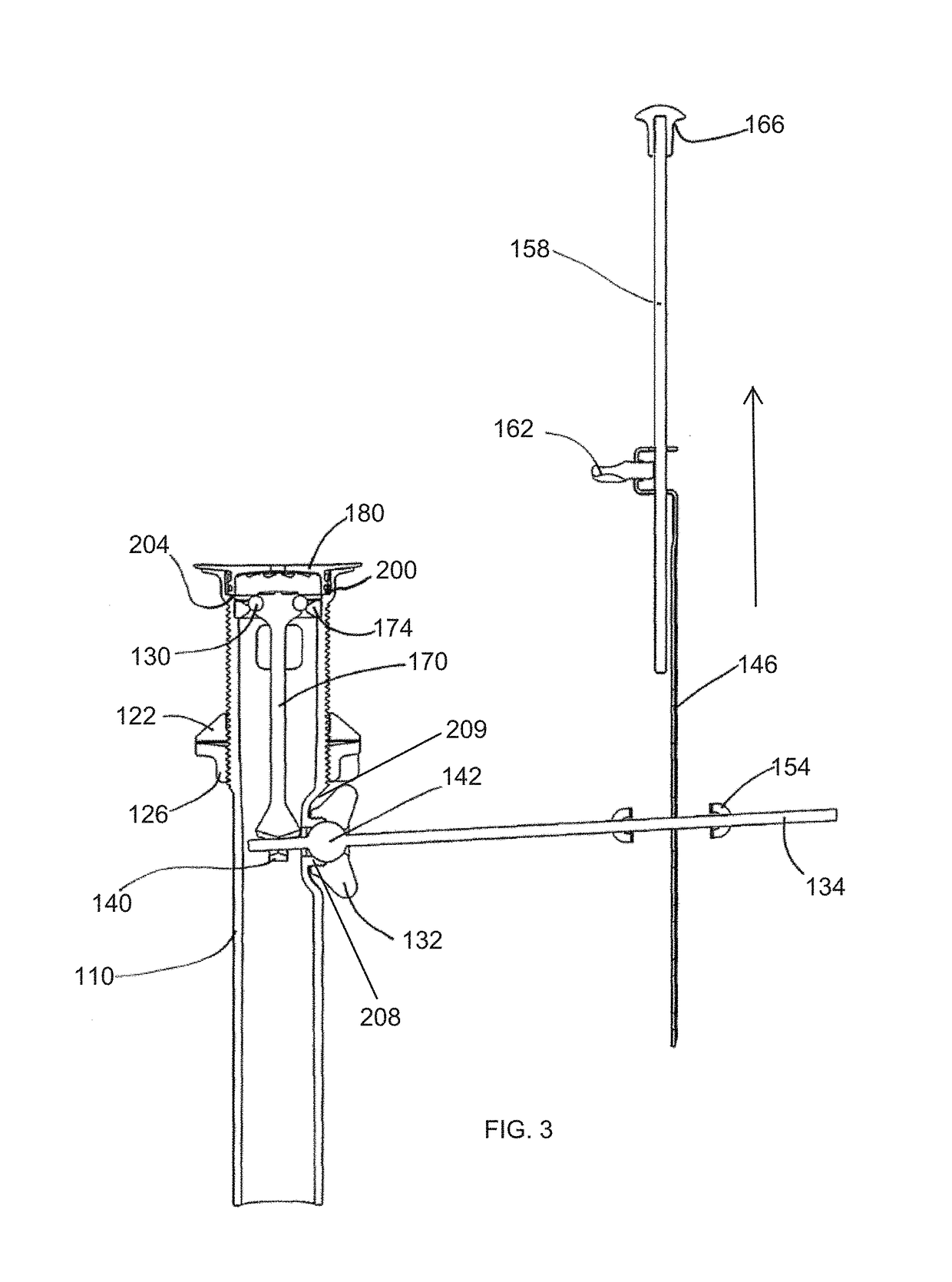

Wastewater drain stopper system

ActiveUS10233622B2Reduce manufacturing costHighly efficient to use and operateDomestic plumbingWastewaterFlange

A wastewater drain assembly is provided that includes a selectively openable drain stopper. The wastewater drain assembly is interconnected to a fluid basin wherein a flange, which is interconnected to wastewater plumbing, is situated within the sink. The flange receives an insert that has a portion that conceals the flange.

Owner:WCM IND INC

Hot-dip galvanizing method for high-strength steel

ActiveCN110541136APerformance is not affectedImprove performanceHot-dipping/immersion processesSurface layerRoom temperature

The invention discloses a hot-dip galvanizing method for high-strength steel, and belongs to the technical field of steel hot-dip galvanizing processing. According to the hot-dip galvanizing method, the following steps are carried out to process the formed high-strength steel, the steps are of high-frequency heating, acid pickling, washing, plating assistant treatment, drying, hot-dip galvanizing,placing the high-strength steel subjected to hot-dip galvanizing at room temperature for air cooling, and arranging and collecting after air cooling. The hot-dip galvanizing method utilizes the skineffect of induced current to heat the surface layer of the formed high-strength steel in a high-frequency heating furnace, so that alloying elements contained on the surface of the high-strength steelare changed, the phase and the structure which are unfavorable to the quality of a zinc coating are eliminated, the property of the whole steel is not influenced, the hot-dip galvanized steel which is excellent in quality, proper in thickness and bright in surface can be manufactured, and the proportion of the brittle phase of the zinc coating is effectively reduced; and meanwhile, the mechanicalproperty of the high-strength steel is obviously improved, and the corrosion resistance property is good.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

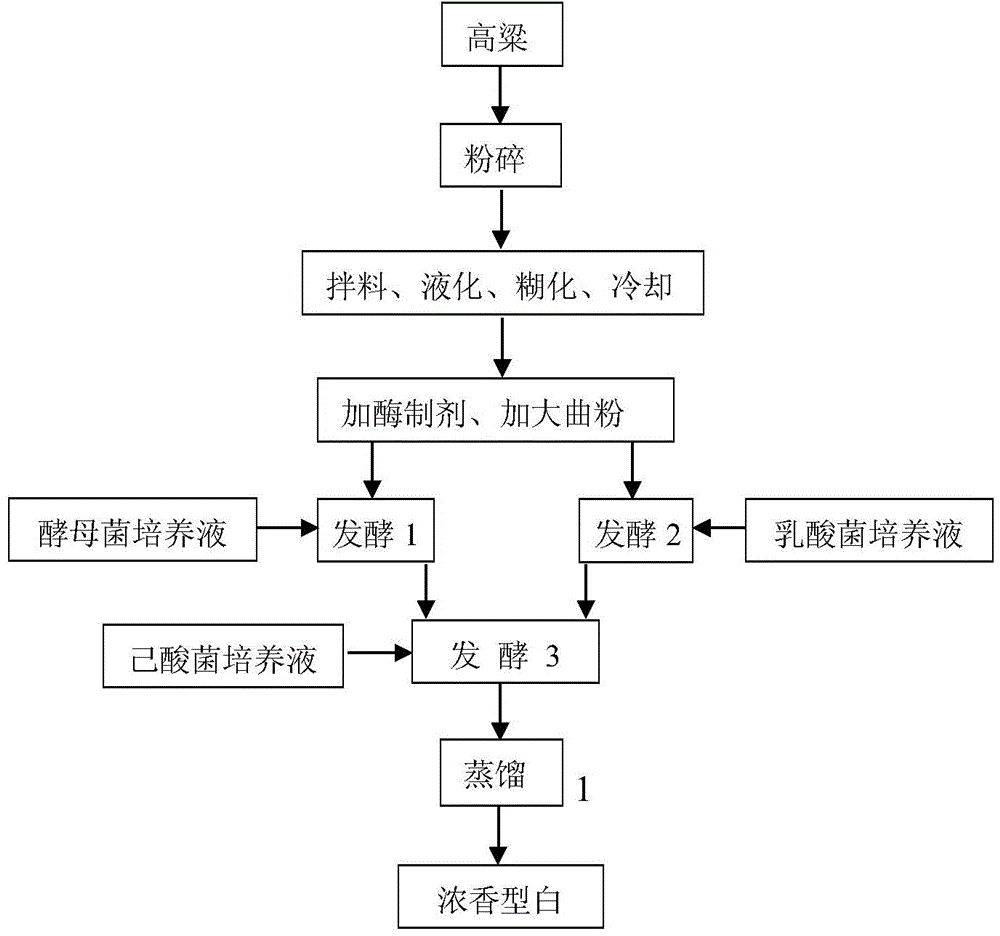

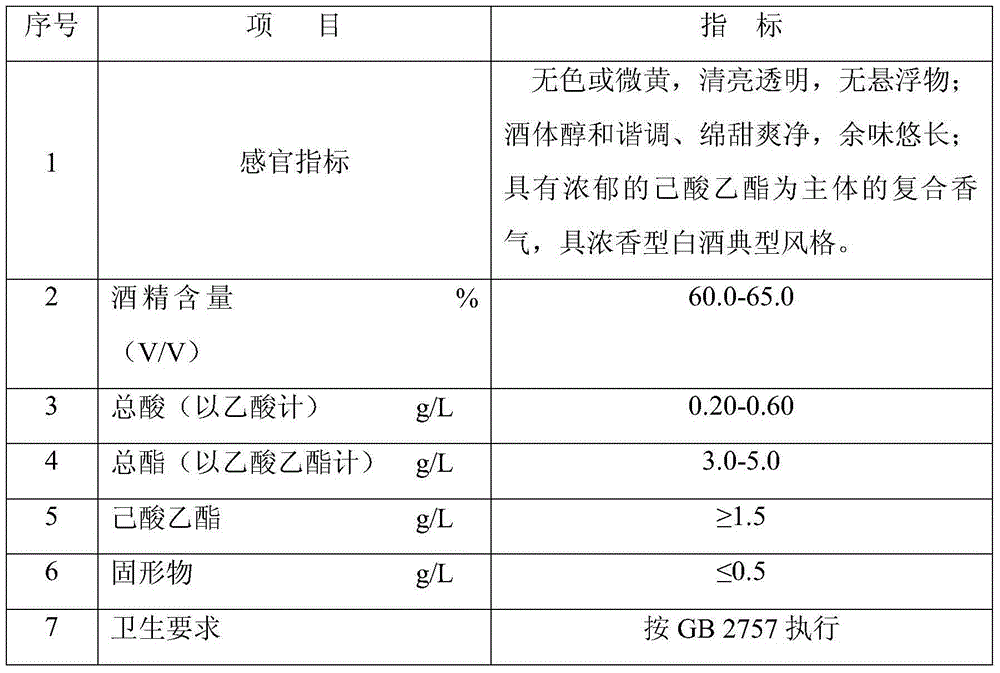

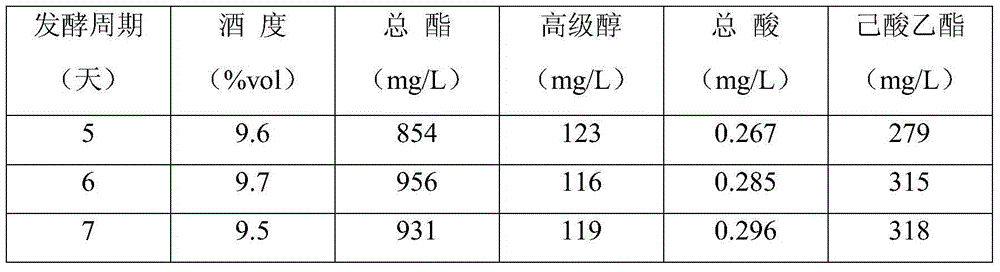

Novel solid fermentation method for producing Luzhou-flavor liquor

InactiveCN104593189AIncrease productivityHigh yieldMicroorganism based processesAlcoholic beverage preparationDistillationFood flavor

The invention discloses a novel solid fermentation method for producing a Luzhou-flavor liquor, and belongs to the technical field of wine brewing. The technology content comprises steps of raw material crushing, liquefaction and gelatinization, starter addition, wort-dividing fermentation, mixed fermentation and distillation, wherein the wort-separating fermentation comprises dividing a wort added with a starter into two portions according to a ratio, and then performing fermentation; concretely, inoculating a high-ester-yield saccharomyces cerevisiae culture solution to a first wort for fermentation, controlling the inoculation amount to be 1-3%, and performing fermentation culturing at 27-33 DEG C for 20-30 h; inoculating a lactic acid bacteria culture solution to a second wort portion, controlling the inoculation amount to be 0.5-2%, and performing fermentation culturing at 33-39 DEG C for 20-30 h; and then performing mixed fermentation. The advantages comprise that influence of environment factors to the fermentation process is eliminated, automatic and mechanized operation during brewing of the Luzhou-flavor liquor is realized, when the content of a high-flavor substance in the Luzhou-flavor liquor is kept, the raw-material liquor yield is substantially improved and the fermentation period is shortened, and thus the production efficiency of the Luzhou-flavor liquor is substantially improved.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

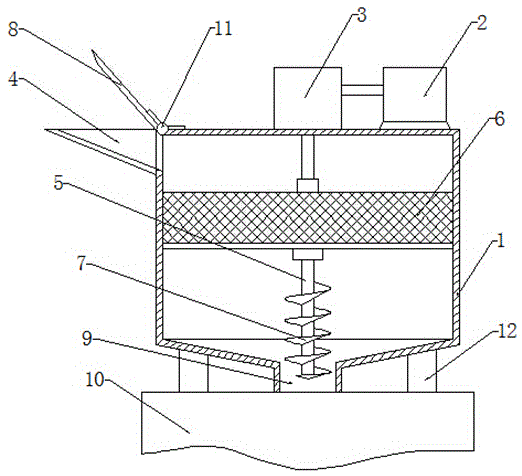

Metallurgical auxiliary material screening type anti-blocking discharging device

InactiveCN105540083AAvoid cloggingContinuous and uniform feedingLarge containersProduction rateDrive shaft

The invention discloses a metallurgical auxiliary material screening type anti-blocking discharging device. The metallurgical auxiliary material screening type anti-blocking discharging device comprises a discharging barrel and an anti-blocking device, wherein a feeding hopper is arranged at the top end of the discharging barrel; a cylindrical discharging outlet is formed in the bottom end of the discharging barrel and located above a ball press machine. The anti-blocking device comprises a motor, a transmission shaft, a screen and an anti-blocking paddle, wherein the motor is located at the top end of the discharging barrel; the transmission shaft is located inside the discharging barrel and connected with the motor; the screen is in a circular ring shape and fixed to the upper portion of the transmission shaft; the outer diameter of the screen is smaller than the inner diameter of the discharging barrel; the anti-blocking paddle is in a spirally ascending shape and fixed to the lower end of the transmission shaft; the lower end of the transmission shaft extends into the discharging outlet. By means of the scheme, the motor, the transmission shaft, the screen and the anti-blocking paddle can effectively prevent metallurgical auxiliary materials from being blocked, caking, forming a hole and the like in the discharging device, continuous and even discharging of the metallurgical auxiliary materials can be ensured, and the harmful effects on the quality and productivity of metallurgical auxiliary material balling due to uneven and untimely discharging are eliminated.

Owner:CHONGQING HAIDE METALLURGY MATERIAL CO LTD

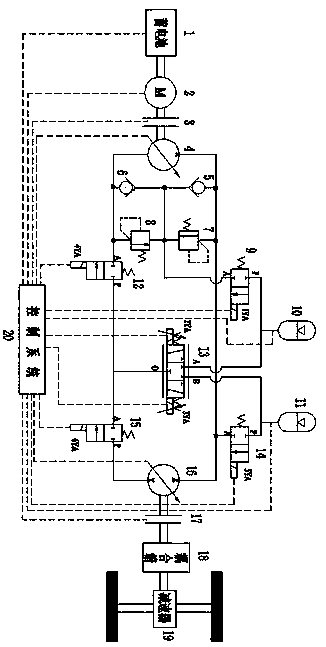

A parallel vehicle hybrid control system and control method

PendingCN108973980AReduce quality problemsEliminate quality issuesHybrid vehiclesSolenoid valveDrive motor

The invention provides a parallel vehicle hybrid control system and a control method. The control system includes a battery, a drive motor, a main clutch, a variable displacement pump, a first one-wayvalve, a second one-way valve, a first safety valve, a second safety valve, a first solenoid valve, a low-pressure accumulator, a high-pressure accumulator, a second solenoid valve, a third solenoidvalve, a fourth solenoid valve, a fifth solenoid valve, a motor, a second clutch, a coupler, a speed reducer, and a control system. The control method comprises a forward start control mode, a reversestart control mode, a forward braking energy recovery control mode and a reverse hydraulic energy regenerative braking control mode. As that control mode is closed, components of the hydraulic pow control system can be reduced and the weight of the whole vehicle can be reduced; The invention can effectively eliminate the starting impulse current, adjust the starting time, prolong the service lifeof the battery and increase the mileage of the vehicle; The forward and reverse braking energy can be recovered effectively, the energy utilization rate can be improved, and the energy waste of the vehicle during braking can be avoided effectively.

Owner:XUCHANG UNIV

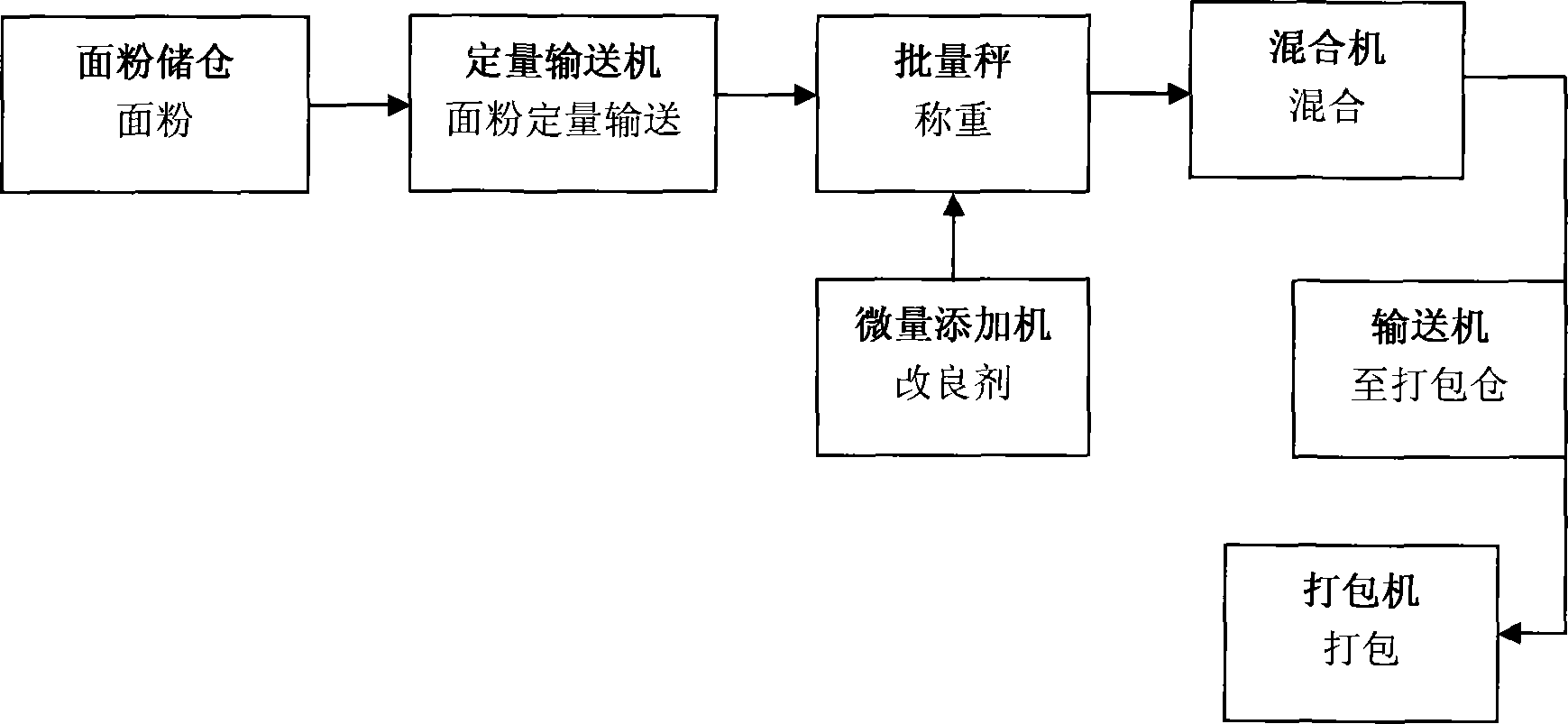

Selenium-enriched spontaneous flour and manufacture method thereof

The invention provides self-leavening flour with rich selenium, which includes raw materials by the weight percentages as follows: flour 100.0%, Mary leaven with high sugar 1%-1.2%, sweet baking powder 1.2%-1.8%, soft sugar 2.0%-3.0%, iodized edible salt 0.3%, steamed bread flour modifier 0.1%, malt flour with rich selenium 0.2%, glucolactone 2.0%, and saleratus 1.0%. When in use, the inventive self-leavening flour with rich selenium can be formed after fermenting for 30 minutes, and then be steamed on a tray to make steamed bread or other fermented food. The using process of utilizing biological agents and food agents is fast, sanitary and safe.

Owner:HEILONGJIANG BEIDAHUANG FENGWEI FOOD

Cigarette bundle filling device of side-opening type molded cigarette box

InactiveCN102616399ARealize mechanized fillingSimple structurePackaging cigaretteEngineeringMechanical engineering

The invention discloses a cigarette bundle filling device of a side-opening type molded cigarette box, comprising a bracket and a half-opening type mould box erected on the bracket, wherein the mould box comprises first and second side plates which are oppositely arranged in parallel, and top plates connected with the upper ends of the first and second side plates; the mould box is provided with a cigarette bundle inlet, and a cigarette bundle outlet is arranged on the bottom surface of the mould box; the outlet is surrounded by packaging paper for bearing a cigarette bundle; clamping mechanisms for clamping the packaging paper are arranged at the outer sides of the first and second side plates; the mould is internally provided with a pressing plate for pressing the cigarette bundle entering the mould box and the packing paper surrounding on the outlet into the side-opening type molded cigarette box below the half-opening type mould box; and the upper part of the half-opening type mould box is provided with a hoisting mechanism for driving the pressing plate to hoist. The cigarette bundle filling device of the side-opening type molded cigarette box, disclosed by the invention, has the advantage of simple structure, realizes the automatic filling of a side-opening type molded box, eliminates the quality problem caused by manual filling, and improves the production efficiency.

Owner:CHINA TOBACCO SHANDONG IND

Welding jig and welding process for planar magnetic components

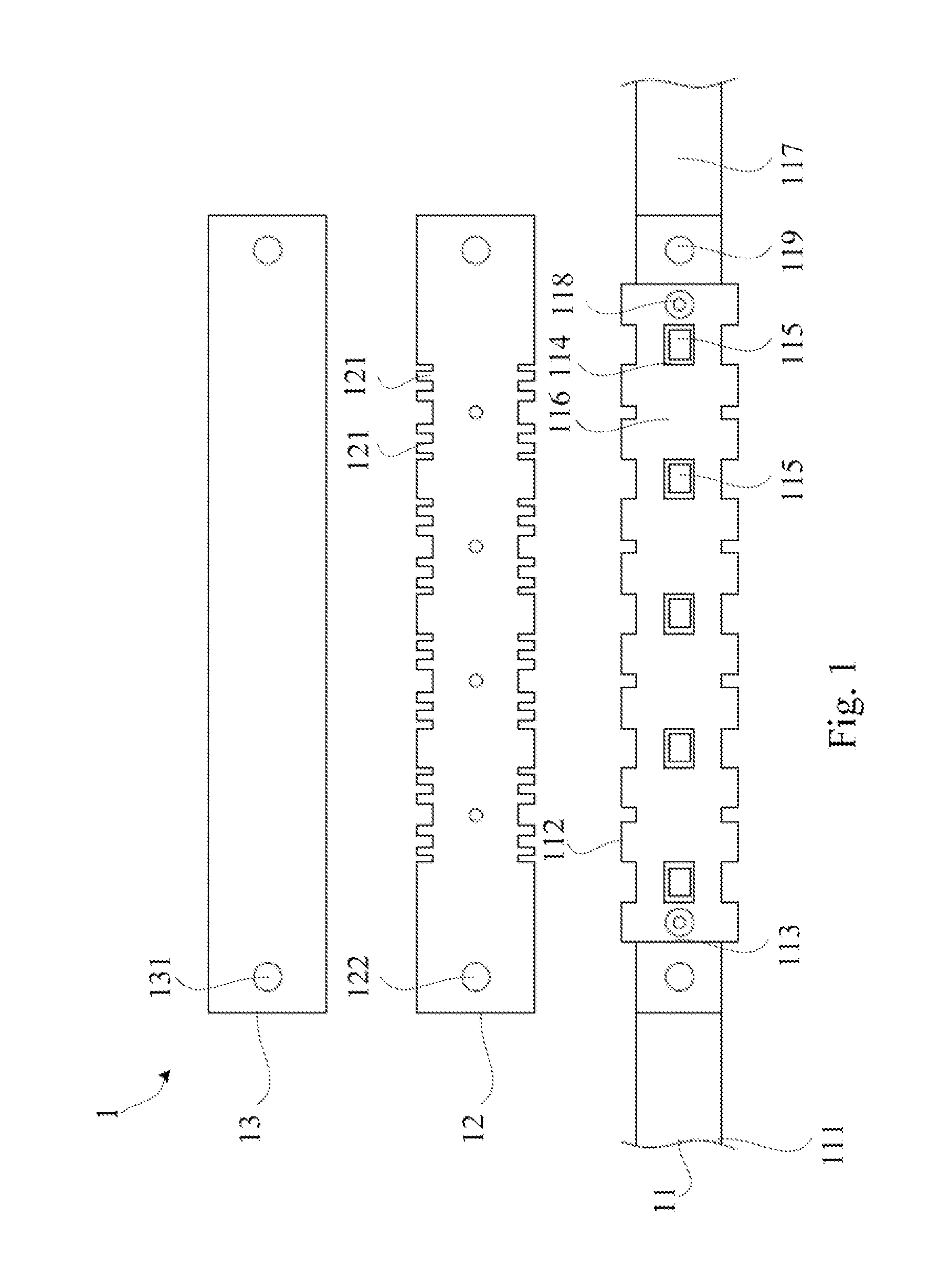

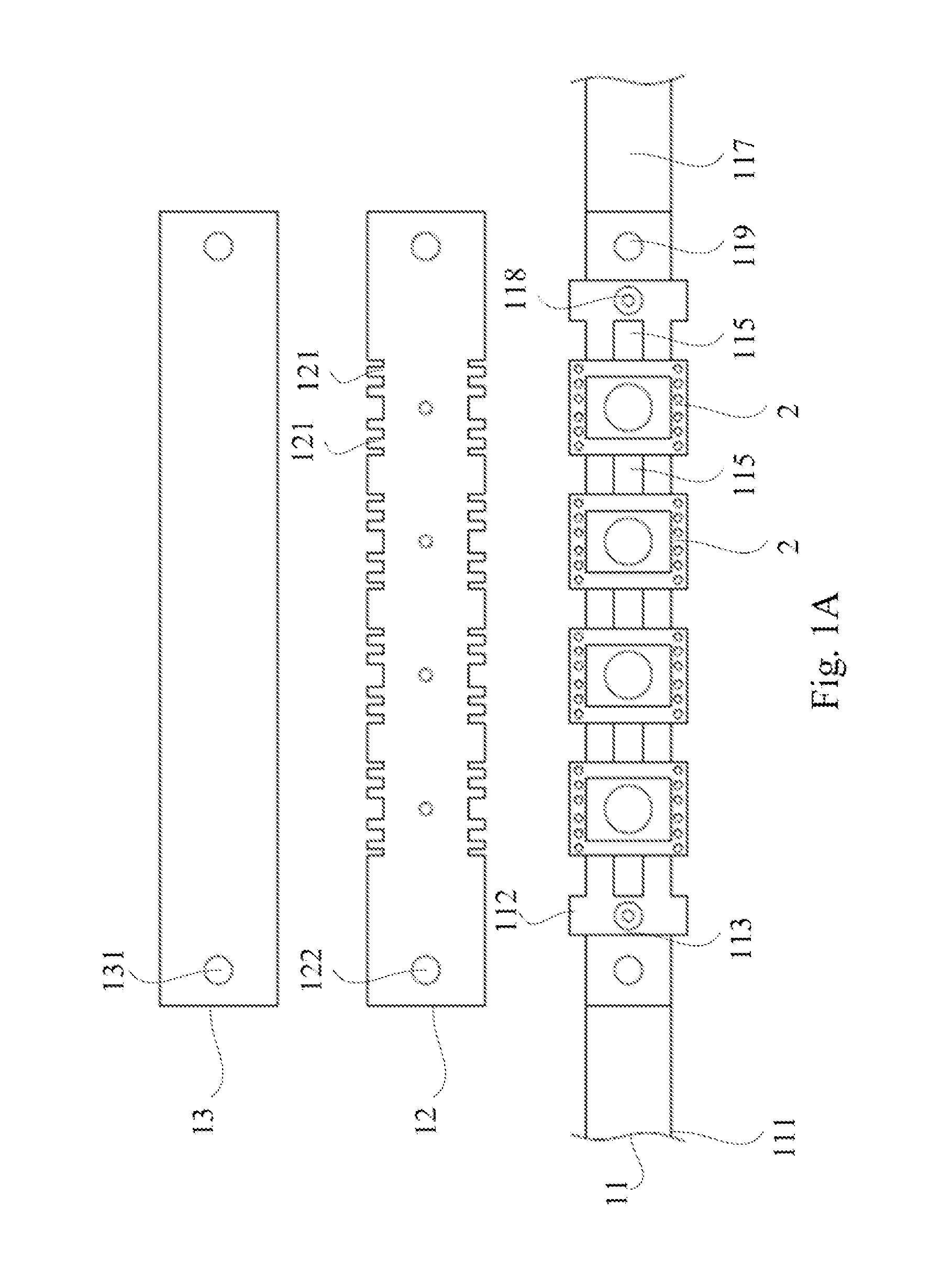

ActiveUS20130082042A1Reduce labor costsReduce time costElectric heatingWelding/cutting auxillary devicesEngineeringWelding process

A welding jig and welding process for planar magnetic components are provided. The welding jig includes a fixed piece and an elastic piece. The fixed piece includes a base and a carrier. The base has an opening, bumps at the bottom of the opening and a pair of operation ends extending from the opening. The carrier is fixed on the base and located in the opening, and has multiple through holes. When the bumps are located respectively in the through holes, an accommodation interval is formed between adjacent pairs of the bumps for the placement of the planar magnetic components. The elastic piece is secured to the fixed piece, and when the planar magnetic components are placed in the accommodation intervals of the fixed piece, the elastic piece covers the planar magnetic components and the planar magnetic components abut against two side edges of the elastic piece.

Owner:DELTA ELECTRONICS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com